Process Optimization on Trepanning Drilling in Titanium Alloy Using a Picosecond Laser via an Orthogonal Experiment

Abstract

1. Introduction

2. Experimentation Details

2.1. Materials and Equipment

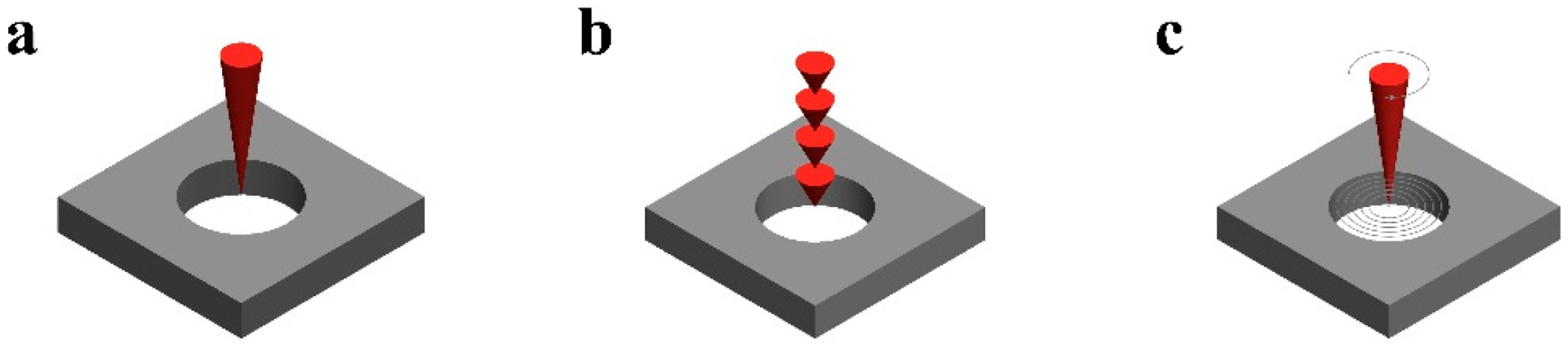

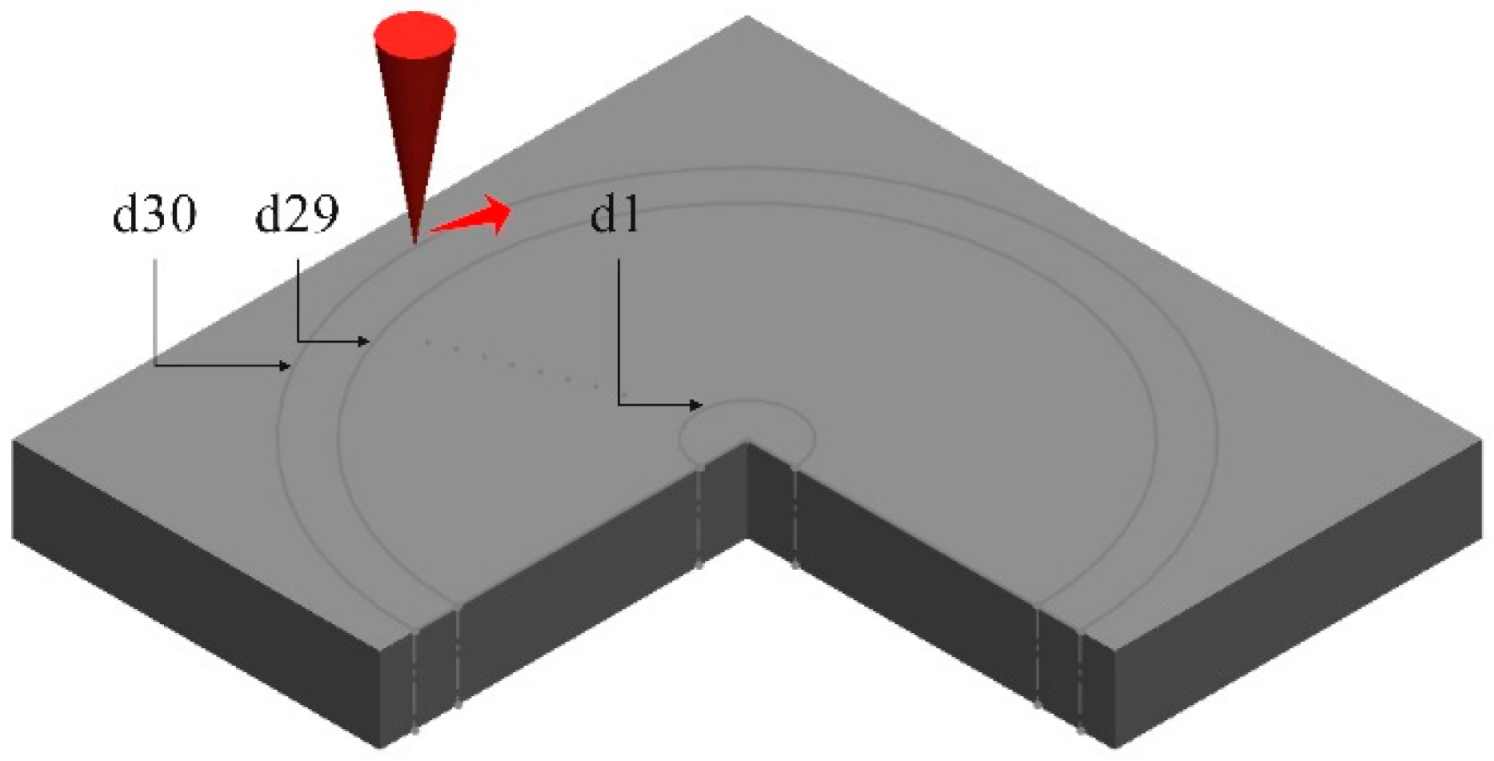

2.2. Experimentation Program

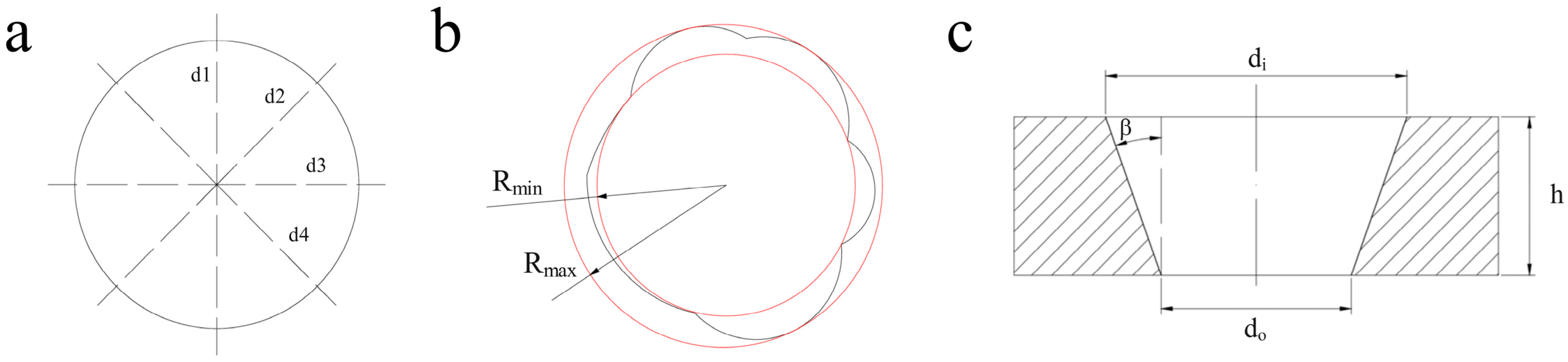

2.3. Quality Assessment Methods

2.4. Process Optimization Methods

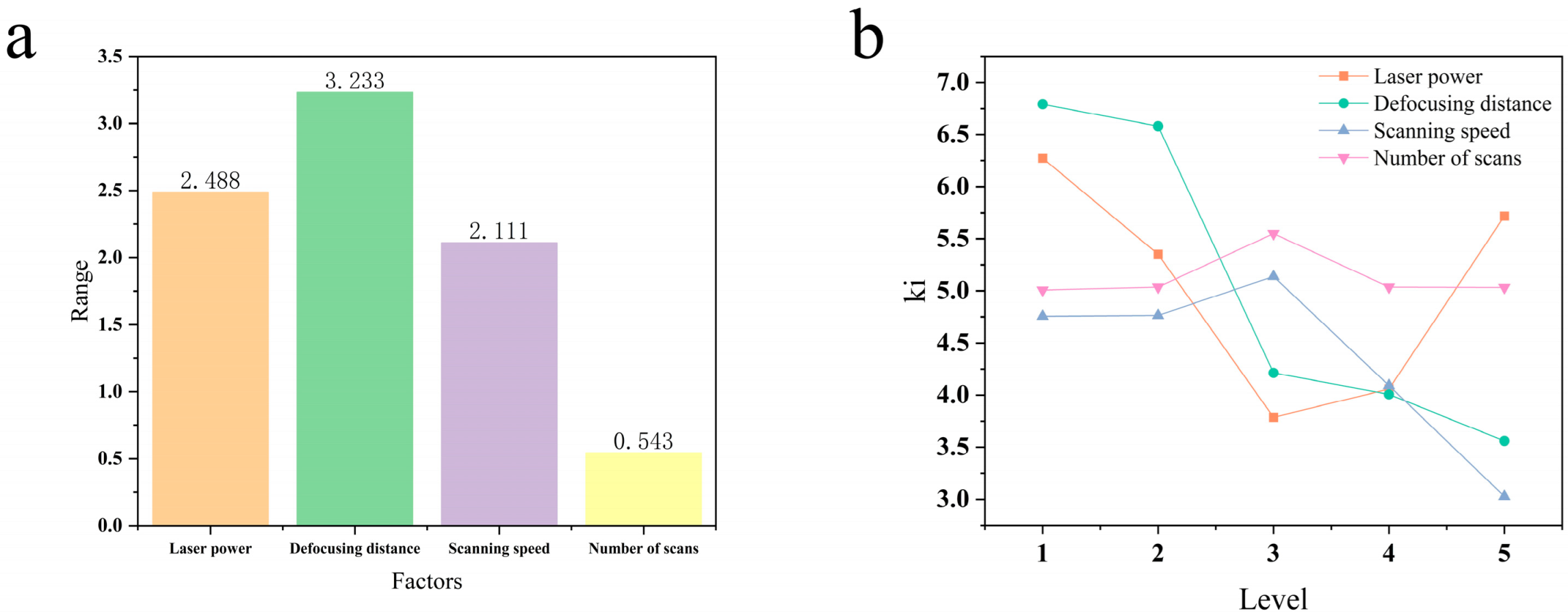

2.4.1. Range Analysis

2.4.2. Comprehensive Balancing Method

- (1)

- If a factor’s rank of influence varies across different metrics, priority is given to the factor level that is optimal for the metric on which it has the most significant impact;

- (2)

- If a factor exhibits a low overall influence across all metrics, its optimal level is selected based on a “majority rule” principle, choosing the level that appears most frequently as the optimum in the individual analyses;

- (3)

- When the differences in influence among various factors are indistinct, certain less impactful factors may be excluded to avoid redundancy and resource waste, thereby defining a more rational and efficient parameter set;

- (4)

- If a factor has a pronounced effect on a particularly critical performance metric, its optimal level should be determined primarily to satisfy the requirements of that key metric.

3. Results

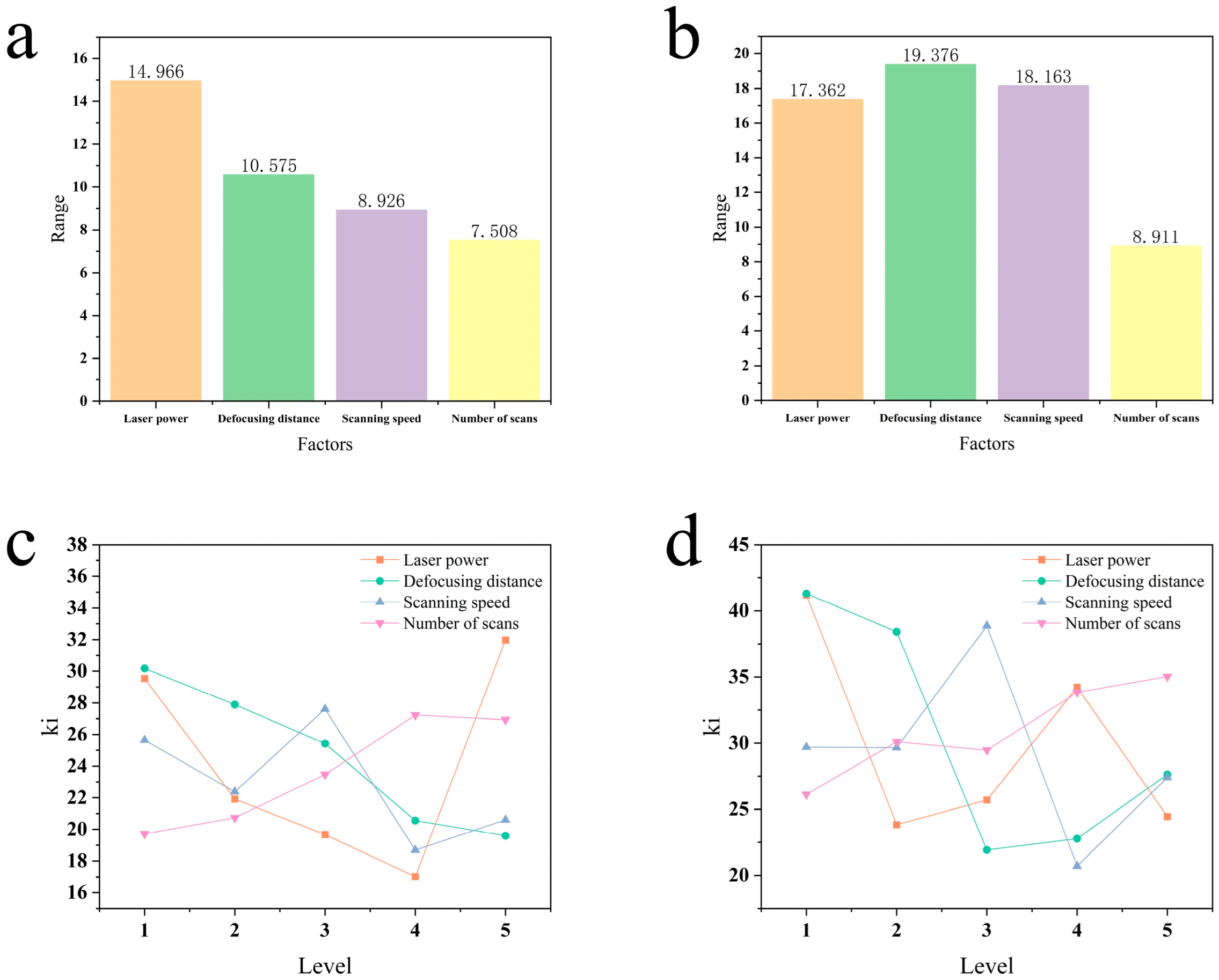

3.1. Hole Diameter Analysis

3.2. Hole Taper Analysis

3.3. Hole Roundness Analysis

3.4. Process Optimization

4. Discussion

4.1. Comprehensive Optimization Strategy

4.2. Comparative Analysis with Existing Research

- Advantages over Millisecond Lasers: Compared to conventional millisecond laser drilling [23], the picosecond process used in this study achieved a significantly smaller taper and superior surface quality, as evidenced by the clean exit hole shown in Figure 8. This is a direct result of the “cold ablation” mechanism characteristic of ultrashort pulses, where material removal is completed before significant thermal diffusion can occur. This fundamentally suppresses the melt pool effects and thermal damage inherent to long-pulse laser processing.

- Competitive Performance against Femtosecond Lasers: Although femtosecond lasers [16] can achieve nearly perfect “athermal” ablation, our picosecond laser process presents a highly competitive alternative. We achieved excellent taper control with minimal thermal damage. Critically, picosecond laser systems typically offer higher average power and greater cost-effectiveness, enabling significantly higher processing throughput than their femtosecond counterparts.

5. Conclusions

- Scanning speed and laser power predominantly affect the entrance and exit diameters of micro-holes, whereas other parameters exhibit lesser influence. The defocusing distance directly correlates with micro-hole taper. The laser power demonstrates the strongest correlation with entrance roundness, while the defocusing distance, number of scans, and laser power collectively influence exit roundness. The number of scans exhibits negligible correlation with the entrance/exit diameters, taper, or roundness characteristics of produced micro-holes.

- For entrance diameter optimization, the optimal parameter combination is A4B3C4D5, with a laser power of 90% (30 W), defocusing distance of 0 mm, scanning speed of 27 mm/s, and number of scans of 55. Regarding the exit diameter, the combination A1B1C4D3 delivers optimal results: a laser power of 75% (30 W), defocusing distance of −0.2 mm, scanning speed of 27 mm/s, and number of scans of 35. Taper optimization is achieved with combination A3B5C5D1: a laser power of 85% (30 W), defocusing distance of 0.2 mm, scanning speed of 30 mm/s, and number of scans of 15. For entrance roundness, the combination A4B5C4D1 is optimal: a laser power of 90% (30 W), defocusing distance of 0.2 mm, scanning speed of 27 mm/s, and number of scans of 15. Finally, exit roundness optimization requires the combination A2B3C4D1: a laser power of 80% (30 W), defocusing distance of 0 mm, scanning speed of 27 mm/s, and number of scans of 15.

- The optimal parameter levels vary significantly depending on the specific quality metric being evaluated. In applications involving film cooling holes in superalloys, hole taper and roundness are critical geometric indicators that determine the fluid dynamic characteristics and in-service performance; therefore, they should be given the highest priority during the optimization process. By employing range analysis and a comprehensive balancing method to evaluate the multiple hole quality metrics, a final, globally optimal parameter combination was identified as A3B5C4D1, corresponding to a laser power of 90%, a defocusing distance of +0.2 mm, a scanning speed of 27 mm/s, and 15 scans.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yuan, C.G.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S. Drilling of titanium alloy (Ti6Al4V)—A review. Mach. Sci. Technol. 2021, 25, 637–702. [Google Scholar] [CrossRef]

- Li, Z.; Wei, X.; Guo, Y.; Sealy, M.P. State-of-art, challenges, and outlook on manufacturing of cooling holes for turbine blades. Mach. Sci. Technol. 2015, 19, 361–399. [Google Scholar] [CrossRef]

- Liu, W.; Liu, S.; Wang, L. Surface modification of biomedical titanium alloy: Micromorphology, microstructure evolution and biomedical applications. Coatings 2019, 9, 249. [Google Scholar] [CrossRef]

- Jia, X.; Chen, Y.; Liu, L.; Wang, C.; Duan, J. Advances in laser drilling of structural ceramics. Nanomaterials 2022, 12, 230. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Dechun, G.; Tong, C.; Daoli, L.; Chen, B. Second-derivative laser-induced fluorescence spectroscopy combined with chemometrics for authentication of the adulteration of camellia oil. CyTA-J. Food 2018, 16, 747–754. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, R.; Dabbour, M.; Mintah, B.K.; Gao, X.; He, R.; Ma, H. Enhancing acid production of Acetobacter pasteurianus by laser and intense pulsed light mutagenesis and its molecular mechanism based on transcriptomic analysis. LWT 2023, 182, 114803. [Google Scholar] [CrossRef]

- Xia, K.; Ren, N.; Lin, Q.; Yang, H. Femtosecond laser drilling in superalloy with water-based magnetic assistance. Opt. Commun. 2023, 527, 128902. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, J.; Wang, X.; Zhang, J.; Hayasaki, Y.; Kim, D.; Sun, S. Experimental study of nickel-based superalloy IN792 with femtosecond laser drilling method. Opt. Laser Technol. 2021, 143, 107335. [Google Scholar] [CrossRef]

- Lu, F.; Ruan, S.; Wang, Y.; Li, Y.; Ma, F.; Ma, H. Unveiling underlying mechanism of combined He–Ne laser and UV mutagenesis in Bacillus subtilis CICC 21927: A transcriptomic analysis. Food Biosci. 2024, 61, 104694. [Google Scholar] [CrossRef]

- Tian, X.Y.; Aheto, J.H.; Dai, C.; Ren, Y.; Bai, J.W. Monitoring microstructural changes and moisture distribution of dry-cured pork: A combined confocal laser scanning microscopy and hyperspectral imaging study. J. Sci. Food Agric. 2021, 101, 2727–2735. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.D.; Zou, X.B.; Shi, J.Y.; Zhao, J.W.; Huang, X.W. Observation of the Oil Content of Fried Lotus (Nelumbo nucifera Gaertn.) Root Slices by Confocal Laser Scanning Microscopy Based on Three-Dimensional Model. J. Food Process. Preserv. 2017, 41, e12762. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, D.; Jing, X.; Zheng, S.; Sun, H. Experimental investigation and optimization on trepanning drilling in K24 superalloy by femtosecond laser via orthogonal experiment. Int. J. Adv. Manuf. Technol. 2023, 128, 3343–3356. [Google Scholar] [CrossRef]

- Amiri, S.; Khajehzadeh, M.; Razfar, M.R. Magnetic field and ultrasonic aided laser drilling effect on Ti6Al4V microstructural characteristics. Mater. Manuf. Process. 2020, 35, 1832–1841. [Google Scholar] [CrossRef]

- Ku, K.A.I.F.B.; Halil, A.B.M.; Ishak, M.B.; Yusof, M.F.B.M.; Shah, L.H.B.A. Effect of Laser Process Loops on the Hole Diameter and Hole Formation of Laser Micro Drilling on TC4. J. Phys. Conf. Ser. 2024, 2688, 012013. [Google Scholar]

- Saravanan, M.; Raja, V.B.; Palanikumar, K.; Vaidyaa, P.; Sundar, S.; Prakash, M.S. Laser drilling parameter optimization for Ti6Al4v alloy. Mater. Today Proc. 2021, 46, 4003–4007. [Google Scholar] [CrossRef]

- Deepu, P.; Jagadesh, T.; Duraiselvam, M. Investigations into morphology and surface integrity of micro-hole during femtosecond laser drilling of titanium alloy. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 516. [Google Scholar] [CrossRef]

- Bupesh Raja, V.; Sonawwanay, P.D.; Duraivelu, K.; Alphonse, M.; Muhammad, N.; Lazar, P. Optimization of Cutting Parameters of Laser Drilling on Ti6Al4V Alloy Using ANN. In Proceedings of the International Conference on Advanced Materials Manufacturing and Structures, Chennai, India, 22–23 February 2024; pp. 37–47. [Google Scholar]

- Shin, J.; Mazumder, J. Shallow angle drilling of inconel 718 using a helical laser drilling technique. J. Manuf. Sci. Eng. 2017, 139, 031004. [Google Scholar] [CrossRef]

- Du, T.; Liang, X.; Yu, Y.; Zhou, L.; Cai, Z.; Wang, L.; Jia, W.; Pan, X. Optimization of femtosecond laser drilling process for DD6 single crystal alloy. Metals 2023, 13, 333. [Google Scholar] [CrossRef]

- Schulz, W.; Eppelt, U.; Poprawe, R. Review on laser drilling I. Fundamentals, modeling, and simulation. J. Laser Appl. 2013, 25, 012006. [Google Scholar]

- Holder, D.; Weber, R.; Graf, T.; Onuseit, V.; Brinkmeier, D.; Förster, D.J.; Feuer, A. Analytical model for the depth progress of percussion drilling with ultrashort laser pulses. Appl. Phys. A 2021, 127, 302. [Google Scholar] [CrossRef]

- Webster, P.J.; Yu, J.X.; Leung, B.Y.; Anderson, M.D.; Yang, V.X.; Fraser, J.M. In situ 24 kHz coherent imaging of morphology change in laser percussion drilling. Opt. Lett. 2010, 35, 646–648. [Google Scholar] [CrossRef] [PubMed]

- Bahar, N.; Marimuthu, S.; Yahya, W. Pulsed Nd: YAG laser drilling of aerospace materials (Ti-6Al-4V). IOP Conf. Ser. Mater. Sci. Eng. 2016, 152, 012056. [Google Scholar] [CrossRef]

| Composition | Ti | Al | V | Fe |

|---|---|---|---|---|

| Mass fraction/% | Allowance | 6.5~6.8 | 4.2~4.5 | 0.3 |

| Composition | C | N | H | O |

| Mass fraction/% | 0.1 | 0.05 | 0.015 | 0.2 |

| Level | Factor | |||

|---|---|---|---|---|

| A Laser Power (%) | B Defocusing Distance (mm) | C Scanning Speed (mm/s) | D Number of Scans (n) | |

| 1 | 75 | −0.2 | 18 | 15 |

| 2 | 80 | −0.1 | 21 | 25 |

| 3 | 85 | 0 | 24 | 35 |

| 4 | 90 | 0.1 | 27 | 45 |

| 5 | 95 | 0.2 | 30 | 55 |

| Level | A Laser Power (%) | B Defocusing Distance (mm) | C Scanning Speed (mm/s) | D Number of Scans (n) |

|---|---|---|---|---|

| k1 | 327.7965 | 332.9658 | 331.7113 | 332.3041 |

| k2 | 331.668 | 335.7154 | 303.6404 | 317.6234 |

| k3 | 339.2347 | 311.4376 | 329.0273 | 319.8893 |

| k4 | 314.6515 | 335.664 | 253.2778 | 320.3007 |

| k5 | 323.1115 | 318.8621 | 264.0036 | 316.2983 |

| R | 24.58315 | 24.27783 | 78.43353 | 16.00585 |

| Level | A Laser Power (%) | B Defocusing Distance (mm) | C Scanning Speed (mm/s) | D Number of Scans (n) |

|---|---|---|---|---|

| k1 | 272.9397 | 273.5901 | 290.1488 | 288.5664 |

| k2 | 284.9136 | 278.2018 | 292.3072 | 288.6472 |

| k3 | 306.1691 | 289.9006 | 284.1174 | 286.4271 |

| k4 | 294.2274 | 300.674 | 232.7996 | 291.3311 |

| k5 | 288.4133 | 302.811 | 237.5614 | 287.3594 |

| R | 33.2294 | 29.2209 | 59.50765 | 4.904 |

| Level | A Laser Power (%) | B Defocusing Distance (mm) | C Scanning Speed (mm/s) | D Number of Scans (n) |

|---|---|---|---|---|

| k1 | 6.274851 | 6.79256 | 4.75646 | 5.00718 |

| k2 | 5.351858 | 6.579758 | 4.764565 | 5.037405 |

| k3 | 3.786666 | 4.213454 | 5.138486 | 5.550425 |

| k4 | 4.05852 | 4.006434 | 4.091225 | 5.036334 |

| k5 | 5.717751 | 3.559572 | 3.027081 | 5.032606 |

| R | 2.488186 | 3.232988 | 2.111404 | 0.543245 |

| Level | A Laser Power (%) | B Defocusing Distance (mm) | C Scanning Speed (mm/s) | D Number of Scans (n) |

|---|---|---|---|---|

| k1 | 29.5468 | 30.1784 | 25.6492 | 19.7216 |

| k2 | 21.9214 | 27.891 | 22.38 | 20.7368 |

| k3 | 19.6728 | 25.4246 | 27.6158 | 23.4764 |

| k4 | 17.0136 | 20.5604 | 18.69 | 27.2294 |

| k5 | 31.9798 | 19.6034 | 20.602 | 26.9362 |

| R | 14.9662 | 10.575 | 8.9258 | 7.5078 |

| Level | A Laser Power (%) | B Defocusing Distance (mm) | C Scanning Speed (mm/s) | D Number of Scans (n) |

|---|---|---|---|---|

| k1 | 41.1982 | 41.3 | 29.6976 | 26.1204 |

| k2 | 23.8358 | 38.42 | 29.6526 | 30.1074 |

| k3 | 25.6982 | 21.924 | 38.8708 | 29.4642 |

| k4 | 34.23 | 22.78 | 20.708 | 33.8316 |

| k5 | 24.4476 | 27.6326 | 27.4046 | 35.031 |

| R | 17.3624 | 19.376 | 18.1628 | 8.9106 |

| Hole entrance diameter | Range | 24.58315 | 24.27783 | 78.43353 | 16.00585 |

| Optimal factor | A4 | B3 | C4 | D5 | |

| Hole exit diameter | Range | 33.2294 | 29.2209 | 59.50765 | 4.904 |

| Optimal factor | A1 | B1 | C4 | D3 | |

| Hole taper | Range | 2.488186 | 3.232988 | 2.111404 | 0.543245 |

| Optimal factor | A3 | B5 | C5 | D1 | |

| Hole entrance roundness | Range | 14.9662 | 10.575 | 8.9258 | 7.5078 |

| Optimal factor | A4 | B5 | C4 | D1 | |

| Hole exit roundness | Range | 17.3624 | 19.376 | 18.1628 | 8.9106 |

| Optimal factor | A2 | B3 | C4 | D1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Rong, Y.; Xu, L.; Wu, C.; Xia, K. Process Optimization on Trepanning Drilling in Titanium Alloy Using a Picosecond Laser via an Orthogonal Experiment. Micromachines 2025, 16, 846. https://doi.org/10.3390/mi16080846

Wang L, Rong Y, Xu L, Wu C, Xia K. Process Optimization on Trepanning Drilling in Titanium Alloy Using a Picosecond Laser via an Orthogonal Experiment. Micromachines. 2025; 16(8):846. https://doi.org/10.3390/mi16080846

Chicago/Turabian StyleWang, Liang, Yefei Rong, Long Xu, Changjian Wu, and Kaibo Xia. 2025. "Process Optimization on Trepanning Drilling in Titanium Alloy Using a Picosecond Laser via an Orthogonal Experiment" Micromachines 16, no. 8: 846. https://doi.org/10.3390/mi16080846

APA StyleWang, L., Rong, Y., Xu, L., Wu, C., & Xia, K. (2025). Process Optimization on Trepanning Drilling in Titanium Alloy Using a Picosecond Laser via an Orthogonal Experiment. Micromachines, 16(8), 846. https://doi.org/10.3390/mi16080846