I–V Characteristics and Electrical Reliability of Metal–SixNy–Metal Capacitors as a Function of Nitrogen Bonding Composition

Abstract

1. Introduction

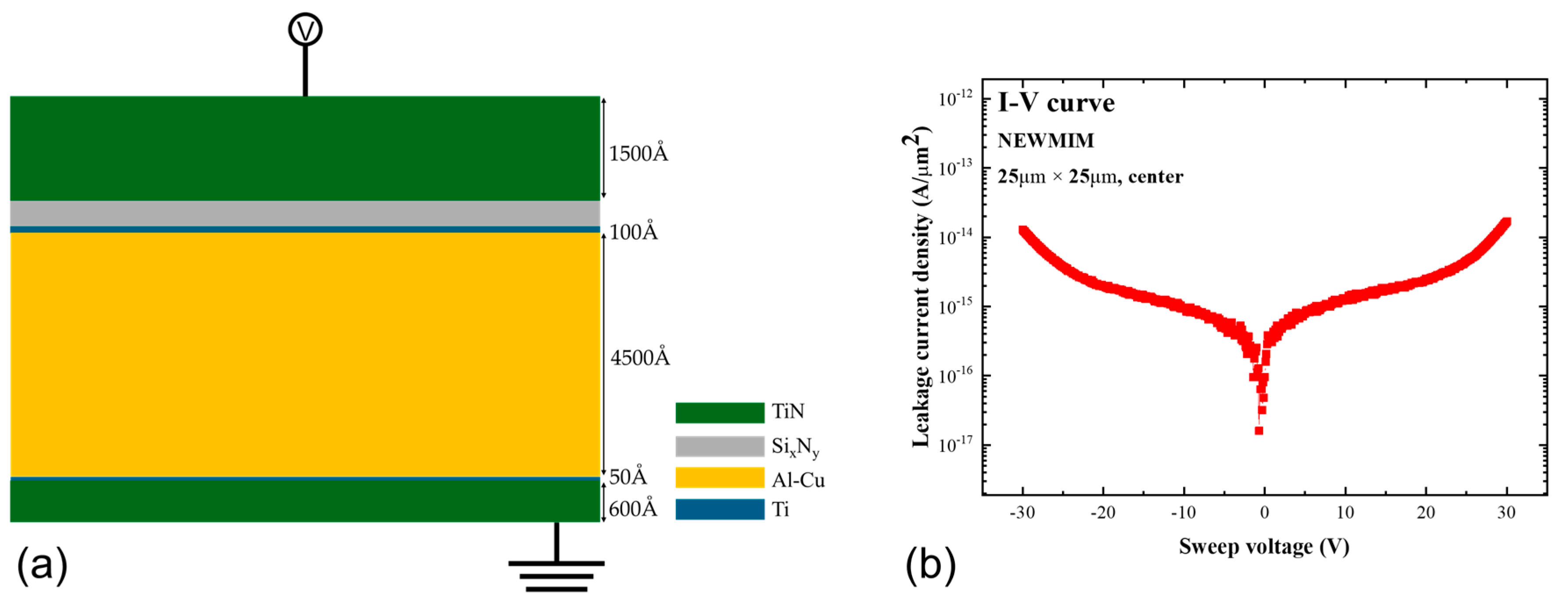

2. Materials and Methods

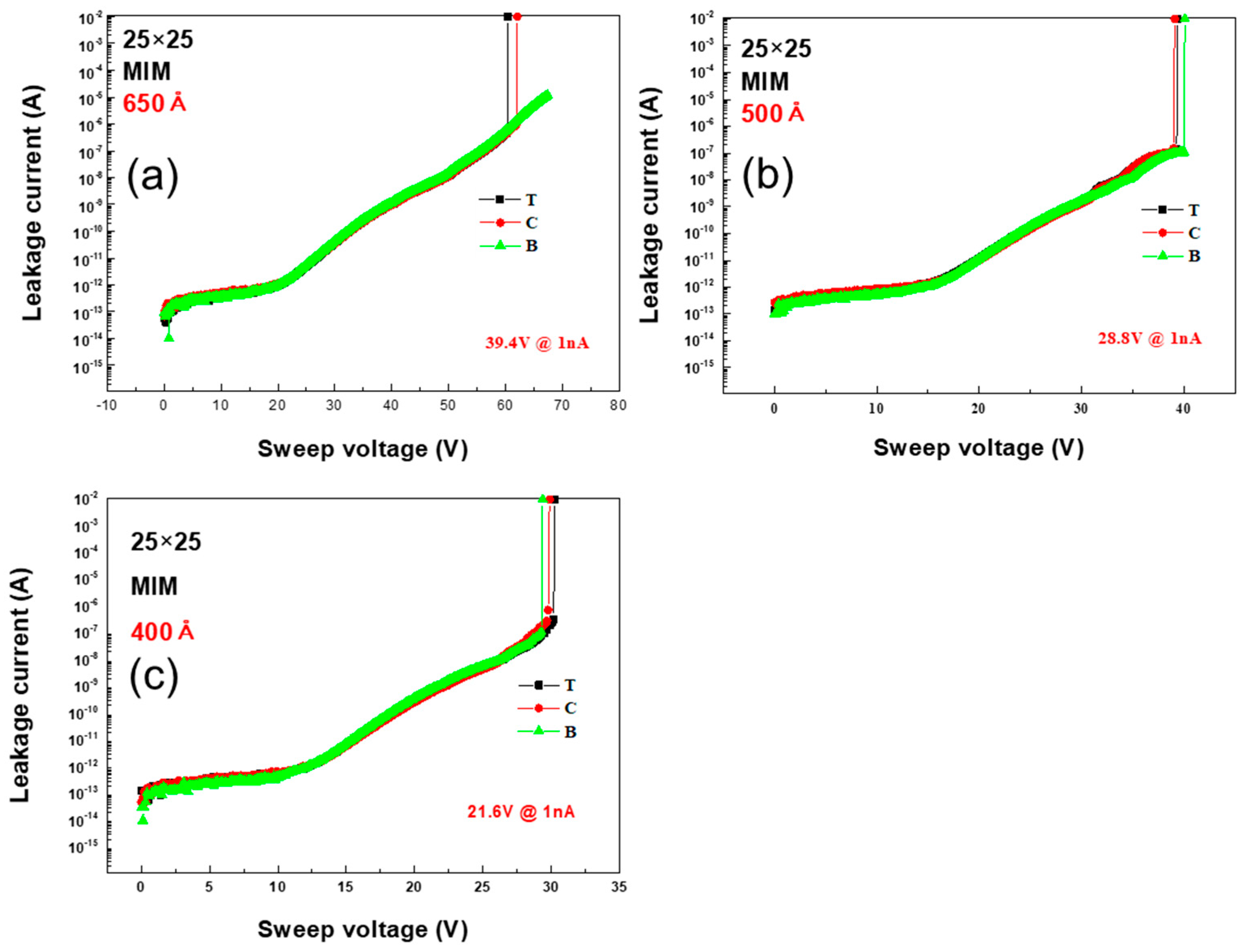

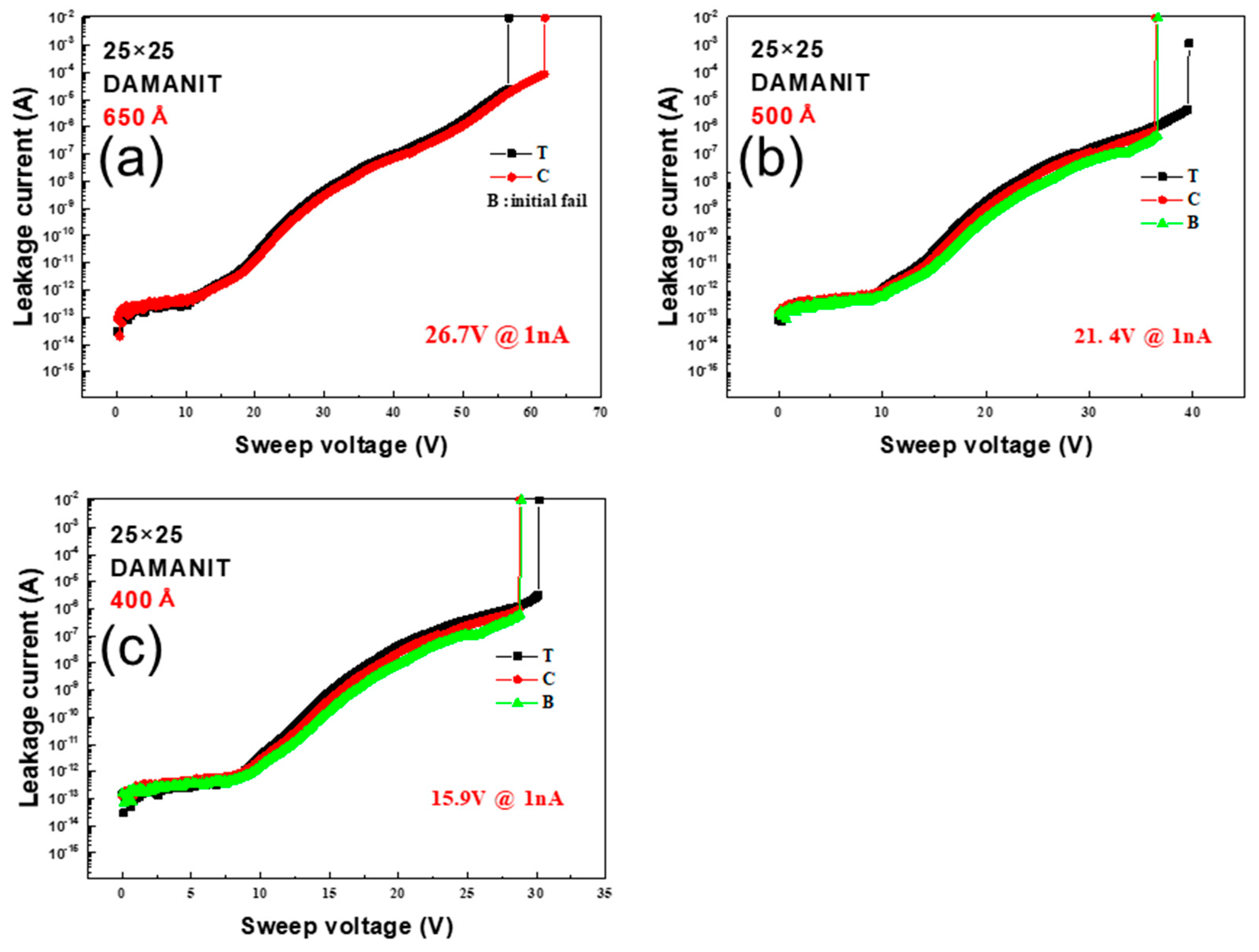

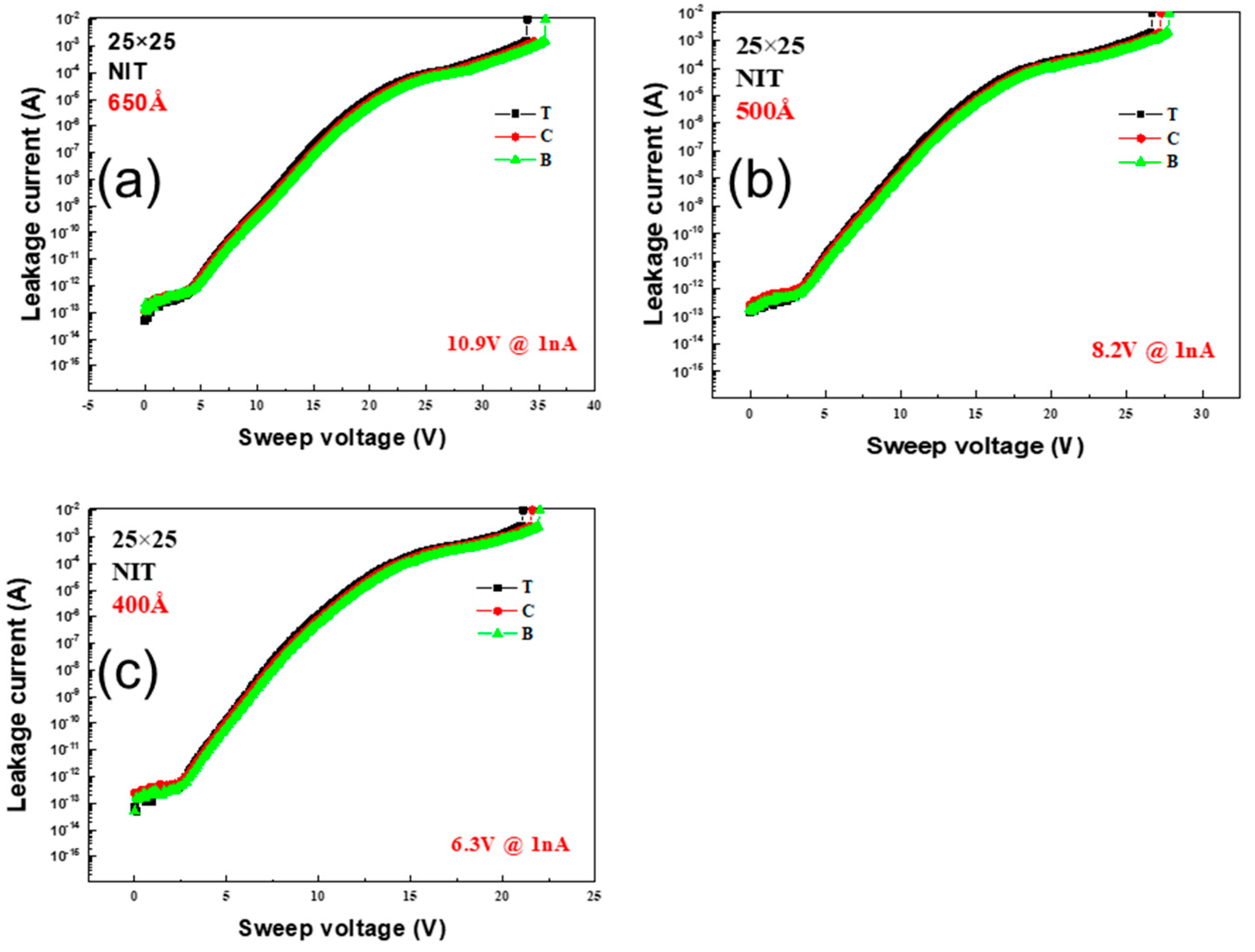

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiong, L.; Hu, J.; Yang, Z.; Li, X.; Zhang, H.; Zhang, G. Dielectric Properties Investigation of Metal–Insulator–Metal (MIM) Capacitors. Molecules 2022, 27, 3951. [Google Scholar] [CrossRef] [PubMed]

- Khaldi, O.; Jomni, F.; Gonon, P.; Mannequin, C.; Yangui, B. Investigation of electrical properties of HfO2 metal–insulator–metal (MIM) devices. Appl. Phys. A 2014, 116, 1647–1653. [Google Scholar] [CrossRef]

- Shin, H.; Choi, H.; Lim, J.; Lee, W.; Mohit, K.; Kim, Y.; Jung, H.-S.; Lim, H.; Seo, H. Interfacial engineering of ZrO2 metal-insulator-metal capacitor using Al2O3/TiO2 buffer layer for improved leakage properties. J. Asian Ceram. Soc. 2022, 10, 649–659. [Google Scholar] [CrossRef]

- Sul, W.S.; Pyo, S.G. RF Characteristic Analysis Model Extraction on the Stacked Metal–Insulator–Metal Capacitors for Radio Frequency Applications. IEEE Trans. Electron Devices 2014, 61, 3011–3013. [Google Scholar] [CrossRef]

- Mu, J.; Chou, X.; Ma, Z.; He, J.; Xiong, J. High-Performance MIM Capacitors for a Secondary Power Supply Application. Micromachines 2018, 9, 69. [Google Scholar] [CrossRef]

- Patil, S.R.; Barhate, V.N.; Patil, V.S.; Agrawal, K.S.; Mahajan, A.M. The effect of post-deposition annealing on the chemical, structural and electrical properties of Al/ZrO2/La2O3/ZrO2/Al high-k nanolaminated MIM capacitors. J. Mater. Sci. Mater. Electron. 2022, 33, 11227–11235. [Google Scholar] [CrossRef]

- Banerjee, P.; Perez, I.; Henn-Lecordier, L.; Lee, S.B.; Rubloff, G.W. Nanotubular metal–insulator–metal capacitor arrays for energy storage. Nat. Nanotechnol. 2009, 4, 292–296. [Google Scholar] [CrossRef]

- Lim, H.; Choi, J.H.; Cho, G.; Chang, J.; Kim, Y.; Jung, H.-S.; Shin, K.-S.; Seo, H.; Jeon, H. Study of Metal–Dielectric Interface for Improving Electrical Properties and Reliability of DRAM Capacitor. Adv. Mater. Technol. 2023, 8, 2200412. [Google Scholar] [CrossRef]

- Lau, W.S. Some Key Modifications of Theory Required to Understand the Leakage Current Mechanisms for MIM Capacitors used in Dram Technology. In Proceedings of the 2020 China Semiconductor Technology International Conference (CSTIC), Shanghai, China, 26 June–17 July 2020; pp. 1–3. [Google Scholar]

- Ding, S.-J.; Hu, H.; Lim, H.; Kim, S.; Yu, X.; Zhu, C.; Li, M.; Cho, B.J.; Chan, D.S.; Rustagi, S.C. High-performance MIM capacitor using ALD high-k HfO2-Al2O3 laminate dielectrics. IEEE Electron Device Lett. 2003, 24, 730–732. [Google Scholar] [CrossRef]

- Das, N.; Karar, A.; Vasiliev, M.; Tan, C.L.; Alameh, K.; Lee, Y.T. Analysis of nano-grating-assisted light absorption enhancement in metal–semiconductor–metal photodetectors patterned using focused ion-beam lithography. Opt. Commun. 2011, 284, 1694–1700. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, H.; Chen, Y.; Luo, Q.; Xu, K. All-silicon microdisplay using efficient hot-carrier electroluminescence in standard 0.18μm CMOS technology. IEEE Electron Device Lett. 2021, 42, 541–544. [Google Scholar] [CrossRef]

- van Delden, M.H.W.M.; van der Wel, P.J. Reliability and electric properties for PECVD a-SiN/sub x/:H films with an optical band-gap ranging from 2.5 to 5.38 eV. In Proceedings of the 2003 IEEE International Reliability Physics Symposium Proceedings, 2003. 41st Annual, Dallas, TX, USA, 30 March–4 April 2003; pp. 293–297. [Google Scholar]

- Chang, C.S. Applications of Metal-Insulator-Metal (MIM) Capacitors; International Sematech: Austin, TX, USA, 2000. [Google Scholar]

- Choi, E.; Kim, A.; Kwon, S.H.; Pyo, S.G. Effect of Interface Treatment on the Voltage Linearity in 8 fF/μm2 High-k Dielectric and Combination Stacks on Metal Insulator Metal (MIM) Capacitor. Sci. Adv. Mater. 2018, 10, 467–470. [Google Scholar] [CrossRef]

- Li, W.; Lu, X.; Yang, R.; Liang, F.; Chen, W.; Xie, Z.; Zheng, J.; Zhu, J.; Huang, Y.; Yue, W.; et al. Highly sensitive and reproducible SERS substrates with binary colloidal crystals (bCCs) based on MIM structures. Appl. Surf. Sci. 2022, 597, 153654. [Google Scholar] [CrossRef]

- Jeon, S.; Sung, S.-K.; Jang, E.-H.; Jeong, J.; Surabhi, S.; Choi, J.-H.; Jeong, J.-R. Multilayer metal-oxide-metal nanopatterns via nanoimprint and strip-off for multispectral resonance. Appl. Surf. Sci. 2018, 428, 280–288. [Google Scholar] [CrossRef]

- Shin, Y.; Nam, S.G.; Heo, J.; Nam, S. Broadband Characterization of Thin Dielectrics Using Heterolayer and Monolayer MIM Capacitors. IEEE Trans. Instrum. Meas. 2022, 71, 6006008. [Google Scholar] [CrossRef]

- PS, S.; Jayan, J.S.; Saritha, A.; Suresh Babu, V.; G, S. Synthesis and Performance Evaluation of BaxSr1—xTiO3 Ceramic-Based MIM Capacitor for Energy Storage Application. Integr. Ferroelectr. 2020, 212, 177–189. [Google Scholar] [CrossRef]

- Gopika, S.; Shyju, S. Performance Evaluation of Symmetric Supercapacitors based on Pelletized MnO2 and MnO2 doped V2O5 Electrodes. In Proceedings of the 2020 4th International Conference on Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 5–7 November 2020; pp. 281–288. [Google Scholar]

- Jin Chung, J.; Hyuk Kim, T.; Ahsan Saeed, M.; Won Shim, J. Laminated indium-oxide/molybdenum-oxide nanocomposites for high-work-function electrodes in organic photovoltaics and capacitor devices. Appl. Surf. Sci. 2023, 610, 155526. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, S.; Du, X.; Liang, S.; Huang, S.; Peng, S.; Xie, Y.; Ma, M.; Xiong, L. Construction of ultrahigh capacity density carbon nanotube based MIM capacitor. Energy Storage Mater. 2023, 63, 103064. [Google Scholar] [CrossRef]

- Han, D.H.; Choi, S.J.; Kim, Y.; Jeon, W. Investigating Dielectric Relaxation Currents for a Deeper Understanding of Capacitance and Interface in Metal–Insulator–Metal Capacitor. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 1276–1280. [Google Scholar] [CrossRef]

- Natori, K.; Otani, D.; Sano, N. Thickness dependence of the effective dielectric constant in a thin film capacitor. Appl. Phys. Lett. 1998, 73, 632–634. [Google Scholar] [CrossRef]

- Miller, J.R. Perspective on electrochemical capacitor energy storage. Appl Surf Sci 2018, 460, 3–7. [Google Scholar] [CrossRef]

- Nam, M.; Kim, A.; Kang, K.; Choi, E.; Kwon, S.H.; Lee, S.J.; Pyo, S.G. Characterization of atomic layer deposited Al2O3/HfO2 and Ta2O5/Al2O3 combination stacks. Sci. Adv. Mater. 2016, 8, 1958–1962. [Google Scholar] [CrossRef]

- Jamison, P.C.; Massey, J.; Ando, T.; Cartier, E.A.; Jagannathan, H.; Chen, P.J.; Liu, E.; Romero, A.; Naczas, S.; Narayanan, V.; et al. BEOL Compatible High-Capacitance MIMCAP Structure Using a Novel High k Material. ECS Trans. 2020, 97, 81. [Google Scholar] [CrossRef]

- Holden, K.E.K.; Hall, G.D.R.; Cook, M.; Kendrick, C.; Pabst, K.; Greenwood, B.; Daugherty, R.; Gambino, J.P.; Allman, D.D.J. Dielectric Relaxation, Aging and Recovery in High-K MIM Capacitors. In Proceedings of the 2021 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 21–25 March 2021; pp. 1–10. [Google Scholar]

- Spahr, H.; Nowak, C.; Hirschberg, F.; Reinker, J.; Kowalsky, W.; Hente, D.; Johannes, H.-H. Enhancement of the maximum energy density in atomic layer deposited oxide based thin film capacitors. Appl. Phys. Lett. 2013, 103, 042907. [Google Scholar] [CrossRef]

- Choi, T.-M.; Jung, E.-S.; Yoo, J.-U.; Lee, H.-R.; Pyo, S.-G. Capacitance–Voltage Fluctuation of SixNy-Based Metal–Insulator–Metal Capacitor Due to Silane Surface Treatment. Micromachines 2024, 15, 1204. [Google Scholar] [CrossRef] [PubMed]

- Allers, K.H. Prediction of dielectric reliability from I–V characteristics: Poole–Frenkel conduction mechanism leading to √E model for silicon nitride MIM capacitor. Microelectron. Reliab. 2004, 44, 411–423. [Google Scholar] [CrossRef]

- Hung, C.-C.; Oates, A.S.; Lin, H.-C.; Chang, Y.-E.P.; Wang, J.-L.; Huang, C.-C.; Yau, Y.-W. An innovative understanding of metal–insulator–metal (MIM)-capacitor degradation under constant-current stress. IEEE Trans. Device Mater. Reliab. 2007, 7, 462–467. [Google Scholar] [CrossRef]

- Koszewski, A.; Souchon, F.; Ouisse, T. Conduction and trapping in RF MEMS capacitive Switches with a SiN Layer. In Proceedings of the 2009 European Solid State Device Research Conference, Athens, Greece, 14–18 September 2009; pp. 339–342. [Google Scholar]

- Chiu, F.-C. A Review on Conduction Mechanisms in Dielectric Films. Adv. Mater. Sci. Eng. 2014, 2014, 578168. [Google Scholar] [CrossRef]

- Zhang, S.; Wei, K.; Xiao, Y.; Ma, X.-H.; Zhang, Y.-C.; Liu, G.-G.; Lei, T.-M.; Zheng, Y.-K.; Huang, S.; Wang, N.; et al. Effect of SiN:Hx passivation layer on the reverse gate leakage current in GaN HEMTs. Chin. Phys. B 2018, 27, 097309. [Google Scholar] [CrossRef]

- Ho, C.-C.; Chiou, B.-S. Effect of size and plasma treatment and the application of Weibull distribution on the breakdown of PECVD SiNx MIM capacitors. Microelectron. Eng. 2008, 85, 110–114. [Google Scholar] [CrossRef]

- Suzuki, M.; Sagawa, M.; Kusunoki, T.; Nishimura, E.; Ikeda, M.; Tsuji, K. Enhancing electron-emission efficiency of MIM tunneling cathodes by reducing insulator trap density. IEEE Trans. Electron Devices 2012, 59, 2256–2262. [Google Scholar] [CrossRef]

- Gupta, H.; Van Overstraeten, R. Role of trap states in the insulator region for MIM characteristics. J. Appl. Phys. 1975, 46, 2675–2682. [Google Scholar] [CrossRef]

- Okada, K.; Ito, Y.; Suzuki, S. A new model for dielectric breakdown mechanism of silicon nitride metal-insulator-metal structures. In Proceedings of the 2016 IEEE International Reliability Physics Symposium (IRPS), Pasadena, CA, USA, 17–21 April 2016; pp. 3A-6-1–3A-6-6. [Google Scholar]

| (a) | MIM | NEW MIM | DAMA NIT | NIT |

| Dep. rate | ~149 Å/s | ~29 Å/s | ~59 Å/s | 88 Å/s |

| Within Wafer uniformity (1σ) | 1.14% | 1.90% | 2.34% | 2.77% |

| Wafer-to-Wafer uniformity (1σ) | 1.58% | 2.21% | 1.05% | 2.30% |

| Stress | −2.23 × 109 | −1.75 × 1010 | −2.34 × 109 | |

| H content (N–H: Si–H) | 12.7%: 8.5% | 22.5%: 0.8% | 10.5%: 7.3% | 4.4%: 14.8% |

| N content (N–H/Si–H) | 1.49 | 28.1 | 1.43 | 0.30 |

| (b) | MIM | NEW MIM | DAMA NIT | NIT |

| Step end control | By time | By time | By time | By time |

| Maximum step time | 4.4 s | 22.8 s | 11.0 s | |

| Endpoint selection | No endpoint | No endpoint | No endpoint | No endpoint |

| Pressure | Servo 4.25 Torr | Servo 4.25 Torr | Servo 4.2 Torr | Servo 4.5 Torr |

| RF power | 690 W | 690 W | 420 W | 425 W |

| Susceptor temperature | 400 °C | 400 °C | 400 °C | 400 °C |

| Susceptor spacing | 620 mils | 620 mils | 550 mils | 475 mils |

| N2 | 3800 sccm | 3800 sccm | 2500 sccm | 4000 sccm |

| NH3 | 130 sccm | 50 sccm | 38 sccm | 60 sccm |

| SiH4 | 260 sccm | 100 sccm | 110 sccm | 170 sccm |

| Parameter | Setting |

|---|---|

| Sweep voltage | −70 V to 70 V |

| Compliance | 10 mA |

| Forcing | Top electrode |

| Capacitor sizes | 10 × 10 µm2, 15 × 15 µm2, 20 × 20 µm2, 25 × 25 µm2, 30 × 30 µm2, 50 × 50 µm2 |

| Measurement points | Three points (top, center, bottom) |

| Temperature | Room temperature |

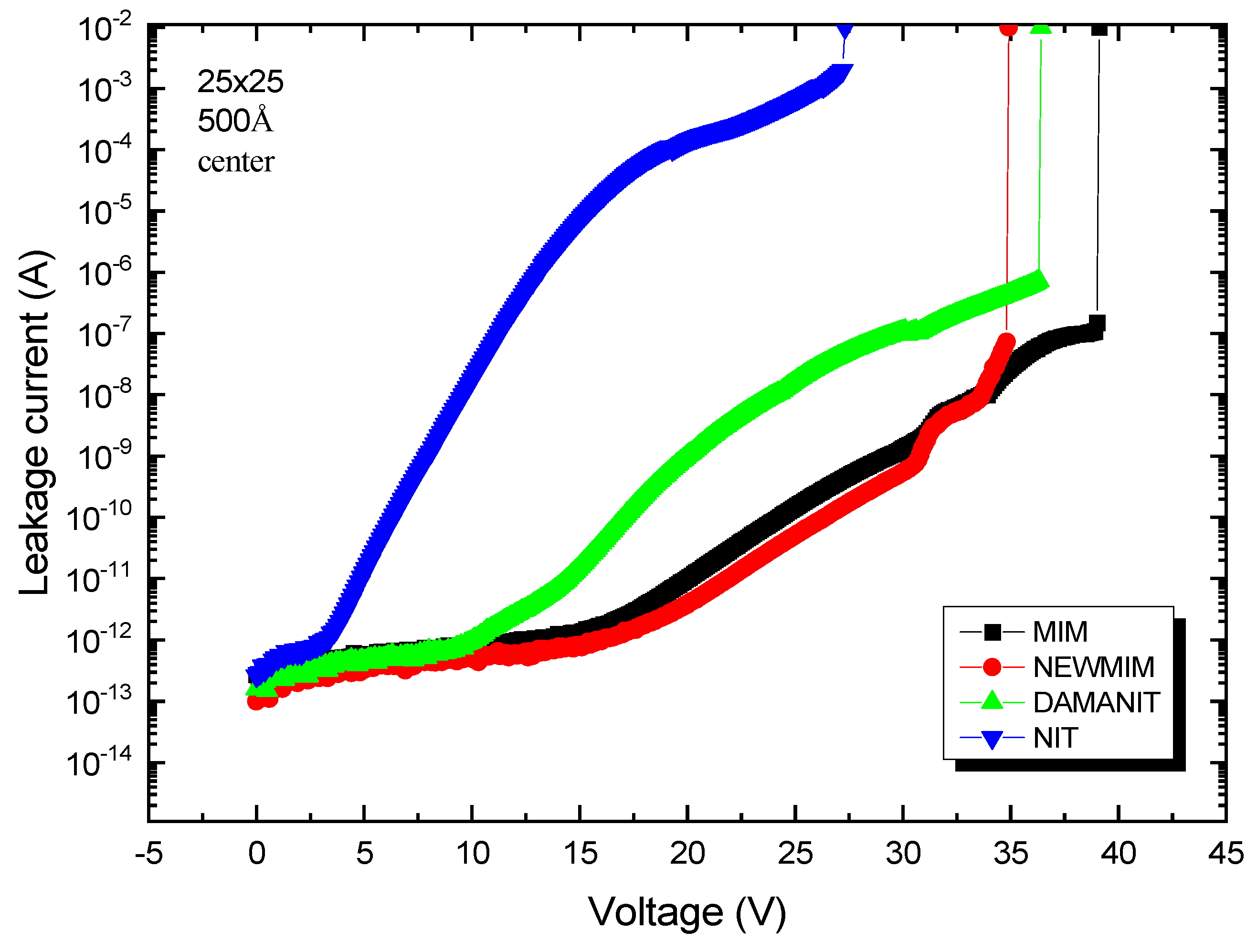

| SixNy Deposition Condition | Thickness (Å) | Leakage Current Density (fA/µm2 @ 3.7 V) |

|---|---|---|

| MIM | 650 | 0.336 |

| 500 | 0.72 | |

| 400 | 0.32 | |

| NEWMIM | 650 | 0.656 |

| 500 | 0.336 | |

| 400 | 0.72 | |

| DAMANIT | 650 | 0.416 |

| 500 | 0.432 | |

| 400 | 0.496 | |

| NIT | 650 | 0.896 |

| 500 | 1.728 | |

| 400 | 8.288 |

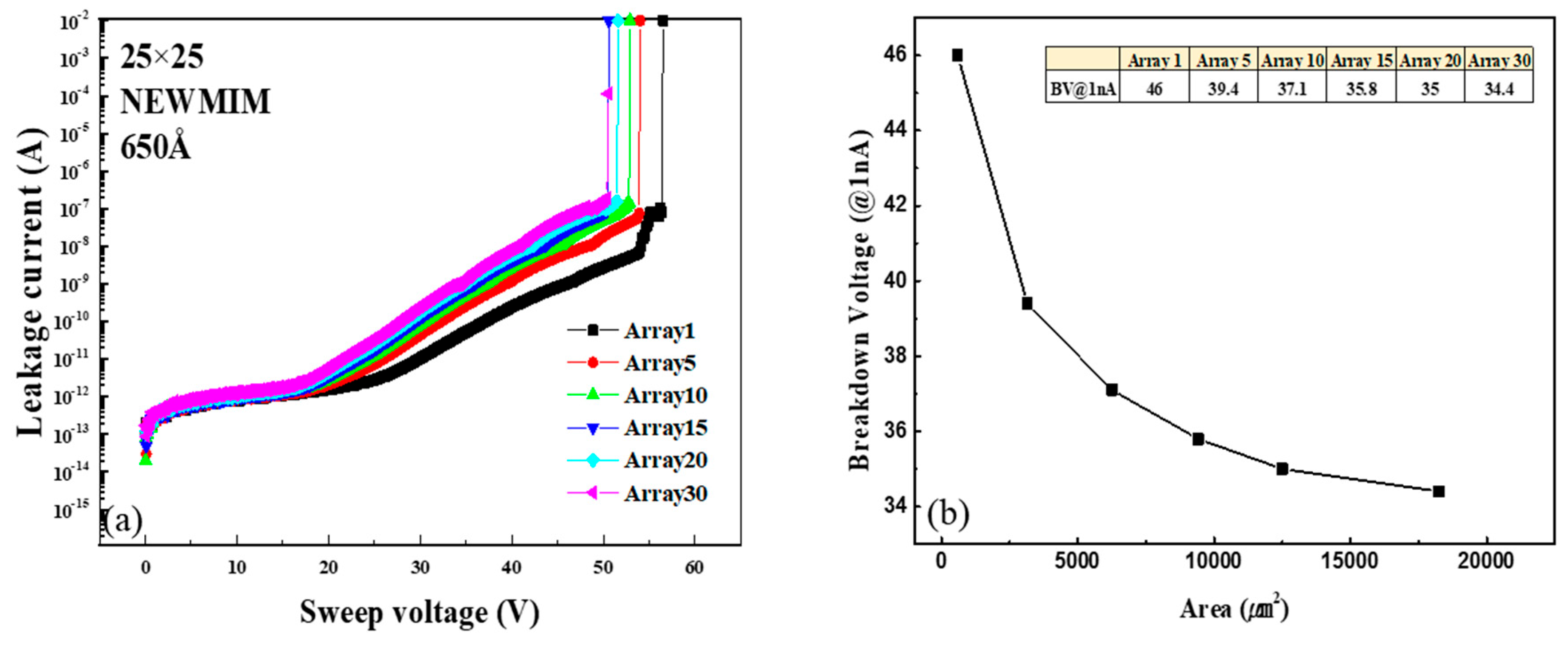

| SixNy Deposition Condition | Thickness (Å) | Breakdown Voltages (V) |

|---|---|---|

| MIM | 650 | 39.4 |

| 500 | 28.8 | |

| 400 | 21.6 | |

| NEW MIM | 650 | 45.2 |

| 500 | 30.8 | |

| 400 | 23.7 | |

| DAMA NIT | 650 | 26.7 |

| 500 | 21.4 | |

| 400 | 15.9 | |

| NIT | 650 | 10.9 |

| 500 | 8.2 | |

| 400 | 6.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, T.-M.; Jung, E.-S.; Yoo, J.-U.; Lee, H.-R.; Yoon, S.; Pyo, S.-G. I–V Characteristics and Electrical Reliability of Metal–SixNy–Metal Capacitors as a Function of Nitrogen Bonding Composition. Micromachines 2025, 16, 615. https://doi.org/10.3390/mi16060615

Choi T-M, Jung E-S, Yoo J-U, Lee H-R, Yoon S, Pyo S-G. I–V Characteristics and Electrical Reliability of Metal–SixNy–Metal Capacitors as a Function of Nitrogen Bonding Composition. Micromachines. 2025; 16(6):615. https://doi.org/10.3390/mi16060615

Chicago/Turabian StyleChoi, Tae-Min, Eun-Su Jung, Jin-Uk Yoo, Hwa-Rim Lee, Songhun Yoon, and Sung-Gyu Pyo. 2025. "I–V Characteristics and Electrical Reliability of Metal–SixNy–Metal Capacitors as a Function of Nitrogen Bonding Composition" Micromachines 16, no. 6: 615. https://doi.org/10.3390/mi16060615

APA StyleChoi, T.-M., Jung, E.-S., Yoo, J.-U., Lee, H.-R., Yoon, S., & Pyo, S.-G. (2025). I–V Characteristics and Electrical Reliability of Metal–SixNy–Metal Capacitors as a Function of Nitrogen Bonding Composition. Micromachines, 16(6), 615. https://doi.org/10.3390/mi16060615