Fabrication and Performance of a Photonic-Microfluidic Integrated Device

Abstract

:1. Introduction

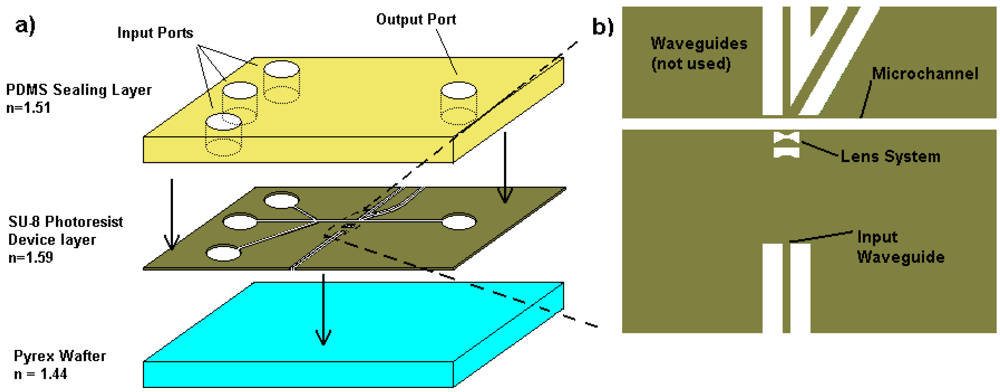

2. Experimental

2.1. Materials

2.2. Processing and Device Fabrication

2.3. Testing

3. Results and Discussion

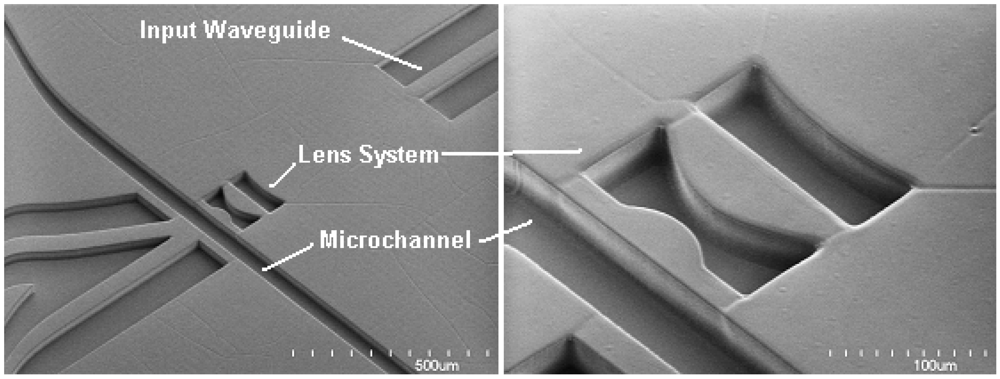

3.1. Device Fabrication

3.1.1. SU-8 Patterning

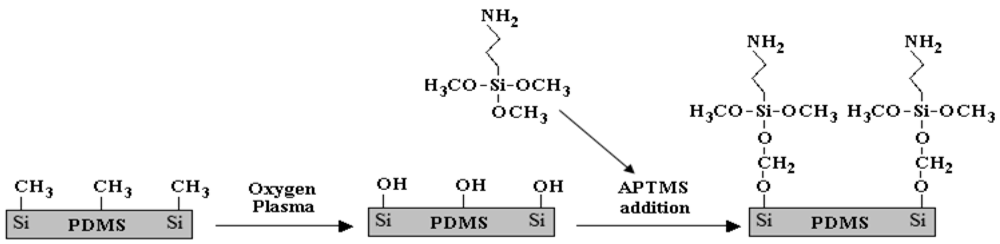

3.1.2. SU-8 Channel Sealing Using PDMS

| Concentration (wt% APTMS) | Fracture in PDMS (%) | ||

|---|---|---|---|

| Ethanol | Hexane | Toluene | |

| 1 | 0.5 | 75–90 | 95–100 |

| 0.5 | 0.5 | 75–90 | 95–100 |

| 0.1 | 0.5 | 75–90 | 95–100 |

| Drying Time | Fracture in PDMS (%) | ||

|---|---|---|---|

| 1 wt% APTMS | 0.5 wt% APTMS | 0.1 wt% APTMS | |

| 1–2 min | 95–100 | 95–100 | 95–100 |

| 30 min | 95–100 | 95–100 | 95–100 |

| 1 hour | 95–100 | 95–100 | 95–100 |

| 2 h | 95–100 | 95–100 | 95–100 |

| 4 h | 85–95 | 75–85 | 75–85 |

| 1 day | 40–60 | 25–40 | 25–40 |

| 2 days | 0–10 | 0–10 | 0–10 |

| 4 days | 0–5 | 0–5 | 0–5 |

| 1 week | NA | NA | NA |

| 2 week | NA | NA | NA |

3.2. Device Performance

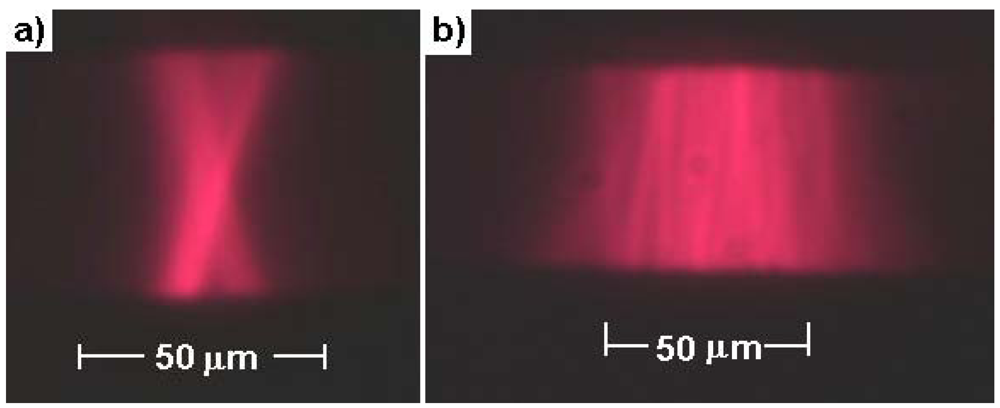

3.2.1. Beam Shaping

3.2.2. Bead Detection

4. Conclusions

Acknowledgments

References

- Whitesides, G.M. The origins and future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef]

- Krogmeier, J.R.; Schaefer, I.; Seward, G.; Yantz, G.R.; Larson, J.W. An integrated optics microfluidic device for detecting single DNA molecules. Lab Chip 2007, 7, 1767–1774. [Google Scholar] [CrossRef]

- Squires, T.M.; Quake, S.R. Microfluidics: Fluid physics at the nanoliter scale. Rev. Mod. Phys. 2005, 77, 977–1026. [Google Scholar] [CrossRef]

- Manz, A.; Harrison, D.J.; Verpoorte, E.M.J.; Fettinger, J.C. Planar chips technology for miniaturization and integration of separation techniques into monitoring system-Capillary electrophoresis on a chip. J. Chromatogr. 1992, 593, 253–258. [Google Scholar] [CrossRef]

- Harrison, D.J.; Fluri, K.; Seiler, K.; Fan, Z.; Effenhauser, C.S.; Manz, A. Micromachining a miniaturized capillary electrophoresis-based chemical analysis system on a chip. Science 1993, 261, 895–897. [Google Scholar]

- Xia, Y.; Whitesides, G.M. Soft lithography. Annu. Rev. Mater. Sci. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Duffy, D.C.; McDonald, J.C.; Schueller, O.J.A.; Whitesides, G.M. Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal. Chem. 1998, 70, 4974–4984. [Google Scholar]

- Chang, C.M.; Hsiung, S.K.; Lee, G.B. Micro flow cytometer chip integrated with micro-pumps/micro-valves for multi-wavelength cell counting and sorting. Jpn. J. Appl. Phys. 2007, 46, 3126–3134. [Google Scholar] [CrossRef]

- Thorsen, T.; Maerkl, S.J.; Quake, S.R. Microfluidic large-scale integration. Science 2002, 298, 580–584. [Google Scholar]

- Zhang, C.; Xing, D.; Li, Y. Micropumps, microvalves, and micromixers within PCR microfluidic chips: Advances and trends. Biotechnol. Adv. 2007, 25, 483–514. [Google Scholar] [CrossRef]

- Stroock, A.D.; Dertinger, S.K.W.; Ajdari, A.; Mezic, I.; Stone, H.A.; Whitesides, G.M. Chaotic mixer for microchannels. Science 2002, 295, 247–251. [Google Scholar]

- deMello, A. Control and detection of chemical reactions in microfluidic systems. Nature 2006, 442, 394–402. [Google Scholar] [CrossRef]

- Fu, A.Y.; Chou, H.P.; Spence, C.; Arnold, F.H.; Quake, S.R. An integrated microfabricated cell sorter. Anal. Chem. 2002, 74, 2451–2457. [Google Scholar] [CrossRef]

- Wolff, A.; Perch-Nielsen, I.R.; Larsen, U.D.; Friis, P.; Goranovic, G.; Poulsen, C.R.; Kutter, J.P.; Telleman, P. Integrating advanced functionality in a microfabricated high-throughput fluorescent-activated cell sorter. Lab Chip 2003, 3, 22–27. [Google Scholar] [CrossRef]

- Ramsey, J.M.; Jacobson, S.C.; Knapp, M.R. Microfabricated chemical measurement systems. Nat. Med. 1995, 1, 1093–1096. [Google Scholar] [CrossRef]

- Hong, J.W.; Quake, S.R. Integrated nanoliter systems. Nat. Biotechnol. 2003, 21, 1179–1183. [Google Scholar] [CrossRef]

- Ocvirk, G.; Munroe, M.; Tang, T.; Oleschuk, R.; Westra, K.; Harrison, D.J. Electrokinetic control of fluid flow in native poly(dimethylsiloxane) capillary electrophoresis devices. Electrophoresis 2000, 21, 107–115. [Google Scholar] [CrossRef]

- Bliss, C.L.; McMullin, J.N.; Backhouse, C.J. Rapid fabrication of a microfluidic device with integrated optical waveguides for DNA fragment analysis. Lab Chip 2007, 7, 1280–1287. [Google Scholar] [CrossRef]

- Krogmeier, J.R.; Schaefer, I.; Seward, G.; Yantz, G.R.; Larson, J.W. An integrated optics microfluidic device for detecting single DNA molecules. Lab Chip 2007, 7, 1767–1774. [Google Scholar]

- Salehi-Reyhani, A.; Kaplinsky, J.; Burgin, E.; Novakova, M.; deMello, A.J.; Templer, R.H.; Parker, P.; Neil, M.A.A.; Ces, O.; French, P.; et al. A first step towards practical single cell proteomics: A microfluidic antibody capture chip with TIRF detection. Lab Chip 2011, 11, 1256–1261. [Google Scholar]

- Jiang, H.; Weng, X.; Li, D. Microfluidic whole-blood immunoassays. Microfluid. Nanofluid. 2011, 10, 941–964. [Google Scholar] [CrossRef]

- Wu, M.-H.; Cai, H.; Xu, X.; Urban, J.P.G.; Cui, Z.-F.; Cui, Z. A SU-8/PDMS hybrid microfluidic device with integrated optical fibers for online monitoring of lactate. Biomed. Microdev. 2005, 7, 323–329. [Google Scholar] [CrossRef]

- Mogensen, K.B.; El-Ali, J.; Wolff, A.; Kutter, J.P. Integration of polymer waveguides for optical detection in microfabricated chemical analysis systems. Appl. Opt. 2003, 42, 4072–4079. [Google Scholar] [CrossRef]

- Watts, B.R.; Kowpak, T.; Zhang, Z.; Xu, C.Q.; Zhu, S. A microfluidic-photonic-integrated device with enhanced excitation power density. Proc. SPIE 2010, 7555. [Google Scholar] [CrossRef]

- Watts, B.R.; Kowpak, T.; Zhang, Z.; Xu, C.Q.; Zhu, S. Formation and characterization of an ideal excitation beam geometry in an optofluidic device. Biomed. Opt. Exp. 2010, 1, 848–860. [Google Scholar] [CrossRef]

- Hsiung, S.K.; Lin, C.H.; Lee, G.B. A microfabricated capillary electrophoresis chip with multiple buried optical fibres and microfocusing lens for multiwavelength detection. Electrophoresis 2005, 26, 1122–1129. [Google Scholar] [CrossRef]

- Hsiung, S.K.; Lee, C.H.; Lee, G.B. Microcapillary electrophoresis chips utilizing controllable micro-lens structures and buried optical fibres for on-line optical detection. Electrophoresis 2008, 29, 1866–1873. [Google Scholar] [CrossRef]

- Hofmann, O.; Wang, X.; Cornwell, A.; Beecher, A.; Raja, A.; Bradley, D.D.C.; deMello, A.J.; deMello, J.C. Monolithically integrated dye-doped PDMS long-pass filters for disposable on-chip fluorescence detection. Lab Chip 2006, 6, 981–987. [Google Scholar] [CrossRef]

- Bliss, C.L.; McMullin, J.N.; Backhouse, C.J. Integrated wavelength-selective optical waveguides for microfluidic-based laser-induced fluorescence detection. Lab Chip 2007, 7, 143–151. [Google Scholar]

- Yamazaki, M.; Hofmann, O.; Ryu, G.; Xiaoe, L.; Lee, T.K.; deMello, A.J.; deMello, J.C. Non-emissive colour filters for fluorescence detection. Lab Chip 2011, 11, 1228–1233. [Google Scholar] [CrossRef]

- Seo, J.; Lee, L.P. Diposable integrated microfluidics with self-aligned planar microlenses. Sens. Actuat. B 2004, 99, 615–622. [Google Scholar] [CrossRef]

- Wang, Z.; El-Ali, J.; Engelund, M.; Gotsaed, T.; Perch-Nielsen, I.R.; Mogensen, K.B.; Snakenborg, D.; Kutter, J.P.; Wolff, A. Measurements of scattered light on a microchip flow cytometer with integrated polymer based optical elements. Lab Chip 2004, 4, 372–377. [Google Scholar] [CrossRef]

- Schonbrun, E.; Steinvurzel, P.E.; Crozier, K.B. A microfluidic fluorescence measurement system using an astigmatic diffractive microlens array. Opt. Express 2011, 19, 1385–1394. [Google Scholar]

- Yao, B.; Luo, G.; Wang, L.; Gao, Y.; Lei, G.; Ren, K.; Chen, L.; Wang, Y.; Hu, Y.; Qiu, Y. A microfluidic device using a green organic light emitting diode as an integrated excitation source. Lab Chip 2005, 5, 1041–1047. [Google Scholar] [CrossRef]

- Balslev, S.; Jorgensen, A.M.; Bilenberg, B.; Mogensen, K.B.; Snakenborg, D.; Geschke, O.; Kutter, J.P.; Kristensen, A. Lab-on-a-chip with integrated optical transducers. Lab Chip 2006, 6, 213–217. [Google Scholar] [CrossRef]

- Godin, J.; Chen, C.H.; Cho, S.H.; Qiao, W.; Tsai, F.; Lo, Y.H. Microfluidics and photonics for Bio-System-on-a-Chip: A review of advancements in technology towards a microfluidic flow cytometry chip. J. Biophotonics 2008, 1, 355–376. [Google Scholar] [CrossRef]

- Ateya, D.A.; Erickson, J.S.; Howell, P.B., Jr.; Hilliard, L.R.; Golden, J.P.; Ligler, F.S. The good, the bad, and the tiny: A review of microflow cytometry. Anal. Bioanal. Chem 2008, 391, 1485–1498. [Google Scholar] [CrossRef]

- Mu, C.; Zhang, F.; Zhang, Z.; Lin, M.; Cao, X. Highly efficient dual-channel cytometric-detection of micron-sized particles in microfluidic device. Sens. Actuat. B 2011, 151, 402–409. [Google Scholar] [CrossRef]

- Kowpak, T.; Watts, B.R.; Zhang, Z.; Zhu, S.; Xu, C.Q. Fabrication of SU-8 microfluidic-photonic-integrated devices on glass. Macromol. Mater. Eng. 2010, 295, 559–565. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, P.; Xiao, G. The fabrication of polymer microfluidic devices using a solid-to-solid interfacial polyaddition. Polymer 2009, 50, 5358–5361. [Google Scholar] [CrossRef]

- Watts, B.R.; Kowpak, T.M.; Zhang, Z.; Xu, C.Q.; Zhu, S. Formation of bowtie-shaped excitation in a photonic-microfluidic integrated devices. Microw. Opt. Technol. Lett. 2011, 53, 2583–2586. [Google Scholar]

- Mao, X.; Lin, S.C.S.; Dong, C.; Huang, T.J. Single-layer planar on-chip flow cytometer using microfluidic drifting based three-dimensional (3D) hydrodynamic focusing. Lab Chip 2009, 9, 1583–1589. [Google Scholar] [CrossRef]

- Kennedy, M.J.; Stelick, S.J.; Sayam, L.G.; Yen, A.; Erickson, D.; Batt, C.A. Hydrodynamic optical alignment for microflow cytometry. Lab Chip 2011, 11, 1138–1143. [Google Scholar] [CrossRef]

- Rosenauer, M.; Buchegger, W.; Finoulst, I.; Verhaert, P.; Vellekoop, M. Miniaturized flow cytometer with 3D hydrodynamic particle focusing and integrated optical elements applying silicon photodiodes. Microfluid. Nanofluid. 2011, 10, 761–771. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Watts, B.R.; Kowpak, T.; Zhang, Z.; Xu, C.-Q.; Zhu, S.; Cao, X.; Lin, M. Fabrication and Performance of a Photonic-Microfluidic Integrated Device. Micromachines 2012, 3, 62-77. https://doi.org/10.3390/mi3010062

Watts BR, Kowpak T, Zhang Z, Xu C-Q, Zhu S, Cao X, Lin M. Fabrication and Performance of a Photonic-Microfluidic Integrated Device. Micromachines. 2012; 3(1):62-77. https://doi.org/10.3390/mi3010062

Chicago/Turabian StyleWatts, Benjamin R., Thomas Kowpak, Zhiyi Zhang, Chang-Qing Xu, Shiping Zhu, Xudong Cao, and Min Lin. 2012. "Fabrication and Performance of a Photonic-Microfluidic Integrated Device" Micromachines 3, no. 1: 62-77. https://doi.org/10.3390/mi3010062

APA StyleWatts, B. R., Kowpak, T., Zhang, Z., Xu, C.-Q., Zhu, S., Cao, X., & Lin, M. (2012). Fabrication and Performance of a Photonic-Microfluidic Integrated Device. Micromachines, 3(1), 62-77. https://doi.org/10.3390/mi3010062