Process Development Methods in Microtechnology and the Associated Process Environment

Abstract

1. Introduction

2. Overview of Failure Sources Caused by the Process Environment

3. Methodology

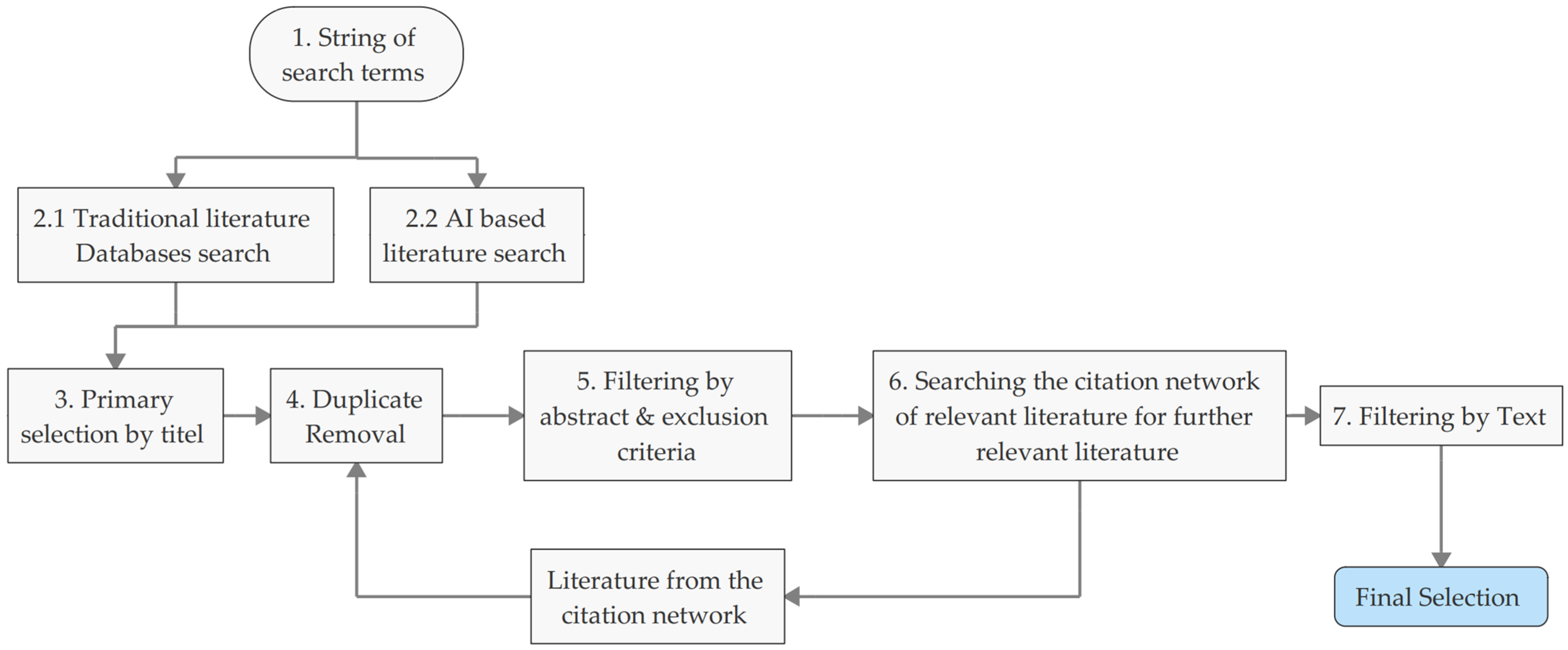

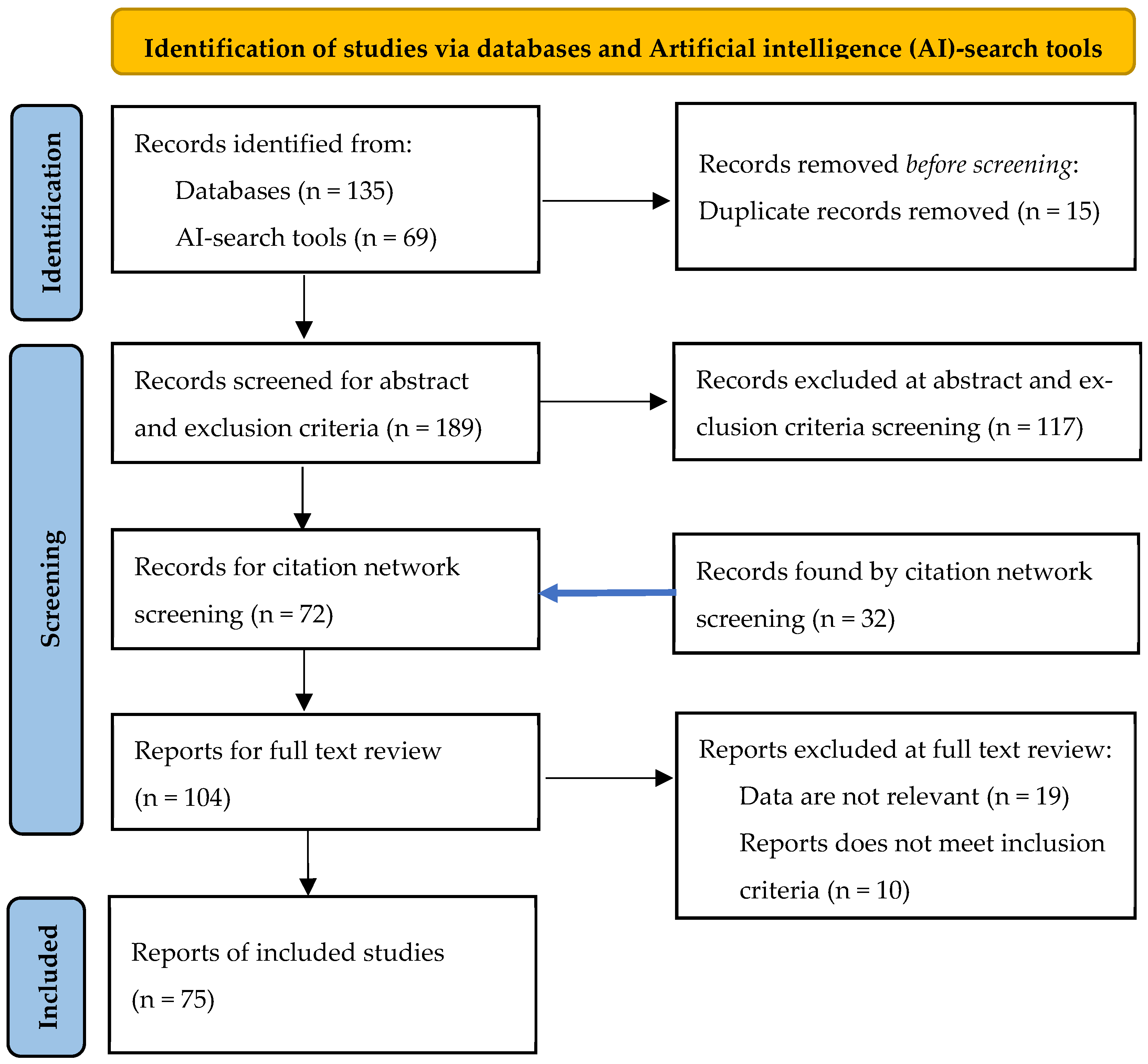

3.1. Systematic Literature Review (SLR)

3.1.1. Phase I: Planning Systematic Search

3.1.2. Phase II: Carrying out the Systematic Search

3.1.3. Phase III: Documentation and Evaluation of Relevant Methods

3.2. Modified GRADE Analysis

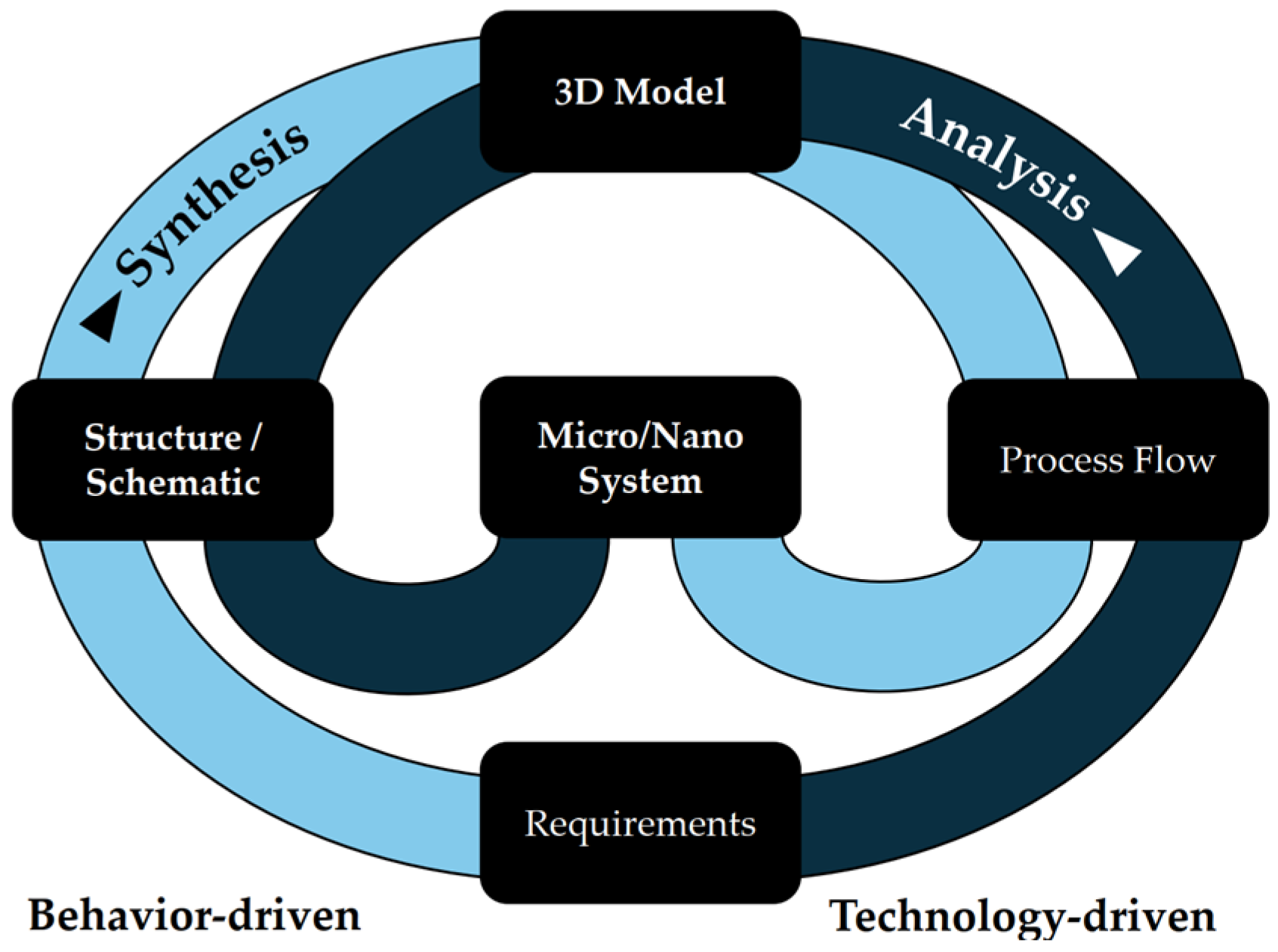

4. Overview of Process Development Methods

5. Methods for Process Development in Microtechnology

5.1. Microspecific Product Development Process for Tool-Based Microtechnologies (μPEP) (2005)

5.2. Adapted V-Model for MEMS Development (2005)

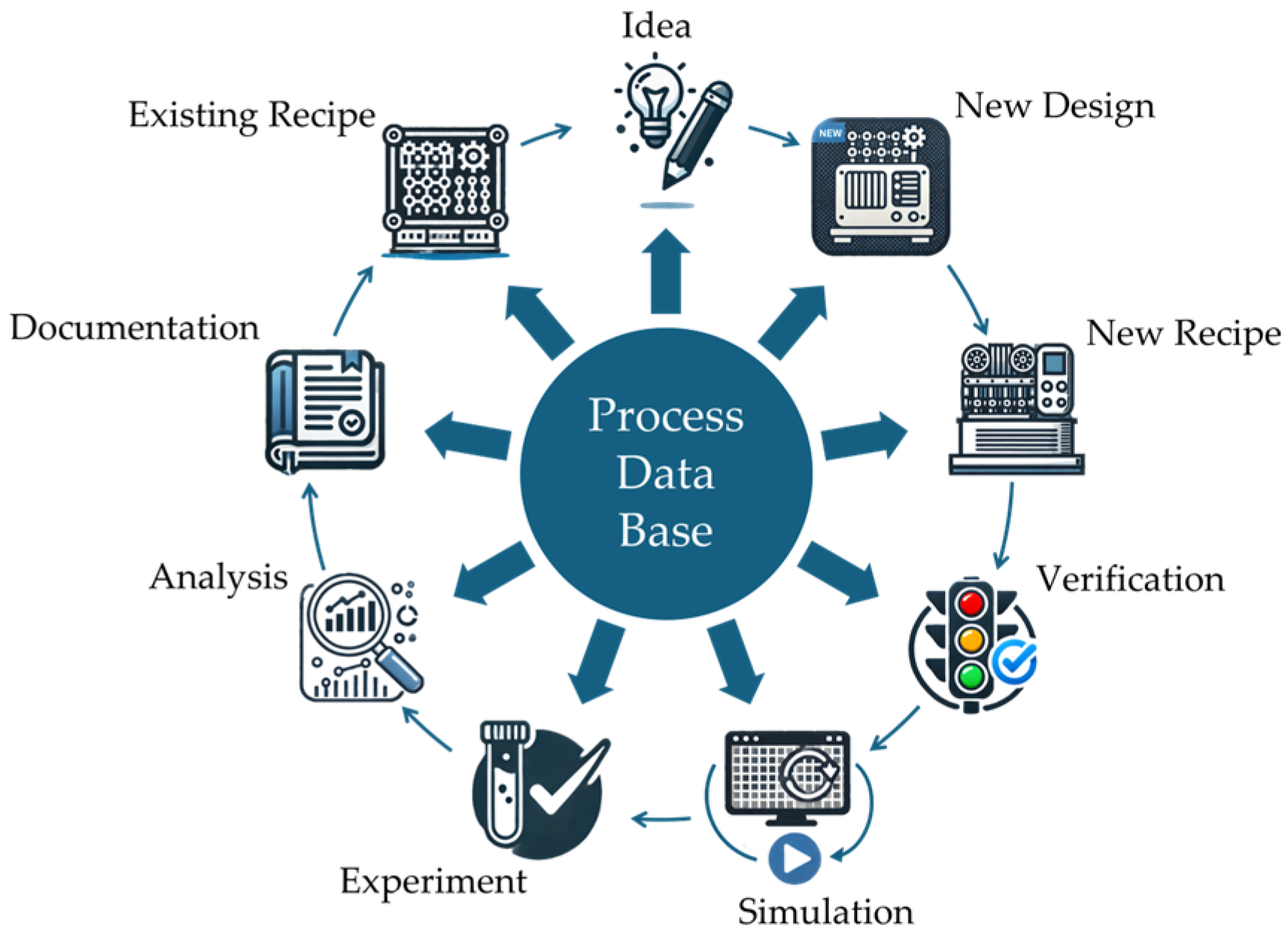

5.3. Software-Supported Process Development Execution System (PDES) XperiDesk (2008)

5.4. Micro-Process Planning and Analysis (µ-ProPlAn) Method (2013)

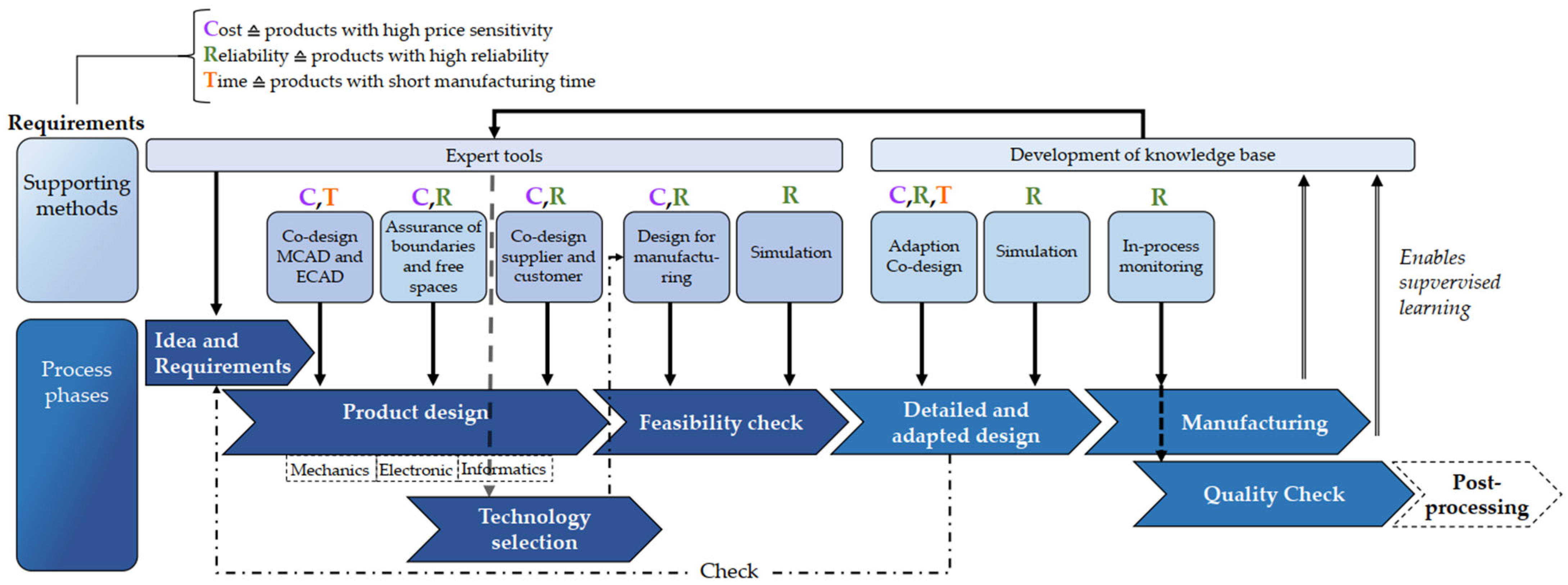

5.5. Product Development Methodology for iMST (2023)

5.6. Comparative Overview of Selected Process Development Methods in MST

6. Analysis of the Categorized Methods Using the Adapted GRADE System

6.1. Quality Levels of Evidence: Structure and Application

6.2. Evaluation of the Method Categories According to Modified GRADE Criteria

6.2.1. Risk of Bias

- Production-oriented product development

- Development/planning of process chains

- Selection of manufacturing processes

- Material selection

- Material flow planning

6.2.2. Indirectness of Evidence

- Production-oriented product development

- Development/planning of process chains

- Selection of manufacturing processes

- Material selection

- Material flow planning

6.2.3. Imprecision of Results

- Production-oriented product development

- Development/Planning of process chains

- Selection of manufacturing processes

- Material selection

- Material flow planning

6.2.4. Adaptability for Considering the Process Environment (New Category)

- Production-oriented product development

- Development/Planning of process chains

- Selection of manufacturing processes

- Material selection

- Material flow planning

6.2.5. Publication Bias

- Production-oriented product development

- Development/Planning of process chains

- Selection of manufacturing processes

- Material selection

- Material flow planning

6.3. Overall Evaluation of the Method Categories and Summary of Findings

- Production-oriented product development

- Development/Planning of process chains

- Selection of manufacturing processes

- Material selection

- Material flow planning

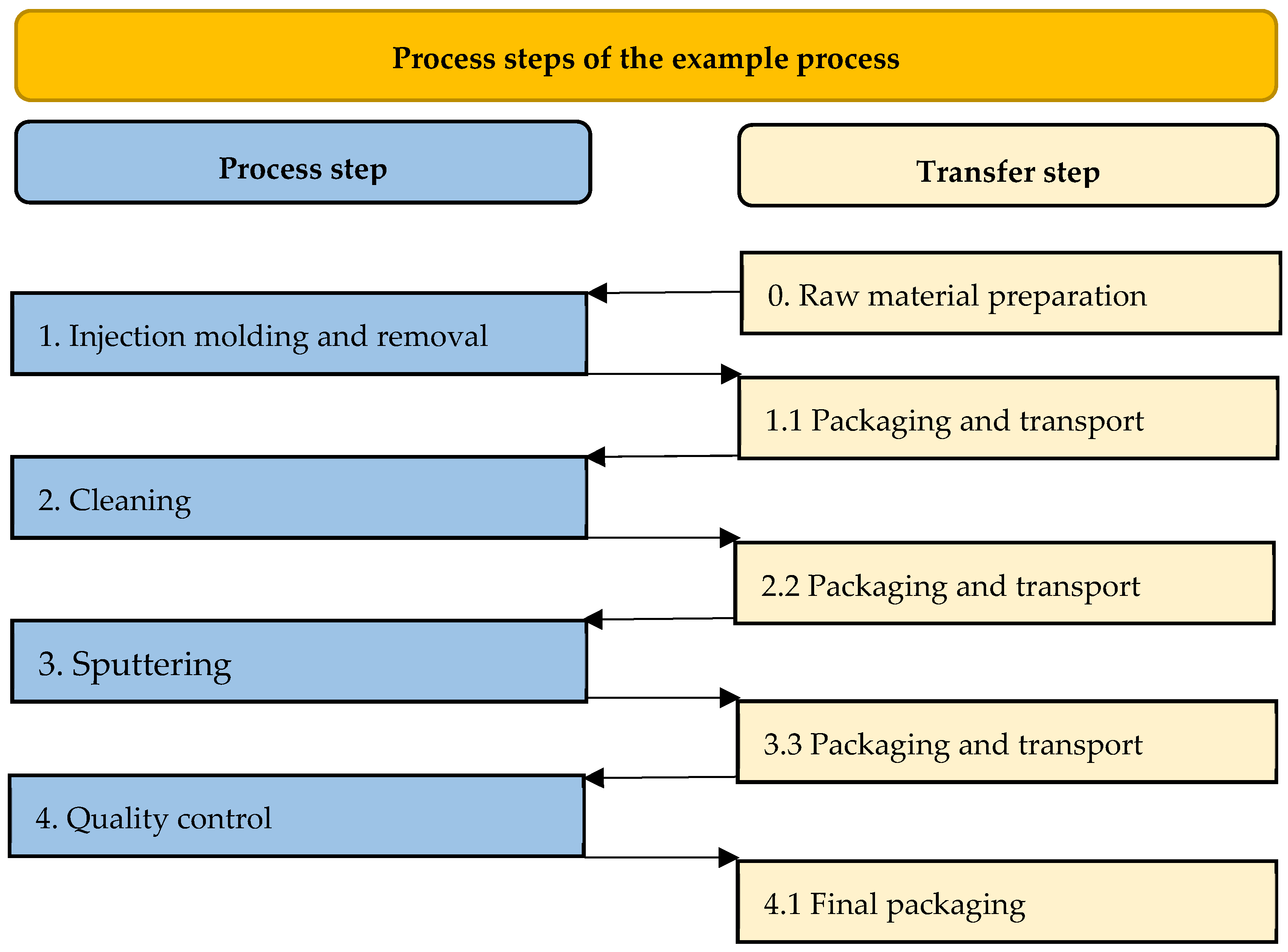

7. From Theory to Practice: The Influence of External Factors on an Example Process

8. Discussion and Outlook

8.1. Publication Bias and Indirectness of Evidence

8.2. Practical Implications and Adaptation of Existing Methods

- Method by Vella et al.: Consideration of sub-processes and interfaces in a Process Pair Maturity Matrix (PPMM) to analyze how they influence each other.

- PDES: Simulation of processes based on known process data.

- µ-ProPlAn: Simulation of processes and process changes with the help of cause–effect networks and change propagation.

- Modified V-model by Watty and Binz: Consideration of PEnv via a checklist and additional methods.

8.3. Conclusion and Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nagel, D.J.; Zaghloul, M.E. MEMS: Micro Technology, Mega Impact. IEEE Circuits Devices Mag. 2001, 17, 14–25. [Google Scholar] [CrossRef]

- Bryzek, J.; Roundy, S.; Bircumshaw, B.; Chung, C.; Castellino, K.; Stetter, J.R.; Vestel, M. Marvelous MEMs. IEEE Circuits Devices Mag. 2006, 22, 8–28. [Google Scholar] [CrossRef]

- Wise, K.D. Integrated sensors, MEMS, and microsystems: Reflections on a fantastic voyage. Sens. Actuators A Phys. 2007, 136, 39–50. [Google Scholar] [CrossRef]

- Marinis, T.F. The Future of Microelectromechanical systems (MEMS). Strain 2009, 45, 208–220. [Google Scholar] [CrossRef]

- Esashi, M. MEMS development focusing on collaboration using common facilities: A retrospective view and future directions. Microsyst. Nanoeng. 2021, 7, 60. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, X.; Shi, Q.; He, T.; Sun, Z.; Guo, X.; Liu, W.; Sulaiman, O.B.; Dong, B.; Lee, C. Development Trends and Perspectives of Future Sensors and MEMS/NEMS. Micromachines 2020, 11, 7. [Google Scholar] [CrossRef]

- Ko, W.H. Trends and frontiers of MEMS. Sens. Actuators A Phys. 2007, 136, 62–67. [Google Scholar] [CrossRef]

- Fitzgerals, A.M.; White, C.D.; Chung, C.C. MEMS Product Development: From Concept to Commercialization; Springer Nature: Cham, Switzerland, 2021; ISBN 978-3-030-61708-0. [Google Scholar]

- Shukor, S.A.; Axinte, D.A. Manufacturability analysis system: Issues and future trends. Int. J. Prod. Res. 2008, 47, 1369–1390. [Google Scholar] [CrossRef]

- Watty, R. Methodik zur Produktentwicklung in der Mikrosystemtechnik. Ph.D. Dissertation, University of Stuttgart, Stuttgart, Germany, 2006. [Google Scholar]

- Civelek, F.; Fritz, K.-P.; Zimmermann, A. Towards a Tailored Engineering Design Process for Individualized Micro-Mechatronic Systems with a Novel Case-Based Methodology. Appl. Sci. 2021, 11, 7909. [Google Scholar] [CrossRef]

- Yole Developpement. MEMS: Global MEMS/Microsystems Markets and Opportunities 2008; Semi and Yole Development: Villeurbanne, France, 2008. [Google Scholar]

- Schmidt, T. Technologiemanagement und Anwendungsspezifische Prozessentwicklung in der Mikrosystemtechnik. D.Eng Dissertation, University of Siegen, Siegen, Germany, 2011. [Google Scholar]

- Hahn, K.; Schmidt, T.; Mielke, M.; Brück, R. Technologiegerechte Produktentwicklung von MEMS. In Proceedings of the Dresdner Arbeitstagung Schaltungs- und Systementwurf, Dresden, Germany, 18–19 May 2010; Elst, G., Ed.; Fraunhofer Verlag: Stuttgart, Germany, 2010; pp. 49–54. ISBN 978-3-8396-0126-6. [Google Scholar]

- Gleadall, A.; Vladov, N.; Segal, J.; Ratchev, S.; Plasch, M.; Kimmig, D.; Dickerhof, M. A decision support methodology for embodiment design and process chain selection for hybrid manufacturing platforms. Int. J. Adv. Manuf. Technol. 2016, 87, 553–569. [Google Scholar] [CrossRef]

- Eloy, J.C.; Mounier, E. Status of the MEMS Industry. In SPIE Proceedings Vol. 5715: MEMS/MOEMS Components and Their Applications II, Proceedings of the SPIE Photonics West MOEMS-MEMS Micro & Nanofabrication 2005, San Jose, CA, USA, 22–27 January 2005; Henning, A.K., Ed.; SPIE: Bellingham, WA, USA, 2005; pp. 43–49. ISBN 978-0819456915. [Google Scholar]

- Iacopi, F.; Balestra, F. (Eds.) More-Than-Moore Devices and Integration for Semiconductors; Springer: Cham, Switzerland, 2023; ISBN 9783031216091. [Google Scholar]

- Barnett, J.; Baugart, G.; Beitia, C. IEEE International Roadmap for Devices and Systems: Yield Enhancement; IEEE—The Institute of Electrical and Electronics Engineers, Inc.: Piscataway, NJ, USA, 2023. [Google Scholar]

- Wulfsberg, J.P.; Redlich, T.; Kohrs, P. Square Foot Manufacturing—A new production concept for micro manufacturing. Prod. Eng. Res. Devel. 2010, 4, 75–83. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Akinlabi, E.T.; Adeoye, A.; Fatoba, S.O. Microfabrication and nanotechnology in manufacturing system—An overview. Mater. Today Proc. 2021, 44, 1154–1162. [Google Scholar] [CrossRef]

- Rudtsch, V. Methodik zur Bewertung von Produktionssystemen in der Frühen Entwicklungsphase. Ph.D. Thesis, University of Paderborn, Paderborn, Germany, 2016. [Google Scholar]

- Vella, P.C.; Dimov, S.S.; Minev, R.; Brousseau, E.B. Technology maturity assessment of micro and nano manufacturing processes and process chains. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1362–1383. [Google Scholar] [CrossRef]

- Huff, M. Process Variations in Microsystems Manufacturing; Springer Nature: Cham, Switzerland, 2020; ISBN 978-3-030-40558-8. [Google Scholar]

- Ortloff, D.; Schmidt, T.; Hahn, K.; Bieniek, T.; Janczyk, G.; Brück, R. MEMS Product Engineering: Handling the Diversity of an Emerging Technology. Best Practices for Cooperative Development; Springer: Wien, Austria, 2014; ISBN 978-3-7091-0706-5. [Google Scholar]

- Gerlach, G.; Dötzel, W. Introduction to Microsystem Technology: A Guide for Students; John Wiley & Sons Ltd: Chichester, UK, 2008; ISBN 978-0-470-77092-4. [Google Scholar]

- Bhushan, B. (Ed.) Springer Handbook of Nanotechnology, 4th ed.; Springer: Berlin, Germany, 2017; ISBN 978-3-662-54355-9. [Google Scholar]

- Watty, R.; Binz, H. Entwicklungsmethodik für die Mikrosystemtechnik unter Besonderer Berücksichtigung von Qualitätsaspekten. In Design for X, Proceedings of the 16. Symposium “Design for X”, Neukirchen, Germany, 13–14 October 2005; Meerkamm, H., Ed.; Lehrstuhl für Konstruktionstechnik, FAU Erlangen-Nuremberg: Erlangen-Nuremberg, Germany, 2005; ISBN 978-3-9808539-3-4. [Google Scholar]

- Fu, M.W.; Chan, W.L. A review on the state-of-the-art microforming technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 2411–2437. [Google Scholar] [CrossRef]

- Razali, A.R.; Qin, Y. A Review on Micro-manufacturing, Micro-forming and their Key Issues. Procedia Eng. 2013, 53, 665–672. [Google Scholar] [CrossRef]

- Qin, Y.; Brockett, A.; Ma, Y.; Razali, A.; Zhao, J.; Harrison, C.; Pan, W.; Dai, X.; Loziak, D. Micro-manufacturing: Research, technology outcomes and development issues. Int. J. Adv. Manuf. Technol. 2010, 47, 821–837. [Google Scholar] [CrossRef]

- Gao, S.; Huang, H. Recent advances in micro- and nano-machining technologies. Front. Mech. Eng. 2017, 12, 18–32. [Google Scholar] [CrossRef]

- Cui, Z.; Leach, R.; Flack, D. Microsystems Technology Standardisation Roadmap; National Physical Laboratory (NPL): Teddington, UK, 2003. [Google Scholar]

- Scholz-Reiter, B.; Rippel, D. Eine Methode zum Design von Mikroprozessketten. Ind. Manag. 2013, 29, 15–19. [Google Scholar]

- Civelek, F.; Brem, A.; Fritz, K.-P.; Zimmermann, A. Product Development Processes for Individualized Products: A Case Study. IEEE Trans. Eng. Manage. 2023, 71, 6190–6204. [Google Scholar] [CrossRef]

- Marigo, E.; Kumaaran, S.; Safwan, M.; Weng Wong, G. Process Control Monitoring Devices for CMOS-MEMS Monolithic PMUT Technology. In MEMS 2024, Proceedings of the 37th International Conference on Micro Electro Mechanical Systems, Austin, TX, USA, 21–25 January 2024; Li, W., Weinstein, D., Eds.; IEEE: Piscataway, NJ, USA, 2024; ISBN 979-8-3503-5792-9. [Google Scholar]

- Watty, R.; Binz, H. Design for manufacturing and integration of micro-electro-mechanical systems. In Engineering Design and the Global Economy, Proceedings of the 15th International Conference on Engineering Design, Melbourne, Australia, 15–18 August 2005; Samuel, A.E., Ed.; The Design Society: Glasgow, UK, 2005; ISBN 0-85825-788-2. [Google Scholar]

- Qin, Y. Overview of Micro-manufacturing. In Micromanufacturing Engineering and Technology, 2nd ed.; Qin, Y., Ed.; Elsevier Sience: Amsterdam, The Netherlands, 2015; pp. 1–33. ISBN 978-0-323-31149-6. [Google Scholar]

- Wolter, A.; Herrmann, A.; Yildiz, G.; Schenk, H.; Lakner, H. Designing MEMS for manufacturing. In SPIE Proceedings Vol. 5604: Optomechatronic Micro/Nano Components, Devices, and Systems, Proceedings of the SPIE OPTICS EAST 2004, Philadelphia, PA, USA, 27–28 October 2004; Katagiri, Y., Ed.; SPIE: Bellingham, WA, USA, 2004; pp. 74–85. ISBN 978-0819455574. [Google Scholar]

- Polosky, M.-A.; Garcia, E.-J. Microsystem Product Development. In DTIP of MEMS & MOEMS 2006, Proceedings of the Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS 2006, Stresa, Italy, 26–28 April 2006; Shawn Blanton, A.B., Ed.; TIMA Eds: Grenoble, Frace, 2006; ISBN 2-916187-03-0. [Google Scholar]

- Albers, A.; Marz, J. Restrictions of production engineering on micro-specific product development. Microsyst. Technol. 2004, 10, 205–210. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure, e.V. Entwicklung Mechatronischer und Cyber-Physischer Systeme; VDI/VDE 2206; Beuth Verlag GmbH: Berlin, Germany, 2021. [Google Scholar]

- Brück, R.; Hahn, K.; Popp, J.; Schmidt, T.; Wagener, A.; Wahl, M. A MEMS-EDA-Methodology based on Process Management. In MIXDES 2006, Proceedings of the International Conference Mixed Design of Integrated Circuits and Systems, Gdynia, Poland, 22–24 June 2006; Napieralski, A., Ed.; IEEE: Piscataway, NJ, USA, 2006; pp. 198–201. ISBN 83-922632-1-9. [Google Scholar]

- Hahn, K.; Schmidt, T.; Ortloff, D.; Popp, J.; Wagener, A.; Brück, R. MEMS product engineering using fabrication process development tools. In Micro- and Nanotechnology: Materials, Processes, Packaging, and Systems IV, Proceedings of the SPIE Smart Materials, Nano- and Micro-Smart Systems, Melbourne, Australia, 10–12 December 2008; Chiao, J.-C., Hariz, A.J., Thiel, D.V., Yang, C., Eds.; SPIE: Bellingham, WA, USA, 2008; ISBN 9780819475213. [Google Scholar]

- Niekiel, M.F.; Meyer, J.M.; Lewitz, H.; Kittmann, A.; Nowak, M.A.; Lofink, F.; Meyners, D.; Zollondz, J.-H. What MEMS Research and Development Can Learn from a Production Environment. Sensors 2023, 23, 5549. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.; Botha, B. Process development: A theoretical framework. Int. J. Prod. Res. 2006, 44, 2977–2996. [Google Scholar] [CrossRef]

- Xuan, F.Z. Manufacturing Advisory Service System for Concurrent and Collaborative Design of MEMS Devices. In MEMS/NEMS: Handbook Techniques and Applications; Leondes, C.T., Ed.; Springer Science: New York, NY, USA, 2006; pp. 1–32. ISBN 978-0-387-24520-1. [Google Scholar]

- Leondes, C.T. (Ed.) MEMS/NEMS: Handbook Techniques and Applications; Springer Science: New York, NY, USA, 2006; ISBN 978-0-387-24520-1. [Google Scholar]

- Civelek, F. Methodik zur Entwicklung von Individualisierten Mikrosystemen. D.Eng Dissertation, University of Stuttgart, Stuttgart, Germany, 2023. [Google Scholar]

- Farooq, A.; Tavares, S.; Nóvoa, H.; Araújo, A. An application of Knowledge Management in Design Structure Matrix for a process improvement phase. In Risk and Change Management in Complex Systems, Proceedings of the 16th International DSM Conference Paris, Paris, Frace, 2–4 July 2014; Marle, F., Jankovic, M., Maurer, M., Schmidt, D.M., Lindemann, U., Eds.; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2014; pp. 287–296. ISBN 978-1-56990-491-6. [Google Scholar]

- Leo Kumar, S.P. Knowledge-based expert system in manufacturing planning: State-of-the-art review. Int. J. Prod. Res. 2019, 57, 4766–4790. [Google Scholar] [CrossRef]

- Hahn, K.; Gradek, I.; Ortloff, D.; Brück, R. Methodology and tool support for micro and nano product engineering for SMEs. In Nanotechnology 2013 (Vol.2): Electronics, Devices, Fabrication, MEMS, Fluidics and Computational, Proceedings of the 16th NSTI Nanotechnology Conference and Expo, Washington, DC, USA, 12–16 May 2013; Nano Science and Technology Institute (NSTI), Ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2013; pp. 493–496. ISBN 9781482205848. [Google Scholar]

- Hahn, K.; Schmidt, T.; Mielke, M.; Brück, R. Distributed Product Engineering for Microsystems Devices. In MIXDES 2010, Proceedings of the 17th International Conference Mixed Design of Integrated Circuits and Systems, Wroclaw, Pland, 24–26 June 2010; Napieralski, A., Ed.; IEEE: Piscataway, NJ, USA, 2010; pp. 453–457. ISBN 9781424470112. [Google Scholar]

- Schmidt, T.; Hahn, K.; Mielke, M.; Brück, R.; Ortloff, D.; Popp, J. Distributed and Collaborative Product Engineering for MEMS. In Int. J. Microelectron Comput. Sci. 2010, 1, 277–286. [Google Scholar]

- Song, Y.S.; Thoutam, L.R.; Tayal, S.; Rahi, S.B.; Samuel, T.S.A. Handbook of Emerging Materials for Semiconductor Industry; Springer Nature: Singapore, 2024; ISBN 978-981-99-6648-6. [Google Scholar]

- Gupta, P.; Papadopoulou, E. Yield Analysis and Optimization. In Handbook of Algorithms for Physical Design Automation; Alpert, C.J., Mehta, D.P., Sapatnekar, S.S., Eds.; Auerbach Publications: Boca Raton, FL, USA, 2008; pp. 771–790. ISBN 9780429118173. [Google Scholar]

- Watty, R.; Binz, H. Methodology for the development of micro-electro-mechanical systems. In Design for Society: Kowledge, Innovation and Sustainability, Proceedings of the 16th International Conference on Engineering Design, Paris, Frace, 28–31 August 2007; Bocquet, J.-C., Ed.; The Design Society: Glasgow, UK, 2007. [Google Scholar]

- Watty, R.; Binz, H. A specific design methodology for micro-electro-mechanical systems to support lifelong learning. In Engineering Design and the Global Economy, Proceedings of the 15th International Conference on Engineering Design, Melbourne, Australia, 15–18 August 2005; Samuel, A.E., Ed.; The Design Society: Glasgow, UK, 2005; ISBN 0-85825-788-2. [Google Scholar]

- Thomy, C.; Wilhelmi, P.; Onken, A.-K.; Schenck, C.; Kuhfuß, B.; Tracht, K.; Rippel, D.; Lütjen, M.; Freitag, M. Process Design. In Cold Micro Metal Forming: Research Report of the Collaborative Research Center “Micro Cold Forming”; Vollertsen, F., Friedrich, S., Kuhfuß, B., Maaß, P., Thomy, C., Zoch, H.-W., Eds.; Springer Nature: Cham, Switzerland, 2020; pp. 95–132. ISBN 978-3-030-11279-0. [Google Scholar]

- Linde, H.; Hall, M.; Her, H. The Integration of existing Tools and Techniques into a powerful and structured Innovation Strategy. In ICED ‘99 Communication and Cooperation of Practice and Science, Proceedings of the 12th International Conference on Engineering Design ICED ‘99, Munich, Germany, 24–26 August 1999; Lindemann, U., Birkhofer, H., Meerkamm, H., Vajna, S., Eds.; TU Munich: Munich, Germany, 1999; ISBN 3-922979-53-X. [Google Scholar]

- Rafiee, P.; Khatibi, G.; Zehetbauer, M. A review of the most important failure, reliability and nonlinearity aspects in the development of microelectromechanical systems (MEMS). MI 2017, 34, 9–21. [Google Scholar] [CrossRef]

- Zhou, Q.; Aurelian, A.; Del Corral, C.; Esteban, P.J.; Kallio, P.; Chang, B.; Koivo, H.N. Microassembly station with controlled environment. In Microrobotics and Microassembly III, Proceedings of the Intelligent Systems and Advanced Manufacturing, Boston, MA, USA, 28 October 2001; Nelson, B.J., Breguet, J.-M., Eds.; SPIE: Bellingham, WA, USA, 2001; pp. 252–260. [Google Scholar]

- Qin, Y. (Ed.) Micromanufacturing Engineering and Technology, 2nd ed.; Elsevier Sience: Amsterdam, The Netherlands, 2015; ISBN 978-0-323-31149-6. [Google Scholar]

- DIN EN ISO 9001; Qualitätsmanagementsysteme_-Anforderungen (ISO_9001:2015). Beuth Verlag GmbH: Berlin, Germany, 2015. [CrossRef]

- DIN EN ISO 14644-4; Reinräume und Zugehörige Reinraumbereiche-Teil 4: Planung, Ausführung und Erst-Inbetriebnahme. Beuth Verlag GmbH: Berlin, Germany, 2023. [CrossRef]

- van Brussel, H.; Peirs, J.; Reynaerts, D.; Delchambre, A.; Reinhart, G.; Roth, N.; Weck, M.; Zussman, E. Assembly of Microsystems. CIRP Ann. 2000, 49, 451–472. [Google Scholar] [CrossRef]

- Tietje, C.; Ratche, S. Design for Microassembly—A Methodology for Product Design and Process Selection. In ISAM ‘07, Proceedings of the IEEE International Symposium on Assembly and Manufacturing, Ann Arbor, MI, USA, 22–25 July 2007; Saitou, K., Ed.; IEEE: Piscataway, NJ, USA, 2007; pp. 178–183. ISBN 9781424405629. [Google Scholar]

- Zhou, Q.; del Corral, C.; Esteban, P.J.; Aurelian, A.; Koivo, H.N. Environmental influences on microassembly. In IEEE/RSJ International Conference on Intelligent Robots and System, Proceedings of the IROS 2002: IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–5 October 2002; IEEE: Piscataway, NJ, USA, 2002; pp. 1760–1765. ISBN 0-7803-7398-7. [Google Scholar]

- Soueid, A.; Teague, E.C.; Murday, J. Buildings for Advanced Technology; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-24890-5. [Google Scholar]

- Pearce, J.V.; Tucker, D.L.; Veltcheva, R.I.; Machin, G. New Paradigms in Traceable Process Control Thermometry. In Proceedings of the 2022 UKACC 13th International Conference on Control (CONTROL), Plymouth, UK, 20–22 April 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 102–107, ISBN 978-1-6654-5200-7. [Google Scholar]

- Wolpert, D.; Ampadu, P. Managing Temperature Effects in Nanoscale Adaptive Systems; Springer: New York, NY, USA, 2012; ISBN 978-1-4614-0747-8. [Google Scholar]

- Tan, Ö.; Schmid, H.; Seyfried, V. A new evaluation method for interferometric surface topography measurements which is robust against environmental disturbances. CIRP J. Manuf. Sci. Technol. 2021, 33, 234–239. [Google Scholar] [CrossRef]

- Mahalik, N.P. Micromanufacturing and Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 978-3-540-25377-8. [Google Scholar]

- Song, J.; Huang, Q.-A.; Li, M.; Tang, J.-Y. Influence of environmental temperature on the dynamic properties of a die attached MEMS device. Microsyst. Technol. 2009, 15, 925–932. [Google Scholar] [CrossRef]

- Khanna, V.K. Adhesion–delamination phenomena at the surfaces and interfaces in microelectronics and MEMS structures and packaged devices. J. Phys. D Appl. Phys. 2011, 44, 034004. [Google Scholar] [CrossRef]

- Zhou, Q.; Chang, B.; Koivo, H.N. Temperature and Humidity Effects on Micro/Nano Handling. MSF 2006, 532–533, 681–684. [Google Scholar] [CrossRef]

- Zhou, Y.; Nelson, B.J. Adhesion force modeling and measurement for micromanipulation. In Microrobotics and Micromanipulation, Proceedings of the Photonics East (ISAM, VVDC, IEMB), Boston, MA, USA, 1 November 1998; Sulzmann, A., Nelson, B.J., Eds.; SPIE: Bellingham, WA, USA, 1998; pp. 169–180. [Google Scholar]

- Lee, K.; Kim, T. Investigation of Cu Corrosion Defects Induced by Humidity Imbalance in the Cu Damascene Process of Semiconductors. Meet. Abstr. 2024, MA2024-01, 1236. [Google Scholar] [CrossRef]

- Jeong, J.; Park, J.; Han, E.; Kim, J.; Kim, H. Control of Wafer Slot-Dependent Outgassing Defects during Semiconductor Manufacture Processes. In Proceedings of the 2019 30th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), Saratoga Springs, NY, USA, 6 May–9 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4, ISBN 978-1-5386-7601-1. [Google Scholar]

- van Roijen, R.; Conti, S.G.; Keyser, R.; Arndt, R.; Burda, R.; Ayala, J.; Henry, R.O.; Levy, J.; Maxson, J.; Meyette, E.; et al. Reducing Environmentally Induced Defects While Maintaining Productivity. IEEE Trans. Semicond. Manufact. 2013, 26, 35–41. [Google Scholar] [CrossRef]

- Fujiwara, R.; Iguchi, Y.; Takahashi, K.; Saito, S. Humidity dependence of electrostatic pick-and-place operation of a micro dielectric particle considering surface conductivity and capillary condensation. J. Appl. Phys. 2018, 124, 064303. [Google Scholar] [CrossRef]

- Busnaina, A.A.; Elsawy, T. The Effect of Relative Humidity on Particle Adhesion and Removal. J. Adhes. 2000, 74, 391–409. [Google Scholar] [CrossRef]

- Wu, J.-H.; Zhao, G.; Chu, J.-R. Influences of environmental humidity on micro object handling efficiency. J. Micromech. Microeng. 2007, 17, 187–192. [Google Scholar] [CrossRef]

- Deb, N.; Blanton, R.D. Analysis of failure sources in surface-micromachined MEMS. In Proceedings of the International Test Conference 2000, Atlantic City, NJ, USA, 3–5 October 2000; pp. 739–749, ISBN 0-7803-6546-1. [Google Scholar]

- Geschke, O.; Klank, H.; Telleman, P. Microsystem Engineering of Lab-on-a-Chip Devices/[Editors], Oliver Geschke, Henning Klank, Pieter Tellemann; Wiley-VCH: Weinheim, Germany, 2004; ISBN 9783527606368. [Google Scholar]

- Kumar, A.; Ahmed, L.; Camenzind, M.J. Investigating yield loss caused by airborne organophosphates. Micro Mag. 2001, 1–9. [Google Scholar]

- Palinkas, L.A. Mixed method designs. In Implementation Science; Rapport, F., Clay-Williams, R., Braithwaite, J., Eds.; Routledge: London, UK, 2022; pp. 118–122. ISBN 9781003109945. [Google Scholar]

- Mulrow, C.D. Rationale for systematic reviews. BMJ 1994, 309, 597–599. [Google Scholar] [CrossRef]

- vom Brocke, J.; Simons, A.; Riemer, K.; Niehaves, B.; Plattfaut, R.; Cleven, A. Standing on the Shoulders of Giants: Challenges and Recommendations of Literature Search in Information Systems Research. Commun. Assoc. Inf. Syst. 2015, 37, 205–224. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D.; van Aken, J.E. Developing Design Propositions through Research Synthesis. Organ. Stud. 2008, 29, 393–413. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- McGowan, J.; Sampson, M.; Salzwedel, D.M.; Cogo, E.; Foerster, V.; Lefebvre, C. PRESS Peer Review of Electronic Search Strategies: 2015 Guideline Statement. J. Clin. Epidemiol. 2016, 75, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. J. Clin. Epidemiol. 2021, 134, 178–189. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. PLoS Med. 2021, 18, e1003583. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Fabiano, N.; Gupta, A.; Bhambra, N.; Luu, B.; Wong, S.; Maaz, M.; Fiedorowicz, J.G.; Smith, A.L.; Solmi, M. How to optimize the systematic review process using AI tools. JCPP Adv. 2024, 4, e12234. [Google Scholar] [CrossRef]

- Bolaños, F.; Salatino, A.; Osborne, F.; Motta, E. Artificial intelligence for literature reviews: Opportunities and challenges. Artif Intell Rev 2024, 57, 259. [Google Scholar] [CrossRef]

- Schünemann, H.J.; Oxman, A.D.; Brozek, J.; Glasziou, P.; Jaeschke, R.; Vist, G.E.; Williams, J.W.; Kunz, R.; Craig, J.; Montori, V.M.; et al. Grading quality of evidence and strength of recommendations for diagnostic tests and strategies. BMJ 2008, 336, 1106–1110. [Google Scholar] [CrossRef]

- Guyatt, G.H.; Oxman, A.; Gunn, E.V.; Kunz, R.; Falck-Yitter, Y.; Alonso-Coello, P.; Schünemann, H. GRADE: An emerging consensus on rating quality of evidence and strength of recommendations. BMJ 2008, 336, 924–926. [Google Scholar] [CrossRef]

- Schünemann, H.; Brożek, J.; Guyatt, G.; Oxman, A. GRADE Handbook for Grading Quality of Evidence and Strength of Recommendations; GRADE Working Group: Hamilton, Kanada, 2013. [Google Scholar]

- Bilotta, G.S.; Milner, A.M.; Boyd, I.L. Quality assessment tools for evidence from environmental science. Environ. Evid. 2014, 3, 14. [Google Scholar] [CrossRef]

- Albers, A.; Burkard, N.; Hauser, S.; Marz, J. Knowledge-based design environment for primary shaped micro parts. Microsyst. Technol. 2005, 11, 254–260. [Google Scholar] [CrossRef]

- Albers, A.; Burkard, N.; Deigendesch, T. Knowledge-based Support of Decision Making at the Example of Microtechnology. J. Autom. Mob. Robot. Intell. Syst. 2007, 4, 16–20. [Google Scholar]

- Albers, A.; Marz, J. Design Environment and Design Flow. In Advanced Micro and Nanosystems Vol. 3: Microengineering of Metals and Ceramics; Baltes, H., Brand, O., Fedder, G.K., Hierold, C., Korvink, J., Tabatta, O., Eds.; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; pp. 3–28. ISBN 3-527-31208-0. [Google Scholar]

- Lanza, G.; Albers, A.; Kippenbrock, K.; Börsting, P. Support for Micro-Tolerancing Through the Feedback of Existing Quality-Related Data to Product Developers. In Euspen Conference Proceedings Volume II, Proceedings of the 11th International Conference of the European Society for Precision Engineering and Nanotechnology, Como, Italy, 23–26 May 2011; Spaan, H., Shore, P., van Brussel, H., Burke, T., Eds.; euspen: Bedford, UK, 2011; ISBN 978-0-9553082-9-1. [Google Scholar]

- Marz, J. Mikrospezifischer Produktentwicklungsprozess (μPEP) für Werkzeuggebundene Mikrotechniken. D.Eng Dissertation, University of Karlsruhe, Karlsruhe, Germany, 2005. [Google Scholar]

- Breitfeld, A. Aktorkonstruktion in der Mikrosystemtechnik: Mikro-QFD—Ein Transdisziplinärer Ansatz zur Innovationsorientierten Entwicklung Mikrotechnischer Aktorsysteme. D.Eng Dissertation, Helmut Schmidt University, Hamburg, Germany, 2017. [Google Scholar]

- Sagoo, J.; Tiwari, A.; Alcock, J. A Descriptive Model of the Current Microelectromechanical Systems (MEMS) Development Process. In ICED 09 Vol.1: Design Processes, Proceedings of the 17th International Conference on Engineering Design, Stanford, CA, USA, 24–27 August 2009; Norell Bergendahl, M., Grimheden, M., Leifer, L., Skogstad, P., Lindemann, U., Eds.; Design Society: Glasgow, UK, 2009; pp. 607–616. ISBN 9781904670056. [Google Scholar]

- Albers, A.; Turki, T. Supporting design of primary shaped micro parts and systems through provision of experience. Microsyst. Technol. 2013, 19, 471–476. [Google Scholar] [CrossRef]

- Baltes, H.; Brand, O.; Fedder, G.K.; Hierold, C.; Korvink, J.; Tabatta, O. (Eds.) Advanced Micro and Nanosystems Vol. 3: Microengineering of Metals and Ceramics; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; ISBN 3-527-31208-0. [Google Scholar]

- Rippel, D.; Lütjen, M.; Freitag, M. Enhancing Expert Knowledge Based Cause-Effect Networks Using Continuous Production Data. Procedia Manuf. 2018, 24, 128–134. [Google Scholar] [CrossRef]

- Hahn, K.; Ortloff, D.; Brück, R. A visual approach on MEMS process modeling using device cross-sections. TechConnect Briefs 2010, 2, 673–676. [Google Scholar]

- Hahn, K.; Popp, J.; Wagener, A. Process management and design for MEMS and microelectronics technologies. In Microelectronics: Design, Technology, and Packaging, Proceedings of the Microelectronics, MEMS, and Nanotechnology, Perth, Australia, 9 December 2003; Abbott, D., Eshraghian, K., Musca, C.A., Pavlidis, D., Weste, N., Eds.; SPIE: Bellingham, WA, USA, 2003; pp. 322–330. [Google Scholar]

- Ortloff, D.; Popp, J.; Schmidt, T.; Bruck, R. Process development support environment: A tool suite to engineer manufacturing sequences. Int. J. Comput. Mater. Sci. Surf. Eng. 2009, 2, 312. [Google Scholar] [CrossRef]

- Ortloff, D.; Popp, J.; Schmidt, T.; Hahn, K.; Mielke, M.; Brück, R. MEMS product engineering: Methodology and tools. In SPIE Proceedings Vol. 7926: Micromachining and Microfabrication Process Technology XVI, Proceedings of the SPIE Photonics West 2011, San Francisco, CA, USA, 22–27 January 2011; Maher, M.A., Chiao, J.-C., Resnick, P.J., Eds.; SPIE: Bellingham, WA, USA, 2011; 79260D 1-10. [Google Scholar]

- Ortloff, D.; Popp, J.; Wagener, A.; Hahn, K. Breaking through the process development barriers. In COMS 2008, Proceedings of the International Conference on Commercialization of Micro and Nano Systems, Puerto Vallarta, Mexico, 31 August–4 September 2008; Micro and Nanotechnology Commercialization Education Foundation MANCEF: Albuquerque, NM, USA, 2008. [Google Scholar]

- Wagener, A. Fertigungsnahe Entwurfsunterstützung für die Mikrosystemtechnik. D.Eng Dissertation, University of Siegen, Siegen, Germany, 2005. [Google Scholar]

- Schmidt, T.; Hahn, K.; Bruck, R. A knowledge based approach for MEMS fabrication process design automation. In IEMT 2008, Proceedings of the 33rd IEEE/CPMT Electronic Manufacturing Technology Symposium (IEMT), Penang, Malaysian, 4–6 November 2008; IEEE: Piscataway, NJ, USA, 2008; ISBN 978-1-4244-3392-6. [Google Scholar]

- Triltsch, U. Baukastenbasierte Entwicklungsmethodik für die Rechnerunterstützte Konstruktion von Mikrosystemen. D.Eng Dissertation, TU Braunschweig, Braunschweig, Germany, 2007. [Google Scholar]

- Triltsch, U.; Buttgenbach, S. Next generation of TCAD environments for MEMS design. In DTIP of MEMS & MOEMS 2008, Proceedings of the 2008 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS, Nice, Frace, 9–11 April 2008; Bright, V.M., Ed.; IEEE: Piscataway, NJ, USA, 2008; pp. 91–95. ISBN 978-2-35500-006-5. [Google Scholar]

- Wang, Q.-H.; Gong, H.-Q. Computer-aided process planning for fabrication of three-dimensional microstructures for bioMEMS applications. Int. J. Prod. Res. 2009, 47, 6051–6067. [Google Scholar] [CrossRef]

- Gielisch, C.; Fritz, K.-P.; Wigger, B.; Zimmermann, A. Conceptual Planning of Micro-Assembly for a Better Utilization of Reconfigurable Manufacturing Systems. Appl. Sci. 2020, 10, 2806. [Google Scholar] [CrossRef]

- Hansen, U. Wissensbasierte Überprüfung Mikrotechnologischer Fertigungsabläufe. D.Eng Dissertation, TU Braunschweig, Braunschweig, Germany, 2004. [Google Scholar]

- Gralla, P.; Rippel, D.; Lütjen, M.; Piotrowska-Kurczewski1, I.; Maaß, P. Eine Methode zur Invertierung von Vorhersagemodellen in der Mikrofertigung. In Proceedings of the 8. Kolloquium Mikroproduktion, Bremen, Germany, 27–28 November 2017; Vollertsen, F., Hopmann, C., Schulze, V., Wulfsberg, J.P., Eds.; BIAS Verlag: Bremen, Germany, 2017. ISBN 978-3-933762-56-6. [Google Scholar]

- Rippel, D.; Lutjen, M.; Scholz-Reiter, B. A framework for the quality-oriented design of micro manufacturing process chains. J. Manuf. Technol. Manag. 2014, 25, 1028–1048. [Google Scholar] [CrossRef]

- Rippel, D.; Lütjen, M.; Freitag, M. Domain-Specific Modelling of Micro Manufacturing Processes for the Design of Alternative Process Chains. In EUROSIM 2016, Oulu, Finland, Proceedings of the 9th EUROSIM Congress on Modelling and Simulation and 57th SIMS Conference on Simulation and Modelling, 12–16 September 2016; Juuso, E., Dahlquist, E., Leiviskä, K., Eds.; Linköping University Electronic Press: Linköping, Sweden, 2018; pp. 700–706. ISBN 978-91-7685-399-3. [Google Scholar]

- Rippel, D.; Lütjen, M.; Freitag, M. Geometrieorientierter Prozessketten-entwurf für die Mikrofertigung. Ind. 4.0 Manag. 2016, 32, 50–53. [Google Scholar]

- Rippel, D.; Lütjen, M.; Freitag, M. Local characterisation of variances for the planning and configuration of process chains in micro manufacturing. J. Manuf. Syst. 2017, 43, 79–87. [Google Scholar] [CrossRef]

- Rippel, D.; Moumi, E.; Lütjen, M.; Scholz-Reiter, B.; Kuhfuß, B. Application of Stochastic Regression for the Configuration of Microrotary Swaging Processes. Math. Probl. Eng. 2014, 1–12. [Google Scholar] [CrossRef]

- Weimer, D.; Rippel, D.; Thamer, H.; Lütjen, M.; Scholz-Reiter, B. Prediction of Process Stability in Laser-chemical Ablation by Using a Multivariate Gaussian Distribution. In Recent Advances in Intelligent Control, Modelling and Computational Science, Proceedings of the 1st International Conference on Intelligent Control, Modelling and Systems Engineering (ICMS’13), Valencia, Spain, 6–8 August 2013; Zak, A., Ed.; WSEAS Press: Athen, Germany, 2013; pp. 68–72. ISBN 978-960-474-319-3. [Google Scholar]

- Büttner, H.; Maradia, U.; Suarez, M.; Stirnimann, J.; Wegener, K. Development of Process Chain for Micro-Injection Molding. In Procedia CIRP Volume 95, Proceedings of the 20th CIRP Conference on Electro Physical and Chemical Machining (ISEM 2021), Zurich, Switzerland, 19–21 January 2021; Wegener, K., Wiessner, M., Eds.; Elsevier Sience: Amsterdam, The Netherlands, 2020; pp. 584–589. [Google Scholar]

- Zha, X.F.; Du, H. Manufacturing process and material selection in concurrent collaborative design of MEMS devices. J. Micromech. Microeng. 2003, 13, 509–522. [Google Scholar] [CrossRef]

- Cho, S.; Lee, K.; Kim, T.-W. Development of a geometry-based process planning system for surface micromachining. Int. J. Prod. Res. 2002, 40, 1275–1293. [Google Scholar] [CrossRef]

- Mehmood, Z.; Haneef, I.; Udrea, F. Material selection for Micro-Electro-Mechanical-Systems (MEMS) using Ashby’s approach. Mater. Des. 2018, 157, 412–430. [Google Scholar] [CrossRef]

- Rahim, A.A.A.; Musa, S.N.; Ramesh, S.; Lim, M.K. A systematic review on material selection methods. J. Mater. Des. Appl. 2020, 234, 1032–1059. [Google Scholar] [CrossRef]

- Guisbiers, G.; Wautelet, M. Materials selection for micro-electromechanical systems. Mater. Des. 2007, 28, 246–248. [Google Scholar] [CrossRef]

- Srikar, V.T.; Spearing, S.M. Materials selection for microfabricated electrostatic actuators. Sens. Actuators A Phys. 2003, 102, 279–285. [Google Scholar] [CrossRef]

- Parate, O.; Gupta, N. Material selection for electrostatic microactuators using Ashby approach. Mater. Des. 2011, 32, 1577–1581. [Google Scholar] [CrossRef]

- Yazdani, M.; Payam, A.F. A comparative study on material selection of microelectromechanical systems electrostatic actuators using Ashby, VIKOR and TOPSIS. Mater. Des. 2015, 65, 328–334. [Google Scholar] [CrossRef]

- Patra, P.; Angira, M. Investigation on Dielectric Material Selection for RF-MEMS Shunt Capacitive Switches Using Ashby, TOPSIS and VIKOR. Trans. Electr. Electron. Mater. 2020, 21, 157–164. [Google Scholar] [CrossRef]

- Bonthu, M.K.; Sharma, A.K. An investigation of dielectric material selection of RF-MEMS switches using Ashby’s methodology for RF applications. Microsyst. Technol. 2018, 24, 1803–1809. [Google Scholar] [CrossRef]

- Sawant, V.B.; Mohite, S.S.; Cheulkar, L.N. Comprehensive contact material selection approach for RF MEMS switch. Mater. Today Proc. 2018, 5, 10704–10711. [Google Scholar] [CrossRef]

- Hildebrandt, T. Jasima-an Efficient Java Simulator for Manufacturing and Logistics. Available online: https://jasima.net/ (accessed on 4 April 2024).

- Sun, L.; Peng, L.; Deng, G.; Chien, K. A novel FMEA tool application in semiconductor manufacture. In Proceedings of the China Semiconductor Technology International Conference (CSTIC 2017), Shanghai, China, 12–13 March 2017; Claeys, C., Ed.; IEEE: Piscataway, NJ, USA, 2017; pp. 1–4, ISBN 9781509066940. [Google Scholar]

- Hering, E.; Schloske, A. Fehlermöglichkeits- und Einflussanalyse: Methode zur Vorbeugenden, Systematischen Qualitätsplanung unter Risikogesichtspunkten; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019; ISBN 978-3-658-25762-0. [Google Scholar]

- Walker, R.A.; Thomas, D.E. A model of design representation and synthesis. In Proceedings 1985, Proceedings of the 22nd ACM/IEE Design Automation Conference, Las Vegas, NV, USA, 23–26 June 1985; IEEE: Piscataway, NJ, USA, 1985; pp. 453–459. ISBN 0-8186-0635-5. [Google Scholar]

- McCorquodale, M.S.; Gebara, F.H.; Kraver, K.L.; Marsman, E.D.; Senger, R.M.; Brown, R.B. A top-down microsystems design methodology and associated challenges. In Design, Automation and Test in Europe Conference and Exhibition, 2003, Proceedings of the 6th Design Automation and Test in Europe (DATE 03), Munich, Germany, 3–7 March 2003; IEEE Computer Society: Los Alamitos, CA, USA, 2003; pp. 292–296. ISBN 0-7695-1870-2. [Google Scholar]

- Albers, A.; Burkard, N.; Deigendesch, T.; Marz, J. Micro-specific design flow for tool-based microtechnologies. Microsyst. Technol. 2007, 13, 305–310. [Google Scholar] [CrossRef]

- Kasper, M. Mikrosystementwurf: Entwurf und Simulation von Mikrosystemen; Springer: Berlin, Germany, 2000; ISBN 978-3-642-57123-7. [Google Scholar]

- Binz, H.; Watty, R. Improved design and development process for MEMS sensors. Conference, Rome, Italy: September 2004. In Eurosensors XVIII 2004, Proceedings of the 18th European Conference on Solid-State Transducers 2004, Rome, Italy, 13–15 September 2004; French, P.J., Ed.; Elsevier Sience: Amsterdam, The Netherlands, 2004. [Google Scholar]

- camLine GmbH. XperiDesk. Available online: https://www.camline.com/de/produkte/xperidesk/ (accessed on 11 May 2024).

- Denkena, B.; Tönshoff, H.K. Spanen: Grundlagen; Springer: Berlin, Germany, 2011; ISBN 978-3-642-19771-0. [Google Scholar]

- Ashby, M.F.; Cebon, D. Materials selection in mechanical design. J. Phys. IV France 1993, 3, C7-1–C7-9. [Google Scholar] [CrossRef]

- Mehdizadeh, E.; Kumar, V.; Wilson, J.C.; Pourkamali, S. Inertial Impaction on MEMS Balance Chips for Real-Time Air Quality Monitoring. Sens. J. 2017, 17, 2329–2337. [Google Scholar] [CrossRef]

- Podder, I.; Bub, U. A Design Science Research Approach Towards Knowledge Discovery and Predictive Maintenance of MEMS Inertial Sensors Using Machine Learning. In Advances in Computational Collective Intelligence, Proceedings of the 15th International Conference on Computational Collective Intelligence (ICCCI 2023), Budapest, Hungary, 27–29 September 2023; Nguyen, N.T., Botzheim, J., Gulyas, L., Nunez, M., Treur, J., Vossen, G., Kozierkiewicz, A., Eds.; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Nguyen, N.T.; Botzheim, J.; Gulyas, L.; Nunez, M.; Treur, J.; Vossen, G.; Kozierkiewicz, A. (Eds.) Advances in Computational Collective Intelligence. In Proceedings of the 15th International Conference on Computational Collective Intelligence (ICCCI 2023), Budapest, Hungary, 27–29 September 2023; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

| Failure Sources | Failure Effects | Literary Sources |

|---|---|---|

| Temperature | Thermal expansion and tension of materials (measurement errors, cracks and delamination) | [61,67,68,70,71,72,73,74] |

| Condensation on components | [70] | |

| Changes in chemical reactions | [70,72] | |

| Material aging and degradation | [67,70] | |

| Inaccuracies in the handling process of components due to changed adhesion | [61,67,75,76] | |

| Distortion of lithographic patterns | [70,72,74] | |

| Humidity effects | Corrosion and oxidation | [68,77,78] |

| Condensation defects | [72,79,80] | |

| Materials expansion caused by moisture | [68] | |

| Layer delamination and cracks | [74] | |

| Inaccuracies in the handling of components due to changed adhesion caused by capillary forces | [61,67,74,75,76,80,81,82] | |

| Electrostatic charge | [18,68,75,76] | |

| Particles and contaminants | Corrosion caused by hygroscopic contaminants | [78,81] |

| Uncontrolled doping of components | [68,83] | |

| Defects in lithography and etching steps | [18,72,74,79,83,84] | |

| Electrical short circuits | [60,61] | |

| Opacities of lithographic optics | [68] | |

| Electrostatics | Inaccuracies in the handling process of components | [61,75,76,81,82] |

| Sticking of parts or adhesion of particles due to electrical charge | [18,61,74,81] | |

| Gases | Damage caused by outgassing components in the area around components or in transport containers | [18,79,85] |

| Vibrations and acoustic sources of vibration | Measurement error | [61,68] |

| Inaccuracies in the handling process of components | [61,67,68,75] | |

| Electromagnetic and radio frequency interference | Data loss or faulty signals | [68] |

| Human factors | Vibrations | [68] |

| Incorrect cleaning | [68,74] | |

| Particulate impurities | [18,68] |

| Subject Area | Keywords |

|---|---|

| Development | process-/product development |

| process-/product engineering | |

| process planning | |

| process optimisation | |

| process design | |

| Microsystems technology | microtechnology |

| nanotechnology | |

| microsystem technology | |

| microengineering | |

| micro-electromechanical system | |

| MEMS | |

| Process environment | technical cleanliness |

| cleanroom | |

| contamination control | |

| process environment | |

| fabrication environment | |

| Methodical approach | method |

| technique | |

| strategy | |

| approach |

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Product development methods for microsystems technology, in which process planning is also considered | General planning methods that are not focused on microsystems technology |

| Development methods for parts of process planning in microsystems technology | Methods for assessing the impact of processes on nature and the climate |

| Development methods for the whole process planning in microsystems technology | Methodological approaches for technical processes |

| Conventional Literature Databases and Publishers | AI Tools |

|---|---|

| arXiv | Chat GPT |

| Google Scholar | Connected Papers |

| IEEE | Elicit |

| Jstor | Litmaps |

| MDPI | Paperdigest |

| PubMed | Perplexity |

| ResearchGate | Scholar AI |

| ScienceDirect | SciSpace |

| Scopus | |

| SpringerLink | |

| Web of Science | |

| Wiley |

| Category | Software-Based Methods | Framework-Based Methods | |

|---|---|---|---|

| Production-oriented product development (PPD) |  | [15,40,46,52,103,104,105,106,107] | [8,10,11,27,34,39,46,47,48,56,57,66,104,107,108,109,110,111] |

| Development/planning of process chains (DPP) |  | [9,13,14,22,24,43,50,51,52,53,112,113,114,115,116,117,118,119,120,121,122,123,124] | [8,9,11,13,15,23,24,33,34,36,42,44,48,50,53,58,66,114,116,118,125,126,127,128,129,130,131,132] |

| Selection of manufacturing processes (SMP) |  | [9,13,15,24,34,43,52,53,112,113,115,116,117,118,123,133,134] | [9,11,23,36,46,48,56,58,66,125,126,127,129] |

| Material selection (MS) |  | [9,13,24,43,52,53,113,116,117] | [9,23,34,46,133,135,136,137,138,139,140,141,142,143] |

| Material flow planning (MFP) |  | [13,24,43,52,53,116,117,118,144] | [23,34,44,126,129] |

| Possibility to include the process environment |  | [13,22,53,124,133,145] | [15,39,57,146] |

| Method | Application in the Development Process | PEnv Explicit? | Data-Based? | Model-Based? | Main Advantage |

|---|---|---|---|---|---|

| μPEP | Early product development | No | No | No | Combining design rules and requirements for MST manufacturing processes |

| μ-ProPlAn | Process design and evaluation | Yes (implicit) | Yes | Yes | Model-based analysis of interdependencies |

| V-model (Watty & Binz) | Analysis of early manufacturing requirements | Yes (checklist) | No | No | Systematic consideration of PEnv |

| iMST | Customized system configuration | No | No | No | High degree of adaptability to individual projects |

| PDES | Continuous process development | Yes (implicit) | Yes | Simulation | Digital management and simulation of process variations |

| Evaluation Criteria | Explanation of the Evaluation Criterion | |

|---|---|---|

| 1 | Risk of bias | This evaluation criterion checks if the methods are potentially susceptible to systematic failures if the process environment is not considered. |

| 2 | Indirectness of evidence | This assesses if the category of methods is suitable for the specific application of considering the process environment. It analyzes the extent to which the methods are appropriate for integrating environmental influences. |

| 3 | Imprecision of the results | This criterion assesses the accuracy of results related to the process environment. Precise data from process planning is required for planning and analyzing the process environment. Methods that provide inaccurate or incomplete data are assessed more critically. |

| 4 | Adaptability for considering the process environment (new category) | This criterion evaluates whether methods can be flexibly adapted or extended to consider specific requirements of the process environment. |

| 5 | Publication bias | This criterion evaluates whether methods for planning and assessing a suitable process environment are underrepresented in the literature and whether the inclusion of the process environment is even meaningful in the respective category. |

| Quality Level | Explanation of the Quality Level |

|---|---|

| High | The evidence is of high quality, and there is great confidence that the method provides a reliable result in the context of the process environment. |

| Moderate | The evidence is solid but has some uncertainties regarding the process environment that could slightly reduce confidence. |

| Low | The evidence is limited, or there are significant uncertainties regarding the process environment that could substantially impair confidence. |

| Very low | There is little confidence in the evidence regarding the process environment, as it may be significantly biased or incomplete. |

| Method Categories | Risk of Bias | Indirectness of Evidence | Imprecision of the Results | Adaptability for Considering the Process Environment | Publication Bias | Overall Evaluation |

|---|---|---|---|---|---|---|

| Production- oriented product development | Low | Low | Very low | Low | Low | Low |

| Development/planning of process chains | Low | Low | Low | Moderate | Very low | Low |

| Selection of manufacturing processes | Moderate | Very low | Very low | Low | Moderate | Very low |

| Material selection | Moderate | Very low | Moderate | Low | Moderate | Low |

| Material flow planning | Moderate | Very low | Very low | Moderate | High | Very low |

| Process Step | Possible Process Environment Influences | Potential Component Defects | Method Category |

|---|---|---|---|

| 0 | Excessive humidity | Defectively manufactured component due to residual moisture in the raw material | DPP, MS, MFP |

| 0 | Contamination that gets onto the raw material during handling—the resulting electrostatic charge increases the effect | Defectively manufactured components due to contamination in the raw material | DPP, MS, MFP |

| 1 | Particles and impurities due to inadequate cleanroom class or contamination generated by the process | Defective microstructures due to impurities in the component | PPD, DPP, SMP |

| 1 | The hot thermals of the injection molding tool create an upward airflow | Particles from the floor or the machine bed contaminate the component | DPP, SMP |

| 1, 2, 3, 4 | Process influences from workers operating the machine | Contamination due to improper cleaning or manual handling and packaging of the component | PPD, DPP |

| 1, 1.1, 2.1, 3.1 | Electrostatic charging of the component due to the injection molding process, the plastic transport container, or humidity | Particles adhering to the component due to electrostatic charge | PPD, DPP, SMP |

| 2.1, 3 | Particles and contaminants due to inadequate cleanroom classification after cleaning | Enclosed contaminants after sputtering | DPP, MFP |

| 3 | Condensation formation due to temperature differences | Holes in the surface coating | DPP, MFP |

| 4 | Vibrations caused by nearby external processes or personnel | Measurement errors in quality control | PPD, DPP |

| 1.1, 2.1, 3.1, 4.1 | Contamination in packaging due to improper cleaning or incorrect storage | Contamination of the component due to transport packaging | DPP, MFP |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metz, K.T.; Civelek, F.; Zimmermann, A. Process Development Methods in Microtechnology and the Associated Process Environment. Micromachines 2025, 16, 606. https://doi.org/10.3390/mi16060606

Metz KT, Civelek F, Zimmermann A. Process Development Methods in Microtechnology and the Associated Process Environment. Micromachines. 2025; 16(6):606. https://doi.org/10.3390/mi16060606

Chicago/Turabian StyleMetz, Korbinian T., Faruk Civelek, and André Zimmermann. 2025. "Process Development Methods in Microtechnology and the Associated Process Environment" Micromachines 16, no. 6: 606. https://doi.org/10.3390/mi16060606

APA StyleMetz, K. T., Civelek, F., & Zimmermann, A. (2025). Process Development Methods in Microtechnology and the Associated Process Environment. Micromachines, 16(6), 606. https://doi.org/10.3390/mi16060606