End Surface Grinding Machinability of Zirconia Ceramics via Longitudinal–Torsional Coupled Vibration Rotary Ultrasonic Machining

Abstract

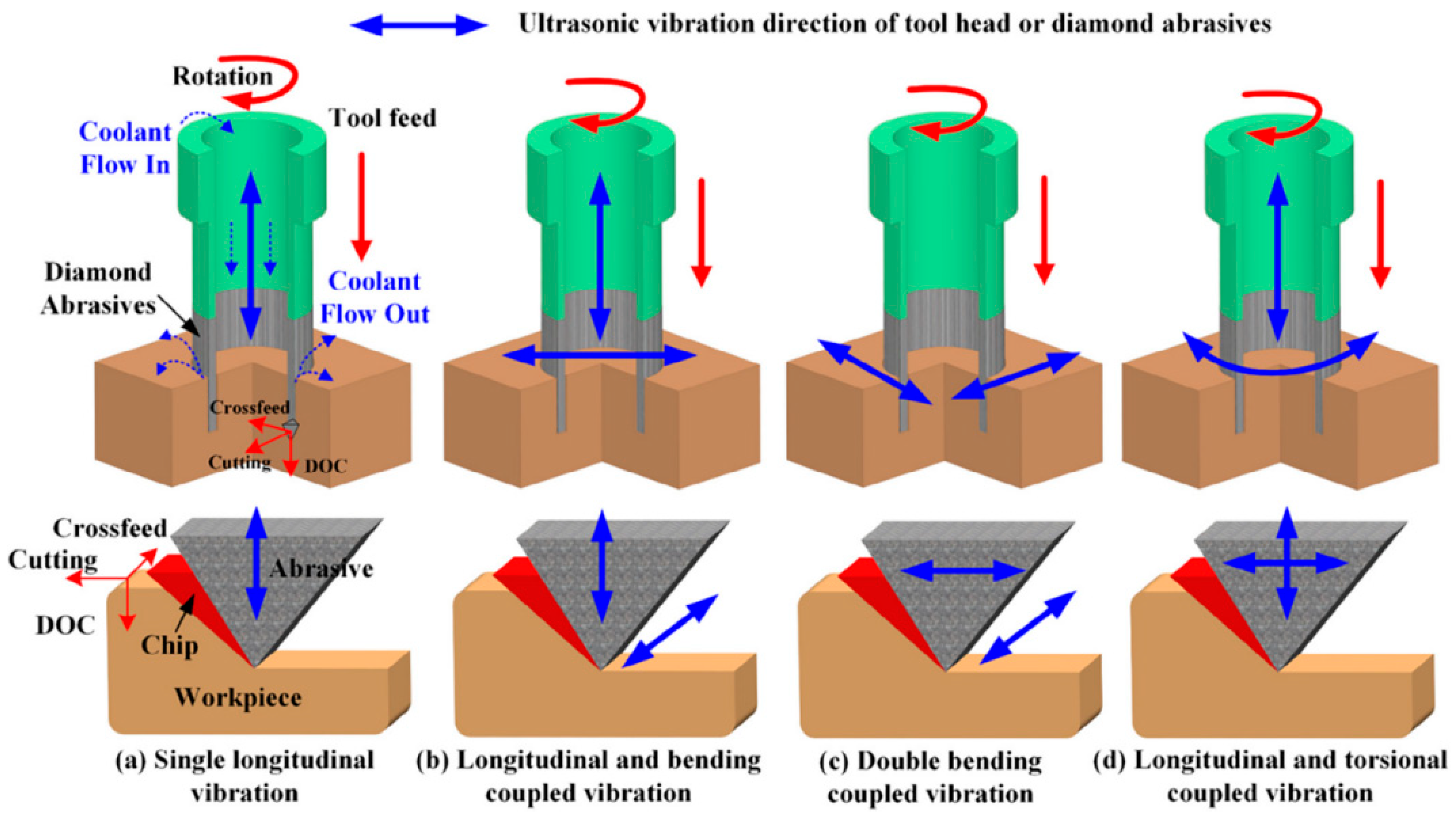

1. Introduction

2. Mechanism of Material Removal

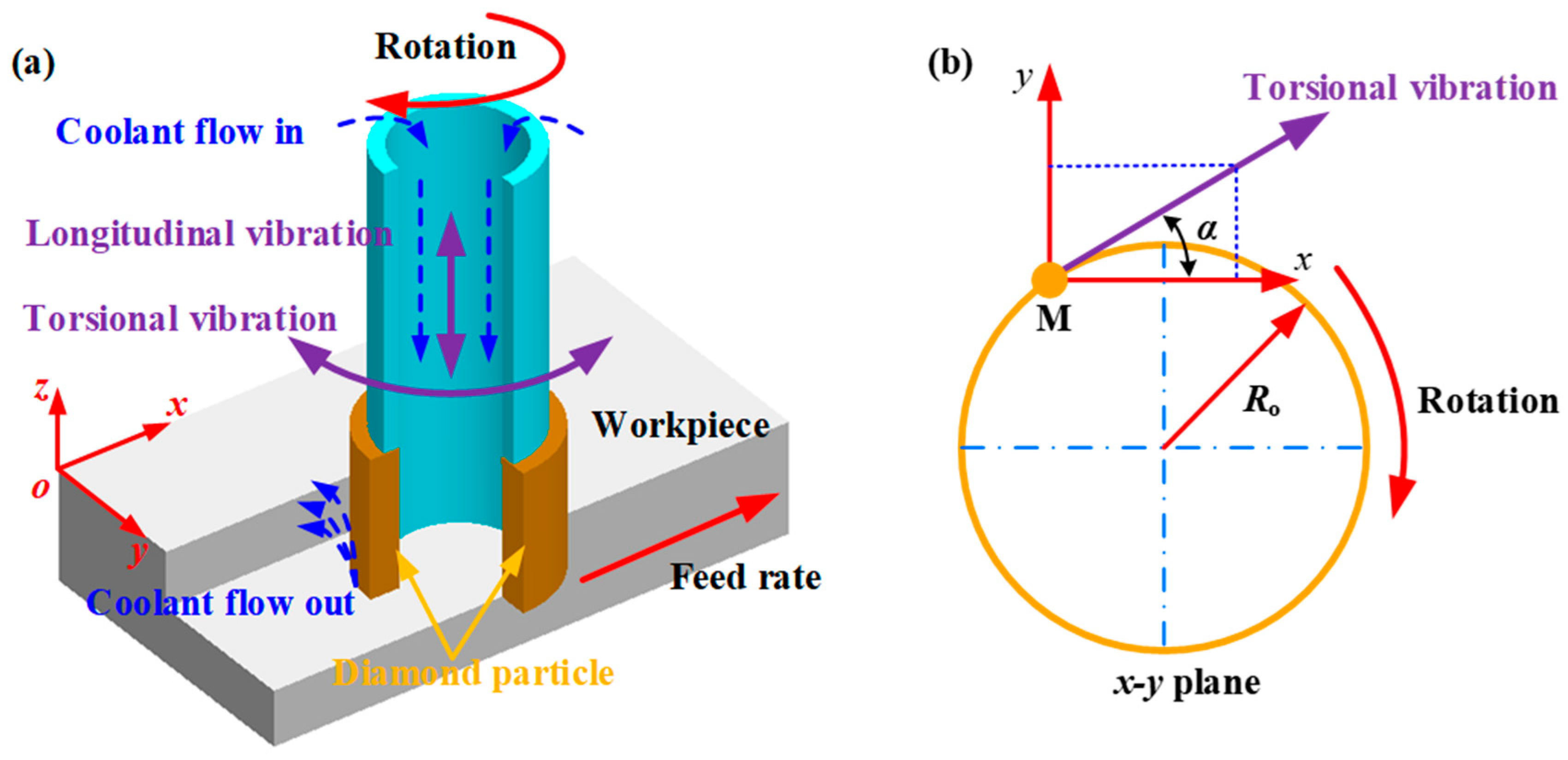

2.1. Kinematic Analysis of a Single Abrasive Grain

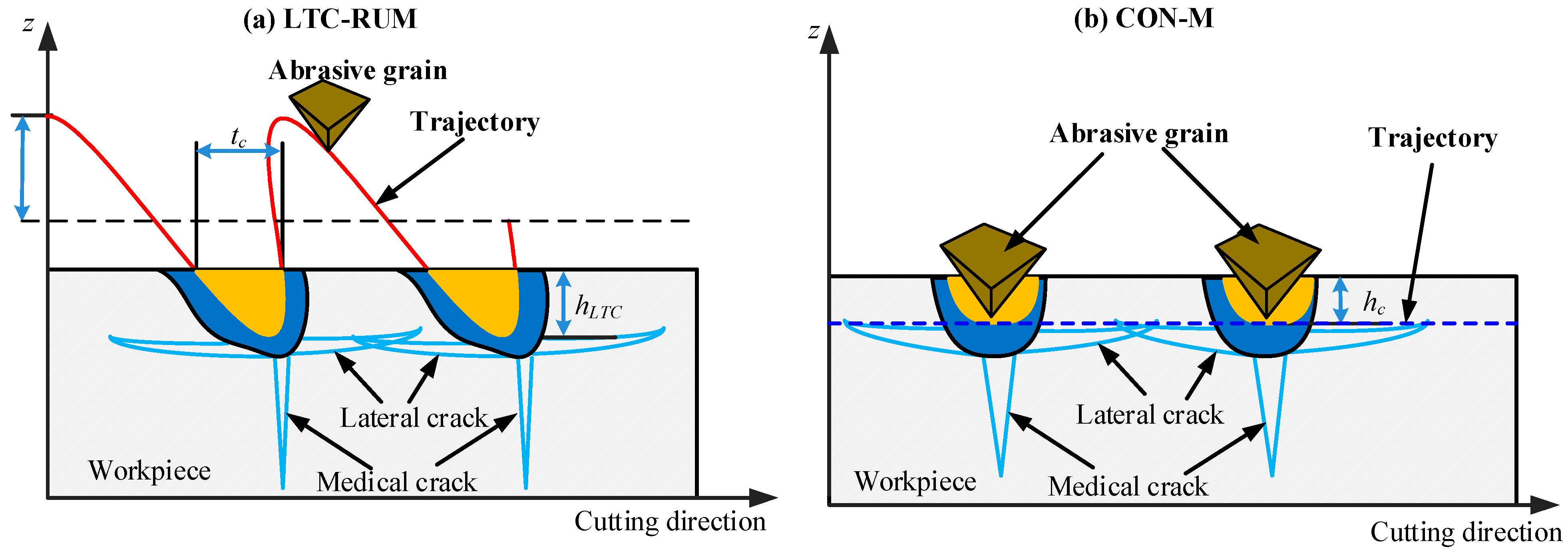

2.2. Material Removal Mechanism by a Single Abrasive Grain

3. Experimental Setup and Methodology

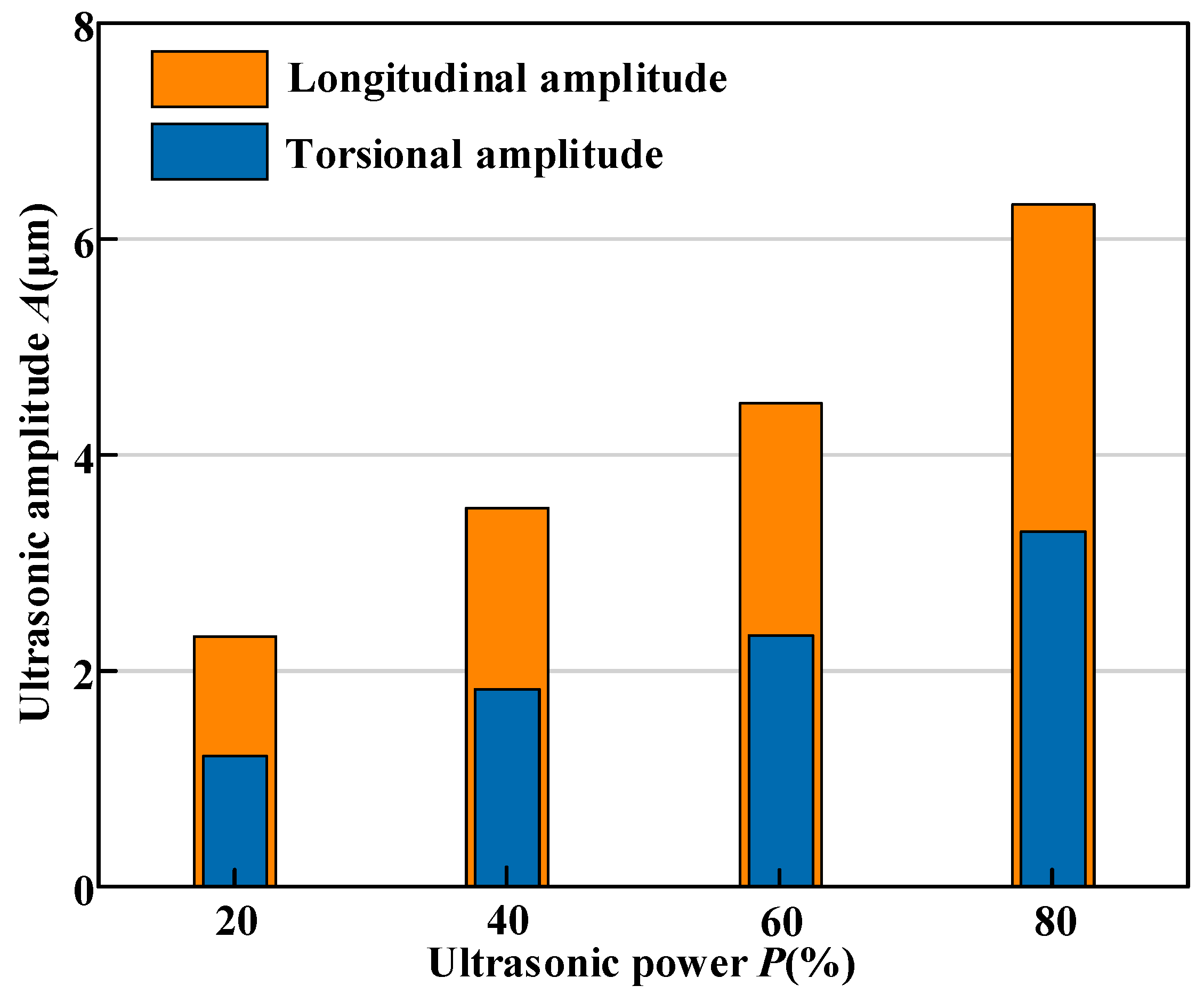

3.1. Experimental Setup

3.2. Design of Experiment

4. Results and Discussion

4.1. Cutting Force

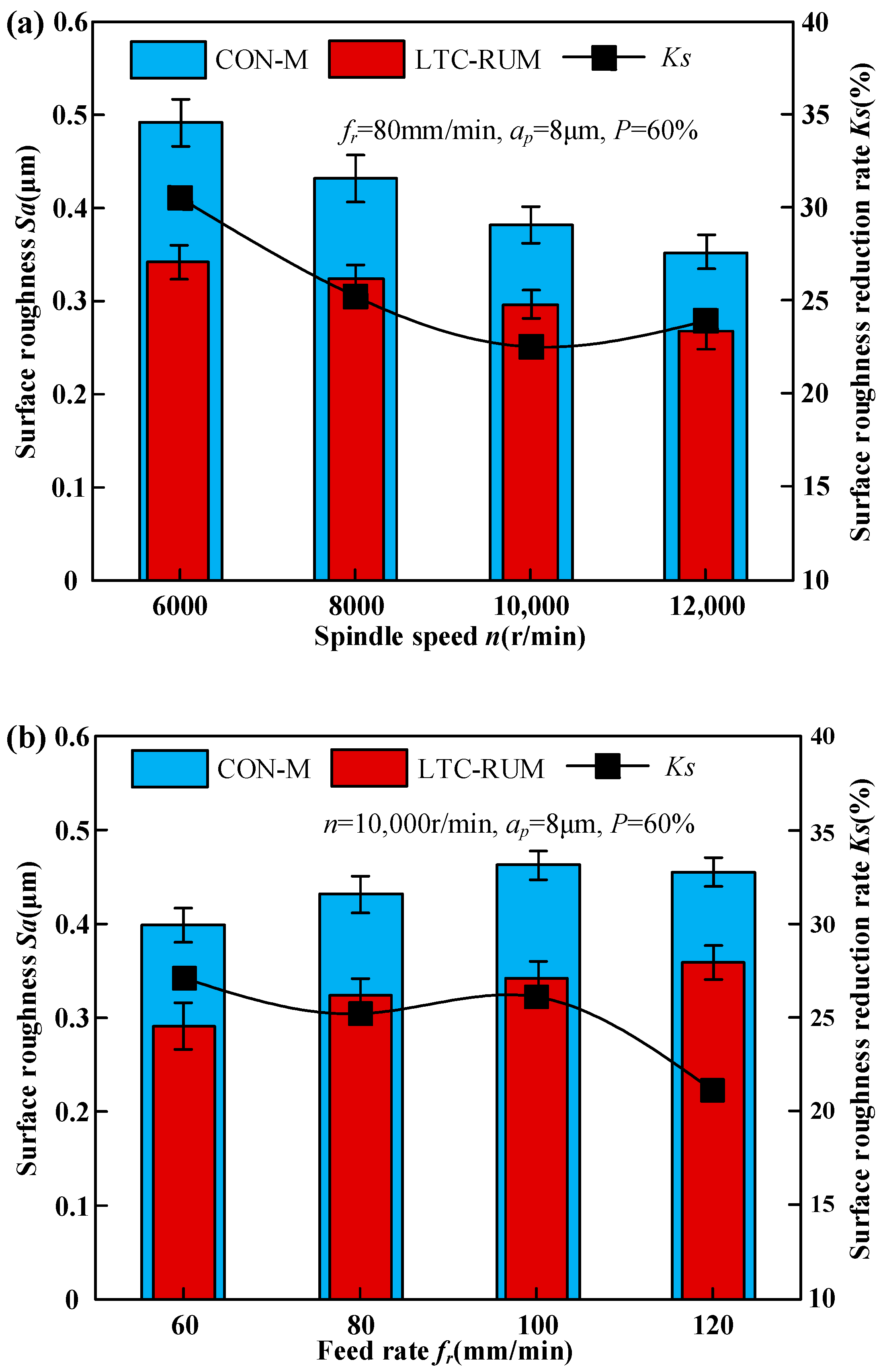

4.2. Surface Roughness

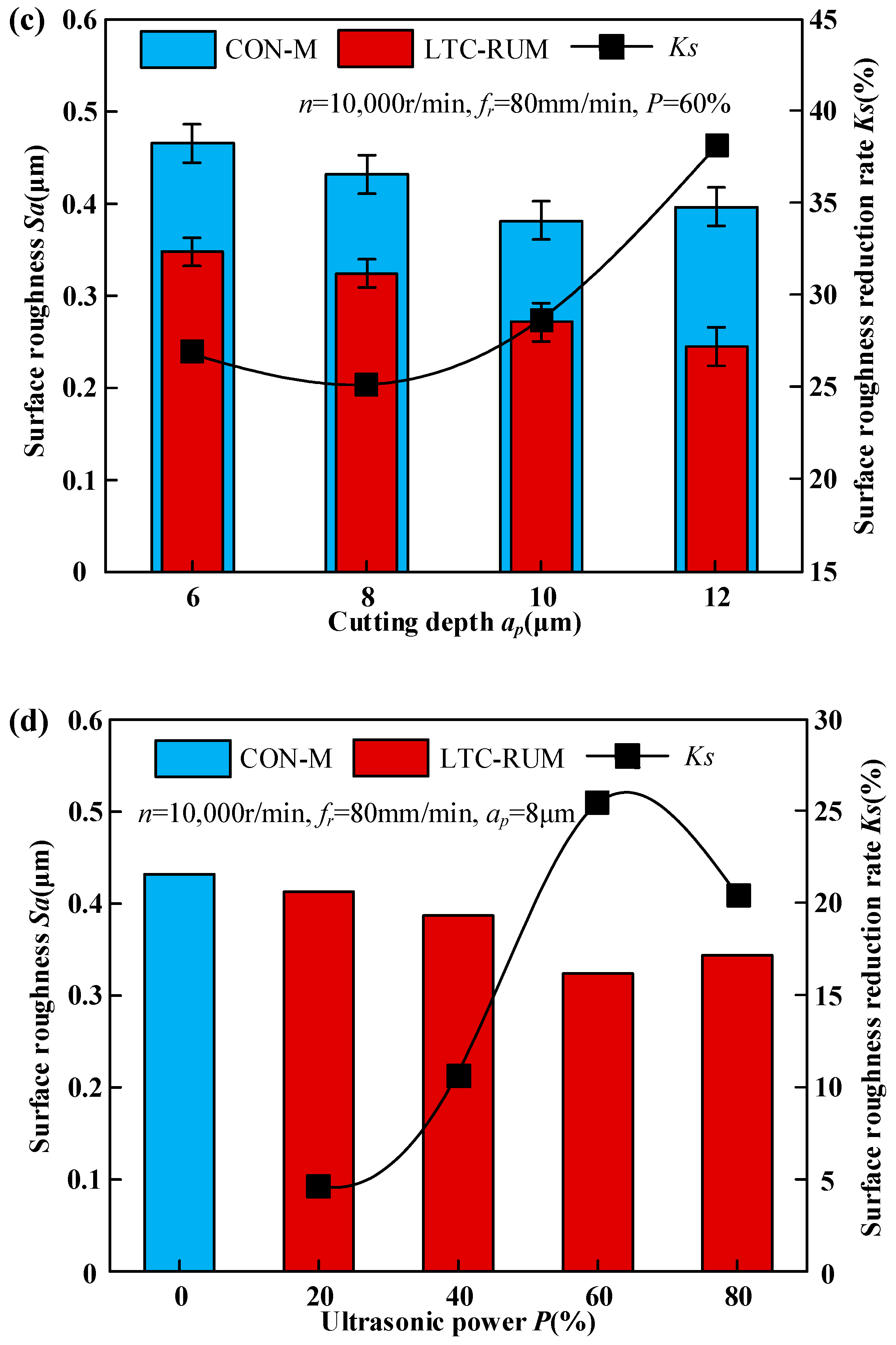

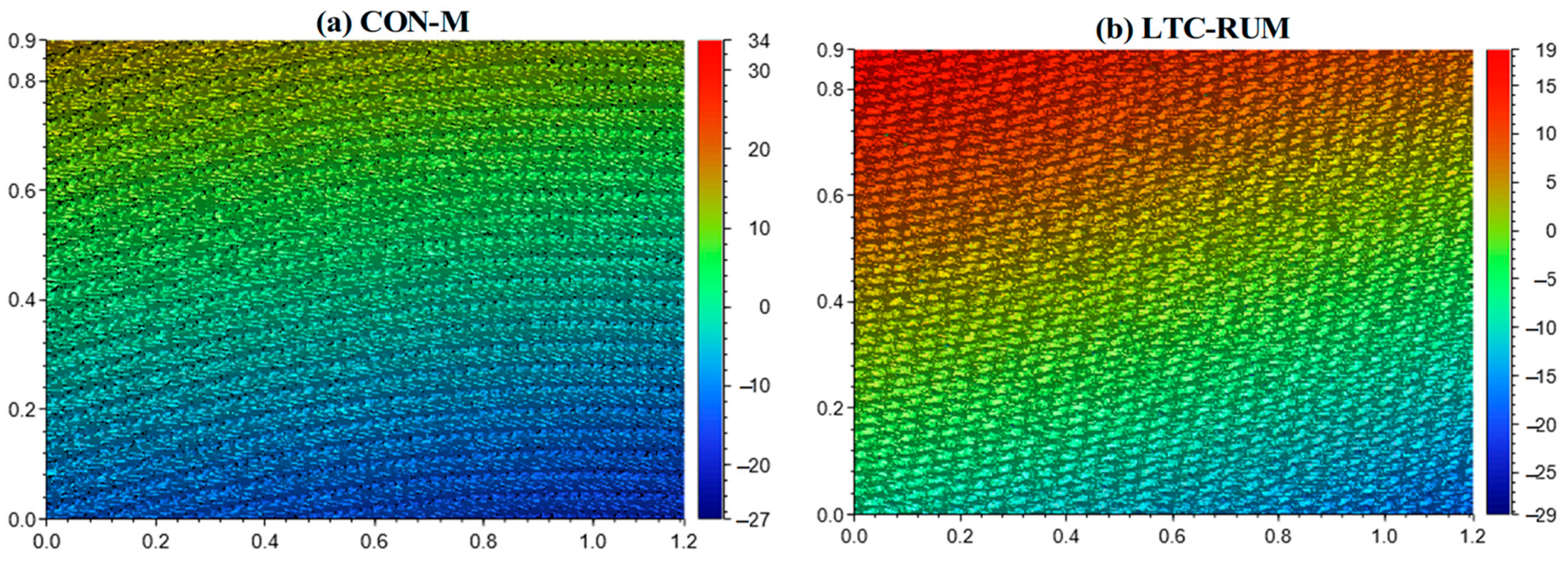

4.3. Surface Morphology

5. Conclusions

- (1)

- A kinematic analysis of the motion paths of individual abrasive grains in both machining methods was carried out. The intermittent interaction between the abrasive grains and the workpiece in LTC-RUM altered the material removal mechanism, thereby enhancing the efficiency of plastic material removal.

- (2)

- Both cutting force Fc and surface roughness showed a decreasing trend with increased spindle speed and ultrasonic power, while they increased with higher feed rates and cutting depths in both LTC-RUM and CON-M. Experimental results demonstrated that LTC-RUM, when operated under appropriate machining conditions, including optimal spindle speed, feed rate, cutting depth, and ultrasonic power, achieved considerable reductions in cutting force and surface roughness compared to CON-M. Specifically, cutting force was reduced by 33.87% to 38.35%, and surface roughness improvement ranged from 24.8% to 38.1%.

- (3)

- The material removal mechanisms in CON-M and LTC-RUM were found to differ significantly. The critical cutting depth in LTC-RUM was higher than that in CON-M, as material removal in CON-M primarily involved crack propagation, whereas LTC-RUM relied more on plastic deformation. The integration of longitudinal–torsional coupled vibration notably enhanced the surface microstructural quality of the machined ZrO2 ceramics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Chen, F.; Li, G.X.; Zhao, B.; Bie, W.B. Thermomechanical coupling effect on characteristics of oxide film during ultrasonic vibration-assisted ELID grinding ZTA ceramics. Chin. J. Aeronaut. 2021, 34, 125–140. [Google Scholar] [CrossRef]

- Yang, Z.C.; Zhu, L.D.; Zhang, G.X.; Ni, C.B.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tools. Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

- Zhao, B.; Chang, B.Q.; Wang, X.B.; Bie, W.B. System design and experimental research on ultrasonic assisted elliptical vibration grinding of Nano-ZrO2 ceramics. Ceram. Int. 2019, 45, 24865–24877. [Google Scholar] [CrossRef]

- Chen, F.; Bie, W.B.; Wang, X.B.; Zhao, B. Longitudinal-torsional coupled rotary ultrasonic machining of ZrO2 ceramics: An experimental study. Ceram. Int. 2022, 48, 28154–28162. [Google Scholar] [CrossRef]

- Qin, S.Q.; Zhu, L.D.; Hao, Y.P.; Shi, C.L.; Wang, S.F.; Yang, Z.C. Theoretical and experimental investigations of surface generation induced by ultrasonic assisted grinding. Tribol. Int. 2023, 179, 108120. [Google Scholar] [CrossRef]

- Li, H.B.; Chen, T.; Duan, Z.Y.; Zhang, Y.W.; Li, H.T. A grinding force model in two-dimensional ultrasonic-assisted grinding of silicon carbide. J. Mater. Process. Tech. 2022, 304, 117568. [Google Scholar] [CrossRef]

- Yuan, Z.J.; Xiang, D.H.; Peng, P.C.; Zhang, Z.Q.; Li, B.H.; Ma, M.Y.; Zhang, Z.P.; Gao, G.F.; Zhao, B. A comprehensive review of advances in ultrasonic vibration machining on SiCp/Al composites. J. Mater. Res. Technol. 2023, 24, 6665–6698. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, D.Y.; Qin, W.; Geng, D.X. Removal analyses of chip and rod in rotary ultrasonic-assisted drilling of carbon fiber-reinforced plastics using core drill. J. Reinf. Plast. Comp. 2016, 35, 1173–1190. [Google Scholar] [CrossRef]

- Lv, D.; Huang, Y.; Tang, Y.; Wang, H. Relationship between subsurface damage and surface roughness of glass BK7 in rotary ultrasonic machining and conventional grinding processes. Int. J. Adv. Manuf. Technol. 2013, 67, 613–622. [Google Scholar] [CrossRef]

- Bertsche, E.; Ehmann, K.; Malukhin, K. An analytical model of rotary ultrasonic milling. Int. J. Adv. Manuf. Technol. 2013, 65, 1705–1720. [Google Scholar] [CrossRef]

- Zhang, C.L.; Feng, P.F.; Pei, Z.J.; Cong, W.L. Rotary ultrasonic machining of sapphire: Feasibility study and designed experiments. Key Eng. Mater. 2014, 589–590, 523–528. [Google Scholar] [CrossRef]

- Pei, Z.J.; Prabhakar, D.; Ferreira, P.M.; Haselkorn, M. A mechanistic approach to the prediction of material removal rates in rotary ultrasonic machining. J. Manuf. Sci. Eng. 1995, 117, 142–151. [Google Scholar] [CrossRef]

- Liu, D.F.; Cong, W.L.; Pei, Z.J.; Tang, Y.J. A cutting force model for rotary ultrasonic machining of brittle materials. Int. J. Mach. Tools. Manuf. 2012, 52, 77–84. [Google Scholar] [CrossRef]

- Xiao, X.Z.; Zheng, K.; Liao, W.H.; Meng, H. Study on cutting force model in ultrasonic vibration assisted side grinding of zirconia ceramics. Int. J. Mach. Tools. Manuf. 2016, 104, 58–67. [Google Scholar] [CrossRef]

- Yang, Z.C.; Zhu, L.D.; Lin, B.; Zhang, G.X.; Ni, C.B.; Sui, T.Y. The grinding force modeling and experimental study of ZrO2 ceramic materials in ultrasonic vibration assisted grinding. Ceram. Int. 2019, 45, 8873–8889. [Google Scholar] [CrossRef]

- Huang, C.; Zhou, M.; Zhang, H.J. A cutting force prediction model in axial ultrasonic vibration end grinding for BK7 optical glass considering protrusion height of abrasive grits. Measurement 2021, 180, 109512. [Google Scholar] [CrossRef]

- Tang, X.T.; Liu, Y.X.; Shi, S.J.; Chen, W.S. Development of a novel ultrasonic drill using longitudinal-bending hybrid mode. IEEE Access. 2017, 5, 7362–7370. [Google Scholar] [CrossRef]

- Geng, D.X.; Lu, Z.H.; Yao, G.; Liu, J.J.; Li, Z.; Zhang, D.Y. Cutting temperature and resulting infuence on machining performance in rotary ultrasonic elliptical machining of thick CFRP. Int. J. Mach. Tools. Manuf. 2017, 123, 160–170. [Google Scholar] [CrossRef]

- Zhao, B.; Bie, W.B.; Wang, X.; Chen, F.; Chang, B.Q. Design and experimental investigation on longitudinal-torsional composite horn considering the incident angle of ultrasonic wave. Int. J. Adv. Manuf. Technol. 2019, 105, 325–341. [Google Scholar] [CrossRef]

- Gao, G.F.; Xia, Z.W.; Yuan, Z.J.; Xiang, D.H.; Zhao, B. Infuence of longitudinal-torsional ultrasonic-assisted vibration on microhole drilling Ti-6Al-4V. Chin. J. Aeronaut. 2021, 34, 247–260. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhang, J.F.; Feng, P.F.; Guo, P. Reducing cutting force in rotary ultrasonic drilling of ceramic matrix composites with longitudinal-torsional coupled vibration. Manuf. Lett. 2018, 18, 1–5. [Google Scholar] [CrossRef]

- Ma, W.J.; Xue, J.X.; Yang, Y.H.; Zhao, H.; Hu, G.H.; Long, Z.L. Kinematics characteristics and experimental analysis of longitudinal torsional ultrasonic grinding for Zirconia ceramics. Mech. Sci. Technol. Aerosp. Eng. 2020, 39, 1580–1586. [Google Scholar]

- Qiao, G.C.; Cheng, Z.; Zheng, W.; Yi, S.C.; Zhang, F.J. Grinding force model for longitudinal-torsional ultrasonic-assisted face grinding of ceramic matrix composites. Int. J. Adv. Manuf. Technol. 2022, 120, 7721–7733. [Google Scholar] [CrossRef]

- Chen, F.; Bie, W.B.; Chang, Y.L.; Zhao, B.; Wang, X.B.; Zhang, Y.M. Analytical and experimental investigation on cutting force in longitudinal-torsional coupled rotary ultrasonic machining zirconia ceramics. Int. J. Adv. Manuf. Technol. 2022, 120, 4051–4064. [Google Scholar] [CrossRef]

- Jin, J.W.; Wang, X.B.; Bie, W.B.; Chen, F.; Zhao, B. Machinability of sicf/sic ceramic matrix composites using longitudinal-torsional coupled rotary ultrasonic machining. Int. J. Adv. Manuf. Technol. 2023, 13, 2465–2476. [Google Scholar] [CrossRef]

- Sun, Q.X.; Ren, K.; An, Q.L.; Tao, D.Y.; Yu, M.Q.; Miao, Q.; Zhang, M.; Li, H.; Yi, Z. Study on removal mechanism and surface quality of SiCf/SiC composites by longitudinal torsional ultrasonic vibration-assisted grinding. Precis. Eng. 2024, 91, 47–58. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Jiao, F.; Li, Y.X.; Wang, X.; Niu, Y.; Tong, J.L. Experimental study on rotary longitudinal-torsional ultrasonic machining of unidirectional CFRP. Chin. J. Aeronaut. 2024, 37, 517–534. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhang, J.F.; Feng, P.F.; Guo, P.; Zhang, Q.L. Feasibility study of longitudinal-torsional-coupled rotary ultrasonic machining of brittle material. J. Manuf. Sci. Eng. 2018, 40, 51008. [Google Scholar] [CrossRef]

- Jiao, F. The Theoretical and Experimental Studies on Ultrasonic Aided High Efficiency Lapping with Solid Abrasive of Engineering Ceramic. Ph. D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2008. [Google Scholar]

- Arif, M.; Zhang, X.Q.; Rahman, M.; Kumar, S. A predictive model of the critical undeformed chip thickness for ductilebrittle transition in nano-machining of brittle materials, International journal of machine tools and manufacture. Int. J. Mach. Tools. Manuf. 2013, 64, 114–122. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, Q.; Dong, S.; Li, D. The critical conditions of brittle-ductile transition and the factors influencing the surface quality of brittle materials in ultra-precision grinding. J. Mater. Process. Technol. 2005, 168, 75–82. [Google Scholar] [CrossRef]

- George, J.; Peter, G. Microindentation analysis of diammonium hydrogen citrate single crystals. J. Mater. Sci. 1985, 20, 3150–3156. [Google Scholar] [CrossRef]

- Kalthoff, J.F.; Bürgel, A. Influence of loading rate on shear fracture toughness for failure mode transition. Int. J. Impact. Eng. 2004, 30, 957–971. [Google Scholar] [CrossRef]

- Tong, F.Q.; Zhang, Y.; Zhang, F.H.; Gu, L.Z.; Sun, P. Influence of stress fluctuation in vibrating cutting on crack creation and chip formation. J. Vib. Shock. 2008, 27, 136–139. [Google Scholar]

- Cong, W.L.; Pei, Z.J.; Sun, X.; Zhang, C.L. Rotary ultrasonic machining of CFRP: A mechanistic predictive model for cutting force. Ultrasonics 2014, 54, 663–675. [Google Scholar] [CrossRef] [PubMed]

| Property | Elastic Modulus (GPa) | Hardness (GPa) | Fracture Toughness (MPa m1/2) | Density (g/cm3) | Poisson’s Ratio |

|---|---|---|---|---|---|

| Value | 210 | 12 | 6 | 6.05 | 0.3 |

| Mesh Size | Abrasive Particle Size da (mm) | Abrasive Concentration Ca | Outer Diameter do (mm) | Inner Diameter di (mm) |

|---|---|---|---|---|

| #80–100 | 0.162 | 100 | 8.07 | 6.80 |

| Variable | Values |

|---|---|

| Spindle speed n (r/min) | 6000, 8000, 10,000, 12,000 |

| Cutting depth ap (μm) | 6, 8, 10, 12 |

| Feed rate fr (mm/min) | 60, 80, 100, 120 |

| Ultrasonic power P (%) | 0, 20, 40, 60, 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Bie, W.; Li, K.; Ma, X. End Surface Grinding Machinability of Zirconia Ceramics via Longitudinal–Torsional Coupled Vibration Rotary Ultrasonic Machining. Micromachines 2025, 16, 1065. https://doi.org/10.3390/mi16091065

Chen F, Bie W, Li K, Ma X. End Surface Grinding Machinability of Zirconia Ceramics via Longitudinal–Torsional Coupled Vibration Rotary Ultrasonic Machining. Micromachines. 2025; 16(9):1065. https://doi.org/10.3390/mi16091065

Chicago/Turabian StyleChen, Fan, Wenbo Bie, Kuohu Li, and Xiaosan Ma. 2025. "End Surface Grinding Machinability of Zirconia Ceramics via Longitudinal–Torsional Coupled Vibration Rotary Ultrasonic Machining" Micromachines 16, no. 9: 1065. https://doi.org/10.3390/mi16091065

APA StyleChen, F., Bie, W., Li, K., & Ma, X. (2025). End Surface Grinding Machinability of Zirconia Ceramics via Longitudinal–Torsional Coupled Vibration Rotary Ultrasonic Machining. Micromachines, 16(9), 1065. https://doi.org/10.3390/mi16091065