Safety Monitoring Method for Pipeline Crossing the Mining Area Based on Vibration–Strain Fusion Analysis

Abstract

1. Introduction

2. Principle of the Fiberoptic Strain and Vibration Sensing Technologies

2.1. Principle of FBG Sensing Technology

2.2. Principle of Distributed Brillouin Optical Fiber Sensing Technology

2.3. Principle of the Distributed Optical Fiber Vibration Sensing Technology

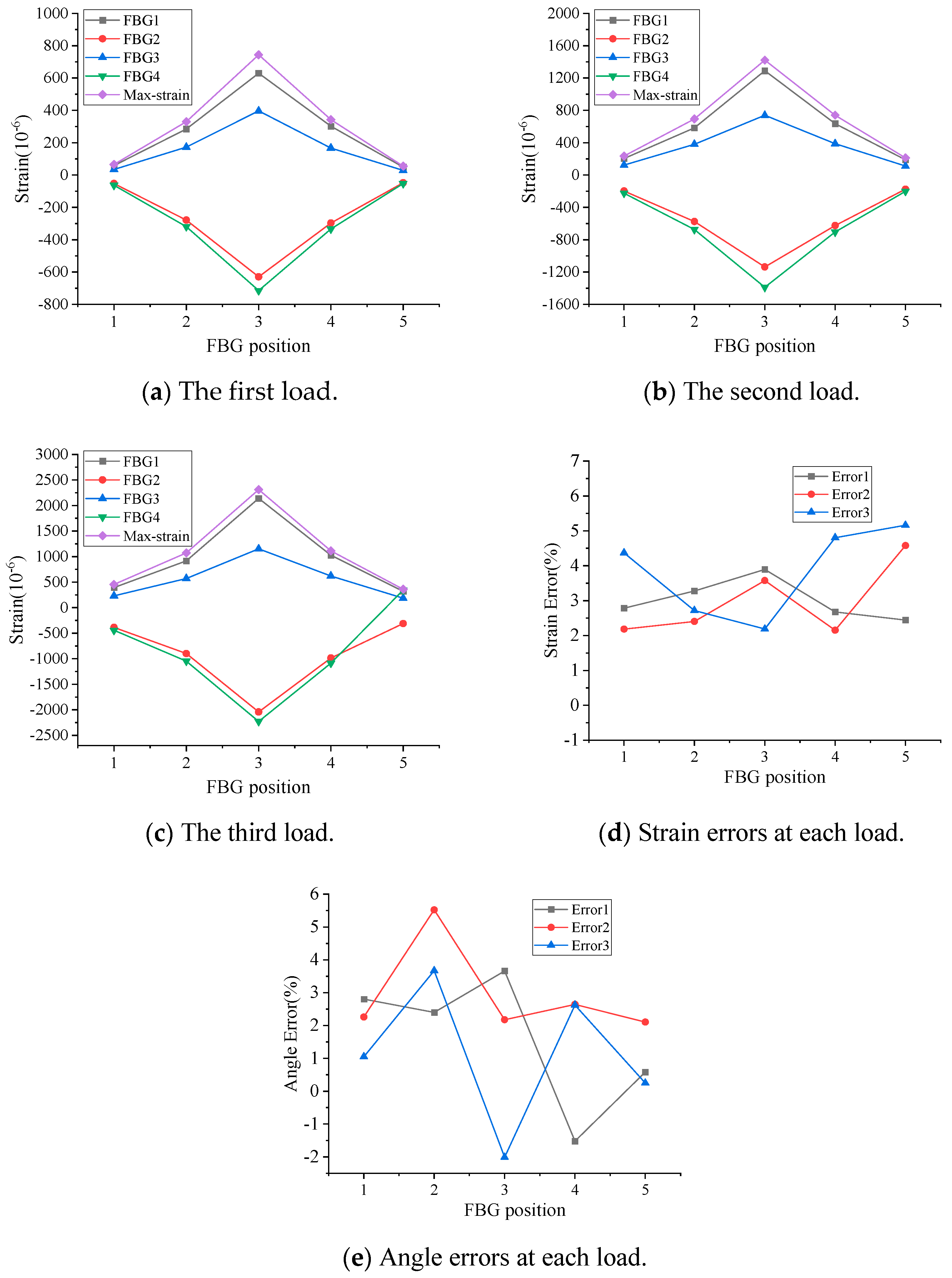

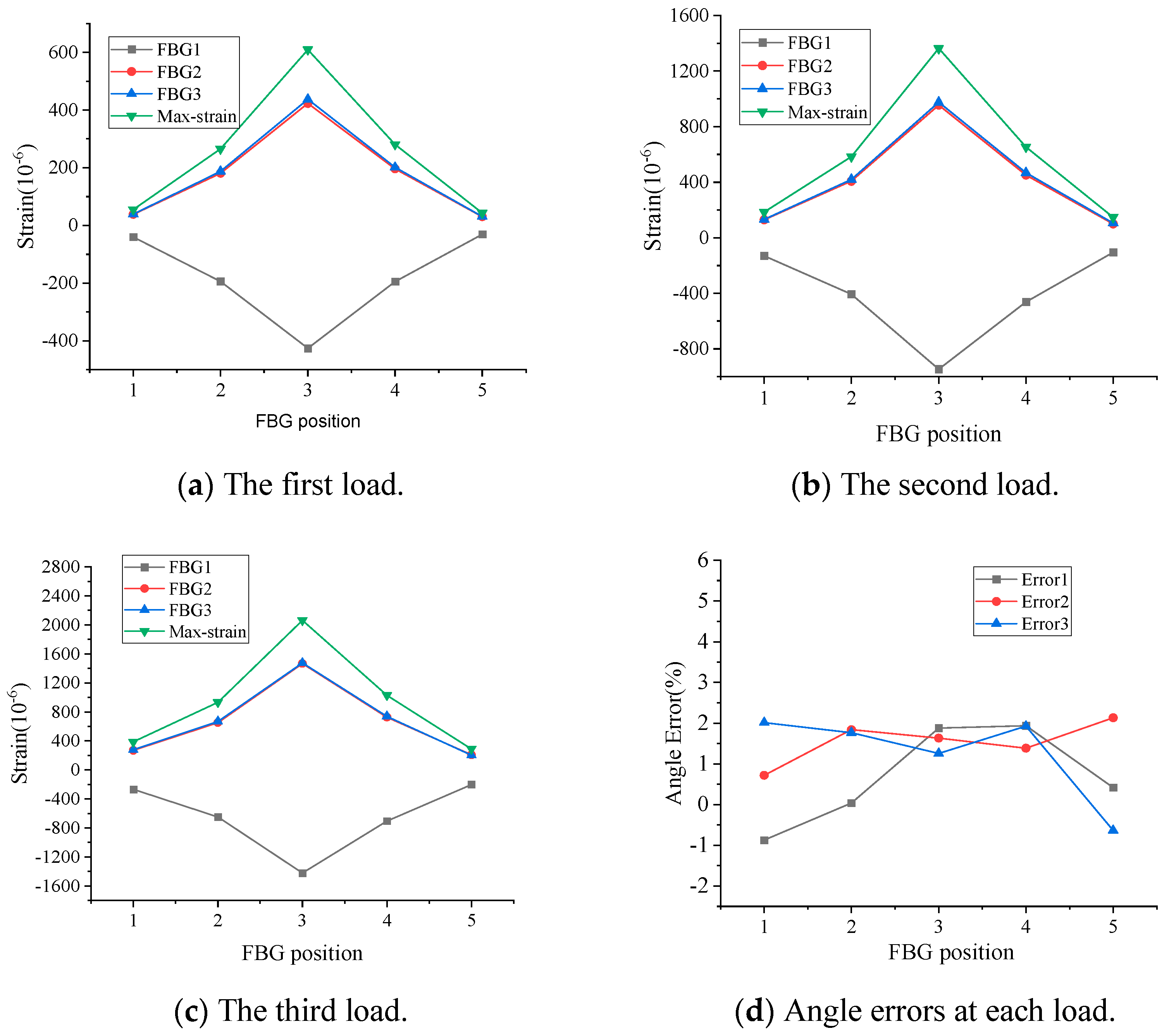

3. Pipeline Deformation Monitoring Test Under Unknown Direction

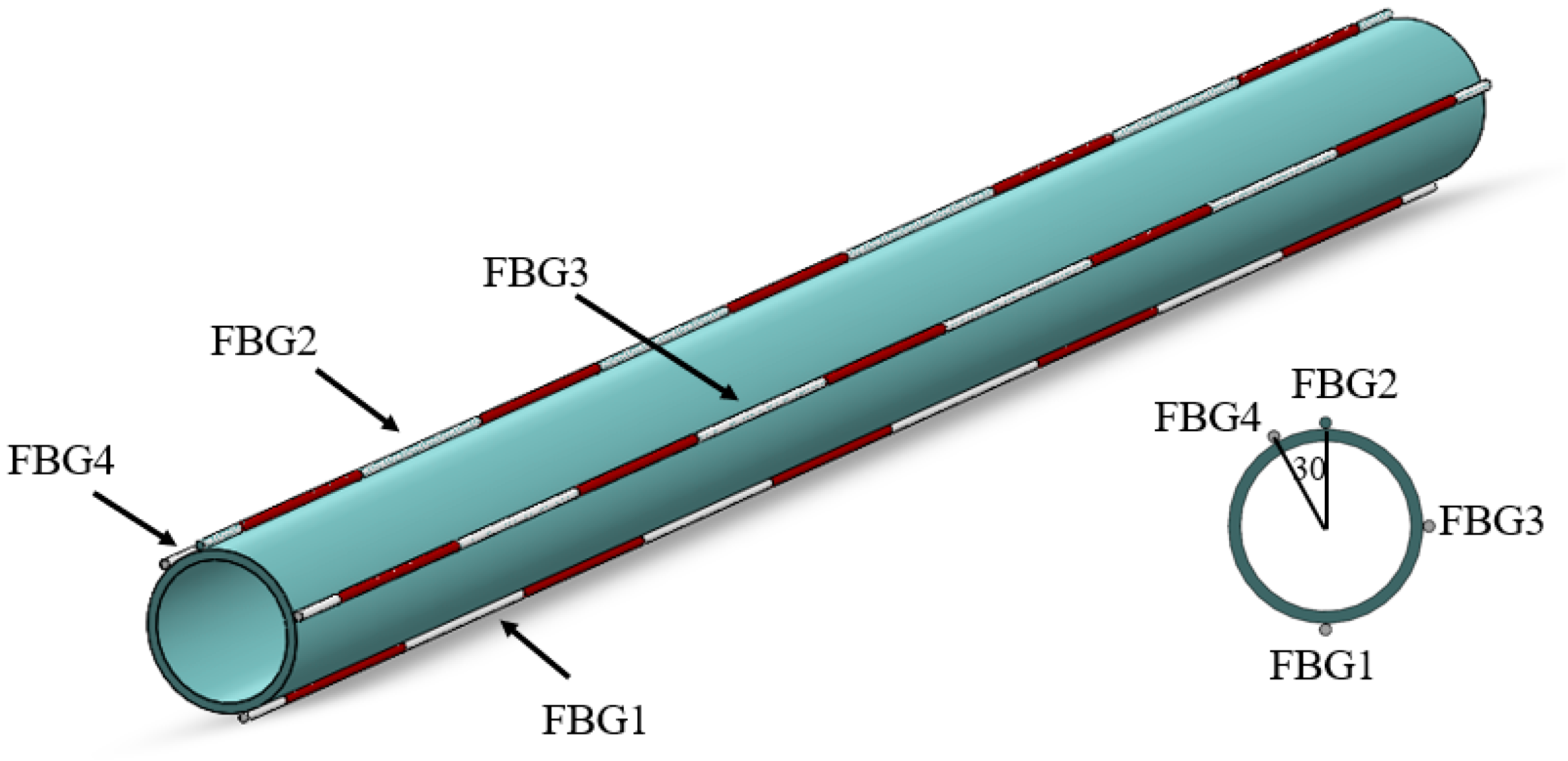

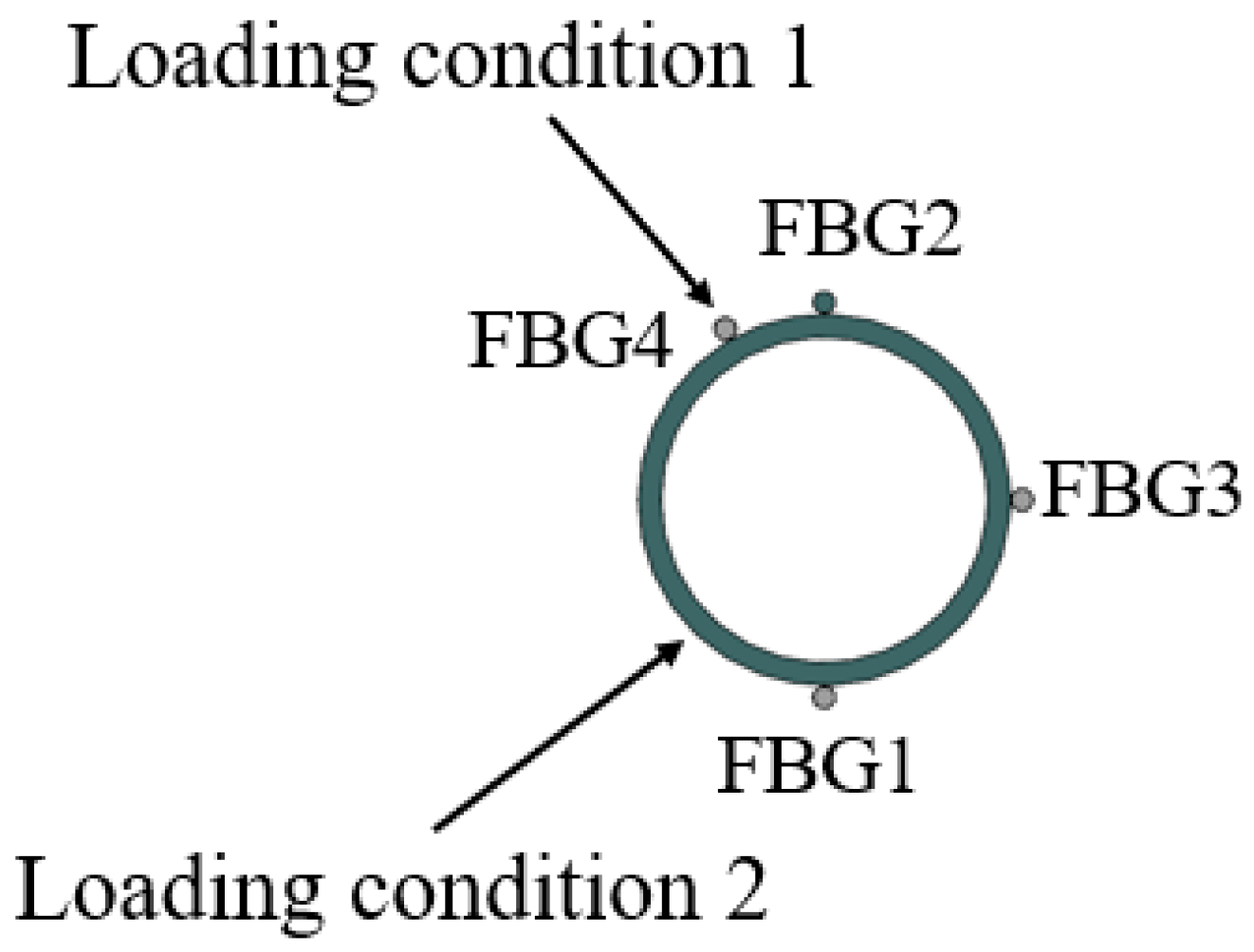

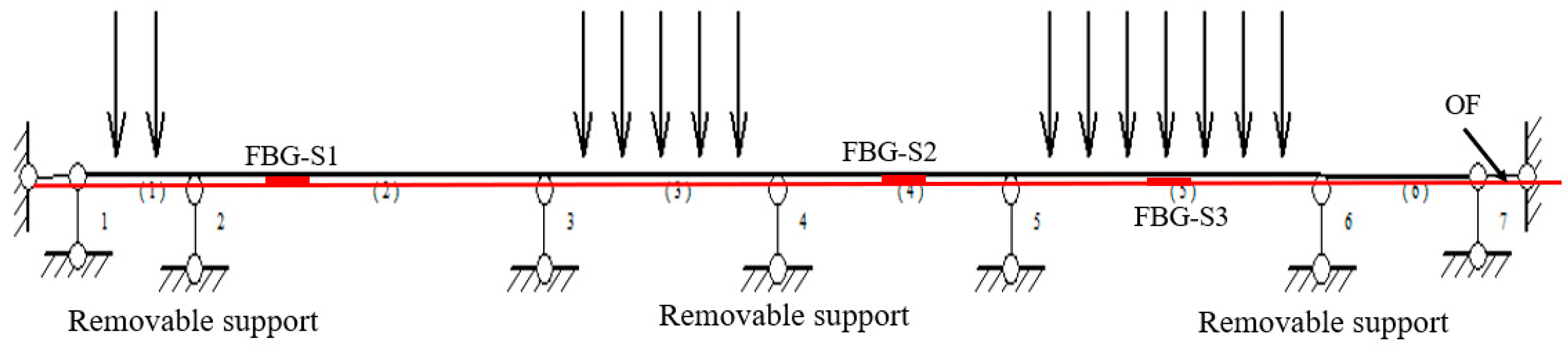

3.1. Sensor Layout

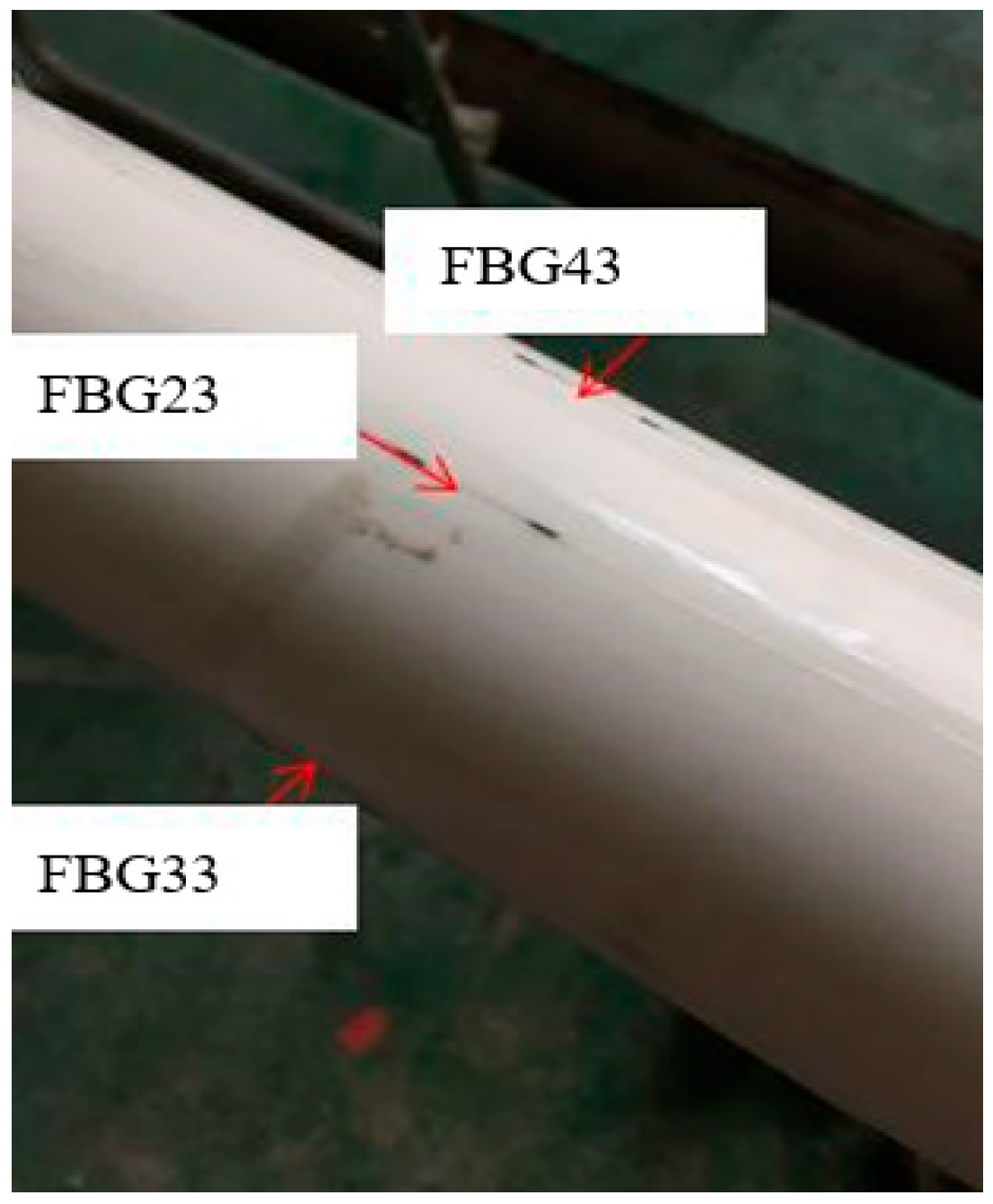

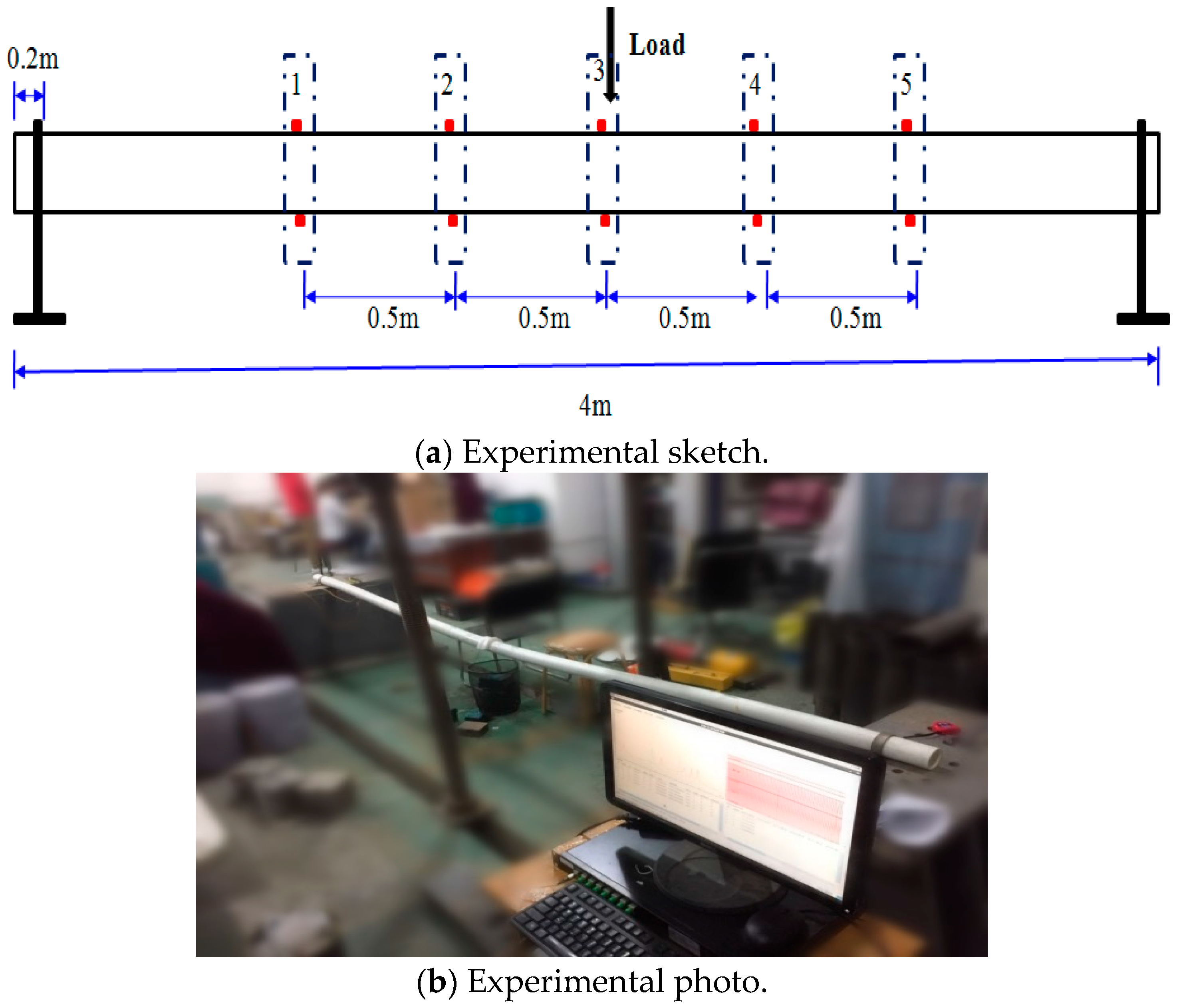

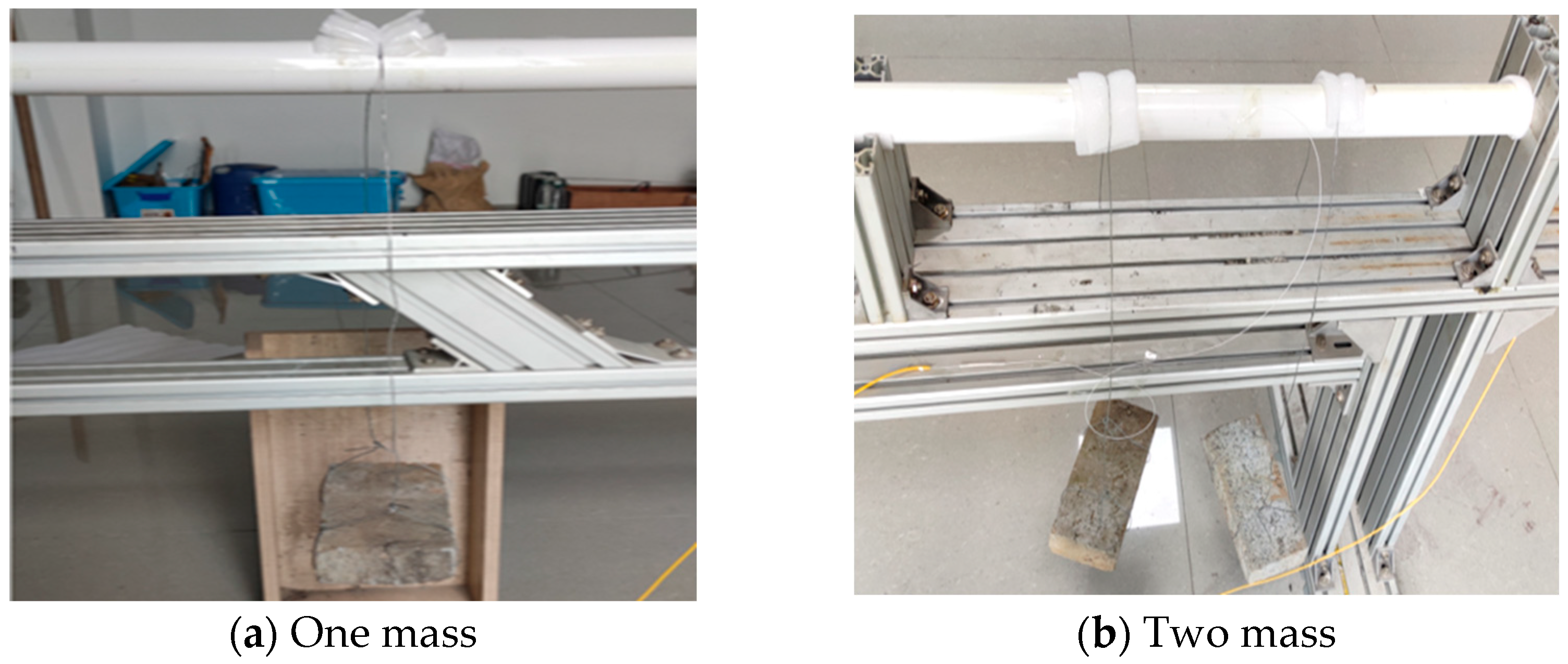

3.2. Deformation Measurement Test of the PVC Pipe

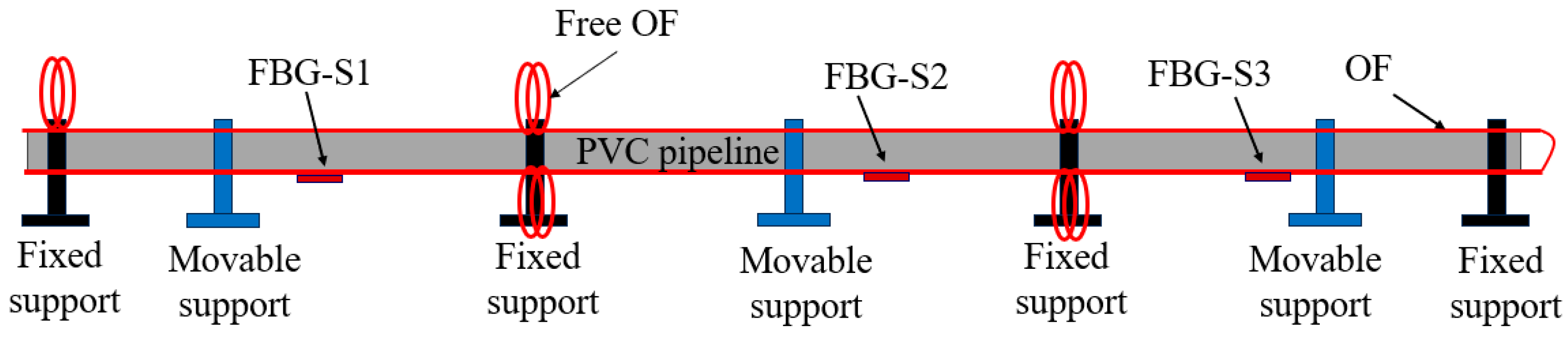

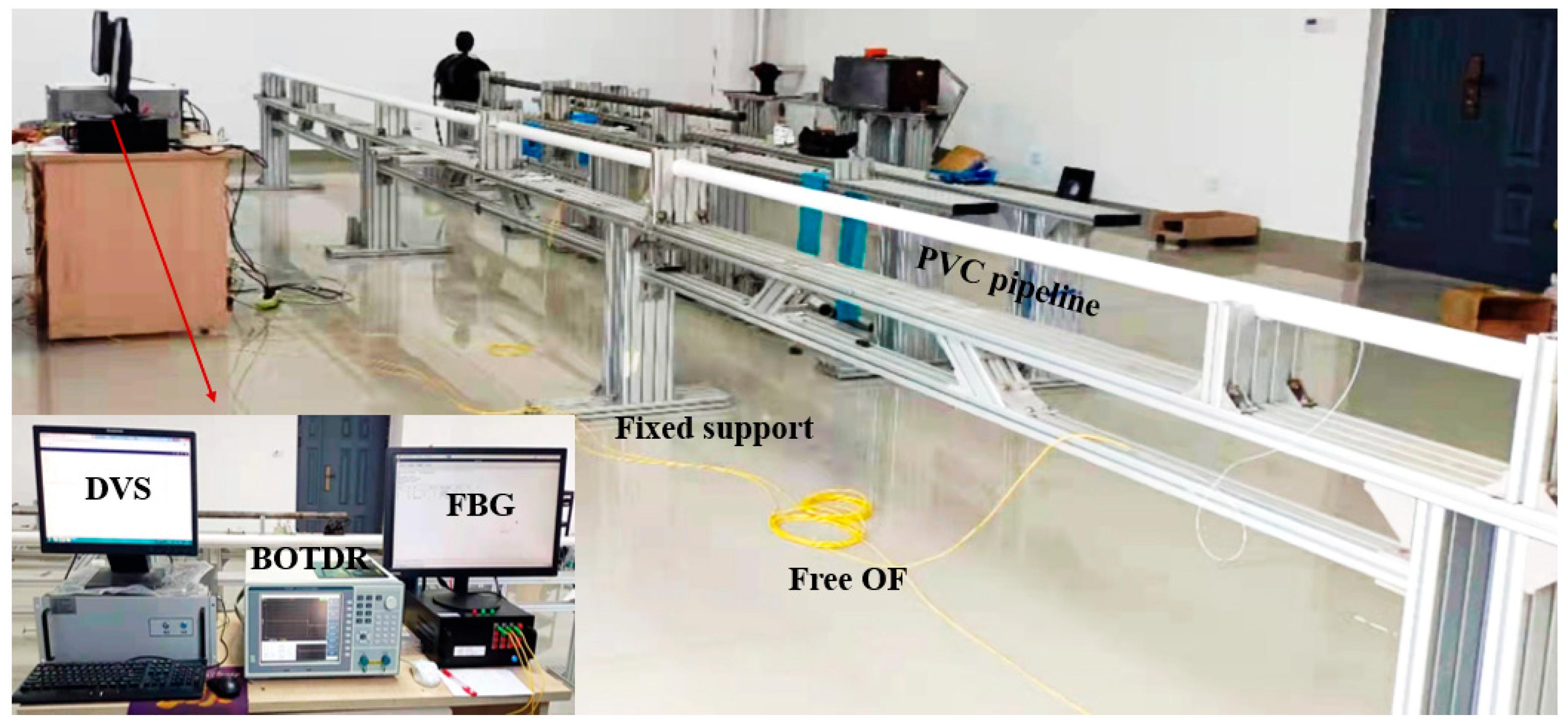

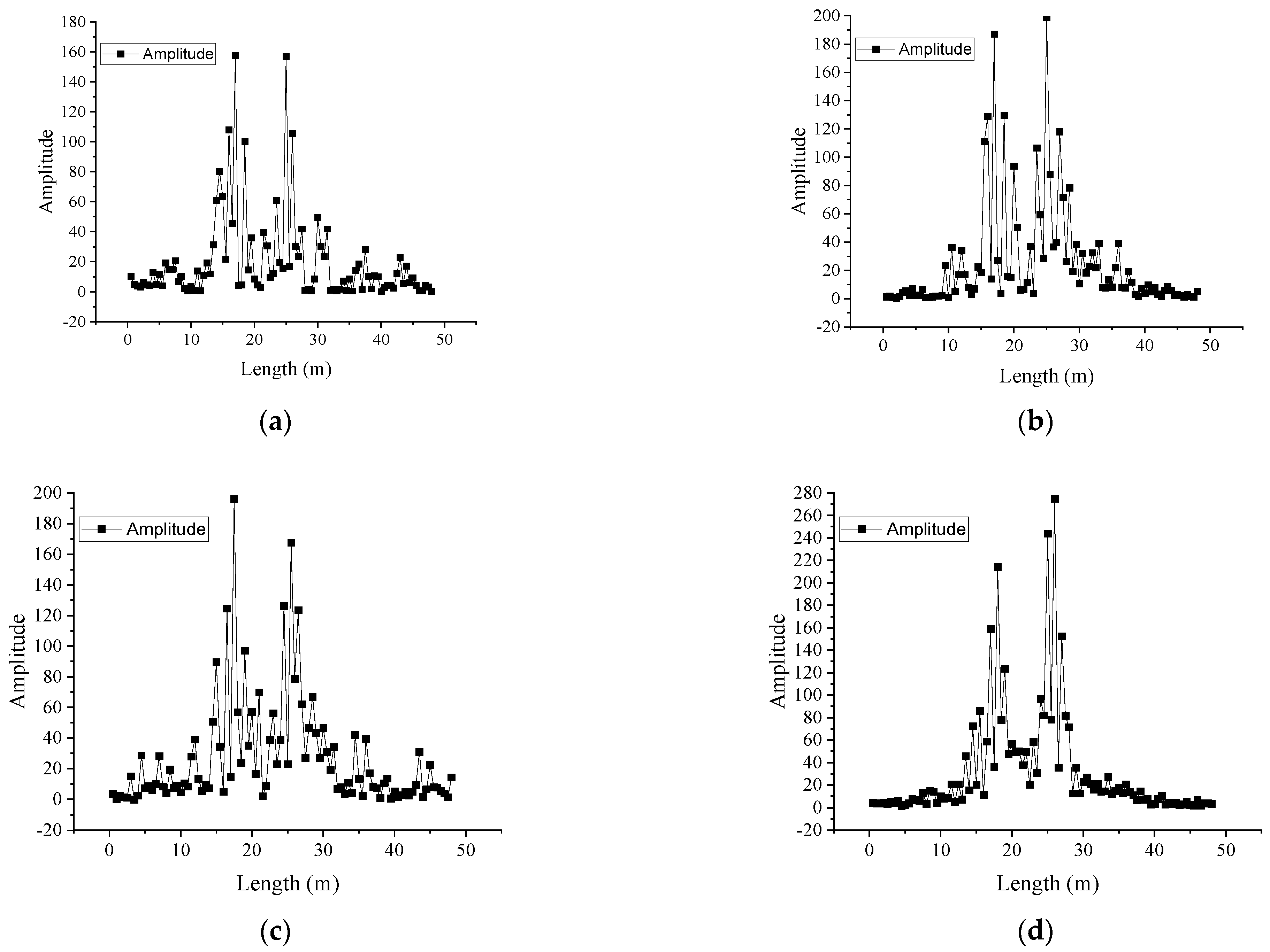

4. Pipeline Vibration and Deformation Monitoring Test Through the Mining Area

4.1. Test Introduction

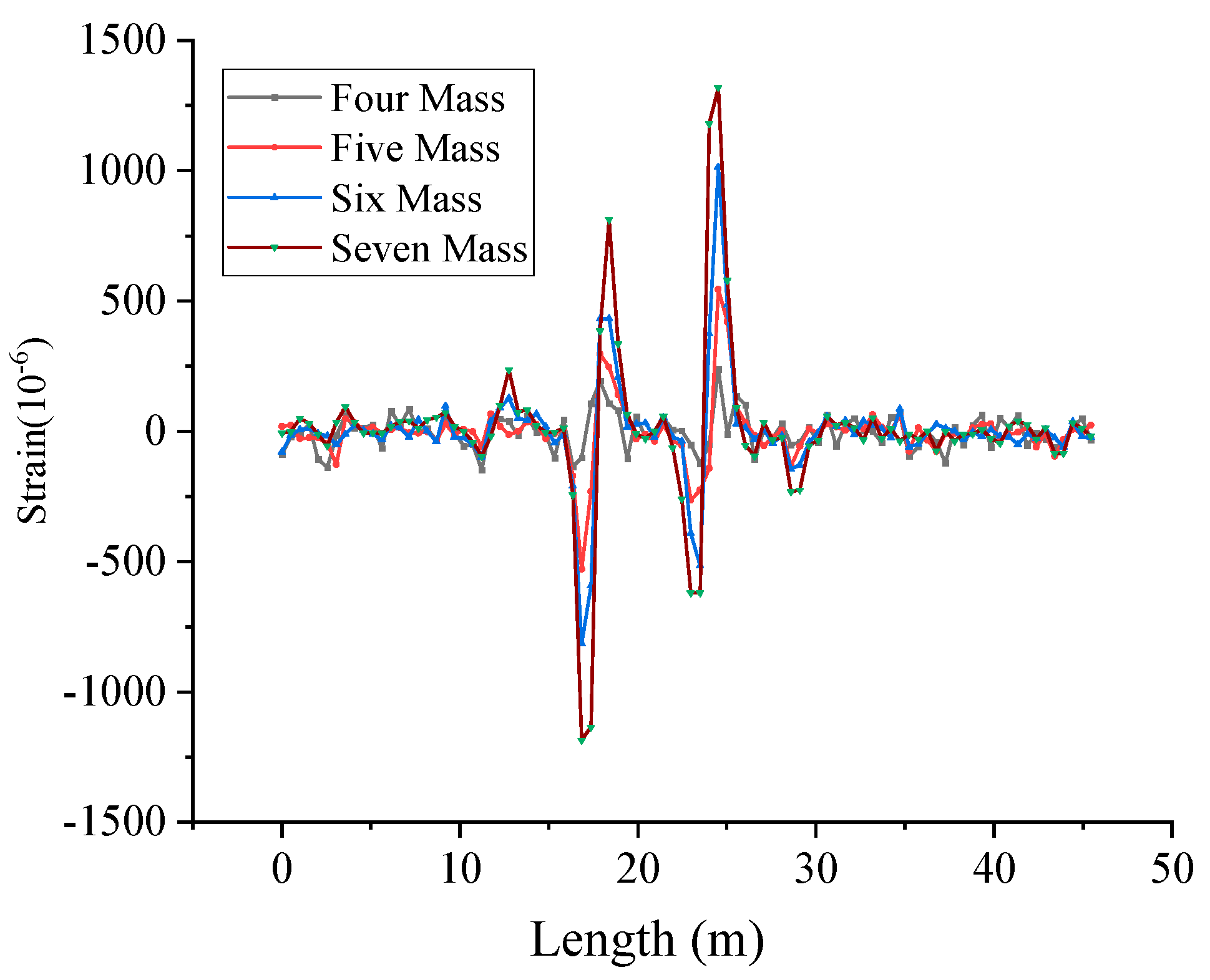

4.2. Experimental Process and Data Analysis

5. Conclusions

- The FBG strings laid at 90° intervals can correctly identify the force direction of the PVC pipe and obtain the maximum strain value of the PVC pipe, and the error of the test with two different angles of rotation is within 5.2%.

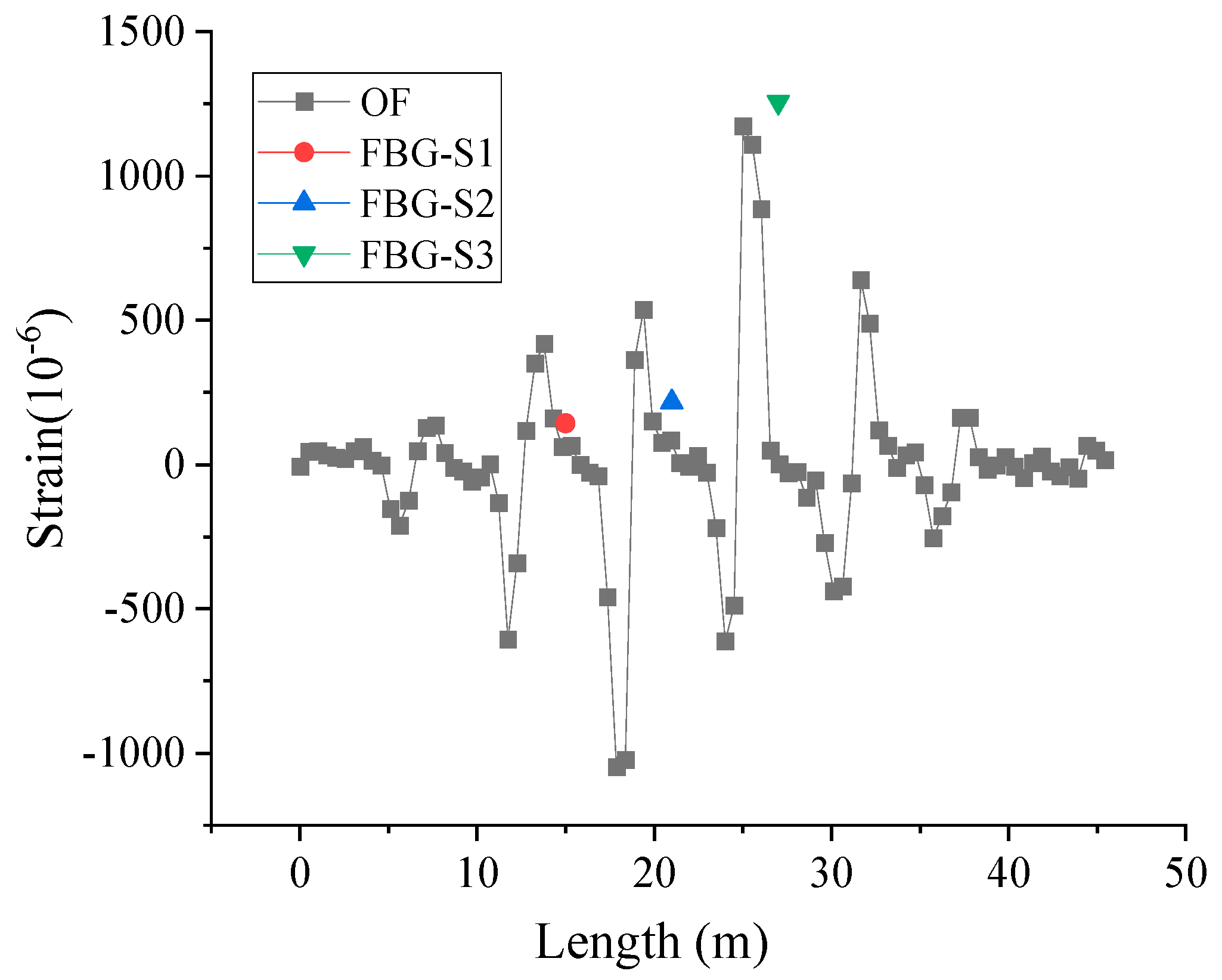

- Results from the goaf expansion simulation test indicate that distributed fiberoptic vibration sensors can effectively identify and locate vibration signals during the expansion process of soil cavities. Meanwhile, distributed fiberoptic strain sensors and localized fiber Bragg grating sensors can accurately measure the deformation of PVC pipelines. Based on the vibration and strain data collected during goaf expansion, a two-tiered early warning strategy for pipeline damage has been established.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Gu, X.; Zhang, Z.; Long, Z.; Zhao, Y. On-line leakage detection in buried tap water distribution pipes using distributed temperature sensing. J. Pipeline Syst. Eng. Pract. 2022, 13, 04022010. [Google Scholar] [CrossRef]

- Apperl, B.; Pressl, A.; Schulz, K. Feasibility of locating leakages in sewage pressure pipes using the distributed temperature sensing technology. Water Air Soil Pollut. 2017, 228, 82. [Google Scholar] [CrossRef]

- Li, H.J.; Zhu, H.H.; Tan, D.Y.; Shi, B.; Yin, J.H. Detecting pipeline leakage using active distributed temperature Sensing: Theoretical modeling and experimental verification. Tunn. Undergr. Space Technol. 2023, 135, 105065. [Google Scholar] [CrossRef]

- Stajanca, P.; Chruscicki, S.; Homann, T.; Seifert, S.; Schmidt, D.; Habib, A. Detection of leak-induced pipeline vibrations using fiber-Optic distributed acoustic sensing. Sensors 2018, 18, 2841. [Google Scholar] [CrossRef]

- Wu, H.; Qian, Y.; Zhang, W.; Tang, C. Feature extraction and identification in distributed optical-fiber vibration sensing system for oil pipeline safety monitoring. Photonic Sens. 2017, 7, 305–310. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Z.; Zhou, X.; Li, S.; Yuan, X.; Zhang, Y.; Shao, L.; Zhang, X. Oil and gas pipeline leakage recognition based on distributed vibration and temperature information fusion. Results Opt. 2021, 5, 100131. [Google Scholar] [CrossRef]

- Xu, L.; Shi, S.; Huang, Y.; Yan, F.; Yang, X.; Bao, Y. Corrosion monitoring and assessment of steel under impact loads using discrete and distributed fiber optic sensors. Opt. Laser Technol. 2024, 174, 110533. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, X.; Han, T.; Huang, H.; Huang, X.; Wang, L.; Wu, Z. Pipeline deformation monitoring based on long-gauge FBG sensing system: Missing data recovery and deformation calculation. J. Civ. Struct. Health Monit. 2025, 15, 2433–2453. [Google Scholar] [CrossRef]

- Gong, Y.; Guo, Y.; Xiong, L.; Liu, C.; Zhou, W.; Hu, Z.; Li, X.; Zhang, Y. A High-Sensitivity Strain Sensor with Femtosecond Fiber Bragg Grating for Pipeline Deformation Monitoring. IEEE Sens. J. 2025, 25, 14830–14841. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y. Research on the leakage monitoring of oil pipeline using BOTDR. J. Pipeline Sci. Technol. 2023, 15, 112–125. [Google Scholar]

- Wen, C.; Hu, S.; Wang, J.; Fang, H.; Xue, X. Fiber optic sensing technology in underground pipeline health monitoring: A comprehensive review. J. Opt. Fiber Technol. 2024, 15, 123–144. [Google Scholar] [CrossRef]

- Wang, Z.; Li, W.; Wang, Q.; Hu, Y.; Du, J. Monitoring the dynamic response of the overlying rock–soil composite structure to underground mining using BOTDR and FBG sensing technologies. Rock Mech. Rock Eng. 2021, 54, 5095–5116. [Google Scholar] [CrossRef]

- Wu, L.; Lu, S.; Zhang, H.; Shu, Q.; Xiao, W.S. An FBG-based high-sensitivity structure and its application in non-intrusive detection of pipeline. Measurement 2022, 199, 111498. [Google Scholar] [CrossRef]

- Cabral, T.; Zimmermann, A.; Willemann, D.; Armando, A. Pipeline Bonded Joints Assembly and Operation Health Monitoring with Embedded FBG Sensors. J. Compos. Mater. 2020, 54, 1234–1244. [Google Scholar]

- Zhang, S.; Liu, B.; He, J. Pipeline deformation monitoring using distributed fiber optical sensor. Measurement 2019, 33, 208–213. [Google Scholar] [CrossRef]

- Lalam, N.; Bhatta, N.; Bukka, S.; Zhang, P.; Diemler, N.; Shumski, A.; Dohodnicki, P. Deep Neural Network Assisted Distributed Strain and Temperature Fiber Sensor System for Natural Gas Pipeline Monitoring. IEEE Trans. Instrum. Meas. 2025, 74, 7003711. [Google Scholar] [CrossRef]

- Zhou, Z.; He, J.; Ou, J. Integrated Optical Fiber Sensing System by Combing Large-Scale Distributed BOTDA_R and Localized FBGs. Int. J. Distrib. Sens. Netw. 2012, 8, 804394. [Google Scholar] [CrossRef]

- Hill, K.; Malo, B.; Bilodeau, F. Bragg grating fabricated in monomode photosensitive optical fiber by UV exposure through a phase mask. Appl. Phys. Lett. 1993, 62, 1035–1037. [Google Scholar] [CrossRef]

- Zhang, S.; He, J.; Zhou, Z. Temperature sensing characteristics of FBG under different level stress and boundary conditions. Pac. Sci. Rev. 2011, 13, 222–226. [Google Scholar]

- Horiguchi, T.; Kurashima, T.; Tateda, M. Tensile Strain Dependence of Brillouin Frequency Shift in Silica Optical Fibers. IEEE Photonics Technol. Lett. 1989, 1, 107–108. [Google Scholar] [CrossRef]

- Culverhouse, D.; Farahi, F.; Pannell, C.N.; Jackson, D.A. Potential of Stimulated Brillouin Scattering as Sensing Mechanism for Distributed Temperature Sensors. Electron. Lett. 1989, 25, 913–915. [Google Scholar] [CrossRef]

- Martins, H.F.; Martin-Lopez, S.; Corredera, P.; Salgado, P.; Frazão, O.; González-Herráez, M. Modulation Instability-Induced Fading in Phase-Sensitive Optical Time-Domain Reflectometry. Opt. Lett. 2013, 38, 872–874. [Google Scholar] [CrossRef] [PubMed]

- Qin, Z.; Zhu, T.; Chen, L.; Bao, X. High Sensitivity Distributed Vibration Sensor Based on Polarization-Maintaining Configurations of Phase-OTDR. IEEE Photonics Technol. Lett. 2011, 23, 1091–1093. [Google Scholar] [CrossRef]

| FBG-S1 | FBG-S2 | FBG-S3 | |

|---|---|---|---|

| Initial center wavelength (nm) | 1539.9610 | 1535.1750 | 1545.4680 |

| Final center wavelength (nm) | 1540.1324 | 1535.4352 | 1546.9745 |

| Strain increment (10−6) | 142.83 | 216.83 | 1255.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Qin, T.; Zhang, Z.; Liu, R.; Bao, Y. Safety Monitoring Method for Pipeline Crossing the Mining Area Based on Vibration–Strain Fusion Analysis. Micromachines 2025, 16, 1074. https://doi.org/10.3390/mi16091074

He J, Qin T, Zhang Z, Liu R, Bao Y. Safety Monitoring Method for Pipeline Crossing the Mining Area Based on Vibration–Strain Fusion Analysis. Micromachines. 2025; 16(9):1074. https://doi.org/10.3390/mi16091074

Chicago/Turabian StyleHe, Jianping, Tongchun Qin, Zhe Zhang, Ronggui Liu, and Yuping Bao. 2025. "Safety Monitoring Method for Pipeline Crossing the Mining Area Based on Vibration–Strain Fusion Analysis" Micromachines 16, no. 9: 1074. https://doi.org/10.3390/mi16091074

APA StyleHe, J., Qin, T., Zhang, Z., Liu, R., & Bao, Y. (2025). Safety Monitoring Method for Pipeline Crossing the Mining Area Based on Vibration–Strain Fusion Analysis. Micromachines, 16(9), 1074. https://doi.org/10.3390/mi16091074