A Reconfigurable Low-Pass Filter Based on Polyurethane Substrate Inspired by the Origami Structure

Abstract

1. Introduction

2. Model and Design

2.1. Theoretical Model

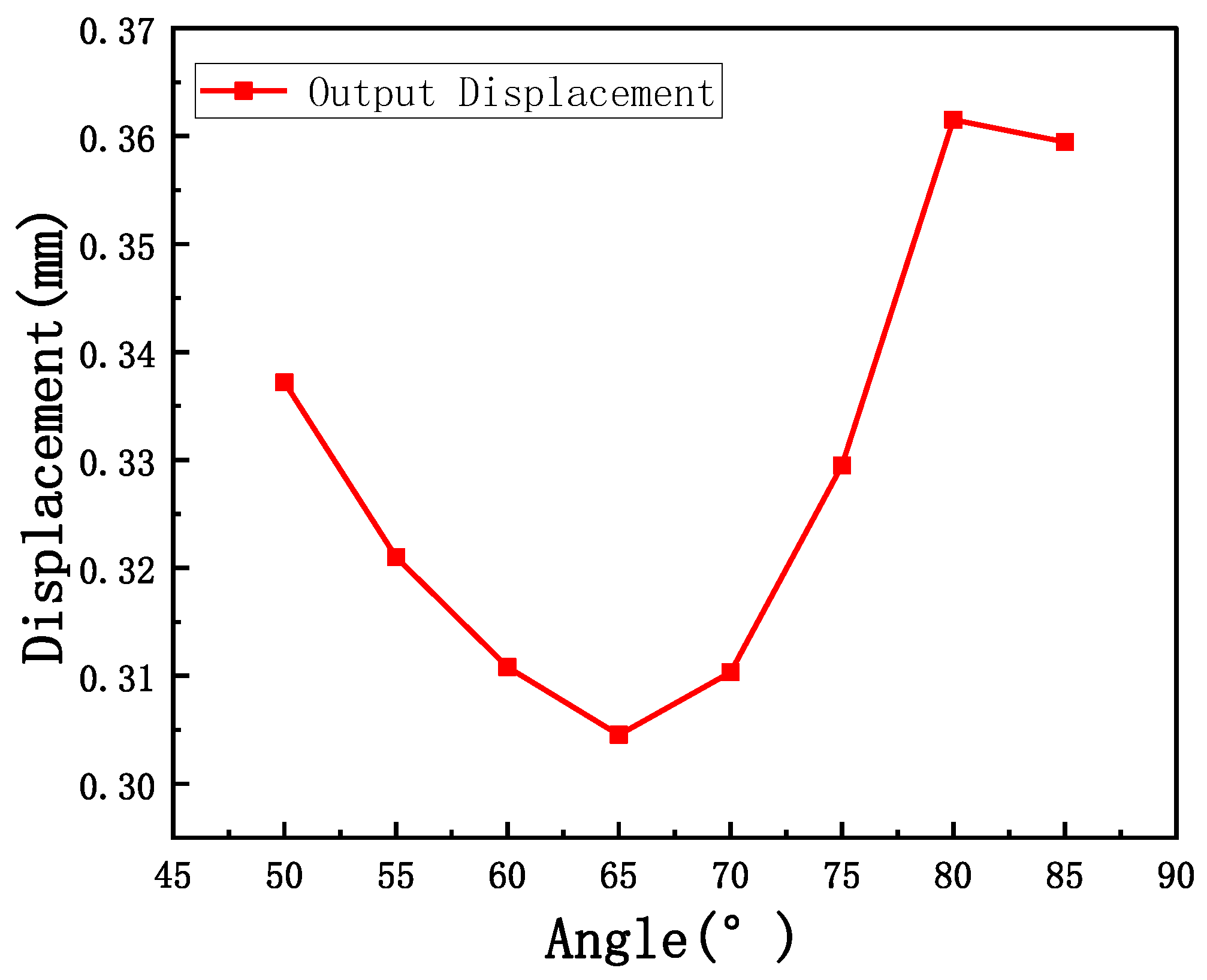

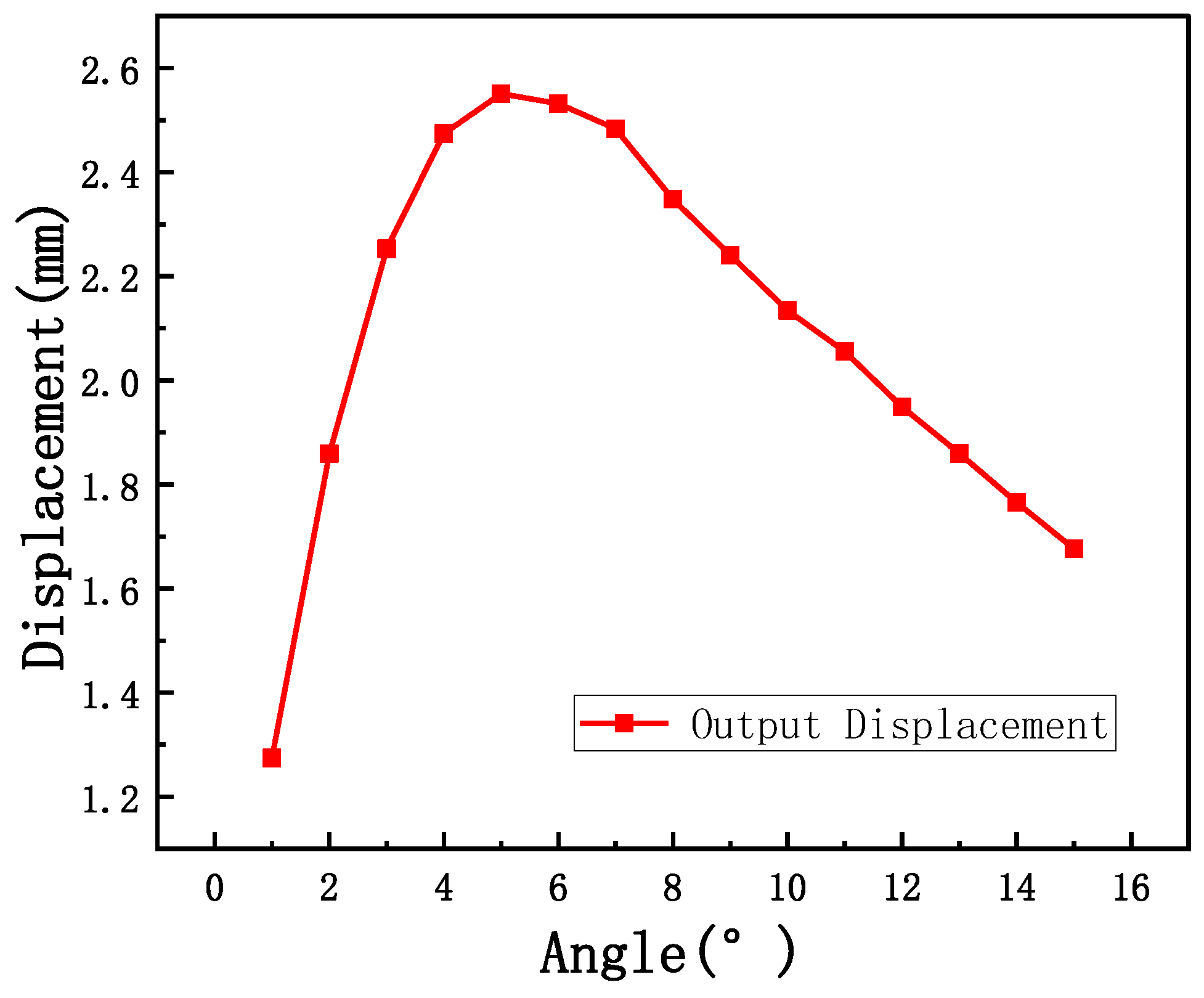

2.2. Structure Design

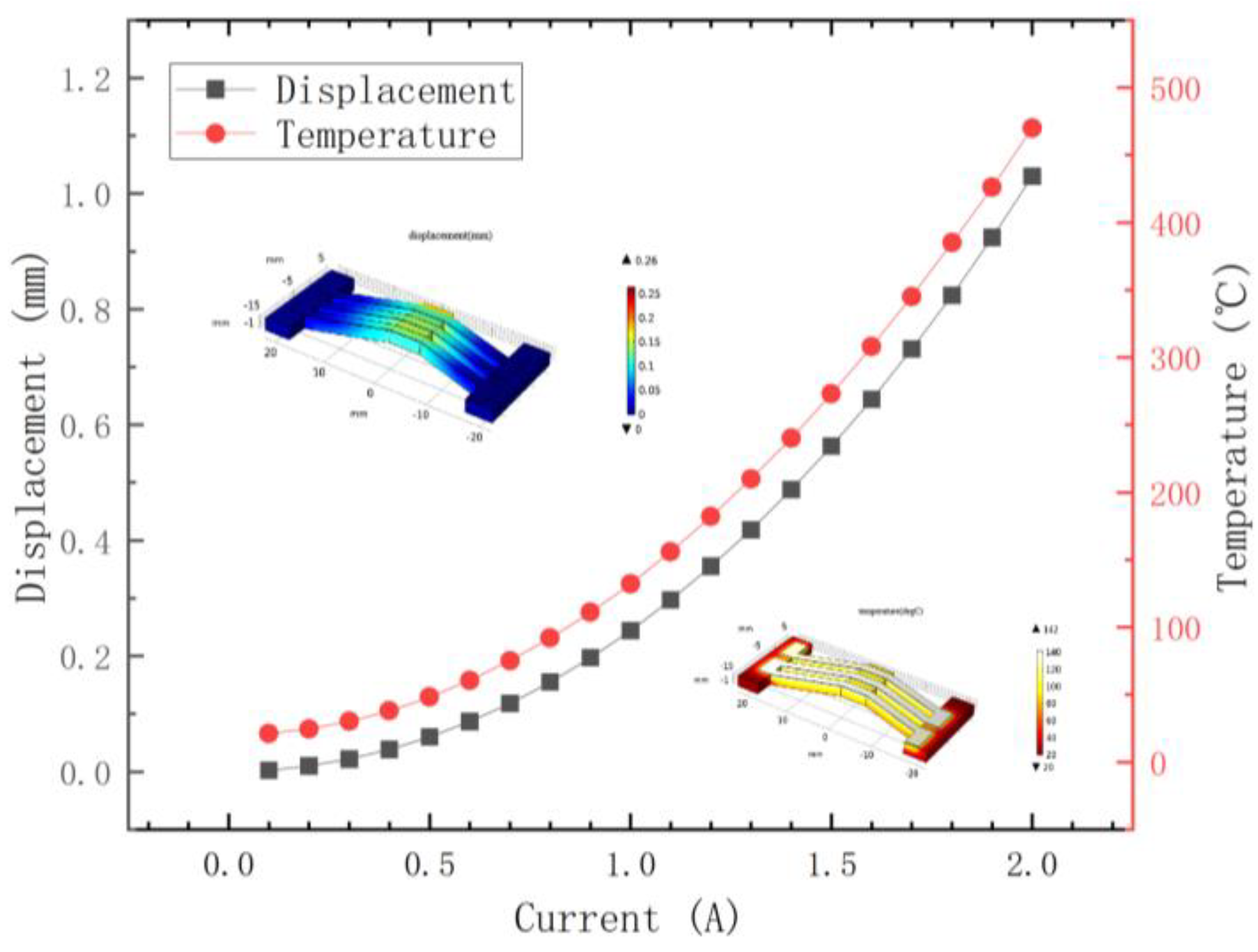

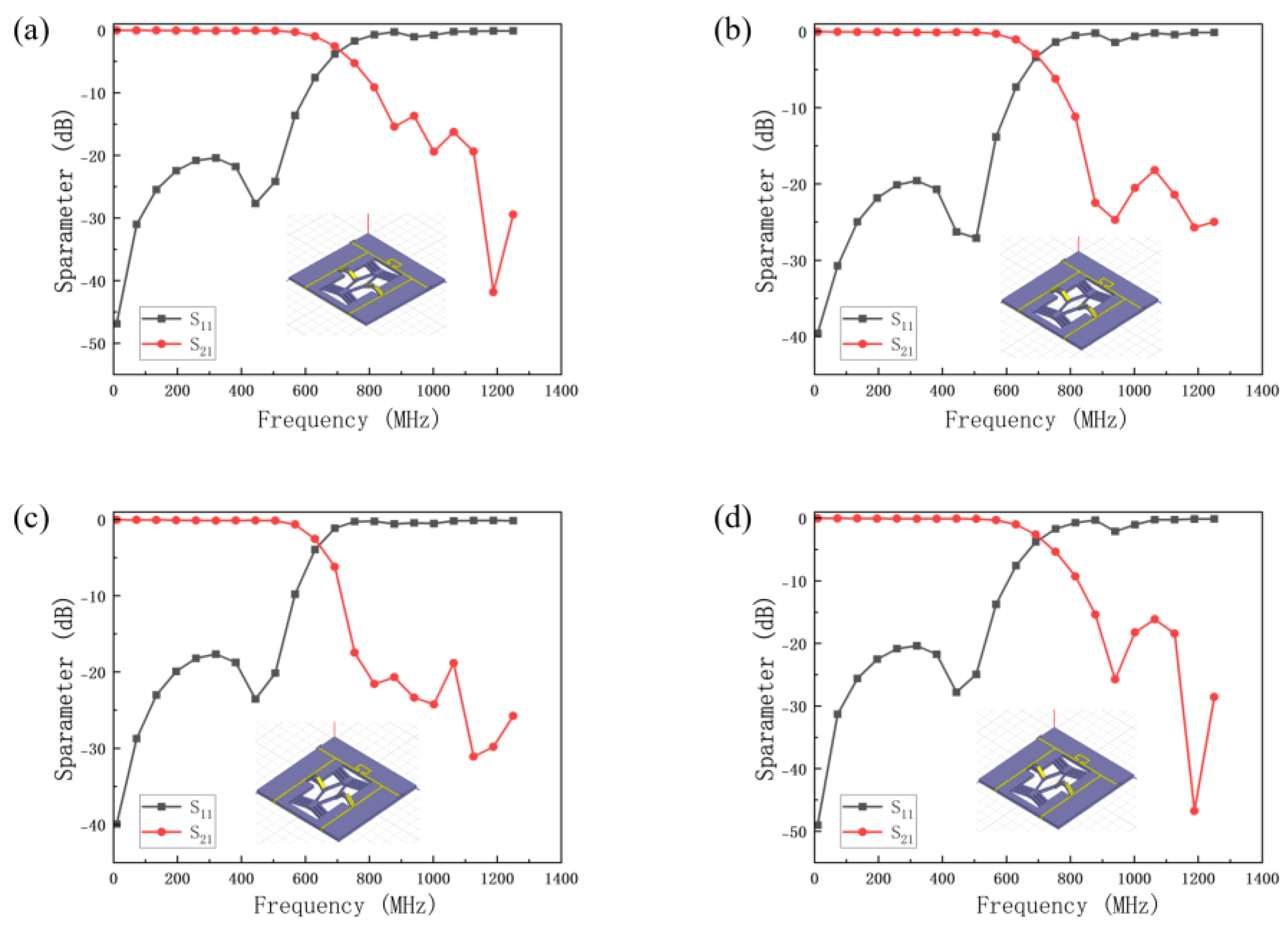

3. Results and Discussion

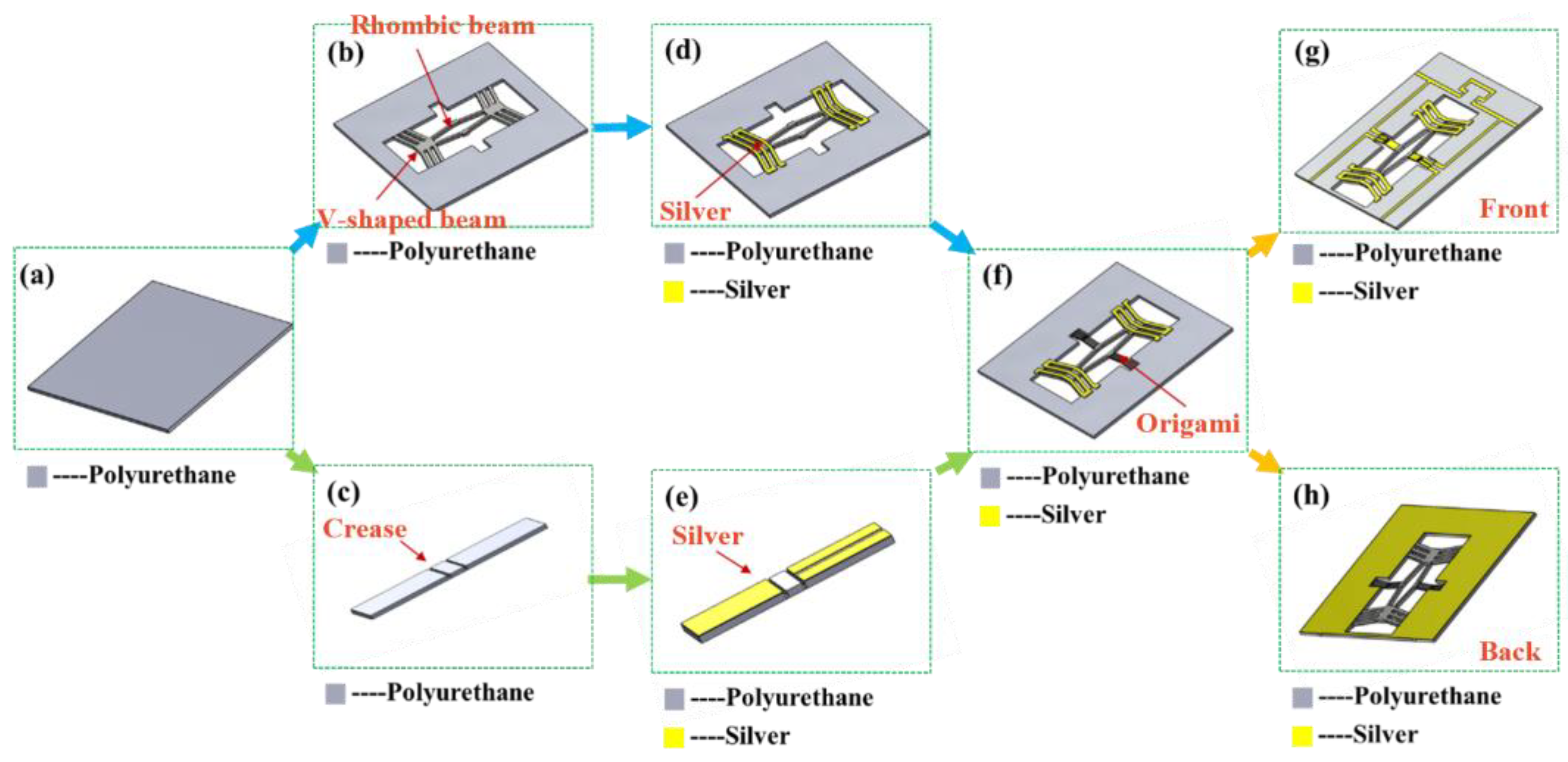

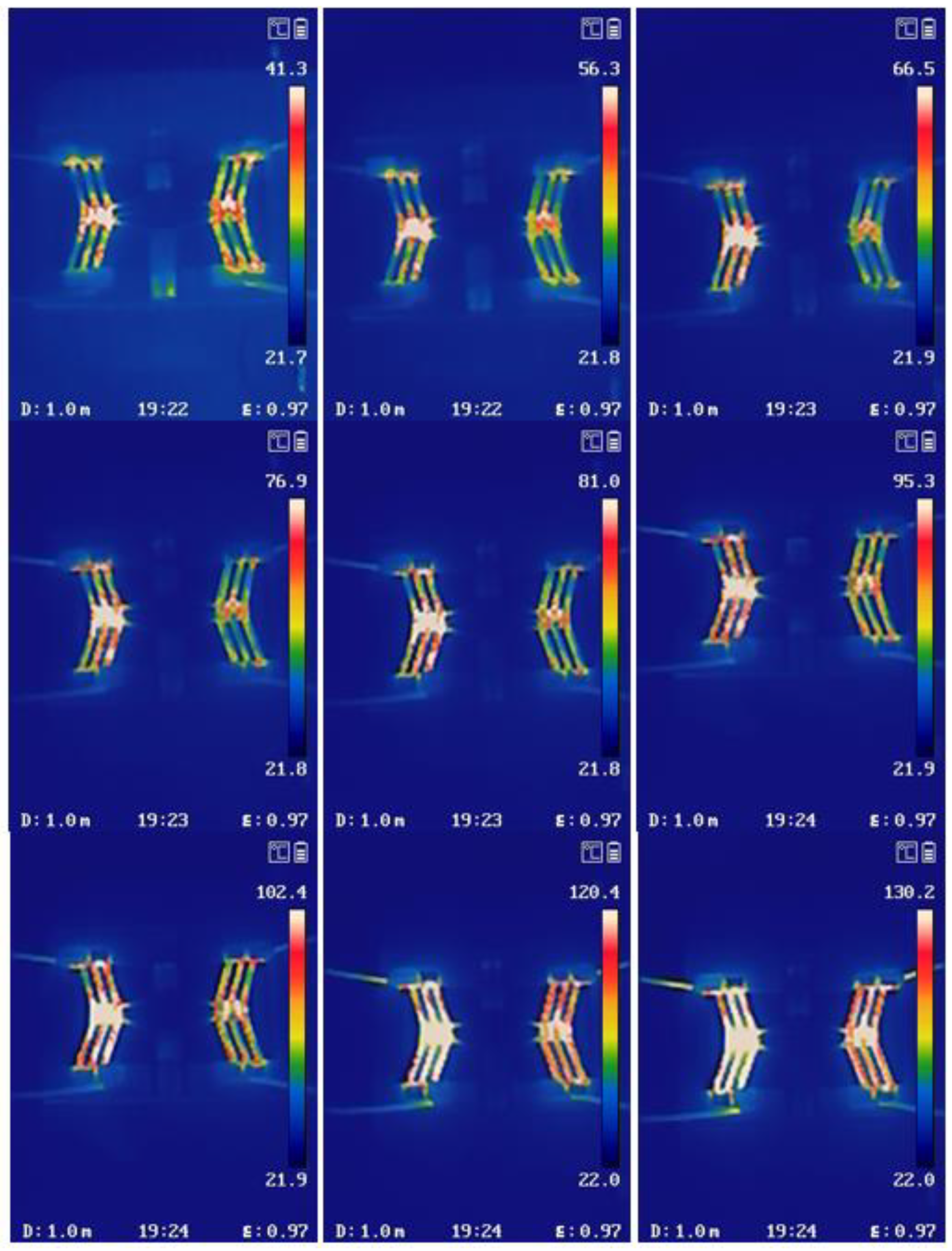

3.1. Fabrication

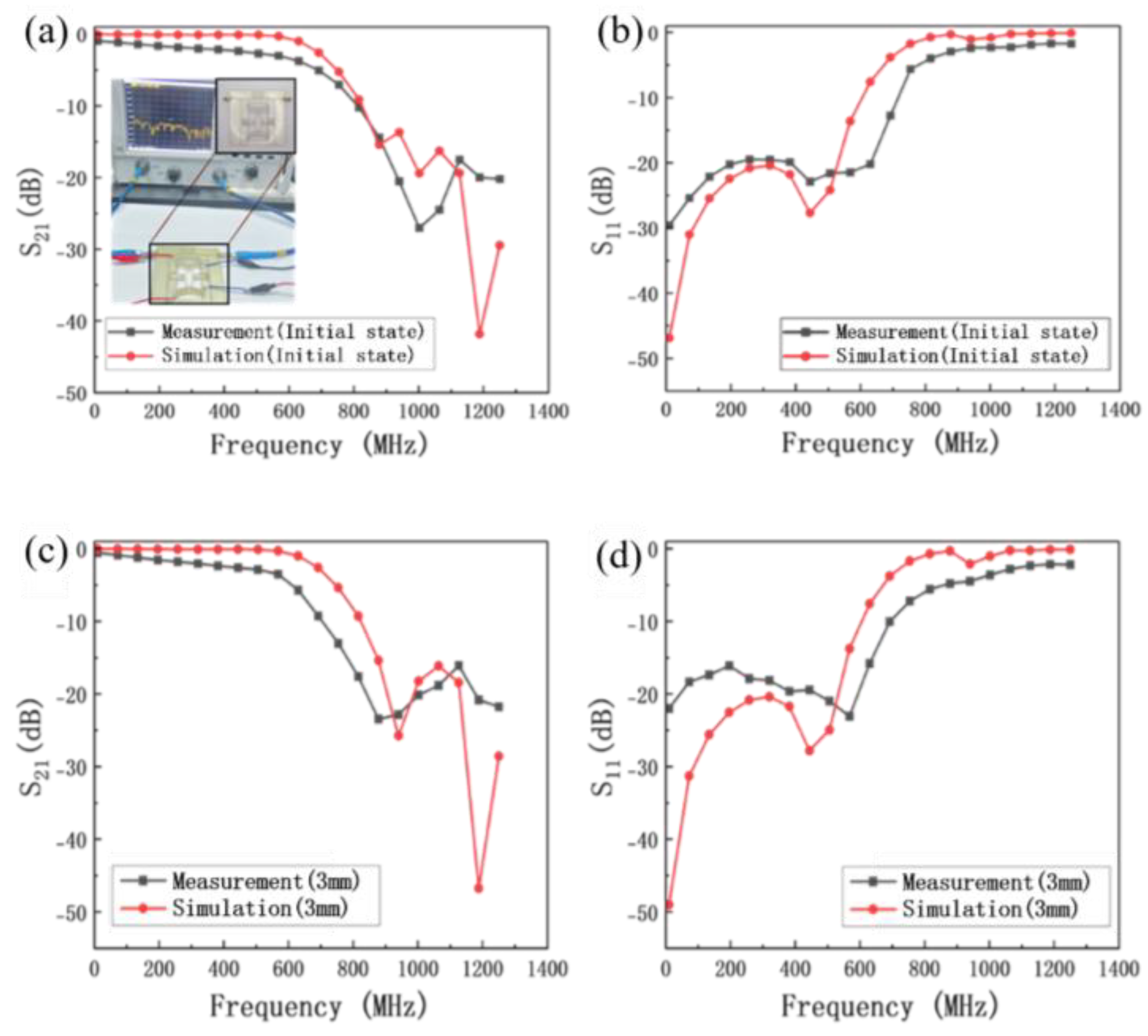

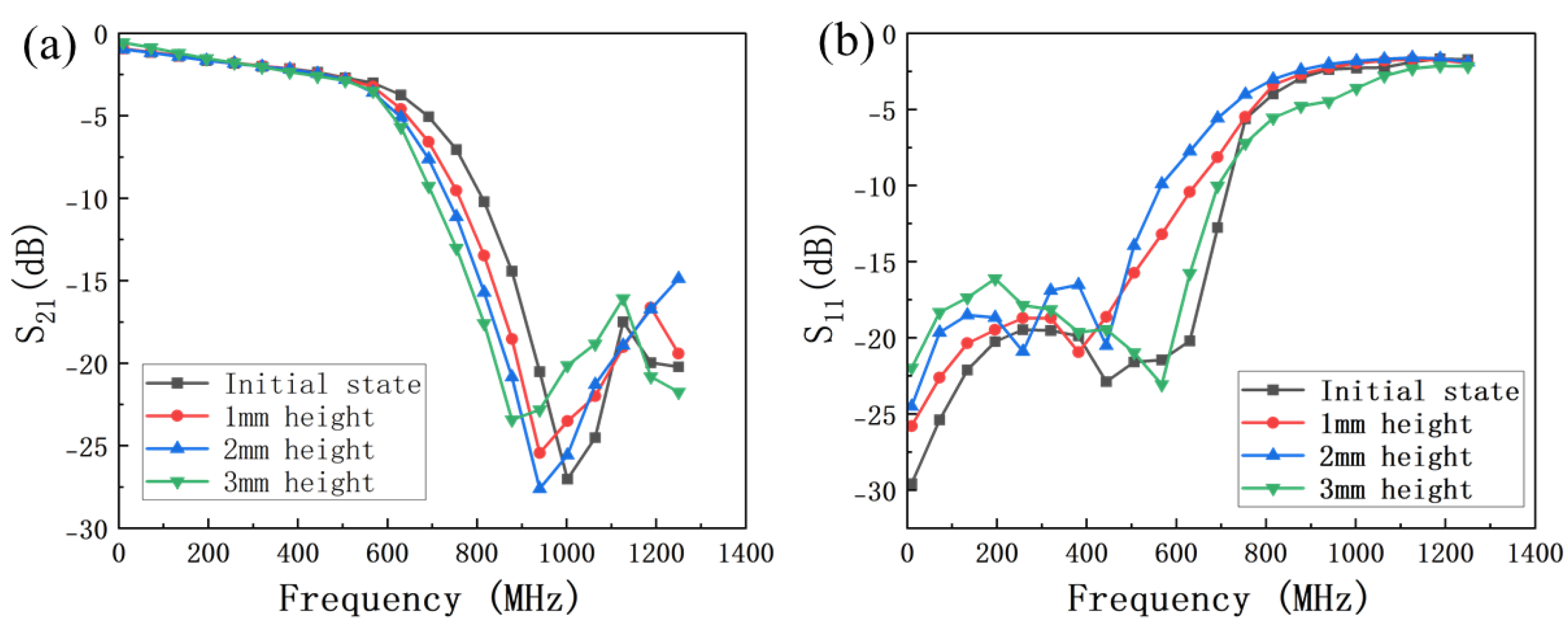

3.2. Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, S.Q.; Wang, W.S.; Zheng, Y.J. Reconfigurable Multimode Microwave Sensor with Resonance and Transmission Sensing Capabilities for Noninvasive Glucose Monitoring. IEEE Trans. Microw. Theory Tech. 2024, 72, 3102–3117. [Google Scholar] [CrossRef]

- Marpaung, D.; Morrison, B.; Pagani, M.; Pant, R.; Choi, D.Y.; Luther-Davies, B.; Madden, S.J.; Eggleton, B.J. Low-power, chip-based stimulated Brillouin scattering microwave photonic filter with ultrahigh selectivity. Optica 2015, 2, 76–83. [Google Scholar] [CrossRef]

- Zhu, S.T.; Chen, X.M.; Pan, X.H.; Dong, X.L.; Shi, H.Y.; Zhang, A.X.; Xu, Z. Self-Adaption Matched Filter and Bi-Directional Difference Method for Moving Target Detection. Sensors 2018, 18, 3177. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, D.; Farias, J.V.M.; Pereira, H.A.; Luiz, A.S.A.; Stopa, M.M.; Cupertino, A.F. Design of Damping Strategies for LC Filter Applied in Medium Voltage Variable Speed Drive. Energies 2022, 15, 5644. [Google Scholar] [CrossRef]

- Casu, E.A.; Müller, A.A.; Fernáandez-Bolañnos, M.; Fumarola, A.; Anna, K.; Schüler, A.; Ionescu, A.M. Vanadium Oxide Bandstop Tunable Filter for Ka Frequency Bands Based on a Novel Reconfigurable Spiral Shape Defected Ground Plane CPW. IEEE Access 2018, 6, 12206–12212. [Google Scholar] [CrossRef]

- Bi, X.K.; Zhang, X.; Wong, S.W.; Guo, S.H.; Yuan, T. Reconfigurable-Bandwidth DWB BPF with Fixed Operation Frequency and Controllable Stopband. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 141–145. [Google Scholar] [CrossRef]

- Donelli, M.; Manekiya, M.; Tagliapietra, G.; Iannacci, J. A Reconfigurable Pseudohairpin Filter Based on MEMS Switches. Sensors 2022, 22, 9644. [Google Scholar] [CrossRef] [PubMed]

- Habbachi, N.; Besbes, K. RF MEMS Filter Based on Dual Liquid Variations. J. Micromechanics Microengineering 2022, 32, 6. [Google Scholar] [CrossRef]

- Azarnaminy, A.F.; Suleiman, A.O.; Chaker, M.; Mansour, R.R. A Reconfigurable SAW Resonator Using Monolithically Integrated Switches. In Proceedings of the 2022 IEEE/MTT-S International Microwave Symposium—IMS 2022, Denver, CO, USA, 19–24 June 2022; pp. 806–808. [Google Scholar]

- Silverberg, J.L.; Evans, A.A.; McLeod, L.; Hayward, R.C.; Hull, T.; Santangelo, C.D.; Cohen, I. Using Origami Design Principles to Fold Reprogrammable Mechanical Metamaterials. Science 2014, 345, 647–650. [Google Scholar] [CrossRef] [PubMed]

- Felton, S.; Tolley, M.; Demaine, E.; Rus, D.; Wood, R. A Method for Building Self-Folding Machines. Science 2014, 345, 644–646. [Google Scholar] [CrossRef] [PubMed]

- Meloni, M.; Cai, J.G.; Zhang, Q.; Lee, D.S.H.; Li, M.; Ma, R.J.; Parashkevov, T.E.; Feng, J. Engineering Origami: A Comprehensive Review of Recent Applications, Design Methods, and Tools. Adv. Sci. 2021, 8, 2170073. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, R.; You, Z. Origami of Thick Panels. Science 2015, 349, 396–499. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.W.; Novelino, L.S.; Wei, H.M.; Alderete, N.A.; Paulino, G.H.; Espinosa, H.D.; Krishnaswamy, S. Folding at the Microscale: Enabling Multifunctional 3D Origami-Architected Metamaterials. Small 2020, 16, 2002229. [Google Scholar] [CrossRef] [PubMed]

- Na, J.H.; Evans, A.A.; Bae, J.; Chiappelli, M.C.; Santangelo, C.D.; Lang, R.J.; Hull, T.C.; Hayward, R.C. Programming Reversibly Self-Folding Origami with Micropatterned Photo-Crosslinkable Polymer Trilayers. Adv. Mater. 2015, 27, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Bircan, B.; Miskin, M.Z.; Lang, R.J.; Cao, M.C.; Dorsey, K.J.; Salim, M.G.; Wang, W.; Muller, D.A.; McEuen, P.L.; Cohen, I. Bidirectional Self-Folding with Atomic Layer Deposition Nanofilms for Microscale Origami. Nano Lett. 2020, 20, 4850–4856. [Google Scholar] [CrossRef] [PubMed]

- Han, L.; Gao, C.Y.; Chen, L.J. A Self-Assembled 3D-Shaped Microstrip Microwave Device Inspired by the Origami Structure. ACS Appl. Electron. Mater. 2023, 5, 1401–1404. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Li, M.; Gao, C.; Dong, Y.; Pan, Y.; Qin, M.; Nie, M.; Han, L. A Reconfigurable Low-Pass Filter Based on Polyurethane Substrate Inspired by the Origami Structure. Micromachines 2025, 16, 1060. https://doi.org/10.3390/mi16091060

Wang K, Li M, Gao C, Dong Y, Pan Y, Qin M, Nie M, Han L. A Reconfigurable Low-Pass Filter Based on Polyurethane Substrate Inspired by the Origami Structure. Micromachines. 2025; 16(9):1060. https://doi.org/10.3390/mi16091060

Chicago/Turabian StyleWang, Kang, Mingcheng Li, Chuyuan Gao, Yupeng Dong, Yutang Pan, Ming Qin, Meng Nie, and Lei Han. 2025. "A Reconfigurable Low-Pass Filter Based on Polyurethane Substrate Inspired by the Origami Structure" Micromachines 16, no. 9: 1060. https://doi.org/10.3390/mi16091060

APA StyleWang, K., Li, M., Gao, C., Dong, Y., Pan, Y., Qin, M., Nie, M., & Han, L. (2025). A Reconfigurable Low-Pass Filter Based on Polyurethane Substrate Inspired by the Origami Structure. Micromachines, 16(9), 1060. https://doi.org/10.3390/mi16091060