Fabrication of Air Cavity Structures Using DRIE for Acoustic Signal Confinement in FBAR Devices

Abstract

1. Introduction

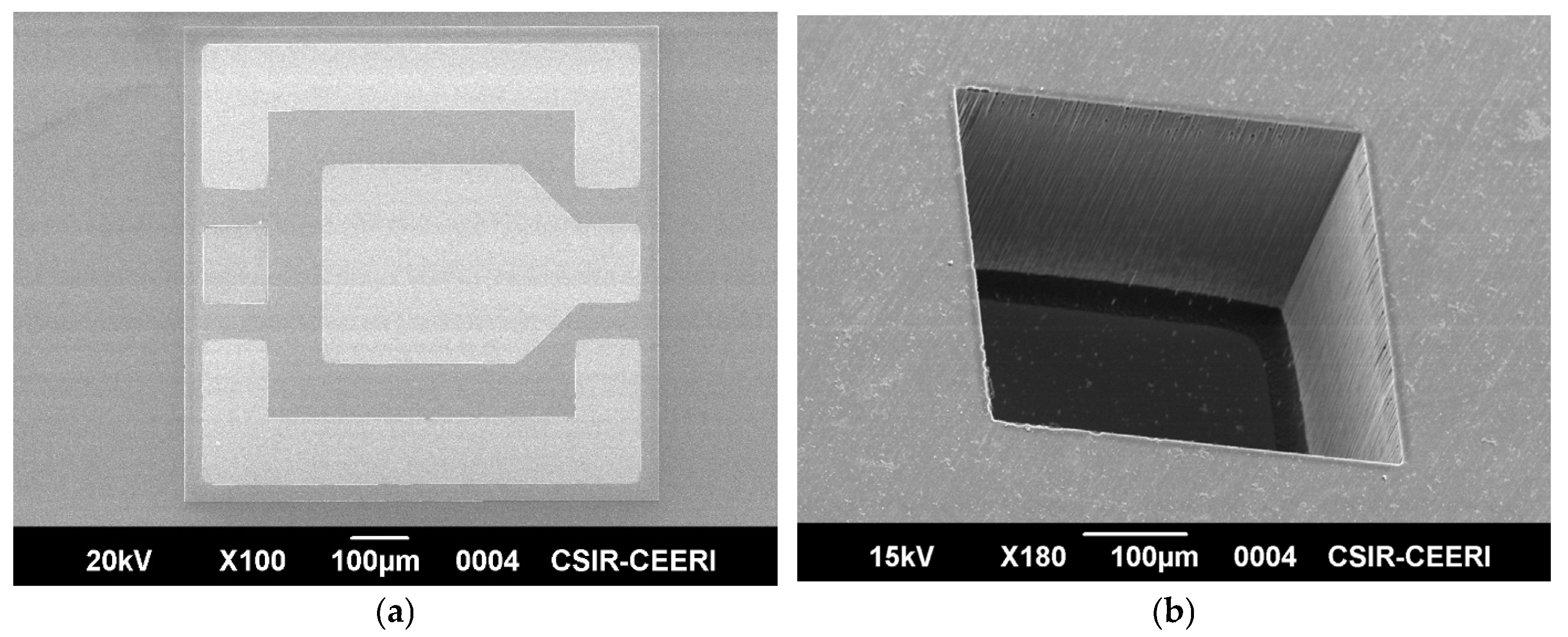

2. Device Fabrication

3. 1D Equivalent Circuit Modeling

4. Results and Discussion

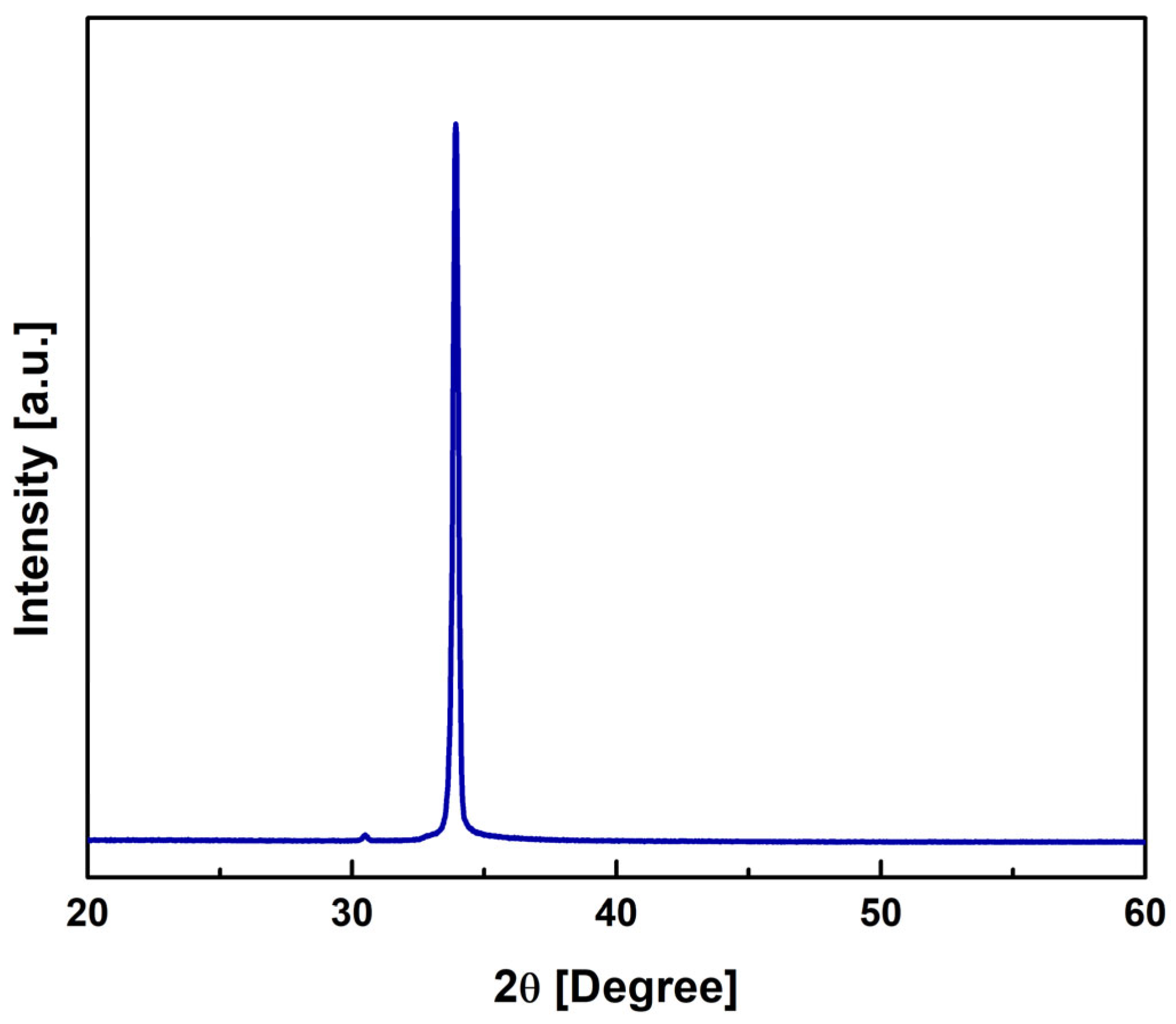

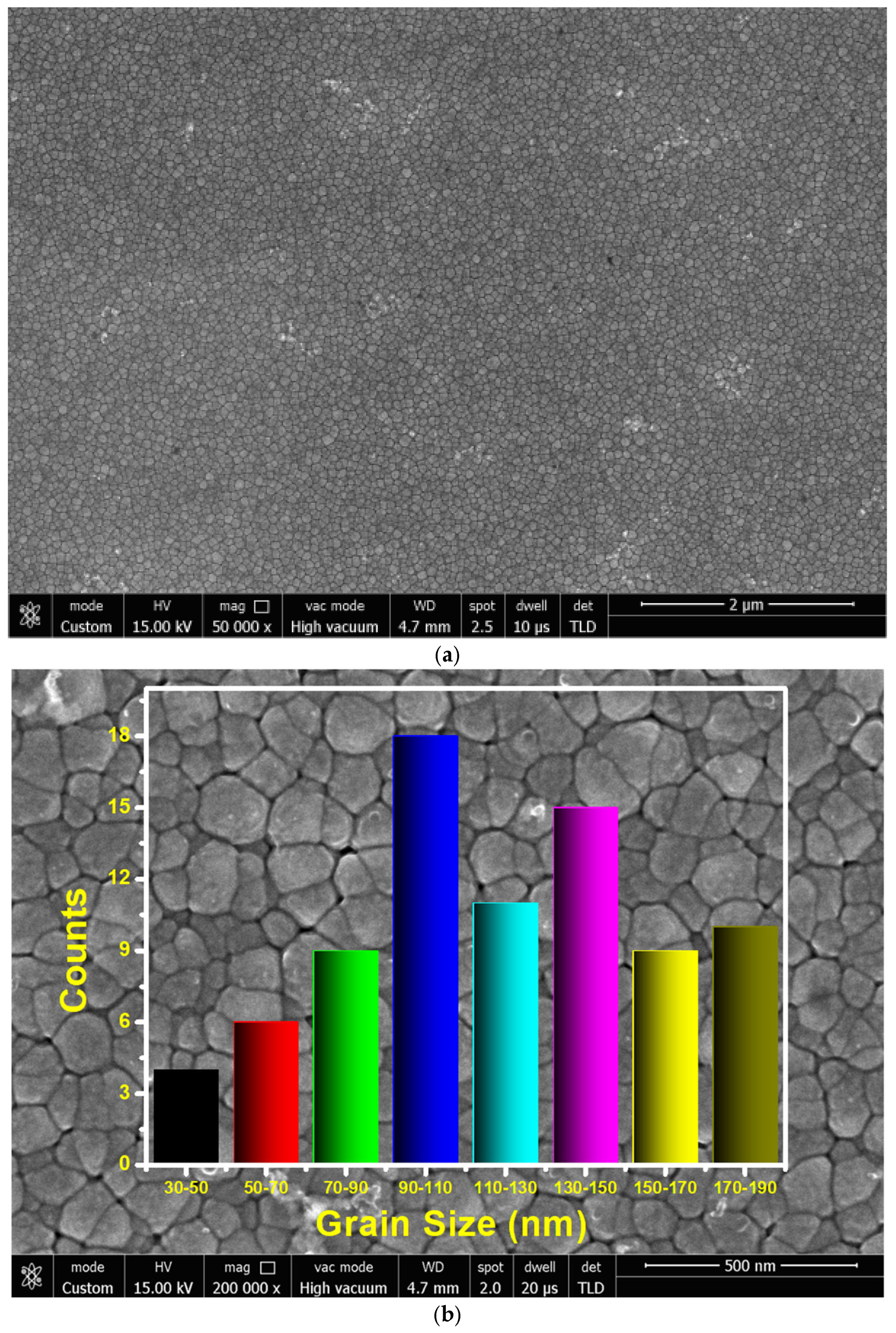

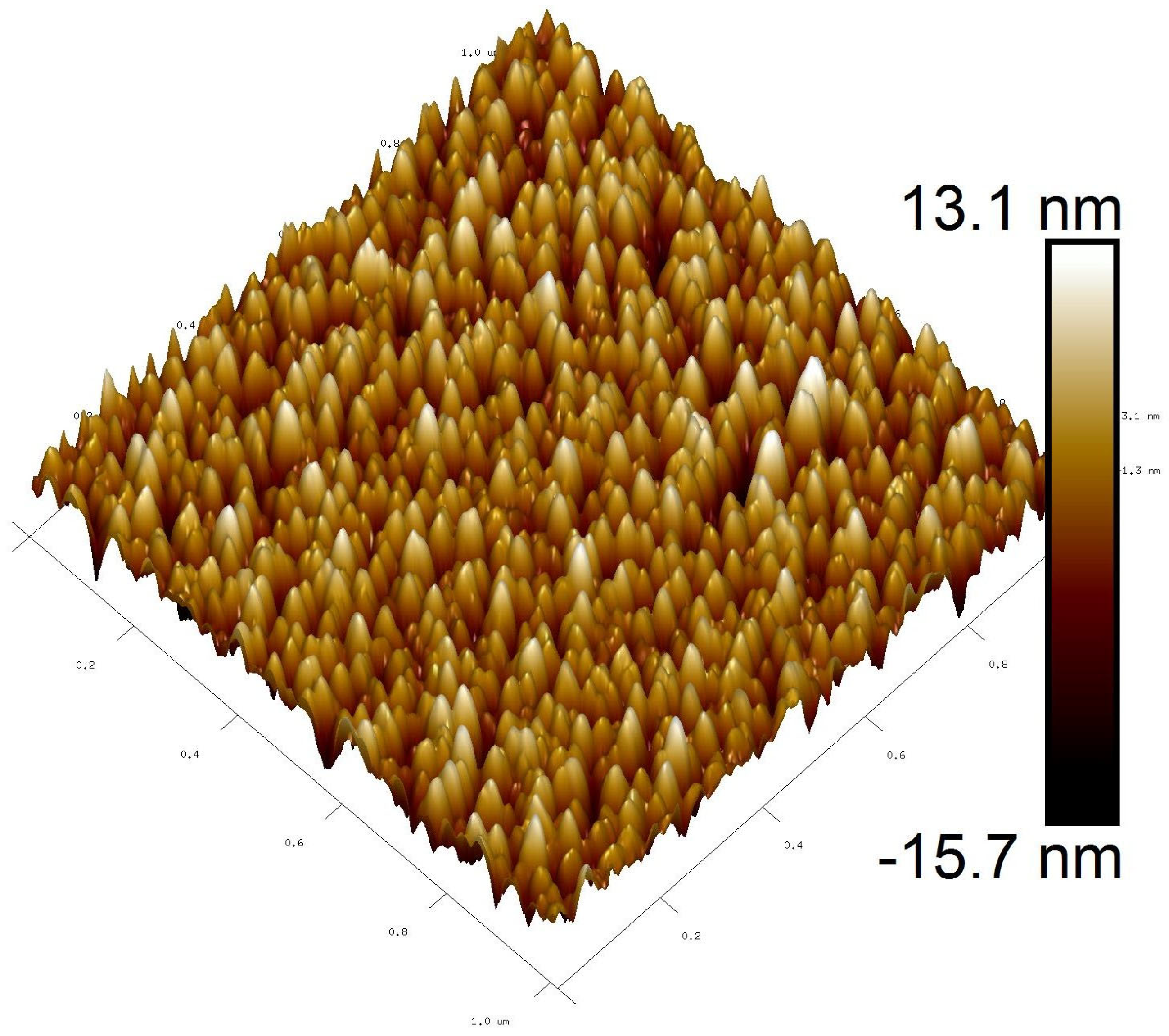

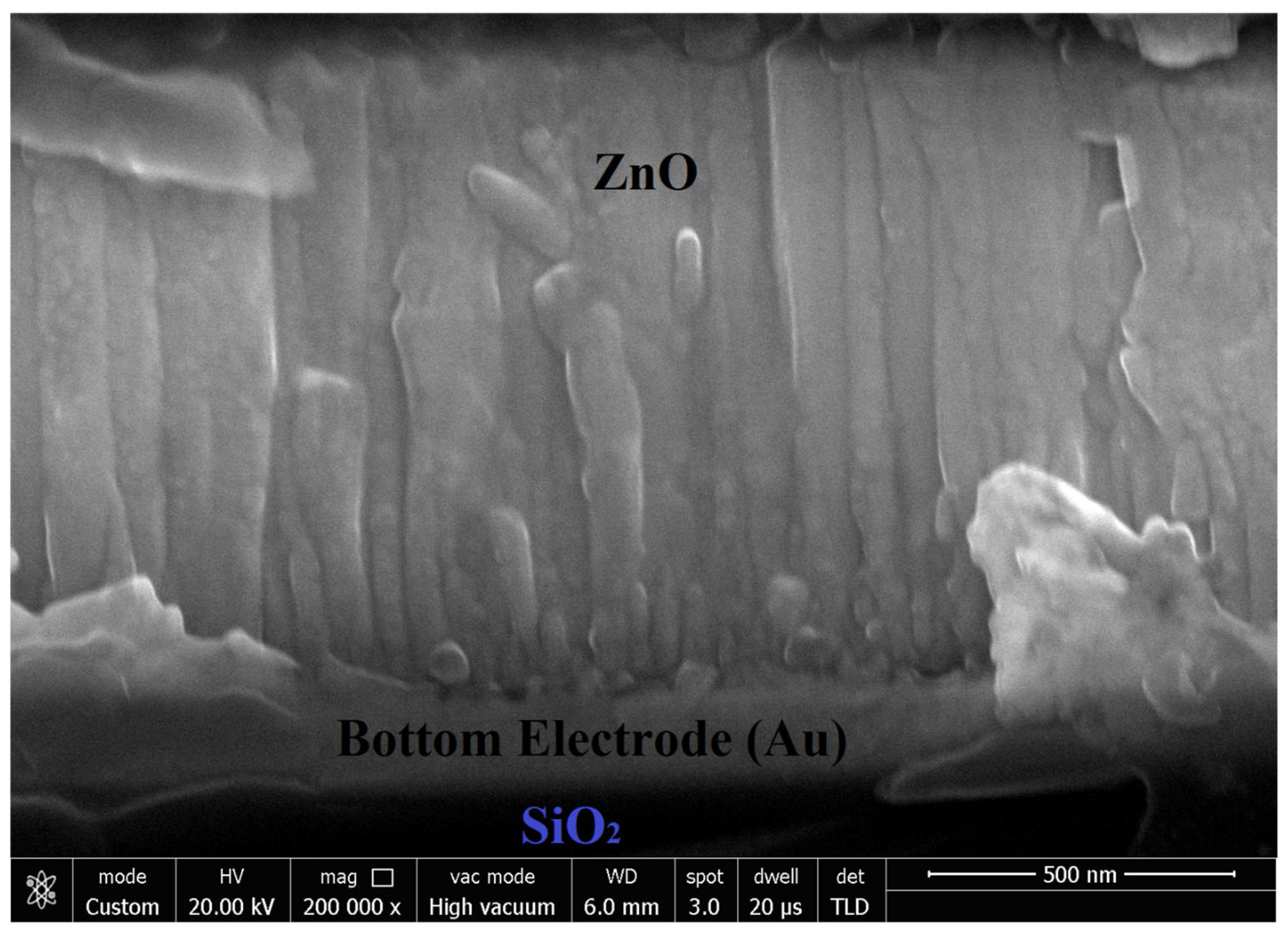

4.1. Structural and Surface Morphology Study

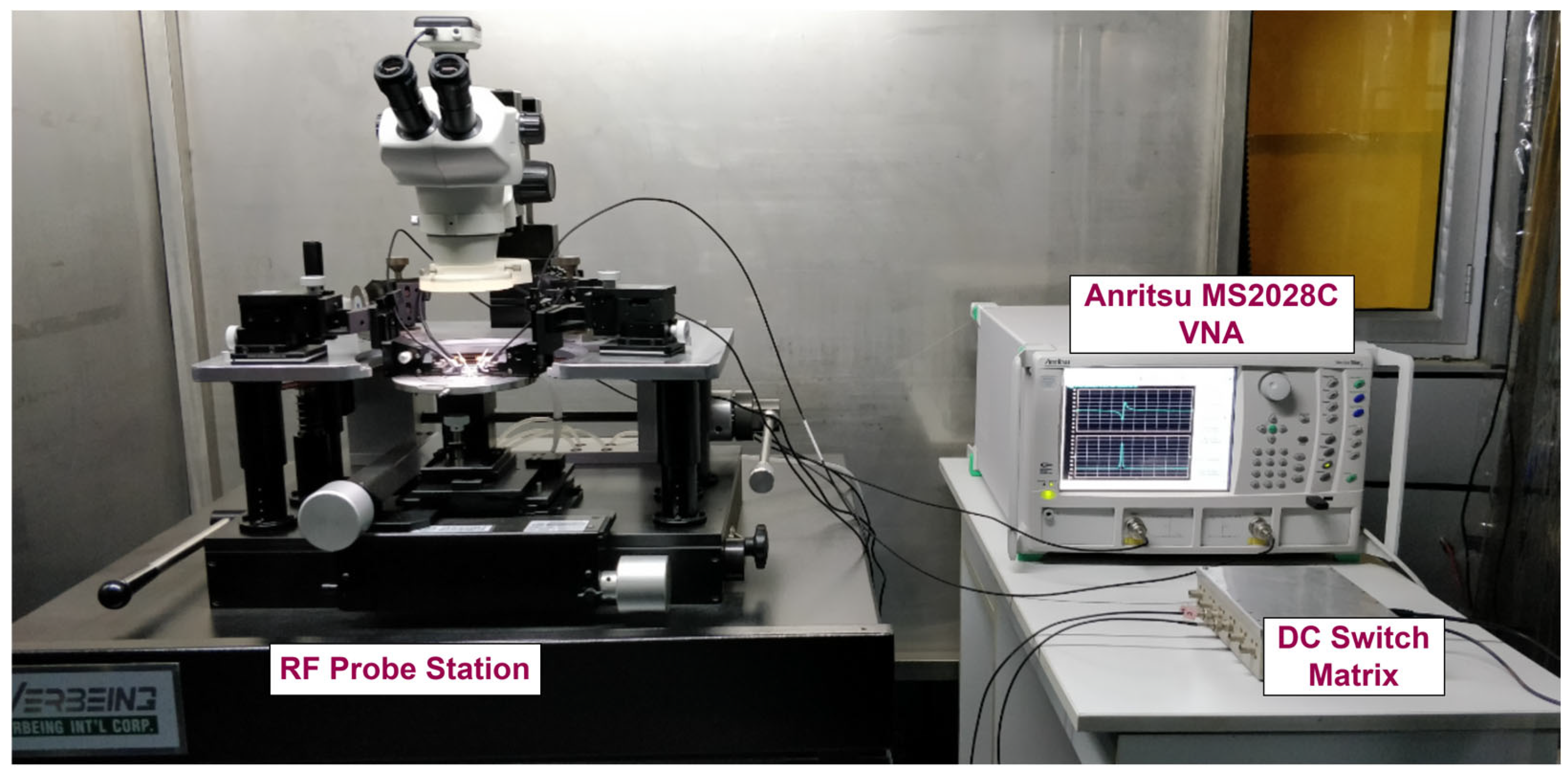

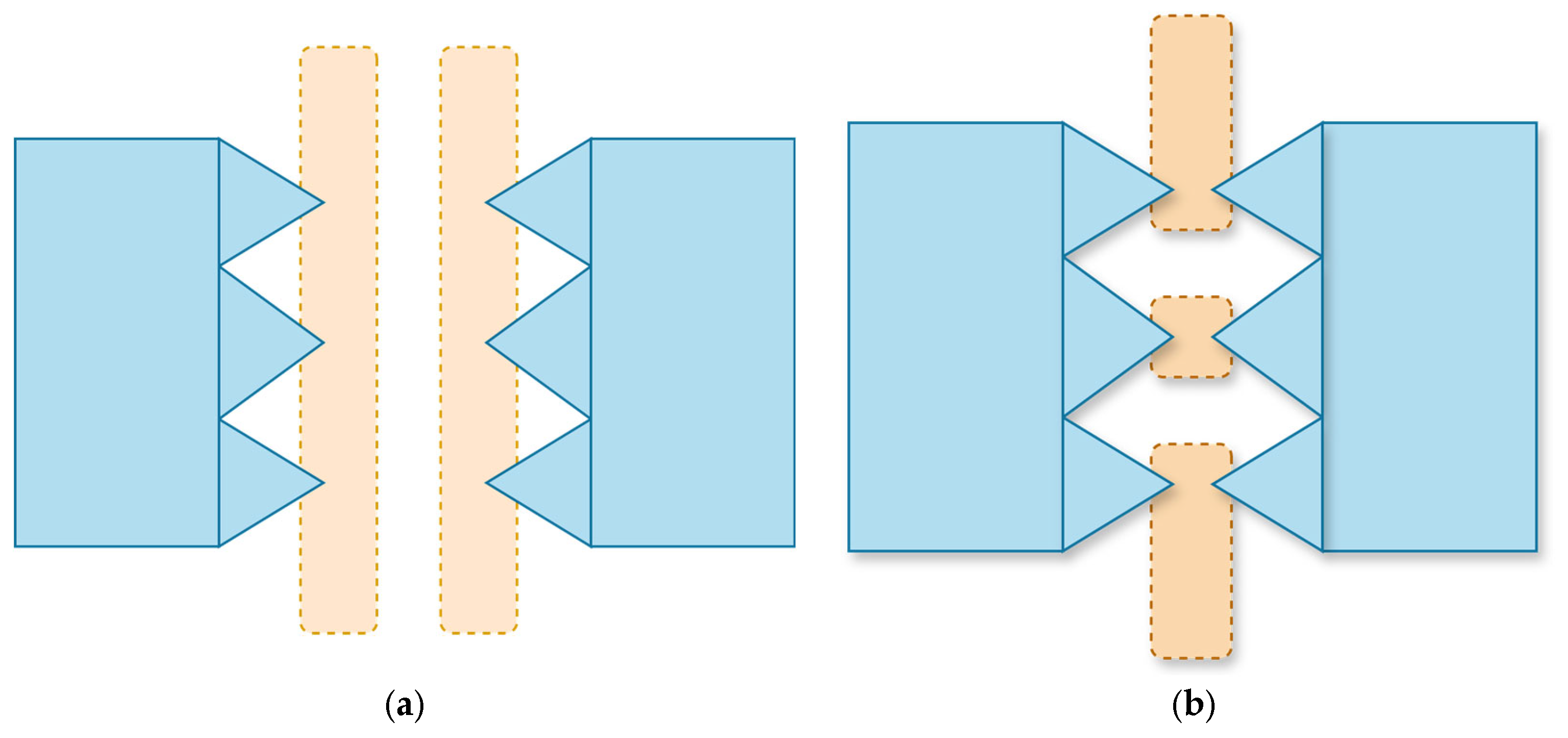

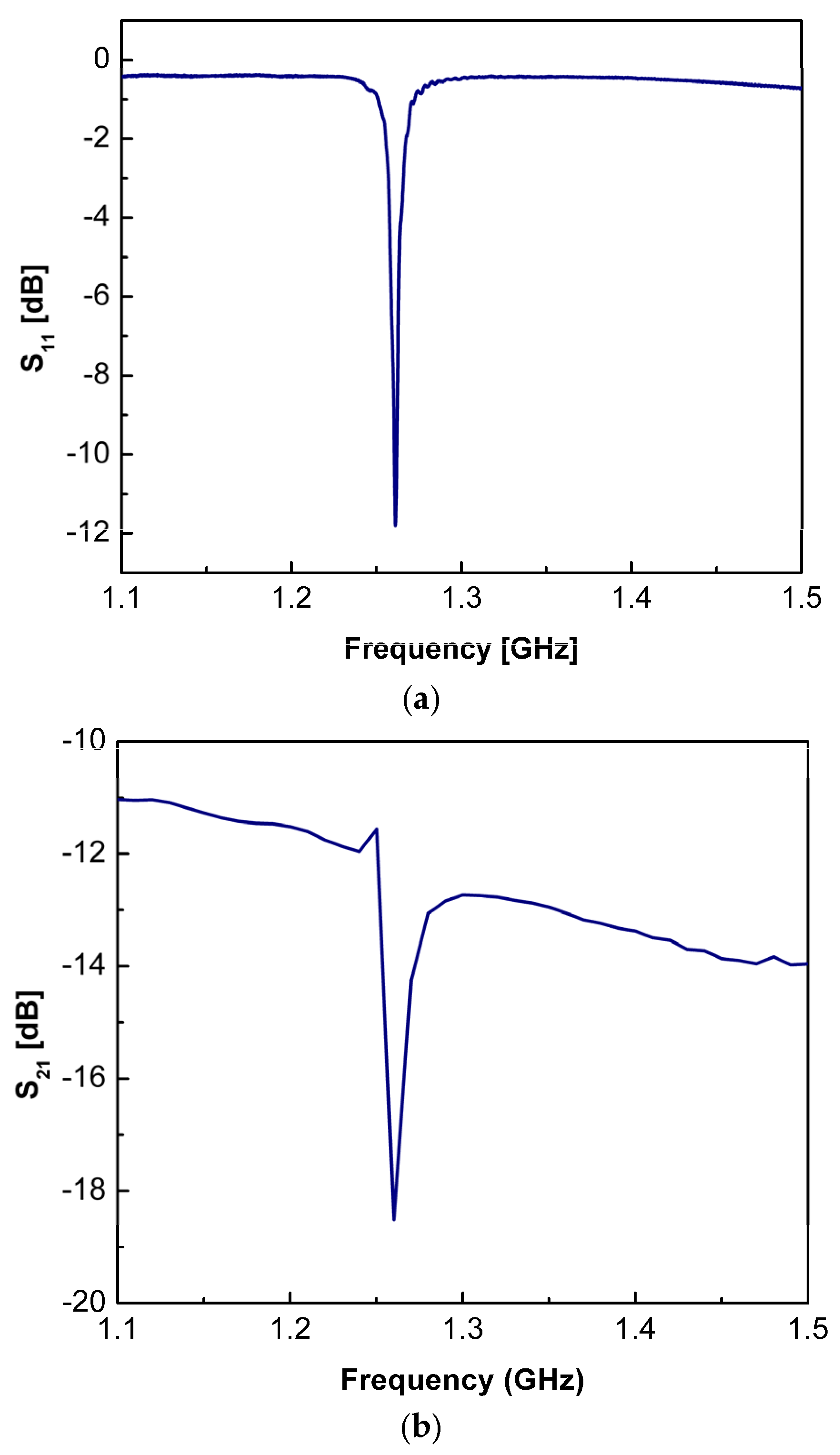

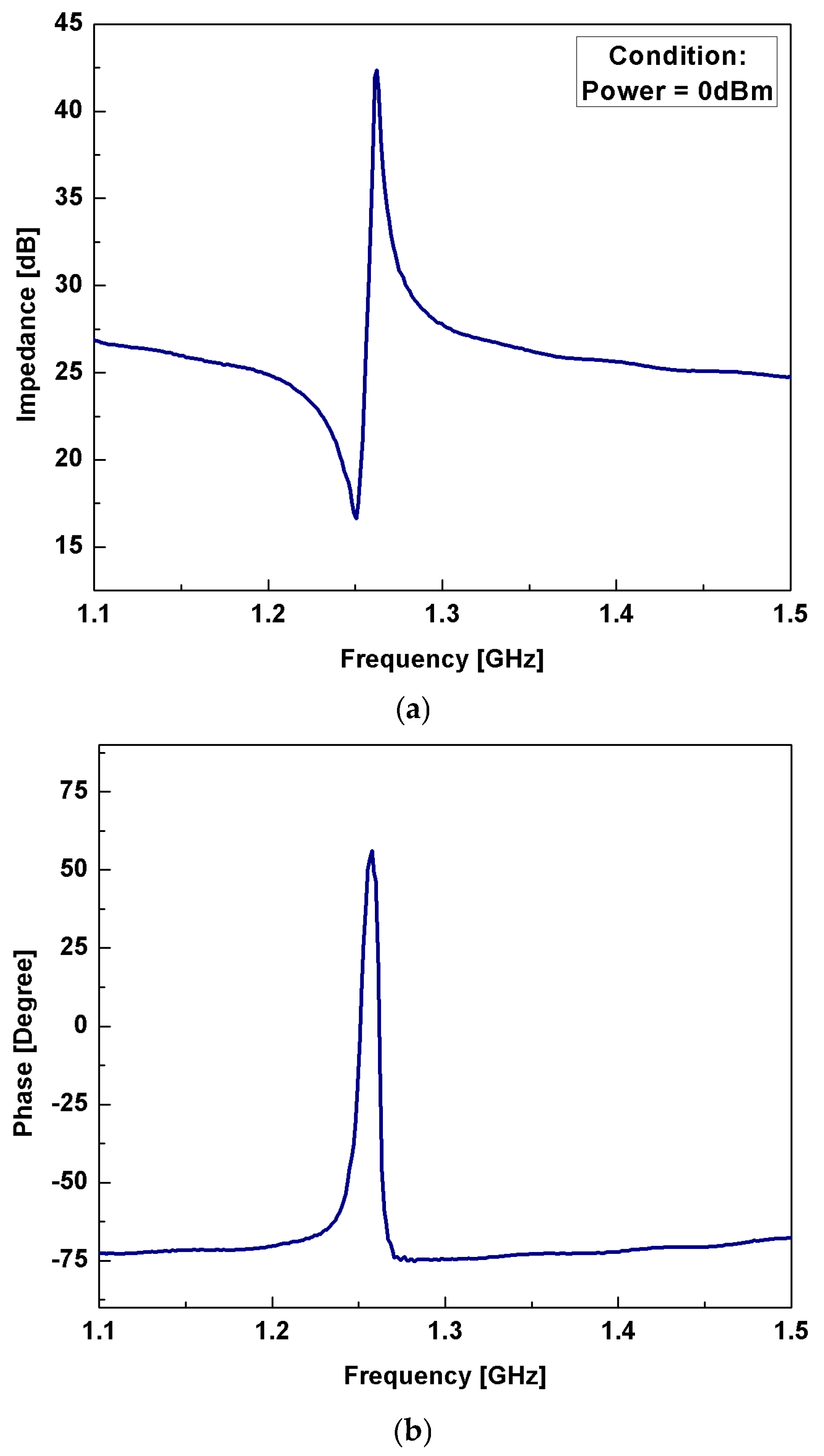

4.2. RF Characterization of FBAR

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DRIE | Deep reactive ion etching |

| PZE | Piezoelectric |

| ZnO | Zinc oxide |

| RF | Radio frequency |

| VOC | Volatile organic compounds |

| IDT | interdigital transducer |

| mBVD | Modified Butterworth–Van Dyke |

| TE | Thickness extension |

| SAW | Surface acoustic wave |

| FBAR | Film bulk acoustic resonator |

| PLD | pulsed laser deposition |

| MOCVD | Metalorganic chemical vapor deposition |

| TLM | Thickness longitudinal mode |

| TSM | Thickness shear mode |

References

- Cai, X.; Zhang, K.; Wu, J.; Li, J.; Jin, H.; Dong, S.; Chen, J.; Xuan, W.; Luo, J. Film Bulk Acoustic Resonators with 400 MHz Ultrawide-Range Tunability Using Crystalline PZT Thin Film. Mater. Sci. Semicond. Process. 2023, 167, 107817. [Google Scholar] [CrossRef]

- Wu, Z.; Niu, B.; Hong, Y.; Zhao, J.; Zhu, Y.; Yang, J. A Novel High-Q Lamé Mode Bulk Acoustic Resonator. MicroElectron Eng. 2025, 295, 112279. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Z.; Jin, S.; Bian, F.; Chang, Y.; Duan, X.; Men, X.; You, R. Investigation of Sorptive Interactions between Volatile Organic Compounds and Supramolecules at Dynamic Oscillation Using Bulk Acoustic Wave Resonator Virtual Sensor Arrays. Microsyst. Nanoeng. 2024, 10, 99. [Google Scholar] [CrossRef]

- Vinita; Pareek, D.; Masiul Islam, S.; Singh, J. Bulk Acoustic Wave Resonators for Sensing Applications: A Review. Sens. Actuators A Phys. 2024, 378, 115839. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L.; Yang, S.; Jia, W.; Zhang, S.; Gu, Y.; Lou, L.; Wu, G. Three-Dimensional Finite Element Analysis and Characterization of Quasi-Surface Acoustic Wave Resonators. Micromachines 2021, 12, 1118. [Google Scholar] [CrossRef]

- Wang, X.; Chang, Y.; Zhang, Q.; Liu, L.; Wang, X.; Wu, H. Design of a High Coupling SAW Resonator Based on an Al/41° Y-X LiNbO3/SiO2/Poly-Si/Si Structure for Wideband Filter. Micromachines 2025, 16, 323. [Google Scholar] [CrossRef]

- Kumar, P.; Vinita; Pawar, S.; Singh, J.; Kaur, D. Magnetic Field Tunable Ferromagnetic Shape Memory Alloy-Based SAW Resonator. IEEE Electron Device Lett. 2022, 43, 446–449. [Google Scholar] [CrossRef]

- Samanta, A.; Roy, S. Tunable Power-Phase Distributions in a Phonon-Magnon-Coupled Magnon Microwave Antenna for Reservoir Computing. Phys. Rev. Appl. 2024, 22, 054076. [Google Scholar] [CrossRef]

- Samanta, A.; Roy, S. Generation of Microwaves With Tuneable Frequencies in Ultracompact “Magnon Microwave Antenna” via Phonon-Magnon-Photon Coupling. IEEE Trans. Electron Devices 2023, 70, 335–342. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, N.; Sun, C.; Merugu, S.; Singh, N.; Gu, Y. A High Coupling Coefficient 2.3-GHz AlN Resonator for High Band LTE Filtering Application. IEEE Electron Device Lett. 2016, 37, 1344–1346. [Google Scholar] [CrossRef]

- Qin, Z.-H.; Wu, S.-M.; Wang, Y.; Liu, K.-F.; Wu, T.; Yu, S.-Y.; Chen, Y.-F. Solidly Mounted Longitudinally Excited Shear Wave Resonator (YBAR) Based on Lithium Niobate Thin-Film. Micromachines 2021, 12, 1039. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Wang, H.; Zhang, F.; Zhang, S.; Cao, G. A Spurious-Free SAW Filter Employing a Novel Transducer Structure on Bulk LiNbO3 Substrates. Sens. Actuators A Phys. 2024, 379, 115940. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, Z.-Y.; Re-Ching, L.; Sun, S.-J. Reliable Formulas for Accurately Determining the Resonance and Antiresonance Frequencies of Thin Film Bulk Acoustic Resonators. Phys. Scr. 2024, 99, 055920. [Google Scholar] [CrossRef]

- Zhu, Y.; Xia, P.; Liu, J.; Fang, Z.; Du, L.; Zhao, Z. Polyimide-Based High-Performance Film Bulk Acoustic Resonator Humidity Sensor and Its Application in Real-Time Human Respiration Monitoring. Micromachines 2022, 13, 758. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, X.; Wang, X.; Jin, H.; Li, S.; Dong, S.; Flewitt, A.J.; Milne, W.I.; Luo, J.K. Film Bulk Acoustic Resonators Integrated on Arbitrary Substrates Using a Polymer Support Layer. Sci. Rep. 2015, 5, 9510. [Google Scholar] [CrossRef]

- Niro, G.; Marasco, I.; Rizzi, F.; D’Orazio, A.; Grande, M.; De Vittorio, M. Design and Fabrication of a Flexible Gravimetric Sensor Based on a Thin-Film Bulk Acoustic Wave Resonator. Sensors 2023, 23, 1655. [Google Scholar] [CrossRef]

- Xu, J.; Liu, Z.; Zheng, J.; Qian, F.; Wong, M.; Yang, Y. Sealed-Cavity Bulk Acoustic Resonator for Subsequent Fabrication and Higher Order Mode. J. Microelectromech. Syst. 2024, 33, 3–5. [Google Scholar] [CrossRef]

- Ouyang, P.; Yi, X.; Li, G. Single-Crystalline Bulk Acoustic Wave Resonators Fabricated With AlN Film Grown by a Combination of PLD and MOCVD Methods. IEEE Electron Device Lett. 2024, 45, 538–541. [Google Scholar] [CrossRef]

- Patel, R.; Adhikari, M.S.; Boolchandani, D. Active Area Optimisation of Film Bulk Acoustic Resonator for Improving Performance Parameters. Electron. Lett. 2020, 56, 1191–1194. [Google Scholar] [CrossRef]

- Vinita; Chelvane, J.A.; Singh, J. Investigation of Magnetostrictive Film Bulk Acoustic Resonators (MFBAR) for Magnetic Field Sensing Applications. Sens. Actuators A Phys. 2023, 362, 114636. [Google Scholar] [CrossRef]

- Zhao, L.; Ouyang, P.; Yi, X.; Li, G. Highly Improved Quality Factor of the Film Bulk Acoustic Wave Resonator by Introducing a High Quality ZnO Buffer Layer. Appl. Surf. Sci. 2024, 660, 160025. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, K.; Luo, T.; Zhi, G.; Zhu, Y.; Ouyang, P.; Li, G. High-Performance Film Bulk Acoustic Resonator and Filter Based on an Al0.8 Sc0.2 N Film Prepared by a Low-Temperature Staged Deposition Method. IEEE Trans. Electron Devices 2025, 72, 383–389. [Google Scholar] [CrossRef]

- Cui, J.; Wu, X.; Chen, Y.; Ye, Y.; Zhou, X. Study on the Suppression of Parasitic Resonance of Film Bulk Acoustic Wave Resonators. Microelectron. J. 2024, 154, 106450. [Google Scholar] [CrossRef]

- Rughoobur, G.; Sugime, H.; DeMiguel-Ramos, M.; Mirea, T.; Zheng, S.; Robertson, J.; Iborra, E.; Flewitt, A.J. Carbon Nanotube Isolation Layer Enhancing In-Liquid Quality-Factors of Thin Film Bulk Acoustic Wave Resonators for Gravimetric Sensing. Sens. Actuators B Chem. 2018, 261, 398–407. [Google Scholar] [CrossRef]

- Serhane, R.; Hadj-Larbi, F.; Hassein-Bey, A.; Khelif, A. Selective Band Gap to Suppress the Spurious Acoustic Mode in Film Bulk Acoustic Resonator Structures. J. Vib. Acoust. 2018, 140, 031018. [Google Scholar] [CrossRef]

- Liu, J.; Omori, T.; Ahn, C.; Hashimoto, K. Impact of Surface Periodic Grating on Film Bulk Acoustic Resonator Structures to Spurious Transverse Resonances. J. Appl. Phys. 2013, 113, 144507. [Google Scholar] [CrossRef]

- Pillai, G.; Zope, A.A.; Tsai, J.M.-L.; Li, S.-S. Design and Optimization of SHF Composite FBAR Resonators. IEEE Trans. Ultrason. Ferroelect. Freq. Contr. 2017, 64, 1864–1873. [Google Scholar] [CrossRef]

- Pensala, T.; Ylilammi, M. Spurious Resonance Suppression in Gigahertz-Range ZnO Thin-Film Bulk Acoustic Wave Resonators by the Boundary Frame Method: Modeling and Experiment. IEEE Trans. Ultrason. Ferroelect Freq. Contr. 2009, 56, 1731–1744. [Google Scholar] [CrossRef]

- Li, N.; Wang, B.; Qian, Z. Suppression of Spurious Lateral Modes and Undesired Coupling Modes in Frame-Like FBARs by 2-D Theory. IEEE Trans. Ultrason. Ferroelect. Freq. Contr. 2020, 67, 180–190. [Google Scholar] [CrossRef]

- Jiang, P.; Mao, S.; An, Z.; Fei, C.; Lou, L.; Li, Z.; Zhao, T.; Jiang, S.; Yang, Y. Structure-Size Optimization and Fabrication of 3.7 GHz Film Bulk Acoustic Resonator Based on AlN Thin Film. Front. Mater. 2021, 8, 731611. [Google Scholar] [CrossRef]

- Gao, C.; Zou, Y.; Zhou, J.; Liu, Y.; Liu, W.; Cai, Y.; Sun, C. Influence of Etching Trench on Keff2 of Film Bulk Acoustic Resonator. Micromachines 2022, 13, 102. [Google Scholar] [CrossRef] [PubMed]

- Patel, R.; Adhikari, M.S.; Bansal, D.; Johar, A. Hybrid Film Bulk Acoustic Resonator Fabricated Using a Single Bragg Reflector. J. Electron. Mater. 2024, 53, 2910–2920. [Google Scholar] [CrossRef]

- Catherinot, L.; Giraud, S.; Chatras, M.; Bila, S.; Cros, D.; Baron, T.; Ballandras, S.; Estagerie, L.; Monfraix, P. A General Procedure for the Design of Bulk Acoustic Wave Filters. Int. J. RF Microw. Comp. Aided Eng. 2011, 21, 458–465. [Google Scholar] [CrossRef]

- Lee, S.; Mortazawi, A. An Intrinsically Switchable Ladder-Type Ferroelectric BST-on-Si Composite FBAR Filter. IEEE Trans. Ultrason. Ferroelect. Freq. Contr. 2016, 63, 456–462. [Google Scholar] [CrossRef]

- Qi, H.; Zhang, H.; Gao, N.; Fang, Y.; Xie, X.; Bian, L.; Fang, Y.; Chen, G. Simulation and Preparation of FBARs Based on AlN Thin Films. Mater. Sci. Semicond. Process. 2025, 185, 108886. [Google Scholar] [CrossRef]

- Panda, P.; Chatterjee, S.; Tallur, S.; Laha, A. Beyond 5 GHz Excitation of a ZnO-Based High-Overtone Bulk Acoustic Resonator on SiC Substrate. Sci. Rep. 2023, 13, 13329. [Google Scholar] [CrossRef]

- García-Gancedo, L.; Pedrós, J.; Zhao, X.B.; Ashley, G.M.; Flewitt, A.J.; Milne, W.I.; Ford, C.J.B.; Lu, J.R.; Luo, J.K. Dual-Mode Thin Film Bulk Acoustic Wave Resonators for Parallel Sensing of Temperature and Mass Loading. Biosens. Bioelectron. 2012, 38, 369–374. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, S.; Sun, X.; Zhang, Y.; Zhu, X.; Hwang, H.; Li, Z.; Zhang, Y. Magnesium Composition Effect on UV-Sensing Performance of MgxZn1−xO-Based Solidly Mounted Bulk Acoustic Resonator. J. Mater. Sci. Mater. Electron. 2020, 31, 5511–5520. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, Y.; Xu, Q.; Qu, Y.; Ren, Y.; Huang, X.; Gao, C.; Liu, Y.; Guo, S.; Cai, Y.; et al. Design and Fabrication of 3.5 GHz Band-Pass Film Bulk Acoustic Resonator Filter. Micromachines 2024, 15, 563. [Google Scholar] [CrossRef]

- Lu, H.; Hao, X.; Yang, L.; Hou, B.; Zhang, M.; Wu, M.; Dong, J.; Ma, X. Recent Advances in AlN-Based Acoustic Wave Resonators. Micromachines 2025, 16, 205. [Google Scholar] [CrossRef]

| References | [35] | [17] | [36] | [20] | [37] | [38] | This Work |

|---|---|---|---|---|---|---|---|

| PZE material | AlN | Al0.88Sc0.12N | ZnO | ZnO | ZnO | ZnO | ZnO |

| [μm] | 0.461 | 1 | 0.65 | 2.4 | 2 | 1 | 1.5 |

| [GHz] | 6.84 | 1.58 | 1.85 | 0.879 | 1.44 | 2.127 | 1.251 |

| [%] | 5.64 | 1.47 | 2 | 0.84 | 7.5 | 2.03 | 2.3 |

| Q | 135 | 454 | 350 | 740.74 | 115 | 253.2 | 353 |

| FoM | 7.61 | 6.67 | 7 | 6.22 | 8.62 | 5.35 | 8.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, R.; Adhikari, M.S.; Bansal, D.; Majumder, T. Fabrication of Air Cavity Structures Using DRIE for Acoustic Signal Confinement in FBAR Devices. Micromachines 2025, 16, 647. https://doi.org/10.3390/mi16060647

Patel R, Adhikari MS, Bansal D, Majumder T. Fabrication of Air Cavity Structures Using DRIE for Acoustic Signal Confinement in FBAR Devices. Micromachines. 2025; 16(6):647. https://doi.org/10.3390/mi16060647

Chicago/Turabian StylePatel, Raju, Manoj Singh Adhikari, Deepak Bansal, and Tanmoy Majumder. 2025. "Fabrication of Air Cavity Structures Using DRIE for Acoustic Signal Confinement in FBAR Devices" Micromachines 16, no. 6: 647. https://doi.org/10.3390/mi16060647

APA StylePatel, R., Adhikari, M. S., Bansal, D., & Majumder, T. (2025). Fabrication of Air Cavity Structures Using DRIE for Acoustic Signal Confinement in FBAR Devices. Micromachines, 16(6), 647. https://doi.org/10.3390/mi16060647