High-Quality Manufacturing with Electrochemical Jet Machining (ECJM) for Processing Applications: A Comprehensive Review, Challenges, and Future Opportunities

Abstract

1. Introduction

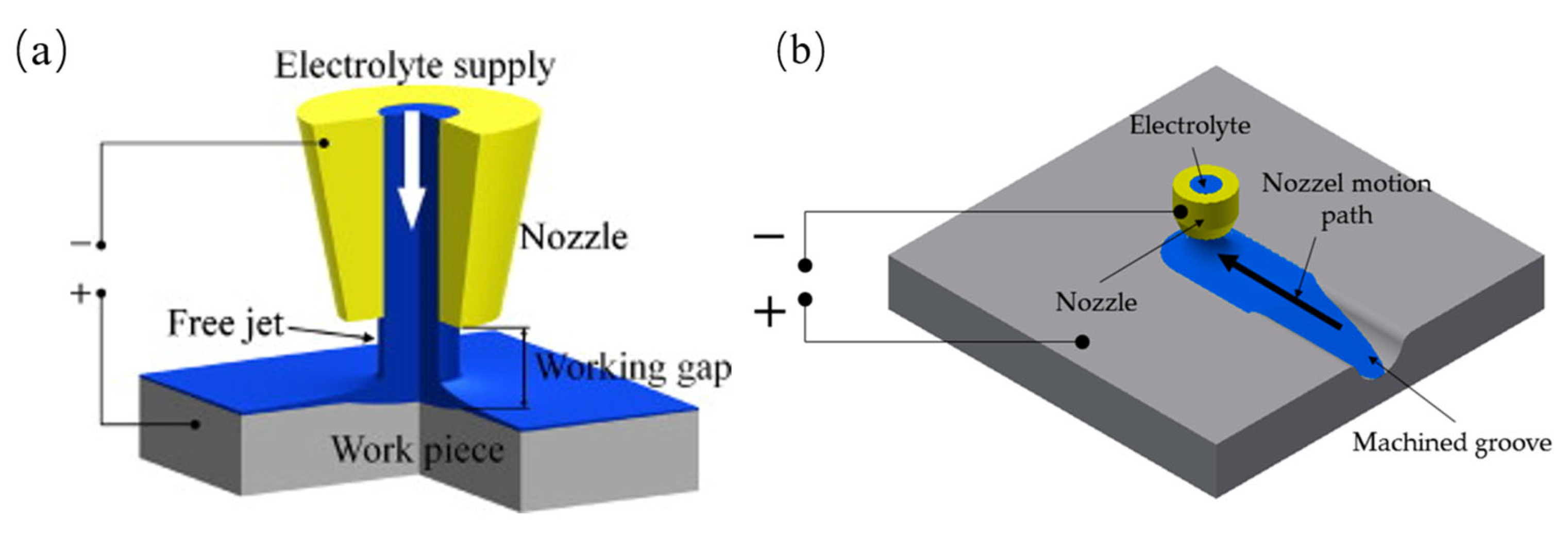

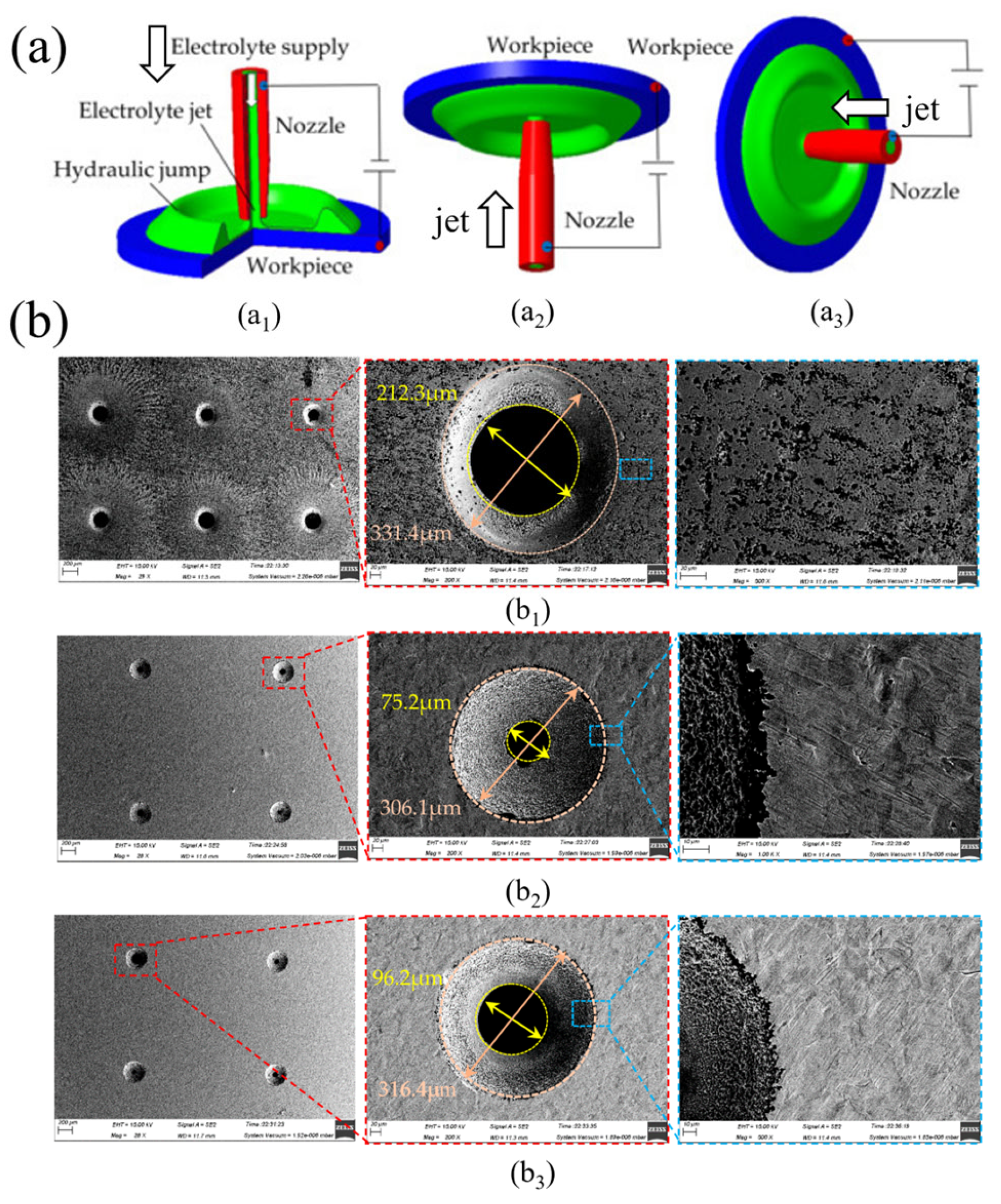

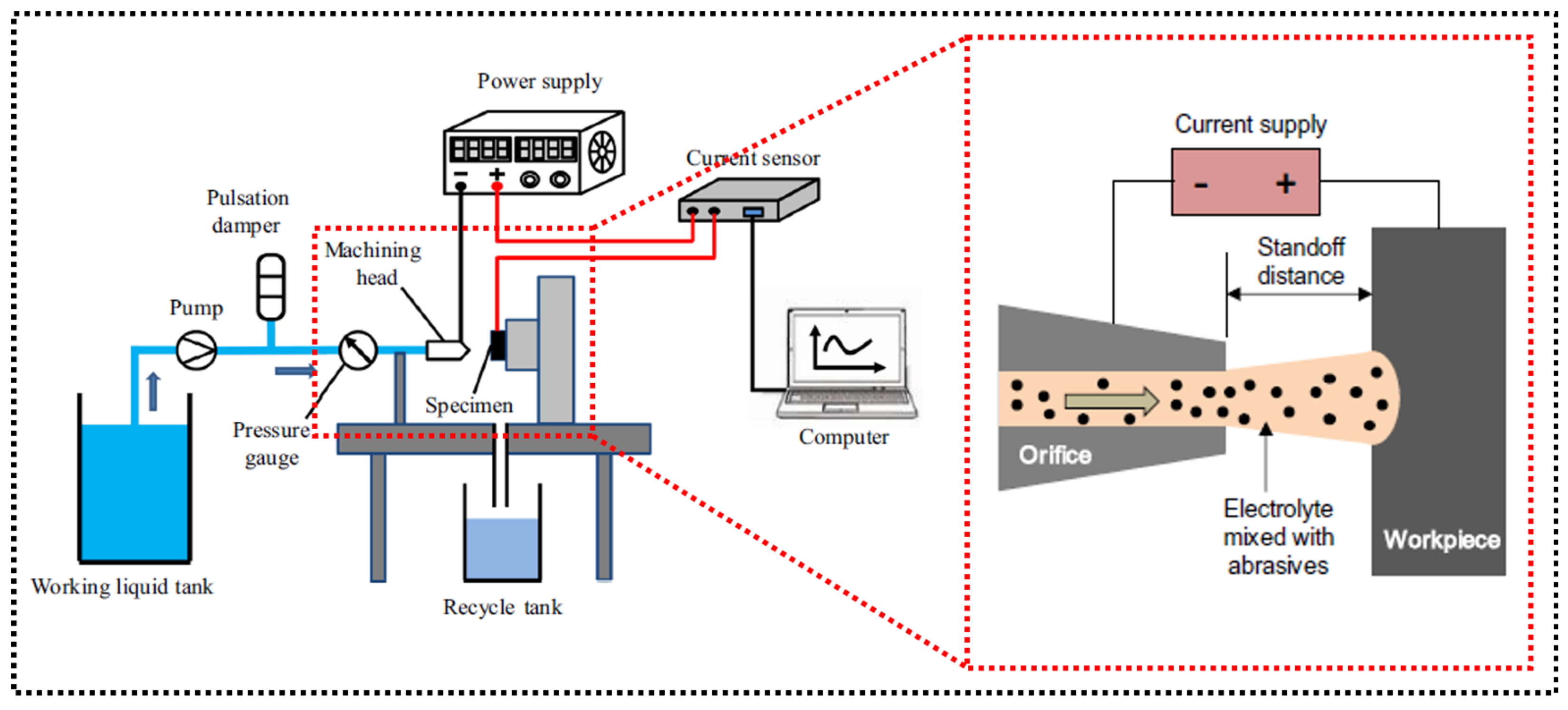

2. Principle of Electrochemical Jet

3. Electrochemical Jet Machining (ECJM)

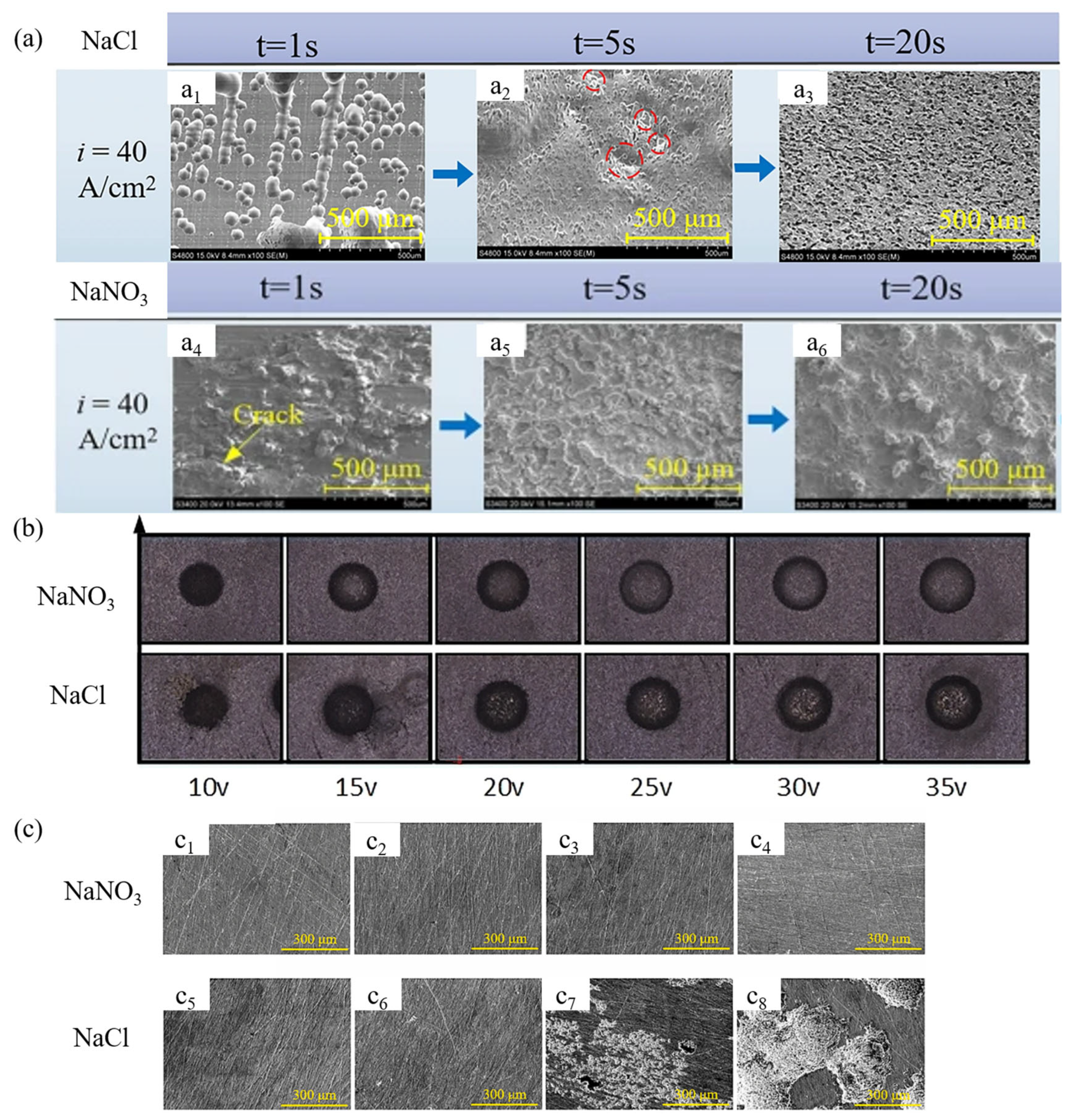

3.1. Electrolyte Type

3.2. Optimization of ECJM

4. Electrochemical Jet Composite Processing Technologies

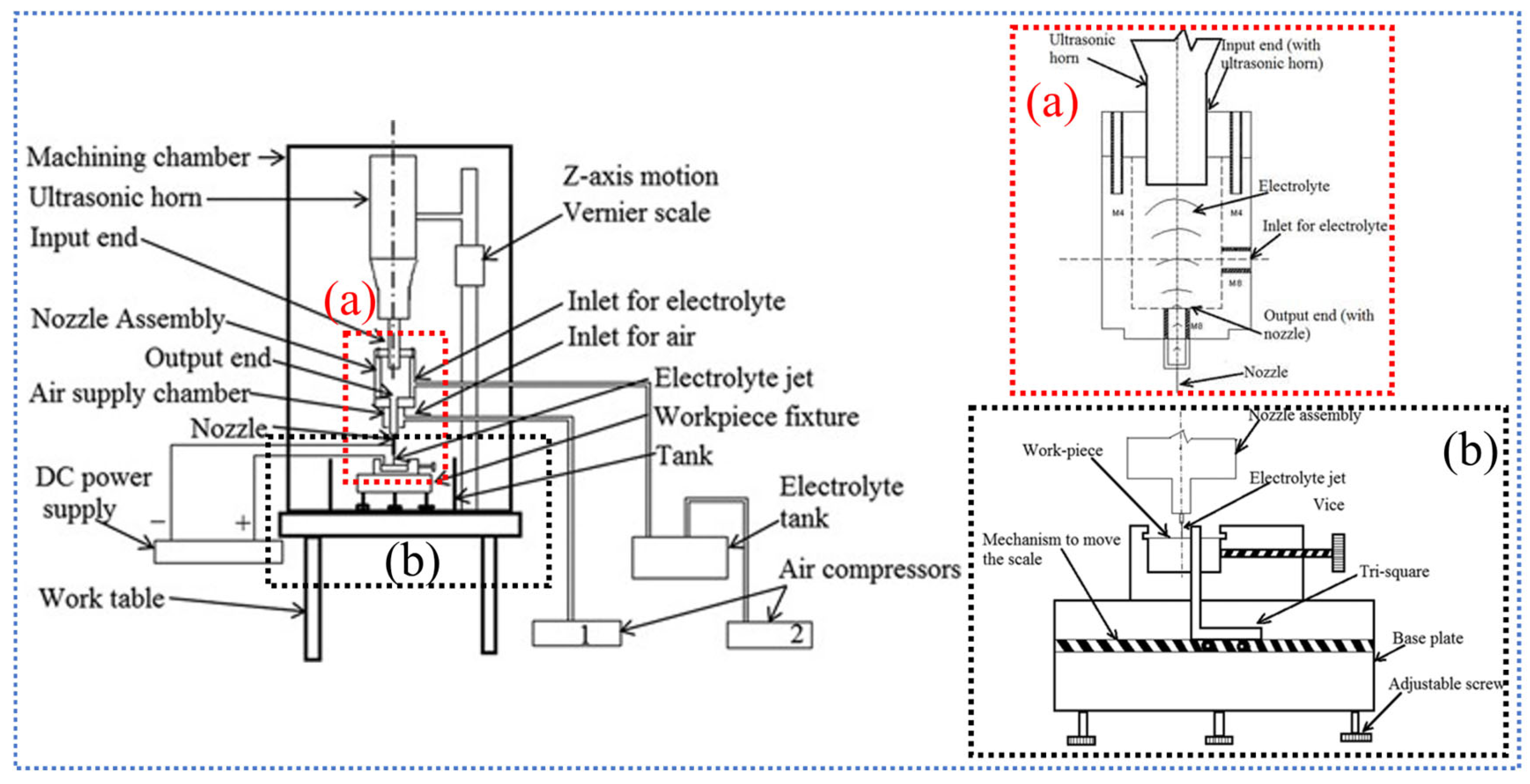

4.1. Ultrasonic-Assisted ECJM

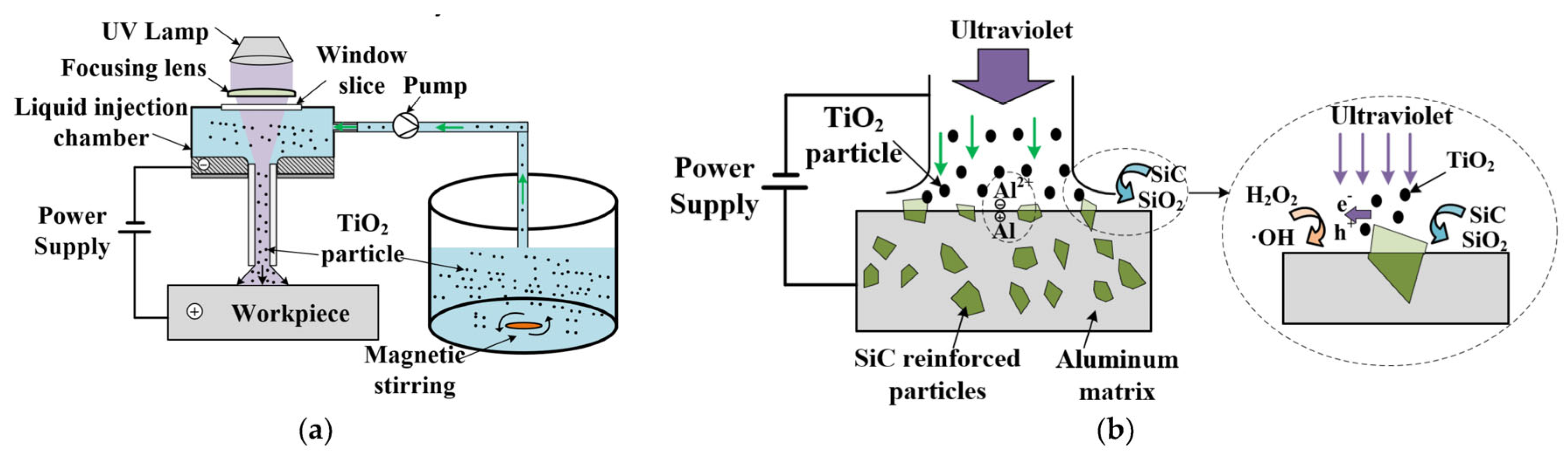

4.2. Laser-Assisted ECJM

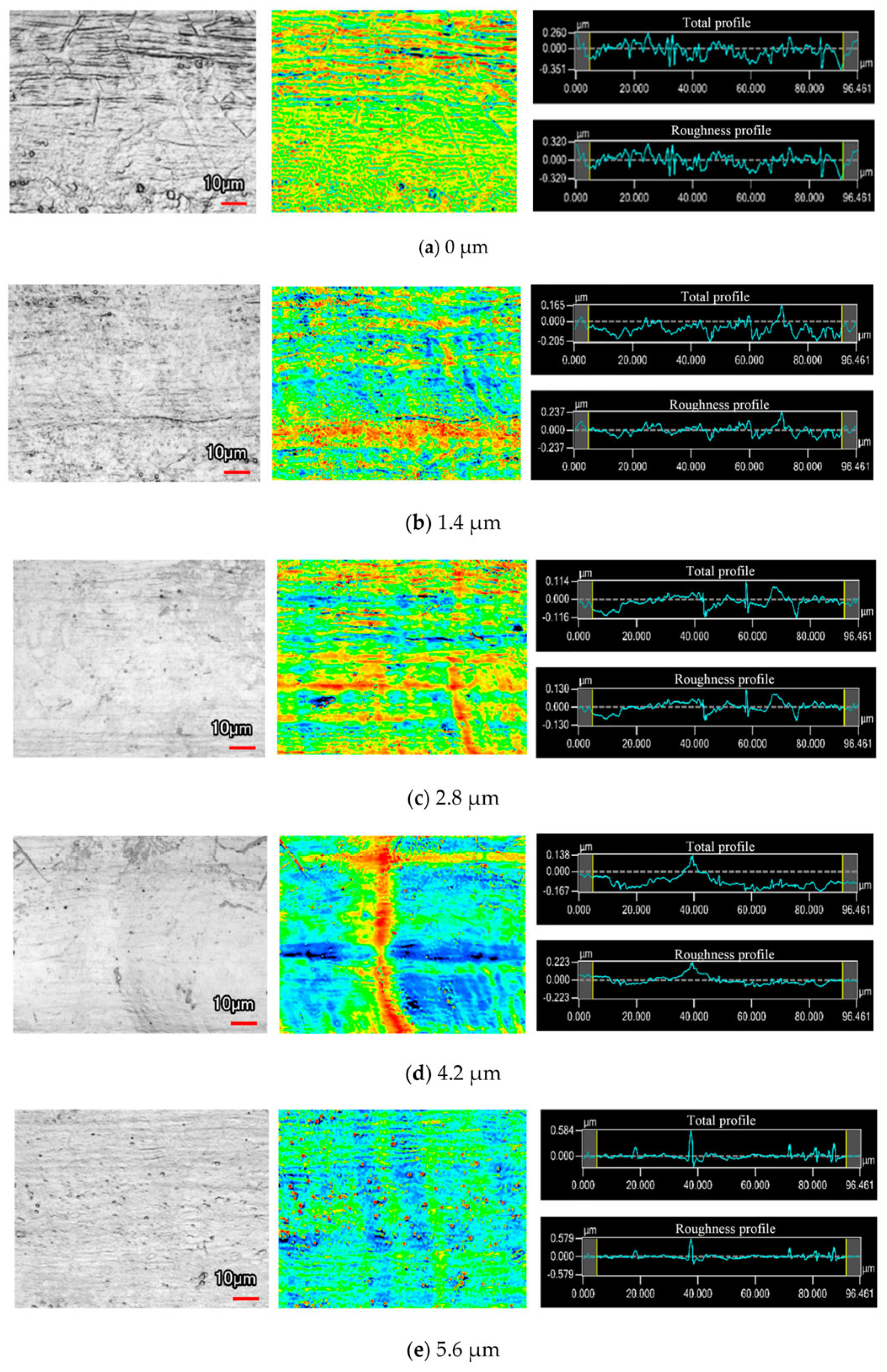

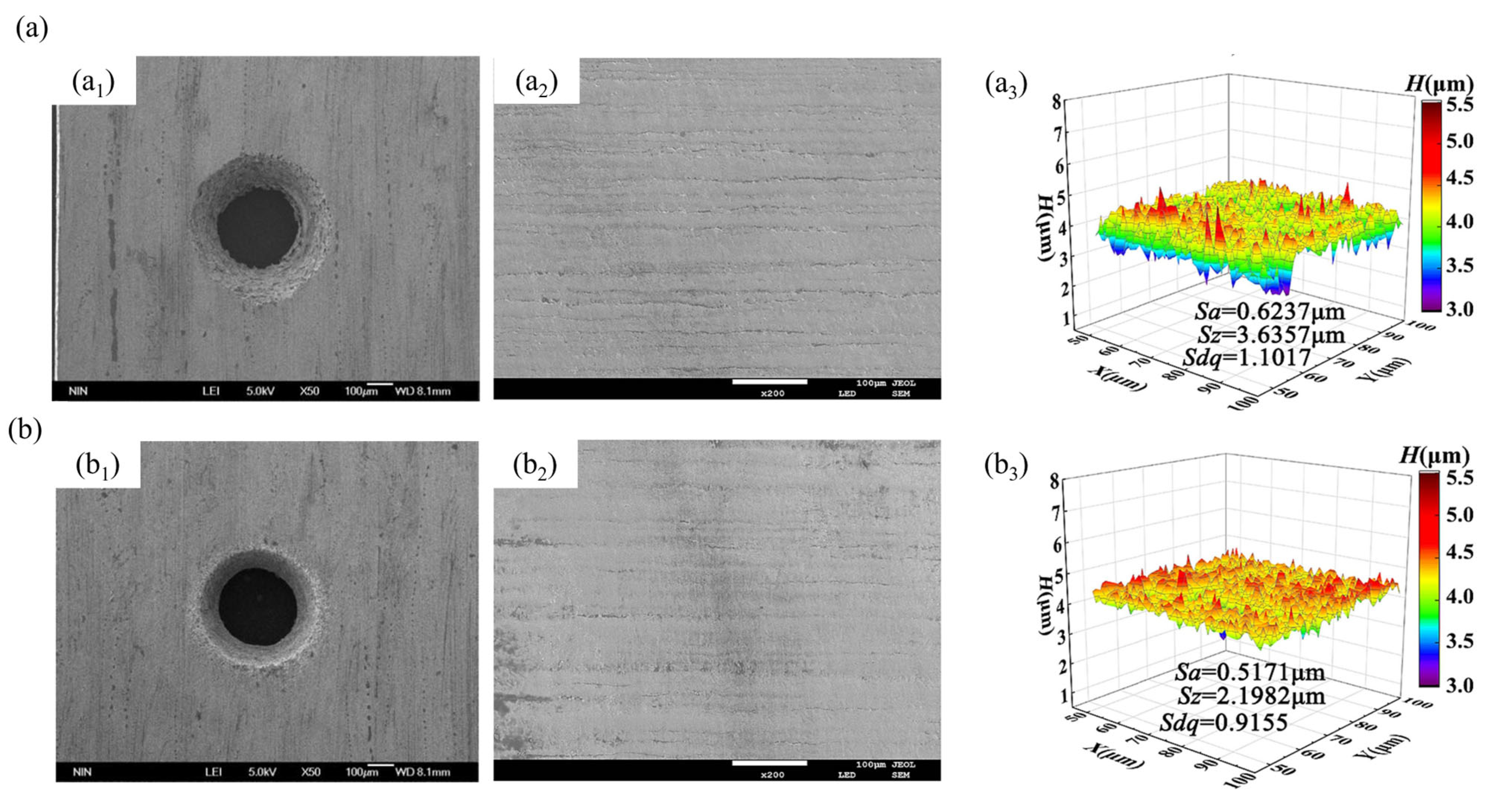

4.3. Magnetism-Assisted ECJM

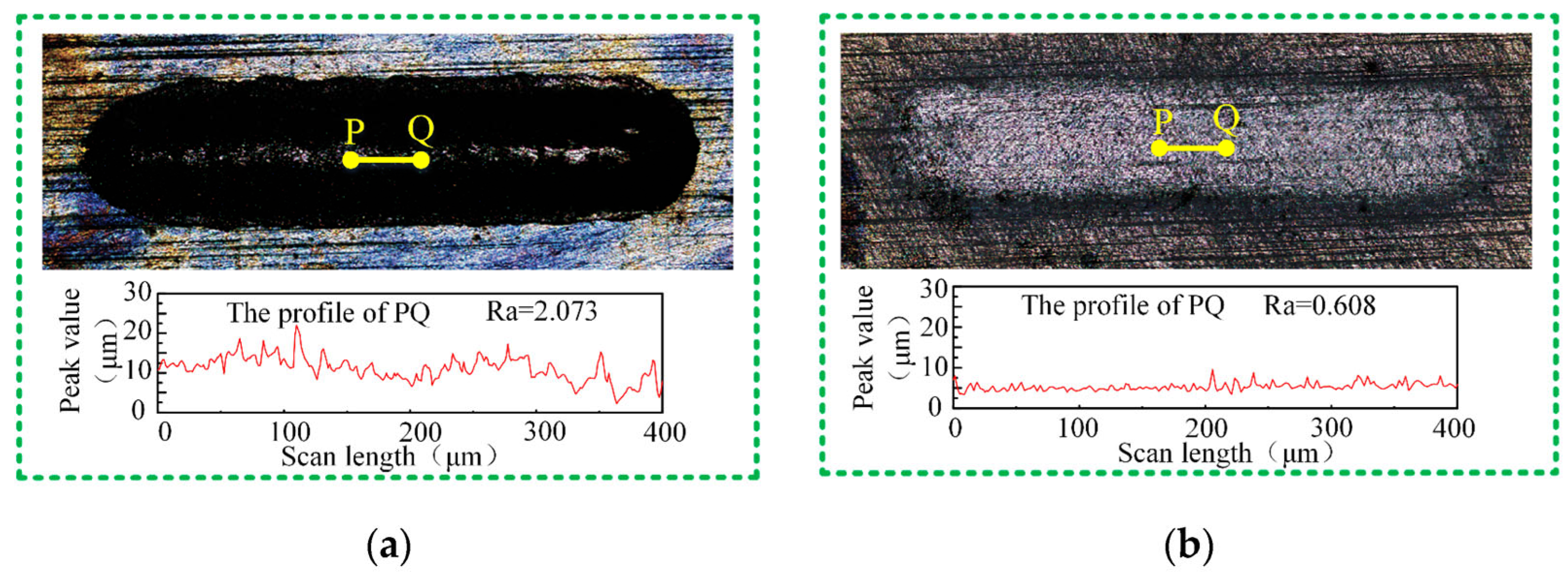

4.4. Abrasive-Assisted ECJM

| References | Abrasive Type | Specimen | Voltage |

|---|---|---|---|

| [123] | Al2O3 | Stellite 12 alloys | 30 V |

| [23] | Al2O3 | Stainless steel 304 | - |

| [48] | - | WC alloys | 60 V, 80 V, 100 V, 120 V |

| [125] | Al2O3 | K110 alloy steel | 9 V, 11.5 V |

| [22] | Al2O3 | SiCp/Al composites | 160 V |

| [122] | Al2O3 | Stainless steel 316 | 80 V, 120 V, 160 V |

| [8] | - | SiCp/Al composites | 150 V |

| [121] | SiC | Ti-6Al-4V alloys | 60 V |

| [124] | Al2O3 | Stainless steel 316 | - |

| [5] | SiC | Superalloy Inconel 718 | 200 V |

5. Challenges and Possible Improvements in Each Technologies

Funding

Conflicts of Interest

References

- Lohrengel, M.M.; Rataj, K.P.; Schubert, N.; Schneider, M.; Höhn, S.; Michaelis, A.; Hackert-Oschätzchen, M.; Martin, A.; Schubert, A. Electrochemical machining of hard metals—WC/Co as example. Powder Metall. 2013, 57, 21–30. [Google Scholar] [CrossRef]

- Praveena Gopinath, T.; Prasanna, J.; Chandrasekhara Sastry, C.; Patil, S. Experimental investigation of the electrochemical micromachining process of Ti-6Al-4V titanium alloy under the influence of magnetic field. Mater. Sci.-Pol. 2021, 39, 124–138. [Google Scholar] [CrossRef]

- Che, J.; Shi, G.; Xu, Y. Experimental study on ultrasonic-assisted electrochemical polishing of NiTi alloy. Phys. Scr. 2024, 99, 045973. [Google Scholar] [CrossRef]

- Wang, M.; Qu, N. Improving material removal rate in macro electrolyte jet machining of TC4 titanium alloy through back-migrating jet channel. J. Manuf. Process. 2021, 71, 489–500. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Hou, N.; Rao, S. Material removal mechanism of superalloy Inconel 718 based on electrochemical abrasive jet processing. Int. J. Adv. Manuf. Technol. 2020, 106, 4663–4673. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, C.; Qiu, Y.; Gao, C. Electrochemical Jet Machining of High Volume Fraction SiCp/Al Composite using Electrolyte of Sodium Chloride. IOP Conf. Ser. Earth Environ. Sci. 2020, 440, 022006. [Google Scholar] [CrossRef]

- Ao, S.; Qin, X.; Li, K.; Luo, Z. Effects of process parameters on jet electrochemical machining of SiC particle-reinforced aluminum matrix composites. Int. J. Adv. Manuf. Technol. 2021, 112, 3351–3361. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, C.; Qiu, Y.; Guo, C. Investigation on Electrochemical Jet Machining of High Volume Fraction SiCp/Al Composite. Int. J. Electrochem. Sci. 2020, 15, 3164–3179. [Google Scholar] [CrossRef]

- Han, L.; Ming, P.; Niu, S.; Yang, G.; Li, D.; Cheng, K. Microfabricating Mirror-like Surface Precision Micro-Sized Amorphous Alloy Structures Using Jet-ECM Process. Micromachines 2024, 15, 375. [Google Scholar] [CrossRef]

- Srividya, K.; Ravichandran, S.; Thirunavukkarasu, M.; Veeranjaneyulu, I.; Satishkumar, P.; Bharadwaja, K.; Rao, N.S.; Subbiah, R.; Manikanta, J.E. Examination of electrochemical machining parameters for AA6082/ZrSiO4/SiC composite using Taguchi-ANN approach. Int. J. Interact. Des. Manuf.-Ijidem 2024, 18, 1459–1473. [Google Scholar] [CrossRef]

- Guo, C.; Du, X.; He, J.; Zhuang, W.; Xu, B. Fabrication of submillimetre structures on pure titanium by non-aqueous electrolyte jet machining. Int. J. Adv. Manuf. Technol. 2024, 134, 4283–4295. [Google Scholar] [CrossRef]

- Niu, S.; Huang, K.; Ming, P.; Wang, S.; Zhao, F.; Qin, G.; Liu, H. Jet Electrochemical Micromilling of Ti-6Al-4V Using NaCl–Ethylene Glycol Electrolyte. Micromachines 2024, 15, 173. [Google Scholar] [CrossRef] [PubMed]

- Hung, J.-C.; Yang, P.-J.; Lin, X.-H.; Jian, S.-Y.; Kao, C.-H.; Ferng, Y.-C.; Huang, Y.-S.; Jen, K.-K. Surface passivation and brightening of titanium-based AM materials using a robotic electrochemical mechanical polishing system. Int. J. Adv. Manuf. Technol. 2024, 134, 4339–4352. [Google Scholar] [CrossRef]

- Zhai, K.; Liang, Y.; Li, T.; Ma, S.; Du, L. Research on jet electrochemical machining with coaxial megasonic assistance. Ultrason. Sonochem. 2024, 110, 107054. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Chen, J.; Lyu, B.; Yuan, J. Material Removal and Surface Modification of Copper under Ultrasonic-Assisted Electrochemical Polishing. Processes 2024, 12, 1046. [Google Scholar] [CrossRef]

- Wu, G.; Jie, S.; Huang, Y.; Yang, Z.; Ye, W.; Yi, T.; Yao, J. Experimental Study of Laser-Assisted Jet Electrochemical Polishing of GH3044 Alloy. Chin. J. Lasers-Zhongguo Jiguang 2024, 51, 124–134. [Google Scholar] [CrossRef]

- Li, G.; Su, Z.; Zhao, T.; Wei, W.; Ding, S. Mechanism of Multi-Physical Fields Coupling in Macro-Area Processing via Laser-Electrochemical Hybrid Machining (LECM). Metals 2024, 14, 1390. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Wang, S.; Tang, W.; Xu, J.; Wang, H.; Fan, S.; Li, C.; Yang, M.; Yan, Z.; et al. Fabrication of high-quality surface and stray corrosion suppression mechanism with magnetic field assistance electrochemical micro-machining. J. Manuf. Process. 2023, 106, 12–18. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Tang, W.; Yang, M.; Wang, S.; Pang, G.; Zhang, Z.; Lan, Z. Magnetohydrodynamics Study on the Mechanism of Improving the Efficiency of Magnetic Field-Assisted Electrochemical Micro-Machining. J. Mater. Eng. Perform. 2023, 33, 7123–7132. [Google Scholar] [CrossRef]

- Wang, M.; Xu, J.; Fan, D.; Liu, C.; Wang, S.; Pang, G. The improvement of the surface morphology via magnetic field-assisted electrochemical machining. Int. J. Adv. Manuf. Technol. 2024, 133, 1823–1831. [Google Scholar] [CrossRef]

- Gao, C.; Liu, Z.; Qiu, Y.; Zhao, K. Modelling of Geometric Features of Micro-Channel Made using Abrasive Assisted Electrochemical Jet Machining. Int. J. Electrochem. Sci. 2020, 15, 94–108. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, C.; Yu, X.; Guo, C. Improving Machining Localization in Abrasive-Assisted Electrochemical Jet Machining of SiCp/Al Composites using Large Standoff Distance. Arab. J. Sci. Eng. 2021, 47, 8629–8642. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, C.; Zhao, K.; Guo, C. An Empirical Model for Controlling Characteristics of Micro Channel Machined Using Abrasive Assisted Electrochemical Jet Machining. Procedia CIRP 2018, 68, 719–724. [Google Scholar] [CrossRef]

- Lohrengel, M.M.; Rataj, K.P.; Münninghoff, T. Electrochemical Machining—Mechanisms of anodic dissolution. Electrochim. Acta 2016, 201, 348–353. [Google Scholar] [CrossRef]

- Natsu, W.; Ikeda, T.; Kunieda, M. Generating complicated surface with electrolyte jet machining. Precis. Eng. 2007, 31, 33–39. [Google Scholar] [CrossRef]

- Kendall, T.; Bartolo, P.; Gillen, D.; Diver, C. A review of physical experimental research in jet electrochemical machining. Int. J. Adv. Manuf. Technol. 2019, 105, 651–667. [Google Scholar] [CrossRef]

- Liu, W.; Ao, S.; Li, Y.; Liu, Z.; Wang, Z.; Luo, Z.; Wang, Z.; Song, R. Jet electrochemical machining of TB6 titanium alloy. Int. J. Adv. Manuf. Technol. 2016, 90, 2397–2409. [Google Scholar] [CrossRef]

- Speidel, A.; Bisterov, I.; Saxena, K.K.; Zubayr, M.; Reynaerts, D.; Natsu, W.; Clare, A.T. Electrochemical jet manufacturing technology: From fundamentals to application. Int. J. Mach. Tools Manuf. 2022, 180, 103931. [Google Scholar] [CrossRef]

- Liu, W.; Luo, Z.; Li, Y.; Liu, Z.; Li, K.; Xu, J.; Ao, S. Investigation on parametric effects on groove profile generated on Ti1023 titanium alloy by jet electrochemical machining. Int. J. Adv. Manuf. Technol. 2018, 100, 2357–2370. [Google Scholar] [CrossRef]

- Liu, W.; Ao, S.; Li, Y.; Liu, Z.; Zhang, H.; Manladan, S.M.; Luo, Z.; Wang, Z. Effect of Anodic Behavior on Electrochemical Machining of TB6 Titanium Alloy. Electrochim. Acta 2017, 233, 190–200. [Google Scholar] [CrossRef]

- Hackert-Oschätzchen, M.; Martin, A.; Meichsner, G.; Zinecker, M.; Schubert, A. Microstructuring of carbide metals applying Jet Electrochemical Machining. Precis. Eng. 2013, 37, 621–634. [Google Scholar] [CrossRef]

- Hackert-Oschätzchen, M.; Paul, R.; Martin, A.; Meichsner, G.; Lehnert, N.; Schubert, A. Study on the dynamic generation of the jet shape in Jet Electrochemical Machining. J. Mater. Process. Technol. 2015, 223, 240–251. [Google Scholar] [CrossRef]

- Wang, J.; Shen, C.; Zhou, P.; Yan, Y.; Guo, D. Effects of Circular Hydraulic Jump on the Material Removal Characteristics of Jet Electrochemical Machining. J. Electrochem. Soc. 2023, 170, 113508. [Google Scholar] [CrossRef]

- Wu, M.; Guo, Z.; Qian, J.; Reynaerts, D. Multi-Ion-Based Modelling and Experimental Investigations on Consistent and High-Throughput Generation of a Micro Cavity Array by Mask Electrolyte Jet Machining. Micromachines 2022, 13, 2165. [Google Scholar] [CrossRef]

- Clare, A.T.; Speidel, A.; Bisterov, I.; Jackson-Crisp, A.; Mitchell-Smith, J. Precision enhanced electrochemical jet processing. CIRP Ann. 2018, 67, 205–208. [Google Scholar] [CrossRef]

- Yahyavi Zanjani, M.; Hackert-Oschätzchen, M.; Martin, A.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Control in Jet Electrochemical Machining of Stainless Steel through Inline Metrology of Current Density. Micromachines 2019, 10, 261. [Google Scholar] [CrossRef]

- Lu, J.; Guan, J.; Dong, B.; Zhao, Y. Control principle of anodic discharge for enhanced performance in jet-electrochemical discharge machining of semiconductor 4H-SiC. J. Manuf. Process. 2023, 92, 435–452. [Google Scholar] [CrossRef]

- Lu, J.; Zhan, S.; Liu, B.; Zhao, Y. Plasma-enabled electrochemical jet micromachining of chemically inert and passivating material. Int. J. Extrem. Manuf. 2022, 4, 045101. [Google Scholar] [CrossRef]

- Lu, J.; Liu, S.; Zhao, Y. Enabling Jet-Electrochemical Discharge Machining on Niobium-Like Passivating Metal and the Single Step Fabrication of Coated Microstructures. J. Electrochem. Soc. 2023, 170, 093508. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, J.; Wu, S.; Kang, X.; Gu, L.; Zhao, W. Material Removal Mechanism in Photocatalytic−Assisted Jet Electrochemical Machining of SiCp/Al. Micromachines 2022, 13, 1482. [Google Scholar] [CrossRef]

- Acharya, B.R.; Sethi, A.; Nayak, D.; Saha, P.; Pratihar, D.K. Selection of a Suitable Ethylene Glycol-based Mixed Electrolyte for Electrochemical Micro-drilling of Ti6Al4V. J. Electrochem. Soc. 2025, 172, 063502. [Google Scholar] [CrossRef]

- Guo, C.; He, J.; Zhuang, W.; Li, K.; Li, D. Fabrication of Dimples by Jet-ECM of Zr-Based Bulk Metallic Glasses with NaCl-Ethylene Glycol Electrolyte. Micromachines 2023, 14, 2196. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Wang, Z.; Wang, J.; Liang, H.; Lian, H. Investigation of the microhole arrays generated by masked jet electrochemical machining with polyaluminum chloride electrolyte. Precis. Eng. 2023, 82, 370–382. [Google Scholar] [CrossRef]

- Liu, Y.; Ouyang, P.; Zhang, Z.; Wang, Y.; Zhu, H.; Xu, K. Electrochemical dissolution behavior and electrochemical jet machining characteristics of titanium alloy in high concentration salt solution. Int. J. Adv. Manuf. Technol. 2023, 129, 3595–3607. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, X.; Qu, N.; Zhang, Z.; Lu, J. Simultaneous gas electrical discharge and electrochemical jet micromachining of titanium alloy in high-conductivity salt solution. J. Mater. Process. Technol. 2023, 317, 118000. [Google Scholar] [CrossRef]

- Liu, W.; Luo, Z.; Kunieda, M. Electrolyte jet machining of Ti1023 titanium alloy using NaCl ethylene glycol-based electrolyte. J. Mater. Process. Technol. 2020, 283, 116731. [Google Scholar] [CrossRef]

- Speidel, A.; Mitchell-Smith, J.; Walsh, D.A.; Hirsch, M.; Clare, A. Electrolyte Jet Machining of Titanium Alloys Using Novel Electrolyte Solutions. Procedia CIRP 2016, 42, 367–372. [Google Scholar] [CrossRef]

- Liu, Z.; Nouraei, H.; Spelt, J.K.; Papini, M. Electrochemical slurry jet micro-machining of tungsten carbide with a sodium chloride solution. Precis. Eng. 2015, 40, 189–198. [Google Scholar] [CrossRef]

- Guo, J.; Zhu, D.; Zhu, D.; Hou, Z. Investigation of the stray corrosion of Inconel 718 at low current density in NaNO3 solution. Int. J. Adv. Manuf. Technol. 2023, 128, 3149–3159. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, Z.; Bao, J.; Zhu, D. Reduction of stray corrosion by using iron coating in NaNO3 solution during electrochemical machining. Int. J. Adv. Manuf. Technol. 2015, 76, 1365–1370. [Google Scholar] [CrossRef]

- Ge, Z.; Wu, H.; Hu, Q.; Zhu, H.; Zhu, Y. Uniformity enhancement of flow field through optimizing nozzle structure for jet electrochemical machining. Int. J. Electrochem. Sci. 2024, 19, 100809. [Google Scholar] [CrossRef]

- Kendall, T.; Diver, C.; Gillen, D.; Bartolo, P. New insights on manipulating the material removal characteristics of Jet-Electrochemical machining through nozzle design. Int. J. Adv. Manuf. Technol. 2021, 118, 1009–1026. [Google Scholar] [CrossRef]

- Wang, F.; Yuan, X.; Zhou, C.; Wan, Y.; Wang, T.; Wu, X. Multi-physical field simulation and experimental research on inner-jet through-mask electrochemical machining of micro-pit arrays. Int. J. Electrochem. Sci. 2025, 20, 101079. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Q.; Qu, N.; Li, H. Improving material removal rate in electrolyte jet machining using stepped cathode tool. Int. J. Adv. Manuf. Technol. 2025, 137, 645–657. [Google Scholar] [CrossRef]

- Li, J.; Wang, D.; Zhu, D. Electrochemical dissolution behavior of cast and forged Ti2 AlNb alloys in NaCl and NaNO3 electrolytes. Electrochim. Acta 2024, 505, 144966. [Google Scholar] [CrossRef]

- Kong, H.; Qu, N. Jet electrochemical milling of Ti-6Al-4 V alloy with ultra-high current density. Int. J. Adv. Manuf. Technol. 2023, 129, 4091–4100. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, N.; Qiu, Z. Flow field simulation and experimental investigation on macro electrolyte jet electrochemical turning of TB6 titanium alloy. Int. J. Adv. Manuf. Technol. 2022, 120, 2617–2632. [Google Scholar] [CrossRef]

- Wang, M.; Qu, N. Macro electrolyte jet machining of TC4 titanium alloy using negative-incidence jet form. J. Mater. Process. Technol. 2021, 294, 117148. [Google Scholar] [CrossRef]

- Wang, X.; Qu, N.; Fang, X. Reducing stray corrosion in jet electrochemical milling by adjusting the jet shape. J. Mater. Process. Technol. 2019, 264, 240–248. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, C.; Wang, S.; Kakudo, S.; Kunieda, M. Selective and localized embrittlement of metal by cathodic hydrogenation utilizing electrochemical jet. Precis. Eng. 2020, 65, 259–268. [Google Scholar] [CrossRef]

- Zhang, X.; Song, X.; Ming, P.; Li, X.; Zeng, Y.; Cai, J. The Effect of Electrolytic Jet Orientation on Machining Characteristics in Jet Electrochemical Machining. Micromachines 2019, 10, 404. [Google Scholar] [CrossRef] [PubMed]

- Xinchao, L.; Pingmei, M.; Xinmin, Z.; Yanhua, Z.; Xudong, S.; Ge, Q.; Xingshuai, Z. Kerosene-Submerged Horizontal Jet Electrochemical Machining with High Localization. J. Electrochem. Soc. 2019, 166, E453–E464. [Google Scholar] [CrossRef]

- Li, X.; Ming, P.; Zhang, X.; Niu, S.; Zheng, X.; Yan, L.; Wang, W.; Zhang, Y. Study on Kerosene-submerged Jet Electrochemical Machining and Optimization of the Electrochemical Machining Parameters. Int. J. Electrochem. Sci. 2021, 16, 151030. [Google Scholar] [CrossRef]

- Wu, M.; Liu, J.; He, J.; Chen, X.; Guo, Z. Fabrication of surface microstructures by mask electrolyte jet machining. Int. J. Mach. Tools Manuf. 2020, 148, 103471. [Google Scholar] [CrossRef]

- Hao, X.; Wang, L.; Wang, Q.; Guo, F.; Tang, Y.; Ding, Y.; Lu, B. Surface micro-texturing of metallic cylindrical surface with proximity rolling-exposure lithography and electrochemical micromachining. Appl. Surf. Sci. 2011, 257, 8906–8911. [Google Scholar] [CrossRef]

- Qu, N.; Chen, X.; Li, H.; Zhu, D. Fabrication of PDMS micro through-holes for electrochemical micromachining. Int. J. Adv. Manuf. Technol. 2014, 72, 487–494. [Google Scholar] [CrossRef]

- Ming, P.; Bao, X.; Hao, Q.; Wang, J. Fabrication of through-hole with biconically shaped cross sections by using electroforming and inert metal mask electrochemical machining. Int. J. Adv. Manuf. Technol. 2015, 76, 501–512. [Google Scholar] [CrossRef]

- Hung, J.-C.; Liu, J.-H.; Fan, Z.-W. Fabrication of microscale concave and grooves through mixed-gas electrochemical jet machining. Precis. Eng. 2019, 55, 310–321. [Google Scholar] [CrossRef]

- Shanu, A.; Dixit, P. Investigation of Debris Removal Mechanism in Ultrasonic-Assisted Electrochemical Discharge Machining. J. Electrochem. Soc. 2025, 172, 063505. [Google Scholar] [CrossRef]

- Sonia, P.; Jain, J.K.; Saxena, K.K. Influence of ultrasonic vibration assistance in manufacturing processes: A Review. Mater. Manuf. Process. 2021, 36, 1451–1475. [Google Scholar] [CrossRef]

- Tong, W.; He, K.; Wang, X.; Xu, X.; Wang, M. Mechanism of 6061 aluminum material erosion in USEMM. Int. J. Adv. Manuf. Technol. 2021, 118, 895–906. [Google Scholar] [CrossRef]

- Goel, H.; Rath, U.; Pandey, P.M. Modelling and simulation of ultrasonic-assisted jet electrochemical micro drilling process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4199–4212. [Google Scholar] [CrossRef]

- Singh, H.; Jain, P.K. Study on ultrasonic-assisted electrochemical honing of bevel gears. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 705–712. [Google Scholar] [CrossRef]

- Skoczypiec, S. Research on ultrasonically assisted electrochemical machining process. Int. J. Adv. Manuf. Technol. 2010, 52, 565–574. [Google Scholar] [CrossRef]

- Goel, H.; Pandey, P.M. Experimental Investigations and Statistical Modeling of Ultrasonic Assisted Jet Electrochemical Micro-Drilling Process with Pulsed DC. J. Adv. Manuf. Syst. 2019, 18, 413–434. [Google Scholar] [CrossRef]

- Goel, H.; Pandey, P.M. Experimental investigations into the ultrasonic assisted jet electrochemical micro-drilling process. Mater. Manuf. Process. 2017, 32, 1547–1556. [Google Scholar] [CrossRef]

- Goel, H.; Pandey, P.M. Performance evaluation of different variants of jet electrochemical micro-drilling process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 451–464. [Google Scholar] [CrossRef]

- Besekar, N.; Bhattacharyya, B. Vibration-Assisted Axial Nozzle Jet Flow Wire Electrochemical Machining for Micromachining. J. Micro Nano-Manuf. 2021, 9, 044501. [Google Scholar] [CrossRef]

- Besekar, N.; Bhattacharyya, B. Experimental investigation and characterization of NiTinol shape memory alloy during wire electrochemical machining. J. Manuf. Process. 2022, 81, 346–361. [Google Scholar] [CrossRef]

- Wang, J.; Chen, W.; Gao, F.; Han, F. Ultrasonically assisted electrochemical micro drilling with sidewall-insulated electrode. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 230, 466–474. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, C.; Li, H.; Li, Z.; He, G.; Jiang, W. Overall performance of Ni-Co-WC nanocomposite coatings prepared by ultrasonic vibration-assisted scanning jet electrodeposition. Surf. Coat. Technol. 2024, 477, 130362. [Google Scholar] [CrossRef]

- Yang, T.; Fang, X.; Hang, Y.; Xu, Z.; Zeng, Y. Workpiece vibration in feed direction assisted electrochemical cutting using tube electrode with inclined holes. Int. J. Adv. Manuf. Technol. 2021, 116, 2651–2660. [Google Scholar] [CrossRef]

- Mitchell-Smith, J.; Clare, A.T. ElectroChemical Jet Machining of Titanium: Overcoming Passivation Layers with Ultrasonic Assistance. Procedia CIRP 2016, 42, 379–383. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Y.; He, Z.; Peng, W. Deep micro-hole fabrication in EMM on stainless steel using disk micro-tool assisted by ultrasonic vibration. J. Mater. Process. Technol. 2016, 229, 475–483. [Google Scholar] [CrossRef]

- Wang, M.; Lv, M.; Zhang, R.; Tong, W.; Xu, X. Effect of ultrasonic cavitation micro-jet impact on corrosion of material in ultrasonic assisted electrochemical micromachining. J. Appl. Electrochem. 2023, 53, 1579–1593. [Google Scholar] [CrossRef]

- Minghao, L.; Yong, L.; Siying, L.; Kan, W.; Yong, J. Theoretical and experimental study on micro ultrasonic-assisted electrochemical drilling with high speed electrode. Int. J. Adv. Manuf. Technol. 2020, 107, 815–826. [Google Scholar] [CrossRef]

- Ling, S.; Li, M.; Liu, Y.; Wang, K.; Jiang, Y. Improving Machining Localization and Surface Roughness in Wire Electrochemical Micromachining Using a Rotating Ultrasonic Helix Electrode. Micromachines 2020, 11, 698. [Google Scholar] [CrossRef]

- Dalabehera, T.; Mullick, S.; Bartarya, G.; Shankar, R. Experimental analysis of electro-jet machining of thin metal sheets under the application of ultrasonic vibration, continuous and pulsed direct current. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 237, 2290–2299. [Google Scholar] [CrossRef]

- Yang, Z.; Wu, G.; Shen, J.; Yin, Y.; Li, L.; Wang, Y.; Tian, Y.; Yao, J. Surface morphological characteristics and mechanisms of laser-assisted electrochemical polishing on Inconel 718 alloy. Opt. Laser Technol. 2025, 181, 111591. [Google Scholar] [CrossRef]

- Yu, M.; Du, L.; Du, B.; Wang, F.; Zhang, C.; Li, D. Efficient evolution mechanism of electrolytic gas products from laser-assisted electrolyte jet machining. J. Mater. Process. Technol. 2024, 333, 118617. [Google Scholar] [CrossRef]

- Malik, A.; Manna, A. Investigation on the laser-assisted jet electrochemical machining process for improvement in machining performance. Int. J. Adv. Manuf. Technol. 2018, 96, 3917–3932. [Google Scholar] [CrossRef]

- Pajak, P.T.; De Silva, A.K.M.; McGeough, J.A.; Harrison, D.K. Modelling the aspects of precision and efficiency in laser-assisted jet electrochemical machining (LAJECM). J. Mater. Process. Technol. 2004, 149, 512–518. [Google Scholar] [CrossRef]

- Pajak, P.T.; Desilva, A.K.M.; Harrison, D.K.; McGeough, J.A. Precision and efficiency of laser assisted jet electrochemical machining. Precis. Eng. 2006, 30, 288–298. [Google Scholar] [CrossRef]

- DeSilva, A.K.M.; Pajak, P.T.; Harrison, D.K.; McGeough, J.A. Modelling and Experimental Investigation of Laser Assisted Jet Electrochemical Machining. CIRP Ann. 2004, 53, 179–182. [Google Scholar] [CrossRef]

- De Silva, A.K.M.; Pajak, P.T.; McGeough, J.A.; Harrison, D.K. Thermal effects in laser assisted jet electrochemical machining. CIRP Ann. 2011, 60, 243–246. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, J.; Wang, J. Investigation of a novel hybrid process of laser drilling assisted with jet electrochemical machining. Opt. Lasers Eng. 2009, 47, 1242–1249. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, J. Laser drilling assisted with jet electrochemical machining for the minimization of recast and spatter. Int. J. Adv. Manuf. Technol. 2011, 62, 1055–1062. [Google Scholar] [CrossRef]

- Hua, Z.; Jiawen, X. Modeling and Experimental Investigation of Laser Drilling with Jet Electrochemical Machining. Chin. J. Aeronaut. 2010, 23, 454–460. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, P.; Xu, J.; Yuan, L. Effect of Electrochemical Dissolving in Laser Drilling Assisted with Jet Electrochemical Machining. Int. J. Electrochem. Sci. 2021, 16, 21056. [Google Scholar] [CrossRef]

- Yuan, L.; Xu, J.; Zhao, J.; Zhang, H. Research on Hybrid Process of Laser Drilling With Jet Electrochemical Machining. J. Manuf. Sci. Eng. 2012, 134, 064502. [Google Scholar] [CrossRef]

- Long, Y.; Liu, Q.; Zhong, Z.; Xiong, L.; Shi, T. Experimental study on the processes of laser-enhanced electrochemical micromachining stainless steel. Opt.-Int. J. Light Electron Opt. 2015, 126, 1826–1829. [Google Scholar] [CrossRef]

- Malik, A.; Manna, A. Study on Precision Microholes Using Pulsed Laser with Jet Electrochemical Machining. Arab. J. Sci. Eng. 2017, 43, 4593–4608. [Google Scholar] [CrossRef]

- Malik, A.; Manna, A. Multi-response optimization of laser-assisted jet electrochemical machining parameters based on gray relational analysis. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 148. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, F.; Zhang, G.; Zhang, W. Fabrication of deep and small holes by synchronized laser and shaped tube electrochemical machining (Laser-STEM) hybrid process. Int. J. Adv. Manuf. Technol. 2019, 105, 2721–2731. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W. Theoretical and experimental study on hybrid laser and shaped tube electrochemical machining (Laser-STEM) process. Int. J. Adv. Manuf. Technol. 2021, 112, 1601–1615. [Google Scholar] [CrossRef]

- Saxena, K.K.; Qian, J.; Reynaerts, D. A tool-based hybrid laser-electrochemical micromachining process: Experimental investigations and synergistic effects. Int. J. Mach. Tools Manuf. 2020, 155, 103569. [Google Scholar] [CrossRef]

- Saxena, K.K.; Qian, J.; Reynaerts, D. Development and investigations on a hybrid tooling concept for coaxial and concurrent application of electrochemical and laser micromachining processes. Precis. Eng. 2020, 65, 171–184. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, C.; Mao, S.; Zhang, Z.; Zhao, D.; Xu, K.; Liu, Y.; Li, L.; Zhou, J. Localized and efficient machining of germanium based on the auto-coupling between picosecond laser irradiation and electrochemical dissolution: Mechanism validation and surface characterization. J. Manuf. Process. 2022, 77, 665–677. [Google Scholar] [CrossRef]

- Zhu, H.; Jiang, Z.; Han, J.; Saetang, V.; Xu, K.; Liu, Y.; Zhang, Z.; Huang, S.; Zhou, J. Fabrication of oxide-free dimple structure on germanium via electrochemical jet machining enhanced by opposing laser irradiation. J. Manuf. Process. 2023, 85, 623–635. [Google Scholar] [CrossRef]

- Speidel, A.; Lutey, A.H.A.; Mitchell-Smith, J.; Rance, G.A.; Liverani, E.; Ascari, A.; Fortunato, A.; Clare, A. Surface modification of mild steel using a combination of laser and electrochemical processes. Surf. Coat. Technol. 2016, 307, 849–860. [Google Scholar] [CrossRef]

- Duan, W.; Mei, X.; Fan, Z.; Li, J.; Wang, K.; Zhang, Y. Electrochemical corrosion assisted laser drilling of micro-hole without recast layer. Optik 2020, 202, 163577. [Google Scholar] [CrossRef]

- Peruri, S.R.; Chaganti, P.K. A review of magnetic-assisted machining processes. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 450. [Google Scholar] [CrossRef]

- Salman, L.A.; Ibrahim, A.F.; Hossien, B.M. The influence of magnetic field on the material removal rate in electrochemical machining process. Adv. Sci. Technol.-Res. J. 2025, 19, 356–365. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.-Y.; Tsai, T.-H.; Hourng, L.-W.; Wang, W.-k. The effects of magnetic field and ethanol addition on the electrochemical discharge machining. Int. J. Adv. Manuf. Technol. 2019, 105, 2461–2467. [Google Scholar] [CrossRef]

- Pang, G.; Cao, X.; Zhang, J.; Wang, S.; Lin, B.; Li, M.; Wang, M.; Zhang, Z. Mechanism Analysis of Electrochemical Micro-machining Behavior Assisted by Magnetic Field with Local Magnetic Induction Lines Deformation. Jom 2023, 75, 3249–3256. [Google Scholar] [CrossRef]

- Zhai, K.; Tang, L.; Liu, J.; Zhang, X.; Yan, Y.; Feng, X. Study on improving the surface roughness of multi-stage internal cone hole by rotating magnetic field assisted electrochemical machining. Int. J. Adv. Manuf. Technol. 2021, 115, 1227–1236. [Google Scholar] [CrossRef]

- Li, L.; Baoji, M.A. Effect of magnetic field on anodic dissolution in electrochemical machining. Int. J. Adv. Manuf. Technol. 2017, 94, 1177–1187. [Google Scholar] [CrossRef]

- Liao, C.J.; Zhang, X.M.; Luo, Z.J. Magnetic field effects on electrochemical dissolution behavior and surface quality of electrochemical machining of Ti-48Al-2Cr-2Nb alloy. J. Appl. Electrochem. 2022, 53, 49–63. [Google Scholar] [CrossRef]

- Zhang, C.; Zheng, P.; Liang, R.; Yun, K.; Jiang, X.; Yan, Z. Effects of a Magnetic Field on the Machining Accuracy for the Electrochemical Drilling of Micro Holes. Int. J. Electrochem. Sci. 2020, 15, 1148–1159. [Google Scholar] [CrossRef]

- Frotscher, O.; Schaarschmidt, I.; Lauwers, D.; Paul, R.; Meinke, M.; Steinert, P.; Schubert, A.; Schröder, W.; Richter, M. Investigation of Lorentz force–induced flow of NaNO3-electrolyte for magnetic field–assisted electrochemical machining. Int. J. Adv. Manuf. Technol. 2022, 121, 937–947. [Google Scholar] [CrossRef]

- Tsai, F.C.; Lee, Y.L.; Yeh, J.C. The technical development of titanium alloy surface process using electrochemical abrasive jet machining. Ind. Lubr. Tribol. 2018, 70, 1545–1551. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, C.; Zhao, K.; Wang, K. Machining of microchannel at SS316 surface using abrasive-assisted electrochemical jet machining. Int. J. Adv. Manuf. Technol. 2017, 95, 1143–1152. [Google Scholar] [CrossRef]

- Liu, Z.; Nouraei, H.; Papini, M.; Spelt, J.K. Abrasive enhanced electrochemical slurry jet micro-machining: Comparative experiments and synergistic effects. J. Mater. Process. Technol. 2014, 214, 1886–1894. [Google Scholar] [CrossRef]

- Zhao, K.; Gao, C.; Liu, Z.; Guo, C. Prediction of Surface Roughness in Abrasive Assisted Electrochemical Jet Machining of Micro-Channels. Int. J. Electrochem. Sci. 2018, 13, 5460–5473. [Google Scholar] [CrossRef]

- Yehia, H.M.; Hakim, M.; El-Assal, A. Effect of the Al2O3 powder addition on the metal removal rate and the surface roughness of the electrochemical grinding machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1538–1548. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, H.; Kim, J.G.; Chu, C.N. Fabrication of various shaped tungsten micro pin arrays using micro carving technology. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2017, 47, 389–396. [Google Scholar] [CrossRef]

- Singh, S.R.; Tak, M.; Mishra, S.K.; Mote, R.G. Investigation of Microstructural Effects on Electrochemical Micro-machining Behaviour of Inconel 718 Superalloy in Mixed Solution of NaNO3 and NaOH. J. Electrochem. Soc. 2025, 172, 053504. [Google Scholar] [CrossRef]

- Cebi, A.; Demirtas, H.; Kaleli, A. Implementation of robotic electrochemical machining in freeform surface machining with material removal rate prediction using different machine learning algorithms. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2024, 238, 3835–3849. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, Z.; Chen, F.; Lu, J.; Shen, Z.; Wang, S.; Cao, L. Machine Learning Intelligent Assisted Correction of Tool Cathode for Blisk Electrochemical Machining. Int. J. Precis. Eng. Manuf. 2025, 1–18. [Google Scholar] [CrossRef]

- Kasdekar, D.K.; Parashar, V.; Arya, C. Artificial neural network models for the prediction of MRR in Electro-chemical machining. Int. Conf. Process. Mater. Miner. Energy (PMME) 2016, 5, 772–779. [Google Scholar] [CrossRef]

- Wu, M.; Hazak Arshad, M.; Kumar Saxena, K.; Reynaerts, D.; Guo, Z.; Liu, J. Experimental and Numerical Investigations on Fabrication of Surface Microstructures Using Mask Electrolyte Jet Machining and Duckbill Nozzle. J. Manuf. Sci. Eng.-Trans. Asme 2023, 145, 051006. [Google Scholar] [CrossRef]

- Wang, S.; Liu, J.; Bao, C.; Zhu, D. Flow field design and experiment of high-efficiency electrochemical milling with large machining area. Chin. J. Aeronaut. 2025, 38, 103211. [Google Scholar] [CrossRef]

- Guo, C.; Gao, Y.; He, J.; Li, K.; Ye, L. Electrolyte jet machining of Zr-based amorphous alloys in non-aqueous medium with assistance of magnetic field. Int. J. Adv. Manuf. Technol. 2025, 137, 2851–2862. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, A.; He, J.; Xiao, H.; Li, D. An Investigation in Sub-Millimeter Channel Fabrication by the Non-Aqueous Electrolyte Jet Machining of Zr-Based Bulk Metallic Glasses. Micromachines 2023, 14, 2232. [Google Scholar] [CrossRef]

- Arshad, M.H.; Saxena, K.K.; Reynaerts, D. Hybrid laser-ECM processing of advanced materials in neutral electrolyte without aggressive reagents: Machining performance, removal characteristics and sustainability aspects. J. Clean. Prod. 2024, 467, 143034. [Google Scholar] [CrossRef]

- Cao, G.; Wu, H.; Wang, G.; Nie, L.; Yuan, K.; Ji, B. Electrochemical corrosion and product formation mechanism of M42 high-speed steel in NaH2PO4-Na2SO4 passivating electrolyte. Arab. J. Chem. 2024, 17, 105940. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Wang, K.; Qin, Y.; Wu, X. Electrochemical oxidation and corrosion behavior of 3D printed reaction-bonded silicon carbide ceramics in eco-friendly electrolyte. Ceram. Int. 2025, 51, 8997–9011. [Google Scholar] [CrossRef]

- Niu, S.; Wang, H.; Ming, P.; Qin, G.; Ren, L.; Liu, H.; Li, X. Electrochemical Properties and Jet Electrochemical Micromilling of (TiB+TiC)/Ti6Al4V Composites in NaCl+NaNO3 Mixed Electrolyte. Materials 2024, 17, 4904. [Google Scholar] [CrossRef]

- Wang, J.; Yang, S.; Zhang, J.; Zhang, Z.; Xue, W.; Zhu, H.; Xu, K.; Liu, Y. Corrosion Properties and Passive Film Interface of Inconel 718 in NaNO3 Solution for Laser-Assisted Electrochemical Machining. Langmuir 2024, 40, 14384–14398. [Google Scholar] [CrossRef]

- Pawar, A.B.; Chavan, S.S.; Jadhav, P.V.; Jadhav, D.B. Emerging trends in hybrid ECM: A review of multi-assisted machining techniques. Eng. Res. Express 2025, 7, 012504. [Google Scholar] [CrossRef]

- Ren, M.; Zhu, D.; Zhou, X.; Wang, Y.; Li, S. Surface quality enhancement in ultrasonic vibration-assisted electrochemical machining. Colloids Surf. A-Physicochem. Eng. Asp. 2024, 703, 135188. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Wang, T.; Xu, H.; Wang, K. A green and precision compound machining method for glass micro components—Ultrasonic assisted electrochemical discharge grinding with multi-hole tube electrode. Cirp J. Manuf. Sci. Technol. 2024, 52, 129–148. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Y.; Sun, C.; Wu, Q.; Yan, J.; Liu, Y.; Yao, J.; Zhang, W. Processing of titanium alloys with improved efficiency and accuracy by laser and electrochemical machining. Int. J. Adv. Manuf. Technol. 2024, 130, 4013–4025. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Shi, X.; Ouyang, P.; Zhang, Z.; Zhu, H.; Xu, K.; Liu, Y. Anodic dissolution behavior and microstructure preparation of nickel based superalloy in cryogenic-shielded and laser-assisted electrochemical machining. J. Mater. Process. Technol. 2025, 338, 118777. [Google Scholar] [CrossRef]

- Yang, C.; Qi, H.; Yang, X.; Lu, Z.; Duan, W.; Li, Z.; Wang, C.; Yang, Z. Multifield Simulation and Experimental Research on Laser Electrochemical Composite Micromachining. Nanomanuf. Metrol. 2025, 8, 4. [Google Scholar] [CrossRef]

- Singh, A.; Anandita, S.; Gangopadhyay, S. Microstructural Analysis and Multiresponse Optimization During ECM of Inconel 825 Using Hybrid Approach. Mater. Manuf. Process. 2015, 30, 842–851. [Google Scholar] [CrossRef]

- Sriram, D.; Sunil, B.D.Y.; Jeyakrishnan, S.; Rakesh, C.; Vijayakumar, S.; Kumar, A.; Cheepurupalli, N.R.; Sehgal, L. Investigation of different electrolyte effects on micro-hole machining of scrapped wheel alloy. Results Surf. Interfaces 2025, 18, 100429. [Google Scholar] [CrossRef]

- Mishra, D.K.; Verma, A.K.; Arab, J.; Maria, D.; Dixit, P. Numerical and experimental investigations into microchannel formation in glass substrate using electrochemical discharge machining. J. Micromech. Microeng. 2019, 29, 075004. [Google Scholar] [CrossRef]

- Janardhanan, N.K.; Perianna, H. Investigation on the effect of inclination angle of electrochemical machined deep inclined holes by hybrid multi genetic-based criteria decision making. Int. J. Adv. Manuf. Technol. 2025, 138, 4019–4041. [Google Scholar] [CrossRef]

- Saricicek, I.; Caydas, A.U.; Cihangir, S.; Say, Y. Effects of Magnetic Abrasive Finishing Process Parameters on the Inner Surface Machining of AISI 304 Austenitic Stainless Steel Pipes. J. Mater. Eng. Perform. 2025, 1–16. [Google Scholar] [CrossRef]

- Mandal, K.; Kalita, K.; Chakraborty, S. Gene expression programming for parametric optimization of an electrochemical machining process. Int. J. Interact. Des. Manuf.-Ijidem 2023, 17, 649–666. [Google Scholar] [CrossRef]

- Siva, M.; ArunKumar, N.; Ganesh, M.; Sathishkumar, N. Optimization of process parameters in micro electrochemical machining using TOPSIS technique with Analytical Hierarchy Process (AHP). Eng. Res. Express 2024, 6, 035534. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Hu, Y.; Liu, X.; Wang, X.; Wu, S.; Shi, H. High-Quality Manufacturing with Electrochemical Jet Machining (ECJM) for Processing Applications: A Comprehensive Review, Challenges, and Future Opportunities. Micromachines 2025, 16, 794. https://doi.org/10.3390/mi16070794

Huang Y, Hu Y, Liu X, Wang X, Wu S, Shi H. High-Quality Manufacturing with Electrochemical Jet Machining (ECJM) for Processing Applications: A Comprehensive Review, Challenges, and Future Opportunities. Micromachines. 2025; 16(7):794. https://doi.org/10.3390/mi16070794

Chicago/Turabian StyleHuang, Yong, Yi Hu, Xincai Liu, Xin Wang, Siqi Wu, and Hanqing Shi. 2025. "High-Quality Manufacturing with Electrochemical Jet Machining (ECJM) for Processing Applications: A Comprehensive Review, Challenges, and Future Opportunities" Micromachines 16, no. 7: 794. https://doi.org/10.3390/mi16070794

APA StyleHuang, Y., Hu, Y., Liu, X., Wang, X., Wu, S., & Shi, H. (2025). High-Quality Manufacturing with Electrochemical Jet Machining (ECJM) for Processing Applications: A Comprehensive Review, Challenges, and Future Opportunities. Micromachines, 16(7), 794. https://doi.org/10.3390/mi16070794