Simulation-Based Design of an Electrically Tunable Beam-Steering Metasurface Driven by a Triboelectric Nanogenerator

Abstract

1. Introduction

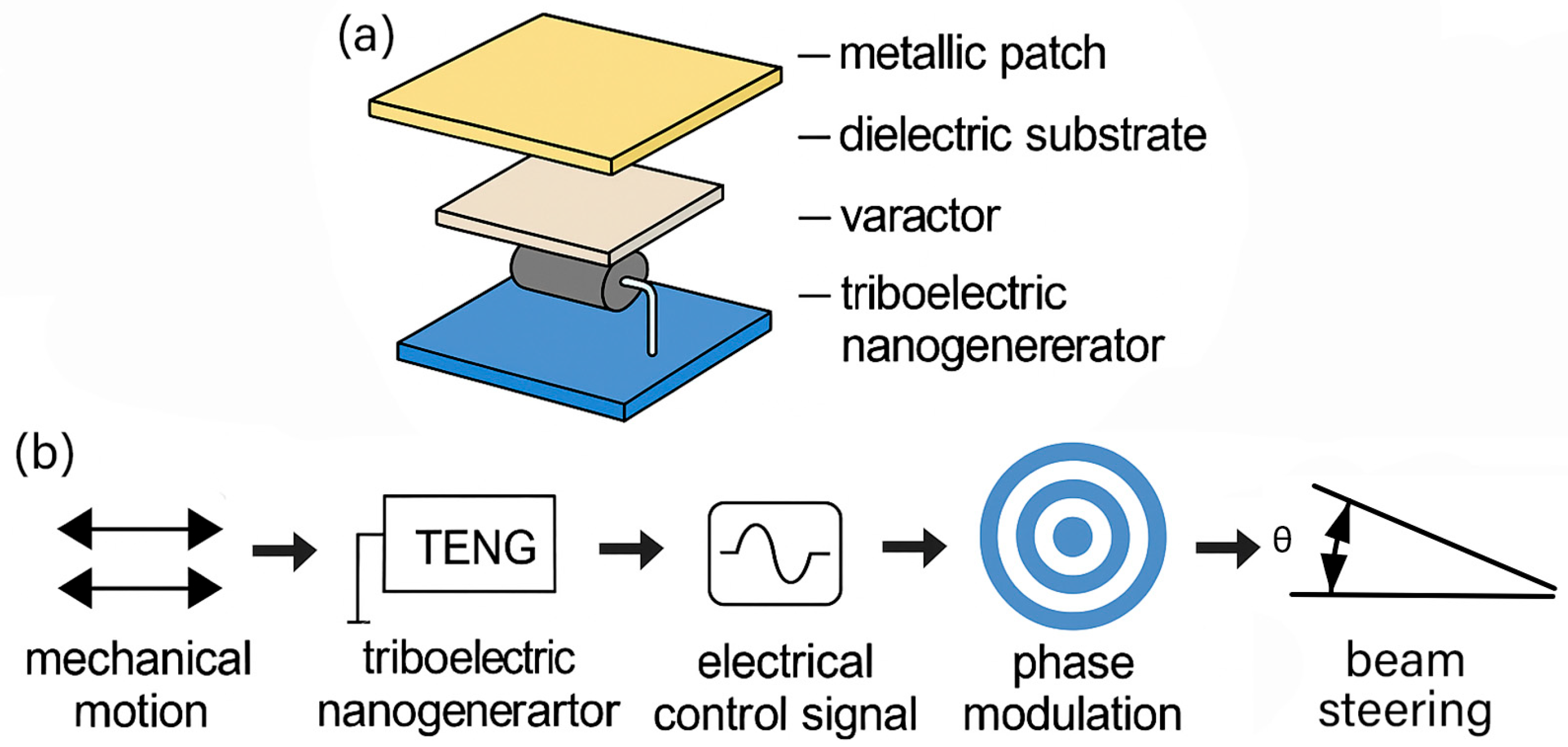

2. TENG-Driven Metasurface Theory

3. Electrical Output Characteristics of TENG

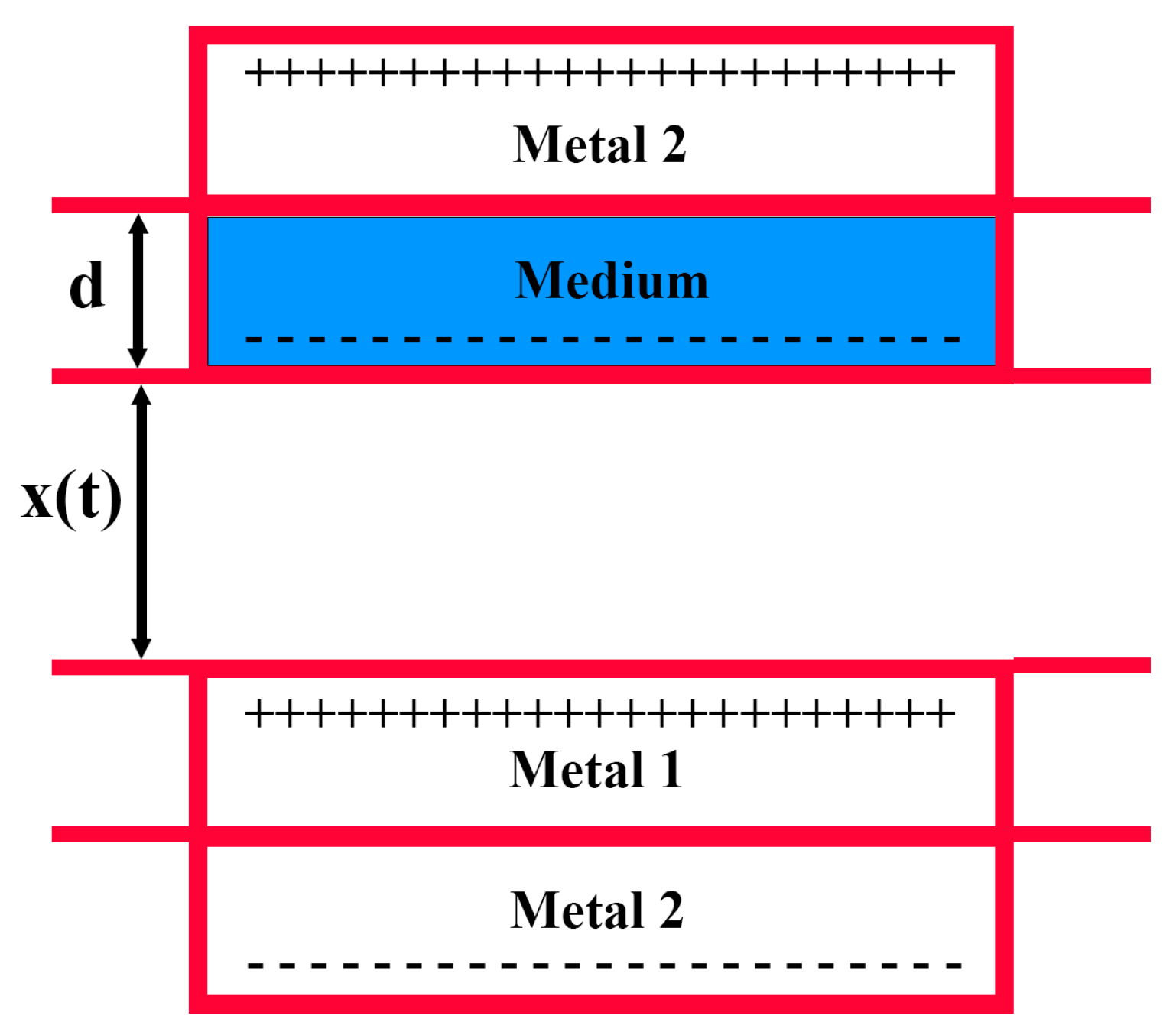

3.1. Fundamental Working Principle of TENG

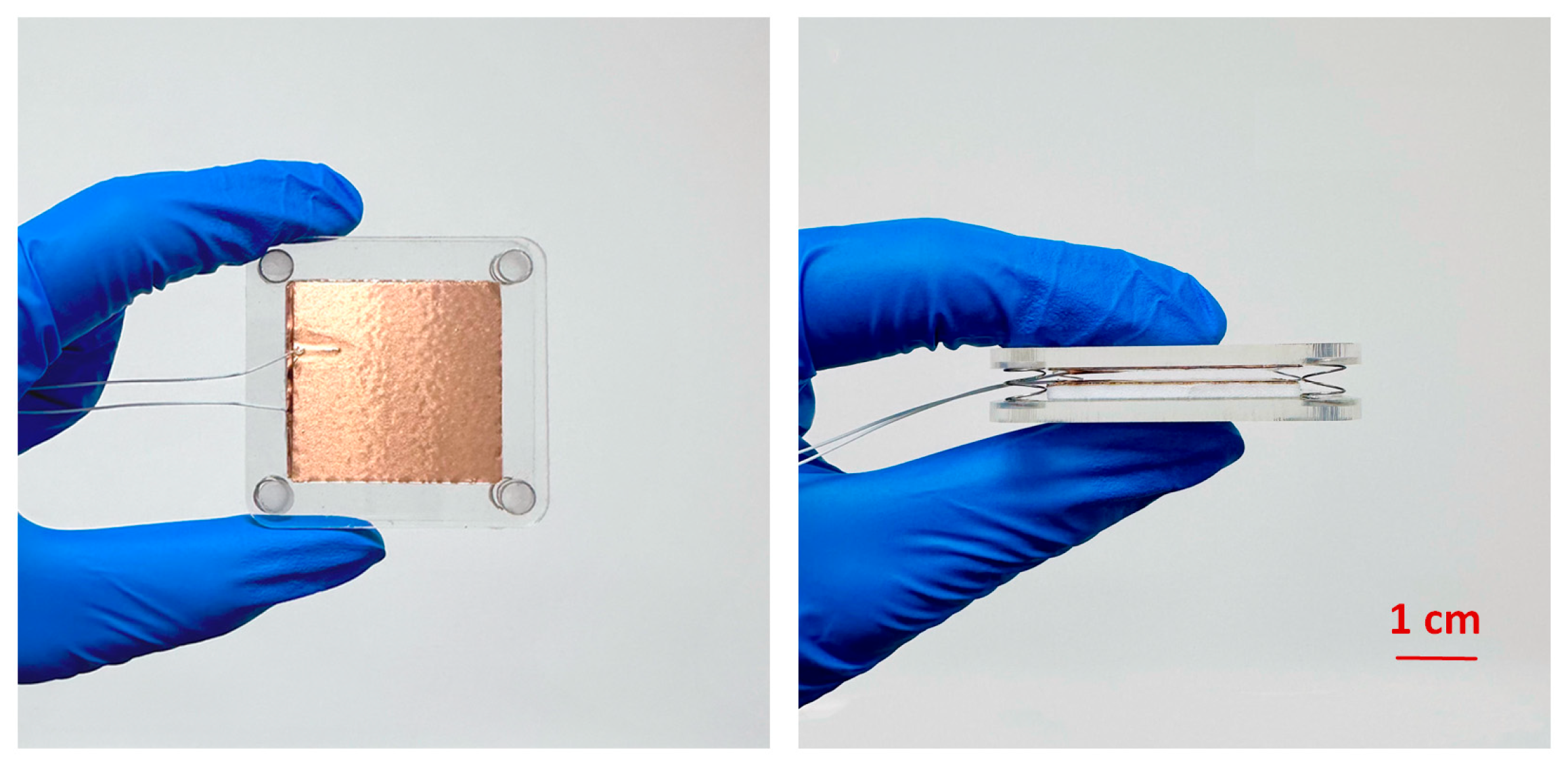

3.2. Fabrication and Working Principle of TENG

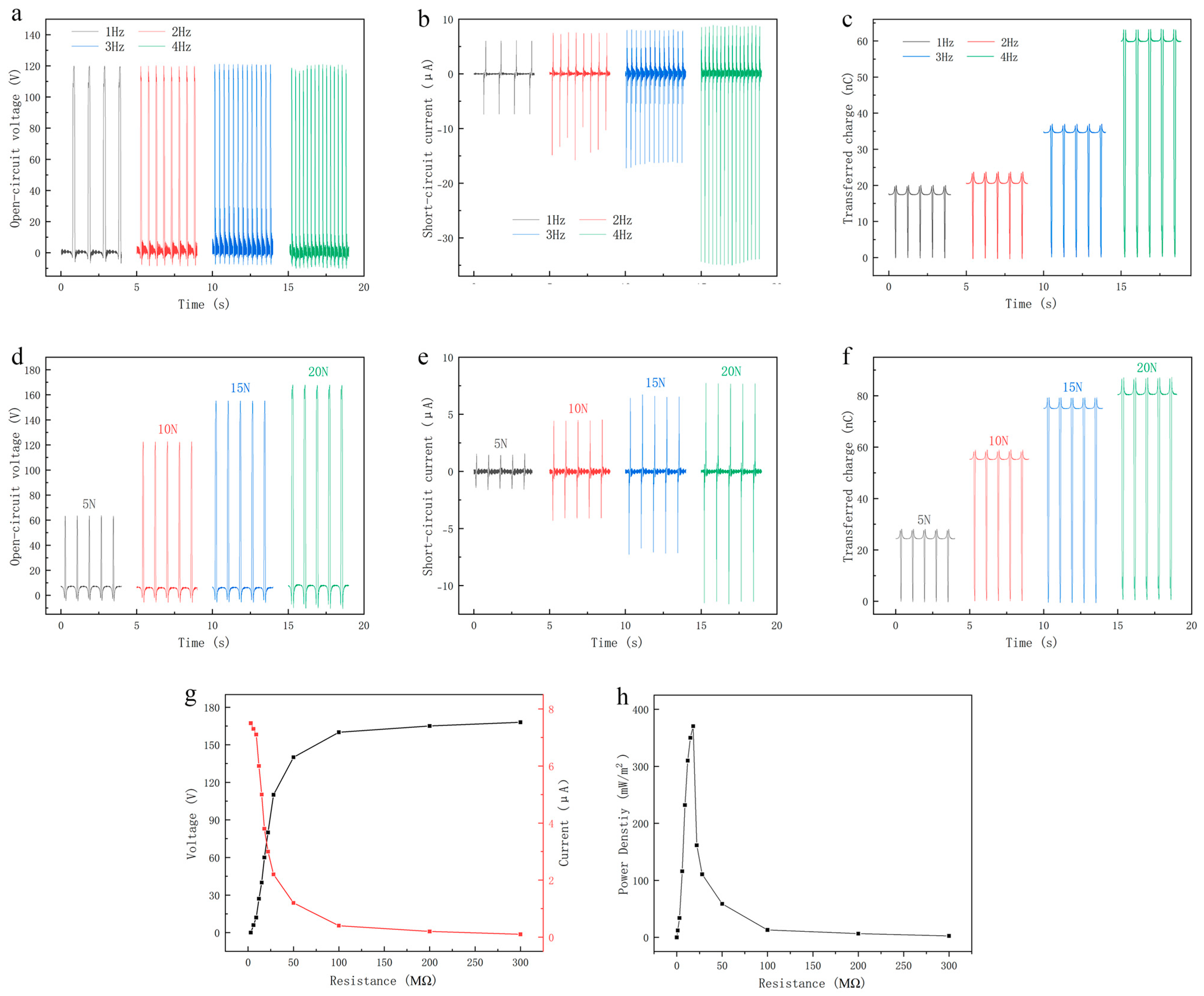

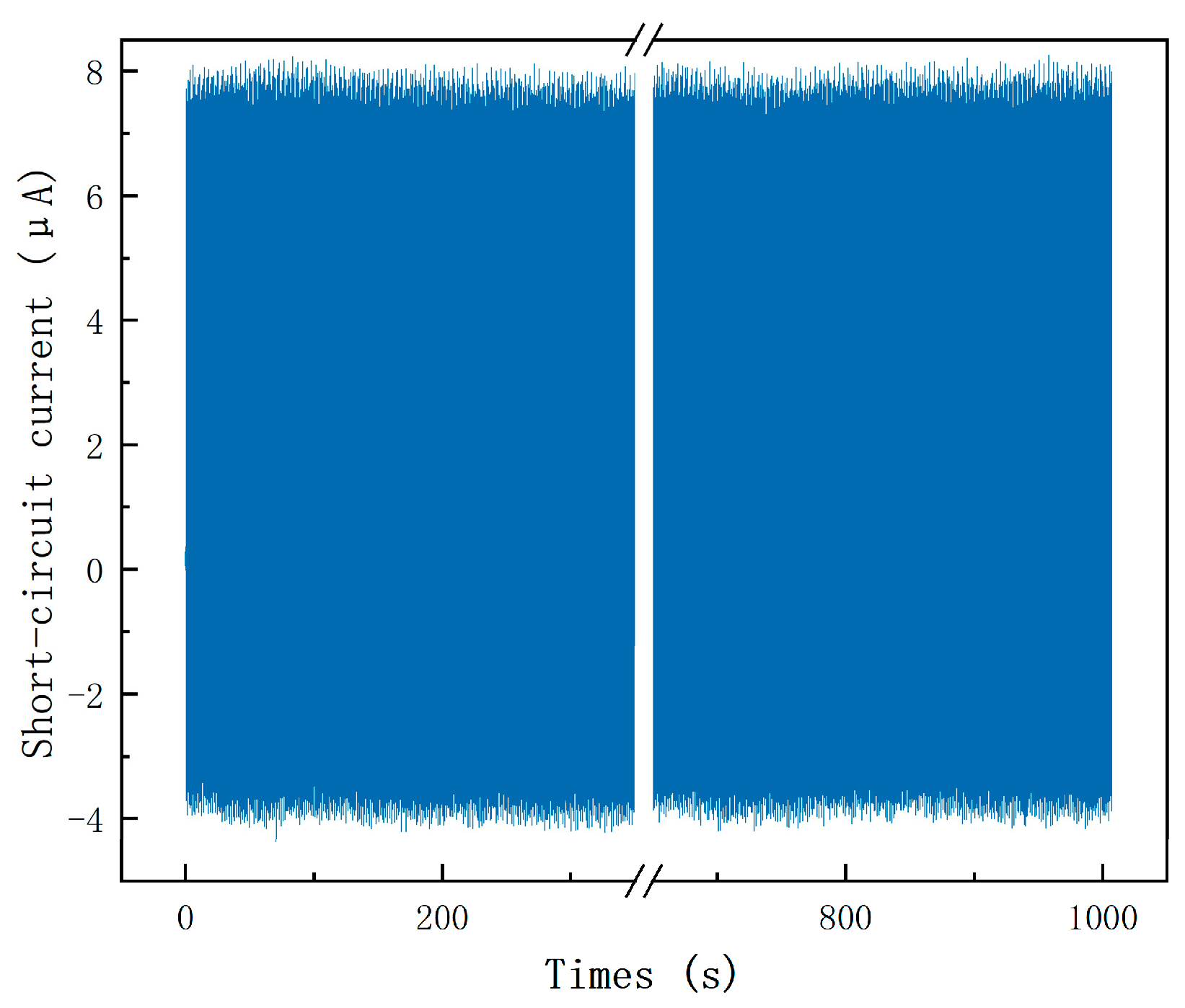

3.3. Performance Characterization of TENG

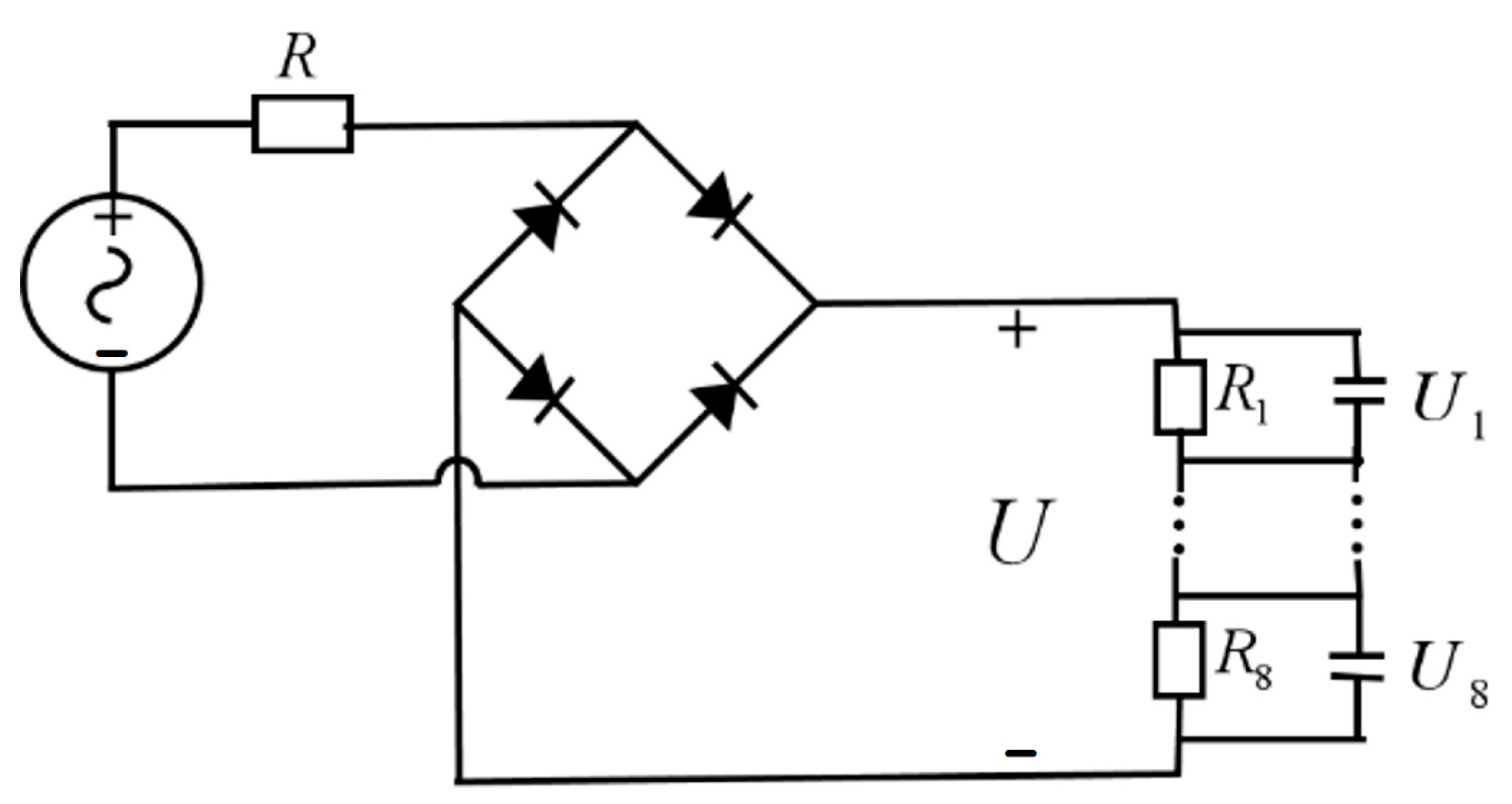

4. Energy Conversion Based on Rectifier Circuit

5. Electrically Tunable Beam-Steering Metasurface

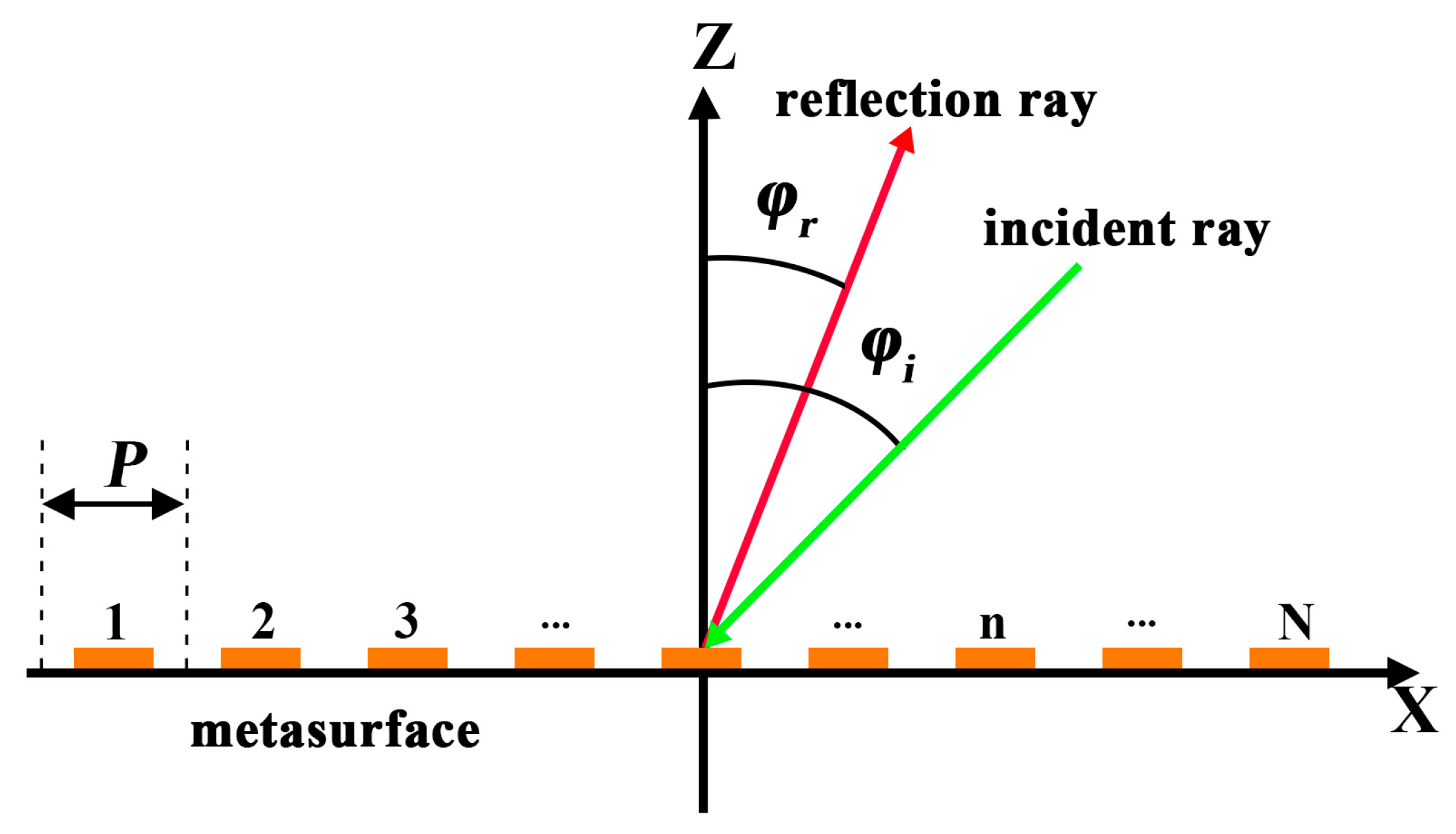

5.1. Principle of Beam-Steering

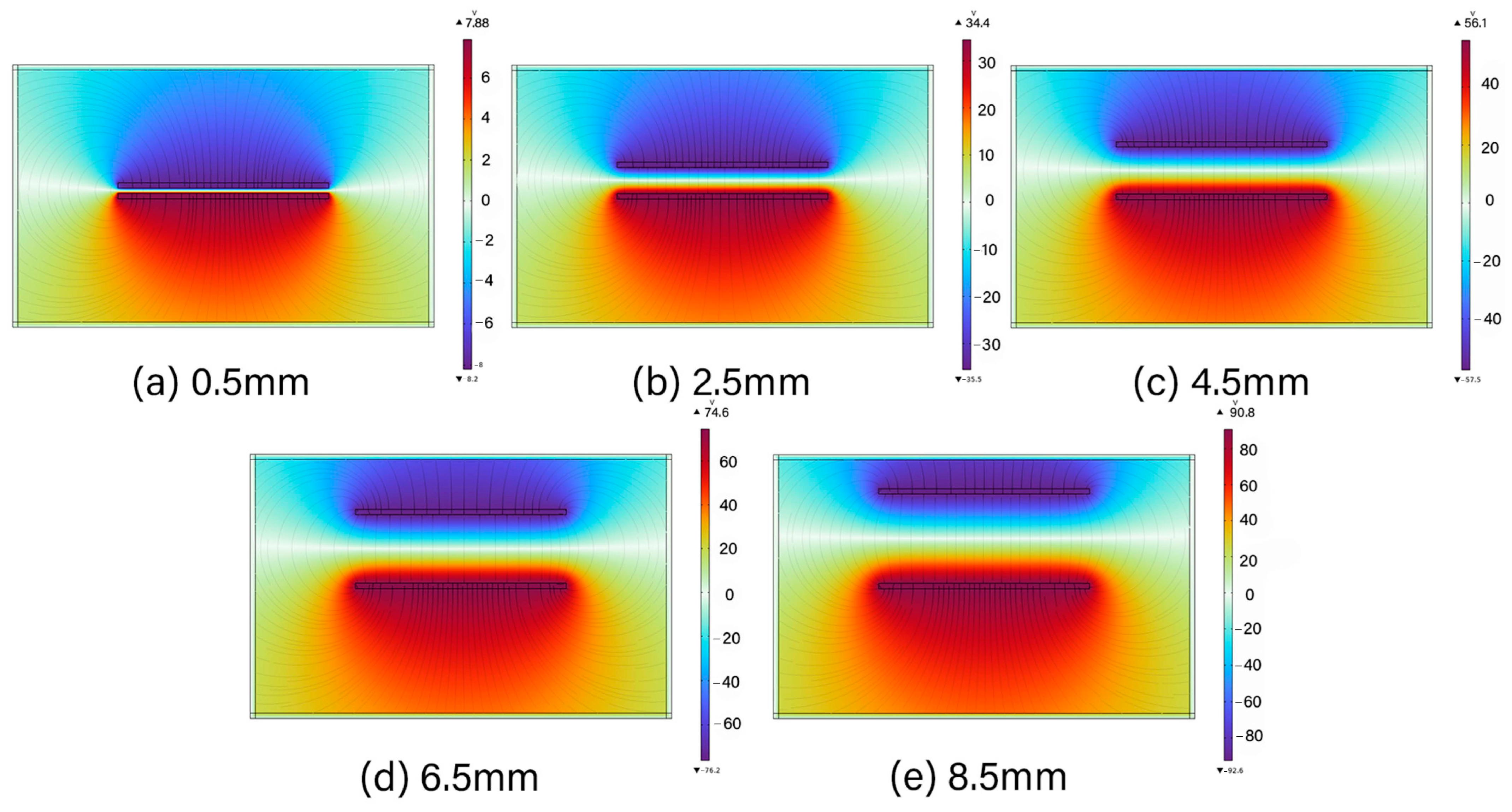

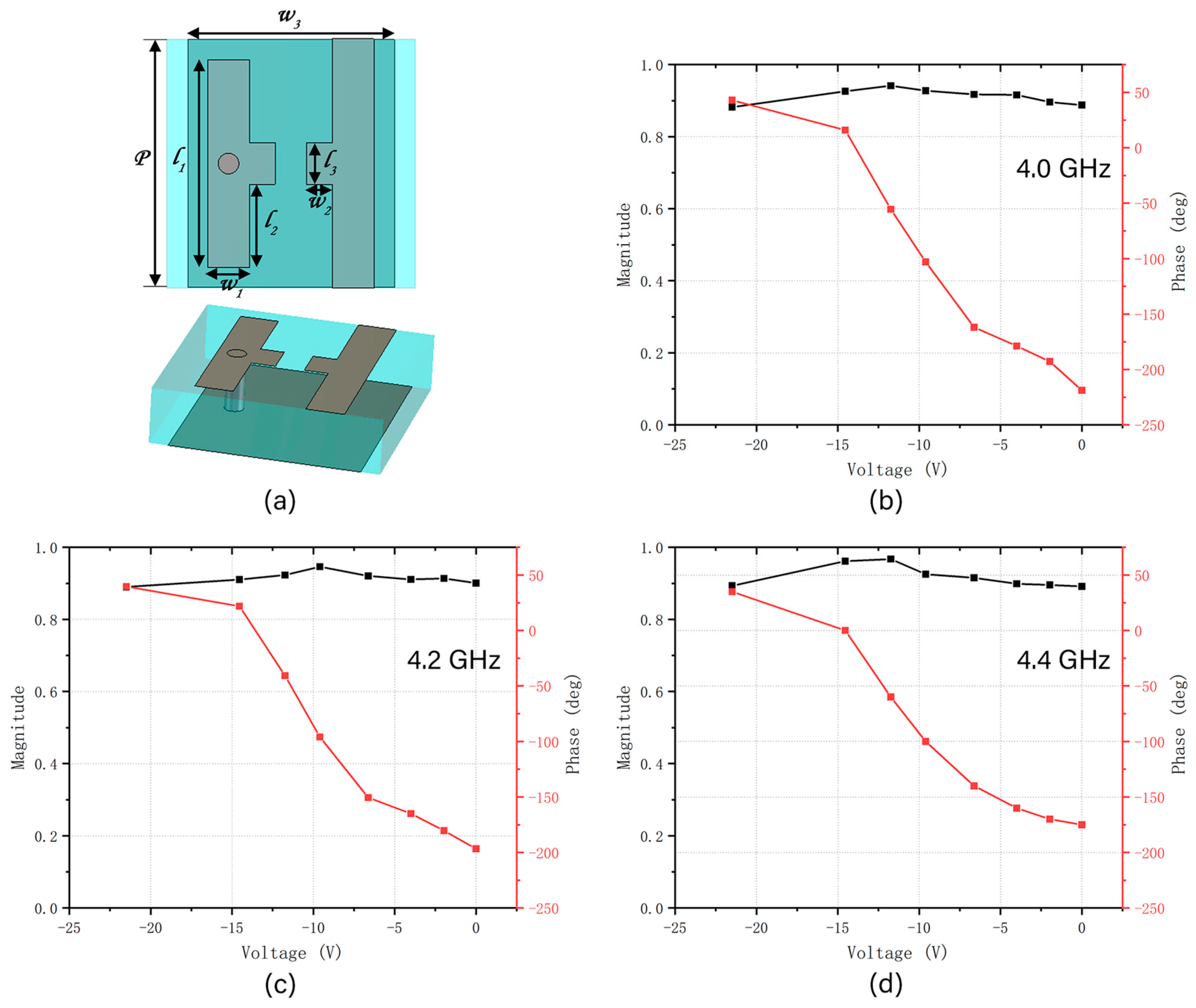

5.2. Electrically Tunable Beam-Steering Metasurface Unit Design Simulation

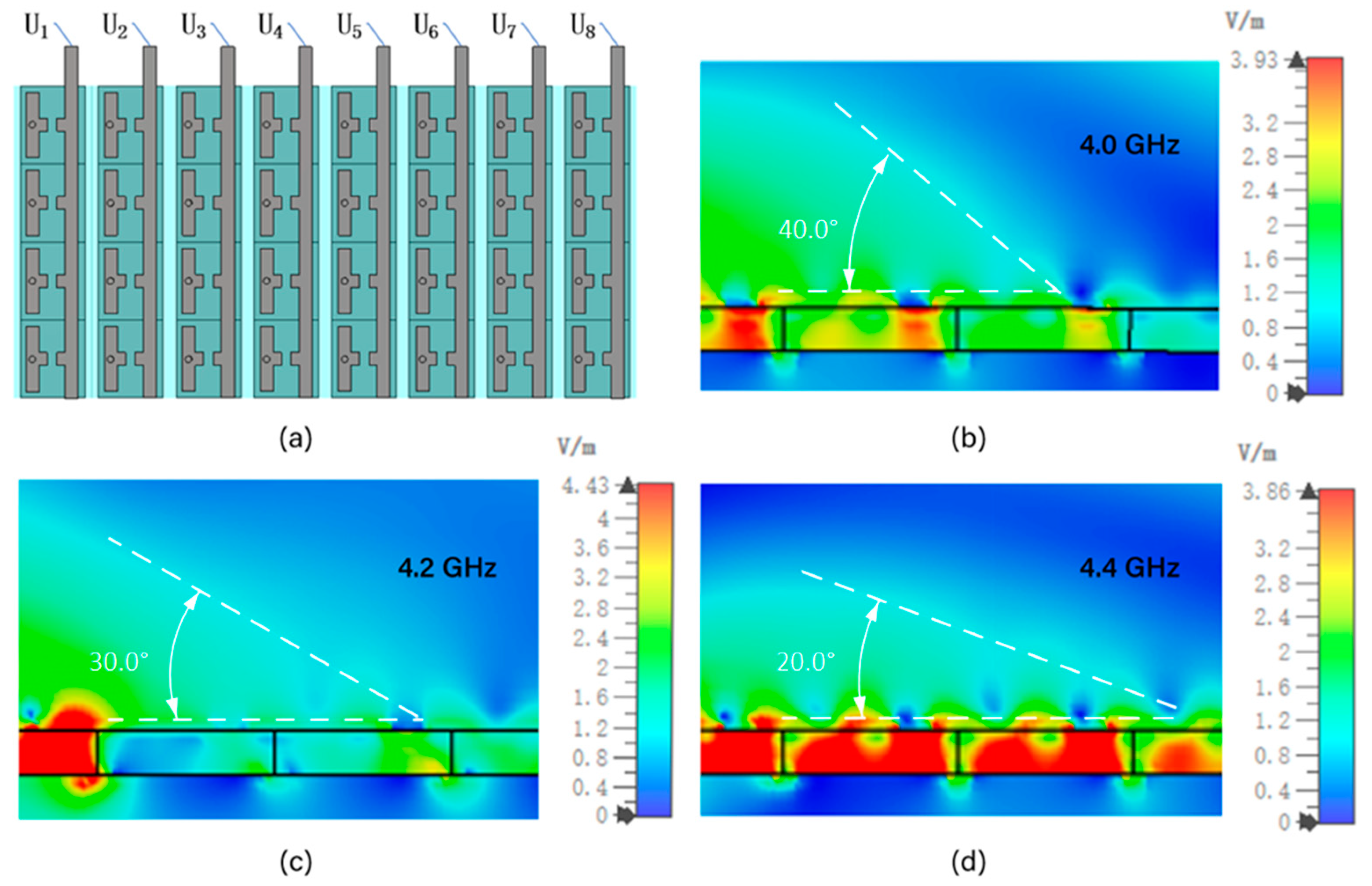

5.3. Electrically Tunable Beam-Steering Metasurface Array Design Simulation

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sharma, A.; Sharma, V.; Jaiswal, M.; Wang, H.-C.; Jayakody, D.N.K.; Basnayaka, C.M.W.; Muthanna, A. Recent Trends in AI-Based Intelligent Sensing. Electronics 2022, 11, 1661. [Google Scholar] [CrossRef]

- Tang, W.; Sun, Q.; Wang, Z.L. Self-Powered Sensing in Wearable Electronics—A Paradigm Shift Technology. Chem. Rev. 2023, 123, 12105–12134. [Google Scholar] [CrossRef]

- Lai, Z.; Xu, J.; Bowen, C.R.; Zhou, S. Self-Powered and Self-Sensing Devices Based on Human Motion. Joule 2022, 6, 1501–1565. [Google Scholar] [CrossRef]

- Colone, F.; Filippini, F.; Pastina, D. Passive Radar: Past, Present, and Future Challenges. IEEE Aerosp. Electron. Syst. Mag. 2023, 38, 54–69. [Google Scholar] [CrossRef]

- Wu, Z.; Cheng, T.; Wang, Z.L. Self-Powered Sensors and Systems Based on Nanogenerators. Sensors 2020, 20, 2925. [Google Scholar] [CrossRef]

- Yang, J.; Chen, J.; Quan, L.; Chen, X.; Shi, H.; Xue, W.; Liu, Y. Dynamic Radiation Steering with Transmission-Type Coding Metasurface. Opt. Express 2022, 30, 28038–28048. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Jiang, Z.H.; Shi, T.; Tang, M.-C.; Zhou, Z.; Chen, Z.N.; Qiu, C.-W. Metantenna: When Metasurface Meets Antenna Again. IEEE Trans. Antennas Propag. 2020, 68, 1332–1347. [Google Scholar] [CrossRef]

- Kandwal, A.; Dutt, S.; Liu, L.W.Y.; Nie, Z.; Jasrotia, R.; Chan, C.K.; Almuhlafi, A.M.; Vettikalladi, H. Frequency Selective Metasurface Based Radio Frequency Glucose Sensor with a Periodic Array of Meta Cells. Sci. Rep. 2024, 14, 25716. [Google Scholar] [CrossRef] [PubMed]

- Xia, D.X.; Han, J.Q.; Mu, Y.J.; Guan, L.; Wang, X.; Ma, X.J.; Zhu, L.H.; Lv, T.G.; Liu, H.X.; Shi, Y.; et al. Adaptive Wireless-Powered Network Based on CNN near-Field Positioning by a Dual-Band Metasurface. Nat. Commun. 2024, 15, 10358. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Chen, Y.; Wong, Z.J. High-Performance Optical Beam Steering with Nanophotonics. Nanophotonics 2022, 11, 2617–2638. [Google Scholar] [CrossRef]

- Hutchison, D.N.; Sun, J.; Doylend, J.K.; Kumar, R.; Heck, J.; Kim, W.; Phare, C.T.; Feshali, A.; Rong, H. High-Resolution Aliasing-Free Optical Beam Steering. Optica 2016, 3, 887–890. [Google Scholar] [CrossRef]

- Ahmed, F.; Singh, K.; Esselle, K.P. State-of-the-Art Passive Beam-Steering Antenna Technologies: Challenges and Capabilities. IEEE Access 2023, 11, 69101–69116. [Google Scholar] [CrossRef]

- Han, J.; Yu, S.; Yi, S. Adaptive Control for Robust Air Flow Management in an Automotive Fuel Cell System. Appl. Energy 2017, 190, 73–83. [Google Scholar] [CrossRef]

- Cai, Z.; Chen, Q.; Shi, T.; Zhu, T.; Chen, K.; Li, Y. Battery-Free Wireless Sensor Networks: A Comprehensive Survey. IEEE Internet Things J. 2023, 10, 5543–5570. [Google Scholar] [CrossRef]

- Annaswamy, A.M.; Guha, A.; Cui, Y.; Tang, S.; Fisher, P.A.; Gaudio, J.E. Integration of Adaptive Control and Reinforcement Learning for Real-Time Control and Learning. IEEE Trans. Autom. Control 2023, 68, 7740–7755. [Google Scholar] [CrossRef]

- Tripathi, M.; Mittelberger, A.; Pike, N.A.; Mangler, C.; Meyer, J.C.; Verstraete, M.J.; Kotakoski, J.; Susi, T. Electron-Beam Manipulation of Silicon Dopants in Graphene. Nano Lett. 2018, 18, 5319–5323. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Wang, Z.L. Triboelectric Nanogenerators as Flexible Power Sources. npj Flex. Electron. 2017, 1, 10. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Wang, J.; Wang, Z.L. Triboelectric Nanogenerators: Fundamental Physics and Potential Applications. Friction 2020, 8, 481–506. [Google Scholar] [CrossRef]

- Askari, H.; Khajepour, A.; Khamesee, M.B.; Saadatnia, Z.; Wang, Z.L. Piezoelectric and Triboelectric Nanogenerators: Trends and Impacts. Nano Today 2018, 22, 10–13. [Google Scholar] [CrossRef]

- Xie, B.; Ma, Y.; Luo, N.; Chen, Y.; Liu, Y.; Nie, K.; Jia, Y.; Yin, R.; Liu, Y. Triple Network Hydrogel-Based Structure Triboelectric Nanogenerator for Human Motion Detection and Structural Health Monitoring. Nano Energy 2024, 130, 110095. [Google Scholar] [CrossRef]

- Zeng, Y.; Xiang, H.; Zheng, N.; Cao, X.; Wang, N.; Wang, Z.L. Flexible Triboelectric Nanogenerator for Human Motion Tracking and Gesture Recognition. Nano Energy 2022, 91, 106601. [Google Scholar] [CrossRef]

- Huang, L.; Bu, X.; Zhang, P.; Zhang, K.; Li, Y.; Wang, D.; Ding, C. Self-Powered Motion State Monitoring System Based on Combined Triboelectric Nanogenerators for Human Physiological Signal Monitoring and Energy Collection. Microelectron. Eng. 2024, 284–285, 112127. [Google Scholar] [CrossRef]

- Tan, D.; Zhou, J.; Wang, K.; Zhang, C.; Li, Z.; Xu, D. Wearable Bistable Triboelectric Nanogenerator for Harvesting Torsional Vibration Energy from Human Motion. Nano Energy 2023, 109, 108315. [Google Scholar] [CrossRef]

- Lin, H.; He, M.; Jing, Q.; Yang, W.; Wang, S.; Liu, Y.; Zhang, Y.; Li, J.; Li, N.; Ma, Y.; et al. Angle-Shaped Triboelectric Nanogenerator for Harvesting Environmental Wind Energy. Nano Energy 2019, 56, 269–276. [Google Scholar] [CrossRef]

- Wang, H.; Han, M.; Song, Y.; Zhang, H. Design, Manufacturing and Applications of Wearable Triboelectric Nanogenerators. Nano Energy 2021, 81, 105627. [Google Scholar] [CrossRef]

- Pu, X.; Zhang, C.; Wang, Z.L. Triboelectric Nanogenerators as Wearable Power Sources and Self-Powered Sensors. Natl. Sci. Rev. 2023, 10, nwac170. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Hu, G.; Zhang, Y.; Ding, W.; Qu, S.; Tang, Q.; Zhao, C.; Yang, Y.; Yang, F. Metasurface-Enhanced Multifunctional Flag Nanogenerator for Efficient Wind Energy Harvesting and Environmental Sensing. Nano Energy 2024, 124, 109508. [Google Scholar] [CrossRef]

- Wang, J.; Deng, J.; Ren, S.; Qu, G.; Wang, C.; Guo, R.; Zhao, X. Acoustic Wave Propagation Characteristics and Spontaneous Combustion Warning of Coal during Oxidative Warming of Loose Coal. Fuel 2025, 398, 135528. [Google Scholar] [CrossRef]

- Xu, L.; Lu, J.; Wu, J.; Li, J.; Hazarika, D.; Zhang, C.; Xuan, W.; Jin, H.; Luo, J. Universal Analysis Method for Metamaterial-Based Wireless Power Transfer with Arbitrary Energy Source Waveforms: Application to Triboelectric Nanogenerators. ACS Appl. Mater. Interfaces 2025, 17, 9243–9252. [Google Scholar] [CrossRef] [PubMed]

| Item | Model/Name | Manufacturer |

|---|---|---|

| Electrometer | Keithley 6514 | Keithley Instruments, Inc., Cleveland, OH, USA |

| Linear Motor | R-LP4 | Rigol Technologies Co., Ltd., Beijing, China |

| Force Gauge | HF-5K | Yueqing Aidebao Instrument Co., Ltd., Wenzhou, China |

| Polydimethylsiloxane | PDMS | Sichuan Shengjili Industrial Co., Ltd., Chengdu, China |

| Aluminum | Al | Sichuan Shengjili Industrial Co., Ltd., Chengdu, China |

| Polymethyl methacrylate | PMMA | Sichuan Shengjili Industrial Co., Ltd., Chengdu, China |

| Copper | Cu | Ubesure Technology Co., Ltd., Shenzhen, China |

| Parameter | Value | Unit |

|---|---|---|

| length 1 (l1) | 10 | mm |

| length 2 (l2) | 4 | mm |

| length 3 (l3) | 2 | mm |

| width 1 (w1) | 2 | mm |

| width 2 (w2) | 1.35 | mm |

| width 3 (w3) | 10 | mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, P.; Zhang, L.; Wang, S.; Zhu, Z. Simulation-Based Design of an Electrically Tunable Beam-Steering Metasurface Driven by a Triboelectric Nanogenerator. Micromachines 2025, 16, 948. https://doi.org/10.3390/mi16080948

Luo P, Zhang L, Wang S, Zhu Z. Simulation-Based Design of an Electrically Tunable Beam-Steering Metasurface Driven by a Triboelectric Nanogenerator. Micromachines. 2025; 16(8):948. https://doi.org/10.3390/mi16080948

Chicago/Turabian StyleLuo, Penghui, Longlong Zhang, Shuaixing Wang, and Zhiyuan Zhu. 2025. "Simulation-Based Design of an Electrically Tunable Beam-Steering Metasurface Driven by a Triboelectric Nanogenerator" Micromachines 16, no. 8: 948. https://doi.org/10.3390/mi16080948

APA StyleLuo, P., Zhang, L., Wang, S., & Zhu, Z. (2025). Simulation-Based Design of an Electrically Tunable Beam-Steering Metasurface Driven by a Triboelectric Nanogenerator. Micromachines, 16(8), 948. https://doi.org/10.3390/mi16080948