Improvement of Micro-Hole Processing in SiCf/SiC Ceramic Matrix Composite Using Efficient Two-Step Laser Drilling

Abstract

1. Introduction

2. Material and Experiment

2.1. Material

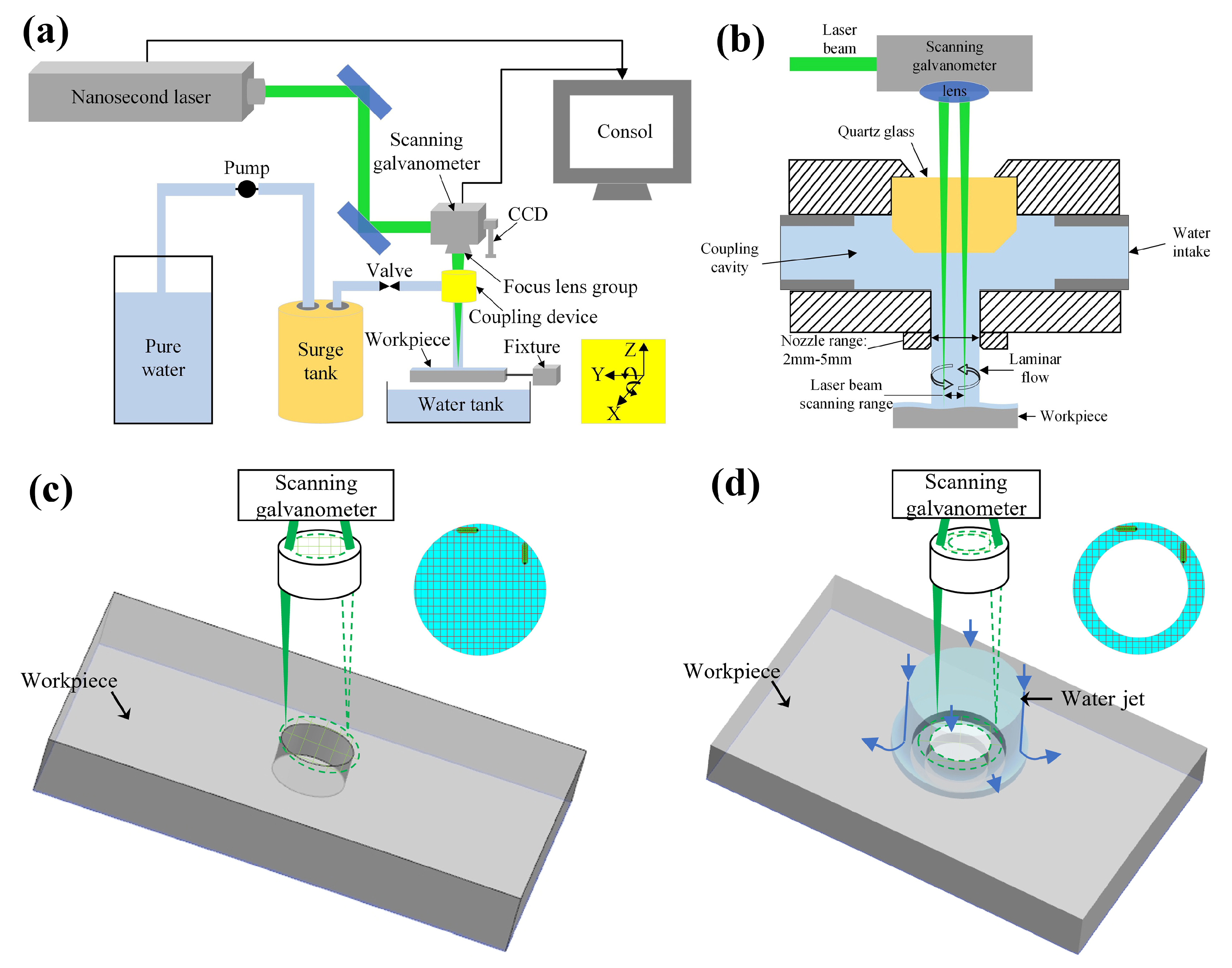

2.2. Laser Drilling

2.2.1. Laser Pre-Drilling in Air

2.2.2. Laser Final-Drilling with Water Jet

2.3. Characterization

3. Results and Discussion

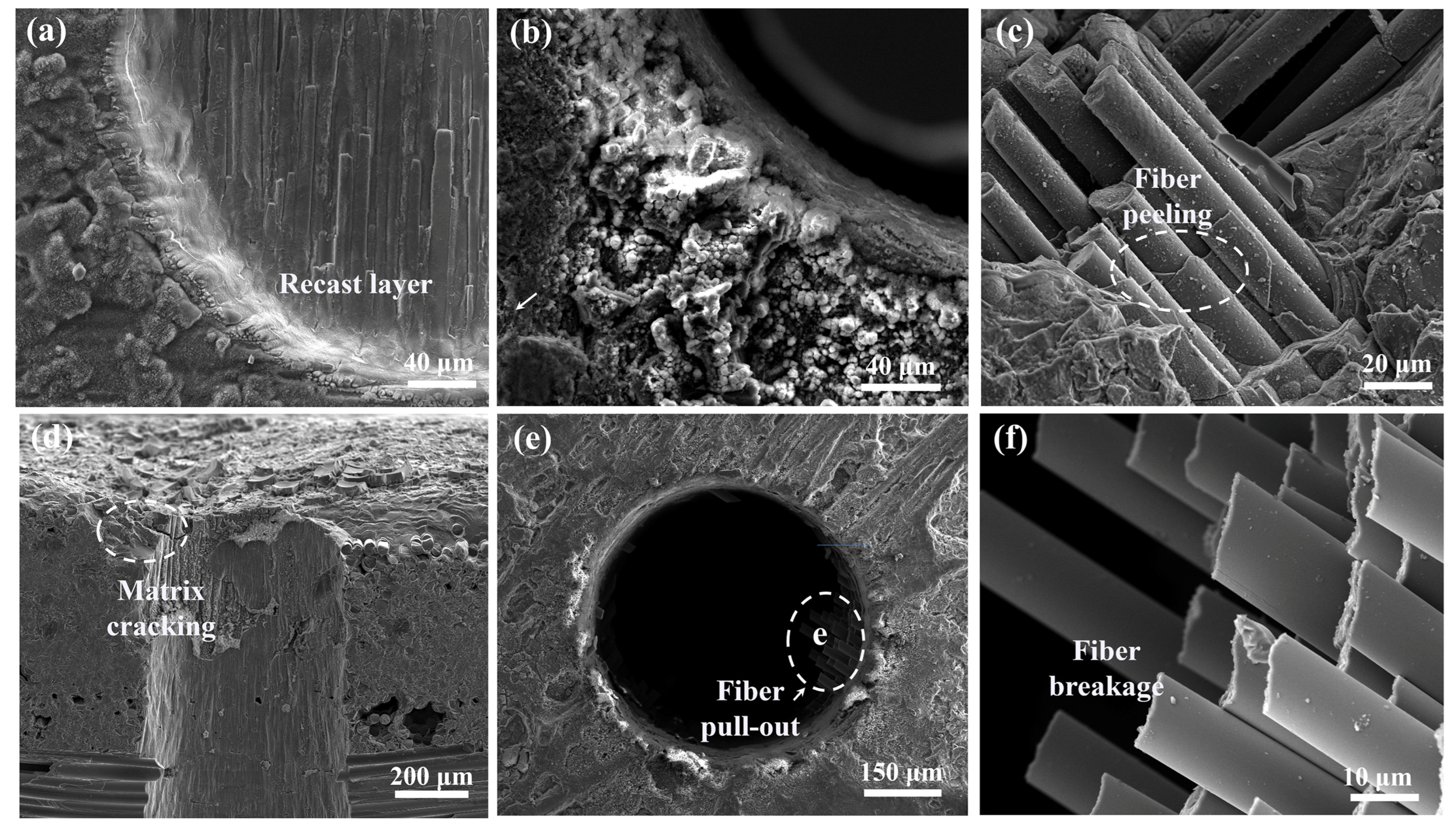

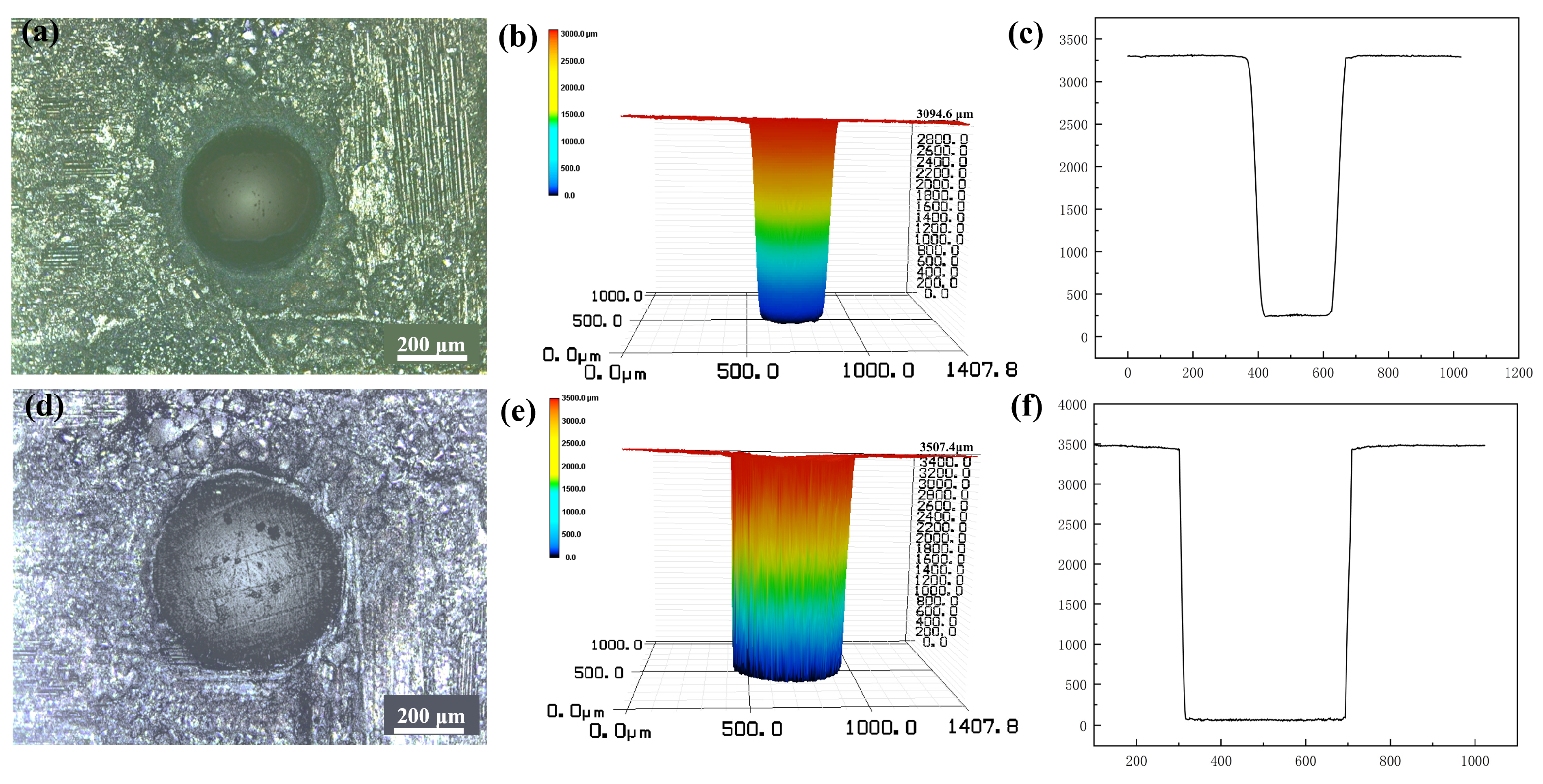

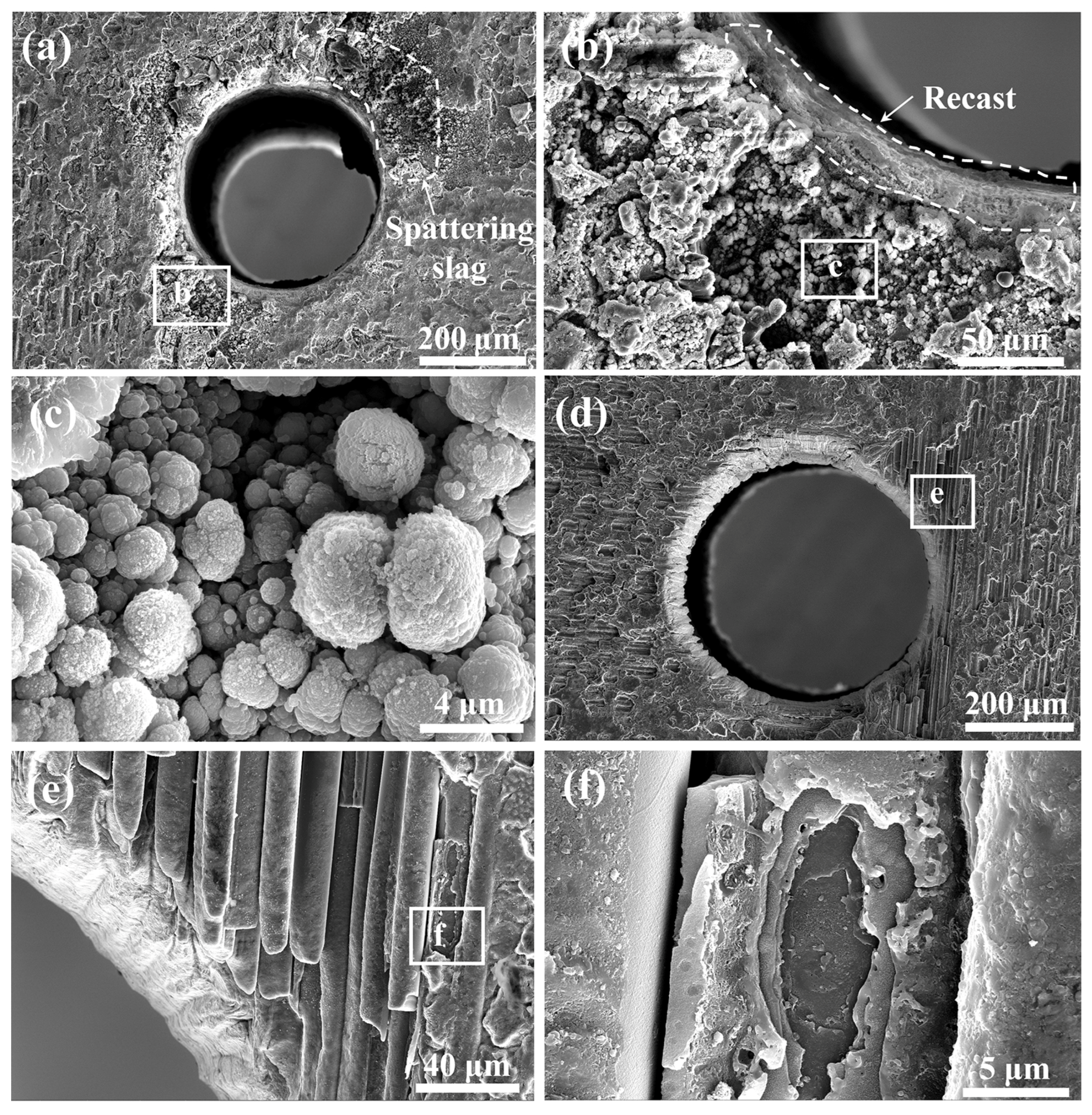

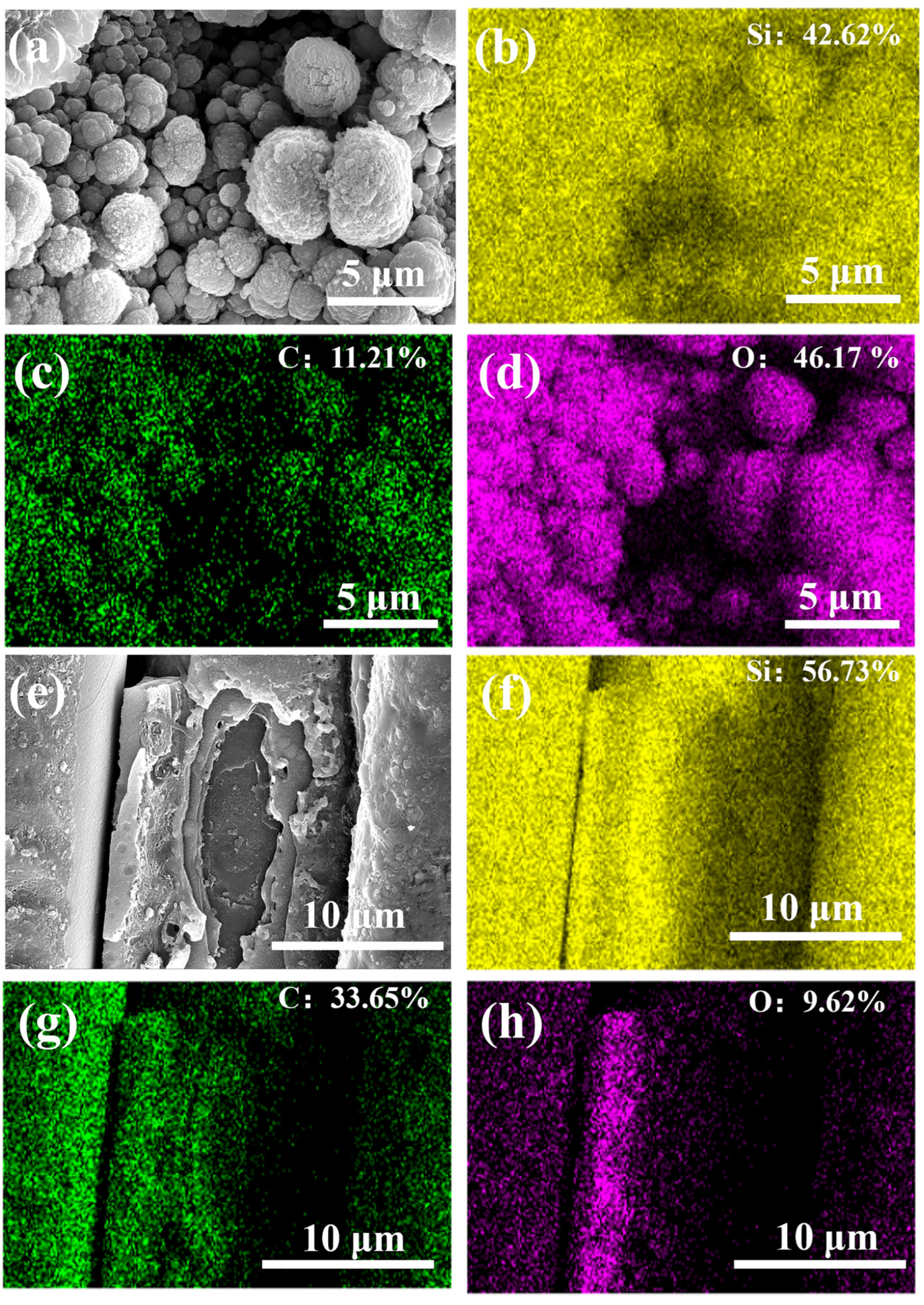

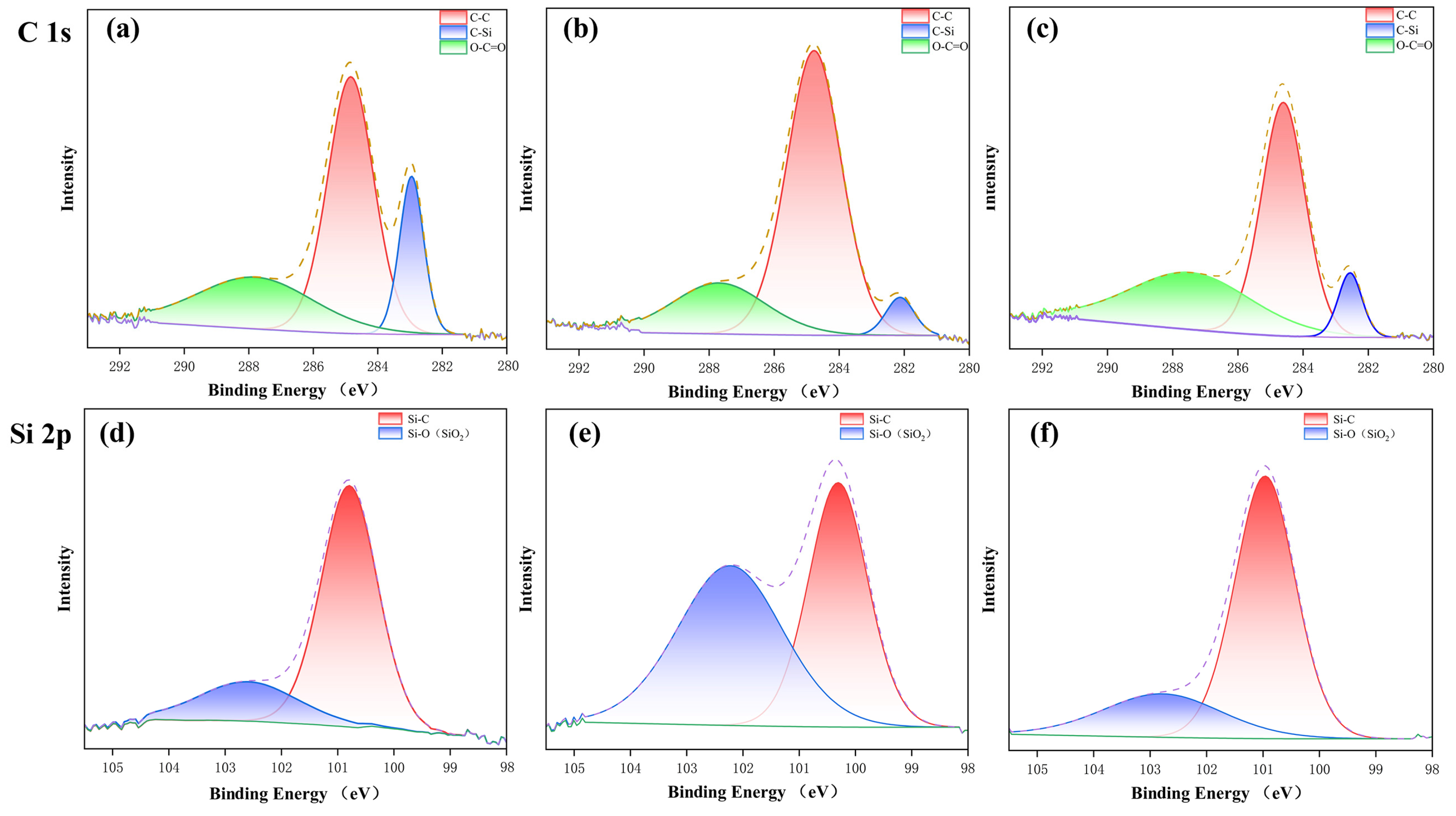

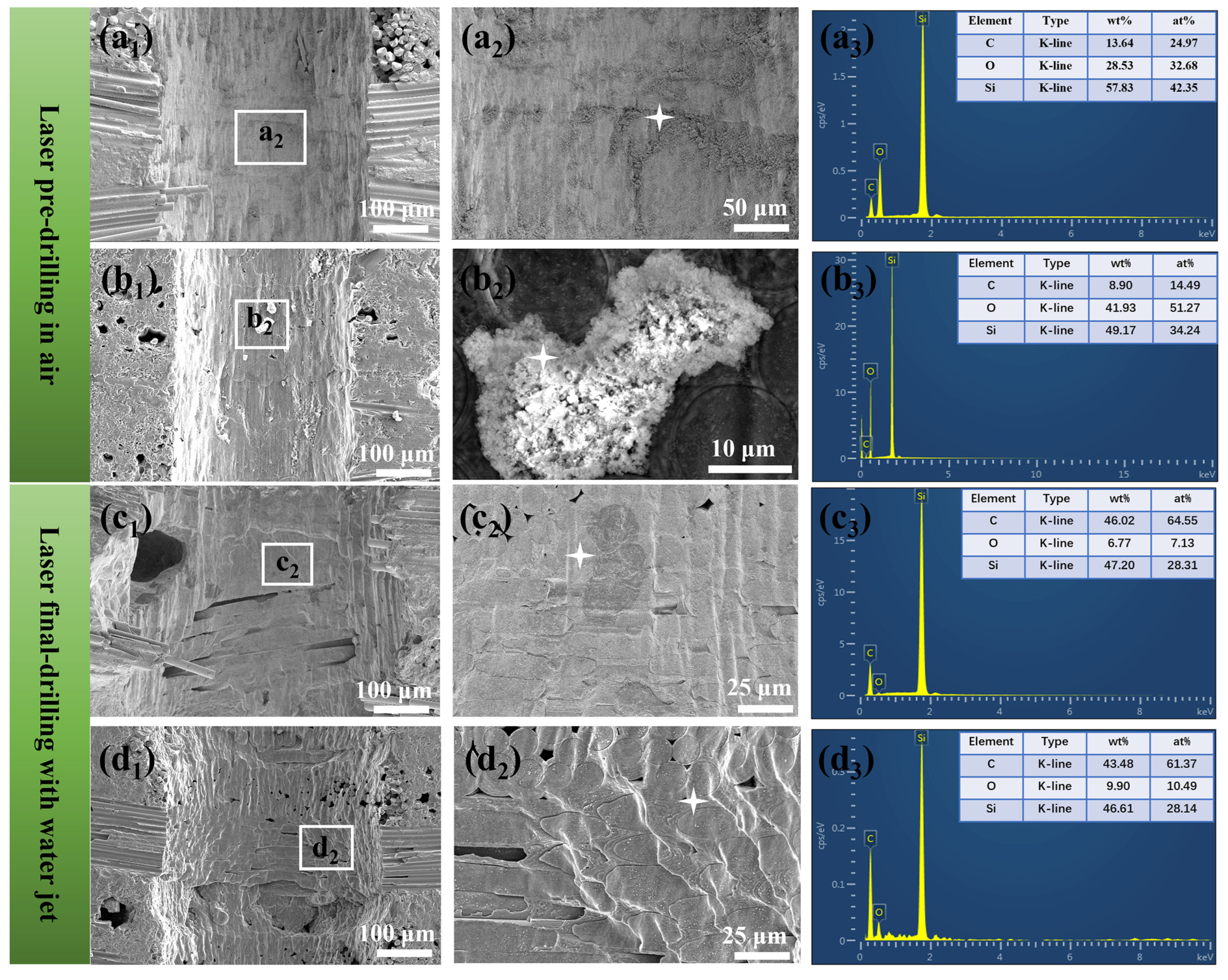

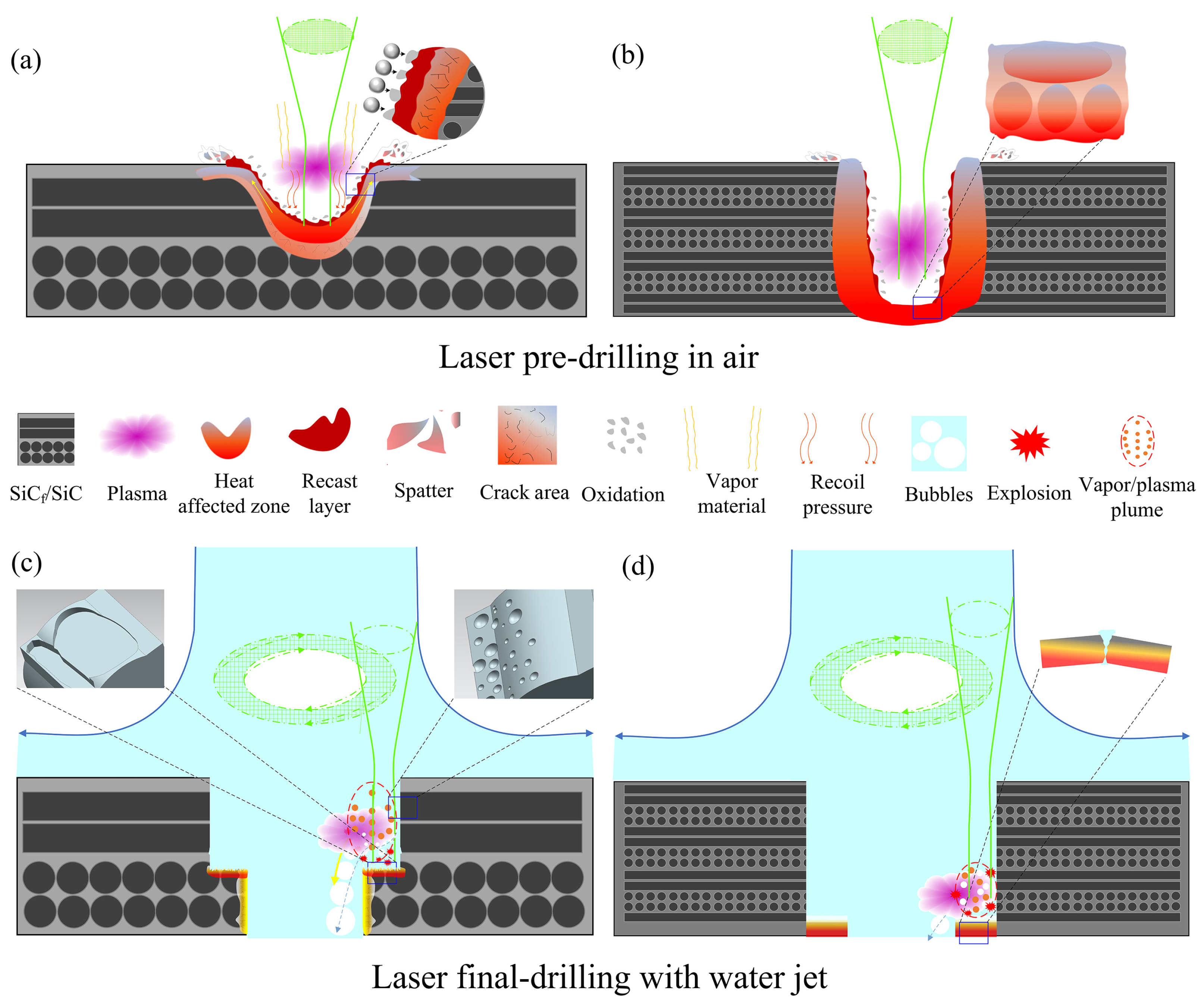

3.1. Laser Pre-Drilling in Air of SiCf/SiC CMC

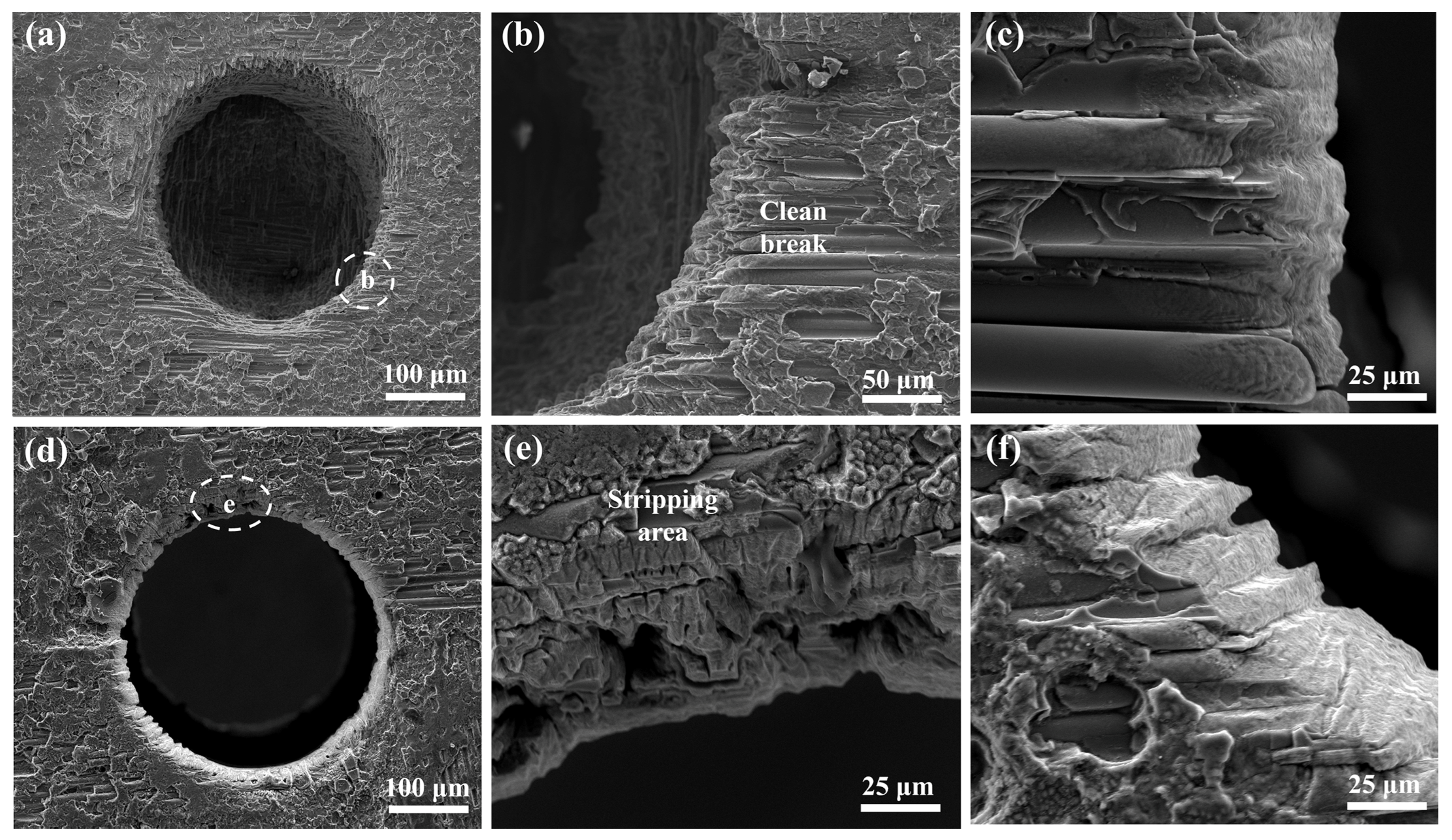

3.2. Laser Final-Drilling with Water Jet of SiCf/SiC CMC

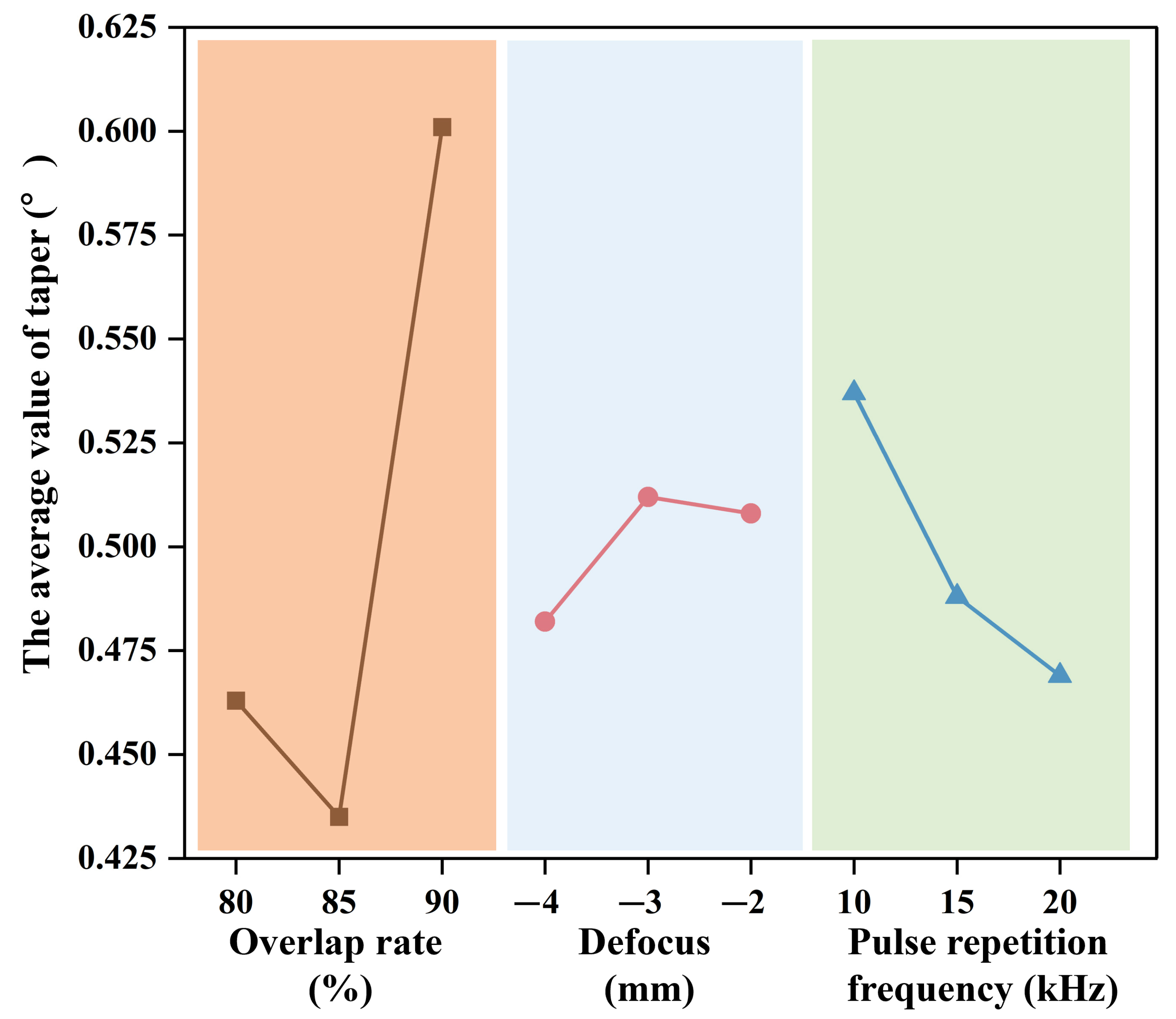

3.3. Influence of Medium and Laser Parameters on Laser Drilled Micro-Hole

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lemos, D.M.; Marques, F.D.; Ferreira, A.J.M. A review on bistable composite laminates for aerospace applications. Compos. Struct. 2024, 329, 117756. [Google Scholar] [CrossRef]

- Zhao, C.; Wen, M.; Wang, Q.; Ouyang, W.; Xu, D.; Jia, Z.; Zheng, Y.; Xi, T.; Sheng, L. Tailoring the corrosion resistance and biological performance of Mg-Zn-Y-Nd bioimplants with multiphasic, pore-sealed cerium-doped ceramic coatings via facile one-pot plasma electrolytic oxidation. J. Mater. Sci. Technol. 2025, 230, 60–79. [Google Scholar] [CrossRef]

- Sheng, L.; Yang, F.; Guo, J.; Xi, T. Anomalous yield and intermediate temperature brittleness behaviors of directionally solidified nickel-based superalloy. T. Nonferr. Metal Soc. 2014, 24, 673–681. [Google Scholar] [CrossRef]

- Yilmaz, S.; Theodore, M.; Ozcan, S. Silicon carbide fiber manufacturing: Cost and technology. Compos. Part B Eng. 2024, 269, 111101. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications, Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Biswas, S.; Ramachandra, S.; Hans, P.; Kumar, S.P.S. Materials for Gas Turbine Engines: Present Status, Future Trends and Indigenous Efforts. J. Indian Inst. Sci. 2022, 102, 297–309. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Tian, Y.X.; Guo, J.T. Microstructural Characteristics and Mechanical Properties of a Nb/Nb5Si3 based Composite with and without Directional Solidification. Adv. Compos. Lett. 2018, 27, 168–175. [Google Scholar]

- Pollock, T.M. Alloy design for aircraft engines. Nat. Mater. 2016, 15, 809–815. [Google Scholar] [CrossRef]

- Du, B.; Hu, Z.; Sheng, L.; Cui, C.; Yang, J.; Zheng, Y.; Sun, X. Tensile, creep behavior and microstructure evolution of an as-cast Ni-based K417G polycrystalline superalloy. J. Mater. Sci. Technol. 2018, 34, 1805–1816. [Google Scholar] [CrossRef]

- Sheng, L.; Yang, F.; Xi, T.; Zheng, Y.; Guo, J. Microstructure and room temperature mechanical properties of NiAl–Cr(Mo)–(Hf, Dy) hypoeutectic alloy prepared by injection casting. T. Nonferr. Metal Soc. 2013, 23, 983–990. [Google Scholar] [CrossRef]

- Wang, P.; Liu, F.; Wang, H.; Li, H.; Gou, Y. A review of third generation SiC fibers and SiCf/SiC composites. J. Mater. Sci. Technol. 2019, 35, 2743–2750. [Google Scholar] [CrossRef]

- Chen, J.; An, Q.; Ming, W.; Chen, M. Investigations on continuous-wave laser and pulsed laser induced controllable ablation of SiCf/SiC composites. J. Eur. Ceram. Soc. 2021, 41, 5835–5849. [Google Scholar] [CrossRef]

- Tong, Y.; Bai, S.; Zhang, H.; Ye, Y. Laser ablation behavior and mechanism of C/SiC composite. Ceram. Int. 2013, 39, 6813–6820. [Google Scholar] [CrossRef]

- Hu, M.; Ming, W.; An, Q.; Chen, M. Experimental study on milling performance of 2D C/SiC composites using polycrystalline diamond tools. Ceram. Int. 2019, 45, 10581–10588. [Google Scholar] [CrossRef]

- Tawakoli, T.; Azarhoushang, B. Intermittent grinding of ceramic matrix composites (CMCs) utilizing a developed segmented wheel. Int. J. Mach. Tools Manuf. 2011, 51, 112–119. [Google Scholar] [CrossRef]

- Sun, D.-R.; Wang, G.; Li, Y.; Yu, Y.; Shen, C.; Wang, Y.; Lu, Z. Laser drilling in silicon carbide and silicon carbide matrix composites. Opt. Laser Technol. 2024, 170, 110166. [Google Scholar] [CrossRef]

- Samant, A.N.; Dahotre, N.B. Laser machining of structural ceramics—A review. J. Eur. Ceram. Soc. 2009, 29, 969–993. [Google Scholar] [CrossRef]

- Bilal, A.; Jahan, M.; Talamona, D.; Perveen, A. Electro-Discharge Machining of Ceramics: A Review. Micromachines 2018, 10, 10. [Google Scholar] [CrossRef]

- Yin, J.; Li, M.; Xu, J.; Ding, W.; Su, H. Edge chipping characteristics in grinding SiCf/SiC composite. Ceram. Int. 2022, 48, 7126–7135. [Google Scholar] [CrossRef]

- Zan, Z.; Guo, K.; Sun, J.; Lu, Y.; Yang, B.; Jia, X.; Sivalingam, V.; Xi, J. Investigation on scratching force and material removal mechanism of 3D SiCf/C–SiC composites during single grain scratching. J. Eur. Ceram. Soc. 2022, 42, 5366–5379. [Google Scholar] [CrossRef]

- Yuan, S.; Li, Z.; Zhang, C.; Guskov, A. Research into the transition of material removal mechanism for C/SiC in rotary ultrasonic face machining. Int. J. Adv. Manuf. Technol. 2018, 95, 1751–1761. [Google Scholar] [CrossRef]

- Pachaury, Y.; Tandon, P. An overview of electric discharge machining of ceramics and ceramic based composites. J. Manuf. Process. 2017, 25, 369–390. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, X.; Lu, Y.; Duan, X. Electrical discharge-mechanical hybrid drilling of micro-holes in carbon fibre-reinforced polymers. Int. J. Mach. Tools Manuf. 2025, 205, 104243. [Google Scholar] [CrossRef]

- Wei, C.; Zhao, L.; Hu, D.; Ni, J. Electrical discharge machining of ceramic matrix composites with ceramic fiber reinforcements. Int. J. Adv. Manuf. Technol. 2013, 64, 187–194. [Google Scholar] [CrossRef]

- Srinivasu, D.S.; Axinte, D.A.; Shipway, P.H.; Folkes, J. Influence of kinematic operating parameters on kerf geometry in abrasive waterjet machining of silicon carbide ceramics. Int. J. Mach. Tools Manuf. 2009, 49, 1077–1088. [Google Scholar] [CrossRef]

- Gavalda Diaz, O.; Garcia Luna, G.; Liao, Z.; Axinte, D. The new challenges of machining Ceramic Matrix Composites (CMCs): Review of surface integrity. Int. J. Mach. Tools Manuf. 2019, 139, 24–36. [Google Scholar] [CrossRef]

- Chao, Y.; Liu, Y.; Xu, Z.; Xie, W.; Zhang, L.; Ouyang, W.; Wu, H.; Pan, Z.; Jiao, J.; Li, S.; et al. Improving superficial microstructure and properties of the laser-processed ultrathin kerf in Ti-6Al-4V alloy by water-jet guiding. J. Mater. Sci. Technol. 2023, 156, 32–53. [Google Scholar] [CrossRef]

- Ouyang, W.; Zhang, L.; Wu, H.; Wu, D.; Zhang, S.; Qin, X.; Jiang, S.; Li, S.; Zhang, W.; Sheng, L. Optimized mechanical properties of the hot forged Ti–6Al–4V alloy by regulating multiscale microstructure via laser shock peening. Int. J. Mach. Tools Manuf. 2024, 201, 104192. [Google Scholar] [CrossRef]

- Chang, C.; Yao, G.; Cox, S.C.; Zhang, X.; Sheng, L.; Liu, M.; Cheng, W.; Lu, Y.; Yan, X. From macro-, through meso- to micro-scale: Densification behavior, deformation response and microstructural evolution of selective laser melted Mg-RE alloy. J. Magnes. Alloys 2025, in press. [CrossRef]

- Sheng, L.; Cheng, X.; Jiang, S.; Zhao, C.; Liu, J.; Jing, C.; Wang, J.; Xu, L.; Xiao, Y.; Wang, B.; et al. Investigation on cutting of CFRP composite by nanosecond short-pulsed laser with rotary drilling method. Sci. Eng. Compos. Mater. 2025, 32, 20240047. [Google Scholar] [CrossRef]

- Ouyang, W.; Jiao, J.; Xu, Z.; Xia, H.; Ye, Y.; Zou, Q.; Tian, R.; Sheng, L. Experimental study on CFRP drilling with the picosecond laser “double rotation” cutting technique. Opt. Laser Technol. 2021, 142, 107238. [Google Scholar] [CrossRef]

- Jiao, H.; Chen, B.; Wang, J.; Su, F. Ablation of definite-depth blind holes in 2.5-dimensional C/SiC composites by nanosecond laser. J. Manuf. Process. 2023, 91, 78–88. [Google Scholar] [CrossRef]

- Wu, M.L.; Ren, C.Z.; Xu, H.Z. Comparative study of micro topography on laser ablated C/SiC surfaces with typical uni-directional fibre ending orientations. Ceram. Int. 2016, 42, 7929–7942. [Google Scholar] [CrossRef]

- Ren, N.; Gao, F.; Wang, H.; Xia, K.; Song, S.; Yang, H. Water-induced effect on femtosecond laser layered ring trepanning in silicon carbide ceramic sheets using low-to-high pulse repetition rate. Opt. Commun. 2021, 496, 127040. [Google Scholar] [CrossRef]

- Gietl, H.; Karakoc, O.; Koyanagi, T.; Harrison, S.; Katoh, Y. Emerging continuous SiC fibers for high-temperature applications. Ceram. Int. 2024, 50, 32893–32904. [Google Scholar] [CrossRef]

- Kang, W.; Chen, J.; Zhang, Y.; Zhang, Q.; Chen, T.; Gou, Y. SiC fibers with different diameters exhibiting excellent high-temperature resistance and oxidation resistance. J. Mater. Res. Technol. 2023, 23, 1559–1569. [Google Scholar] [CrossRef]

- Rao, Q.; Chen, X.; Chen, J.; Zhang, W. Processing characteristics and ablation mechanism of CMC-SiCf/SiC by rotational thirteen-beam coupling nanosecond laser. Ceram. Int. 2024, 50, 20247–20259. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.; Chen, J.; An, Q.; Chen, M. Microstructure evolution and ablation mechanism of SiCf/SiC ceramic matrix composite microgrooves processed by pico-second laser. Ceram. Int. 2023, 49, 37356–37365. [Google Scholar] [CrossRef]

- Yang, F.; Dong, Z.; Kang, R.; Ma, H.; Ma, G.; Bao, Y. Femtosecond laser rotary drilling for SiCf/SiC composites. Chin. J. Aeronaut. 2025, 38, 103056. [Google Scholar] [CrossRef]

- Hu, T.; Yuan, S.; Wei, J.; Zhou, N.; Zhang, Z.; Zhang, J.; Li, X. Water jet guided laser grooving of SiCf/SiC ceramic matrix composites. Opt. Laser Technol. 2024, 168, 109991. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, Y.; Bai, J.; Qian, L. An efficient high-quality cutting method for thick SiCf/SiC ceramic matrix composites using UV laser multiline layered scanning with focus increment optimization. J. Mater. Process. Technol. 2025, 335, 118674. [Google Scholar] [CrossRef]

- Madhukar, Y.K.; Mullick, S.; Nath, A.K. An investigation on co-axial water-jet assisted fiber laser cutting of metal sheets. Opt. Lasers Eng. 2016, 77, 203–218. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, B.; Wang, J.; Wang, Y.; Sheng, L.; Jiao, J.; Yao, J.; Huang, Y.; Zhang, W. Effects of incidence angle and optimization in femtosecond laser polishing of C/SiC composites. Ceram. Int. 2022, 48, 32290–32304. [Google Scholar] [CrossRef]

- Zeng, J.; Zhang, Q.; Zhao, J.; Cai, Y.; Chu, C.; Zhu, Y.; Xu, J. The formed surface characteristics of SiCf/SiC composite in the nanosecond pulsed laser ablation. Ceram. Int. 2022, 48, 36860–36870. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Liang, C.-C.; Teng, T.-L.; Nguyen, A.-T. A numerical study on high-speed water jet impact. Ocean Eng. 2013, 72, 98–106. [Google Scholar] [CrossRef]

- Ghoreishi, M.; Low, D.K.Y.; Li, L. Comparative statistical analysis of hole taper and circularity in laser percussion drilling. Int. J. Mach. Tools Manuf. 2002, 42, 985–995. [Google Scholar] [CrossRef]

- Dong, Z.; Ma, H.; Ma, G.; Li, Z.; Yang, F.; Kang, R.; Wang, Y. Femtosecond laser spiral scanning ablation of SiCf/SiC composites. Opt. Laser Technol. 2024, 176, 110958. [Google Scholar] [CrossRef]

- Wei, J.; Zhou, N.; Gao, M.; Hu, T.; Li, X.; Zhang, J.; An, W.; Zhang, W.; Yuan, S.; Guo, F. Laser ablation of SiC/SiC ceramic matrix composites: Morphological characterization, component evolution and oxidation mechanisms. Corros. Sci. 2024, 227, 111762. [Google Scholar] [CrossRef]

- Wang, B.; Huang, Y.; Jiao, J.; Wang, H.; Wang, J.; Zhang, W.; Sheng, L. Numerical Simulation on Pulsed Laser Ablation of the Single-Crystal Superalloy Considering Material Moving Front and Effect of Comprehensive Heat Dissipation. Micromachines 2021, 12, 225. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Wang, Y.; Wan, F.; Li, J.; Li, D.; Liu, R. Long-term oxidation performance of SiCf/SiC composites at 1200 °C in air atmosphere manufactured by PIP and hybrid CVI/PIP techniques. Ceram. Int. 2024, 50, 10259–10267. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Z.; Zhang, X.; Liu, Y.; Withers, P.J.; Xiao, P. Oxidation behavior and subsequent mechanical properties of SiC/BN/SiBCN composite after exposure to steam at high temperature. Corro. Sci. 2025, 243, 112584. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, H.; Sun, Z.; Cai, X.; Feng, T.; Wen, Z.; Sun, S. Investigation of in-situ microstructural mechanical properties and thermal damage mechanisms of SiCf/SiC under CVI and PIP processes. Mater. Charact. 2025, 220, 114689. [Google Scholar] [CrossRef]

- Li, L.; Zhen, X.; Zheng, R.; Ma, C.; Liu, C. Further understanding of the improved mechanical properties for SiCf/BN/SiC composites prepared by CVI+PIP hybrid technique: Application of micro-mechanical methods. Compos. Part B Eng. 2024, 283, 111633. [Google Scholar] [CrossRef]

- Wei, J.; Yuan, S.; Yang, S.; Gao, M.; Fu, Y.; Hu, T.; Li, X.; Fan, X.; Zhang, W. Waterjet-guided laser processing of SiC/SiC ceramic matrix composites to obtain high cleanliness and low oxidation damage characteristics surfaces. Surf. Coat. Technol. 2024, 484, 130791. [Google Scholar] [CrossRef]

- Sheng, L.; Xiao, Y.; Jiao, C.; Du, B.; Li, Y.; Wu, Z.; Shao, L. Influence of layer number on microstructure, mechanical properties and wear behavior of the TiN/Ti multilayer coatings fabricated by high-power magnetron sputtering deposition. J. Manuf. Process. 2021, 70, 529–542. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, S.; Meng, X.; Kou, S.; Deng, J.; Fan, S. Heat treatment effects on microstructure and mechanical properties of CVI SiCf/PyC/SiC composites with Cansas-IIISiC fibers. J. Eur. Ceram. Soc. 2023, 43, 5940–5949. [Google Scholar] [CrossRef]

- Wang, J.; Wang, B.; Yuan, C.; Yu, A.; Zhang, W.; Sheng, L. Experimental Study on Coaxial Waterjet-Assisted Laser Scanning Machining of Nickel-Based Special Alloy. Micromachines 2023, 14, 641. [Google Scholar] [CrossRef]

- Gao, M.; Yuan, S.; Wei, J.; Niu, J.; Zhang, Z.; Li, X.; Zhang, J.; Zhou, N.; Luo, M. Optimization of processing parameters for waterjet-guided laser machining of SiC/SiC composites. J. Intell. Manuf. 2023, 35, 4137–4157. [Google Scholar] [CrossRef]

- Chen, J.; An, Q.; Gong, Q.; Zeng, D.; Chen, M. Machinability improvement in milling of SiCf/SiC composites based on laser controllable ablation pretreatment. J. Eur. Ceram. Soc. 2023, 43, 1352–1365. [Google Scholar] [CrossRef]

- Xu, Y.; Tian, J.; Wang, Z.; Zhang, J.; Li, S.; Yan, Y.; Ge, M. A comprehensive study on the flow field of cylindrical cavitation nozzle jet under different turbulence models. Ocean Eng. 2025, 315, 119596. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Xu, Y.; Zhang, J.; Li, S.; Zhang, G.; Ge, M. Experimental investigation of rotating self-propelled cavitation jet for efficient mineral scale removal in oil field tubes. Int. J. Oil Gas Coal Technol. 2024, 36, 272–295. [Google Scholar] [CrossRef]

- Wang, C.; Chen, J.; Zhang, X.; Wang, T.; Yang, L.; An, Q.; Ming, W.; Chen, M. Effects of ultrasonic vibration assisted milling with laser ablation pretreatment on fatigue performance and machining efficiency of SiCf/SiC composites. J. Eur. Ceram. Soc. 2023, 43, 5925–5939. [Google Scholar] [CrossRef]

| Parameters | Processing Cycles | Overlap Rate (%) | Pulse Energy (mJ) | Defocus (mm) | Pulse-Repetition Frequency (kHz) |

|---|---|---|---|---|---|

| Values | 600, 700, 800, 900, 1000, 1100, 1200, 1300 | 65, 70, 75, 80, 85, 90, 95 | 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 | −5, −4, −3, −2, −1, 0, 1 | 0, 5, 10, 15, 20, 25, 0 |

| Parameters | Processing Cycles | Overlap Rate (%) | Pulse Energy (mJ) | Defocus (mm) | Pulse-Repetition Frequency (kHz) | Water Jet Velocity (m/s) |

|---|---|---|---|---|---|---|

| Values | 1400, 1600, 1800, 2000, 2200, 2400 | 65, 70, 75, 80, 85, 90 | 0.3, 0.4, 0.5, 0.6 | −4, −3, −2, −1, 0, 1 | 5, 10, 15, 20, 25, 30 | 3.37, 4.03, 4.78, 5.43, 6.07, 6.61, 7.2 |

| Experiment Number | Pulse-Repetition Frequency (kHz) | Defocus (mm) | Overlap Rate (%) | Micro-Hole Entrance Diameter (μm) | Micro-Hole Exit Diameter (μm) | Micro-Hole Taper Angle (°) |

|---|---|---|---|---|---|---|

| P1 | 10 | −1 | 75 | 411.19 | 231.56 | 1.71 |

| P2 | 10 | −2 | 80 | 410.93 | 260.86 | 1.43 |

| P3 | 10 | −3 | 85 | 415.36 | 283.99 | 1.25 |

| P4 | 10 | −4 | 90 | 414.03 | 291.07 | 1.17 |

| P5 | 15 | −1 | 80 | 408.90 | 257.60 | 1.44 |

| P6 | 15 | −2 | 75 | 410.69 | 250.38 | 1.53 |

| P7 | 15 | −3 | 90 | 413.26 | 298.34 | 1.09 |

| P8 | 15 | −4 | 85 | 412.27 | 291.81 | 1.15 |

| P9 | 20 | −1 | 85 | 413.45 | 262.48 | 1.44 |

| P10 | 20 | −2 | 90 | 413.71 | 296.24 | 1.21 |

| P11 | 20 | −3 | 75 | 402.36 | 251.57 | 1.44 |

| P12 | 20 | −4 | 80 | 411.35 | 281.72 | 1.24 |

| P13 | 25 | −1 | 90 | 409.14 | 264.91 | 1.38 |

| P14 | 25 | −2 | 85 | 408.57 | 269.47 | 1.33 |

| P15 | 25 | −3 | 80 | 405.57 | 279.85 | 1.20 |

| P16 | 25 | −4 | 75 | 384.25 | 244.70 | 1.33 |

| Experiment Number | Overlap Rate (%) | Defocus (mm) | Pulse-Repetition Frequency (kHz) | Micro-Hole Entrance Diameter (μm) | Micro-Hole Exit Diameter (μm) | Micro-Hole Taper Angle (°) |

|---|---|---|---|---|---|---|

| F1 | 80 | −2 | 20 | 532.91 | 475.76 | 0.55 |

| F2 | 80 | −3 | 15 | 552.32 | 505.47 | 0.45 |

| F3 | 80 | −4 | 10 | 563.78 | 521.88 | 0.40 |

| F4 | 85 | −2 | 15 | 545.52 | 501.66 | 0.42 |

| F5 | 85 | −3 | 10 | 558.53 | 511.14 | 0.45 |

| F6 | 85 | −2 | 20 | 561.69 | 515.56 | 0.44 |

| F7 | 90 | −2 | 10 | 556.63 | 497.88 | 0.56 |

| F8 | 90 | −3 | 20 | 565.25 | 499.42 | 0.63 |

| F9 | 90 | −4 | 15 | 564.21 | 500.41 | 0.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Wang, B.; Li, Z.; Wang, J.; Xiao, Y.; Zeng, Q.; Wang, X.; Zhang, W.; Zhang, Q.; Sheng, L. Improvement of Micro-Hole Processing in SiCf/SiC Ceramic Matrix Composite Using Efficient Two-Step Laser Drilling. Micromachines 2025, 16, 430. https://doi.org/10.3390/mi16040430

Cao Y, Wang B, Li Z, Wang J, Xiao Y, Zeng Q, Wang X, Zhang W, Zhang Q, Sheng L. Improvement of Micro-Hole Processing in SiCf/SiC Ceramic Matrix Composite Using Efficient Two-Step Laser Drilling. Micromachines. 2025; 16(4):430. https://doi.org/10.3390/mi16040430

Chicago/Turabian StyleCao, Yue, Bin Wang, Zhehang Li, Jiajia Wang, Yinan Xiao, Qingyang Zeng, Xinfeng Wang, Wenwu Zhang, Qunli Zhang, and Liyuan Sheng. 2025. "Improvement of Micro-Hole Processing in SiCf/SiC Ceramic Matrix Composite Using Efficient Two-Step Laser Drilling" Micromachines 16, no. 4: 430. https://doi.org/10.3390/mi16040430

APA StyleCao, Y., Wang, B., Li, Z., Wang, J., Xiao, Y., Zeng, Q., Wang, X., Zhang, W., Zhang, Q., & Sheng, L. (2025). Improvement of Micro-Hole Processing in SiCf/SiC Ceramic Matrix Composite Using Efficient Two-Step Laser Drilling. Micromachines, 16(4), 430. https://doi.org/10.3390/mi16040430