Influence of Lithography Process Parameters on Continuous Surface Diffractive Optical Elements for Laser Beam Shaping

Abstract

1. Introduction

2. Structural Parameters and Fabrication Methods

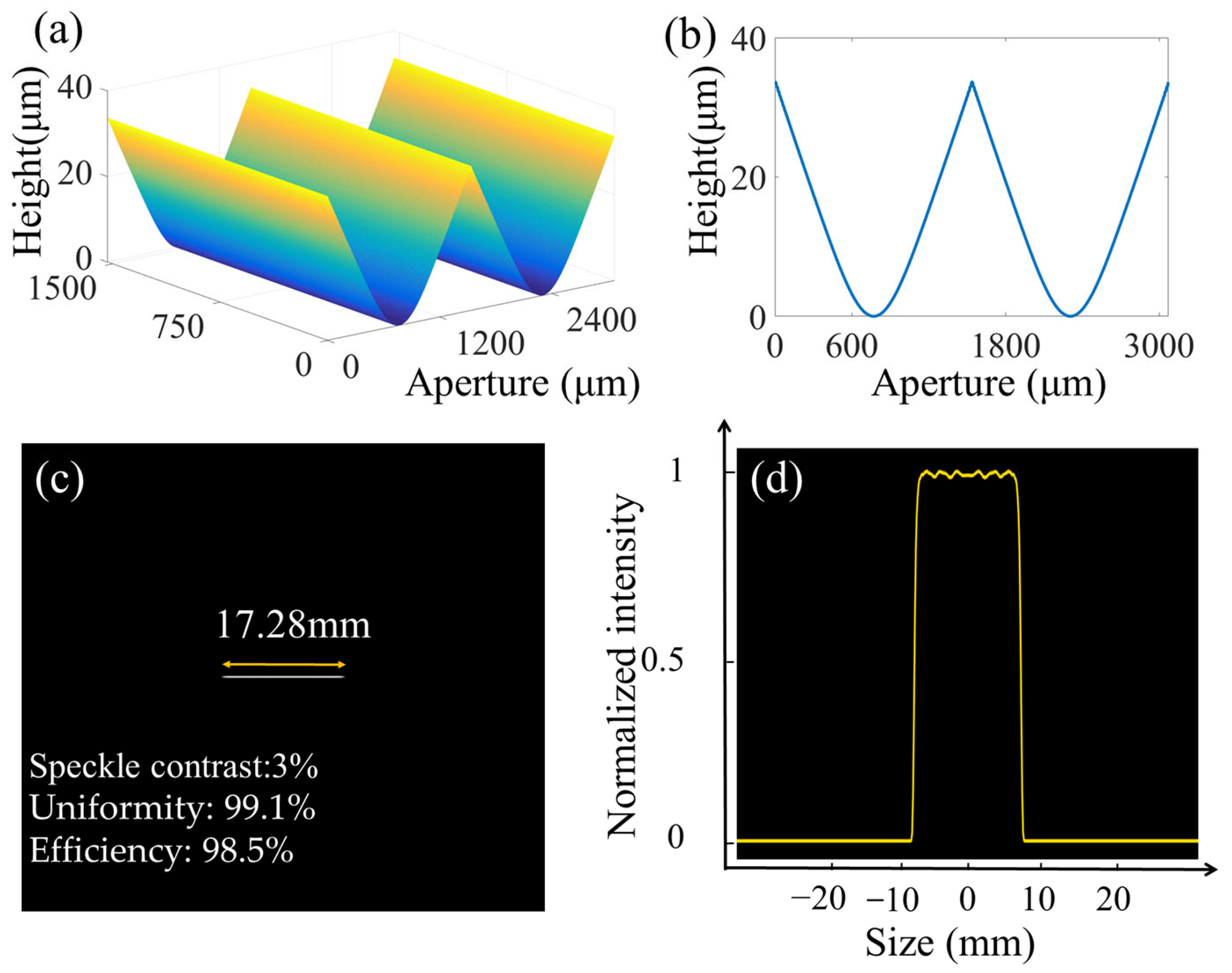

2.1. Structure Parameters of the Continuous-Surface DOE

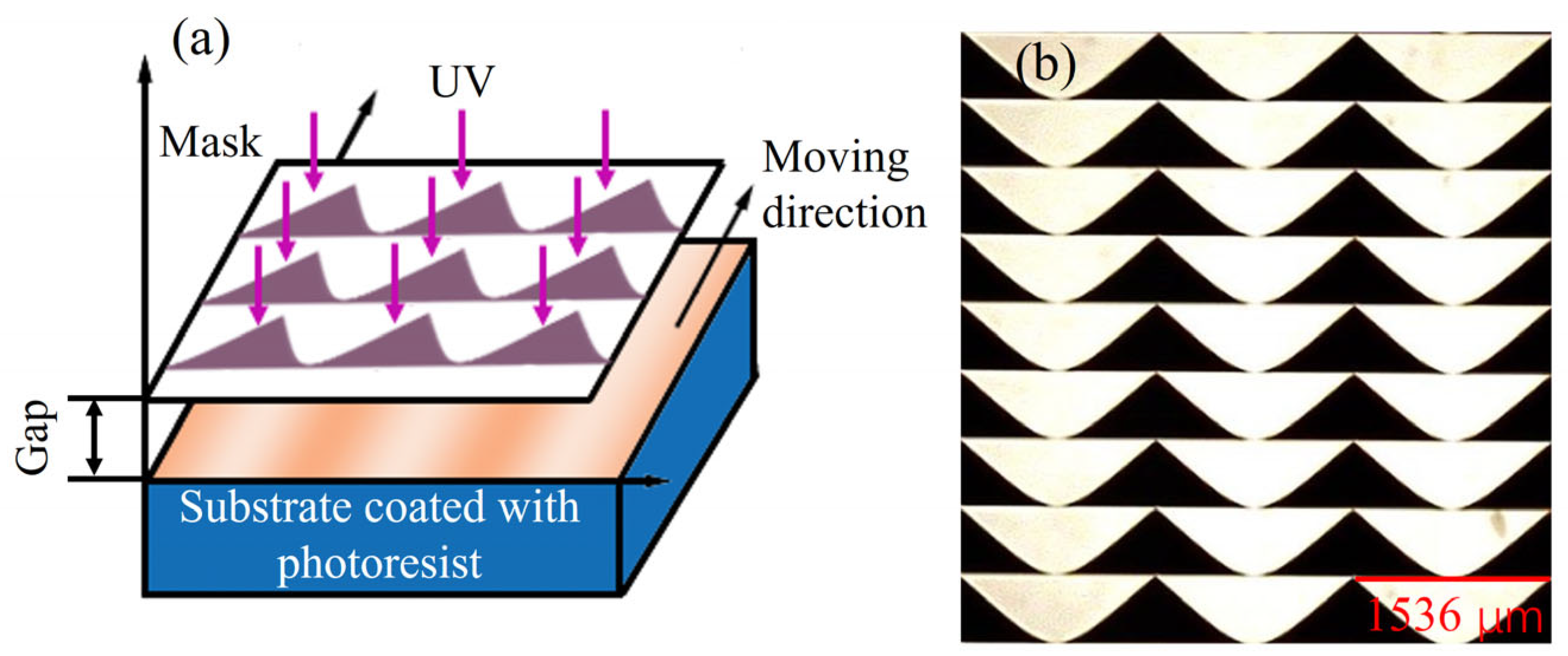

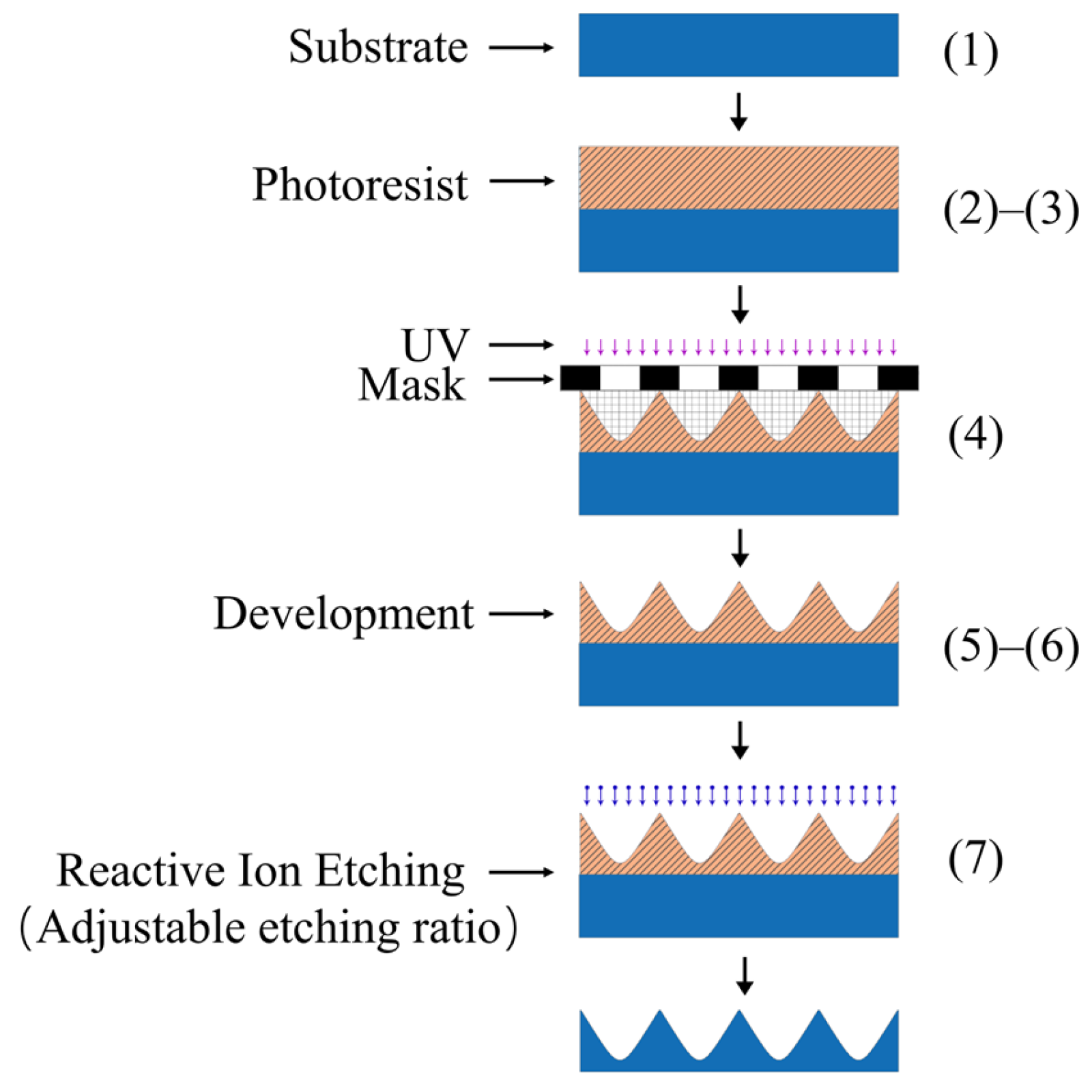

2.2. Fabrication Method

2.3. Preparation Process

3. Influence of Process Parameters

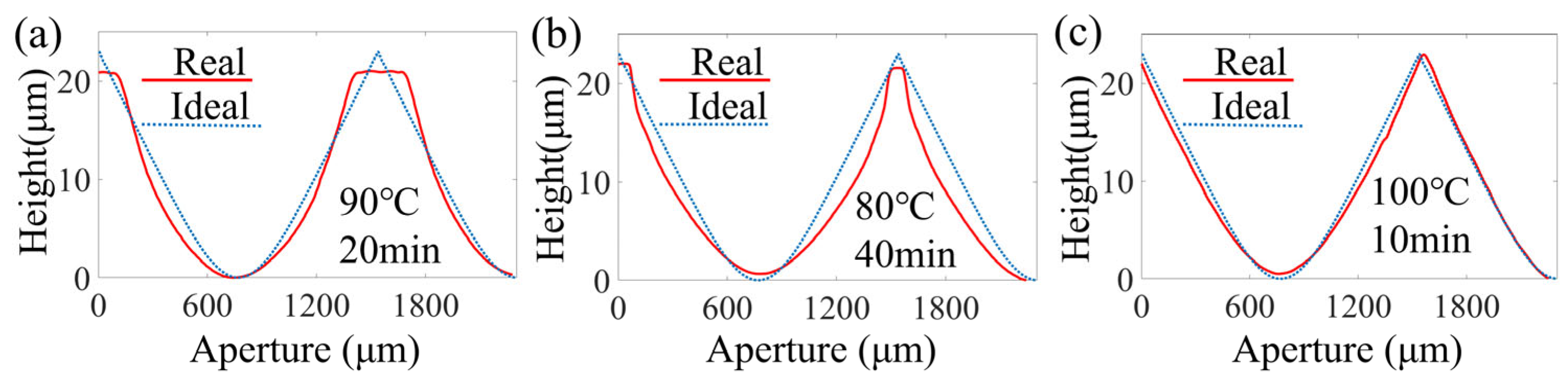

3.1. Influence of Pre-Baking Conditions

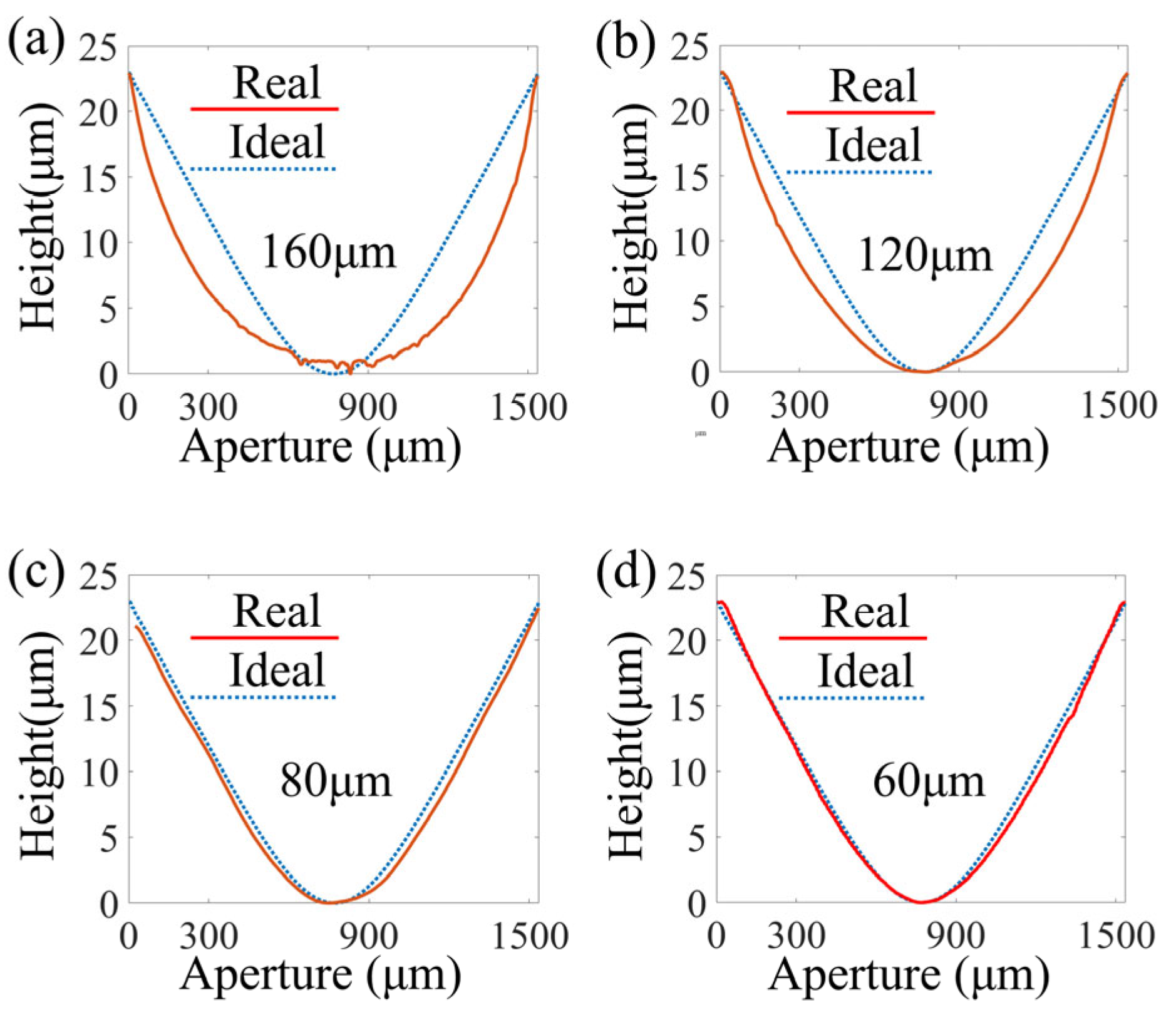

3.2. The Effect of the Exposure Gap

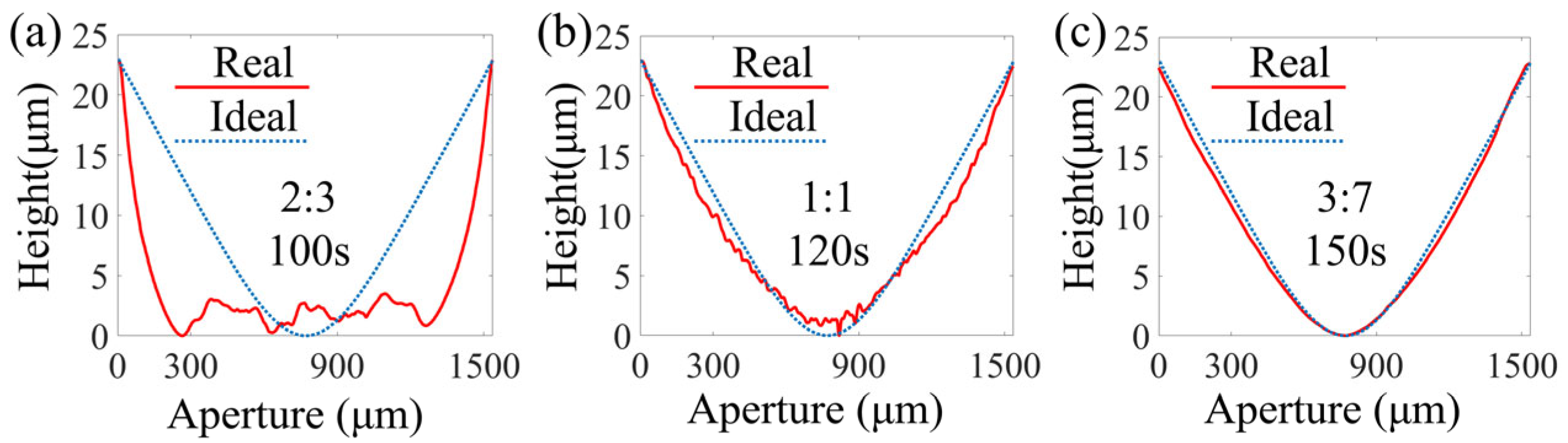

3.3. The Impact of Development Conditions

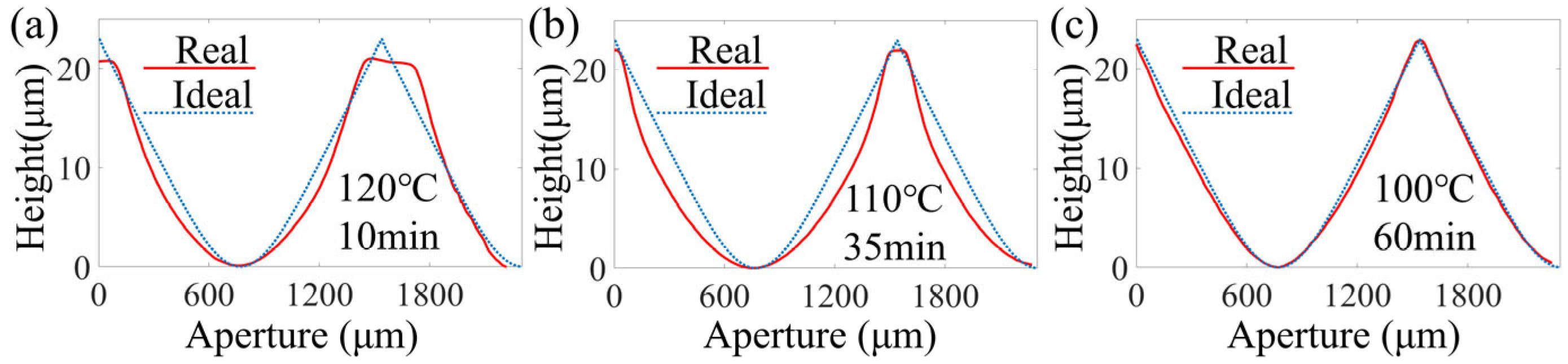

3.4. The Impact of Post-Baking Conditions

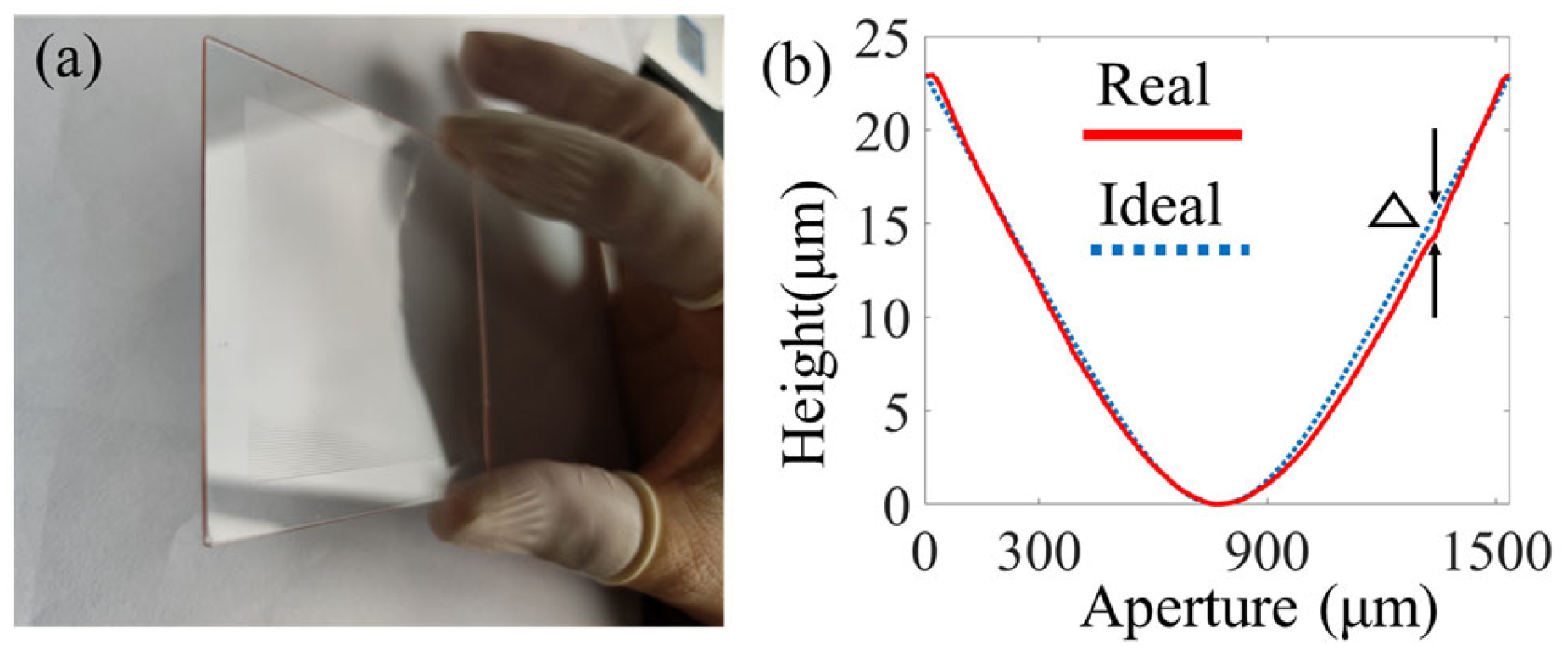

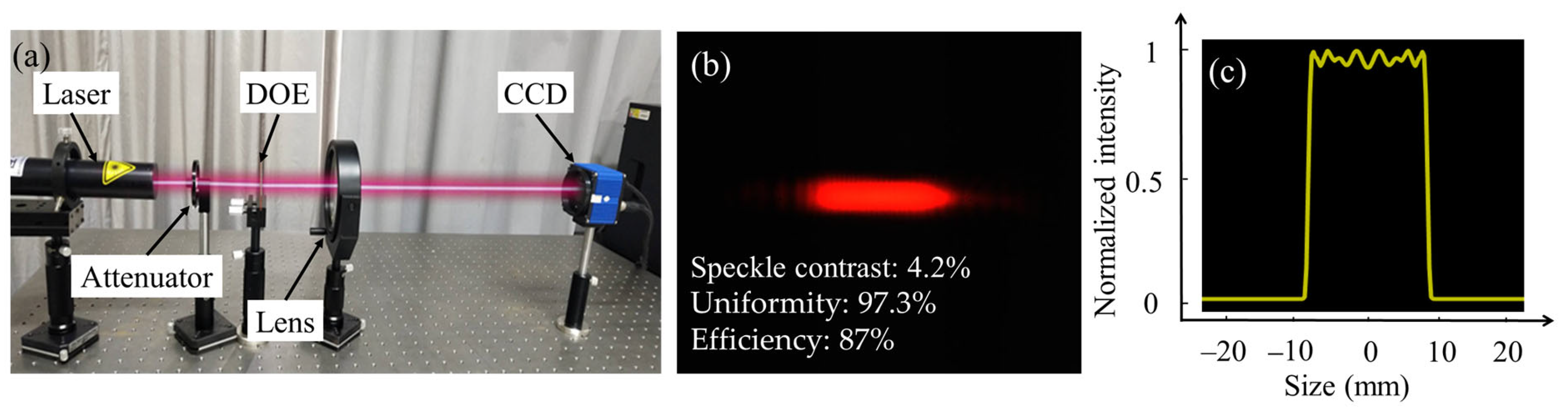

4. Fabrication Results and Optical Testing

5. Conclusions and Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hwang, S.; Kim, T.; Lee, J.; Yu, T. Design of square-shaped beam homogenizer for petawatt-class Ti:sapphire amplifier. Opt. Express 2017, 25, 9511–9520. [Google Scholar] [CrossRef]

- Chen, C.; He, M.; Wang, J.; Chang, K.; Wang, Q. Generation of phase-only holograms based on aliasing reuse and application in holographic see-through display system. IEEE Photonics J. 2019, 11, 7000711. [Google Scholar] [CrossRef]

- Zhang, W.; Gong, Y. Design of diffractive optical elements for off-axis illumination in projection lithography. Opt. Precis. Eng. 2008, 16, 2081–2086. [Google Scholar] [CrossRef]

- Tillkorn, C.; Heimes, A.; Flamm, D.; Dorer, S.; Hellstern, J.; Marschall, F.; Lingel, C. Anamorphic beam shaping for efficient laser homogenization: Methods and high power applications. In Proceedings of the Laser Resonators, Microresonators, and Beam Control XX, San Francisco, CA, USA, 27 January–1 February 2018; p. 10518. [Google Scholar] [CrossRef]

- Yao, P.; Chen, C.; Chen, C. Low speckle laser illuminated projection system with a vibrating diffractive beam shaper. Opt. Express 2012, 20, 16552–16566. [Google Scholar] [CrossRef]

- Wu, M.; Park, C.; Whitesides, G.M. Fabrication of arrays of microlenses with controlled profiles using gray-scale microlens projection photolithography. Langmuir 2009, 18, 9312–9318. [Google Scholar] [CrossRef]

- Liang, Y.; Zhu, T.; Xi, M.; Abbasi, H.; Fu, J.; Su, R.; Song, Z.; Wang, H.; Wang, K. Fabrication of a diamond concave microlens array for laser beam homogenization. Opt. Laser Technol. 2021, 136, 106738. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, H.; Lu, Z.; Li, Q.; Li, J. A beam homogenizer for digital micromirror device lithography system based on random freeform microlenses. Opt. Commun. 2019, 443, 211–215. [Google Scholar] [CrossRef]

- Nottola, A.; Gerardino, A.; Gentili, M.; Di Fabrizio, E.; Cabrini, S.; Melpignano, P.; Rotaris, G. Fabrication of semi-continuous profile Diffractive Optical Elements for beam shaping by Electron Beam Lithography. Microelectron. Eng. 2000, 53, 325–328. [Google Scholar] [CrossRef]

- Liu, J.; Thomson, M.; Waddie, A.; Taghizadeh, M. Design of diffractive optical elements for high-power laser applications. Opt. Eng. 2004, 43, 2541–2548. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, J.; Zhang, H.; Liu, X. A high-efficiency and accuracy holographic tandem method for arbitrary beam shaping. Opt. Commun. 2013, 294, 96–104. [Google Scholar] [CrossRef]

- Shinonaga, Y.; Ogine, K.; Unne, N.; Yoshida, S.; Yamamoto, M.; Taniguchi, J. Fabrication of eight-step diffractive optical element for hologram-ROM. Microelectron. Eng. 2015, 141, 102–106. [Google Scholar] [CrossRef]

- Prongue, D.; Herzig, H.; Dandliker, R.; Gale, M. Optimized kinoform structures for highly efficient fan-out elements. Appl. Opt. 1992, 31, 5706–5711. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Arrizon, V.; Testorf, M.; Sinzinger, S.; Jahns, J. Iterative optimization of phase-only diffractive optical elements based on a lenslet array. J. Opt. Soc. Am. A 2000, 17, 2157–2164. [Google Scholar] [CrossRef]

- Pang, H.; Liu, W.; Cao, A. Speckle-reduced holographic beam shaping with modified Gerchberg-Saxton algorithm. Opt. Commun. 2019, 433, 44–51. [Google Scholar] [CrossRef]

- Ni, H.; Yuan, G.; Sun, L.; Chang, N.; Zhang, D.; Chen, R.; Jiang, L.; Chen, H.; Gu, Z.; Zhao, X. Large-scale high-numerical-aperture super-oscillatory lens fabricated by direct laser writing lithography. RSC Adv. 2018, 8, 20117–20123. [Google Scholar] [CrossRef]

- Cunha, J.; Garcia, I.S.; Santos, J.D.; Fernandes, J.; González-Losada, P.; Silva, C.; Gaspar, J.; Cortez, A.; Sampaio, M.; Aguiam, D.E. Assessing tolerances in direct write laser grayscale lithography and reactive ion etching pattern transfer for fabrication of 2.5D Si master molds. Micro Nano Eng. 2023, 19, 100182. [Google Scholar] [CrossRef]

- Zeng, H.; Chen, B.; Guo, L.; Qu, C.; Du, C. Edge effect and its application in mask moving technique. OEE 2000, 27, 19–22. [Google Scholar] [CrossRef]

- Kato, N.; Kai, T.; Hirano, M. Moving-mask Lithography for 3D Microstructure Molding. J. Photopolym. Sci. Technol. 2014, 27, 85–89. [Google Scholar] [CrossRef]

- Yuan, W.; Xu, C.; Xue, L.; Pang, H.; Cao, A.; Fu, Y.; Deng, Q. Integrated double-sided random microlens array used for laser beam homogenization. Micromachines 2021, 12, 673. [Google Scholar] [CrossRef]

- Yuan, W.; Cai, Y.; Xu, C.; Pang, H.; Cao, A.; Fu, Y.; Deng, Q. Fabrication of multifocal microlens array by one step exposure process. Micromachines 2021, 12, 1097. [Google Scholar] [CrossRef]

- Lu, Y.; Chu, C.; Lin, H. Characterization of the gray-scale photolithography with high-resolution gray steps for the precise fabrication of diffractive optics. Opt. Eng. 2004, 43, 2666–2670. [Google Scholar] [CrossRef]

| Process Flow | Process Parameters |

|---|---|

| Photoresist coating | First spin coating: 4 s, 600 rpm, and 600 rpm/s. Second spin coating: 100 s, 400 rpm, and 400 rpm/s. |

| Pre-baking | Temperature: 100 °C; time: 10 min |

| Lithography | Moving distance, 1536 μm; moving interval, 1 μm every 0.05 s; intensity, 3 mV; separation gap, 60 μm. |

| Development | Ratio of developer to deionized water, 3:7; time, 150 s. |

| Post-baking | Temperature: 100 °C; time: 60 min. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Cao, A.; Liu, J.; Pang, H.; Deng, Q.; Wang, J.; Hu, S. Influence of Lithography Process Parameters on Continuous Surface Diffractive Optical Elements for Laser Beam Shaping. Micromachines 2025, 16, 601. https://doi.org/10.3390/mi16050601

Liu W, Cao A, Liu J, Pang H, Deng Q, Wang J, Hu S. Influence of Lithography Process Parameters on Continuous Surface Diffractive Optical Elements for Laser Beam Shaping. Micromachines. 2025; 16(5):601. https://doi.org/10.3390/mi16050601

Chicago/Turabian StyleLiu, Wenjing, Axiu Cao, Junbo Liu, Hui Pang, Qiling Deng, Jian Wang, and Song Hu. 2025. "Influence of Lithography Process Parameters on Continuous Surface Diffractive Optical Elements for Laser Beam Shaping" Micromachines 16, no. 5: 601. https://doi.org/10.3390/mi16050601

APA StyleLiu, W., Cao, A., Liu, J., Pang, H., Deng, Q., Wang, J., & Hu, S. (2025). Influence of Lithography Process Parameters on Continuous Surface Diffractive Optical Elements for Laser Beam Shaping. Micromachines, 16(5), 601. https://doi.org/10.3390/mi16050601