Wettability-Controlled Hydrophobic Coating of CMP Component Using PTFE and DLC for Mitigating Slurry Agglomeration and Contamination

Abstract

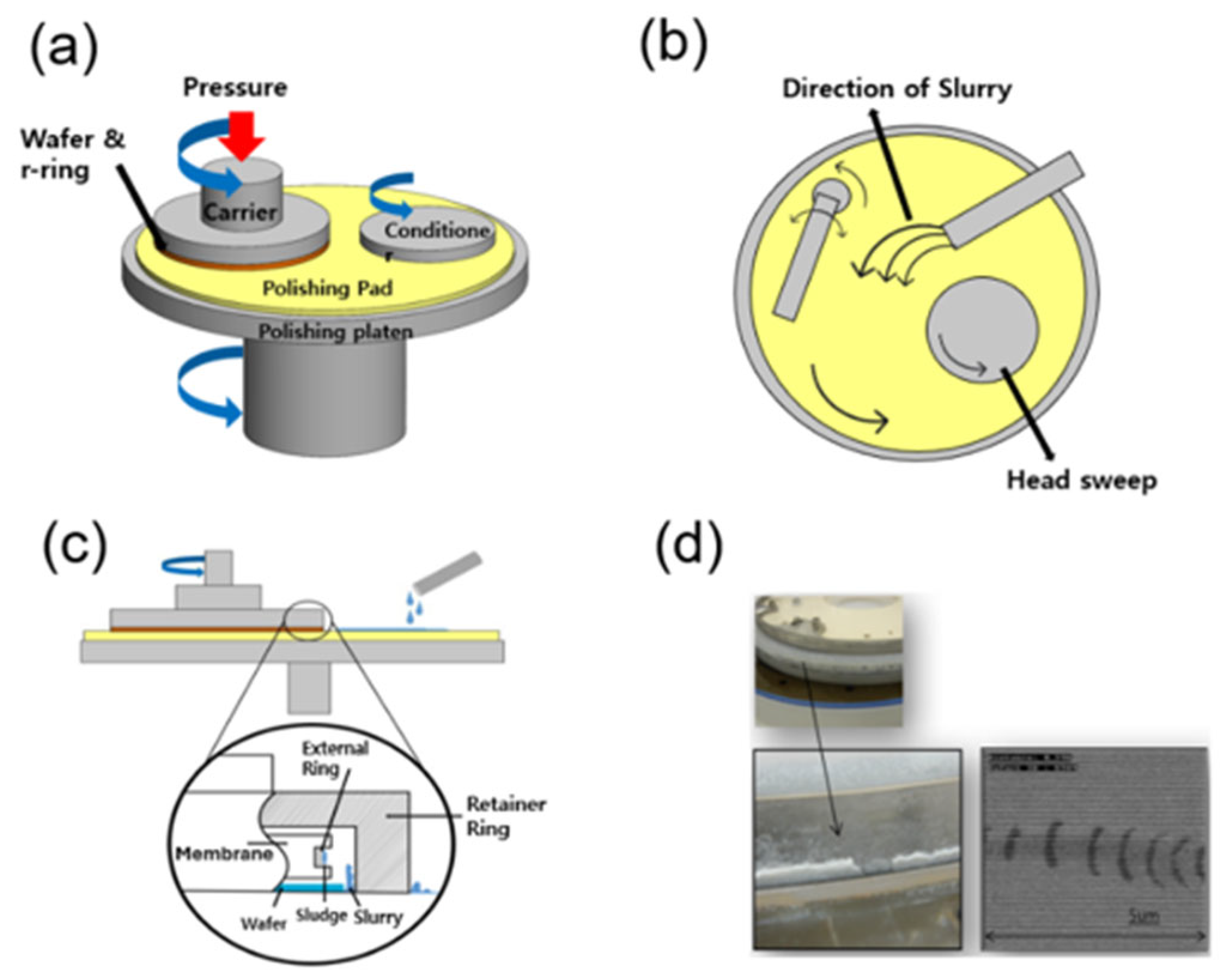

1. Introduction

2. Experimental Section

2.1. Sample Preparation

2.1.1. Type A (PTFE Coatings)

2.1.2. Type B (DLC Coatings)

2.2. Contact Angle and Surface Roughness Evaluation

2.3. Scratch and Fouling Resistance Testing

3. Results & Discussion

3.1. Macroscopic Response to Hydrophobic Coating

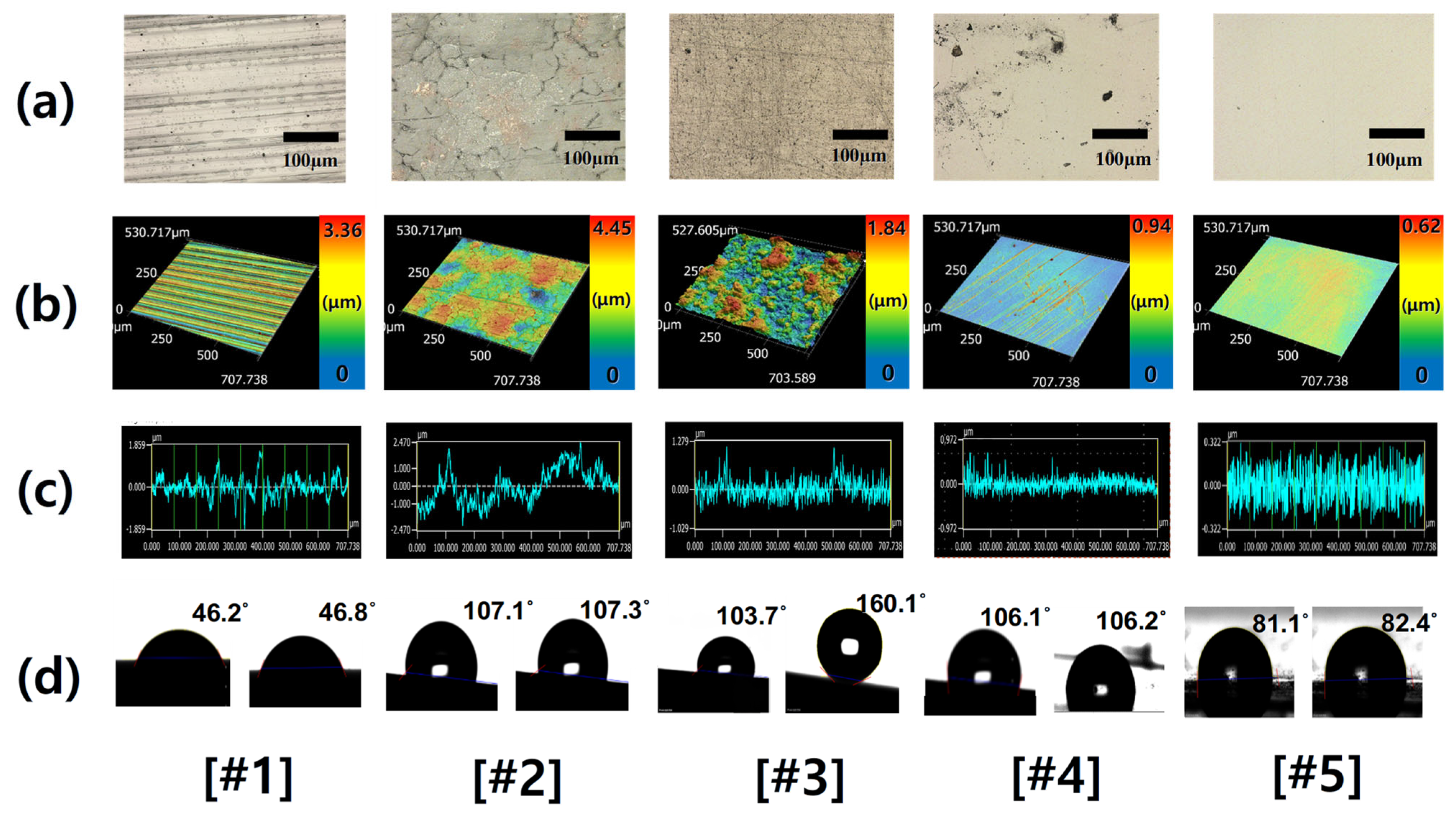

3.2. Coordinated Texture–Wettability Correspondence

3.3. Wetting Mechanism and Governing Equations

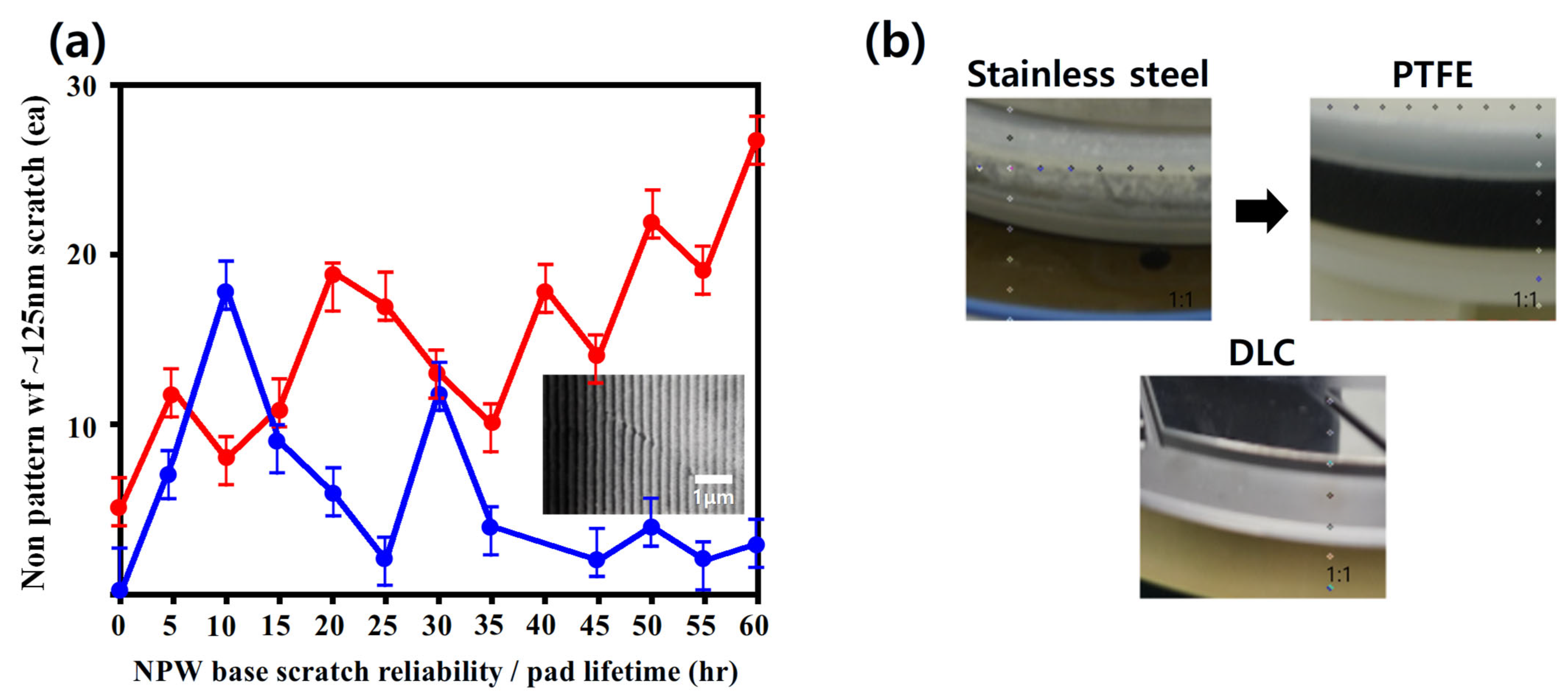

3.4. Reliability Under NPW Oxide-CMP

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, H.; Lee, D.; Jeong, H. Mechanical aspects of the chemical mechanical polishing process: A review. Int. J. Precis. Eng. Manuf. 2016, 17, 525–536. [Google Scholar] [CrossRef]

- Tsujimura, M. The way to zeros: The future of semiconductor device and chemical mechanical polishing technologies. Jpn. J. Appl. Phys. 2016, 55, 06JA01. [Google Scholar] [CrossRef]

- Zantye, P.B.; Kumar, A.; Sikder, A.K. Chemical mechanical planarization for microelectronics applications. Mater. Sci. Eng. R Rep. 2004, 45, 89–220. [Google Scholar] [CrossRef]

- Choi, Y.S.; Lee, E.S. Studies on the scratch reduction through the analysis of sludge formation mechanism. In Proceedings of the 2013 Summer Conference of the Korean Institute of Electrical and Electronic Material Engineers (KIEEME), Yeosu, Republic of Korea, 19–21 June 2013. [Google Scholar]

- Kim, I.-G.; Choi, J.-G.; Park, J.-G. A study on the scratch generating mechanism during the ILD CMP process. In Proceedings of the KIEEME Summer Conference, Sokcho, Republic of Korea, 19–21 June 2008. [Google Scholar]

- Seo, Y.-J.; Kim, S.-Y.; Choi, Y.-O.; Oh, Y.-T.; Lee, W.-S. Effects of slurry filter size on the chemical mechanical polishing (CMP) defect density. Mater. Lett. 2004, 58, 2091–2095. [Google Scholar] [CrossRef]

- Yerriboina, N.P.; Kwon, T.-Y.; Kim, I.-K.; Kim, I.-G.; Park, J.-G. Generation of pad debris during oxide CMP process and its role in scratch formation. J. Electrochem. Soc. 2011, 158, H394–H400. [Google Scholar] [CrossRef]

- Kwon, T.-Y.; Ramachandran, M.; Park, J.-G. Scratch formation and its mechanism in chemical mechanical planarization (CMP). Friction 2013, 1, 279–305. [Google Scholar] [CrossRef]

- Young, T. An essay on the cohesion of fluids. Philos. Trans. R. Soc. London 1805, 95, 65–87. [Google Scholar] [CrossRef]

- Peta, K.; Kubiak, K.J.; Sfravara, F.; Brown, C.A. Dynamic wettability of complex fractal isotropic surfaces—Multiscale correlations. Tribol. Int. 2016, 214, 111145. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, L.; Xie, G.; Li, Z.; Chen, H.; Gong, H.; Xu, W.; Guo, D.; Luo, J. A review on tribology of polymer composite coatings. Friction 2021, 9, 429–470. [Google Scholar] [CrossRef]

- Shah, R.; Pai, N.; Khandekar, R.; Aslam, R.; Wang, Q.; Yan, Z.; Rosenkranz, A. DLC coatings in biomedical applications—Review on current advantages, existing challenges, and future directions. Surf. Coat. Technol. 2024, 489, 131006. [Google Scholar] [CrossRef]

- Veeramasuneni, S.; Drelich, J.; Miller, J.; Yamauchi, G. Hydrophobicity of ion-plated PTFE coatings. Prog. Org. Coat. 1997, 31, 265–270. [Google Scholar] [CrossRef]

- Burkarter, E.; Saul, C.; Thomazi, F.; Cruz, N.; Roman, L.; Schreiner, W. Superhydrophobic electrosprayed PTFE. Surf. Coat. Technol. 2007, 202, 194–198. [Google Scholar] [CrossRef]

- Xi, C.; Zhang, B.; Ye, X.; Yan, H. Fabrication of polytetrafluoroethylene-reinforced fluorocarbon composite coatings and tribological properties under multi-environment working conditions. Polymers 2024, 16, 3595. [Google Scholar] [CrossRef]

- Chaudhuri, R.G.; Paria, S. The wettability of PTFE and glass surfaces by nanofluids. J. Colloid Interface Sci. 2014, 431, 16–23. [Google Scholar] [CrossRef]

- Mashtalyar, D.V.; Pleshkova, A.I.; Piatkova, M.A.; Nadaraia, K.V.; Imshinetskiy, I.M.; Belov, E.A.; Suchkov, S.N.; Sinebryukhov, S.L.; Gnedenkov, S.V. PTFE-containing coating obtained on Ti by spraying and PEO pretreatment. Coatings 2013, 13, 1249. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Mosyanov, M. Influence of DLC coatings deposited by PECVD technology on the wear resistance of carbide end mills and surface roughness of AlCuMg2 and 41Cr4 workpieces. Coatings 2020, 10, 1038. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, F.; Qiang, L.; Gao, K.; Zhang, B.; Zhang, J. Recent advances in the mechanical and tribological properties of fluorine-containing DLC films. RSC Adv. 2014, 5, 9635–9649. [Google Scholar] [CrossRef]

- ISO 25178-2; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 4287; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 1997.

- Nosonovsky, M.; Bhushan, B. Roughness-induced superhydrophobicity: A way to design non-adhesive surfaces. J. Phys. Condens. Matter 2008, 20, 225009. [Google Scholar] [CrossRef]

| Property | Type-A PTFE Coating | Type-B DLC Coating |

|---|---|---|

| Material | Polytetrafluoroethylene | Diamond like carbon |

| Principle | Low coefficient of friction and chemical | High hardness, wear resistance |

| Manufacturing method | Spray, powder coating | PVD, CVD, ion beam deposition |

| Temperature | 350–400 °C | 80–200 °C |

| Substance | C2F4 polymer chains with strong –CF2–CF2– bonding | Amorphous C–H bonding with sp3/sp2 hybridization |

| Chemical formula | (C2F4)n/–CF2–CF2 | C (sp3/sp2) network |

| Manufacturer | Not disclosed | Not disclosed |

| Molecular weight | Avg. polymer: ~106 g/mol | Not defined, variable depending |

| Surface Properties | Non-adhesive, hydrophobic, chemically resistant | High wear resistance, low friction, corrosion resistant |

| Sample Test | Ra | Rpk | Sa | Spk |

|---|---|---|---|---|

| Stainless [#1] | 0.38 | 0.18 | 0.66 | 0.76 |

| PTFE coated Type A [#2] | 0.87 | 0.71 | 0.94 | 0.85 |

| DLC coated Type B [#3] | 0.27 | 0.65 | 0.38 | 1.1 |

| PEEK [#4] | 0.26 | 0.81 | 0.31 | 0.91 |

| Plastic [#5] | 0.09 | 0.08 | 0.08 | 0.09 |

| Material | Surface Roughness (Spk) | Contact Angle (θ) | Hydrophobic Mechanism | Hydrophobic |

|---|---|---|---|---|

| DLC | 1.1 | 160.1 | Cassie-Baxter (f ≈ 0.08) | Super hydro phobic |

| PTFE | 0.85 | 107.3 | Wenzel (r ≈ 1.1) | Ultra hydrophobic |

| PEEK | 0.91 | 106.2 | Low γsp (≈15 mN/m) | Hydrophobic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, E.; Sun, K.; So, Y.; Baek, J.; Shin, J.H.; Kim, H.D.; Youn, Y.B.; Kim, M.-W. Wettability-Controlled Hydrophobic Coating of CMP Component Using PTFE and DLC for Mitigating Slurry Agglomeration and Contamination. Micromachines 2025, 16, 1382. https://doi.org/10.3390/mi16121382

Lee E, Sun K, So Y, Baek J, Shin JH, Kim HD, Youn YB, Kim M-W. Wettability-Controlled Hydrophobic Coating of CMP Component Using PTFE and DLC for Mitigating Slurry Agglomeration and Contamination. Micromachines. 2025; 16(12):1382. https://doi.org/10.3390/mi16121382

Chicago/Turabian StyleLee, Eunseok, Kyoungjun Sun, Yuhan So, Jaewoo Baek, Jun Hyuk Shin, Hae Dong Kim, Yeo Bin Youn, and Min-Woo Kim. 2025. "Wettability-Controlled Hydrophobic Coating of CMP Component Using PTFE and DLC for Mitigating Slurry Agglomeration and Contamination" Micromachines 16, no. 12: 1382. https://doi.org/10.3390/mi16121382

APA StyleLee, E., Sun, K., So, Y., Baek, J., Shin, J. H., Kim, H. D., Youn, Y. B., & Kim, M.-W. (2025). Wettability-Controlled Hydrophobic Coating of CMP Component Using PTFE and DLC for Mitigating Slurry Agglomeration and Contamination. Micromachines, 16(12), 1382. https://doi.org/10.3390/mi16121382