Abstract

The rapid growth of artificial intelligence (AI), data centers, and high-performance computing (HPC) has increased the demand for large bandwidth, high energy efficiency, and high-density optical interconnects. Co-packaged optics (CPO) technology offers a promising solution by integrating photonic integrated circuits (PICs) directly within or close to electronic integrated circuit (EIC) packages. This paper explores the evolution of CPO performance from various perspectives, including fan-out wafer level packaging (FOWLP), through-silicon via (TSV)-based packaging, through-glass via (TGV)-based packaging, femtosecond laser direct writing waveguides, ion-exchange glass waveguides, and optical coupling. Micro ring resonators (MRRs) are a high-density integration solution due to their compact size, excellent energy efficiency, and compatibility with CMOS processes. However, traditional thermal tuning methods face limitations such as high static power consumption and severe thermal crosstalk. To address these issues, non-volatile neuromorphic photonics has made breakthroughs using phase-change materials (PCMs). By combining the integrated storage and computing capabilities of photonic memory with the efficient optoelectronic interconnects of CPO, this deep integration is expected to work synergistically to overcome material, integration, and architectural challenges, driving the development of a new generation of computing hardware with high energy efficiency, low latency, and large bandwidth.

1. Introduction

Driven by the expansion of artificial intelligence computing clusters, data centers, and the future evolution of 6G networks, the global digital transformation process continues to deepen, with the demand for higher communication bandwidth and lower data transmission latency growing exponentially. In the early stages of its development, aluminum was primarily utilized as the interconnect material. However, as the feature sizes of integrated circuits continued to decrease, the limitations of aluminum interconnects became increasingly evident. In 1997, IBM developed copper interconnect technology. It has been demonstrated that copper offers approximately 40% lower resistance than aluminum and 100 times greater reliability. For this reason, copper is the primary material for both on-chip and board-level interconnects in integrated circuits [1]. The advent of large-scale integrated circuits has led to a proliferation of chip pins and a concomitant increase in the density of interconnects on PCB. The spacing and width of these interconnections have been measured to sub-millimeter and micrometer levels. Consequently, wire resistance, parasitic capacitance, and parasitic inductance increase lead to higher losses and delays. Copper interconnects demonstrate insertion loss levels as high as 5 dB/mm under 50 GHz signals [2]. When lane data rates exceed 200 Gbps, the copper trace loss on the PCB surpasses 6 dB. Conventional pluggable solutions incur over 20 dB of loss due to various transitions and path lengths [3]. A comparison of bandwidth loss and energy consumption from data transmission within chips, between chips and circuit boards, and between circuit boards reveals that optical fiber transmission in board-level communication reduces by four orders of magnitude compared to electrical transmission within chips and by two orders of magnitude compared to electrical transmission on the board [4]. Traditional electronic circuit technology based on metal interconnects is limited by bottlenecks such as significant signal delay, transmission loss, and electromagnetic interference, and it is difficult to meet the development requirements of modern high-performance electronic systems. Optoelectronic integration is mainly divided into two categories: integral and heterogeneous. Integral integration is mainly achieved by integrating diverse optical or electrical components into a common substrate [5]. Heterogeneous integration employs multiple process steps to machine different material systems into a substrate or to integrate different platforms [6]. As an important component of heterogeneous packaging, 2.5D/3D advanced packaging technology has great potential in improving interconnection density and reducing data latency, and has attracted the research interest of scholars [7]. CPO integrates optical components into electrical packages through advanced packaging technologies such as 2.5D/3D, which improve bandwidth density and power efficiency in data centers, especially as AI and machine learning (ML) applications increase the demand for complex computing and processing large data sets [8]. CPO builds an electro-optical collaborative transmission architecture by integrating the optical engine (OE) with the graphics processing unit (GPU), high-bandwidth memory (HBM), and application-specific integrated circuits (ASICs) inside the package. It uses millimeter-scale ultra-short electrical interconnects within the package to connect the core units directly. This direct connection significantly reduces both signal processing energy consumption and retiming requirements. At the same time, low-loss optical fiber replaces traditional board-level wires completely, which enables high-bandwidth transmission and low latency through direct optical fiber connection technology at the panel end. This structural innovation brings about a leap in system-level energy efficiency, ultimately. In optical Ethernet switch applications, the overall interconnection power consumption is reduced, providing a disruptive high-bandwidth, low-power transmission solution for data centers [9].

CPO technology realized through 2.5D/3D advanced packaging allows for shortening the interconnect length significantly, breaking through the limitations of planar integration, maximizing the integration density, and effectively suppressing parasitic effects, thus becoming the most promising technological pathway to achieve the next generation of high-efficiency and high bandwidth density. 2.5D/3D advanced packaging development enables the realization of inter-chip vertical interconnect stacking through TSV technology [10,11]. However, traditional intercalation is not favorable for high-frequency applications due to the high dielectric constant and loss tangent, which result in large losses. The high cost of the damascene process and the TSV through-hole preparation further limit the CPO technology [12]. Glass is considered a next-generation substrate material due to its lower dielectric constant and loss tangent, which can significantly reduce high-frequency signal loss [13,14]. Compared with silicon, glass allows optimization of the internal components, which affects thermal expansion coefficients and mechanical strength [15]. The simple process of manufacturing large-scale glass substrates contributes to endorsing glass substrates and TGV as the key technologies for 2.5D/3D packaging. The advantage includes excellent scalability for compactly integrating multiple optical and electronic chips into a single package. Similar to TSV technology, FOWLP allows EIC or PIC chips to be embedded in their adapter boards, enabling high-density interconnections and ultra-short signal paths in critical areas. In addition, FOWLP provides efficient heat dissipation and high compatibility with existing semiconductor manufacturing systems [16,17].

Optical waveguides play a vital role in PICs, and are utilized as basic optical components typically [18,19,20,21]. In recent years, femtosecond laser direct writing (FLDW) technology has shown significant promise for 3D fabrication with photonic devices on a variety of transparent substrates, including glass and crystals. FLDW waveguides are invisible to the naked eye, practically, because of their moderate refractive index variation (typically less than 10−2) and gradient refractive index distribution [22,23]. This technique provides a completely non-contact processing strategy inside transparent materials without additional processing steps, and allows the flexibility to change refractive index spatial distributions, resulting in the fabrication of devices with three-dimensional and complex structures [24,25,26,27]. However, it is not possible for this technique to avoid the disadvantages, including the high cost and low fabrication efficiency attributed to the complexity of the steps in the conventional lithography process. Planar optical waveguides fabricated on glass substrates using ion-exchange technology have significant advantages such as optical compatibility with glass fibers, suitability for mass production, and cost-effectiveness [28,29,30]. Glass waveguides provide the advantages of relatively simple processing, low transmission loss, a wide range of refractive indices, and the ability to be easily matched to glass fibers. Exhibiting excellent mechanical, thermal, electrical, and optical properties, glass waveguides have solved many difficult problems. For the future large-scale integration of CPO to form data centers, low-loss glass, inexpensive, and reliable glass waveguide fabrication techniques are becoming critical.

Optical technology forms the cornerstone of modern high-bandwidth communications, supporting the exploding demand for data exchange, especially in data centers and AI computing clusters. As the key platform for realizing next-generation CPO architectures, silicon photonics (SiPh) is expected to provide low-cost, high-performance, integrated optical transceivers and processing cores for data communications. The SiPh platform is capable of integrating various functional components [31,32,33,34,35,36]. However, the large-scale application of SiPh in CPOs faces a fundamental challenge with low-loss and high-efficiency coupling to optical fibers. This is mainly attributed to the significant mode size mismatch between standard optical fibers and submicron silicon waveguides. The OE and the electronics chip are packaged tightly, and the coupling efficiency directly determines the system’s power budget, transmission distance, and overall energy efficiency (pJ/bit). It is the critical factor in determining whether it can replace traditional pluggable optical modules and meet higher bandwidth requirements in the future. Fiber-to-chip interfaces depend mainly on grating couplers or edge couplers [32,37]. Although grating couplers require less package alignment, it is difficult for them to meet the requirements of CPO for high performance, low power consumption, and mass production due to their low coupling efficiency, narrow wavelength bandwidth, high polarization sensitivity, and complex manufacturing process [38,39,40]. In contrast, edge couplers are considered to provide a considerably more promising solution for realizing the high-density, low-loss optical I/O required for CPO because of their potentially high efficiency, wide wavelength, polarization insensitivity, and relatively simplified process. For CPO applications, researchers have developed a variety of high-efficiency edge coupler structures [41,42,43]. It is the core goal of these technologies to achieve near-lossless optical mode conversion, providing the basis for high-throughput, low-latency, and energy-efficient optical interconnects for a data-driven future.

Advances in glass substrate and waveguide technologies have overcome key barriers to CPO in high-frequency and high-density integration schemes. However, the energy efficiency challenges of the computing units themselves still require revolutionary breakthroughs. Brain-like intelligent computing is inspired by human brain functions and aims to build non-biological systems with brain-like functions. The development of ultra-low-power computers with autonomous learning and cognitive capabilities will lead to future technological advances [44,45,46]. Reconfigurable photonic devices are an essential part of next-generation optical technologies and have important applications in integrated photonics, nanophotonics, metasurfaces, and neuromorphic photonics [47,48,49,50,51]. As a major trend in AI and ML, photonic computing has received significant attention for energy efficiency in data transfer, but photoconversion and repetitive data accesses slow down the overall performance and cause additional energy loss [52,53,54,55]. Historically, memory devices have struggled with nonvolatility, but photonic memories based on phase-change materials (PCMs) can effectively address both compatibility and nonvolatility issues. In this way, complex neuromorphic systems can be modeled to support versatile and diverse artificial neural networks and provide an avenue for the development of AI computing clusters [56,57,58].

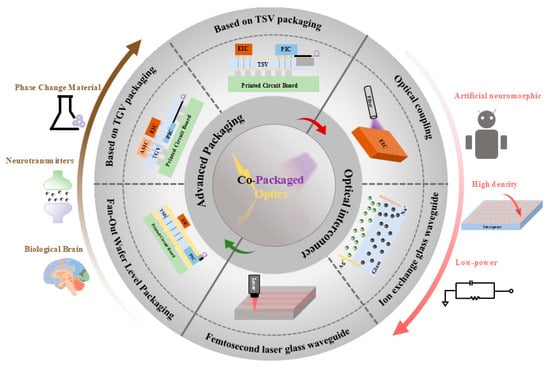

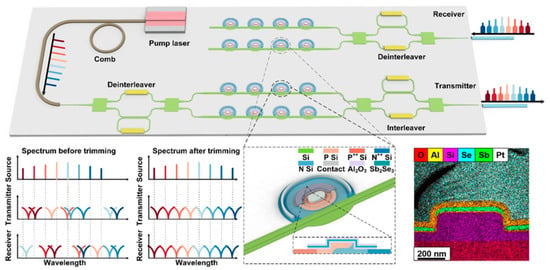

In this paper, we review the recent progress of CPO technology, investigate the performance differences brought by different packaging and glass waveguide technologies, and explore the role of coupling methods in promoting the development of CPO technology, as shown in Figure 1. With the future development of CPO technology, the innovative exploration of the synergistic heterogeneous integration of “optical-electrical-computing”, based on the integrated storage and computing mechanism of artificial neuromorphic photonic memory and the low-loss optical interconnect characteristic of CPO, will help overcome the obstacles faced by the future computing architecture of data centers and build a scalable hyperscale data-center energy efficiency optimization paradigm that provides a possible path.

Figure 1.

Heterogeneity Drives CPO Technology Evolution.

2. Advanced Packaging Technology

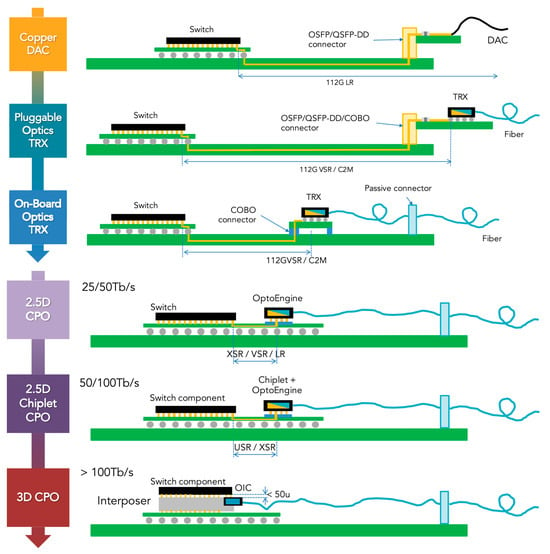

Nowadays, mature optical interconnect solutions include pluggable optical modules and on-board optical modules, but their integration density and data capacity are relatively low, and their power consumption is relatively high. The new generation of high-speed, high-density, and large-bandwidth optical interconnect technology is the key to supporting massive data communication in future switches, servers, and data centers. Chiplet technology has become a reliable technological solution to address these issues. As shown in Figure 2, with the development of CPO technology, the chip has been enabled to significantly increase the integration density and shorten the length of interconnect lines between chips [59]. With the advantages of low power consumption, low cost, and high capacity, it has become the mainstream development direction of optical interconnect [60,61]. With the rapid increase in bandwidth and energy-efficiency requirements in data centers and high-performance computing, CPO technology has become an essential development direction for next-generation optical interconnect solutions owing to its ability to significantly shorten electrical interconnect distances, reduce power consumption, and increase bandwidth density.

Figure 2.

CPO packaging technology roadmap [59].

However, the successful implementation of CPO is highly dependent on breakthrough advanced packaging technologies. High-density heterogeneous integration of OE, complex thermal management requirements, and high-speed signal integrity assurance, as well as overall reliability and cost control, are the core challenges for CPO. Advanced packaging solutions that enable high-density interconnections, excellent thermal dissipation, and heterogeneous integration are key enabling technologies to address these challenges. FOWLP, 2.5D/3D integration technologies based on TSV, and new packaging platforms based on TGV have become a hot topic in research, development, and industrialization due to their unique technological advantages and their great potential to achieve high-performance, high-reliability, and low-cost CPO integration solutions.

2.1. Based on FOWLP Technology

FOWLP is an advanced packaging technology with excellent scalability for integrating different photonic and electronic components. EIC and PIC provide direct embedding into FOWLP interpolators for heterogeneous integration modes with ultrashort signal paths. FWOLP enables efficient heat dissipation and is compatible with current semiconductor fabrication processes [16]. Innovative explorations in silicon photonics play an important role in FOWLP technology. Silicon photonics allows the production of photonic components with low cost and high accuracy by utilizing the mature CMOS fabrication infrastructure. In addition, FOWLP technology enables dense packaging [62,63]. Heterogeneous integration of FOWLP between EIC and PIC has a positive effect on cost reduction and efficiency improvement [64]. The heterogeneous integration platform allows for improved overall signal performance by eliminating the need for discrete components and preventing damage to electrical signals. Tight integration of EIC and PIC enables high-speed interconnections with only 0.05 dB of loss at high frequencies up to 28 GHz. The EIC interconnects to the bottom substrate with less than 0.5 dB of loss as the frequency scales up to 56 GHz. The platform supports high signals above 100 Gbps. The platform supports high-speed signals over 100 Gbps and can be further integrated with larger ASICs to enable larger data centers and higher performance.

The rational design of the organic substrate can further optimize the platform performance [65]. On top of the 2.5D organic substrate, a micro-ring modulator (MRM), photodetector (PD), horizontal coupler, and fiber array (FA) are integrated for high-speed interconnections. The designed 12 × 12 mm2, 850 µm organic substrate contains eight high-speed signal channels with a 3 dB bandwidth of more than 30 GHz on a 10-layer substrate. The high-quality substrate was fabricated with no visible texture or form factor defects, and high-speed signals can be realized in the substrate with 56 Gbps NRZ OOK transmission with a signal-to-noise ratio (SNR) of about four, proving that the organic substrate has good CPO optical transceiver module capabilities. Continued growth in data traffic means continued development of high-speed channels for ASICs. The 1.6 Tbps Silicon Photonic Integrated Circuit (SIPIC) with 16 optical channels (1310 nm) and single-channel 106 Gbps PAM4 performance achieves a smaller footprint and allows for higher density integration in the same area to achieve better performance [66]. Thirty-two hybrid distributed feedback lasers (DFBs) were fabricated using a hybrid silicon laser platform, achieving 20 mW output power at 80 °C with less than a 5% increase in bias current and a 20-year lifetime. The integrated V-shaped array achieves smooth sidewalls through the use of passive SMF28 alignment, which minimizes coupling losses.

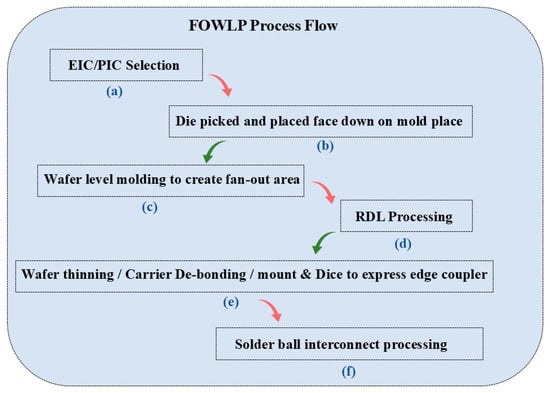

TSV technology is typically used to enable package-level integration, which allows for high manufacturing costs and consumes additional PIC area. In contrast to the high manufacturing costs associated with TSV, FOWLP solutions that integrate PIC with edge couplers for the first time can achieve up to 50% cost reductions to meet the needs of an optical engine, which is significantly different from other solutions [67]. Edge coupling is optimized for high-performance and high-integration packages. While edge coupling offers better performance than vertical coupling, contamination protection of the coupling structure during the packaging process is a significant problem. For this reason, we have innovatively designed a cantilever structure in the PIC coupler region. Compared to vertical grating couplers or edge couplers without cantilever structures, the performance of suspended couplers is excellent [68]. The structure acts as a physical barrier during the molding process, effectively preventing molding compounds from penetrating and contaminating the precise coupling surface. Upon completion of packaging, the cushioning structure is removed, and the coupler is exposed through a precise deep groove cutting process. Experiments have demonstrated that non-destructive exposure can be achieved at different groove widths (50 μm, 80 μm, 100 μm), which ensures the cleanliness and optical performance of the coupling interface. The entire package structure has been tested and proven to have excellent mechanical reliability with no cracks or delamination. For electrical interconnections, the design is optimized for the high-speed data transmission required for system-in-package (SiP). Structures such as the GSSG coplanar waveguide (CPW) ensure the integrity of high-speed signal transmission. The manufacturing process shown in Figure 3 employs a grain-first FOWLP process route and was implemented on a 300 mm state-of-the-art production line, demonstrating the solution’s manufacturability and mass-production potential.

Figure 3.

FOWLP process flow for OE packaging.

While TSV technology has a place in package integration, its inherent high cost and encroachment on the PIC area are becoming increasingly prominent in the quest for high-density, low-cost optical engine packaging. In this context, exploring alternatives to TSVs is not only a matter of optimizing cost but also of finding a technology path that enables the integration of edge couplers. The value of the FOWLP solution lies not in simply lowering cost in fundamentally solving the core contradiction of enabling high-performance, contamination-free edge coupling in embedded packages through unique structural innovations and tooling-advancement processes. Instead of simply reducing costs, the FOWLP solution fundamentally solves the core contradiction of realizing high-performance, pollution-free edge coupling in embedded packages through unique structural innovations and mold-first processes. In addition, FOWLP not only circumvents the pain points of TSVs but also provides the possibility of realizing high-efficiency CPO in compact spaces, which lays the groundwork for subsequent advantages in high-performance interconnections and system-level integrations.

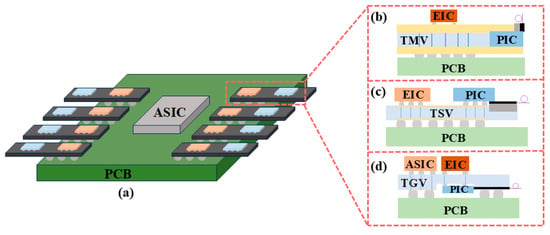

As shown in Figure 4a,b, the FOWLP-based OE platform supports wireless bonding of EIC and PIC integrations to minimize signal loss and improve signal integrity [69]. In the PIC embedding platform, the EIC is encapsulated on the top surface, and a front redistribution layer (FRDL) and a backside redistribution layer (BRDL) are designed for high-density interconnections. The EIC is packaged directly on top of the PIC through an Under Bump Metallurgy (UBM) on the FOWLP FRDL to achieve the smallest path. RF losses are minimized during the interconnect between the high-speed driver and the Transimpedance Amplifier (TIA). Through-mold vias (TMVs) are available for interconnections between the bottom and top of the OE package to achieve rates of 224 Gbps/lane. The photonic engine contains eight high-speed channels with a receive capability of 1.79 Tbps and it has achieved good data-transfer performance in 112 Gbaud NRZ and 224 Gbaud PAM4 tests. By expanding the number of channels in the PIC or increasing the number of PICs in the FOWLP, the total data transfer rate of the OE could be further increased, which will help to reduce the latency of future AI/ML optical interconnects.

Figure 4.

(a) Switch composed of 2.5D advanced packaging; (b) TMV-based, (c) TSV-based, and (d) TGV-based advanced packaging architectures.

Recently, the world’s first 51.2 Tb/s co-packaged optical (CPO) switch prototype was introduced, enabling a paradigm shift in data-center optical interconnects through heterogeneous 3D integration of silicon photonic chips [9]. The solution employs a double-sided FOWLP that integrates eight CMOS silicon photonic engines (O-band channels per engine) with a 512-channel switch chip based on copper pillar bump interconnects and through-mold vias (TMVs). By replacing the traditional TSV technology, it reduces the electrical interconnect distance to the sub-millimeter level while avoiding high process complexity and significantly reducing signal attenuation. Combining the thermally separated construction of an external laser module (RLM) with a blind-mate fiber connector design, all 64 channels were activated. The energy-efficiency ratio of 0.9 pJ/bit reduces power consumption by 50% and increases bandwidth by 100% compared to plug-and-play solutions. Its polyimide dielectric layer warpage control technology is compatible with standard semiconductor packaging processes, providing a key technology pathway for industrializing CPO technology in hyperscale data centers and laying the groundwork for a single-channel 200 Gb/s evolution.

The intermediary layer plays a pivotal role as a crucial intermediate substrate, facilitating seamless electrical connectivity and signal transmission by connecting multiple chips. Among the various intermediary layer technologies, organic intermediary layers emerge as a cost-effective solution, offering scalability to support larger chip sizes and high input/output (I/O) densities [70,71]. Fan-out mediator layer substrate technology, based on 3D printing technology, enables high-density heterogeneous integration through the innovative use of curved through-hole designs [72]. The fabrication of organic substrates with embedded curved through-holes can be accomplished directly through the use of projected microstereoscopic light-curing 3D printers. This method overcomes the limitations of the traditional RDL lamination process, which involves multiple fabrication steps. A key benefit of this approach is the ability to establish vertical interconnections between the chip and the substrate in a single step. The integration of curved through-holes facilitates direct connection between the chip and the package substrate, thereby eliminating the need for multi-layer RDL. Concurrently, the groove-patterned pad facilitates simultaneous metallization through electroplating, integrating chemical copper plating with mechanical polishing to create a low-resistance pathway. Furthermore, the device under consideration facilitates high-density fan-out wiring, thereby reducing the through-hole resistance to a minimum of 0.81 Ω. This value is a substantial reduction of 62% in comparison to that of 90° straight through-holes. Additionally, the insertion loss at 40 GHz is recorded to be less than 0.5 dB. This interposer is compatible with standard copper pillar bump bonding. A 15-micrometer copper pillar, in conjunction with a 20-micrometer Sn/Ag solder cap, has been demonstrated to facilitate reliable interconnections at 280 degrees Celsius, exhibiting a series resistance of 1.85 ohms. This technological advancement significantly reduces the time required for traditional prototype development, from several weeks to a single day. Consequently, it offers a rapid and cost-effective fan-out solution for multi-chip heterogeneous integration in CPO systems; the progress is summarized in Table 1 below.

Table 1.

FOWLP technology progress.

The industry’s first 3.2 Tbs optical engine with on-chip integrated MUX-DMUX for high-bandwidth switching network systems represents a significant advancement in the field [73]. The implementation of a state-of-the-art 3D packaging fan-out technology has enabled the successful integration of four 800 G EICs and a single 3.2 T PIC, facilitating the utilization of wafer-scale redistribution layers (RDLs) for the purpose of achieving a compact design and the establishment of low-parasitic electrical connections. Double-sided RDLs were utilized in the construction of 600 μm ultra-short-distance interconnects between chips, thereby reducing the insertion loss in the 26 GHz band from 1.84 dB to 1.2 dB in comparison to conventional gold wire bonding solutions. For the first time, a large-scale substrate integration solution that is repairable was created. This solution integrates eight optical engine modules on a 110 × 110 mm2 organic substrate. The integration of a customized metal frame and μLGA socket has been demonstrated to achieve 5 μm alignment accuracy, thereby effectively addressing the thermal–mechanical stress problem of large-scale packages during reflow soldering. This approach has been shown to result in a 40% reduction in warpage. The integration of a 24-channel fiber array unit (FAU) at the periphery of the PIC chip, facilitated by high-density fiber-coupling technology, has been demonstrated to result in a single-channel coupling loss of <1.5 dB. A top-mounted heat sink is also employed to optimize thermal management and optical alignment stability concurrently. This technology has been validated in a 25.6 T CPO switch system, achieving a 25% reduction in system-level power consumption at full 100 G PAM4 port traffic compared to traditional pluggable module architectures. This development signifies the transition of CPO technology from the initial proof-of-concept phase to its industrial implementation. This architecture provides a CPO solution for hyperscale data centers that is capable of mass production. The packaging and modular socket design of the 51.2 T switch system has been shown to improve manufacturing yield and field maintainability, thereby establishing the technical foundation for next-generation 51.2 T switch systems.

2.2. Based on TSV Packaging Technology

The increasing data traffic, driven by HPC, has been shown to result in higher-frequency losses in ASICs and optical subassemblies (OSAs) [74]. Existing optical interconnect solutions enable the assembly of optical socket modules with discrete transceiver components on PCB boards. Due to their limited integration density, modest data capacity, and substantial power consumption, these components are constrained in their electrical connection beyond the packaging of computing nodes, thereby hindering scalability to accommodate future data rate demands. This necessitates the development of a novel generation of high-speed, high-density, and high-bandwidth interconnect technologies to facilitate future server and data-center communications [75]. 2.5D CPO technology primarily utilizes silicon interposers or glass interposers as high-density interconnect platforms. It integrates EIC and PIC side by side on the interposer through flip-chip bonding. The integration of high-density RDLs and TSV within or on the surface of the interposer facilitates ultra-short distance, high-bandwidth electrical interconnection between EIC and PIC in the planar dimension, as illustrated in Figure 4c. The integrated interposer is then vertically connected to the underlying package substrate or PCB via a ball grid array (BGA) or other method. Heterogeneous integration facilitates enhanced precision in the alignment of electronic and photonic components, leading to a reduction in interconnect losses at elevated frequencies. Consequently, this integration fosters the augmentation of both the quantity and the velocity of high-speed channels in optical transceivers.

The development of TSV interposers has emerged as a pivotal area of research and innovation, owing to their transformative impact on performance enhancement. In comparison with conventional organic or ceramic packaging substrates, TSV interposers offer a substantial advantage in terms of their remarkably high wiring density and I/O bandwidth, representing a significant advancement in the field. This high interconnection density has increased the number of signals that can be transmitted per unit area, thereby providing fundamental support for meeting the stringent requirements of applications such as HPC, AI accelerators, GPUs, and HBM integration for massive data throughput [76,77]. The fundamental value of TSV technology lies in its ability to fundamentally reshape chip integration. The process entails the vertical penetration of the conductive channel of the silicon interposer, thereby facilitating “direct interconnection” between chips and significantly reducing the interconnection distance. This approach has been demonstrated to significantly reduce signal-transmission delay and power consumption, thereby enhancing the overall performance of the system. Moreover, it has been shown to unlock advanced heterogeneous integration capabilities, which is a key advantage in modern technological applications. Heterogeneous integration facilitates the seamless integration of bare chips that are manufactured on disparate types of semiconductor substrates, employing varying process nodes, and exhibiting diverse functionalities, into a cohesive package through the implementation of high-density interconnection of TSV interposers. This “beyond Moore’s Law” integration approach enables the system to flexibly combine the most optimized technology modules to achieve unprecedented levels of performance, power consumption, cost, and functional diversity.

Given the critical role of TSV interposers in achieving high-density heterogeneous integration, especially in 2.5D packaging architectures, robust and reliable structural and material designs for specific applications are crucial. The process of 2.5D packaging entails multifaceted challenges, including thermal management, mechanical stress, electrical signal integrity, and long-term reliability. Consequently, the design must comprehensively consider the material selection, structural design, thermal interface materials, bottom fill materials, and overall mechanical support solutions of the interposer at the system level to ensure sustained electrical performance and mechanical stability. A significant body of research has been dedicated to the verification and enhancement of the process maturity of 2.5D silicon interposer technology. These studies encompass the critical process steps involved in the overall procedure, encompassing TSV manufacturing, wafer thinning, chip/interposer bonding, micro-bump formation, and the connection between the interposer and the packaging substrate. The objective is to attain high yield and high consistency while adhering to stringent reliability standards [78,79,80].

The primary challenge in implementing silicon photonics technology in data-center interconnects pertains to the necessity of attaining effective collaboration between the photonic PIC and the EIC. Given that computation invariably commences and concludes within the electrical domain, photonic links necessitate the implementation of dedicated driver circuits to establish a high-performance interface with the electronic system. The degree of integration of driver electronics and photonics directly correlates with the bandwidth and energy efficiency of the transceiver. The primary constraints pertain to parasitic effects present within the receive path, the introduction of noise, and bandwidth limitations.

To overcome this challenge, the PIC and EIC are integrated nearby on a silicon-based interposer through a process known as flip-chip bonding. The interposer functions as a high-density interconnection platform, employing micron-level wiring to interconnect chips and connecting the top surface pads to the back package substrate TSV [81]. The interposer pad pitch can be precisely matched with the I/O pads of the PIC/EIC, supporting μbump or copper pillars to achieve low parasitic, high-density connections, while supporting multi-chip integration to expand system functions. A four-channel WDM receiver employs four demultiplexing microdisks, which are coupled with the bus waveguide at the PIC end. The drop port is connected to the germanium PD. The PD output is connected to a single-channel bare chip TIA via a copper pillar bump-interposer trace. The TIA output is routed to the back through the interposer TSV and connected to the PCB via the BGA. The high-speed signal is transmitted by the microstrip line to the SMA interface, supporting 11.3 Gbps transmission per channel. After the deduction of 7.4 dB of edge coupler and microdisk losses, BER < 1 × 10−9 was attained at 5 Gbps/−10.5 dBm received power. This finding substantiates the scalability of 2.5D integration and delineates a technical pathway for integrating silicon photonics into microprocessors.

The utilization of electrical interconnection methods is constrained by two primary factors: the presence of significant delay and severe attenuation at high frequencies. Consequently, optical interconnects are similarly constrained at high transmission rates. The employment of high-resistance silicon as an intermediate layer facilitates the fabrication of the thinnest wires and smallest vias through the silicon intermediate layer process. High-density μbumps/microspheres are utilized for interconnections between EICs and PICs to enhance reliability and expand transmission bandwidth [82]. Following the implementation of electrical performance optimization measures, the insertion loss of the entire link is maintained within −1.55 dB at 40 GHz, thereby ensuring the generation of a clear PAM 4 analog eye diagram at 32 Gbaud/64 Gbps. The transmitter has been demonstrated to attain a clear eye diagram at a PAM 4 signaling rate of 64 Gbps per channel while sustaining a power consumption of 6 pJ/bit. This development aligns with the broader initiative to promote higher-speed PAM4 signaling. The architecture can be applied to 1.6 T/3.2 T CPO optical engines to enhance the scalability of the architecture.

To promote higher-speed connections, a set of two grooves or U-shaped grooves was designed on the silicon interposer [83]. Because μbumps possess low capacitance and inductance, these bumps are designed between the two U-shaped grooves to allow electrical routing between the PIC and EIC while enabling high-frequency electrical connections. The silicon interposer provides facilitation connections with a bandwidth exceeding 100 billion bits per second. In the case of higher-density connections, the routing of electrical signals through the TSVs of the Si interposer is a viable option.

Broadcom’s single optical engine has been demonstrated to achieve 32-channel full-duplex transmission, with a rate of 100 Gb/s per channel and an aggregate bandwidth of 3.2 Tb/s [84]. The system’s energy efficiency is optimized to 5–10 pJ/bit, which is more than 50% lower than that of traditional pluggable modules. The electrical channel insertion loss between the ASIC and the optical engine is only 2–3 dB, which is 90% lower than that of modular solutions. Concerning optical performance, the transmitter TDECQ is less than 2 dB (which is superior to the IEEE 3.4 dB upper limit), and the extinction ratio attains 4 dB. The receiver has been found to meet the bit error rate standard at −10 dBm OMA and has been determined to reserve a 9 dB dynamic margin. The TSV finishing process is employed to attain a 130 μm pitch copper pillar interconnection, ensuring precise alignment with the CMOS/PIC bump density. Concurrently, a 127 μm pitch pluggable optical fiber connector is employed to integrate 72 fibers within a 14.43 mm coastline. A single switch encapsulates four optical engines, thereby achieving a total bandwidth of 12.8 Tb/s. When combined with the RLM architecture, which has four channels driven per laser, this provides a scalable foundation for the evolution of channel rates to 200 Gb/s.

3D CPO technology employs a three-dimensional stacking architecture to integrate EIC and PIC in a vertical direction. Flip-chip stacking is a well-known heterogeneous integration process in the industry that facilitates the interconnection of different chips in either a face-to-face or back-to-back configuration. This integration method has been shown to significantly shorten the interconnection distance between EIC and PIC, thereby effectively reducing the parasitic parameters introduced by the interconnection. This, in turn, has been demonstrated to improve the transmission performance of high-frequency/high-speed signals and to achieve higher system integration density. The crux of three-dimensional integration can be attributed to the design and fabrication of high-performance interposers. Passive interposers are frequently employed to facilitate chip-to-chip interconnection and fan out fine-pitch chip signal pins to a looser package-level pitch [85].

TSV is a pivotal technology for achieving vertical interconnection within the interposer. Active photonic interposers further integrate PIC functions on the basis of providing passive interconnection functions [86]. The vertical transmission and interconnection of electrical signals can be achieved through structures such as RDL, TSV, and microbumps or solder balls. TSV is regarded as the core enabling technology for three-dimensional integration, providing key support for the realization of highly miniaturized and complex next-generation systems. It is a promising solution for continuing the development path of “More than Moore.” Nevertheless, a primary challenge in the development of 3D CPO technology is the construction of reliable and high-performance three-dimensional circuits and systems. Three-dimensional integration has been demonstrated to alleviate the bottleneck of traditional interconnection by shortening the interconnection length and reducing gate delay. However, numerous technical difficulties, such as thermal management and stress control, must still be overcome during the implementation process.

The advent of high-speed data centers and optical interconnection technology has rendered silicon photonics 3D integration a pivotal solution for CPO. This integration enables the reduction of interconnection distances between electro-optical chips, thereby enhancing bandwidth and integration density. The TSV three-dimensional optoelectronic integrated packaging solution, based on a high-resistance SOI substrate, provides a key technical path for high-speed optical interconnection systems of 400 Gbps and above [87]. The study utilized high-resistance SOI wafers to prepare TSV structures with a diameter of 25 μm and a depth-to-width ratio of 4.2:1 by means of deep reactive ion etching. Additionally, the coplanar waveguide and microstrip line design was optimized to reduce RF loss. The experimental results indicate that the 3D packaged test vehicle, which was assembled by thermocompression bonding, exhibits an insertion loss (S21) of less than 3.5 dB in the 50 GHz frequency band and a return loss (S11) of more than −13 dB. The device has been demonstrated to support 50 Gbaud PAM4 modulation and meet the requirements of 400 Gbps optical modules. In comparison with conventional wire bonding methodologies, this innovative approach reduces electrical interconnect lengths to the 100 μm level, thereby significantly mitigating parasitic effects. Furthermore, the integration of wafer-level electroplated micro-bumps facilitates high-density integration, thereby providing a compact solution for applications such as optical transceivers and optically controlled phased array microwave systems. This work not only validates the high-frequency reliability of TSV in optoelectronic co-packaging but also highlights the key value of coordinated optimization of high-resistance silicon materials and advanced interconnect processes in overcoming the bottleneck of next-generation terabit/s bandwidth.

Conventional 2.5D integration grapples with limitations, including a constricted high-frequency response and downward-facing optical interfaces. However, 3D integration based on active photonic adapters has emerged as the prevailing approach, achieving vertical interconnection through TSV and RDL. Notably, this marks the inaugural instance in which edge couplers have been co-designed and manufactured in conjunction with TSVs on SOI substrates [88]. The adoption of an RDL-TSV-RDL configuration, combined with the optimization of the single-hole TSV layout and RDL length, has resulted in an insertion loss of less than 0.35 dB at 67 GHz. Excellent signal integrity was achieved at 112 Gbps eye diagrams. The development of TSV preceded the EC process, effectively preventing the risk of EC contamination in last-via technology. The adapter exhibited commendable high-frequency characteristics and optical performance, thereby establishing a research foundation for the large-scale implementation of system integration based on 3D CPO technology. The relevant progress is illustrated in Table 2.

Table 2.

Progress of TSV/TGV-based packaging.

The recent surge in demand for bandwidth and computing power required to support large AI models and HPC has led to significant advancements in heterogeneous integrated packaging, which has emerged as a pivotal approach to overcoming the limitations of Moore’s Law. However, the warpage problem caused by large-size packaging and high density has restricted assembly yield and reliability, and the power consumption has risen to over 2000 W, posing a severe challenge to thermal management [92,93,94]. In 2.5D advanced packaging for HPC and AI, TSMC’s CoWoS-R technology achieves high-density heterogeneous integration through an organic RDL interposer, supporting large-scale integration of multiple system on a chip (SoC) chips and HBM storage [95]. This platform reduces the RDL line width/spacing from 2/2 μm to 1.4/1.4 μm and decreases the through-hole size from 8 μm to 3 μm. Consequently, the line density is increased from 1100 lines/mm to >2200 lines/mm, thereby providing substantial support for high-speed UCIe (32 Gbps) and HBM3/4 (6–10 Gbps) interconnects. This miniaturization, however, comes with a trade-off between RC impedance and line length. In HBM, long-distance transmission with thin lines leads to an increase in RC impedance, thereby limiting high-speed signal integrity. Furthermore, eye diagram tests demonstrate that a 1.4 μm line width supports only 8 Gbps at a line length of 6.5 mm. Consequently, the line width selection must be optimized based on the specific application scenario.

The issue of warpage is particularly salient in the context of large-sized packages. A 1.3-fold increase in substrate size has been shown to result in a 1.3-fold increase in room-temperature warpage, while a 1.8-fold increase in CoW size has been demonstrated to cause a 2.2-fold increase in warpage [96]. In order to address the issue of warpage, TSMC has proposed a solution that involves the implementation of a warpage compensation layer structure, in conjunction with a sealing ring accessory. This approach has the objective of reducing the warpage of a 5.5-reticle (5.5×) package on a 110 × 110 mm2 substrate by 30–45%. Concurrently, the uniform stress distribution of the organic interposer and the 99.5% yield of CoW bonding establishes the foundation for large-scale integration.

Another significant challenge pertains to thermal management. For CoWoS-R packages with power consumption >1000 W, indium metal TIM (thermal conductivity > 80 W/mK) has been shown to achieve a junction temperature of 105 °C and a thermal resistance of 0.0108 °C/W at 1866 W power consumption. This result is superior to those of graphite film (>20 W/mK) and liquid metal (>8 W/mK) [97]. The application of impingement liquid cooling has been demonstrated to enhance heat dissipation capacity to 2112 W. However, the high voltage drop issue must be addressed to optimize its performance. The innovative direct silicon liquid cooling technology eradicates the thermal resistance of the TIM interface by etching a micro-pillar array on the back of the SoC and connecting the liquid cooling cover with an elastic sealant. The CoWoS-R platform demonstrated the capacity for effective heat dissipation, with IMC-Si achieving 3.4 kW of heat dissipation (power density of 2.5 W/mm2) at a flow rate of 10 LPM. Additionally, the helium leakage rate of the sealant was found to be lower than the critical value of 4.4 × 10−6 Pa·m3/s, a benchmark that was met after 2000 cycles (−40–125°C) and 1000 h. These findings are in alignment with the reliability requirements established for data centers [98].

In 2.5D heterogeneous integration for CPO, Intel’s EMIB-T technology reconstructs the power supply path through silicon via TSV bridge chips, thereby solving the power supply bottleneck of ultra-large form factor [99]. The conventional EMIB configuration exhibits a high voltage drop along its cantilever power supply path. In contrast, the EMIB-T design facilitates direct current flow from the bottom of the package through the TSV bridge to the HBM chip, thereby markedly enhancing power-supply efficiency. This technology supports a 45 μm interconnection pitch and has passed reliability verification, including pre-conditioning and thermal cycling 1500 times in a 77 × 56 mm package size. These findings lay the foundation for HBM4/4e integration and UCle-A 32 Gbps high-speed interconnection.

In response to the demand for sub-micron interconnection density, the multi-layer via architecture (MLV) innovatively divides the bonding layer vias into two categories [100]. The implementation of “power vias” that are directly connected to the power supply layer has been demonstrated to result in a reduction of losses. Additionally, the integration of “signal vias” that are connected to the bottom metal has been shown to facilitate hybrid bonding (HB) pitch reduction to 1 μm. In comparison with conventional stacked vias, MLV has been shown to reduce parasitic capacitance by 24% at a 3-μm pitch. Furthermore, MLV facilitates the penetration of the multi-layer dielectric stack through deep hole etching (>8 μm)-μm with a depth-to-width ratio of >20:1. This architecture is compatible with front/back power supply networks, thereby averting the degradation of the Q factor of RF passive devices caused by thinning of the top metal.

In the context of thermal management, low thermal resistance (LTR) wafer bonding technology has been shown to overcome the thermal limitations of conventional melt bonding methods [101]. Following a process of annealing at a temperature of 350 °C, the bonding energy of the newly developed bonding material is found to be a minimum of 400 mJ/m2, which is at least twice that of oxide bonding. Additionally, there is a 10-fold reduction in thermal resistance, with a value of 10−3 °C cm2/W, as compared to the SiO2 bonding layer, which has a thermal resistance of 1.8–2 × 10−2 °C cm2/W. Thermal simulation indicates that replacing conventional bonding materials in client products and AI accelerators can enhance heat dissipation capacity by 11.1% and 12.1%, respectively, thereby providing a pivotal solution for addressing hot-spot heat dissipation in 3D stacking. Intel employs three innovative technologies: the EMIB-T, MLV architecture, and LTR bonding to address the power supply efficiency, interconnection density, and heat dissipation bottleneck issues in ultra-large packaging. The combination of these technologies has been identified as a key factor contributing to Intel’s competitive advantage in the domain of 2.5D CPO packaging.

2.3. Based on TGV Packaging Technology

Glass interposers have been demonstrated to offer superior scalability for industrial applications in comparison with silicon interposers. This advantage can be attributed to their lower cost, higher integration density, and low dielectric constant. Furthermore, their excellent thermal and mechanical adaptability minimizes warping and cracking. Additionally, their excellent sealing and transparency make them a promising packaging material for next-generation semiconductor devices, demonstrating their significant potential in the future.

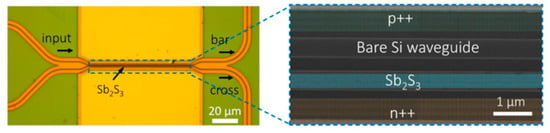

The SiPh platform, which integrates optical devices on Si chips and demonstrates high compatibility, has become the prevailing trend, as illustrated in Figure 4d. This type of packaging typically necessitates sealing and thermal control, reliability, and wavelength stability. It generally utilizes a package composed of ceramic materials. The substantial volume of the package, the high dielectric constant of the ceramic, the high thermal expansion coefficient, and the high power consumption are incompatible with the performance requirements of high-density integration. The utilization of surface photonic packaging with a photon binding-glass interposer (GIP) has been identified as a viable solution to this challenge [102]. The implementation of GIP on a printed circuit board utilizes the Ball Grid Array (BGA) technology. In order to achieve a highly reliable heat dissipation structure, the PIC and EIC are mounted on the BGA side of the GIP and sealed with a glass cover. The digital signal processor (DSP) is mounted on the front side of the general-purpose input/output (GPI) and connected to the electronic interface controller using high-speed electrical signals through TGV. The optical fiber, equipped with an FAU, is affixed to the periphery of the GIP. The PIC is linked to the fiber through a photonic wire and a glass waveguide, facilitating optical communication between the two components. The temperature of the PIC is managed by a high-density TGV that functions as a sealed HTB. This configuration facilitates the extraction of optical signals, electrical signals, and heat from a sealed space. The low thermal expansion coefficient and low dielectric constant are bound and sealed using photonic wires. Direct coupling of the PIC and glass waveguide has been demonstrated to achieve high efficiency in the C-band, with a range of −1.9 dB to −2.3 dB. The transmission line, in conjunction with the TGV, extracts high-speed electrical signals from the EIC, thereby providing 120 GHz high-frequency performance devoid of resonance. This effectively suppresses temperature variations between the EIC and PIC, thereby enabling thermal management and superior control of ultra-high frequency signals.

Glass exhibits a distinctive combination of properties that renders it particularly well-suited to address the challenges associated with co-packaging. Additionally, it possesses the capacity to incorporate optical waveguide interfaces, facilitating the pick-and-place assembly of PIC. Glass substrates with integrated planar IOX optical waveguides beneath the top surface of the glass provide well-defined optical interfaces in terms of position, allowing the assembled PIC to be directly evanescently coupled with low loss. Nevertheless, challenges persist in the precise control of cavity size and depth, as well as the concurrent fabrication of the substrate and the TGV. Consequently, the electro-optical substrate concept was proposed [89]. The system under consideration integrates optical interconnects, electrical RDL, and packaging TGV. Both high-volume ASICs and PICs will be connected to the RDL through electrical connections. The glass substrate is fabricated with different cavity depths, ranging from 30 μm to 140 μm. The photoresist is applied using a spray coating process to achieve uniform photoresist thickness on the cavity bottom and along the top surface. The thickness of the material is uniform at approximately 200 μm from the cavity wall. The optical interface is constituted by an evanescent wave coupler, which is situated between the silicon photonic chip and the glass waveguide that has been integrated into the substrate. Glass waveguides are configured for interconnection with optical fibers via fiber array connectors. The glass waveguides can be extended to the front panel, thereby replacing the fiber bridges. The employment of a photoresist spray coating process has yielded the successful creation of ultra-fine lines and spaces with a width of 5 μm within the glass cavity. This development paves the way for potential applications in 102.4 Tb/s data-center switches.

The 400 Gbps optical engine, based on the TGV interposer, has been demonstrated to overcome the high RF loss of the electrical interconnection between the printed circuit board and the optical engine. This innovation has also been shown to solve the problems of high-frequency signal loss and module maintainability through innovative design [90]. The core breakthrough of this technology is the simultaneous resolution of two significant challenges faced by the industry: high-frequency signal loss and module maintainability. The optical engine exhibits an S21 insertion loss of less than 1.5 dB at a bandwidth of 67 GHz, which is more than 5 dB better than that of traditional PCBs. The E/O bandwidth of the device reaches 51.8 GHz at 25 °C/85 °C. The optical engine module can be expeditiously replaced by means of the original 808 nm laser penetration welding technology. The solder joint melting time is less than 20 s at a power of 14.3 W. After replacement, TDECQ remains below 1.6 dB, and the 10 km transmission reception sensitivity of −8.3 dBm is maintained. These findings substantiate the hypothesis that the TGV glass substrate possesses inherent physical advantages in terms of suppressing RF loss and exhibiting favorable infrared transmission characteristics. The relevant progress is demonstrated in Table 2.

The advent of advanced manufacturing processes based on glass substrates has the potential to catalyze the development of higher speeds and bandwidths [103]. The integration of a cavity structure with a high aspect ratio TGV is achieved through the synergy of mechanical processing and wet etching. The cavity taper ratio can be controlled within the range of 0.1 to 0.6. The innovative use of spray photoresist combined with laser direct write exposure (LDI) technology overcomes the difficulties of traditional photolithography in deep cavities and realizes RDL of fine copper wiring at the bottom of the cavity. This technology offers a pivotal glass substrate solution for the low-loss, high-density optoelectronic co-packaging demanded by AI/HPC and data centers.

Glass substrates are poised to assume a pivotal role in facilitating high-density optoelectronic integration within the CPO framework. To facilitate the subsequent evolution of these technologies, it is imperative to surmount the impediments currently impeding the advancement of three-dimensional architecture and heterogeneous synergy. Current technologies facilitate the fabrication of integrated cavity-TGV and the implementation of deep-cavity micron-scale RDL routing. However, the stringent requirements of AI and HPC for computing power density and energy efficiency underscore the imperative for ongoing advancements in multi-layer heterogeneous stacking. This necessitates the development of cavity-in-cavity structures and three-dimensional TGV interconnect networks to facilitate the deep integration of optoelectronic chips, thereby overcoming the physical limitations inherent to planar layouts. In addition, it is imperative to optimize the thermal expansion coefficient matching of glass substrates to effectively mitigate photon–electron coupling losses. Moreover, the establishment of a comprehensive lifecycle reliability system is imperative to ascertain the stability of deep-cavity structures under dynamic loads through accelerated thermomechanical stress testing. Achieving these breakthroughs is imperative for the advancement of glass substrates from passive substrates to active optoelectronic fusion platforms, thereby facilitating the implementation of optoelectronic symbiosis architectures for data-center switches with a capacity exceeding 102.4 Tb/s.

The development of artificial intelligence has led to a gradual increase in the operating power level of data centers. The next-generation HPC platform, which targets extremely high speeds, has generated diverse power demands and requires an optimized power distribution network (PDN) to minimize losses and maintain power integrity [104]. The glass-substrate-embedded silicon deep trench capacitor (DTC) technology of the 3D stacked integrated voltage regulator (IVR) vertical power supply (VPD) has been demonstrated to yield ultra-high density and ultra-low parasitic parameters through innovative 3D integration [105]. The 3D architecture of the device under consideration embeds a 210 μm-thick, multi-terminal DTC chip within a 200 μm glass substrate. The fabrication of TGV and stacked microvias involves a process of laser ablation, utilizing a semi-additive method to create a vertical current path within the glass layer. Experimental verification has been undertaken to assess the performance of the solution, and the results demonstrate that it can support a total capacitance of hundreds of microfarads. This capacity is sufficient to meet the vertical power supply requirements of a 1 kW-class IVR. The system’s compatibility with the prospective augmentation of 3D stacking of 90 μm ultra-thin glass and 75 μm DTCs is also noteworthy. This model provides a solution for high-bandwidth, low-loss 3D power transmission in co-packaged optical systems.

Fujitsu Laboratories has achieved a significant milestone in the field of silicon photonic transceiver technology, with the development of the world’s first 16-channel × 25 Gb/s silicon photonic transceiver. This advancement has yielded a remarkable result, namely, 400 Gb/s aggregate bandwidth, which is a testament to the transceiver’s advanced capabilities. Furthermore, the transceiver exhibits an industry-leading bandwidth density of 363 Gb/s/cm2, a feat made possible by the implementation of a high-density bridging structure [91]. The 28-nanometer CMOS EIC and PIC are directly interconnected using flip-chip bonding, thereby reducing the electrical interconnection path to its shortest possible form. Concurrently, 100Ω differential signal lines are integrated through a glass ceramic interposer (GCIP) to suppress signal reflection and crosstalk. The optimization of power integrity (PI) and signal integrity (SI) facilitates the integration of the Tx/Rx independent power supply network with the on-chip capacitor layout, thereby reducing Tx-Tx and Rx–Rx crosstalk to 1.4 dB, and ensuring Tx-Rx crosstalk remains below 0.1 dB. The PIC integrates a 4 × 4 laser diode array (LD) and a silicon germanium detector, thereby realizing 32 channels of optical I/O through a grating coupler. The active alignment multi-fiber ferrule facilitates full functional integration within an area of 11 × 10 mm2. The 16-channel 25 Gb/s NRZ signal transmission was found to be BER < 10−12, yet the influence of the traditional MZ modulator suggests potential for enhancement of energy efficiency.

While the industrialization of 3D CPO technology has achieved breakthroughs, the path to next-generation systems with higher speeds and higher density still faces three core challenges. The solutions to these challenges will profoundly impact the direction of technological evolution. The prevailing energy efficiency challenges in conventional devices necessitate the investigation of innovative optoelectronic collaborative architectures to overcome the energy consumption per bit constraints at the system level. Moreover, 3D stacking has been shown to increase thermal density exponentially, thereby further complicating thermal stress management. As transmission rates and bandwidths continue to increase, the system’s heat flux density will gradually increase. The development of technologies aimed at enhancing the thermal conductivity of heterogeneous material interfaces, in conjunction with artificial intelligence (AI)-driven thermal stress models, is poised to assume increasing significance. These technologies are designed to facilitate pre-packaging predictions and prevent thermally induced package failures. As systems continue to evolve, high-frequency interconnects are approaching physical limits, and high-speed channels will face severe loss and crosstalk challenges. The advent of high-aspect-ratio TSV/TGV systems poses a significant challenge to the pursuit of continuous breakthroughs in ALD technology. Additionally, the degree to which industry ecosystem collaboration occurs will be a pivotal factor. The absence of co-packaging interface standards for engine and switch chips underscores the necessity for the establishment of an open, cross-enterprise interoperability framework. In order to effectively address the diagnostic challenges posed by 3D integrated systems, the utilization of wafer-level optoelectronic co-probe stations is imperative during the testing process. Achieving a generational leap from the current optical engine to the future 100 T-level system or beyond necessitates the comprehensive restructuring of the existing chain of “materials-design-manufacturing-verification.”

The vertical stacking of chips in three-dimensional packaging facilitates high-density integration and augments signal transmission performance. However, this approach concomitantly results in a substantial surge in power density, thereby rendering thermal management a pivotal challenge that hinders the reliability of high-capacity 3D CPO devices. Photonic components, including semiconductor optical amplifiers and micro-ring resonators, demonstrate a notable temperature dependence. A temperature variation of 20 °C is generally sufficient to cause a PIC to deviate from its operating range [106]. Conventional underfill materials utilized in packaging, such as epoxy resins, exhibit comparatively low thermal conductivity and are increasingly inadequate in meeting the demands of three-dimensional packaging. In order to address the aforementioned limitation, high-filler-content materials (typically exceeding 50%) with excellent thermal conductivity, such as aluminum nitride (AlN) [107] and boron nitride (BN) [108], can be incorporated into the epoxy resin matrix. In the context of 3D-stacked chips, the absence of direct thermal conduction pathways surrounding the un-bumped area at the periphery of the large-sized chip leads to a significant elevation in temperature within the package. Thermal bridge structures have been demonstrated to facilitate the connection between the un-bumped periphery of large-sized chips and the lid, thereby enhancing thermal management. Zhang et al. [109] addressed the thermal management challenges of 3D-stacked memory chips on processors based on this approach. The thermal bridge, which exhibited a square ring shape, was affixed to the un-bumped area of the processor via die-attach material, arranged in parallel with the memory stack. This connection was then facilitated through the thermal interface material, with the objective of minimizing the interfacial thermal resistance. A fan-cooled heat sink was affixed to the lid. This solution enabled a substantial reduction in the maximum temperature of the 3D stacked package, from 207 °C to 97.3 °C. Furthermore, given the disparate thermal conductivity and thermal expansion coefficients of diverse materials in three-dimensional packaging, numerous thermal stress and deformation problems are likely to arise. In severe cases, the phenomenon can lead to fractures and failures at the connections of each layer. Thermal analysis and research on TSVs have been demonstrated to be effective methods for mitigating these issues [110]. In a seminal study, Liu et al. [111] pioneered a novel approach by integrating research on thermal and signal integrity. They proposed a differentiated TSV structure that exhibits a remarkable capacity to mitigate thermal stress without compromising signal integrity. The large-diameter TSV under a pad was substituted by four identical small-diameter TSVs, and the cross section of the large-diameter TSV was the circumcircle of the four small-diameter TSVs. In comparison with conventional TSV, the peak thermal stress and the occupied silicon area of the differentiated TSV were reduced by 33 MPa and 54 μm2, respectively. The utilization of a differentiated TSV as the grounding TSV has been demonstrated to enhance the efficacy of shielding interference from aggressive TSVs. This approach has been shown to result in a 15 dB reduction in crosstalk noise over a frequency range of 3 GHz.

Among advanced packaging solutions for CPO and high-performance optoelectronic integrated systems, FOWLP, TSV, and TGV are currently the three mainstream three-dimensional interconnect and heterogeneous integration technology platforms. Each exhibits distinct advantages concerning signal integrity, thermal management, optical coupling efficiency, process complexity, and cost control, exhibiting clearly delineated application boundaries. A systematic analysis of these differences in structural principles, process implementation, electrical performance, optical compatibility, integration density, and reliability provides valuable guidance for selecting packaging architectures for CPO systems.

From a structural and process perspective, FOWLP is a fan-out packaging technology based on a reconstructed wafer, interconnecting the PIC and EIC via TMVs. This technology is notable for its silicon substrate independence and cost-effectiveness, offering low material costs and excellent warpage control. These characteristics render it particularly well-suited for high-yield, large-scale optoelectronic hybrid integration scenarios. TSVs, in contrast, employ an alternative method to achieve high-density electrical interconnects in the vertical direction. This method involves the etching of deep vias in a high-resistance silicon wafer, followed by the filling of these vias with metal. These vias are frequently utilized in silicon interposers or three-dimensional stacked structures, providing optimal interconnect density and CMOS process compatibility. However, they also encounter challenges, including elevated manufacturing costs and thermomechanical stress. TGVs employ glass as the interposer material, with through-holes formed via laser-induced etching or wet etching processes. These holes are then metallized for electrical connection. Glass, with its low dielectric constant, low loss, optical transparency, and a coefficient of thermal expansion similar to that of silicon, offers unique advantages in CPO, making it particularly suitable for CPO systems that require high bandwidth, low transmission loss, and high-precision optical coupling. With regard to electrical performance and high-frequency characteristics, TSVs are vulnerable to parasitic capacitance, signal crosstalk, and transmission loss in high-frequency environments due to the high dielectric constant and limited resistivity of the silicon substrate. Despite the potential for enhancement of performance through the implementation of high-resistance silicon and supplementary insulating layers or shielding structures, the high-frequency performance of these materials remains constrained. FOWLP utilizes RDLs with a lower dielectric constant, a strategy that has been demonstrated to effectively mitigate signal loss and crosstalk, thereby showcasing remarkable high-frequency transmission characteristics. TGVs benefit from the low dielectric constant and extremely low dissipation factor of glass itself, exhibiting optimal signal transmission performance in high-frequency and millimeter-wave applications. In terms of optical coupling and packaging compatibility, FOWLP supports edge-emitting or surface-emitting coupling by retaining the optical interface at the edge of the PIC and designing an opening structure. The probability of packaging contamination is minimal, and the optical performance exhibits consistency both before and after packaging. The TSV interposer generally necessitates an auxiliary optical coupling structure. However, silicon materials exhibit absorption losses in particular bands, thereby constraining their range of applicability. The high-temperature steps and chemical–mechanical polishing processes inherent to its fabrication may result in contamination or stress damage to the PIC. Due to the full-band light transmittance of glass, TGV is capable of direct integration with waveguides, grating couplers, and edge-coupling structures. The thermal expansion coefficient of the silicon-based optical chips is matched, thereby helping to suppress optical path deviation caused by thermal mismatch and improve coupling accuracy and long-term stability. Furthermore, TGV supports local heating processes, thereby facilitating the repair and replacement of optical modules. In terms of integration density and scalability, TSV offers the highest vertical interconnect density with micron-level through-hole pitch, making it suitable for high-density 3D stacking and silicon interposer integration. Although FOWLP does not fully meet the requirements of TSV in terms of vertical interconnection, it facilitates multi-chip fan-out integration through multi-layer RDL and μbump technology, ensuring excellent parallel scalability and compatibility with optoelectronic heterogeneous systems characterized by medium-to-high integration density. TGV facilitates double-sided wiring and large-area panel-level processing, showcasing exceptional scalability and multi-chip co-integration capabilities. Its use as an interposer for optoelectronic co-packaging, integrating PICs, EICs, lasers, and fiber arrays, is particularly advantageous, as it enables the achievement of high-bandwidth density and low-power system construction. In regard to the management of thermal processes and the assurance of reliability, TSVs have been demonstrated to facilitate optimal heat dissipation, a consequence of silicon’s high thermal conductivity. However, the mismatch in thermal expansion coefficients between the metal filler and silicon can result in thermal stress and warping. FOWLPs exhibit reduced thermal conductivity and generally necessitate integration with thermal interface materials or embedded metal heat dissipation structures. The utilization of plastic encapsulation is instrumental in the mitigation of warping, thereby ensuring optimal thermomechanical reliability. However, the thermal conductivity of glass is limited, which restricts the effectiveness of TGV in dissipating heat. However, their matching thermal expansion coefficient with silicon has been shown to significantly reduce thermal stress, improve the mechanical stability and fatigue resistance of the package, and excel in thermal cycling tests.

In summary, FOWLP, TSV, and TGV are each suitable for different scenarios in CPO system packaging. FOWLP is suitable for medium-to-high-density, low-cost, and high-yield optoelectronic hybrid integration, typically for short-reach interconnects between PICs and EICs. TSV demonstrates particular proficiency in ultra-high-density 3D stacking and silicon-based heterogeneous integration, rendering it well-suited for scenarios that demand extreme interconnect density, such as AI accelerators and HPC. TGV, with its superior high-frequency performance, optical transparency, and thermomechanical reliability, is an ideal optoelectronic fusion platform in CPO systems, particularly suitable for the packaging of 400 G/800 G and higher-speed optical engines. As the TGV process matures and its cost continues to decline, it is expected to become the mainstream CPO packaging path, propelling silicon photonics technology from integration to a new stage of mass production, maintenance, and scalability.

3. Optical Interconnect Technology

Active and passive photonic devices built on dielectric waveguide technology are essential core components of CPO architectures, and efficient coupling of optical fibers and waveguides is equally crucial in CPO architectures. The significance of these materials lies in their central role in PIC, a field that has seen rapid advancements in recent years. This central role stems from the inherently compact geometry of the waveguide structure, which enables efficient light field confinement at the micron and even submicron scales. This, in turn, results in significantly enhanced optical intensity relative to bulk materials within a limited physical volume. Concurrently, it is imperative to achieve low-loss, high-alignment-tolerance coupling between optical fibers and on-chip waveguides to facilitate the efficient channeling of external optical signals into and out of the PIC. Achieving high-density integration, strong light field confinement, and efficient optical coupling is imperative for CPOs to accomplish the objectives of ultra-high bandwidth density, low-power interconnection, and tight coupling of optoelectronic chips.

3.1. Femtosecond Laser Direct Writing Waveguide

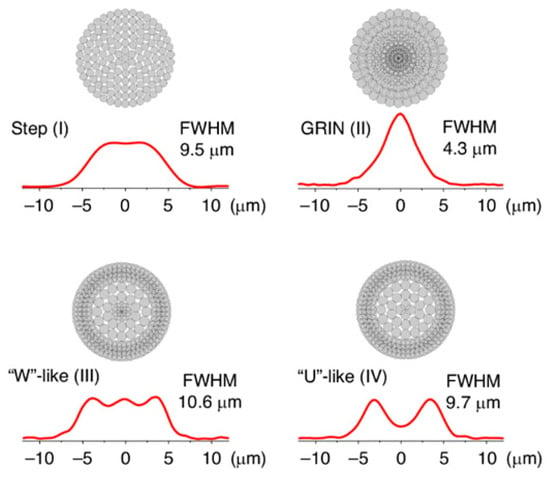

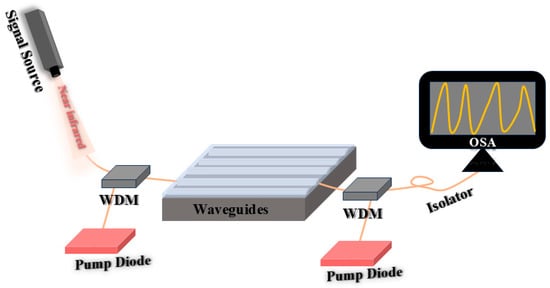

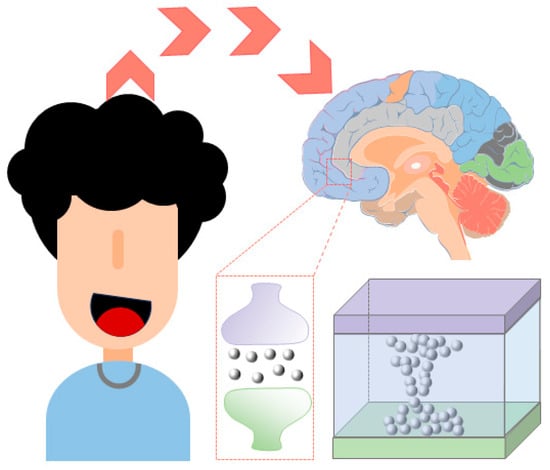

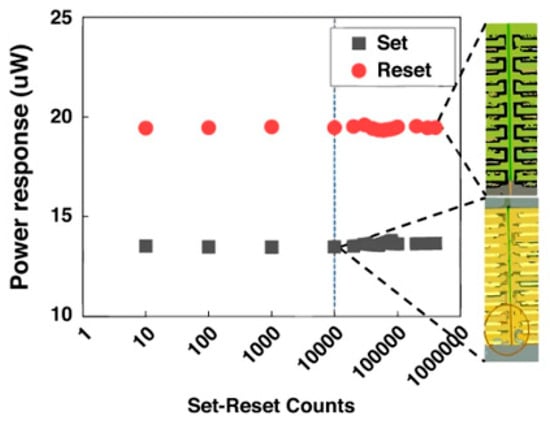

The advent of advanced computing capabilities and the escalating demands for data transmission in the domain of emerging AI have precipitated a surge in research on and development of CPO technology. The pursuit of immersive experiences in augmented reality (AR) and virtual reality (VR) technologies has also contributed to the proliferation of CPO technology, which boasts ultra-high bandwidth density and low-power interconnection advantages [68,112,113]. In this context, the development of transparent screens or substrates that integrate multiple electronic and photonic functional components has become one of the key paths to achieving the next generation of lightweight, highly integrated mobile transparent display devices. This development has attracted widespread attention from the industry and academia. Among the numerous technical solutions for exploring transparent integrated optical devices, FLDW technology has demonstrated unique application potential. The primary advantage of this technology is its capacity to execute 3D micro-nano processing within transparent substrates, encompassing various optical glasses, crystals, and even polymers. It can also “carve” complex photonic structures, such as optical waveguides, grating couplers, and microcavities, with exceptional spatial resolution and adaptability. This non-contact processing feature, with a minimal thermal effect, enables FLDW to directly construct functional photonic circuits and devices inside transparent substrates without significantly affecting the macroscopic optical transparency of the substrate. It provides robust technical support for the development of highly integrated, high-performance transparent photonic subsystems, a crucial element in promoting the application of CPO architecture in transparent display platforms and the miniaturization of optical engines in AR/VR devices.