The Effect of Dual-Layer Carbon/Iron-Doped Buffers in an AlGaN/GaN High-Electron-Mobility Transistor

Abstract

1. Introduction

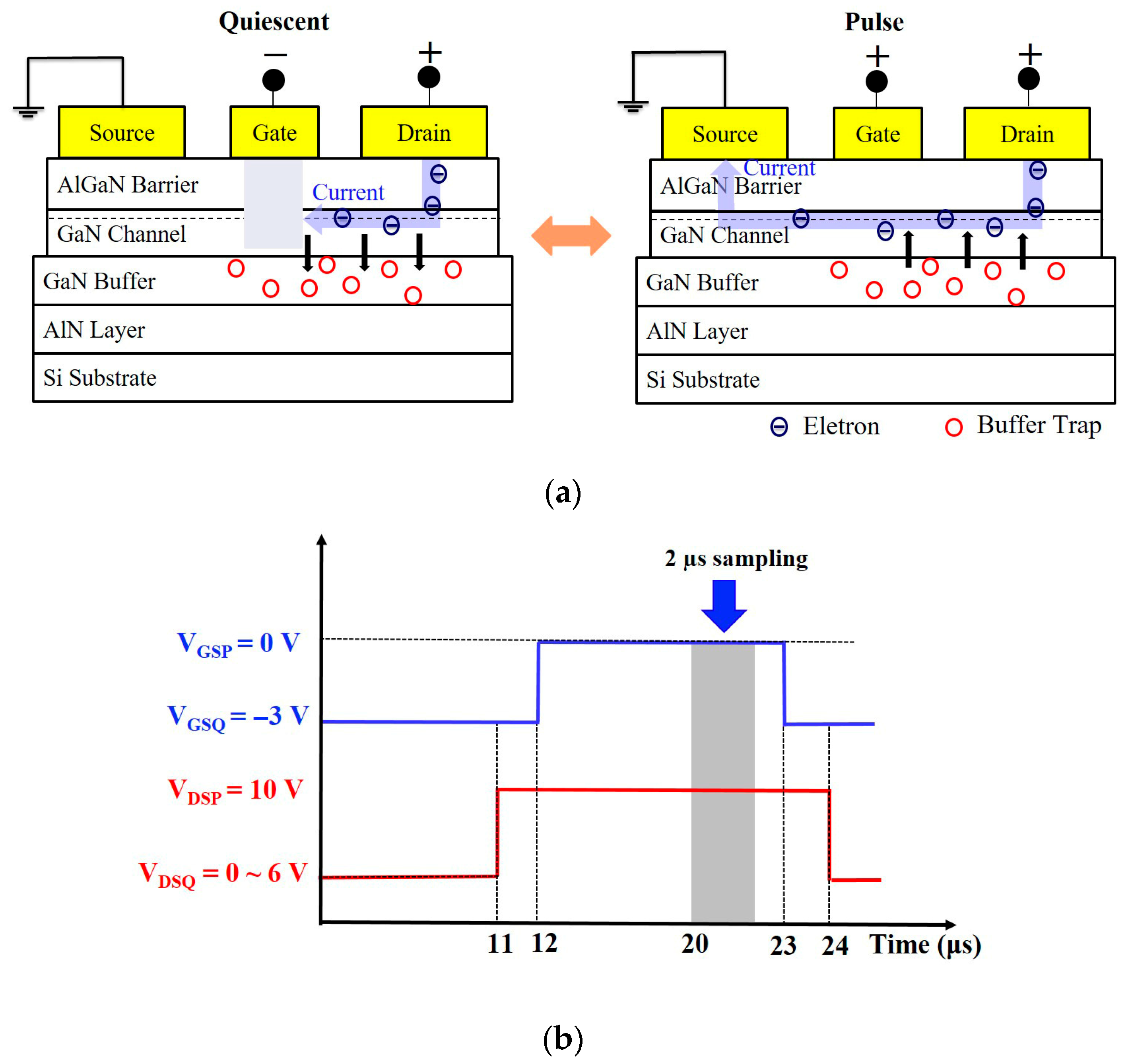

2. Experimental

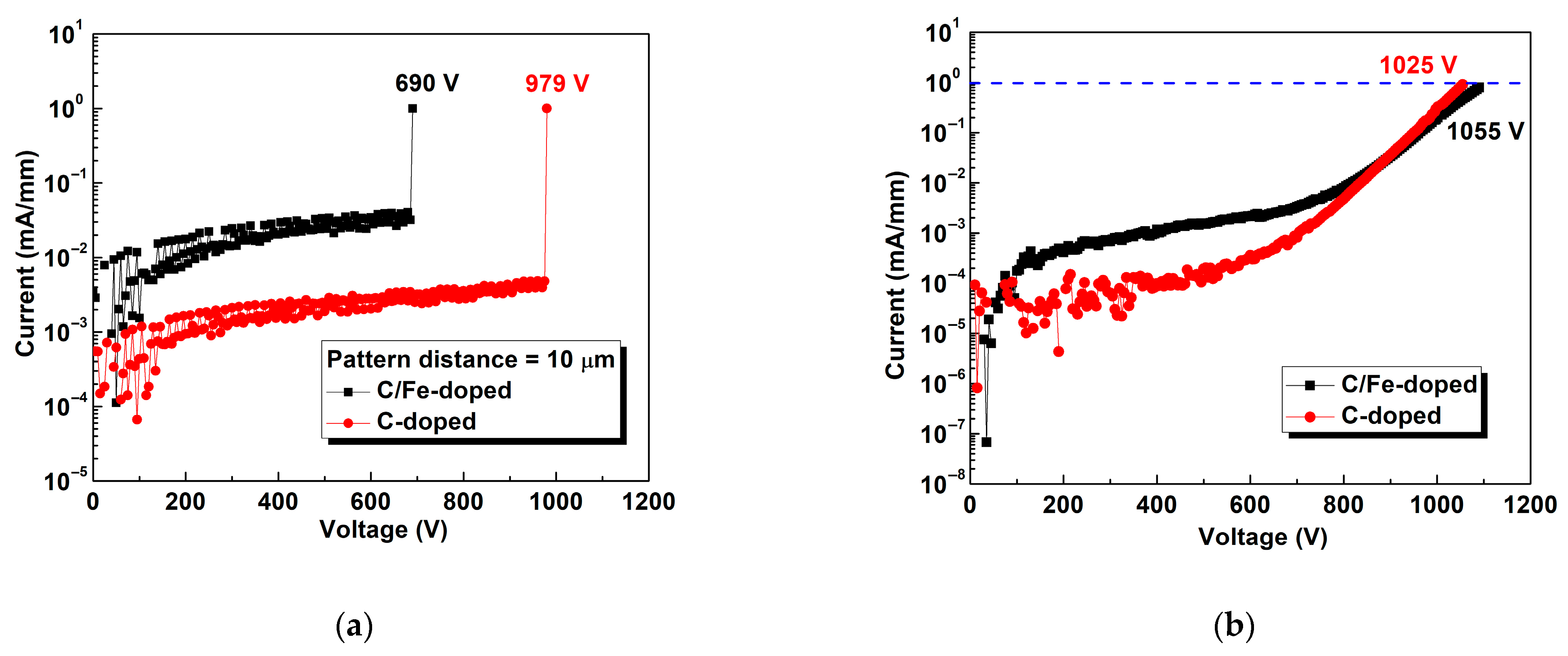

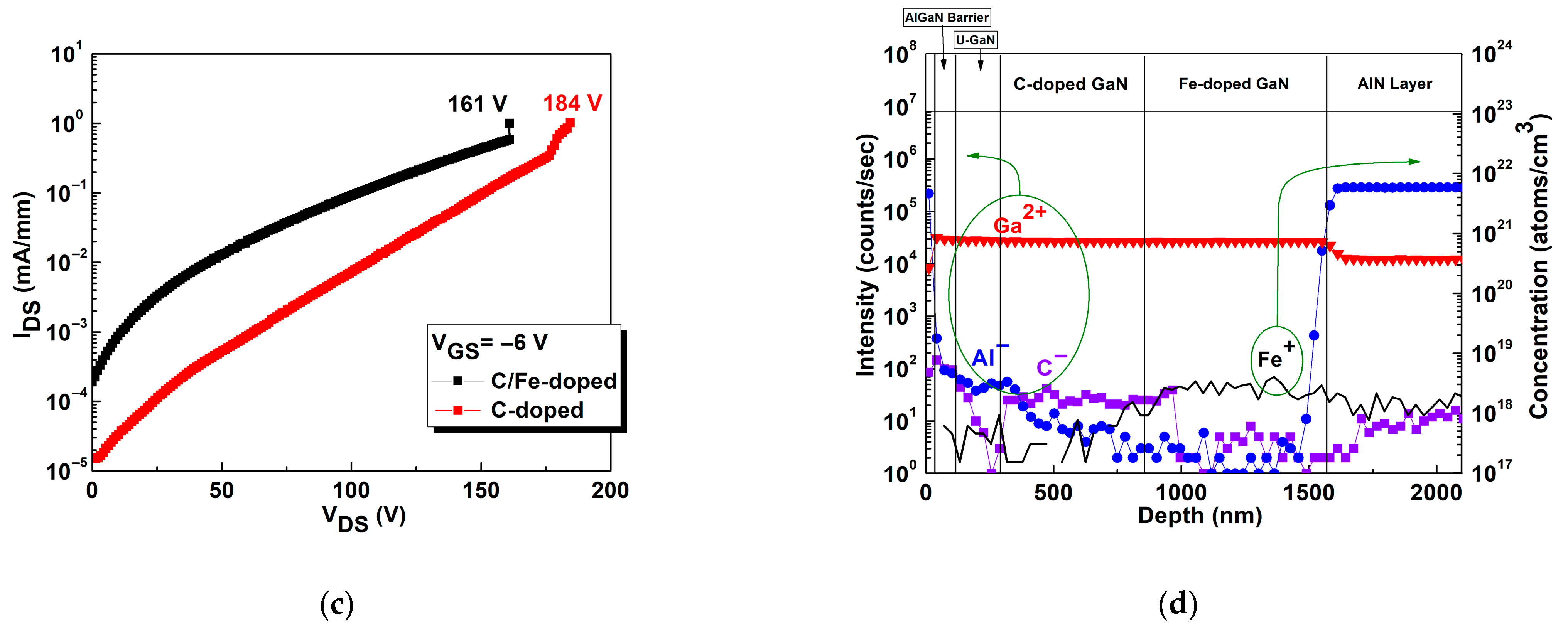

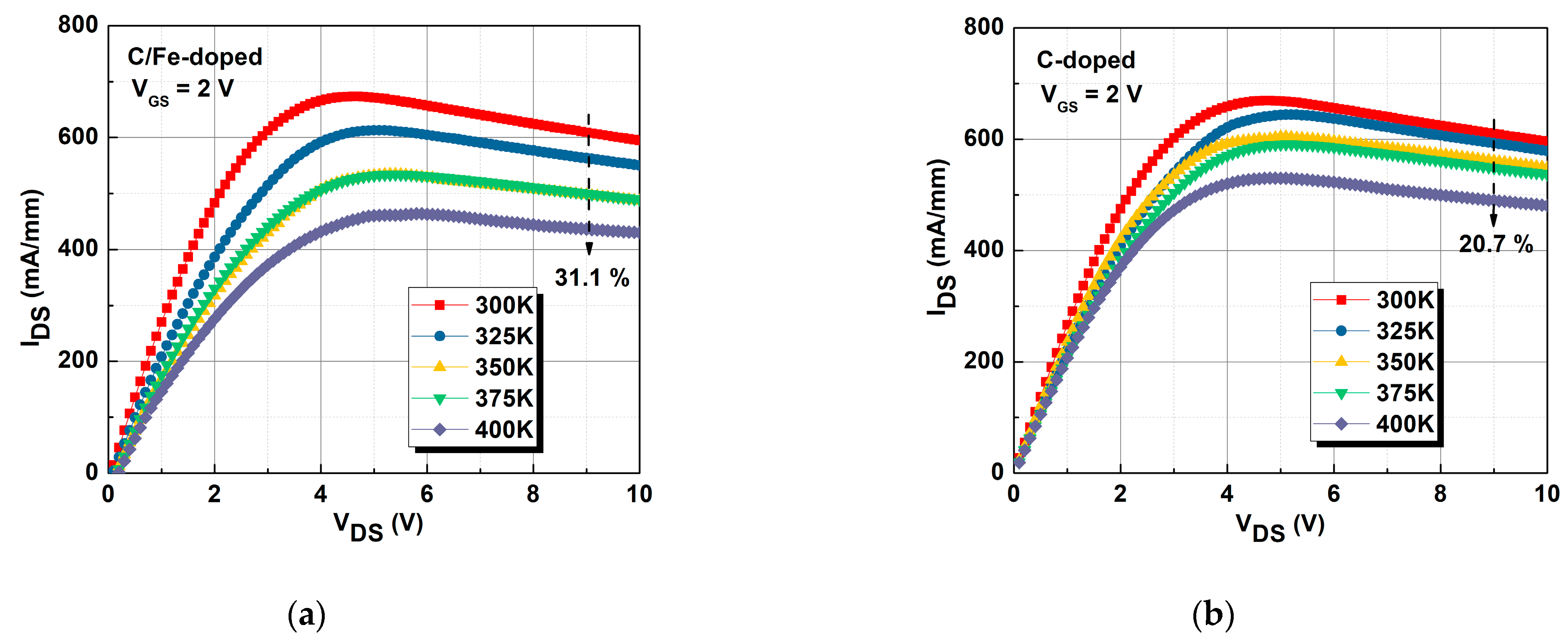

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Waltereit, P.; Bronner, W.; Quay, R.; Dammann, M.; Kiefer, R.; Müller, S.; Musser, M.; Kühn, J.; van Raay, F.; Seelmann, M.; et al. GaN HEMT and MMIC development at Fraunhofer IAF: Performance and reliability. Phys. Status Solidi A Appl. Mater. 2009, 206, 1215–1220. [Google Scholar] [CrossRef]

- Uren, M.J.; Moreke, J.; Kuball, M. Buffer design to minimize current collapse in GaN/AlGaN HFETs. IEEE Trans. Electron Devices 2012, 59, 3327–3333. [Google Scholar] [CrossRef]

- Lee, J.-H.; Ju, J.-M.; Atmaca, G.; Kim, J.-G.; Kang, S.-H.; Lee, Y.-S.; Lee, S.-H.; Lim, J.-W.; Kwon, H.-S.; Lişesivdin, S.B.; et al. High figure-of-merit (V2BR/RON) AlGaN/GaN power HEMT with periodically C-doped GaN buffer and AlGaN back barrier. IEEE J. Electron Devices Soc. 2018, 6, 1179–1186. [Google Scholar] [CrossRef]

- Eckey, L.; Von Gfug, U.; Holst, J.; Hoffmann, A.; Schineller, B.; Heime, K.; Heuken, M.; Schön, O.; Beccard, R. Compensation effects in Mg-doped GaN epilayers. J. Cryst. Growth 1998, 189–190, 523–527. [Google Scholar] [CrossRef]

- Gustafsson, S.; Chen, J.-T.; Bergsten, J.; Forsberg, U.; Thorsel, M.; Janzén, E.; Rorsman, N. Dispersive effects in microwave AlGaN/AlN/GaN HEMTs with carbon-doped buffer. IEEE Trans. Electron Devices 2015, 62, 2162–2169. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Z.; Li, W.; Lee, H.; Karim, R.; Arehart, A.R.; Ringel, S.A.; Rajan, S.; Zhao, H. Probing unintentional Fe impurity incorporation in MOCVD homoepitaxy GaN: Toward GaN vertical power devices. J. Appl. Phys. 2020, 127, 215707. [Google Scholar] [CrossRef]

- Heikman, S.; Keller, S.; DenBaars, S.P.; Mishra, U.K. Growth of Fe doped semi-insulating GaN by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2002, 81, 439–441. [Google Scholar] [CrossRef]

- Chang, K.-P.; Lin, P.-J.; Horng, R.-H.; Wuu, D.-S. Growth characteristics of Fe-doped GaN epilayers on SiC (001) substrates and their effects on high breakdown voltage devices. Mater. Sci. Semicond. Process. 2020, 119, 105228. [Google Scholar] [CrossRef]

- Chiu, H.-C.; Chen, S.-C.; Chiu, J.-W.; Li, B.-H.; Wang, H.-Y.; Peng, L.-Y.; Wang, H.-C.; Hsueh, K.-P. AlGaN/GaN schottky barrier diodes on silicon substrates with various Fe doping concentrations in the buffer layers. Microelectron. Reliab. 2018, 83, 238–241. [Google Scholar] [CrossRef]

- Kawada, Y.; Hanawa, H.; Horio, K. Effects of acceptors in a Fe-doped buffer layer on breakdown characteristics of AlGaN/GaN high electron mobility transistors with a high-k passivation layer. Jpn. J. Appl. Phys. 2017, 56, 108003. [Google Scholar] [CrossRef]

- Uren, M.J.; Caesar, M.; Karboyan, S.; Moens, P.; Vanmeerbeek, P.; Kuball, M. Electric field reduction in C-doped AlGaN/GaN on Si high electron mobility transistors. IEEE Electron Device Lett. 2015, 36, 826–828. [Google Scholar] [CrossRef]

- Oka, T. Recent development of vertical GaN power devices. Jpn. J. Appl. Phys. 2019, 58, SB0805. [Google Scholar] [CrossRef]

- Bergsten, J.; Thorsell, M.; Adolph, D.; Chen, J.-T.; Kordina, O.; Sveinbjornsson, E.O.; Rorsman, N. Electron trapping in extended defects in microwave AlGaN/GaN HEMTs with carbon-doped buffers. IEEE Trans. Electron Devices 2018, 65, 2446–2453. [Google Scholar] [CrossRef]

- Ando, Y.; Makisako, R.; Takahashi, H.; Wakejima, A.; Suda, J. Dependence of electrical chatacteristics on epitaxial layer structure of AlGaN/GaN HEMTs fabricated on freestanding GaN substrates. IEEE Trans. Electron Devices 2022, 69, 89–95. [Google Scholar] [CrossRef]

- Uren, M.J.; Kuball, M. Impact of carbon in the buffer on power switching GaN-on-Si and RF GaN-on-SiC HEMTs. Jpn. J. Appl. Phys. 2021, 60, SB0802. [Google Scholar] [CrossRef]

- Yang, L.; Hou, B.; Jia, F.; Zhang, M.; Wu, M.; Niu, X.; Lu, H.; Shi, C.; Mi, M.; Zhu, Q.; et al. The dc performance and rf characteristics of GaN-based HEMTs improvement using graded AlGaN back barrier and Fe/C co-doped buffer. IEEE Trans. Electron Devices 2022, 69, 4170–4174. [Google Scholar] [CrossRef]

- Huang, C.-R.; Liu, C.-H.; Wang, H.-C.; Kao, H.-L.; Chiu, H.-C.; Chen, C.-T.; Chang, K.-J. The characteristics of 6-inch GaN on Si RF HEMT with high isolation composited buffer layer design. Electronics 2020, 10, 46. [Google Scholar] [CrossRef]

- He, J.; Tang, G.; Chen, K.J. VTH instability of p-GaN gate HEMTs under static and dynamic gate stress. IEEE Electron Device Lett. 2018, 39, 1576–1579. [Google Scholar] [CrossRef]

- Choi, Y.C.; Pophristic, M.; Cha, H.-Y.; Peres, B.; Spencer, M.G.; Eastman, L.F. The effect of an Fe-doped GaN buffer on off-state breakdown characteristics in AlGaN/GaN HEMTs on Si substrate. IEEE Trans. Electron Devices 2006, 53, 2926–2931. [Google Scholar] [CrossRef]

- Desmaris, V.; Rudzinski, M.; Rorsman, N.; Hageman, P.; Larsen, P.; Zirath, H.; Rodle, T.; Jos, H. Comparison of the DC and microwave performance of AlGaN/GaN HEMTs grown on SiC by MOCVD with Fe-doped or unintentionally doped GaN buffer layers. IEEE Trans. Electron Devices 2006, 53, 2413–2417. [Google Scholar] [CrossRef]

- Joh, J.; del Alamo, J. A current-transient methodology for trap analysis for GaN high electron mobility transistors. IEEE Trans. Electron Devices 2011, 58, 132–140. [Google Scholar] [CrossRef]

- Rao, H.; Bosman, G. Simultaneous low-frequency noise characterization of gate and drain currents in AlGaN/GaN high electron mobility transistors. J. Appl. Phys. 2009, 106, 103712. [Google Scholar] [CrossRef]

- Silvestri, M.; Uren, M.J.; Killat, N.; Marcon, D.; Kuball, M. Localization of off-stress-induced damage in AlGaN/GaN high electron mobility transistors by means of low frequency 1/f noise measurements. Appl. Phys. Lett. 2013, 103, 043506. [Google Scholar] [CrossRef]

- Fariza, A.; Lesnik, A.; Neugebauer, S.; Wieneke, M.; Hennig, J.; Bläsing, J.; Witte, H.; Dadgar, A.; Strittmatter, A. Leakage currents and Fermi-level shifts in GaN layers upon iron and carbon-doping. J. Appl. Phys. 2017, 122, 025704. [Google Scholar] [CrossRef]

- Leone, S.; Benkhelifa, F.; Kirste, L.; Manz, C.; Mueller, S.; Quay, R.; Stadelmann, T. Suppression of iron memory effect in GaN epitaxial layers. Phys. Status Solidi B Basic Solid State Phys. 2017, 255, 1700377. [Google Scholar] [CrossRef]

- Booker, I.; Khoshroo, L.R.; Woitok, J.F.; Kaganer, V.; Mauder, C.; Behmenburg, H.; Gruis, J.; Heuken, M.; Kalisch, H.; Jansen, R.H. Dislocation density assessment via X-ray GaN rocking curve scans. Phys. Status Solidi C Curr. Top. Solid State Phys. 2010, 7, 1787–1789. [Google Scholar] [CrossRef]

- Safriuk, N.V.; Stanchu, G.V.; Kuchuk, A.V.; Kladko, V.P.; Belyaev, A.E.; Machulin, V.F. X-ray diffraction investigation of GaN layers on Si(111) and Al2O3(0001) substrates. Semicond. Phys. Quantum Electron. Optoelectron. 2013, 16, 265–272. [Google Scholar] [CrossRef]

- Rowena, I.B.; Selvaraj, S.L.; Egawa, T. Buffer thickness contribution to suppress vertical leakage current with high breakdown field (2.3 MV/cm) for GaN on Si. IEEE Electron Device Lett. 2011, 32, 1534–1536. [Google Scholar] [CrossRef]

- Im, K.-S.; Kang, H.-S.; Kim, D.-K.; Vodapally, S.; Park, Y.; Lee, J.-H.; Kim, Y.-T.; Cristoloveanu, S.; Lee, J.-H. Temperature-dependent characteristics of AlGaN/GaN FinFETs with sidewall MOS channel. Solid-State Electron. 2016, 120, 47–51. [Google Scholar] [CrossRef]

- Zhang, D.; Cheng, X.; Ng, W.T.; Shen, L.; Zheng, L.; Wang, Q.; Qian, R.; Gu, Z.; Wu, D.; Zhou, W.; et al. Reliability improvement of GaN devices on free-standing GaN substrates. IEEE Trans. Electron Devices 2018, 65, 3379–3387. [Google Scholar] [CrossRef]

- Yacoub, H.; Mauder, C.; Leone, S.; Eickelkamp, M.; Fahle, D.; Heuken, M.; Kalisch, H.; Vescan, A. Effect of different carbon doping techniques on the dynamic properties of GaN-on-Si buffers. IEEE Trans. Electron Devices 2017, 64, 991–997. [Google Scholar] [CrossRef]

| Buffer/Substrate | Maximum ID (mA/mm) | Buffer Layer Thickness (µm) | Leakage Current Density (mA/mm) | Breakdown Voltage (V) | Reference |

|---|---|---|---|---|---|

| C-doped GaN/Si with passivation SiN | 600 | 2 | 10−6 * | 700 *, vertical | [31] |

| Fe-doped GaN/SiC with passivation SiO2 | 580 | 1.2 | 10−7 ** | 760 ** LGD = 14 µm | [8] |

| UID/Fe/C-doped GaN/Si with back barrier and passivation Si3N4 | 1000 | 1.5 | 10−7 * | 710 *, horizontal | [17] |

| Fe/C-doped GaN/SiC with back barrier and passivation SiN | 990 | 1.2 | 10−4 ** | >200 ** LGD = 4 µm | [16] |

| C/Fe-doped GaN/Si without passivation | 594 | 1.5 | 10−4 *, horizontal 10−7 *, vertical | 690 *, horizontal 1055 *, vertical | This work |

| C-doped GaN/Si without passivation | 583 | 1.5 | 10−4 *, horizontal 10−6 *, vertical | 979 *, horizontal 1025 *, vertical | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, P.-H.; Huang, C.-R.; Liu, C.-H.; Lee, K.-W.; Chiu, H.-C. The Effect of Dual-Layer Carbon/Iron-Doped Buffers in an AlGaN/GaN High-Electron-Mobility Transistor. Micromachines 2025, 16, 1034. https://doi.org/10.3390/mi16091034

Chang P-H, Huang C-R, Liu C-H, Lee K-W, Chiu H-C. The Effect of Dual-Layer Carbon/Iron-Doped Buffers in an AlGaN/GaN High-Electron-Mobility Transistor. Micromachines. 2025; 16(9):1034. https://doi.org/10.3390/mi16091034

Chicago/Turabian StyleChang, Po-Hsuan, Chong-Rong Huang, Chia-Hao Liu, Kuan-Wei Lee, and Hsien-Chin Chiu. 2025. "The Effect of Dual-Layer Carbon/Iron-Doped Buffers in an AlGaN/GaN High-Electron-Mobility Transistor" Micromachines 16, no. 9: 1034. https://doi.org/10.3390/mi16091034

APA StyleChang, P.-H., Huang, C.-R., Liu, C.-H., Lee, K.-W., & Chiu, H.-C. (2025). The Effect of Dual-Layer Carbon/Iron-Doped Buffers in an AlGaN/GaN High-Electron-Mobility Transistor. Micromachines, 16(9), 1034. https://doi.org/10.3390/mi16091034