Non-Free Cutting Mechanism of Asymmetrical Nanogrooves Under Chip-Removal Interference in Amorphous Nickel Phosphorus

Abstract

1. Introduction

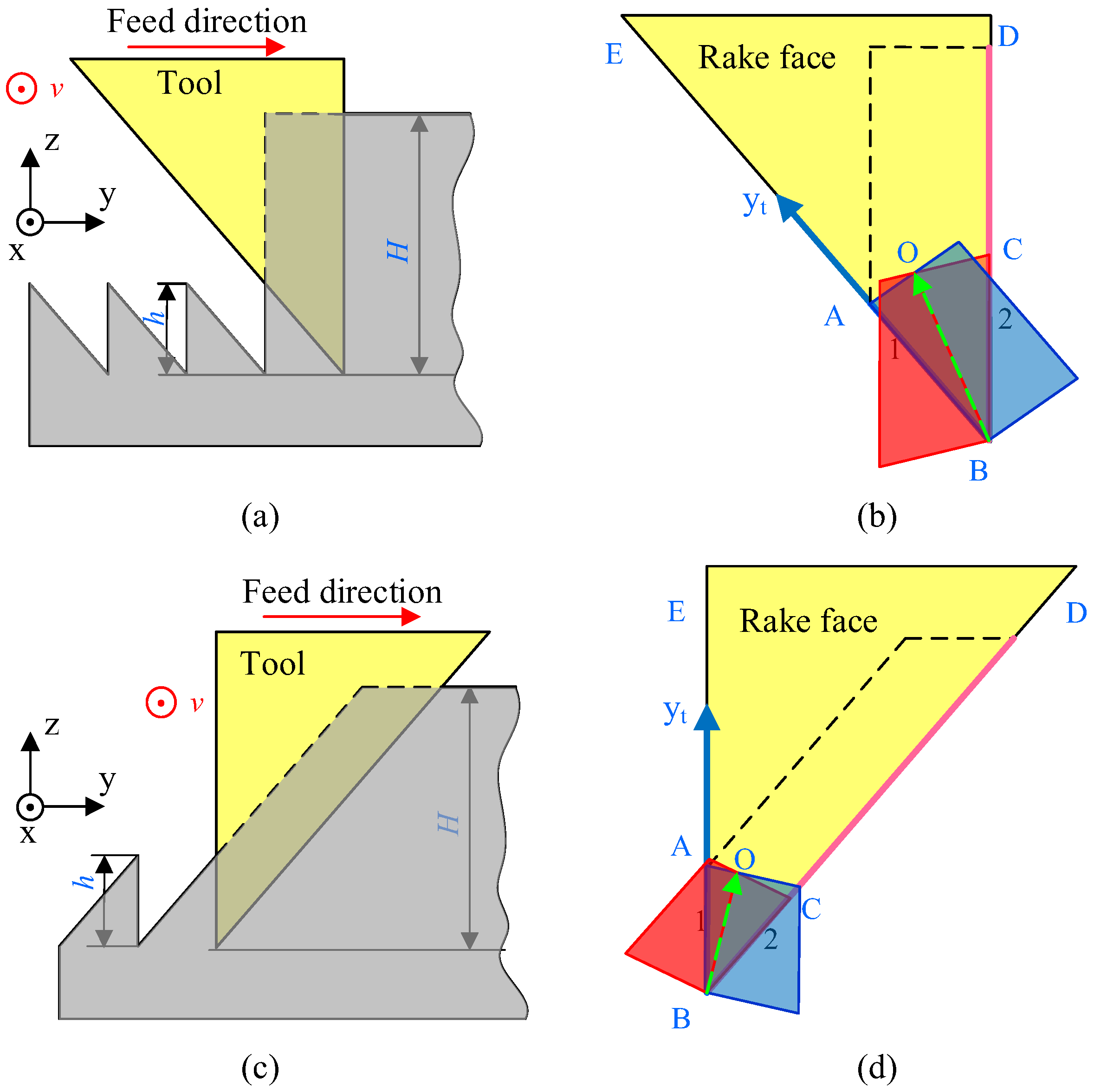

2. Non-Free Cutting Mechanism of Asymmetrical Nanogrooves

2.1. Materials Shear Interference in the Cutting of Asymmetrical Nanogrooves

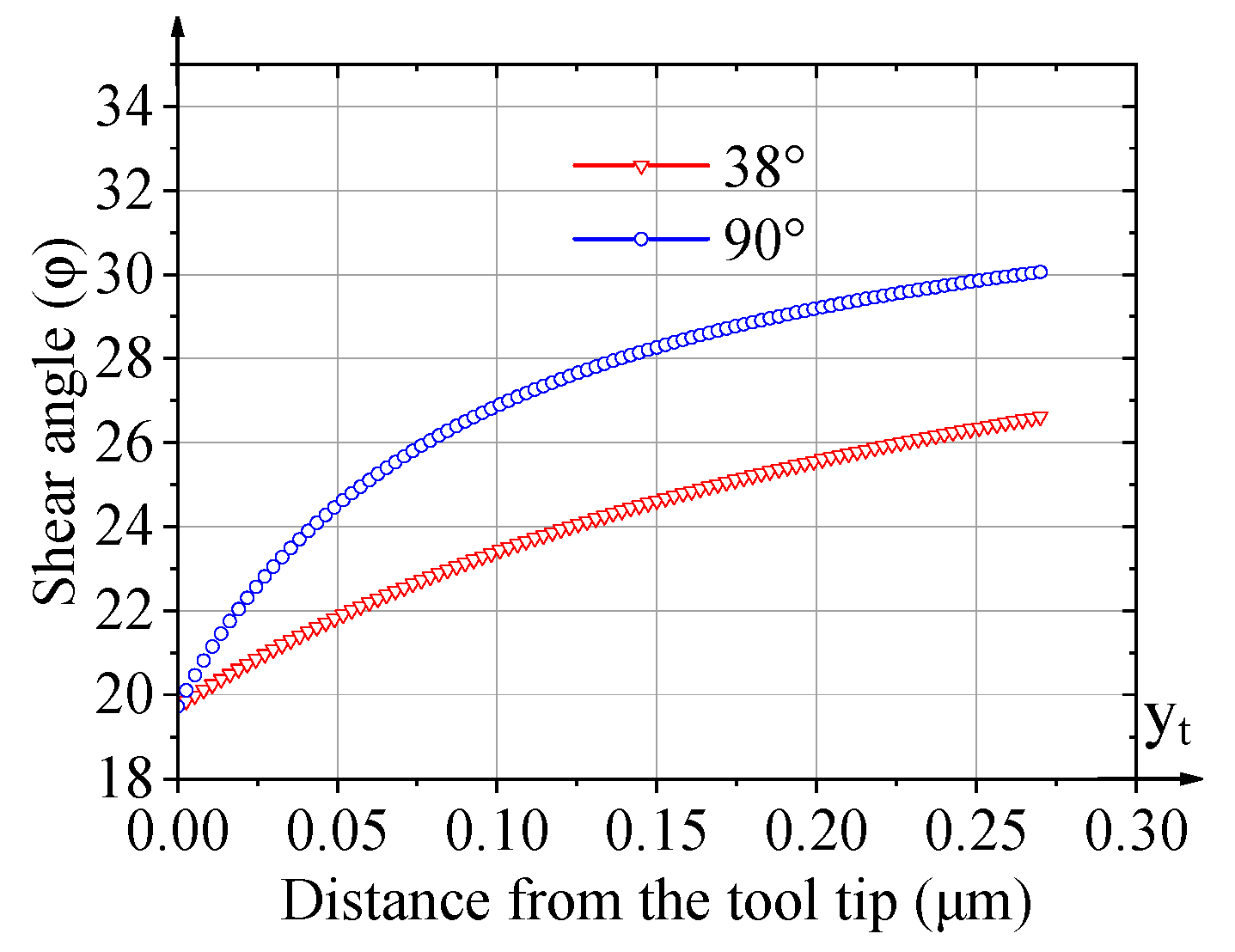

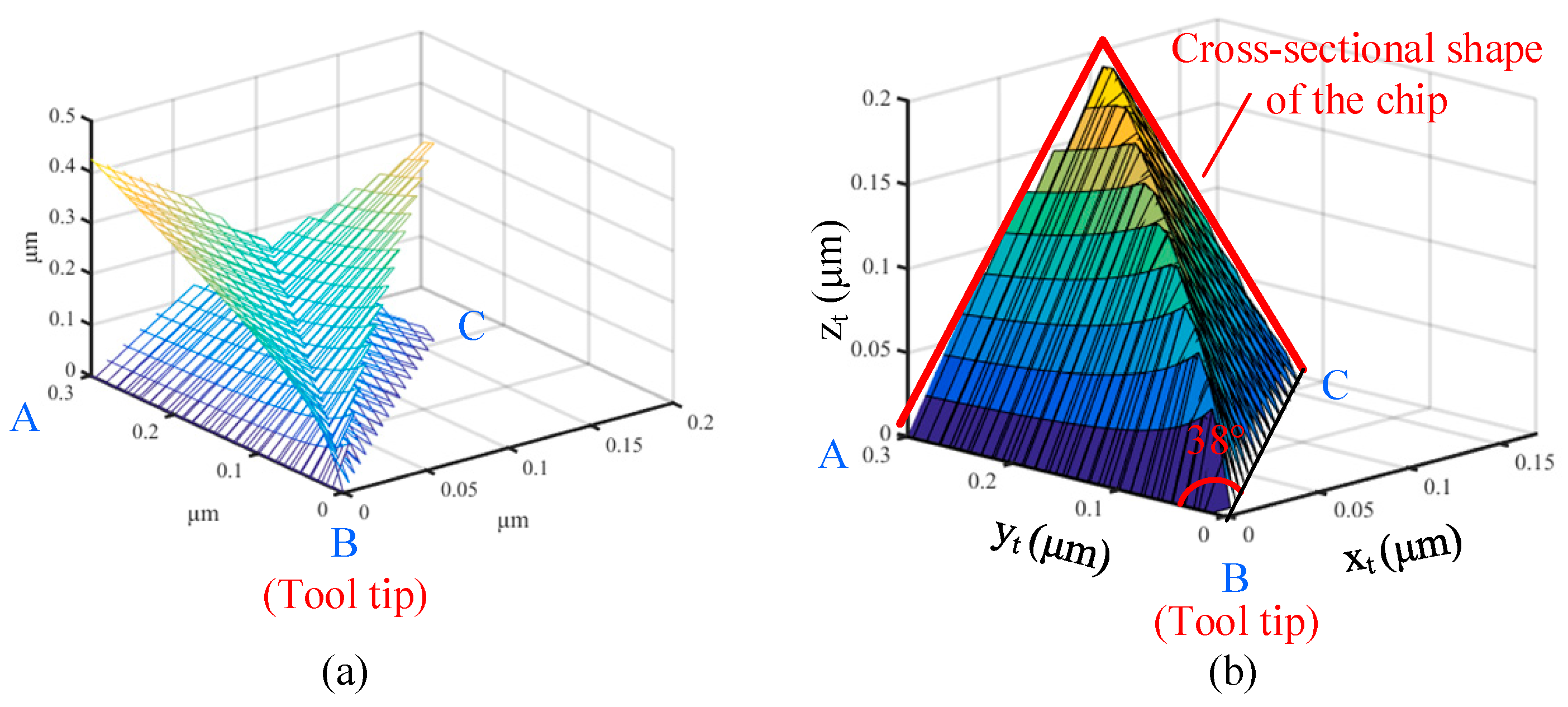

2.2. Material Shear Surface During Asymmetrical Grooves

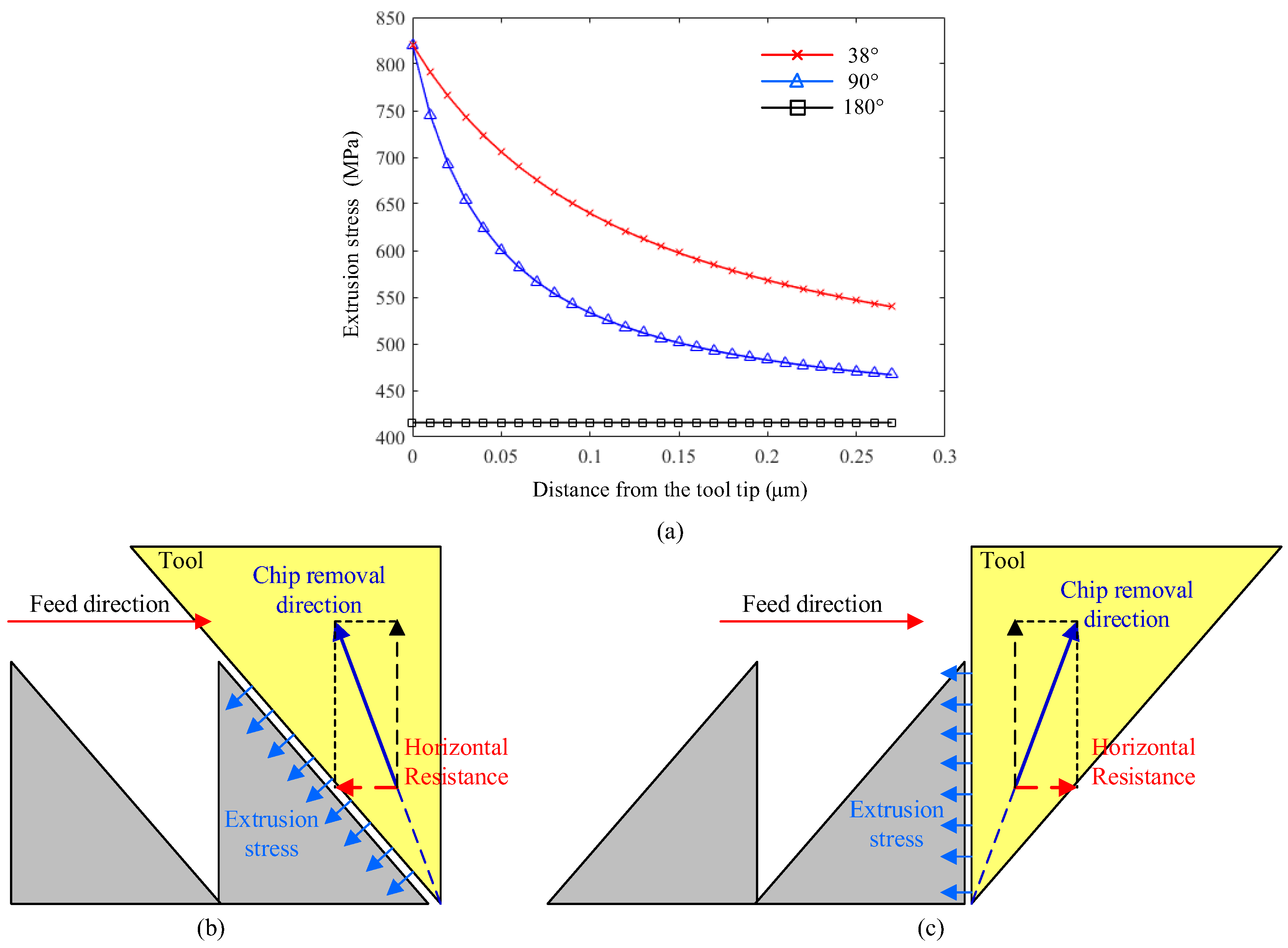

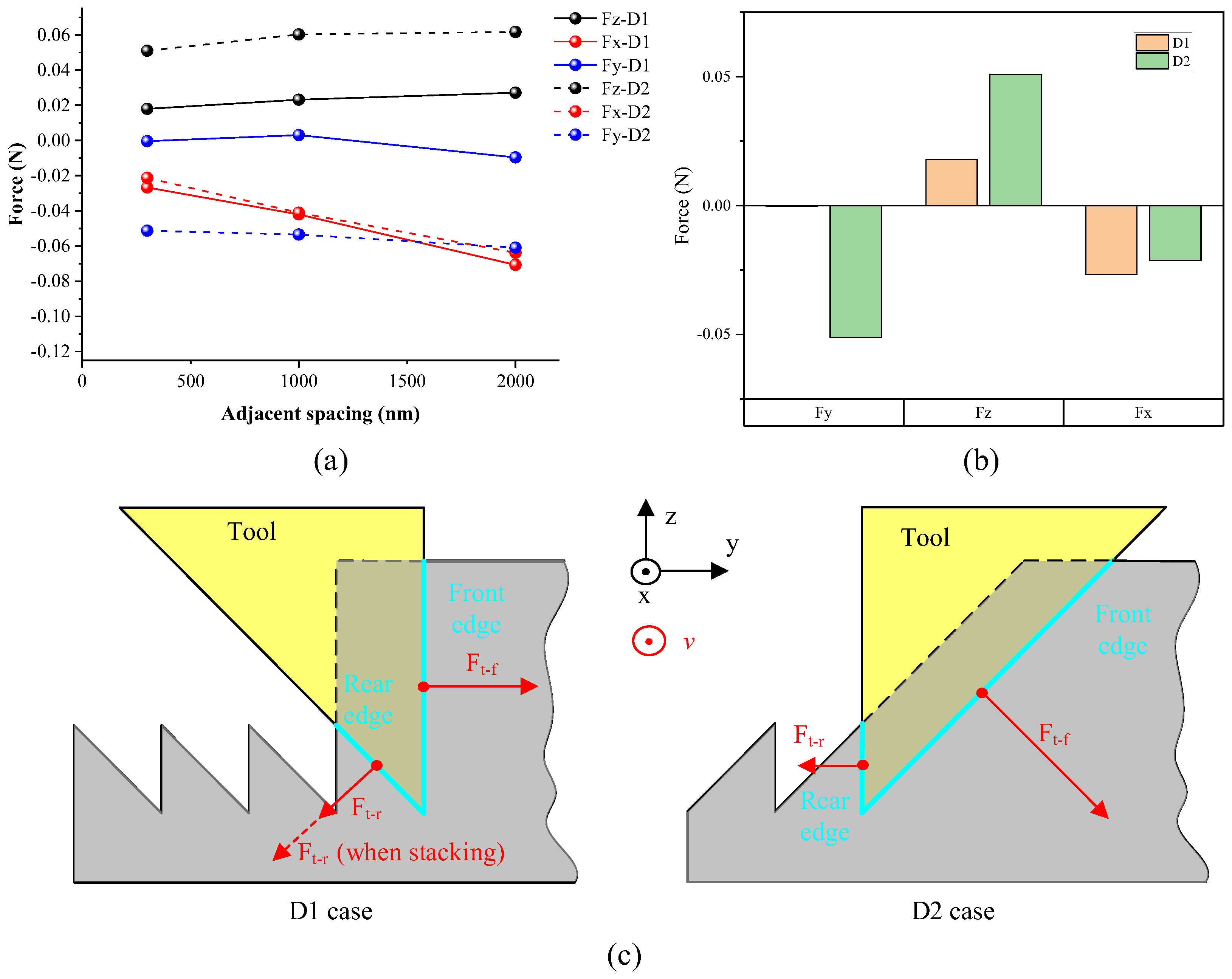

2.3. Mechanics Analysis of Asymmetrical Nanogroove Cutting

3. FEM Simulation of Asymmetrical Nanogroove Cutting

3.1. Material Settings and Simulation Methodology

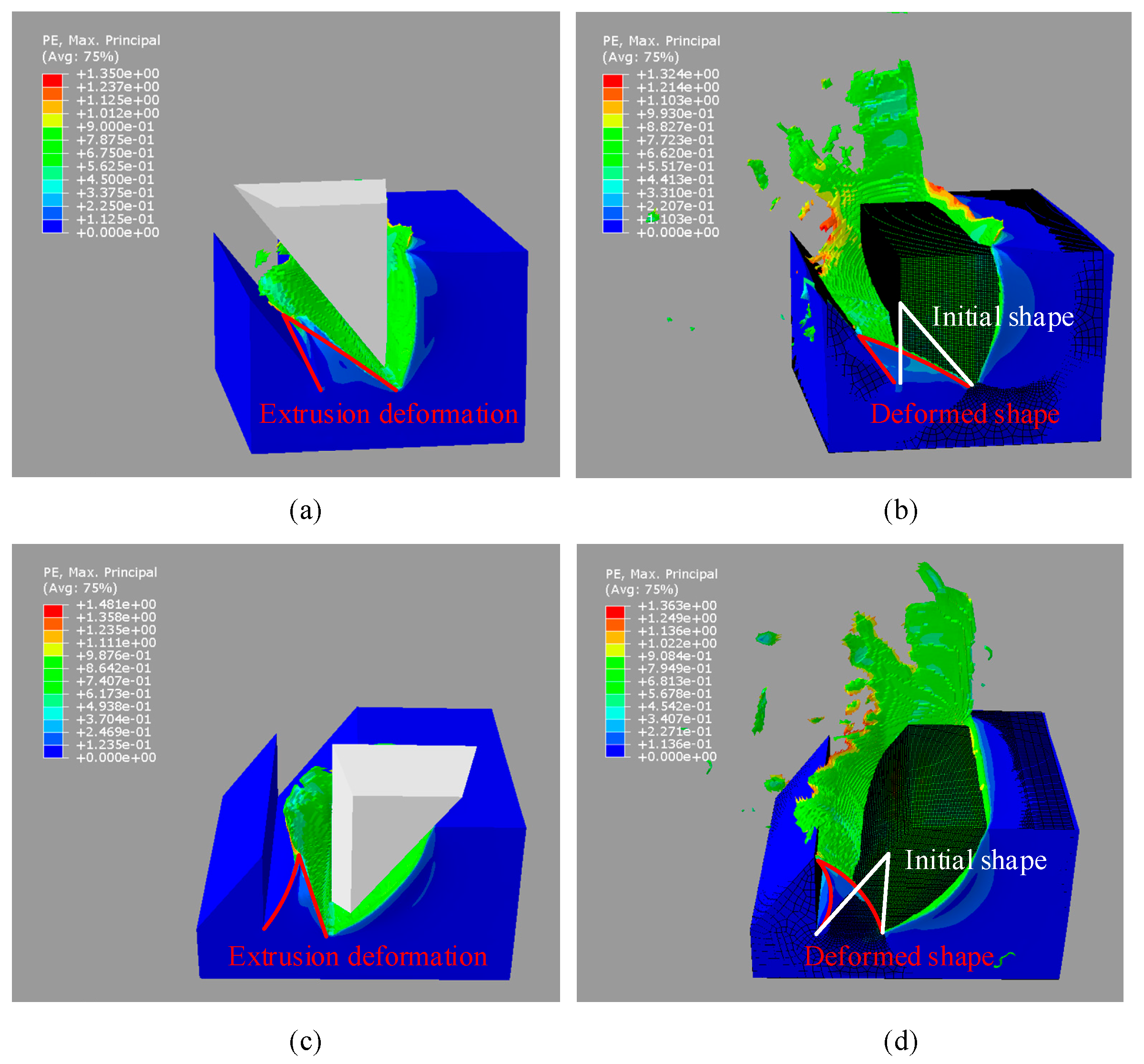

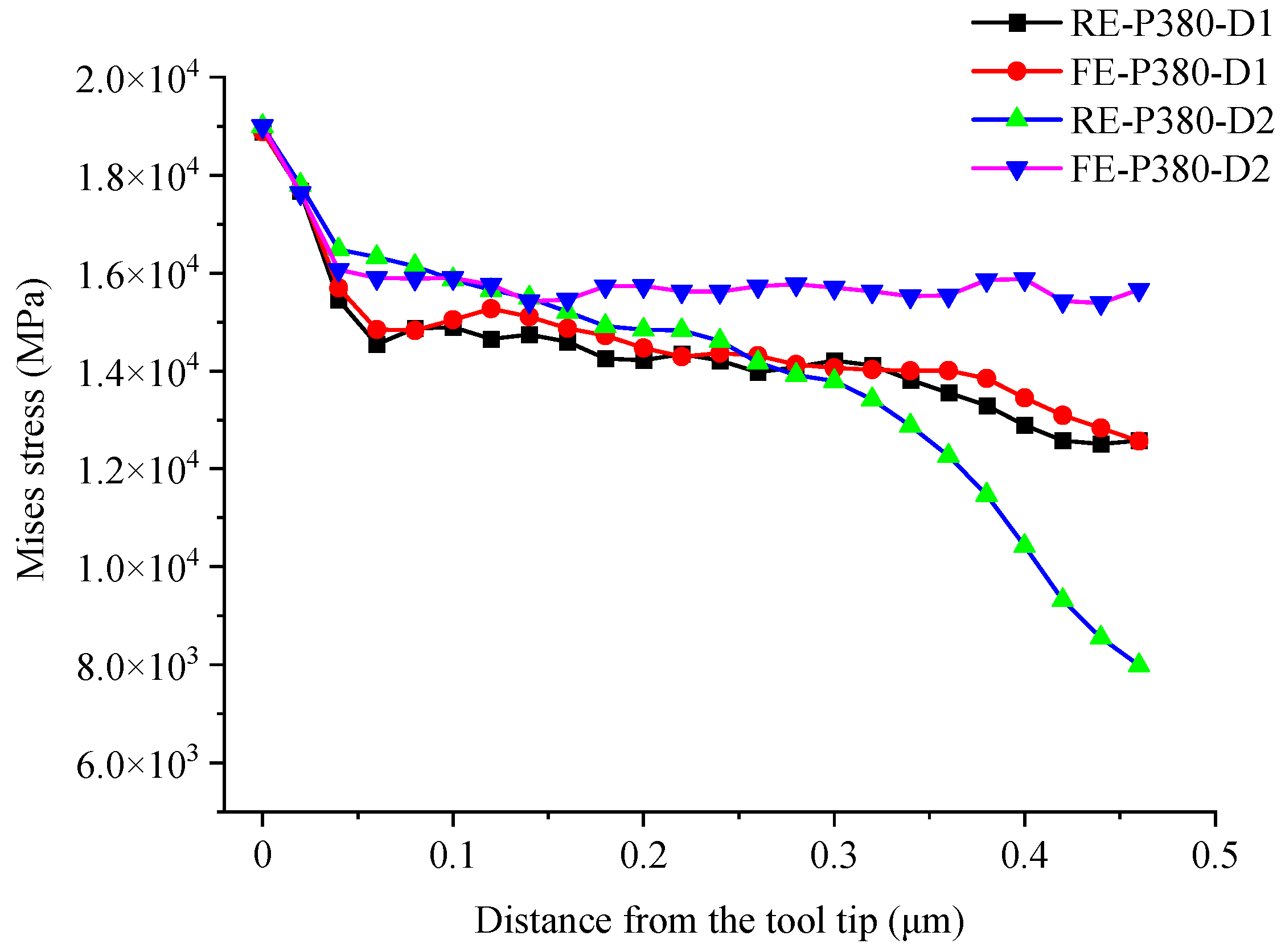

3.2. Simulation Result of Cutting-Caused Deformation of Asymmetrical Nanogrooves

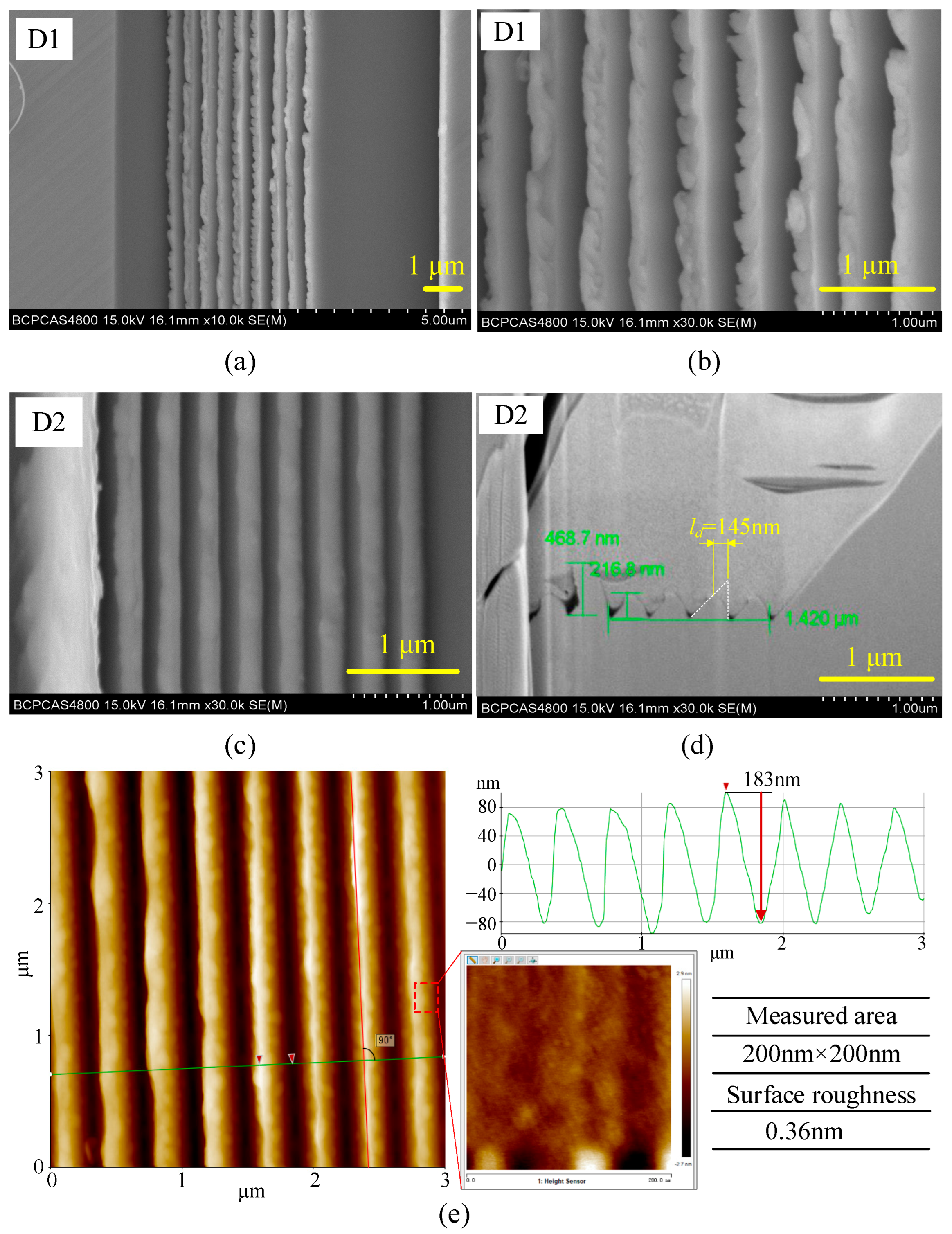

4. Experiment of Asymmetrical Nanogroove Cutting

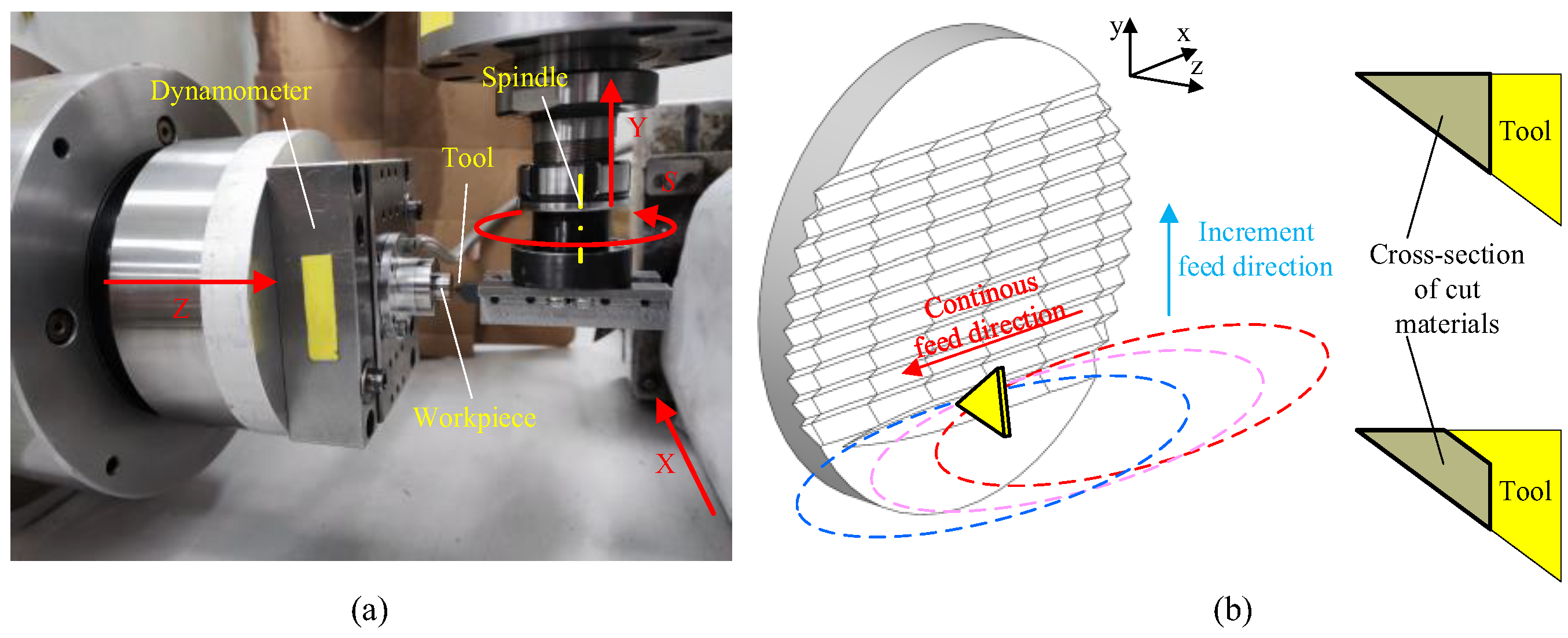

4.1. High-Speed Fly Cutting of Nanogrooves

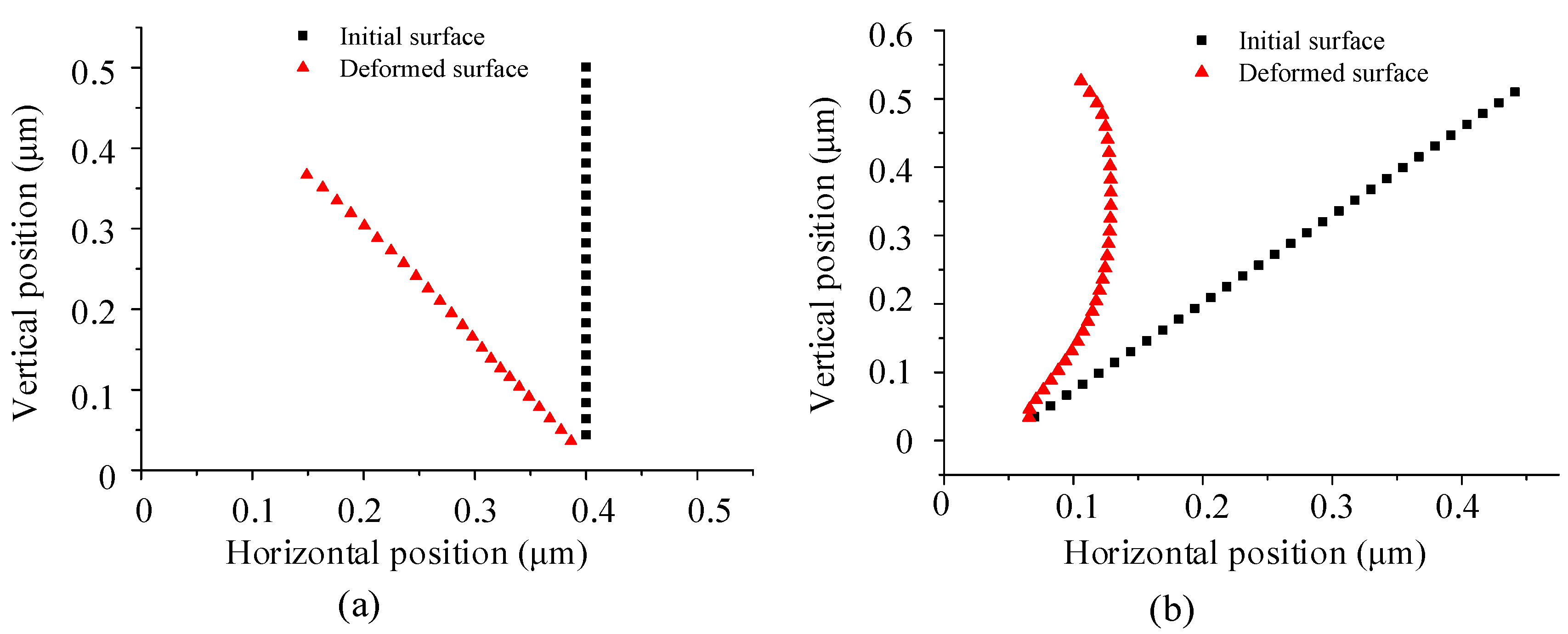

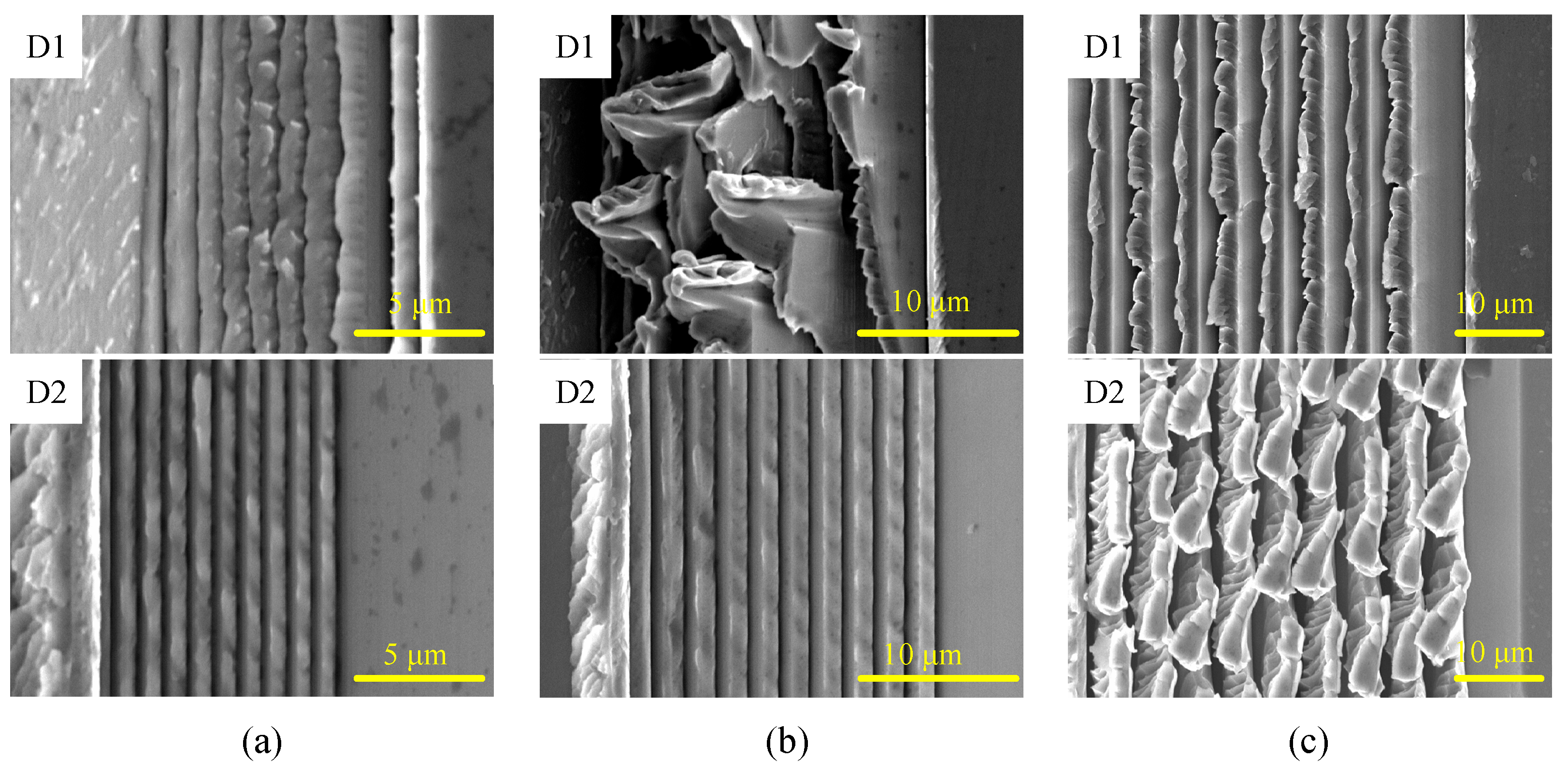

4.2. Deformation Analysis of Asymmetrical Nanogrooves

5. Conclusions

- The analysis of shear interference and chip flow of non-free cutting of asymmetrical nanogrooves shows that extrusion by tool edges and squeezing by the chip flow mainly influence the deformation of nanogrooves. In 38° V-shaped nanogroove cutting, the strong degree of non-free cutting increases the extrusion stress. The flow resistance of the chip squeezes the low-stiffness nanogrooves, prone to exacerbating the deformation of nanogrooves.

- The machining quality of asymmetrical nanogrooves is reliant on the relative feed direction between the tool and workpiece. Therefore, the asymmetrical nanogroove cutting is typed into two cases, D1 and D2, respectively. In the D1 case, the horizontal component of squeezing by the chip flow towards the just-fabricated nanogroove. On the contrary, in the D2 case, the flowing chip squeezes the front uncut materials, relieving the cutting-caused deformation.

- Results of both simulation and experiment verify that the groove bending deformation in the D2 case is substantially suppressed compared with that in the D1 case. In the cutting of the D1 case, the severely deformed nanogrooves are stacked together. The analysis of cutting force finds that the macroscopic total force may underrepresent edge-specific interactions under non-free cutting. Because of this, edge-resolved sensing would be required to quantify forces per tool edge in the future.

- D2 strategy is more suitable for asymmetrical nanogroove machining. However, the removal amount by the tool edge increases with the increase in groove period, making it more difficult to remove the chip and increasing the chip-removal resistance. Therefore, the top area of the nanogroove with a large period is deformed in the one-step cut process, and chips and material residue may be formed on the top ridge. It is suggested that the removal amount in the one-step cutting process of asymmetrical nanogrooves of a-Ni-P material should be kept within 2000 nm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Fang, F.Z.; Zhang, X.D.; Gao, W.; Guo, Y.B.; Byrne, G.; Hansen, H.N. Nanomanufacturing—Perspective and applications. CIRP Ann. 2017, 66, 683–705. [Google Scholar] [CrossRef]

- Wu, D.; Kang, C.; Liang, F.; Yan, G.; Fang, F. Diffractive optical characteristics of nanometric surface topography generated by diamond turning. J. Manuf. Process. 2021, 67, 23–34. [Google Scholar] [CrossRef]

- Xu, Y.; Du, X.; Wang, Z.; Liu, H.; Huang, P.; To, S.; Zhu, L.; Zhu, Z. Room-Temperature Molding of Complex-Shaped Transparent Fused Silica Lenses. Adv. Sci. 2023, 10, 2304756. [Google Scholar] [CrossRef]

- Yan, J.; Maekawa, K.; Tamaki, J.; Kuriyagawa, T. Micro grooving on single-crystal germanium for infrared Fresnel lenses. J. Micromech. Microeng. 2005, 15, 1925–1931. [Google Scholar] [CrossRef]

- Fang, W.; Liu, C.; Zhu, Z.; Wu, C.; Cheng, Q.; Song, Q.; Wang, Y.; Lai, X.; Song, Y.; Jiang, L.; et al. Bioinspired single-shot polarization photodetector based on four-directional grating arrays capped perovskite single-crystal thin film. Sci. Adv. 2024, 10, eadr5375. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Gläbe, R.; Schönemann, L. Review on diamond-machining processes for the generation of functional surface structures. CIRP J. Manuf. Sci. Technol. 2012, 5, 1–7. [Google Scholar] [CrossRef]

- Xu, Y.S.; Li, Z.Z.; Hua, F.L.X.J. Optical near fields for ablation of periodic structures. Opt. Lett. 2023, 48, 2841–2844. [Google Scholar] [CrossRef]

- Qiu, P.; Yuan, D.; Huang, J.; Li, J.; Hu, J.; Xu, S. Polarization-Modulated Patterned Laser Sculpturing of Optical Functional Hierarchical Micro/Nanostructures. Adv. Opt. Mater. 2024, 12, 2302762. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, T.; Yu, Q.; He, Y.; Su, X.; Zhao, B.; Wang, X.; Zhang, Z. Template-Oriented-Assembly microsphere lithography for multi-type SiC microlens arrays. Appl. Surf. Sci. 2024, 673, 160857. [Google Scholar] [CrossRef]

- Huang, W.; Yan, J. 10.08—Ultra-precision grooving technologies. In Comprehensive Materials Processing, 2nd ed.; Hashmi, S., Ed.; Elsevier: Oxford, UK, 2024; pp. 180–204. [Google Scholar]

- Zhang, G.; Ma, S.; Wang, J.; Jiang, J.; Luo, T.; Wang, H. Offset-tool-servo diamond end flycutting multi-layer hierarchical microstructures. Int. J. Mech. Sci. 2022, 233, 107645. [Google Scholar] [CrossRef]

- Yang, Y.; Lin, R.; Zhao, Z. Deterministic rendering of structural color induced by atypical nano-gratings in ultra-precision diamond cutting. Appl. Surf. Sci. 2023, 638, 158065. [Google Scholar] [CrossRef]

- Gao, J.; Chen, P.; Wu, L.; Yu, B.; Qian, L. A review on fabrication of blazed gratings. J. Phys. D Appl. Phys. 2021, 54, 313001. [Google Scholar] [CrossRef]

- Zhou, T.; He, Y.; Wang, T.; Dong, X.; Liu, P.; Zhao, W.; Hu, Y.; Yan, J. Algorithm of Micro-Grooving and Imaging Processing for the Generation of High-Resolution Structural Color Images. Nanomanuf. Metrol. 2020, 3, 187–198. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, K.; Lin, C.; Yao, Y.; Zhang, Y. Scalable patterning of nano-gratings on cylindrical surfaces using elliptical vibration cylindrical turning for novel realization of structural color. J. Manuf. Process. 2025, 143, 306–320. [Google Scholar] [CrossRef]

- Ding, P.; Feng, P.; Wu, K.; Liu, J.; Li, Q.; Zhang, J.; Wang, Y.; Wang, J. Review of vibration texturing. J. Mater. Process. Technol. 2025, 340, 118851. [Google Scholar] [CrossRef]

- Chang, T.; Lin, C.; Zhu, Z.; Huang, P. Ultra-precision rotary scratching of concave blazed gratings. Precis. Eng. 2025, 94, 422–434. [Google Scholar] [CrossRef]

- Luan, M.; Feng, P.; Yu, J.; Wu, K.; Feng, F.; Wang, J. Elliptical vibration ruling of orientation-tuneable blazed gratings for high-flexibility fabrication of structural colours. J. Mater. Process. Technol. 2025, 337, 118729. [Google Scholar] [CrossRef]

- Yan, J.; Oowada, T.; Zhou, T.; Kuriyagawa, T. Precision machining of microstructures on electroless-plated NiP surface for molding glass components. J. Mater. Process. Technol. 2009, 209, 4802–4808. [Google Scholar] [CrossRef]

- Yu, Q.; Zhou, T.; Jiang, Y.; Yan, X.; An, Z.; Wang, X.; Zhang, D.; Ono, T. Preparation of graphene-enhanced nickel-phosphorus composite films by ultrasonic-assisted electroless plating. Appl. Surf. Sci. 2018, 435, 617–625. [Google Scholar] [CrossRef]

- He, Y.; Zhou, T.; Dong, X.; Liu, P.; Zhao, W.; Wang, X.; Hu, Y.; Yan, J. Generation of high-saturation two-level iridescent structures by vibration-assisted fly cutting. Mater. Des. 2020, 193, 108839. [Google Scholar] [CrossRef]

- He, Y.; Zhou, T.; Kumar, A.S.; Wang, X.; Yan, J. Study on the non-free plastic shear removal of material and cutting-induced deformation of micron-submicron grooves. J. Mater. Process. Technol. 2023, 317, 117999. [Google Scholar] [CrossRef]

- Yang, X.; He, Y.; Yu, Q.; Zhou, T.; Sun, T.; Zeng, Z. Chip removal interference control in nano grooving for ultraprecision grating. Int. J. Mech. Sci. 2025, 303, 110642. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Cai, Y.; Huang, M.; Ruan, B.; Liu, P.; Zhou, T. Non-Free Cutting Mechanism of Asymmetrical Nanogrooves Under Chip-Removal Interference in Amorphous Nickel Phosphorus. Micromachines 2025, 16, 1059. https://doi.org/10.3390/mi16091059

He Y, Cai Y, Huang M, Ruan B, Liu P, Zhou T. Non-Free Cutting Mechanism of Asymmetrical Nanogrooves Under Chip-Removal Interference in Amorphous Nickel Phosphorus. Micromachines. 2025; 16(9):1059. https://doi.org/10.3390/mi16091059

Chicago/Turabian StyleHe, Yupeng, Yingzhao Cai, Minkun Huang, Benshuai Ruan, Peng Liu, and Tianfeng Zhou. 2025. "Non-Free Cutting Mechanism of Asymmetrical Nanogrooves Under Chip-Removal Interference in Amorphous Nickel Phosphorus" Micromachines 16, no. 9: 1059. https://doi.org/10.3390/mi16091059

APA StyleHe, Y., Cai, Y., Huang, M., Ruan, B., Liu, P., & Zhou, T. (2025). Non-Free Cutting Mechanism of Asymmetrical Nanogrooves Under Chip-Removal Interference in Amorphous Nickel Phosphorus. Micromachines, 16(9), 1059. https://doi.org/10.3390/mi16091059