Hybrid Inductively Coupled Plasma and Computer-Controlled Optical Surfacing Polishing for Rapid Fabrication of Damage-Free Ultra-Smooth Surfaces

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

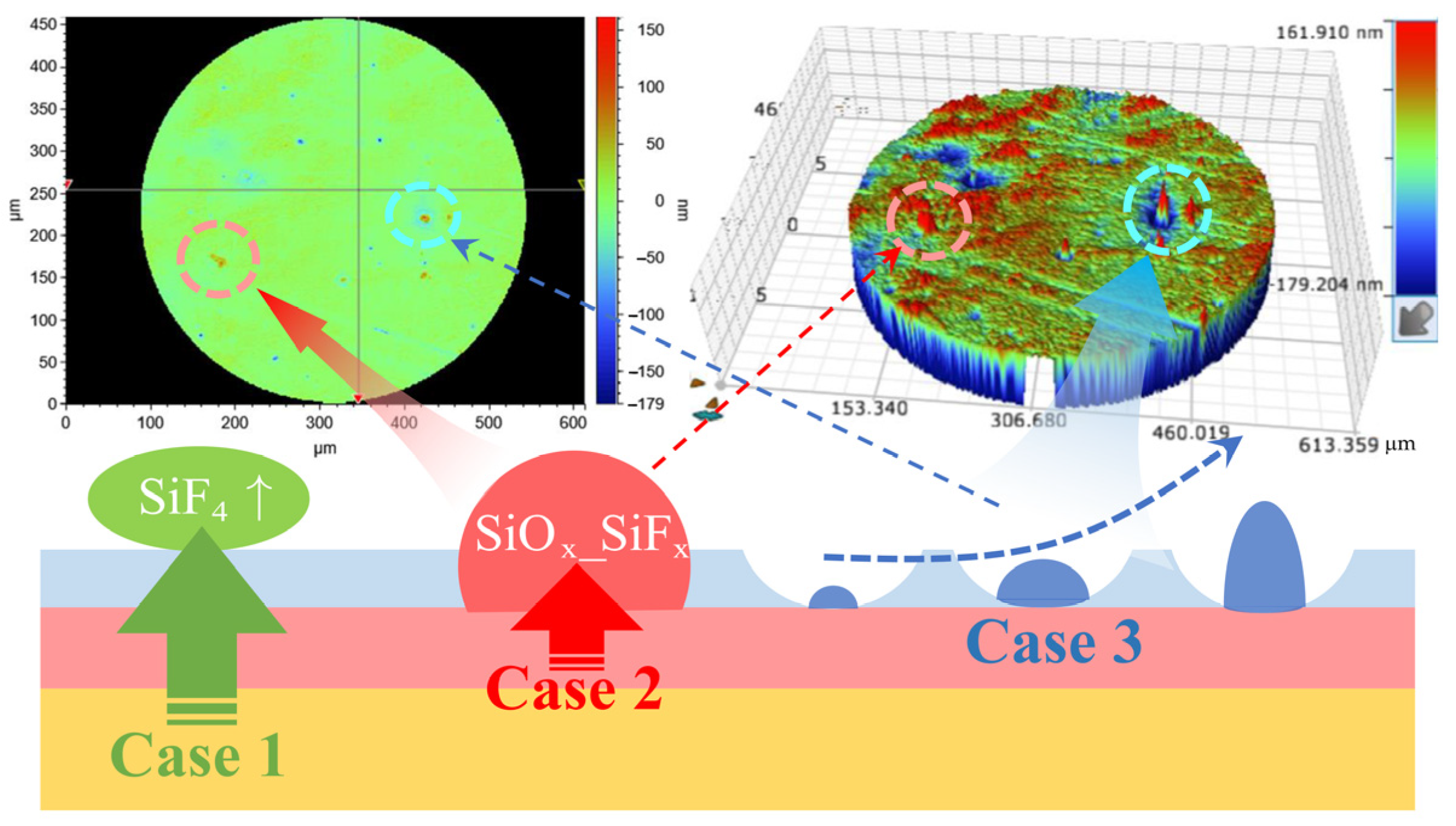

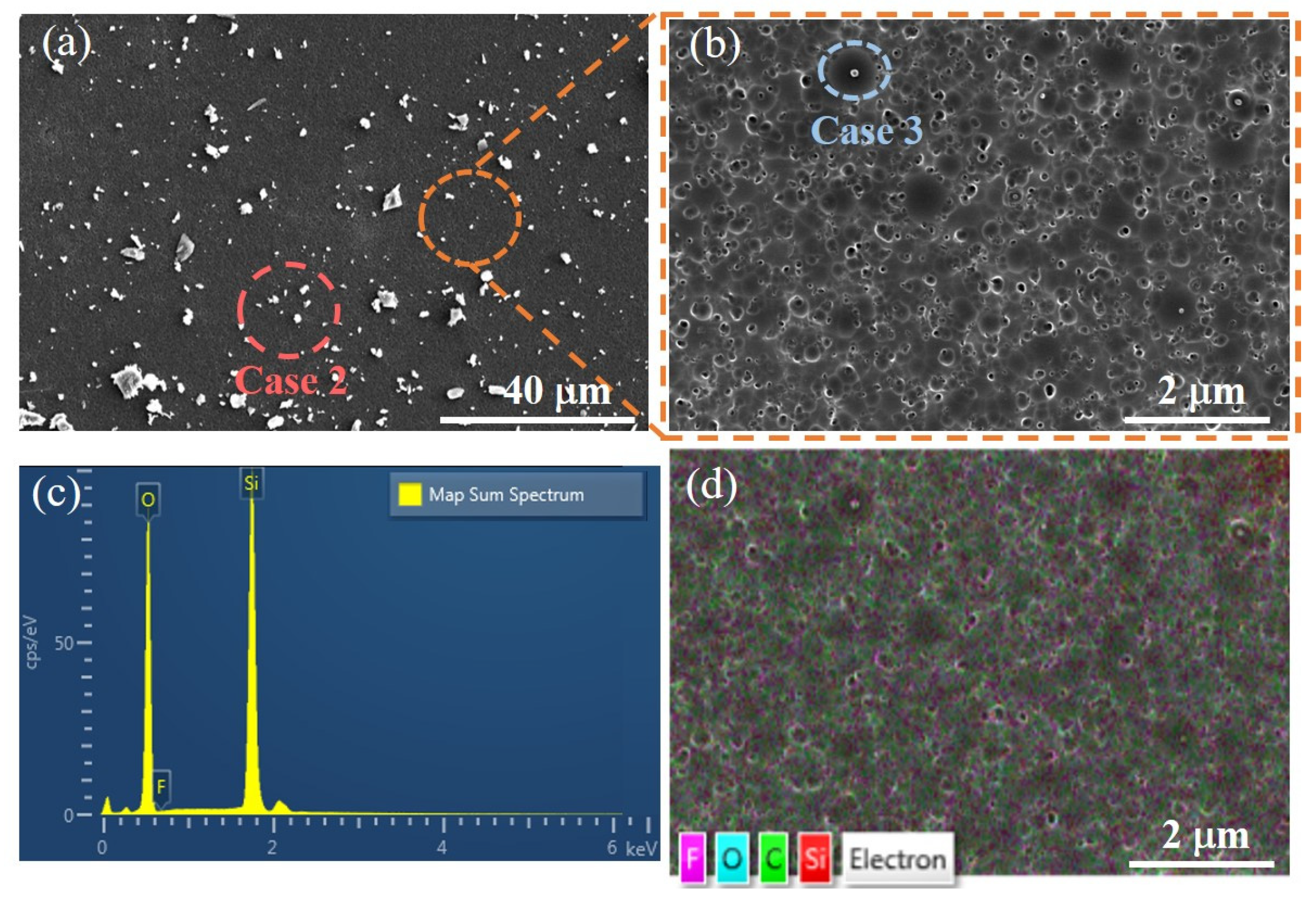

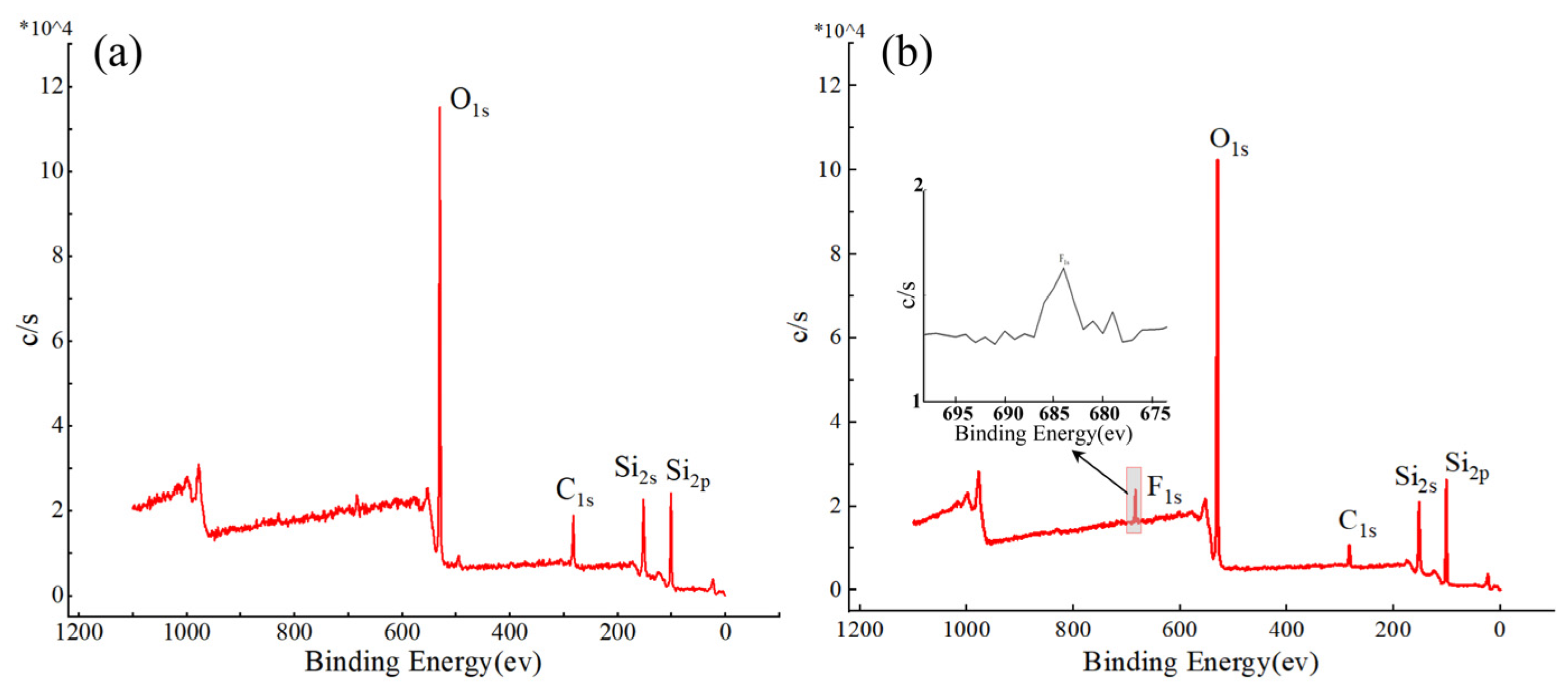

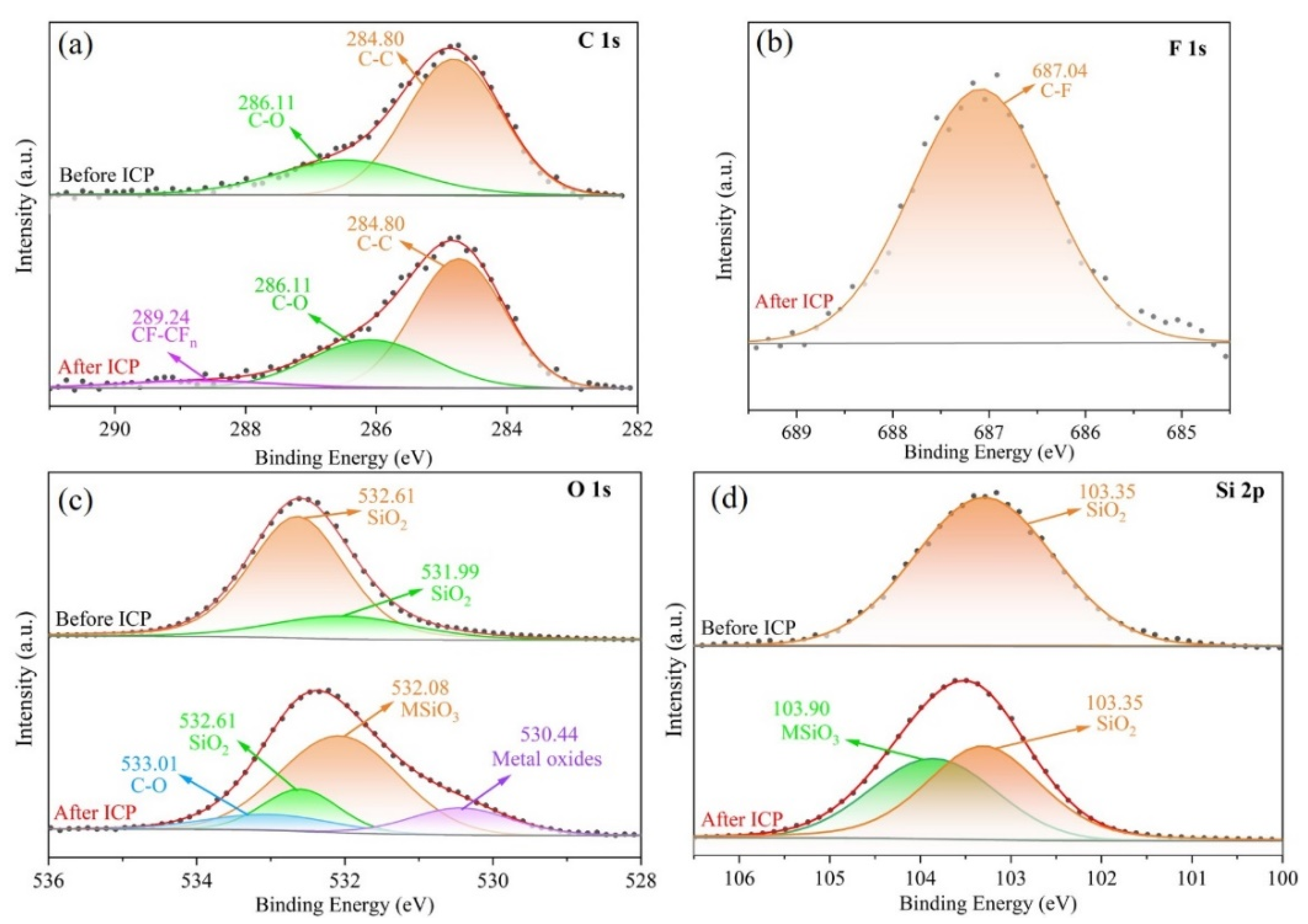

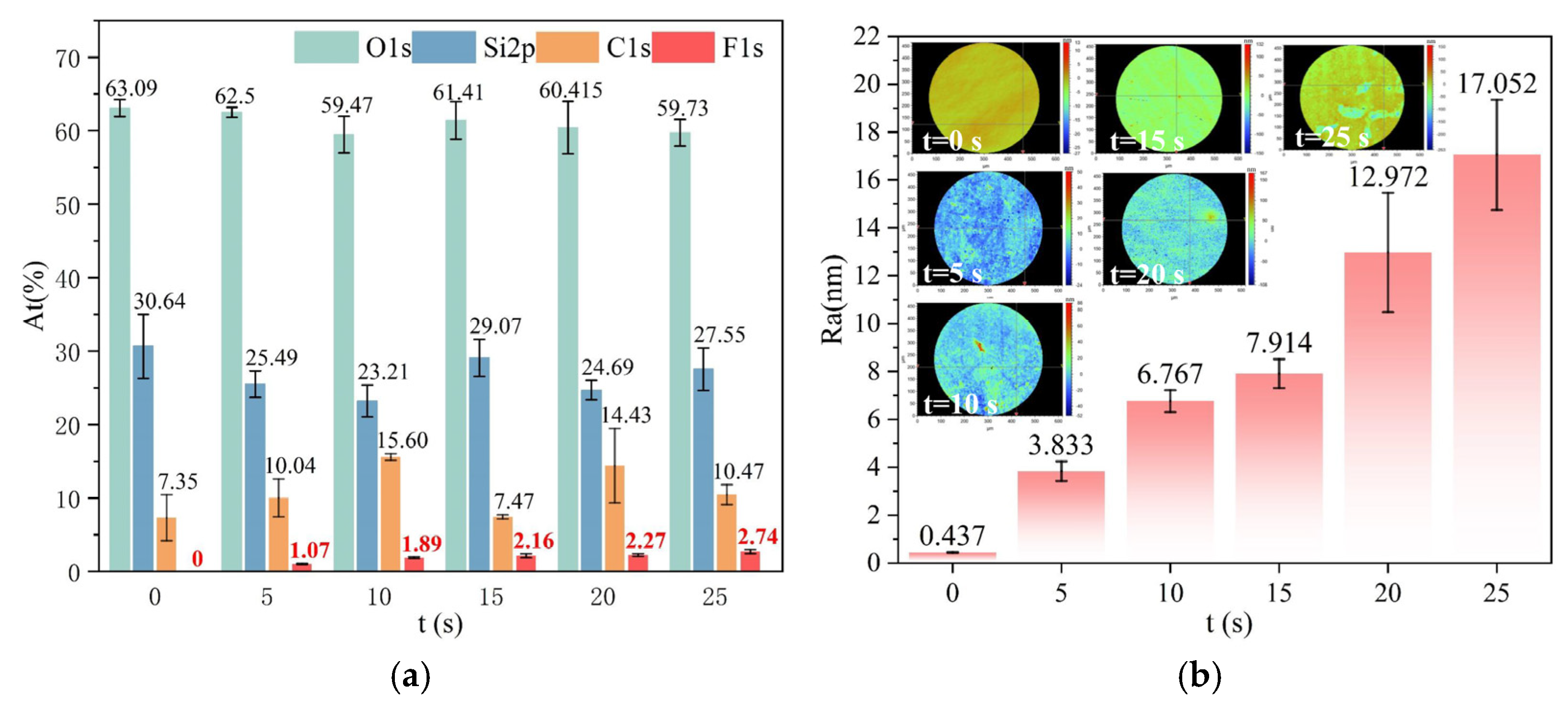

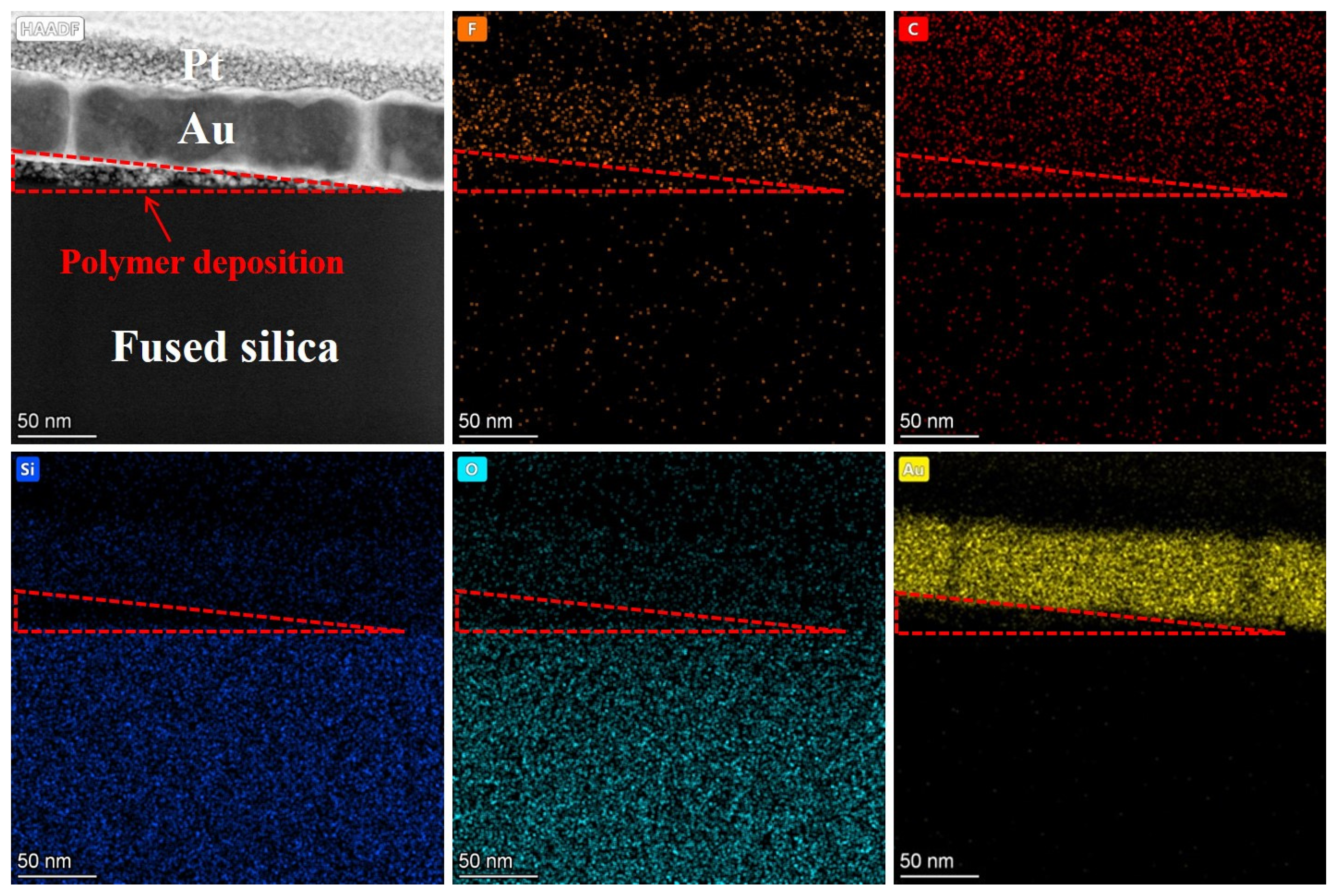

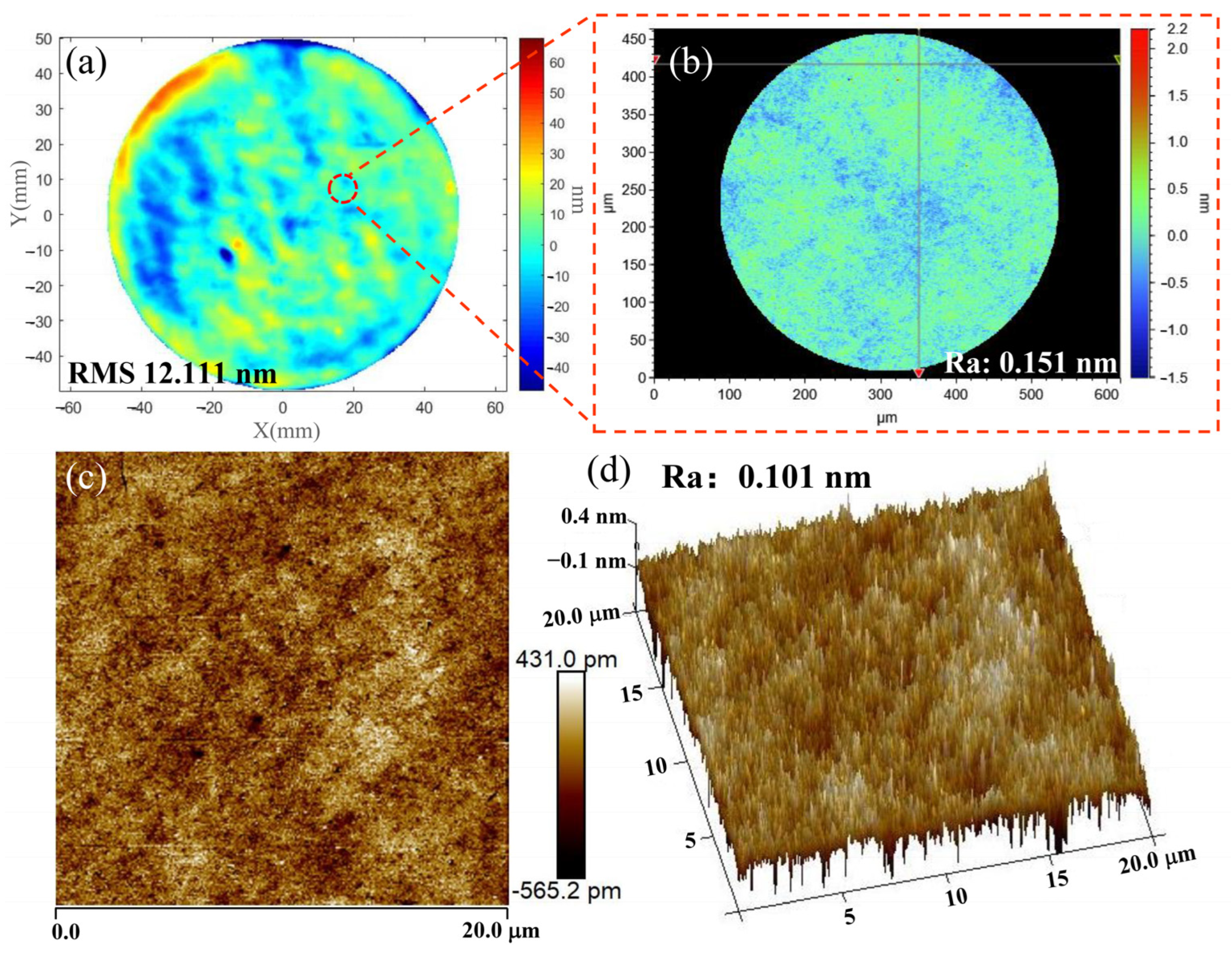

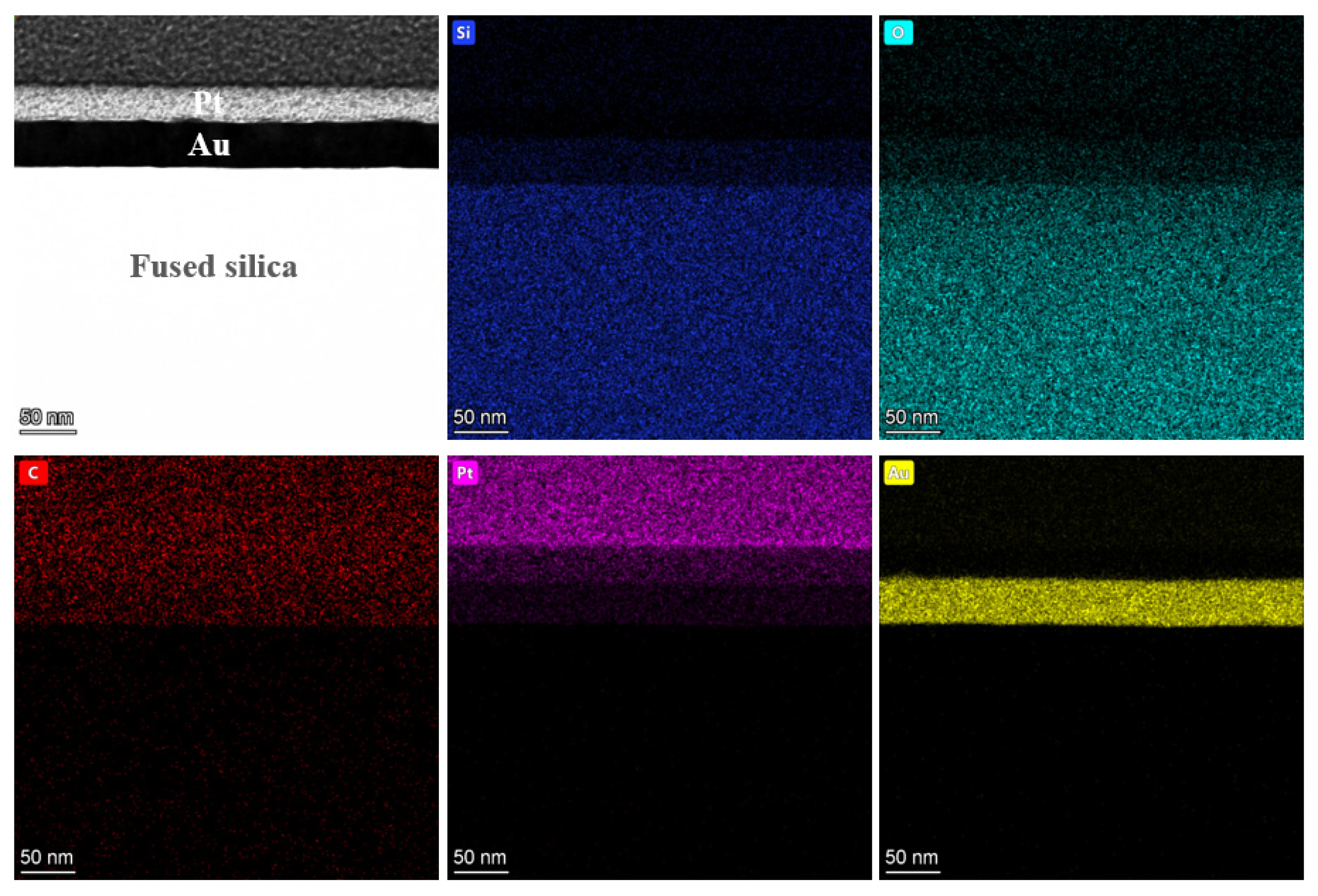

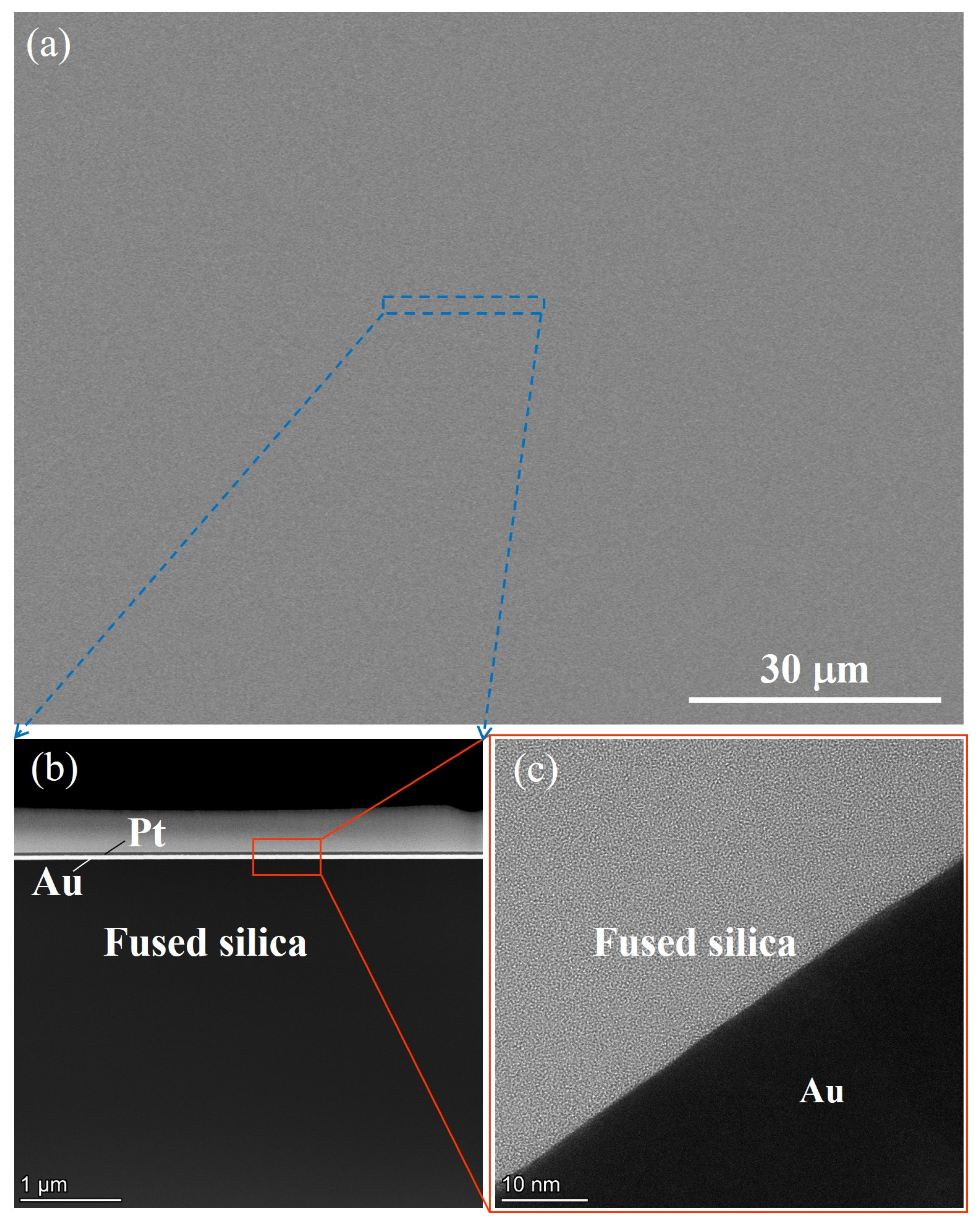

3.1. Characterization and Formation Mechanism of PDL

3.2. ICP Enhances the Surface Shape Accuracy of Optical Components

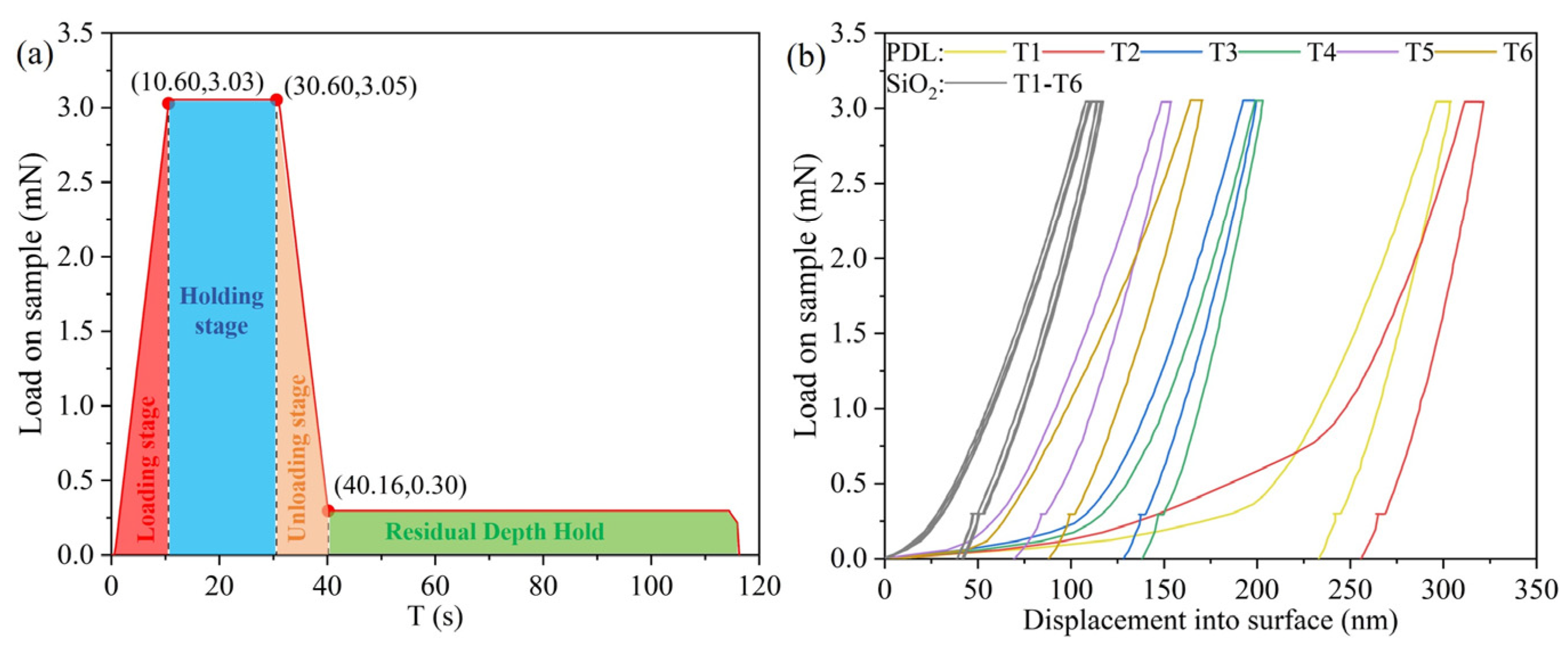

3.3. Mechanical Properties of Deposition Layer

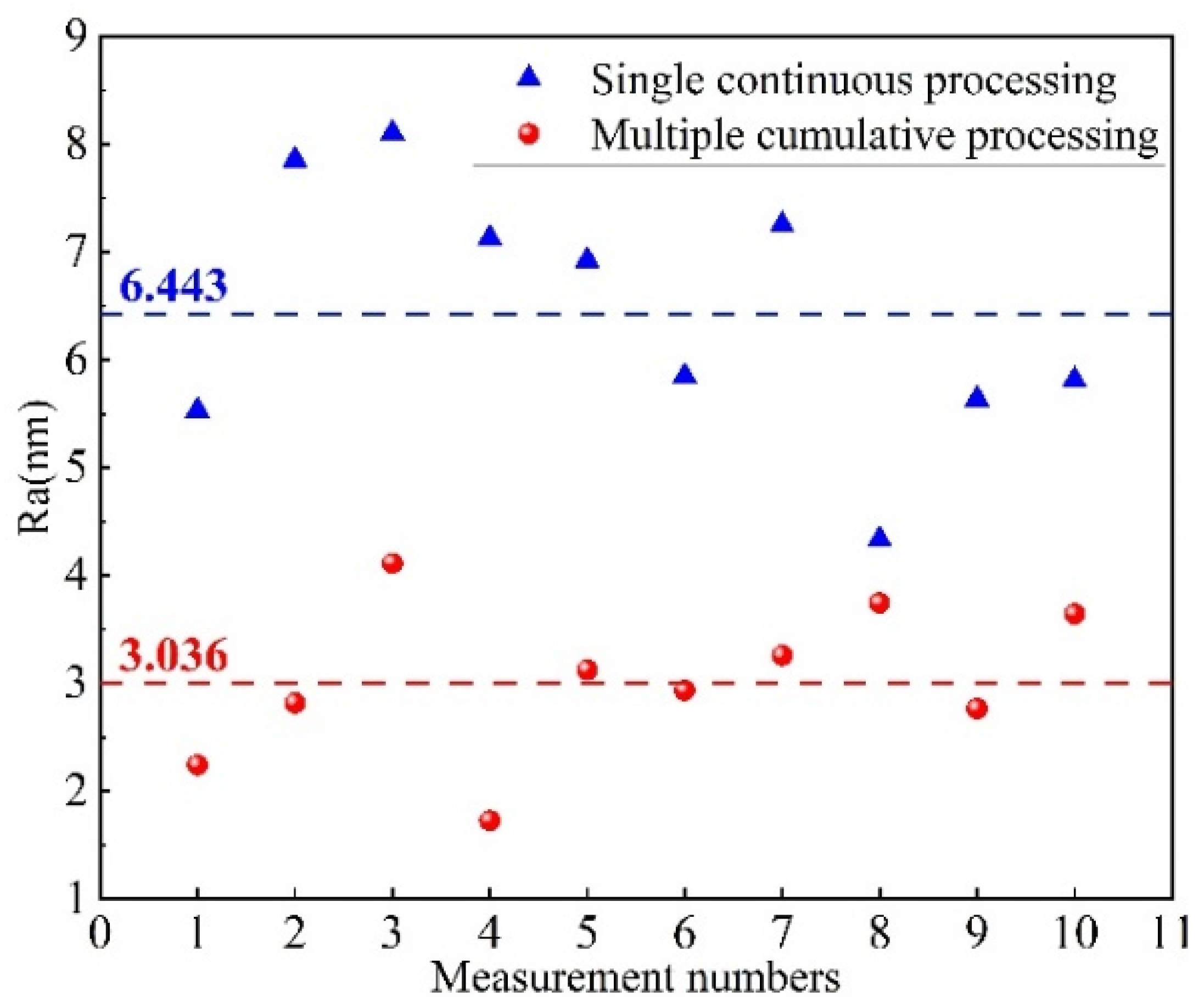

3.4. Experiment on Removing PDL by CCOS

4. Conclusions

- (1)

- The formation mechanism, chemical composition, and mechanical properties of the PDL produced by plasma processing are analyzed, providing a foundation for the proposed method of the gradient division of dwell time for surface shape trimming, which aims to suppress the deterioration of surface roughness.

- (2)

- Utilizing the low hardness and elastic modulus of the PDL layer formed on the surface after ICP modification, the surface is protected from scratches caused by large abrasive particles during the initial stage of CCOS processing. This helps maintain the damage-free surface obtained after ICP modification and mitigates the limitations of ICP processing, such as roughness deterioration caused by polymer deposition.

- (3)

- Applying the ICP-CCOS method with optimized process parameters eliminates the need for multiple cycles of shape modification and roughness reduction. This method efficiently achieves the simultaneous convergence of surface shape error and roughness, resulting in an ultra-smooth surface with high shape accuracy, exceptionally low roughness, and no damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brueckner, R. Properties and structure of vitreous silica. I. J. Non-Cryst. Solids 1970, 5, 123–175. [Google Scholar] [CrossRef]

- Moore, L.A.; Smith, C.M. Fused silica as an optical material. Opt. Mater. Express 2022, 12, 3043–3059. [Google Scholar] [CrossRef]

- Li, W.; Hu, X.; Guo, X.; Xie, S.; Tian, W.; Huang, X.; Ibrahim, A.M.M. Enhanced precision lapping techniques for fused quartz optical elements: Synergistic integration of mechanical and mechanochemical processes. Ceram. Int. 2024, 50, 45382–45397. [Google Scholar] [CrossRef]

- Li, W.; Xin, Q.; Fan, B.; Chen, Q.; Deng, Y. A Review of Emerging Technologies in Ultra-Smooth Surface Processing for Optical Components. Micromachines 2024, 15, 178. [Google Scholar] [CrossRef] [PubMed]

- Bauer, J.; Frost, F.; Lehmann, A.; Ulitschka, M.; Li, Y.; Arnold, T. Finishing of metal optics by ion beam technologies. Opt. Eng. 2019, 58, 092612. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, S.; Huang, H.; Chen, F.; Deng, G. Magnetorheological polishing using a permanent magnetic yoke with straight air gap for ultra-smooth surface planarization. Precis. Eng. 2015, 40, 309–317. [Google Scholar] [CrossRef]

- ZHANG, Y. Formation and evolution behavior of comet-tail defects in magnetorheological finishing. Opt. Precis. Eng 2021, 29, 740–748. [Google Scholar]

- Mahmud, S.; Fukabori, T.; Pahlovy, S.; Miyamoto, I. Low energy ion beam smoothening of artificially synthesized single crystal diamond chips with initial surface roughness of 0.08–0.4 nm rms. Diam. Relat. Mater. 2012, 24, 116–120. [Google Scholar] [CrossRef]

- Liao, W.; Nie, X.; Liu, Z.; Nie, X.; Wan, W. Researches on formation mechanism of ultra-smooth surface during ion beam sputtering of fused silica. Optik 2019, 179, 957–964. [Google Scholar] [CrossRef]

- Dai, Z.; Xie, X.; Chen, H.; Zhou, L. Non-linear compensated dwell time for efficient fused silica surface figuring using inductively coupled plasma. Plasma Chem. Plasma Process. 2018, 38, 443–459. [Google Scholar] [CrossRef]

- Arnold, T.; Böhm, G.; Fechner, R.; Meister, J.; Nickel, A.; Frost, F.; Hänsel, T.; Schindler, A. Ultra-precision surface finishing by ion beam and plasma jet techniques—Status and outlook. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2010, 616, 147–156. [Google Scholar] [CrossRef]

- Jiao, P.; Xin, Q.; Fan, B.; Wu, Y.; Wu, X. Morphology evolution of Vickers indentation in fused silica glass etched by atmospheric pressure plasma jet. Ceram. Int. 2022, 48, 31500–31508. [Google Scholar] [CrossRef]

- Jin, H.; Xin, Q.; Li, N.; Jin, J.; Wang, B.; Yao, Y. The morphology and chemistry evolution of fused silica surface after Ar/CF4 atmospheric pressure plasma processing. Appl. Surf. Sci. 2013, 286, 405–411. [Google Scholar] [CrossRef]

- Efremov, A.; Kim, D.-P.; Kim, C.-I. Effect of gas mixing ratio on gas-phase composition and etch rate in an inductively coupled CF4/Ar plasma. Vacuum 2004, 75, 133–142. [Google Scholar] [CrossRef]

- Choi, J.H.; Yoon, J.; Jung, Y.; Min, K.W.; Im, W.B.; Kim, H.-J. Analysis of plasma etching resistance for commercial quartz glasses used in semiconductor apparatus in fluorocarbon plasma. Mater. Chem. Phys. 2021, 272, 125015. [Google Scholar] [CrossRef]

- Lee, J.; Efremov, A.; Kwon, K.-H. On the relationships between plasma chemistry, etching kinetics and etching residues in CF4+ C4F8+ Ar and CF4+ CH2F2+ Ar plasmas with various CF4/C4F8 and CF4/CH2F2 mixing ratios. Vacuum 2018, 148, 214–223. [Google Scholar] [CrossRef]

- Leech, P.W. Reactive ion etching of quartz and silica-based glasses in CF4/CHF3 plasmas. Vacuum 1999, 55, 191–196. [Google Scholar] [CrossRef]

- Kazemi, F.; Boehm, G.; Arnold, T. Development of a model for ultra-precise surface machining of N-BK7® using microwave-driven reactive plasma jet machining. Plasma Process. Polym. 2019, 16, 1900119. [Google Scholar] [CrossRef]

- Xin, Q.; Li, N.; Wang, J.; Wang, B.; Li, G.; Ding, F.; Jin, H. Surface roughening of ground fused silica processed by atmospheric inductively coupled plasma. Appl. Surf. Sci. 2015, 341, 142–148. [Google Scholar] [CrossRef]

- Heinke, R.; Arnold, T.; Ehrhardt, M.; Lorenz, P.; Zimmer, K. Influence of Fluence and Pulse Number on Laser Cleaning of Atmospheric-Pressure-Plasma-Jet-Etched Optical Glasses. Phys. Status Solidi (a) 2024, 221, 2300485. [Google Scholar] [CrossRef]

- Kazemi, F.; Arnold, T.; Lorenz, P.; Ehrhardt, M.; Zimmer, K. Combined reactive plasma jet-laser etching method for technical optical glass containing metal oxides. Appl. Surf. Sci. 2021, 551, 149339. [Google Scholar] [CrossRef]

- Su, X.; Ji, P.; Liu, K.; Walker, D.; Yu, G.; Li, H.; Li, D.; Wang, B. Combined processing chain for freeform optics based on atmospheric pressure plasma processing and bonnet polishing. Opt. Express 2019, 27, 17979–17992. [Google Scholar] [CrossRef] [PubMed]

- Tozzi, A.; Brucalassi, A.; Canestrari, R.; Chioetto, P.; Del Vecchio, C.; Carbonaro, L.; Cortecchia, F.; Diolaiti, E.; Eccleston, P.; Falcini, G. Toward ARIEL’s Primary Mirror. In Proceedings of the Space Telescopes and Instrumentation 2022: Optical, Infrared, and Millimeter Wave, Montreal, QC, Canada, 17–22 July 2022; pp. 1518–1532. [Google Scholar]

- Song, C.; Zhang, W.; Shi, F.; Lin, Z.; Nie, X. Conformal smoothing of mid-spatial frequency surface error for nano-accuracy Continuous Phase Plates (CPP). Sci. Rep. 2020, 10, 2579. [Google Scholar] [CrossRef] [PubMed]

- Jiao, P.; Xin, Q.; Wu, X.; Wu, Y.; Fan, B.; Chen, Q. Research status of key technologies in plasma optics fabrication. J. Appl. Opt 2022, 43, 359–374. [Google Scholar]

- Xin, Q.; Su, X.; Wang, B. Modeling study on the surface morphology evolution during removing the optics surface/subsurface damage using atmospheric pressure plasma processing. Appl. Surf. Sci. 2016, 382, 260–267. [Google Scholar] [CrossRef]

- Gasvoda, R.J.; van de Steeg, A.W.; Bhowmick, R.; Hudson, E.A.; Agarwal, S. Surface phenomena during plasma-assisted atomic layer etching of SiO2. ACS Appl. Mater. Interfaces 2017, 9, 31067–31075. [Google Scholar] [CrossRef]

- Darcy, A.; Galijatovic, A.; Barth, R.; Kenny, T.; Krantzman, K.D.; Schoolcraft, T.A. Molecular dynamics simulations of silicon-fluorine etching. J. Mol. Graph. 1996, 14, 260–271. [Google Scholar] [CrossRef]

- Satriano, C.; Conte, E.; Marletta, G. Surface chemical structure and cell adhesion onto ion beam modified polysiloxane. Langmuir 2001, 17, 2243–2250. [Google Scholar] [CrossRef]

- Bollinger, L.D.; Steinberg, G.; Zarowin, C.B. Rapid optical figuring of aspherical surfaces with plasma-assisted chemical etching. In Proceedings of the Large Optics II, Rochester, NY, USA, 7–10 October 1991; pp. 14–21. [Google Scholar]

- Sahin, H.T. RF-plasma vapor deposition of siloxane on paper. Part 2: Chemical evolution of paper surface. Appl. Surf. Sci. 2013, 265, 564–569. [Google Scholar] [CrossRef]

- Jin, H. Research on Surface Formation Mechanismin Removal of Subsurface Damage on Fused Silica Byatmospherio Pressure Plasma Processing. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Heinke, R.; Arnold, T.; Ehrhardt, M.; Lorenz, P.; Zimmer, K. Laser-Cleaning of Atmospheric Pressure Plasma Jet Etched Zerodur. In Proceedings of the Eleventh European Seminar on Precision Optics Manufacturing, Teisnach, Germany, 9–10 April 2024; pp. 25–30. [Google Scholar]

- Gasvoda, R.J.; Verstappen, Y.G.; Wang, S.; Hudson, E.A.; Agarwal, S. Surface prefunctionalization of SiO2 to modify the etch per cycle during plasma-assisted atomic layer etching. J. Vac. Sci. Technol. A 2019, 37, 051003. [Google Scholar] [CrossRef]

- Zhang, D.; Kushner, M.J. Investigations of surface reactions during C2F6 plasma etching of SiO2 with equipment and feature scale models. J. Vac. Sci. Technol. A Vac. Surf. Film. 2001, 19, 524–538. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Z.; Shi, C.; Deng, X.; Zhou, H.; Feng, J.; Liu, X.; Liu, X.; Wen, W. Angstrom surface with high material removal rate for quartz glass induced by silk dissolved novel green chemical mechanical polishing. Colloids Surf. A Physicochem. Eng. Asp. 2024, 682, 132957. [Google Scholar] [CrossRef]

- Levis, R.; Winograd, N.; DeLouise, L.A. The influence of surface atomic steps on site-selective adsorption processes. Ethylidyne formation on rhodium {111} and rhodium {331}. J. Am. Chem. Soc. 1987, 109, 6873–6875. [Google Scholar] [CrossRef]

- Valentini, L.; Braca, E.; Kenny, J.M.; Lozzi, L.; Santucci, S. Relationship between the optical and mechanical properties of fluorinated amorphous carbon thin films. J. Non-Cryst. Solids 2001, 291, 153–159. [Google Scholar] [CrossRef]

- Bosman, H.; Pijpers, A.; Jaspers, A. An X-ray photoelectron spectroscopy study of the acidity of SiO2–ZrO2 Mixed oxides. J. Catal. 1996, 161, 551–559. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, Z.; Meng, F.; Liu, L.; Liu, D.; Shi, C.; Cui, X.; Wang, J.; Wen, W. Atomic-scale surface of fused silica induced by chemical mechanical polishing with controlled size spherical ceria abrasives. J. Manuf. Process. 2023, 85, 783–792. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Z.; Shi, C.; Ren, Z.; Feng, J.; Zhou, H.; Liu, Z.; Meng, F.; Zhao, S. Novel green chemical mechanical polishing of fused silica through designing synergistic CeO2/h-BN abrasives with lubricity. Appl. Surf. Sci. 2023, 637, 157978. [Google Scholar] [CrossRef]

- Shi, Y.; Noelle, D.J.; Wang, M.; Le, A.V.; Yoon, H.; Zhang, M.; Meng, Y.S.; Qiao, Y. Role of amines in thermal-runaway-mitigating lithium-ion battery. ACS Appl. Mater. Interfaces 2016, 8, 30956–30963. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, Z.; Shi, C.; Feng, J.; Zhuang, X.; Li, L.; Meng, F.; Li, H.; Xue, Z.; Liu, D. Dispersion and polishing mechanism of a novel CeO2-LaOF-based chemical mechanical polishing slurry for quartz glass. Materials 2023, 16, 1148. [Google Scholar] [CrossRef] [PubMed]

- González-Elipe, A.; Alvarez, R.; Holgado, J.; Espinos, J.; Munuera, G.; Sanz, J. An XPS study of the Ar+-induced reduction of Ni2+ in NiO and Ni-Si oxide systems. Appl. Surf. Sci. 1991, 51, 19–26. [Google Scholar] [CrossRef]

- Hasha, D.; Sierra de Saldarriaga, L.; Saldarriaga, C.; Hathaway, P.E.; Cox, D.F.; Davis, M.E. Studies of silicoaluminophosphates with the sodalite structure. J. Am. Chem. Soc. 1988, 110, 2127–2135. [Google Scholar] [CrossRef]

- Jiao, P.; Fan, B.; Xin, Q.; Wu, X.; Wang, H. Machining Path Optimization of Inductively Coupled Plasma Based on Surface Heat Transfer Model. Micromachines 2025, 16, 71. [Google Scholar] [CrossRef] [PubMed]

| Power (W) | Gas Composition | CF4 Flow Rate (sccm) | Ar Flow Rate (sccm) | Processing Distance (mm) | Point Dwell Time(s) |

|---|---|---|---|---|---|

| 350 | Ar, CF4 | 20.00 | 800.00 | 17.0 | 20 |

| Power (W) | Gas Composition | CF4 Flow Rate (sccm) | Ar Flow Rate (sccm) | Processing Distance (mm) | Point Dwell Time (s) |

|---|---|---|---|---|---|

| 350 | Ar, CF4 | 20.00 | 800.00 | 17.0 | 5 s apart |

| Number | Power (W) | Gas Composition | CF4 Flow Rate (sccm) | Ar Flow Rate (sccm) | Processing Distance (mm) | Residence Mode (s) |

|---|---|---|---|---|---|---|

| A | 300 | Ar, CF4 | 20.00 | 800.00 | 17.0 | Process 5 times, 2 s each time |

| B | 300 | Ar, CF4 | 20.00 | 800.00 | 17.0 | Process once for 10 s |

| Number | Power (W) | Gas Composition | CF4 Flow Rate (sccm) | Ar Flow Rate (sccm) | Processing Distance (mm) | Shape Convergence Rate(%) | Processing Time (min) |

|---|---|---|---|---|---|---|---|

| P1 | 300 | Ar, CF4 | 20.00 | 800.00 | 17.0 | 60 | 26.7 |

| P2 | 300 | Ar, CF4 | 20.00 | 800.00 | 17.0 | 20 | 6.6 |

| Abrasive Particle | Particle Size (nm) | PH | Additive | Ultrasonic Vibration Frequency (Hz) | Ultrasonic Vibration Power (W) | Temperature (°C) |

|---|---|---|---|---|---|---|

| 4.0 wt% CeO2 | 20 | 8.0 | 0.2 wt% DBSA | 20k | 400 | 25–27 |

| Pressure (N) | Rotational Speed (rad/min) | Orbital Speed (rad/min) | Eccentric Distance (mm) | Polishing Time (min) | Polishing Pad Diameter (mm) | Polishing Pad Material | Softening Point of Asphalt (°C) |

|---|---|---|---|---|---|---|---|

| 4 | 50 | 110 | 3.0 | 90 | 20.0 | Asphalt | 52–55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Jiao, P.; Luo, D.; Xin, Q.; Fan, B.; Wu, X.; Gao, B.; Chen, Q. Hybrid Inductively Coupled Plasma and Computer-Controlled Optical Surfacing Polishing for Rapid Fabrication of Damage-Free Ultra-Smooth Surfaces. Micromachines 2025, 16, 1073. https://doi.org/10.3390/mi16091073

Li W, Jiao P, Luo D, Xin Q, Fan B, Wu X, Gao B, Chen Q. Hybrid Inductively Coupled Plasma and Computer-Controlled Optical Surfacing Polishing for Rapid Fabrication of Damage-Free Ultra-Smooth Surfaces. Micromachines. 2025; 16(9):1073. https://doi.org/10.3390/mi16091073

Chicago/Turabian StyleLi, Wei, Peiqi Jiao, Dawei Luo, Qiang Xin, Bin Fan, Xiang Wu, Bo Gao, and Qiang Chen. 2025. "Hybrid Inductively Coupled Plasma and Computer-Controlled Optical Surfacing Polishing for Rapid Fabrication of Damage-Free Ultra-Smooth Surfaces" Micromachines 16, no. 9: 1073. https://doi.org/10.3390/mi16091073

APA StyleLi, W., Jiao, P., Luo, D., Xin, Q., Fan, B., Wu, X., Gao, B., & Chen, Q. (2025). Hybrid Inductively Coupled Plasma and Computer-Controlled Optical Surfacing Polishing for Rapid Fabrication of Damage-Free Ultra-Smooth Surfaces. Micromachines, 16(9), 1073. https://doi.org/10.3390/mi16091073