Thermal Performance of T-Shaped Ultra-Thin Vapor Chamber with Double-Sided Heating for LED Automotive Headlamp Cooling

Abstract

1. Introduction

2. Experiments

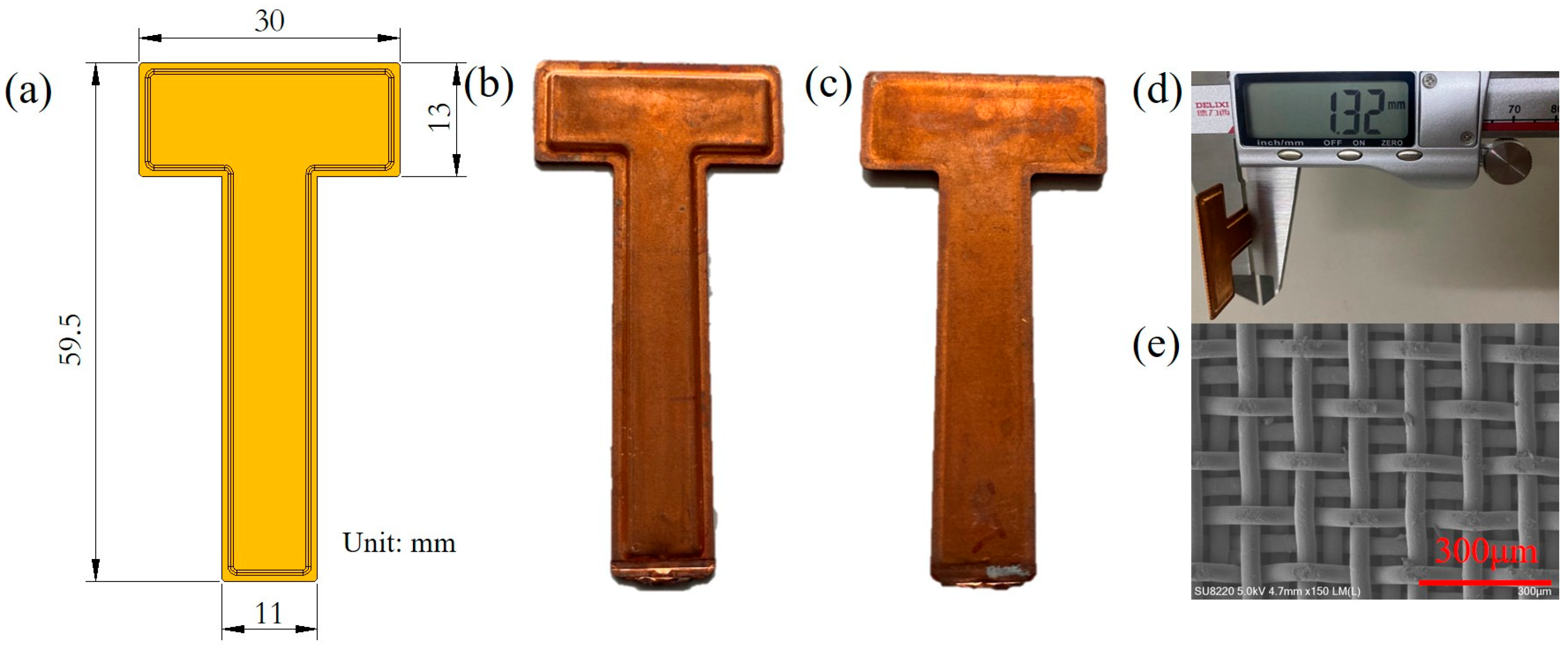

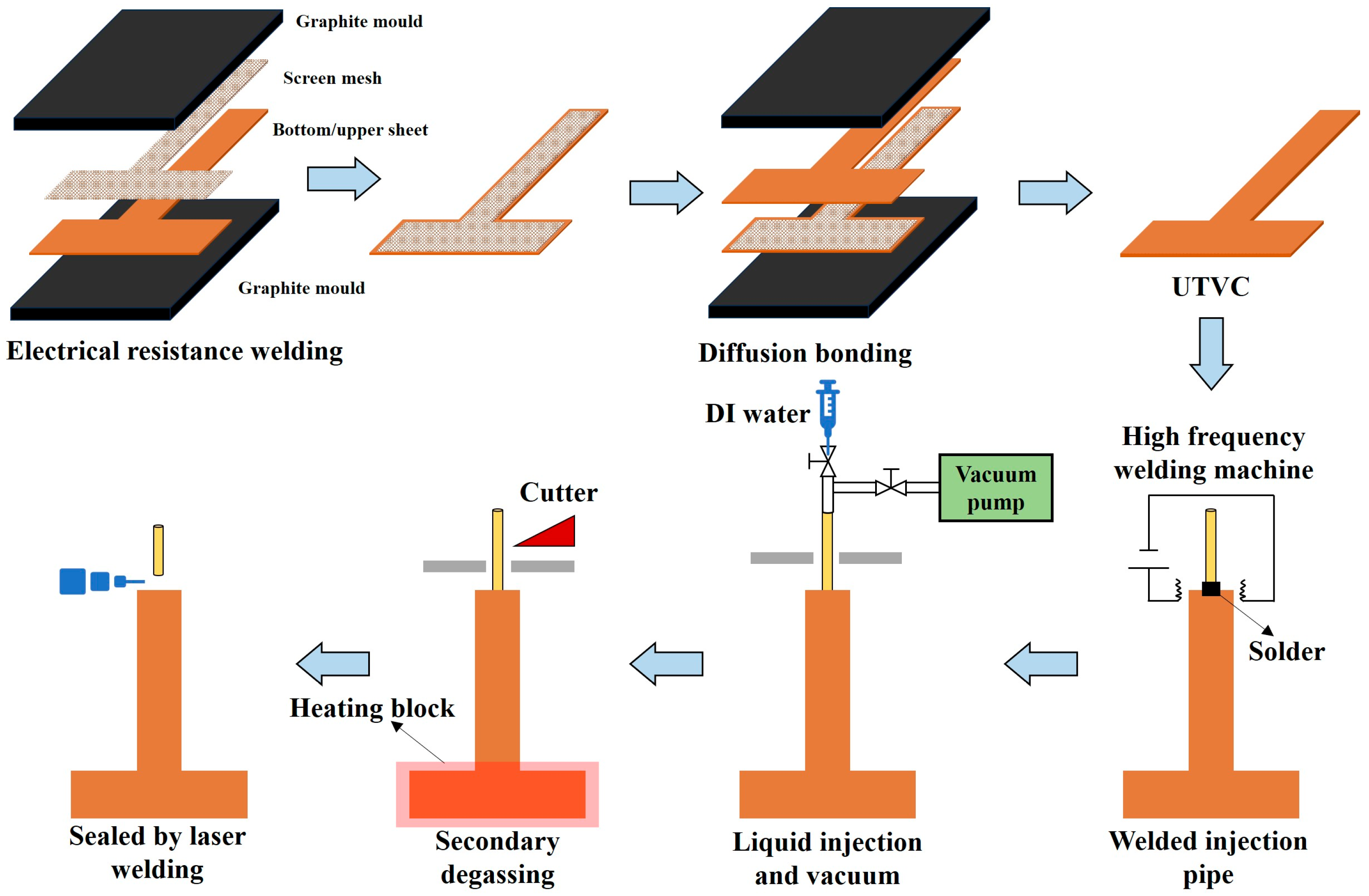

2.1. Description of the T-Shaped In-Plane UTVC

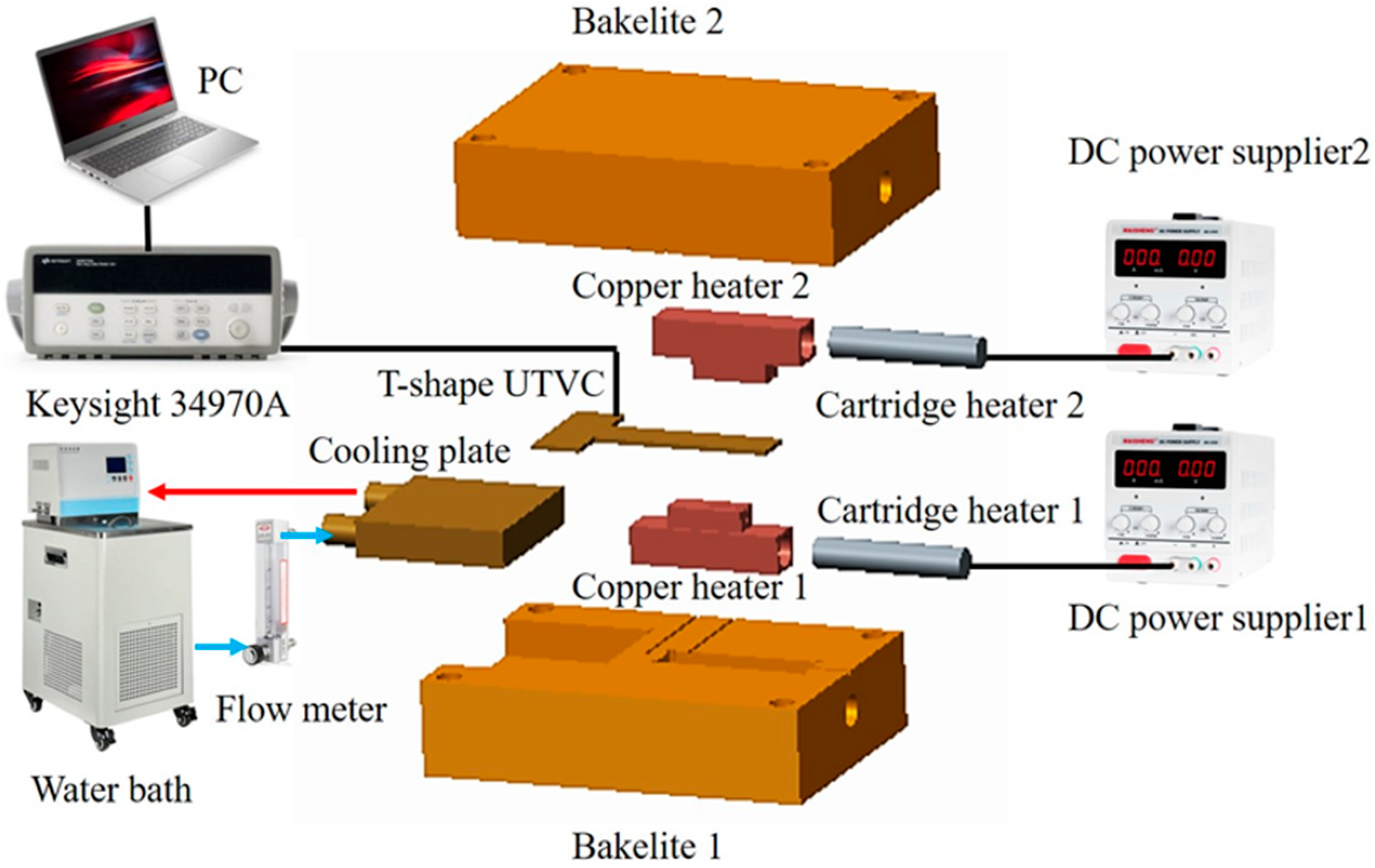

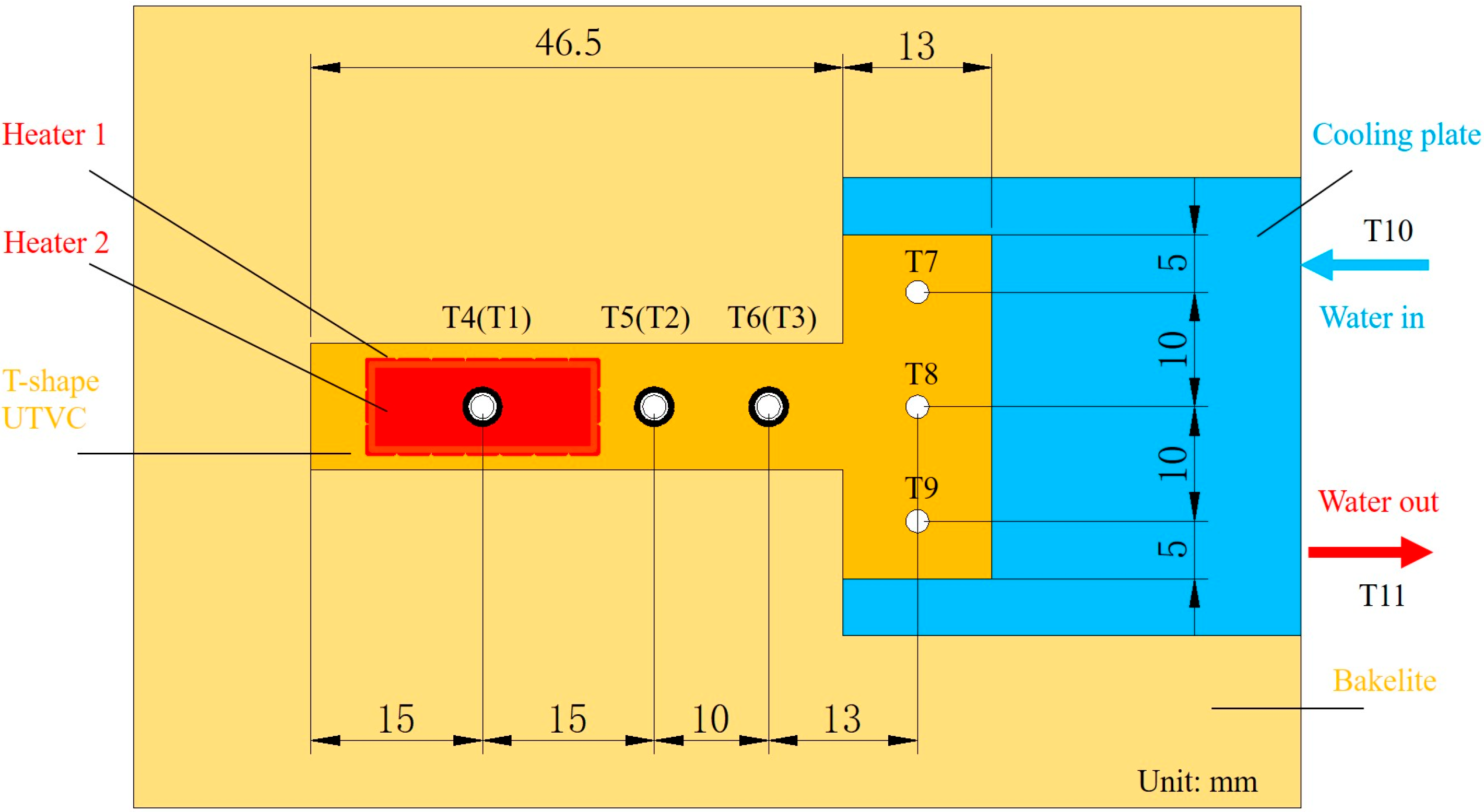

2.2. Experimental Setup and Test Conditions

2.3. Data Reduction and Uncertainty Analysis

3. Results and Discussion

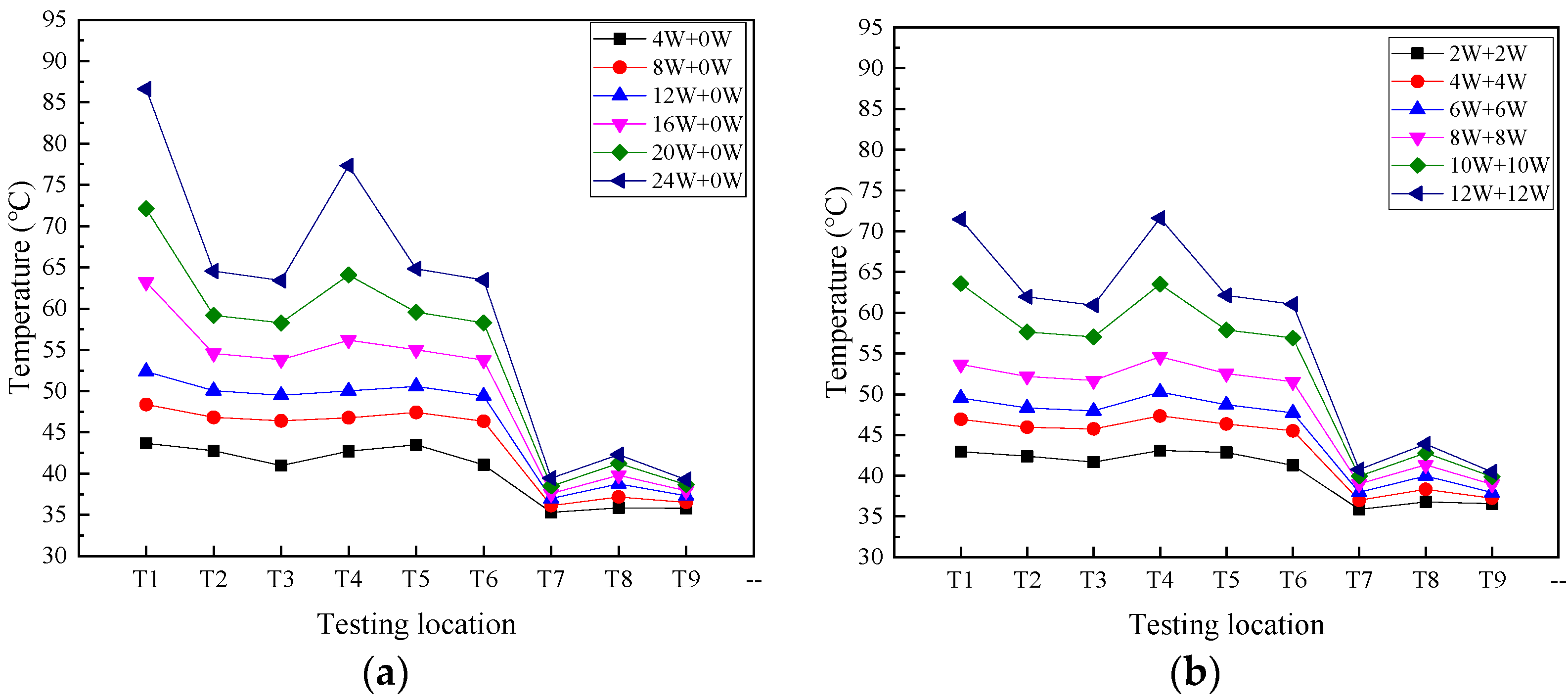

3.1. Effect of Heating Modes

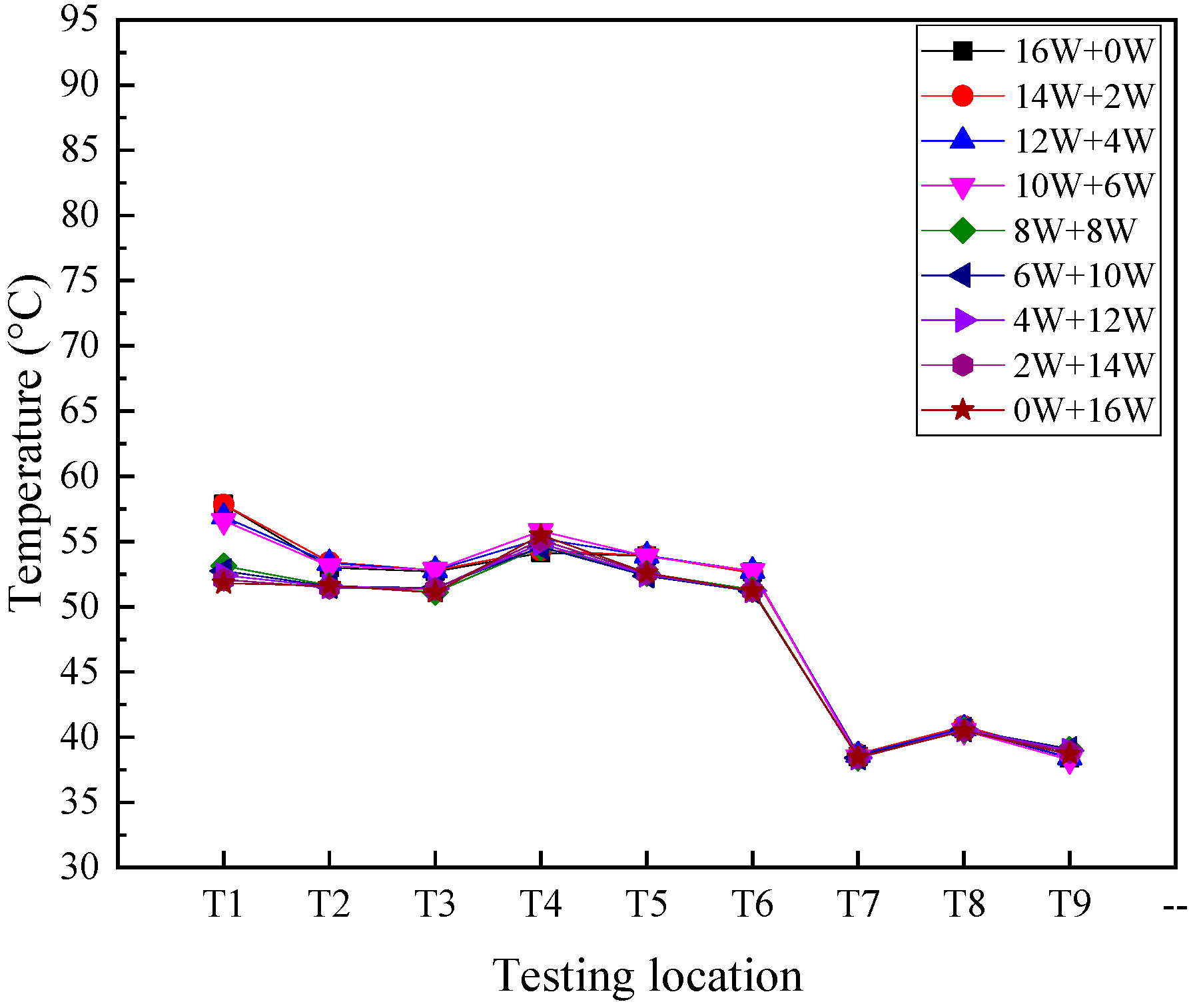

3.2. Effect of Unequal Input Power

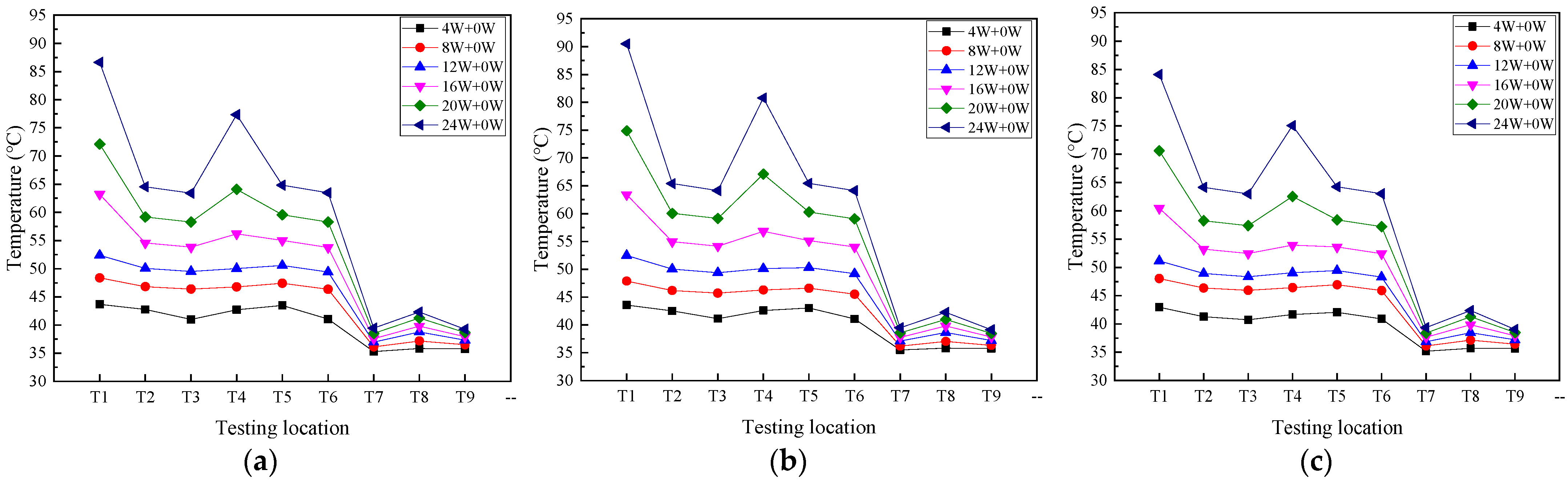

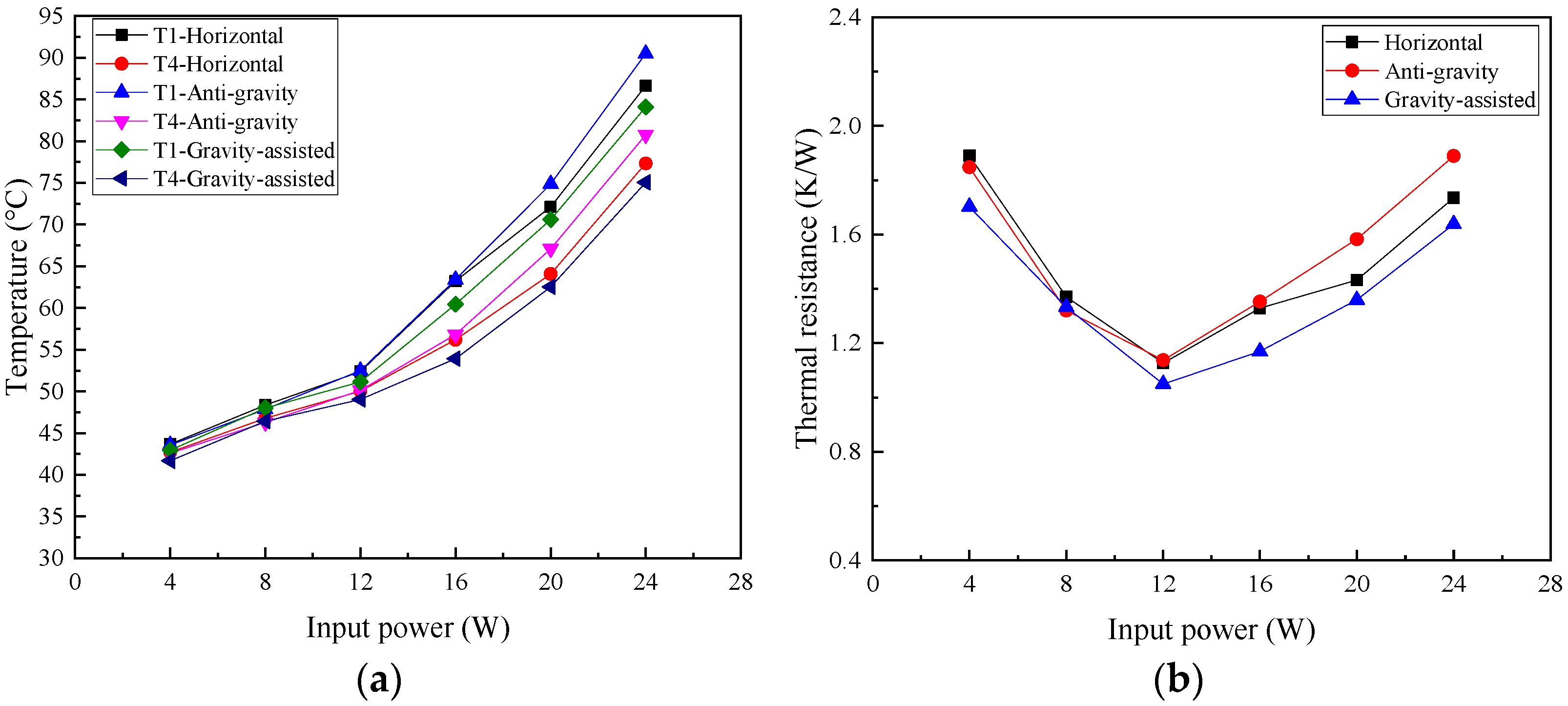

3.3. Effects of Test Orientation

3.4. Comparison of Other Studies

4. Conclusions

- (1)

- The double-sided heating with equal power can improve the temperature uniformity of the T-shaped UTVC and reduce the thermal resistance of the T-shaped UTVC compared to the single-sided heating. The lowest thermal resistances under single-sided and double-sided heating are 1.127 K/W at 12 W and 0.898 K/W at 16 W, respectively.

- (2)

- When the total power is identical, the proposed 2D T-shaped UTVC can work effectively at unequal input power under double-sided heating.

- (3)

- The thermal performance of the 2D T-shaped UTVC under the anti-gravity state is similar to that under the horizontal state at low and medium input power but worse at high input power. The thermal performance of the 2D T-shaped UTVC under the gravity-assisted state is significantly improved by the assistance of gravity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Long, X.; He, J.; Zhou, J.; Fang, L.; Zhou, X.; Ren, F.; Xu, T. A review on light-emitting diode based automotive headlamps. Renew. Sustain. Energy Rev. 2015, 41, 29–41. [Google Scholar] [CrossRef]

- Singh, R.; Mochizuki, M.; Yamada, T.; Nguyen, T. Cooling of LED headlamp in automotive by heat pipes. Appl. Therm. Eng. 2020, 166, 114733. [Google Scholar] [CrossRef]

- Cheng, H.H.; Huang, D.; Lin, M. Heat dissipation design and analysis of high power LED array using the finite element method. Microelectron. Reliab. 2012, 52, 905–911. [Google Scholar] [CrossRef]

- Arik, M.; Petroski, J.; Weaver, S. Thermal challenges in the future generation solid state lighting applications: Light emitting diodes. In Proceedings of the IEEE 8th ITHERM Conference, San Diego, CA, USA, 30 May–1 June 2002. [Google Scholar] [CrossRef]

- Tang, Y.; Ding, X.; Yu, B.; Li, Z.; Liu, B. A high power LED device with chips directly mounted on heat pipes. Appl. Therm. Eng. 2014, 66, 632–639. [Google Scholar] [CrossRef]

- Pekur, D.; Sorokin, V.M.; Nikolaenko, Y.E. Thermal characteristics of a compact LED luminaire with a cooling system based on heat pipes. Therm. Sci. Eng. Prog. 2020, 18, 100549. [Google Scholar] [CrossRef]

- Xiao, C.; Liao, H.; Wang, Y.; Li, J.; Zhu, W. A novel automated heat-pipe cooling device for high-power LEDs. Appl. Therm. Eng. 2017, 111, 1320–1329. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, S.; Huo, J.; Hu, Y.; Chen, J.; Zhang, W.; Lee, E. Heat transfer characteristics and LED heat sink application of aluminum plate oscillating heat pipes. Appl. Therm. Eng. 2011, 31, 2221–2229. [Google Scholar] [CrossRef]

- Chang, C.; Yang, Y.; Pei, L.; Han, Z.; Xiao, X.; Ji, Y. Heat Transfer Performance of 3D-Printed Aluminium Flat-Plate Oscillating Heat Pipes for the Thermal Management of LEDs. Micromachines 2022, 13, 1949. [Google Scholar] [CrossRef]

- Xu, Z. Heat transfer performance of the rectangular heat sinks with non-uniform height thermosyphons for high power LED lamps cooling. Case Stud. Therm. Eng. 2021, 25, 101013. [Google Scholar] [CrossRef]

- Li, J.; Lin, F.; Wang, D.; Tian, W. A loop-heat-pipe heat sink with parallel condensers for high-power integrated LED chips. Appl. Therm. Eng. 2013, 56, 18–26. [Google Scholar] [CrossRef]

- Ušakovs, I.; Ivanovskis, L. Advanced loop heat pipe application for cooling high power LED lights. Case Stud. Therm. Eng. 2024, 57, 104320. [Google Scholar] [CrossRef]

- Wang, J.; Wang, R.; Chang, T.; Hwang, D. Development of 30 Watt high-power LEDs vapor chamber-based plate. Int. J. Heat Mass Transf. 2010, 53, 3990–4001. [Google Scholar] [CrossRef]

- Tang, Y.; Lin, L.; Zhang, S.; Zeng, J.; Tang, K.; Chen, G.; Yuan, W. Thermal management of high-power LEDs based on integrated heat sink with vapor chamber. Energ. Convers. Manag. 2017, 151, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Zhao, X.; Zhang, C. Thermal design and simulation of automotive headlamps using white LEDs. Microelectron. J. 2014, 45, 249–255. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, Y.; Wang, J.; Li, X. Experimental study of thermal management of led automotive headlamps using heat pipes. Heat Transf. Res. 2016, 47, 975–987. [Google Scholar] [CrossRef]

- Huang, D.; Chen, T.; Tsai, L.; Lin, M. Design of fins with a grooved heat pipe for dissipation of heat from high-powered automotive LED headlights. Energy Convers. Manag. 2019, 180, 550–558. [Google Scholar] [CrossRef]

- Tang, Y.; Luo, Y.; Du, P.; Wang, H.; Ma, H.; Qin, Y.; Bai, P.; Zhou, G. Experimental investigation on active heat sink with heat pipe assistance for high-power automotive LED headlights. Case Stud. Therm. Eng. 2021, 28, 101503. [Google Scholar] [CrossRef]

- Jian, Q.; Li, C.; Wang, L. Analysis on thermal and hydraulic performance of a T-shaped vapor chamber designed for motorcycle LED lights. Therm. Sci. 2019, 23, 137–148. [Google Scholar] [CrossRef]

- Lu, Z.; Bai, P.; Huang, B.; Henzen, A.; Coehoorn, R.; Liao, H.; Zhou, G. Experimental investigation on the thermal performance of three-dimensional vapor chamber for LED automotive headlamps. Appl. Therm. Eng. 2019, 157, 113478. [Google Scholar] [CrossRef]

- Pagliarini, L.; Iwata, N.; Bozzoli, F. Pulsating heat pipes: Critical review on different experimental techniques. Exp. Therm. Fluid Sci. 2023, 148, 110980. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Fallahzadeh, R.; Aref, L.; Bozzoli, F.; Cattani, L.; Gholami, H. A novel triple-diameter pulsating heat pipe: Flow regimes and heat transfer performance. Therm. Sci. Eng. Prog. 2023, 42, 101902. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Mesh size M/mm | 7.087 |

| Wire diameter ds/mm | 0.05 |

| Wire spacing ws/mm | 0.0911 |

| Effective capillary radius reff/mm | 0.0490 |

| Porosity ε/% | 70.8 |

| Permeability K/mm2 | 8.511 × 10−5 |

| Mesh thickness thw/mm | 0.20 |

| Sizes of T-Shaped VCs | Thermal Performance |

|---|---|

| This study: 2D T-shaped UTVC, horizontal stripe 30 × 13 × 1.3 mm3, vertical stripe 46.5 × 13 × 1.3 mm3 | Single-sided heating: Rmin = 1.127 K/W, Qmax = 24 W Double-sided heating: Rmin = 0.898 K/W, Qmax = 24 W |

| Ref. [19]: 3D T-shaped vapor chamber, circular vapor chamber ∅39.5 mm and H 4 mm, flattened heat pipe 57.3 × 12.5 × 2.5 mm3 | Rmin = 0.401 K/W, Qmax = 15.84 W |

| Ref. [20]: 3D T-shaped vapor chamber, circular vapor chamber ∅40 mm and H 4 mm, flattened heat pipe ∅8 mm and L 17 mm flattened to 3.5 mm, ∅8 mm, and L 39 mm and flattened to 2.3 mm | Rmin = 0.125 K/W, Qmax = 50 W |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Liu, T.; Bai, Y.; Wang, S.; Zhang, Q.; Kang, H. Thermal Performance of T-Shaped Ultra-Thin Vapor Chamber with Double-Sided Heating for LED Automotive Headlamp Cooling. Micromachines 2025, 16, 571. https://doi.org/10.3390/mi16050571

Zhang Y, Liu T, Bai Y, Wang S, Zhang Q, Kang H. Thermal Performance of T-Shaped Ultra-Thin Vapor Chamber with Double-Sided Heating for LED Automotive Headlamp Cooling. Micromachines. 2025; 16(5):571. https://doi.org/10.3390/mi16050571

Chicago/Turabian StyleZhang, Yaokang, Tengqing Liu, Yu Bai, Shuangfeng Wang, Qianxi Zhang, and Huifeng Kang. 2025. "Thermal Performance of T-Shaped Ultra-Thin Vapor Chamber with Double-Sided Heating for LED Automotive Headlamp Cooling" Micromachines 16, no. 5: 571. https://doi.org/10.3390/mi16050571

APA StyleZhang, Y., Liu, T., Bai, Y., Wang, S., Zhang, Q., & Kang, H. (2025). Thermal Performance of T-Shaped Ultra-Thin Vapor Chamber with Double-Sided Heating for LED Automotive Headlamp Cooling. Micromachines, 16(5), 571. https://doi.org/10.3390/mi16050571