Heavy Ions Induced Single-Event Transient in SiGe-on-SOI HBT by TCAD Simulation

Abstract

1. Introduction

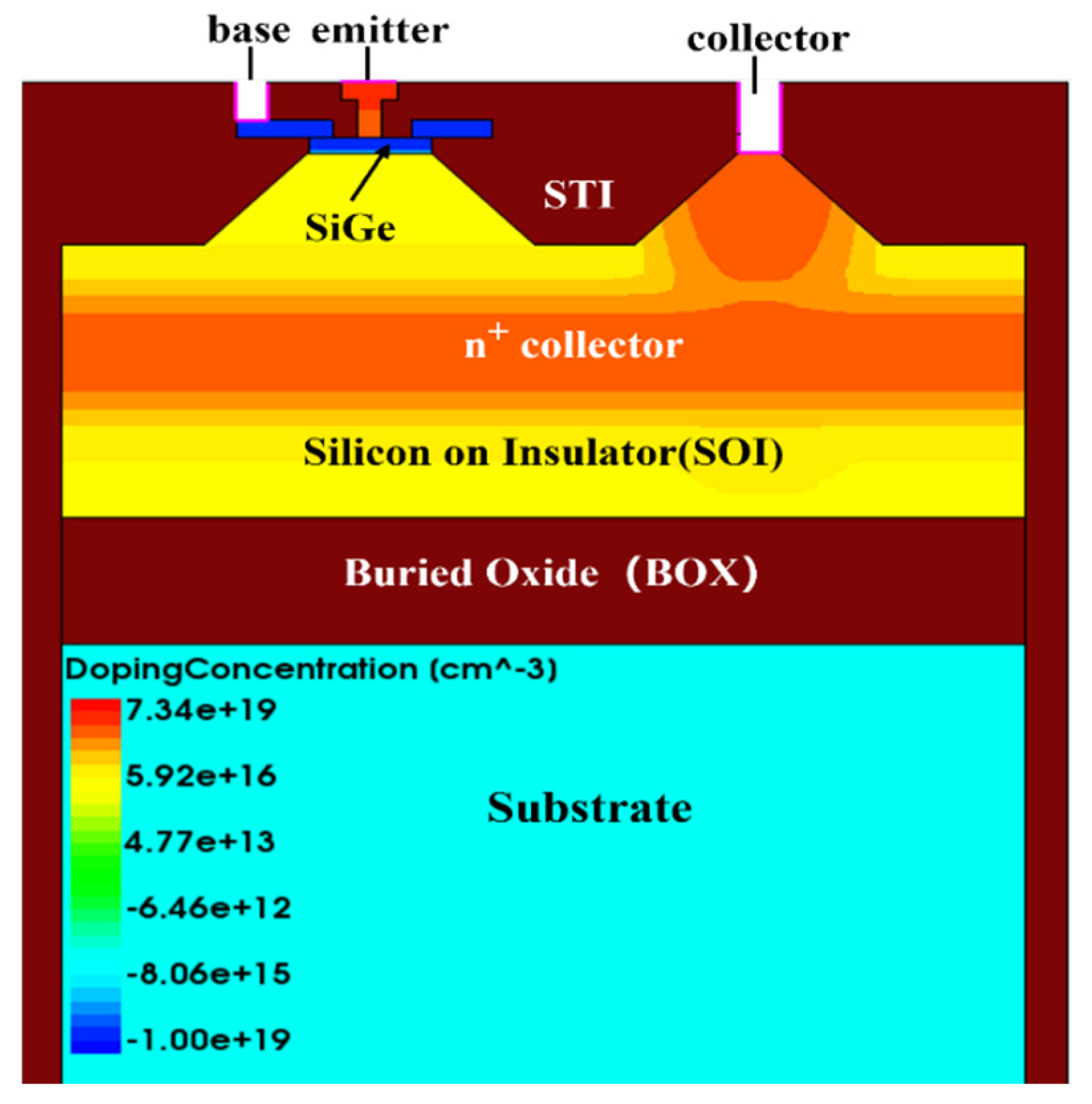

2. Device Structure Model and Numerical Simulation of SET

2.1. SiGe-on-SOI HBT Device Structure Model

2.2. Numerical Simulation of SET

3. Results and Discussion

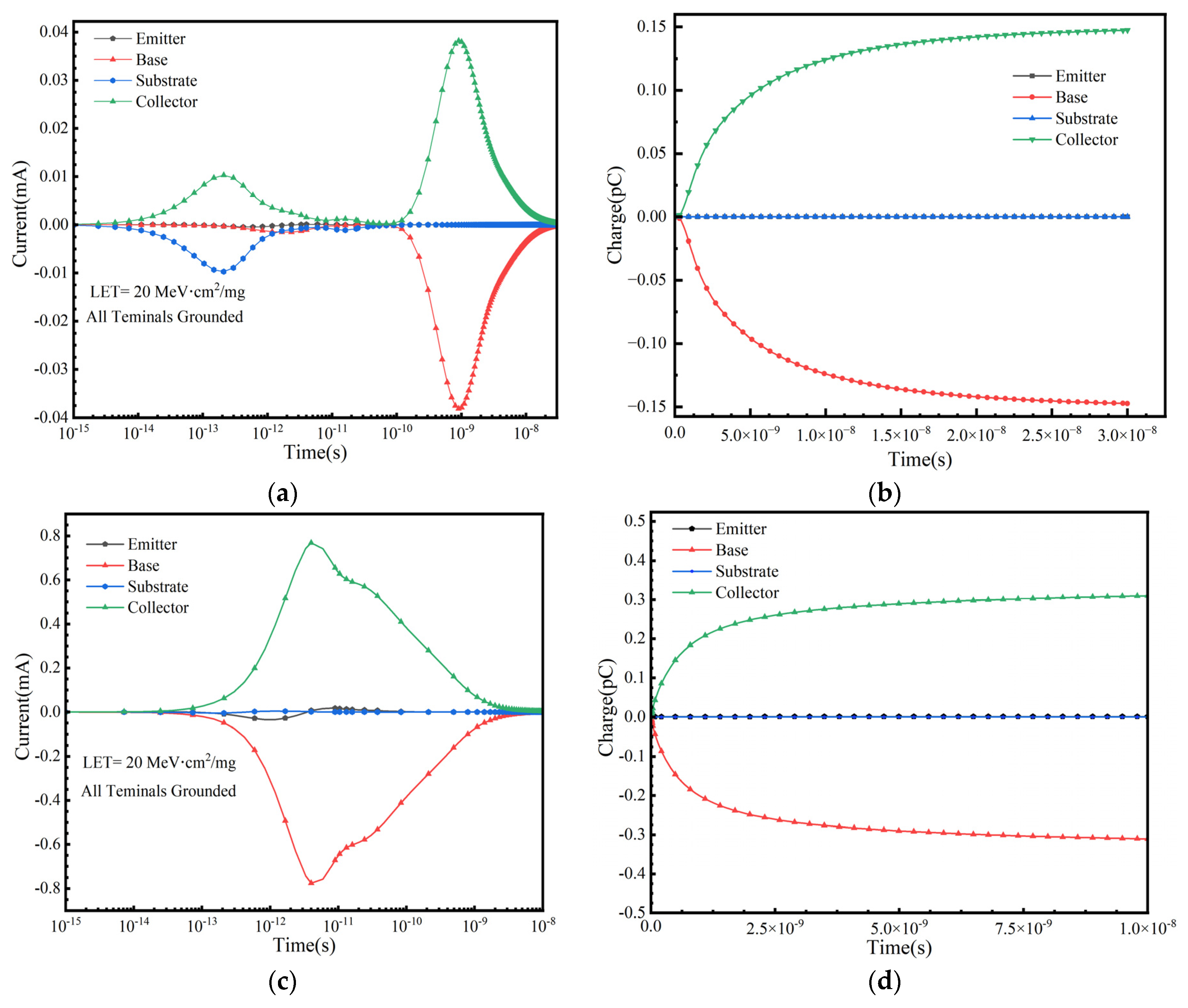

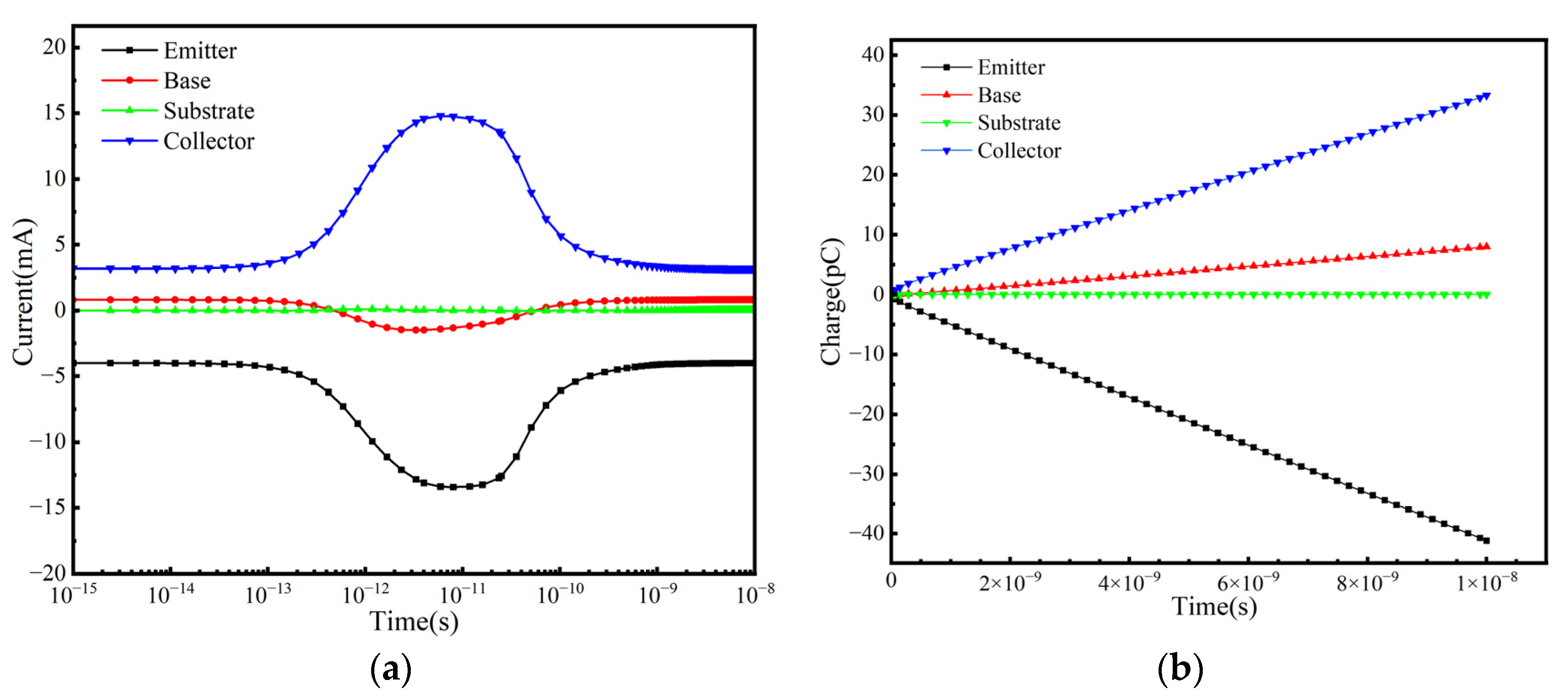

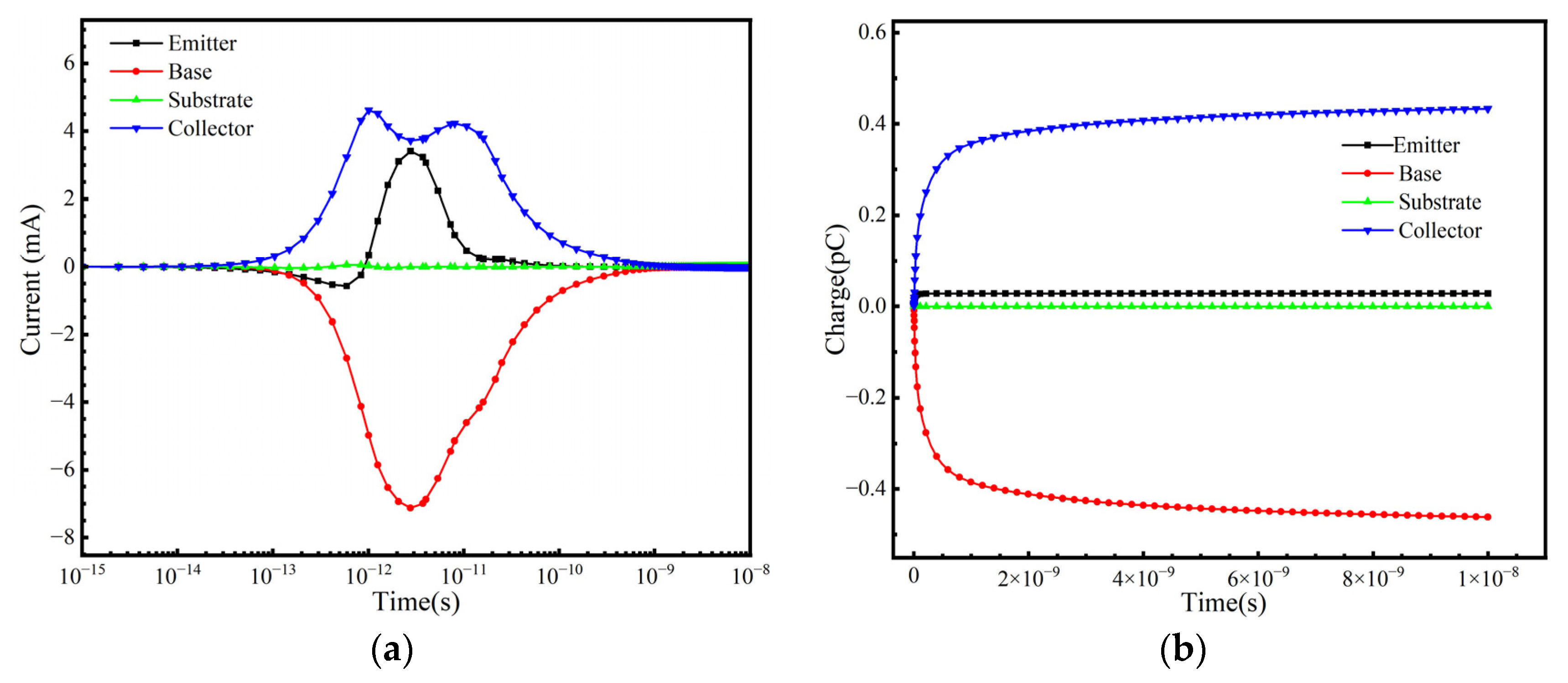

3.1. Comparison Between Bulk SiGe HBT and SiGe-on-SOI HBT

3.2. The Influence of Heavy Ion Strike Positions

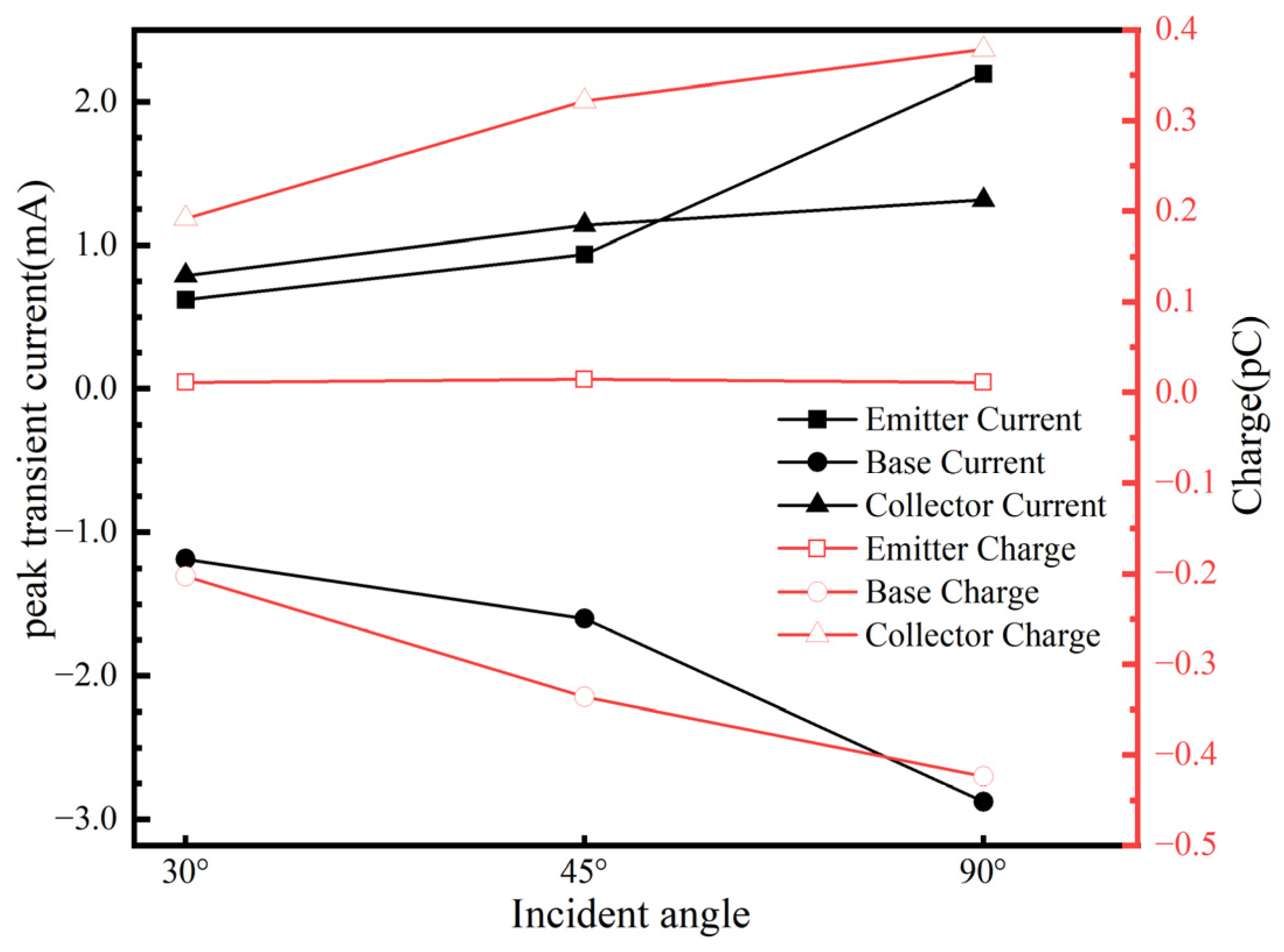

3.3. The Influence of Heavy Ion Incident Angles

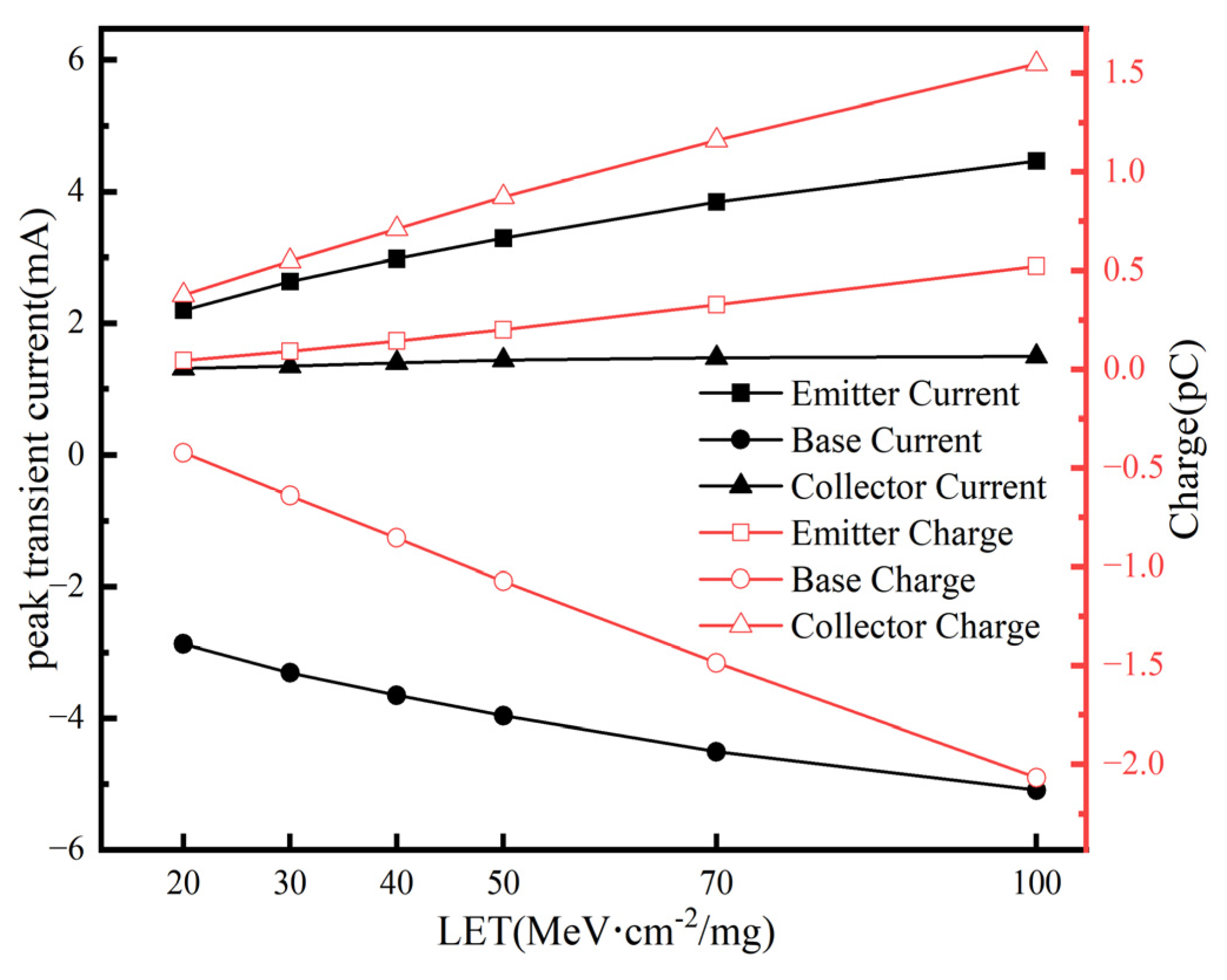

3.4. The Influence of Heavy Ion LET Values

3.5. The Influence of Ambient Temperature

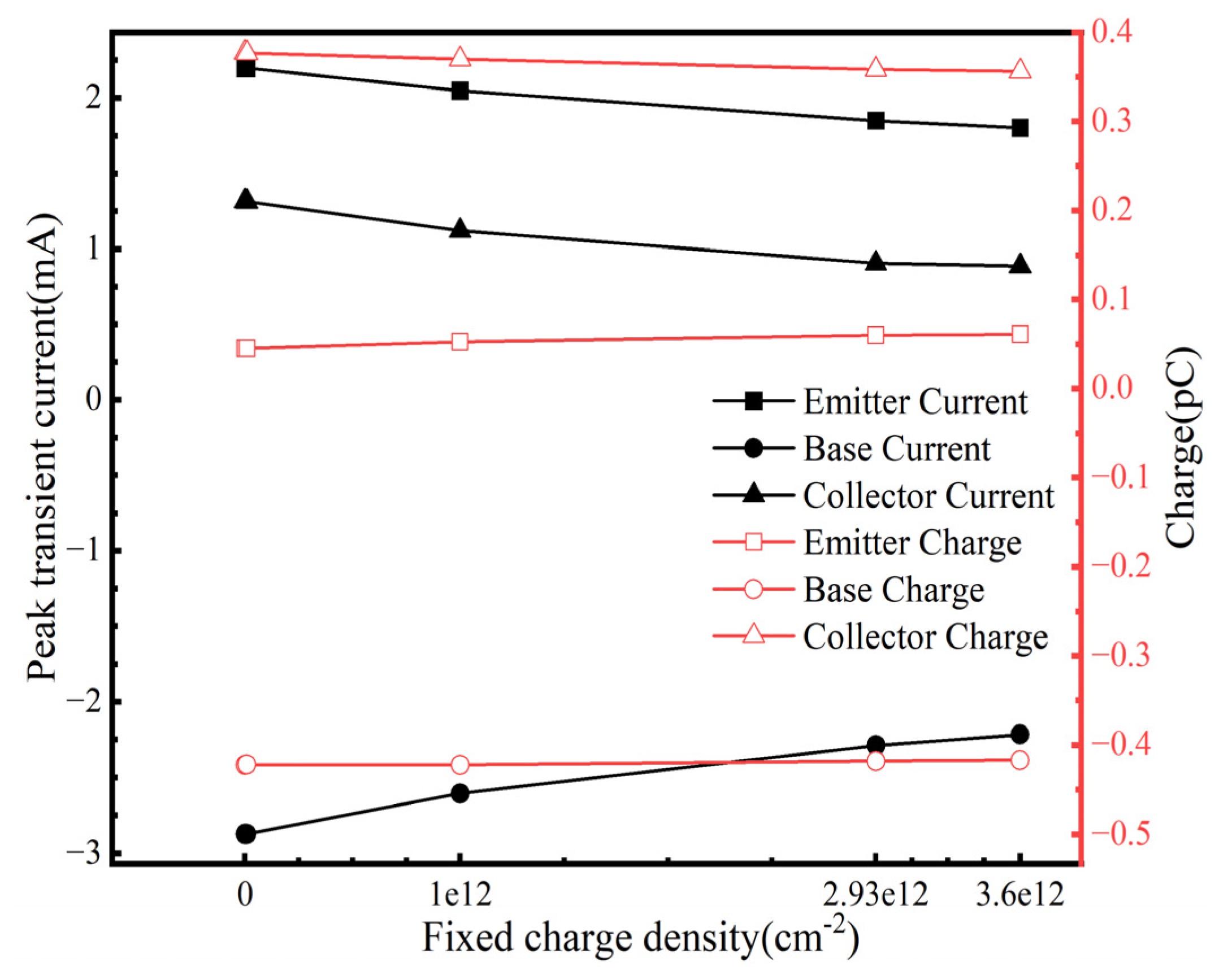

3.6. Synergistic Effects of TID and SET

3.7. The Response of SET Under Different Operating Bias Conditions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Omprakash, A.P.; Chakraborty, P.S.; Ying, H.; Cardoso, A.S.; Ildefonso, A.; Cressler, J.D. On the Potential of Using SiGe HBTs on SOI to Support Emerging Applications up to 300 °C. In Proceedings of the 2015 IEEE Bipolar/BiCMOS Circuits and Technology Meeting (BCTM), Boston, MA, USA, 26–28 October 2015; pp. 27–30. [Google Scholar]

- Nergui, D.; Brumbach, Z.R.; Teng, J.W.; Shin, J.H.; Sam, D.G.; Tzintzarov, G.N.; Taggart, J.L.; Wright, A.W.; Bushmaker, A.W.; Harris, P.; et al. TID and ELDRS Evaluation of SiGe HBTs Integrated in a 45-nm PDSOI BiCMOS Process. In Proceedings of the 2024 IEEE Radiation Effects Data Workshop (REDW) (in conjunction with 2024 NSREC), Ottawa, ON, Canada, 22–27 July 2024; pp. 1–4. [Google Scholar]

- Feng, Y.; Guo, H.; Liu, Y.; Ouyang, X.; Zhang, J.; Ma, W.; Zhang, F.; Bai, R.; Ma, X.; Hao, Y. Sensitivity Investigation of 100-MeV Proton Irradiation to SiGe HBT Single Event Effect. Chin. Phys. B 2024, 33, 016104. [Google Scholar] [CrossRef]

- Bellini, M.; Jun, B.; Chen, T.; Cressler, J.D.; Marshall, P.W.; Chen, D.; Schrimpf, R.D.; Fleetwood, D.M.; Cai, J. X-Ray Irradiation and Bias Effects in Fully-Depleted and Partially-Depleted SiGe HBTs Fabricated on CMOS-Compatible SOI. IEEE Trans. Nucl. Sci. 2006, 53, 3182–3186. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, P.; Yi, X.; Hong, M.; Fu, X.; Tang, X.; Qian, K.; Zhang, X.; Liao, W.; Zang, J.; et al. Cryogenic Total Ionizing Dose Effects and Annealing Behaviors of SiGe HBTs. IEEE Trans. Device Mater. Reliab. 2025, 25, 150–155. [Google Scholar] [CrossRef]

- Lourenco, N.E.; Ildefonso, A.; Tzintzarov, G.N.; Fleetwood, Z.E.; Motoki, K.; Paki, P.; Kaynak, M.; Cressler, J.D. Single-Event Upset Mitigation in a Complementary SiGe HBT BiCMOS Technology. IEEE Trans. Nucl. Sci. 2018, 65, 231–238. [Google Scholar] [CrossRef]

- Balani, W.; Sarvagya, M.; Ali, T.; Samasgikar, A.; Kumar, P.; Pathan, S.; Pai M M, M. A 20–44 GHz Wideband LNA Design Using the SiGe Technology for 5G Millimeter-Wave Applications. Micromachines 2021, 12, 1520. [Google Scholar] [CrossRef]

- Mitrovic, I.Z.; Buiu, O.; Hall, S.; Bagnall, D.M.; Ashburn, P.A. Review of SiGe HBTs on SOI. Solid-State Electron. 2005, 49, 1556–1567. [Google Scholar] [CrossRef]

- Ildefonso, A.; Tzintzarov, G.N.; Nergui, D.; Omprakash, A.P.; Goley, P.S.; Hales, J.M.; Khachatrian, A.; Buchner, S.P.; McMorrow, D.; Warner, J.H.; et al. Comparison of Single-Event Transients in SiGe HBTs on Bulk and Thick-Film SOI. IEEE Trans. Nucl. Sci. 2020, 67, 71–80. [Google Scholar] [CrossRef]

- Chen, T.; Sutton, A.K.; Bellini, M.; Haugerud, B.M.; Comeau, J.P.; Liang, Q.; Cressler, J.D.; Cai, J.; Ning, T.H.; Marshall, P.W.; et al. Proton Radiation Effects in Vertical SiGe HBTs Fabricated on CMOS-Compatible SOI. IEEE Trans. Nucl. Sci. 2005, 52, 2353–2357. [Google Scholar] [CrossRef]

- Jung, S.; Lourenco, N.E.; Song, I.; Oakley, M.A.; England, T.D.; Arora, R.; Cardoso, A.S.; Roche, N.J.-H.; Khachatrian, A.; McMorrow, D.; et al. An Investigation of Single-Event Transients in C-SiGe HBT on SOI Current Mirror Circuits. IEEE Trans. Nucl. Sci. 2014, 61, 3193–3200. [Google Scholar] [CrossRef]

- Omprakash, A.P.; Dao, H.; Raghunathan, U.S.; Ying, H.B.; Chakraborty, P.S.; Babcock, J.A.; Mukhopadhyay, R.; Cressler, J.D. An Investigation of High-Temperature (to 300 °C) Safe-Operating-Area in a High-Voltage Complementary SiGe on SOI Technology. IEEE Trans. Electron Devices 2017, 64, 3748–3755. [Google Scholar] [CrossRef]

- Omprakash, A.P.; Ildefonso, A.; Fleetwood, Z.E.; Tzintzarov, G.N.; Cardoso, A.S.; Babcock, J.A.; Mukhopadhyay, R.; Khachatrian, A.; Warner, J.H.; McMorrow, D.; et al. The Effects of Temperature on the Single-Event Transient Response of a High-Voltage (>30 V) Complementary SiGe-on-SOI Technology. IEEE Trans. Nucl. Sci. 2019, 66, 389–396. [Google Scholar] [CrossRef]

- Varadharajaperumal, M.; Guofu, N.; Cressler, J.D.; Reed, R.A.; Marshall, P.W. Three-Dimensional Simulation of Heavy-Ion Induced Charge Collection in SiGe HBTs on SOI. IEEE Trans. Nucl. Sci. 2004, 51, 3298–3303. [Google Scholar] [CrossRef]

- Bellini, M.; Phillips, S.D.; Diestelhorst, R.M.; Cheng, P.; Cressler, J.D.; Marshall, P.W.; Turowski, M.; Avenier, G.; Chantre, A.; Chevalier, P. Novel Total Dose and Heavy-Ion Charge Collection Phenomena in a New SiGe HBT on Thin-Film SOI Technology. IEEE Trans. Nucl. Sci. 2008, 55, 3197–3201. [Google Scholar] [CrossRef]

- Adekoya, M.A.; Liu, S.; Wang, X.; Xing, T.; Li, H.; Meng, F.; Du, X.; Li, Z.; Huang, T. Simulation and Analysis of Inverse-Mode Operation of Single Event Transient Mechanisms on NPN-SiGe HBT. Phys. Scr. 2024, 99, 055309. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, G.; Li, F.; Sun, H.; Chen, Q.; Zhao, S.; Liu, J.; Ouyang, X. Effects of Different Factors on Single Event Effects Introduced by Heavy Ions in SiGe Heterojunction Bipolar Transistor: A TCAD Simulation. Electronics 2023, 12, 1008. [Google Scholar] [CrossRef]

- Li, P.; He, C.; Guo, H.; Zhang, J.; Li, Y.; Wei, J. Comparison of holes trapping and protons transport induced by low dose rate gamma radiation in oxide on different SiGe processes. Microelectron. Reliab. 2019, 103, 113499. [Google Scholar] [CrossRef]

- Varadharajaperumal, M.; Niu, G.; Krithivasan, R.; Cressler, J.D.; Reed, R.A.; Marshall, P.W.; Vizkelethy, G.; Dodd, P.E.; Joseph, A.J. 3-D simulation of heavy-ion induced charge collection in SiGe HBTs. IEEE Trans. Nucl. Sci. 2003, 50, 2191–2198. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, Y.; Zhang, X.; Chen, C.; Wu, L.; Ma, M.; Lv, H.; Lv, L.; Zheng, X.; Tian, W.; et al. Simulation of Single-Event Transient Effect for GaN High-Electron-Mobility Transistor. Micromachines 2023, 14, 1948. [Google Scholar] [CrossRef]

- Tian, G.; Bi, J.; Xu, G.; Xi, K.; Yang, X.; Yin, H.; Xu, Q.; Wang, W. Heavy ion induced single-event-transient effects in nano-scale ferroelectric vertical tunneling transistors by TCAD simulation. Semicond. Sci. Technol. 2020, 35, 105010. [Google Scholar] [CrossRef]

- Montes, E.J.; Reed, R.A.; Pellish, J.A.; Alles, M.L.; Schrimpf, R.D.; Weller, R.A.; Varadharajaperumal, M.; Niu, G.; Sutton, A.K.; Diestelhorst, R.; et al. Single Event Upset Mechanisms for Low-Energy-Deposition Events in SiGe HBTs. IEEE Trans. Nucl. Sci. 2008, 55, 1581–1586. [Google Scholar] [CrossRef]

- Wei, J.; Li, Y.; Liao, W.; Liu, F.; Li, Y.; Liu, J.; He, C.; Guo, G. Angular Dependence of Proton-Induced Single Event Transient in Silicon-Germanium Heterojunction Bipolar Transistors. Chin. Phys. B 2022, 31, 086106. [Google Scholar] [CrossRef]

- Ye, B.; Mo, L.-H.; Zhai, P.-F.; Cai, L.; Liu, T.; Yin, Y.-N.; Sun, Y.-M.; Liu, J. Impact of Heavy Ion Energy and Species on Single-Event Upset in Commercial Floating Gate Cells. Microelectron. Reliab. 2021, 120, 114326. [Google Scholar] [CrossRef]

- Zhang, J.; He, C.; Guo, H.; Tang, D.; Xiong, C.; Li, P.; Wang, X. 3-D simulation study of single event effects of SiGe heterojunction bipolar transistor in extreme environment. Microelectron. Reliab. 2015, 55, 1180–1186. [Google Scholar] [CrossRef]

- Bi, J.; Zeng, C.; Gao, L.; Liu, G.; Luo, J.; Han, Z. Estimation of pulsed laser-induced single event transient in a partially depleted silicon-on-insulator 0.18-μm MOSFET. Chin. Phys. B 2014, 23, 088505. [Google Scholar] [CrossRef]

- Wei, J.; Qiu, S.; Fu, J.; Fu, X.; Liu, Q.; Zhang, X.; Luo, T.; Su, T.; Zhu, K.; Huang, L.; et al. Anomalous TID Susceptibility on Collector Bias for SOI High-Voltage Polysilicon Emitter Bipolar Transistors. IEEE Trans. Electron Devices 2024, 71, 4033–4038. [Google Scholar] [CrossRef]

- Fan, L.; Bi, J.; Xi, K.; Yan, G. Investigation of Radiation Effects on FD-SOI Hall Sensors by TCAD Simulations. Sensors 2020, 20, 3946. [Google Scholar] [CrossRef]

- Omprakash, A.P.; Fleetwood, Z.E.; Raghunathan, U.S.; Ildefonso, A.; Cardoso, A.S.; Lourenco, N.E.; Babcock, J.; Mukhopadhyay, R.; Zhang, E.X.; McMarr, P.J.; et al. Total Ionizing Dose Effects on a High-Voltage (>30 V) Complementary SiGe on SOI Technology. IEEE Trans. Nucl. Sci. 2017, 64, 277–284. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, H.; Pan, X.; Guo, Q.; Zhang, F.; Feng, J.; Wang, X.; Wei, Y.; Wu, X. Synergistic Effect of Total Ionizing Dose on Single Event Effect Induced by Pulsed Laser Microbeam on SiGe Heterojunction Bipolar Transistor. Chin. Phys. B. 2018, 27, 108501. [Google Scholar] [CrossRef]

- Sun, Y.; Fu, J.; Wang, Y.; Zhou, W.; Liu, Z.; Li, X.; Shi, Y. Experimental study of bias dependence of pulsed laser-induced single-event transient in SiGe HBT. Microelectron. Reliab. 2016, 65, 41–46. [Google Scholar] [CrossRef]

| Region | Thickness (μm) | Materials | Concentration (cm−3) |

|---|---|---|---|

| Substrate | 2 | Silicon | 6.68 × 1016 |

| BOX | 0.7 | Oxide | 0 |

| SiGe Base | 0.09 | SiGe | 2 × 1019 |

| Base | 0.09 | Poly silicon | 1 × 1019 |

| Collector | 2 | Silicon | 1 × 1016 |

| Emitter | 30 | Poly silicon | 6.34 × 1019 |

| Bias State | Emitter (mA) | Collector (mA) | Base (mA) |

|---|---|---|---|

| Positive bias | 9.42 | 11.65 | 2.29 |

| Collector positive bias | 10.00 | 13.61 | 4.11 |

| Cutoff bias | 3.41 | 4.62 | 7.12 |

| Substrate reverse bias | 2.19 | 1.31 | 2.87 |

| Bias State | Emitter (pC) | Collector (pC) | Base (pC) |

|---|---|---|---|

| Positive bias | −1.157 | 1.408 | −2.466 |

| Collector positive bias | −0.519 | 0.918 | −0.398 |

| Cut off bias | 0.028 | 0.433 | −0.461 |

| Substrate reverse bias | 0.045 | 0.379 | −0.424 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, Y.; Aierken, A.; Liu, X.; Liu, M.; Gao, C.; Wang, G.; Wang, D.; Majumdar, S.; Xuan, Y.; Liu, M.; et al. Heavy Ions Induced Single-Event Transient in SiGe-on-SOI HBT by TCAD Simulation. Micromachines 2025, 16, 532. https://doi.org/10.3390/mi16050532

Long Y, Aierken A, Liu X, Liu M, Gao C, Wang G, Wang D, Majumdar S, Xuan Y, Liu M, et al. Heavy Ions Induced Single-Event Transient in SiGe-on-SOI HBT by TCAD Simulation. Micromachines. 2025; 16(5):532. https://doi.org/10.3390/mi16050532

Chicago/Turabian StyleLong, Yuedecai, Abuduwayiti Aierken, Xuefei Liu, Mingqiang Liu, Changsong Gao, Gang Wang, Degui Wang, Sandip Majumdar, Yundong Xuan, Mengxin Liu, and et al. 2025. "Heavy Ions Induced Single-Event Transient in SiGe-on-SOI HBT by TCAD Simulation" Micromachines 16, no. 5: 532. https://doi.org/10.3390/mi16050532

APA StyleLong, Y., Aierken, A., Liu, X., Liu, M., Gao, C., Wang, G., Wang, D., Majumdar, S., Xuan, Y., Liu, M., & Bi, J. (2025). Heavy Ions Induced Single-Event Transient in SiGe-on-SOI HBT by TCAD Simulation. Micromachines, 16(5), 532. https://doi.org/10.3390/mi16050532