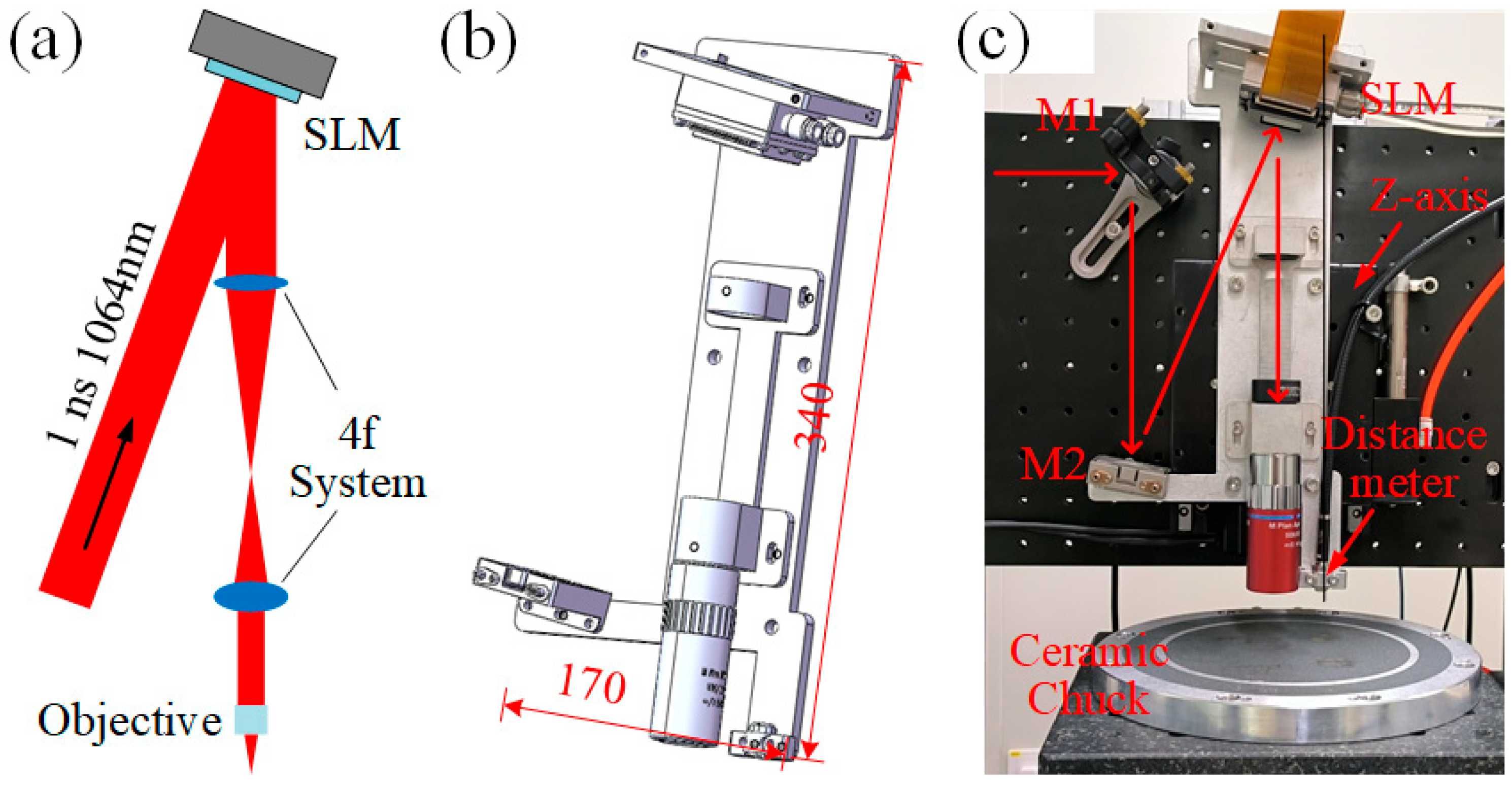

3.1. Aberration Correction Principle

When a parallel light beam is focused by an objective lens in air, ideally, the light spot is elliptical and converges at the geometric focal point.

Figure 2a shows the simulation results of the focusing of light with a wavelength of 1064 nm through an objective lens with a numerical aperture (NA) of 0.65 and a focal length of 4 mm in air (assuming the refractive index is 1). The light spot is elliptical, and the depth of focus is approximately 5 μm. However, when the light beam enters from air into a medium for focusing, the refraction effect causes an optical path difference for the rays with different angles of incidence, significantly changing the focusing characteristics [

Figure 2b]. The focusing position will shift downward, and the amount of this downward shift can be approximately estimated by the product of the refractive index and the focusing depth.

Figure 2c is the simulation result of the light focusing inside a SiC crystal (with a refractive index of 2.6), where the nominal focal point is set at a depth of 100 μm from the upper surface. The focused light spot shows a comet-tail-like distribution. The energy is mainly concentrated in the top region 180 μm below the nominal focal point. In addition, there are local energy concentration points in the tail, and the longitudinal length is greater than 50 μm. This phenomenon of energy dispersion will lead to a decrease in the longitudinal resolution of laser processing and an expansion of the damaged area, which is extremely detrimental to the laser slicing process.

The inverse ray tracing algorithm is used to calculate the aberration correction hologram. This method has significant advantages in correcting aberrations at large depths [

19], and its principle is shown in

Figure 2b. The arc in the diagram represents a spherical reference surface with a curvature radius

f, which passes through the rear principal point F of an ideal objective lens with focal length

f. The rear principal point F is located at the intersection of the spherical reference surface and the optical axis. Point I denotes the intersection point of the optical axis with the interface between the two media. When a plane wave is incident on the ideal objective lens, the output wavefront coincides with the reference surface and converges at the nominal focal point O. The distance from O to the medium’s upper surface is defined as the nominal depth

d. The wanted focal point O’ lies at a depth

dw below the medium’s surface. In the diagram,

θ represents the incident angle of a light ray,

θ1 denotes the incident angle required to focus the beam at point O’, and

θ2 is the corrected refractive angle of the same ray.

n1 and

n2 correspond to the refractive indices of the materials on either side of the interface. The optical path from any point on the reference plane to the wanted focal point

O’ is expressed as follows:

where

ZA is the height difference between point A and point O. Thus,

is defined as the optical path difference requiring compensation for rays with an incident angle

θ. For a given optical system, the value range of

θ is jointly determined by the numerical aperture of the objective lens and the focal length

f. The relationship between

θ1 and

θ2 satisfies Snell’s law, and a unique solution exists for any

θ. The phase that needs to be corrected can be calculated using the optical path difference:

where λ is the wavelength of light. In practical applications, due to the limited phase modulation capability of the SLM, the phase difference must undergo phase wrapping—that is, being projected onto the 0–2π phase range. The final phase loaded onto the SLM is as follows:

However, due to the limited resolution of the SLM, an excessively large phase modulation range before phase wrapping will increase phase jumps after wrapping. This compromises the smoothness of the spatial phase distribution, leading to discontinuous phase transitions in the wavefront of the shaped optical wave and reducing diffraction efficiency. Therefore, we aim to minimize the phase modulation range, which can be quantified using the PV value—defined as the peak-to-valley difference between the maximum and minimum values of the modulation phase [

15,

19].

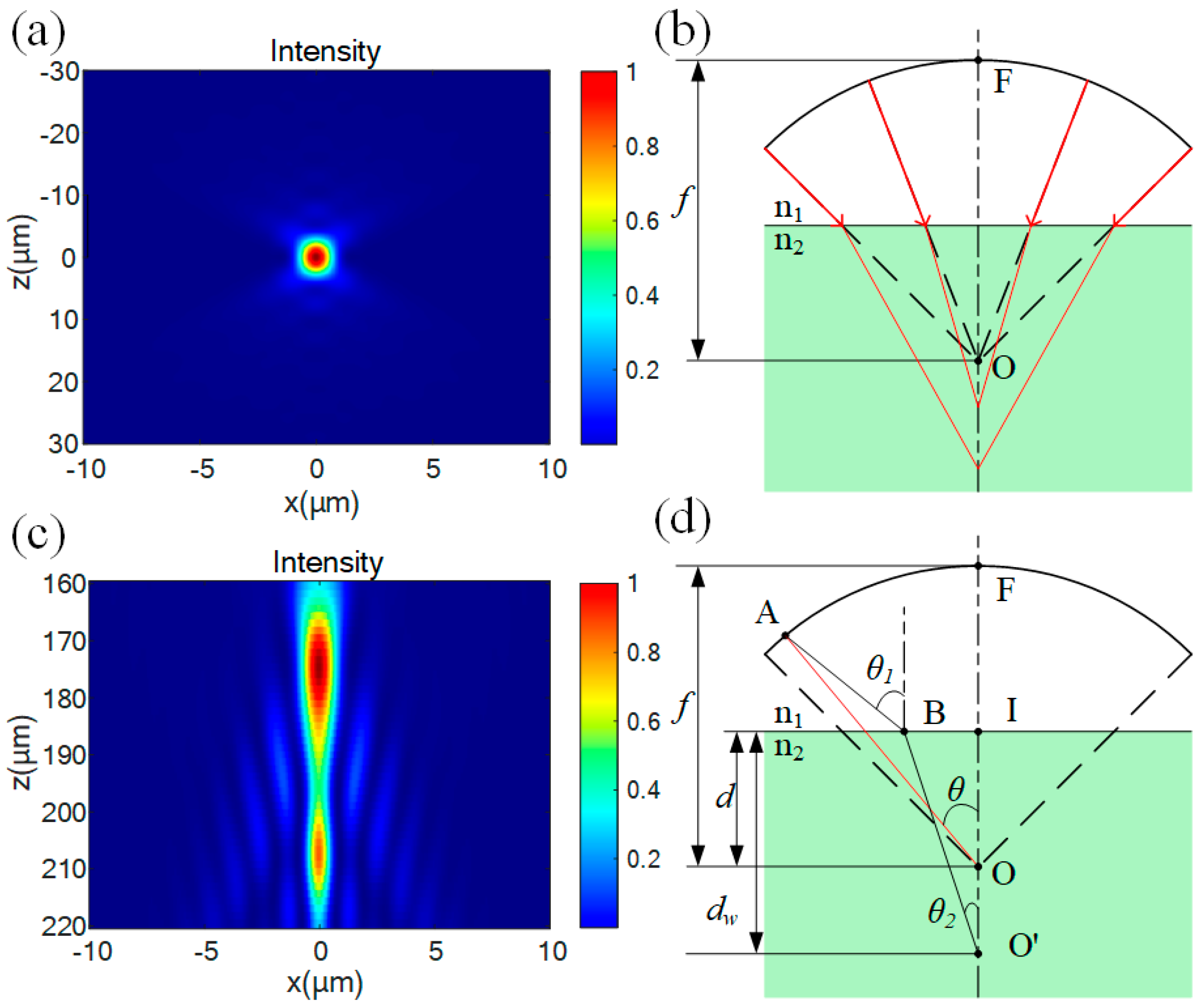

Under specific processing conditions, once the nominal focal depth (

d) of the objective lens is fixed, aberration correction can theoretically be achieved at any arbitrarily set wanted depth (

dw). However, variations in the wanted depth significantly impact the PV value. As shown in

Figure 3, when the nominal depth is 100 μm, the holograms and their PV values are presented for the wanted depths of 100 μm, 200 μm, 300 μm, and 400 μm. It is evident that as the wanted depth increases from 100 μm to 400 μm, the PV value first decreases and then increases. With the rise in PV value, phase discontinuities in the hologram become increasingly pronounced. Areas with larger periodic variations generate stronger zero-order diffraction, which obscures the target image and reduces the signal-to-noise ratio. Therefore, it is essential to establish an optimal relationship between the wanted depth and nominal depth to achieve optimal aberration correction.

For a given

NA and medium refractive index

n2, the optimal defocus factor

s (defined as the ratio of

d/

dw) can be determined by formula [

15]:

for

n2 = 2.6 and

NA = 0.65,

s ≈ 0.3442.

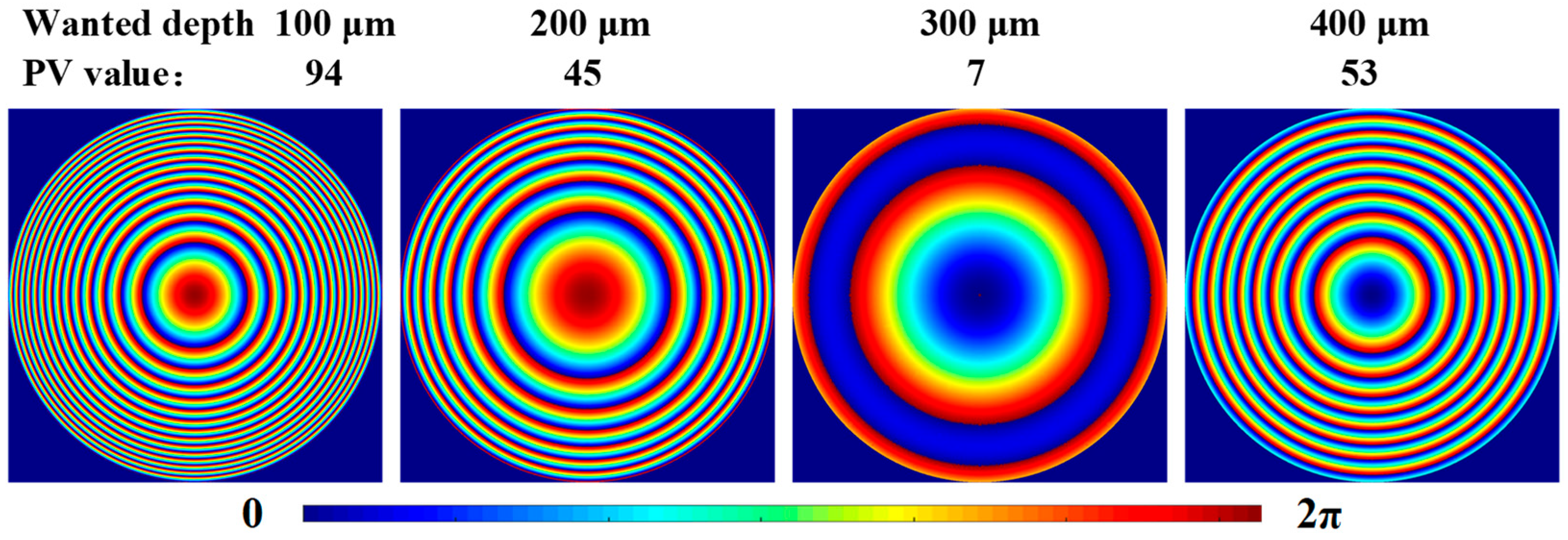

Figure 4a displays the theoretical aberration-corrected hologram (1024 × 1024 pixels) designed for SiC crystal processing, with parameters set to a wanted depth

dw = 200 μm and nominal depth

d = 69 μm.

Figure 4b simulates the correction effect: after aberration correction, the depth of focus is reduced to approximately one-third of its original value (cf.

Figure 2c), and the longitudinal energy distribution becomes significantly more concentrated. Since hologram computation depends solely on objective lens parameters and is independent of laser spot size, spatial matching between the objective’s entrance aperture (diameter: 5.2 mm) and the SLM’s active area must be ensured during hologram loading. After applying a 2.5× demagnification via the 4f system, the projected diameter of the objective aperture onto the SLM plane expands to 13 mm. To address this overshoot relative to the SLM’s effective width (12.8 mm), the hologram is rescaled by a factor of 13/12.8. Furthermore, when the laser illuminates the SLM at a 10° incidence angle, elliptical distortion of the projected spot must be compensated. Based on geometric optics, the major axis of the elliptical spot scales by a factor of 1/cos 10° relative to the original diameter. The hologram adjusted with this correction is shown in

Figure 4c.

3.2. Experimental Results

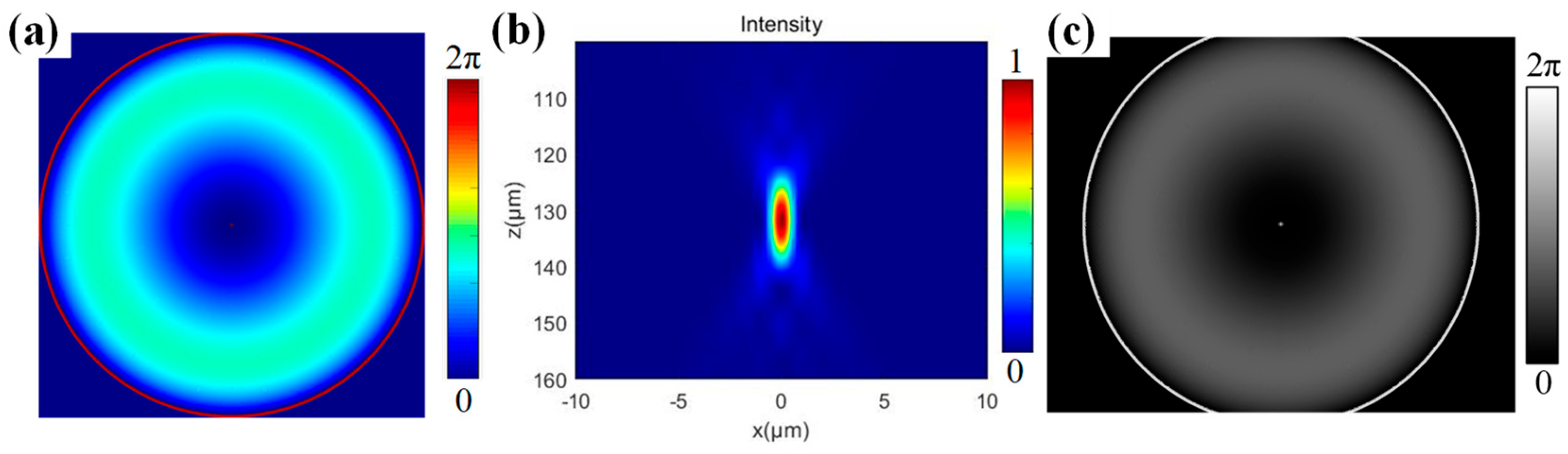

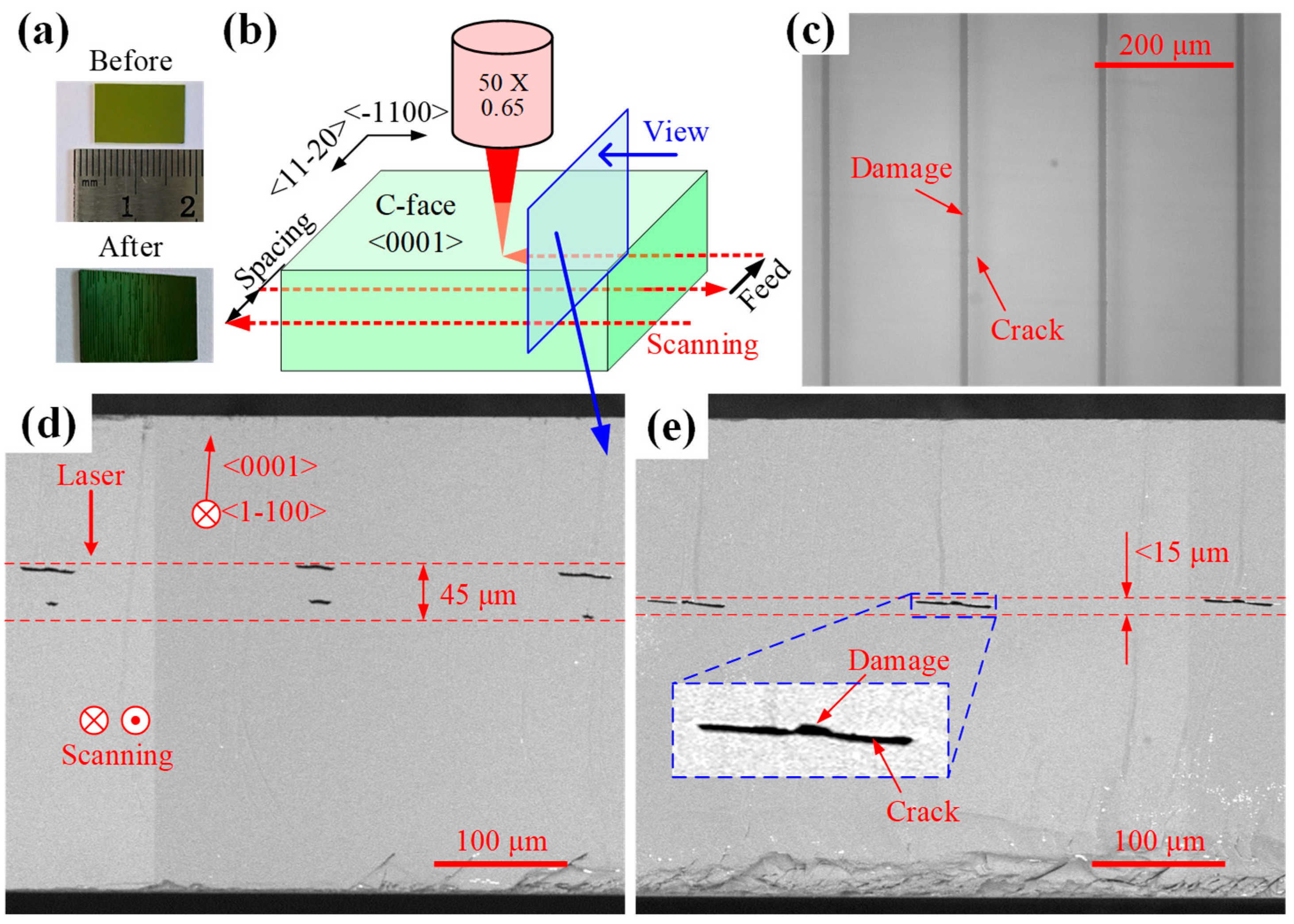

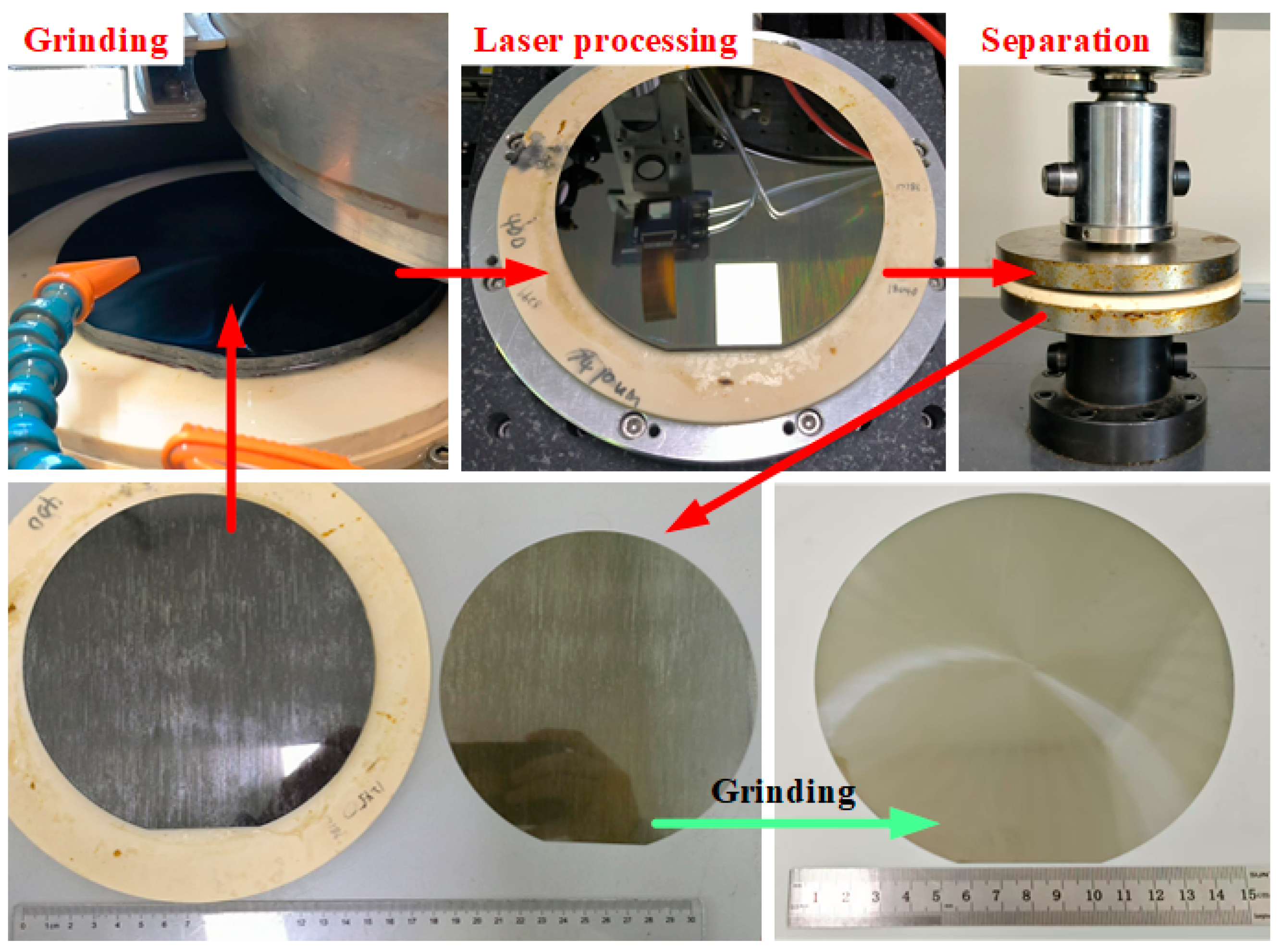

As shown in

Figure 5a, the experimental samples were sourced from a 360 μm-thick N-type 6-inch SiC substrate (TanKeBlue, Beijing, China), diced into rectangular chips via diamond wire sawing. The laser processing configuration, as illustrated in

Figure 5b, employs synchronized scanning and feed motions to achieve full-surface machining coverage. The sample surface height is determined using the laser displacement sensor, and the objective’s focal point is positioned at the surface via a pre-calibrated relationship. The objective is then translated along the z-axis to shift the laser focus into the sample’s interior. To reduce the interference of crystal anisotropy, the scanning direction aligns with the <−1100> crystal direction to ensure that the processing is performed on the same (0001) crystal plane. The feed direction follows <11−20>, with laser incidence normal to the C-face. Processing parameters include a laser power of 0.3 W, repetition rate of 50 kHz, scan spacing of 200 μm, scan speed of 100 mm/s, and nominal depth of 60 μm.

The processed sample exhibits distinct bright white stripes when observed at an inclined angle [

Figure 5a], indicative of internal crack formation, enhancing localized light reflection. The processed sample was observed using an optical microscope (OMT-900HC, OUMIT, Suzhou, China), with the top view shown in

Figure 5c. The damage zone formed by laser scanning exhibits a width of approximately 10 μm, flanked by cracks on both sides of the scanning track, each approximately 20 μm in length.

The sample was subsequently fractured perpendicular to the scanning direction (indicated by the blue arrow in

Figure 5b) for cross-sectional analysis. The fractured samples were initially etched with potassium hydroxide (KOH) to delineate damage zones [

20], followed by ultrasonic cleaning and subsequent fracture surface characterization using scanning electron microscopy (SEM, Phenom ProX, Phenom-World BV, Eindhoven, Netherlands).

Figure 5d,e presents the machining outcomes without and with aberration correction, respectively. Consistent with optical microscopy observations, laser processing induced material damage and crack formation. Under laser irradiation, SiC undergoes amorphization and decomposition, inducing localized volumetric expansion. Given that the (0001) lattice plane of 4H-SiC exhibits the lowest cleavage energy [

21], the induced expansion stress preferentially releases along this plane, generating cleavage cracks. Furthermore, due to the 4° off-axis angle between the N-type 4H-SiC’s lattice plane and its geometric surface [

22], the resultant cracks maintain a 4° angular offset relative to the surface. Under uncorrected conditions (

Figure 5d), the damage zone comprises two distinct crack layers spanning approximately 45 μm. With aberration correction (

Figure 5e), however, a single crack forms, with its longitudinal damage span significantly reduced to approximately 15 μm (about one-third of the uncorrected state), while exhibiting greater lateral extension.

The experimental observations align closely with the simulation outcomes. Specifically, the energy distribution at the tip and tail of the comet-shaped spot in

Figure 2c shows high consistency with the experimentally observed two-layer damage distribution. After aberration correction, the energy concentration significantly improves, as demonstrated by the simulated Gaussian-shaped spot in

Figure 4b. The spatial distribution of laser intensity satisfies the following formula:

where

w(z) represents the beam radius as a function of the longitudinal position

z. For silicon carbide (SiC), a damage threshold exists: when the local laser intensity exceeds the critical value

Ic, the material undergoes melting, amorphization, and decomposition [

23]. The volume of the decomposition zone can be calculated by integrating over the region where the laser intensity exceeds

Ic:

Here, rd(z) and zmax are defined as the transverse and longitudinal boundaries where the laser intensity exceeds the critical value Ic. After aberration correction, the energy distribution becomes more concentrated, resulting in expanded boundary ranges of rd(z) and zmax, and consequently increasing the volume of the decomposition zone. Due to the constrained non-uniform expansion within the material, localized residual stress is significantly elevated, with enhanced stress concentration at crack tips, ultimately leading to increased crack propagation lengths. These results validate the feasibility of the proposed aberration correction method in suppressing aberrations and improving machining precision for SiC laser slicing.

3.3. Depth-Dependent Power Compensation Model

As laser energy is absorbed during propagation through SiC crystals, beam intensity attenuates with depth, necessitating distinct processing powers at different depths. This section examines the laser power attenuation pattern post-aberration-correction and develops a depth-dependent power compensation model. When the laser is incident from air onto the sample surface, reflection, scattering, and transmission occur. For smooth surfaces, scattering is generally negligible. Under normal incidence, the power reflectance

R is given by the following:

where

n1 and

n2 represent the refractive indices of the two media, respectively. Taking the refractive index of air as

n1 = 1 and that of SiC as

n2 = 2.6, the reflectance under normal incidence is calculated to be 19.75%. After entering the sample, the laser intensity attenuates with increasing penetration depth due to material absorption, a phenomenon that can be described by the Lambert–Beer law:

where

α denotes the absorption coefficient,

I0 the initial intensity, and

z the penetration depth. Because the laser power is proportional to the light intensity. Given the known substrate thickness

h, the absorption coefficient can be calculated by measuring the incident power

Pin before the substrate and the transmitted power

Pout after the substrate using a power meter, as shown in

Figure 6a. When the laser is normally incident from air onto the substrate, considering a single reflection at both the upper and lower interfaces, the following equation is derived:

By defining the transmittance

T as the ratio of the transmitted light intensity (

Pout) to the incident light intensity (

Pin), the absorption coefficient

α can be calculated using the following formula:

Experimental measurements show that the transmittance of the sample for the 1064 nm laser wavelength is 21.39% (360 μm thickness), with an absorption coefficient of 30.5 cm−1.

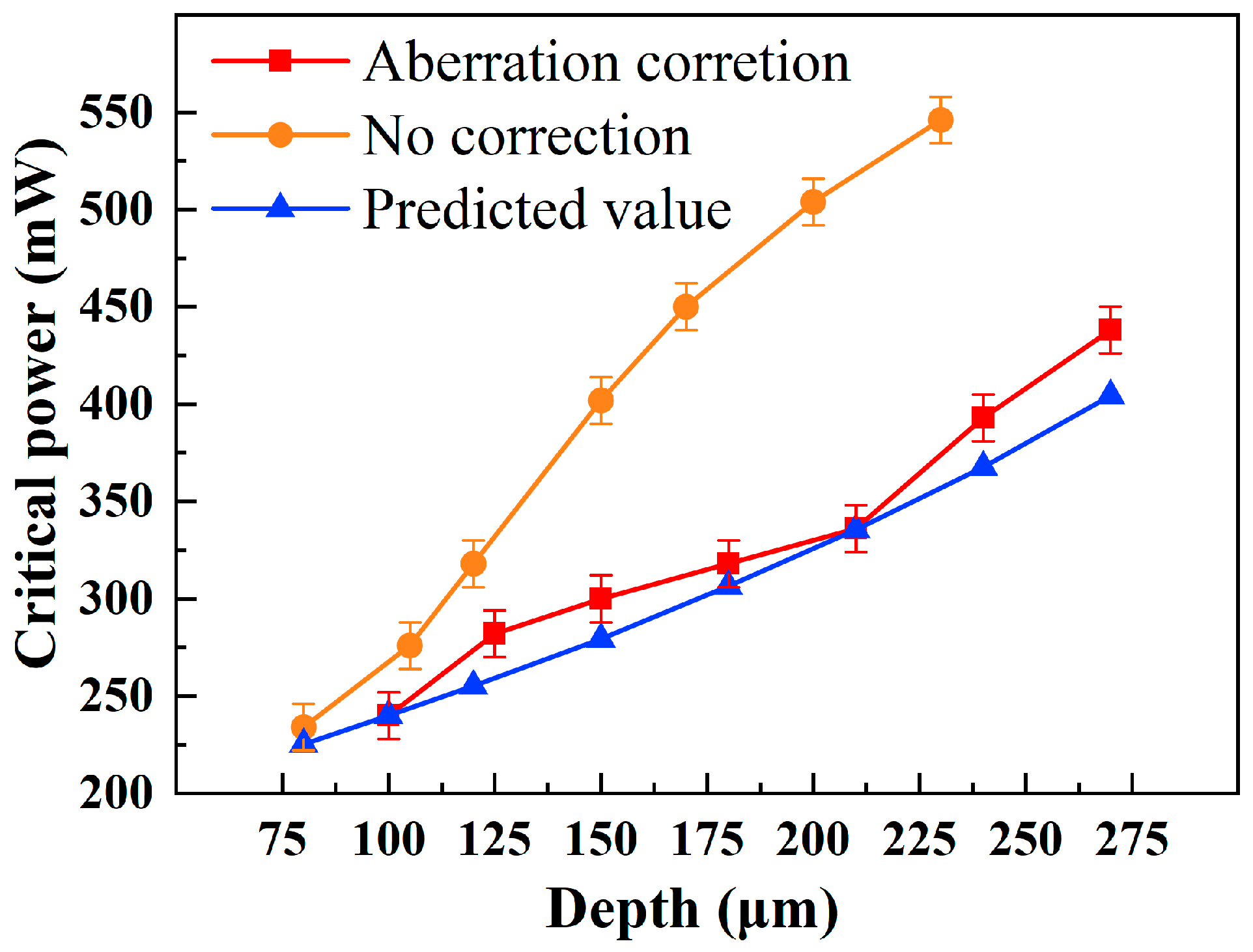

Direct measurement of laser intensity at varying depths within the crystal is challenging. We therefore indirectly assess the intensity magnitude by observing the critical power for crack coalescence. As shown in

Figure 6b, adjacent track cracks remain independent at lower laser powers. When the power increases to a threshold value, cracks from neighboring tracks coalesce (

Figure 6c). Crack propagation requires the energy release rate at the crack tip to exceed a critical value [

24]. Assuming a constant critical energy release rate for identical samples, the critical power for crack coalescence serves as an indirect indicator of laser–SiC interaction equivalence. The experiment maintained a laser frequency of 50 kHz, spacing of 100 μm, and scanning speed of 100 mm/s, while progressively increasing single-pulse energy until crack coalescence occurred. The critical power measurement resolution reached 0.12 μJ (6 mW). Processing depths were verified through cross-sectional observations. In

Figure 7, red and yellow curves represent critical power values with and without aberration correction at different depths, respectively. At identical depths, aberration-corrected conditions require lower critical power compared to non-corrected scenarios, with this difference becoming more pronounced at greater depths.

Currently, unavoidable variations in transmittance exist among individual N-type SiC ingots due to doping concentration differences during crystal growth. To circumvent direct transmittance measurements of the ingots, a power prediction method based on low-depth data is proposed. Accounting for upper surface reflection and the proportional relationship between laser power and intensity, the power at depth

d can be formulated by integrating the Lambert–Beer law:

At a processing depth of 100 μm, the critical power (incident power) is 240 mW, corresponding to an effective power of 141.9 mW at the 100 μm depth. Given the target power

Pw = 141.9 mW, the incident power

P0 can be back-calculated using the following relationship:

The calculated incident power required at different depths, based on the above equation, is plotted as the blue curve in

Figure 7 Experimental results closely match the model predictions, showing a maximum error of 8.4% in critical power measurements under different processing depths. Discrepancies may arise from factors such as laser scattering, interface roughness, and transmittance variations due to doping concentration fluctuations within SiC ingots.

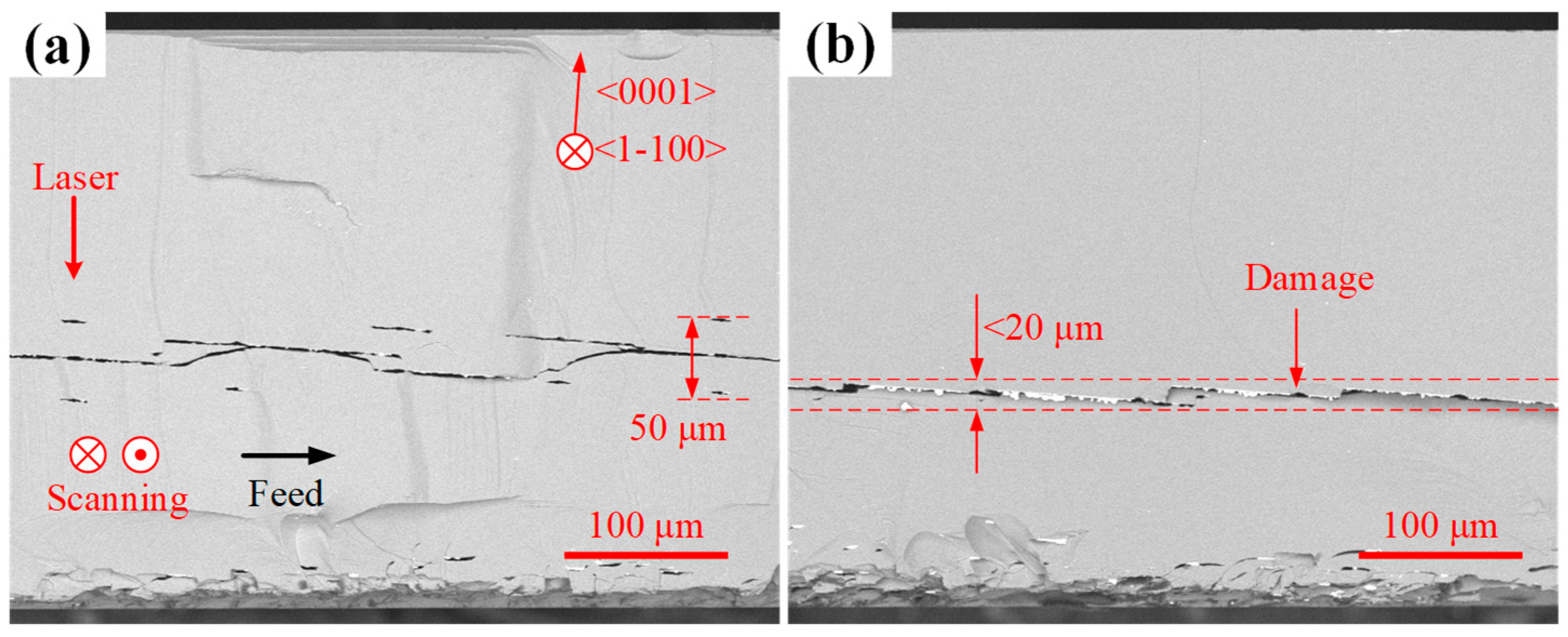

In the absence of aberration correction, the measured critical power deviates significantly from the model prediction (>50%). This occurs because aberration effects become increasingly pronounced with greater processing depths (

Figure 2b,c), causing significant laser energy divergence. As shown in

Figure 8a, at a nominal depth of 86 μm without aberration correction, the longitudinal span of laser-induced damage traces reaches 50 μm. In contrast, aberration-corrected processing (

Figure 8b) maintains tightly focused damage confined to a single point, with damage spans remaining below 20 μm. The enhanced energy concentration under aberration correction directly reduces the required critical power compared to non-corrected conditions. These results not only validate the accuracy of aberration correction but also deliver a computational model for depth-dependent laser power requirements.