The Formation Law of Surface Profile in Fused Silica During Continuous-Wave CO2 Laser Processing

Abstract

1. Introduction

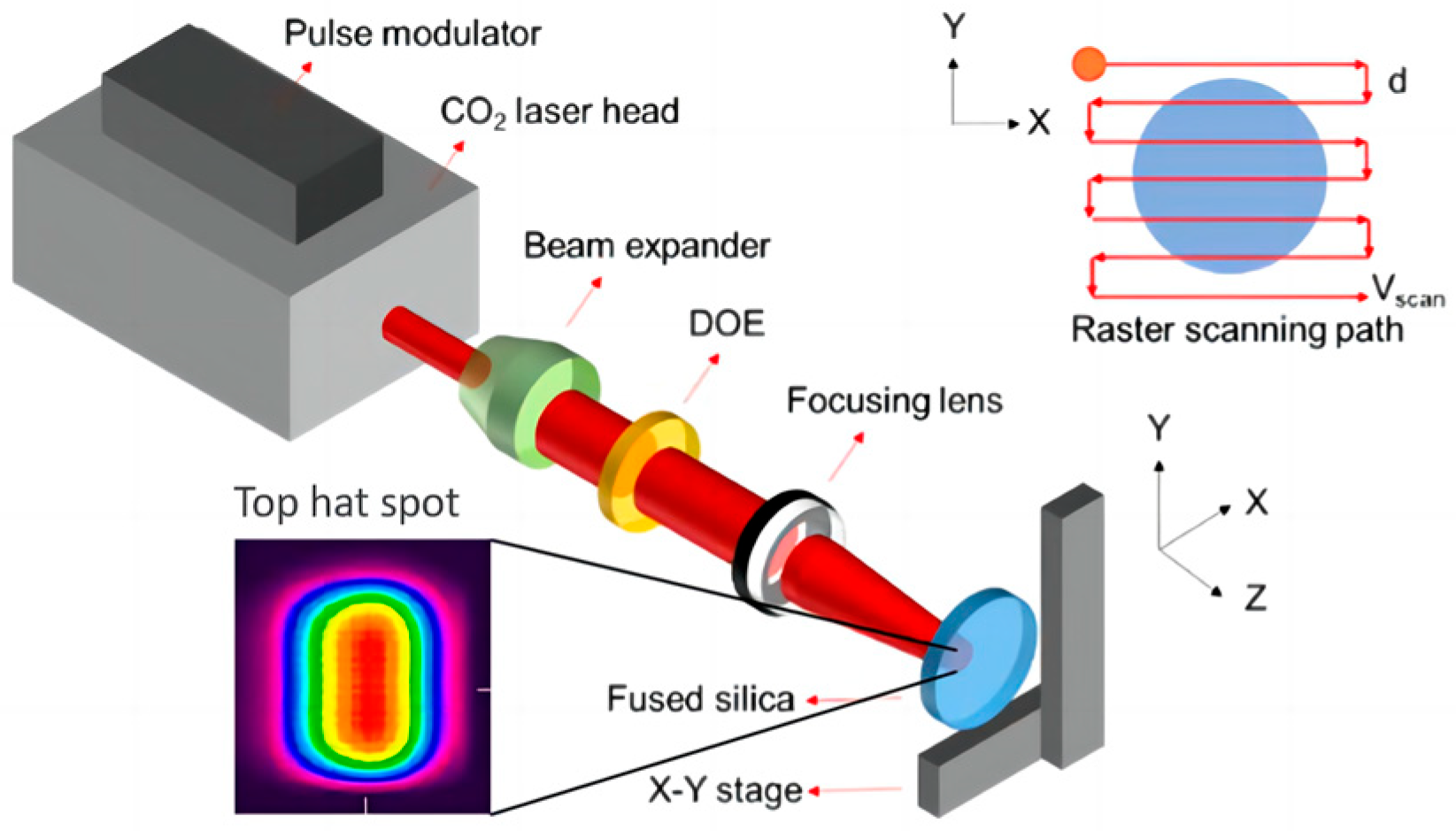

2. Materials and Methods

3. Results and Discussion

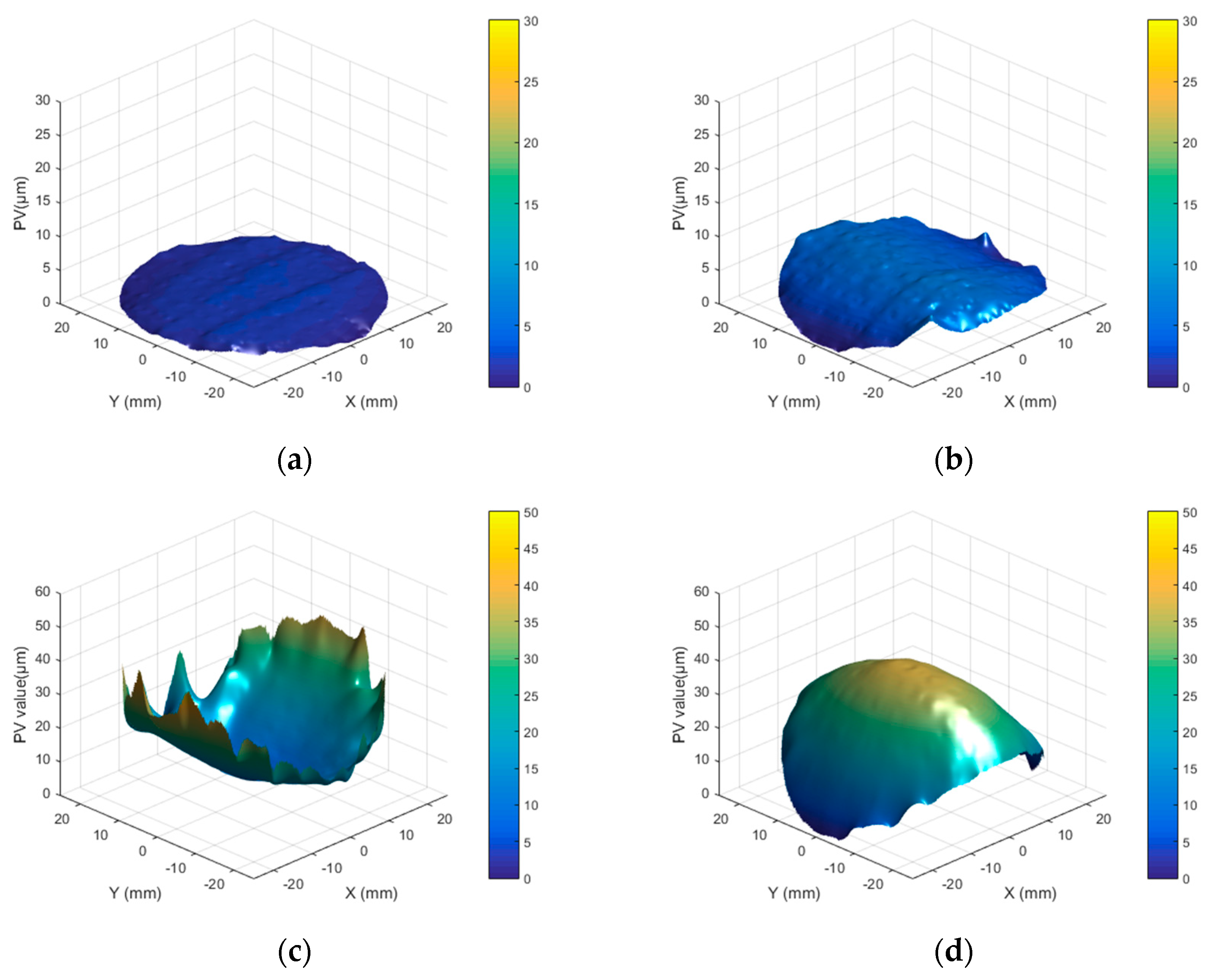

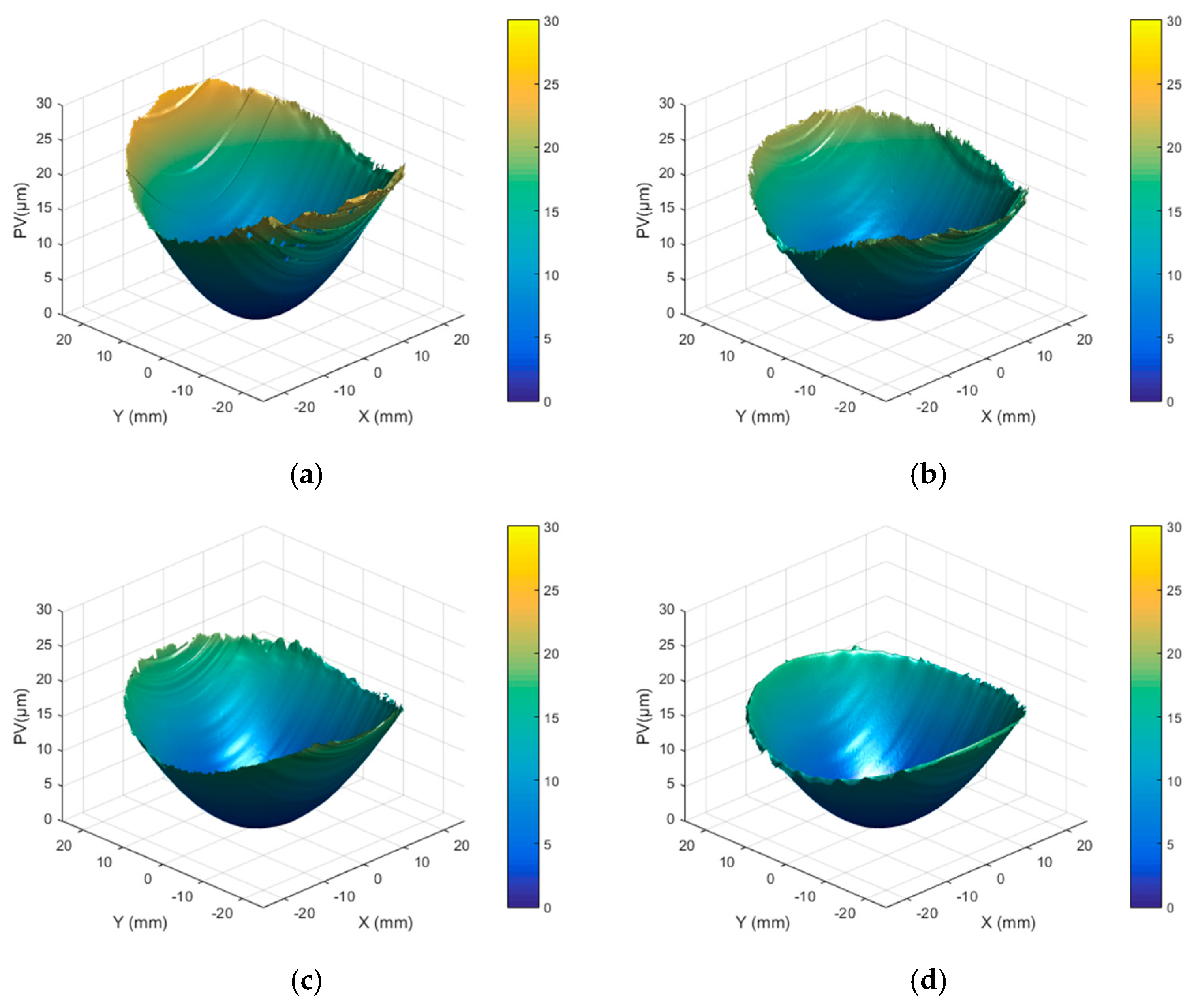

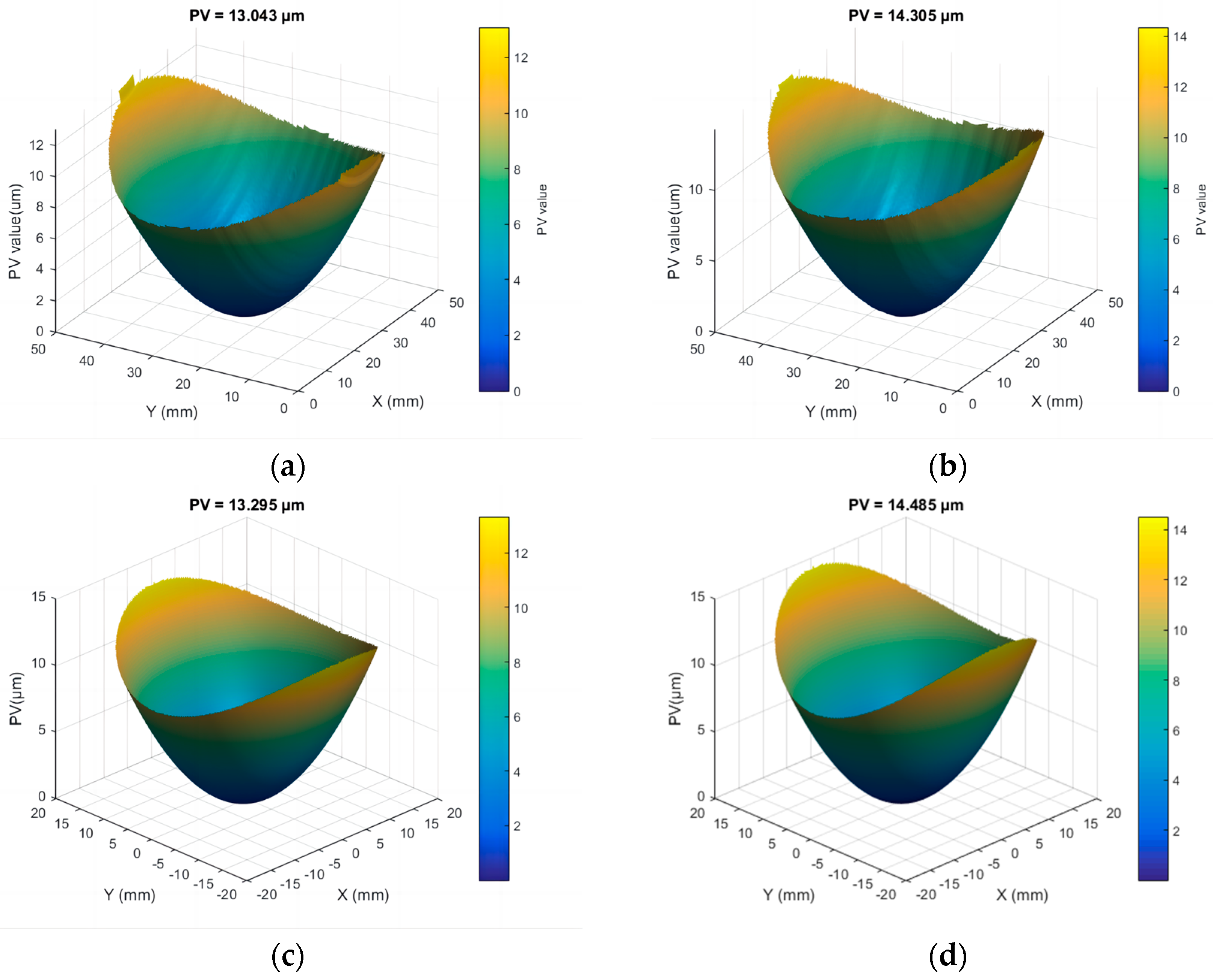

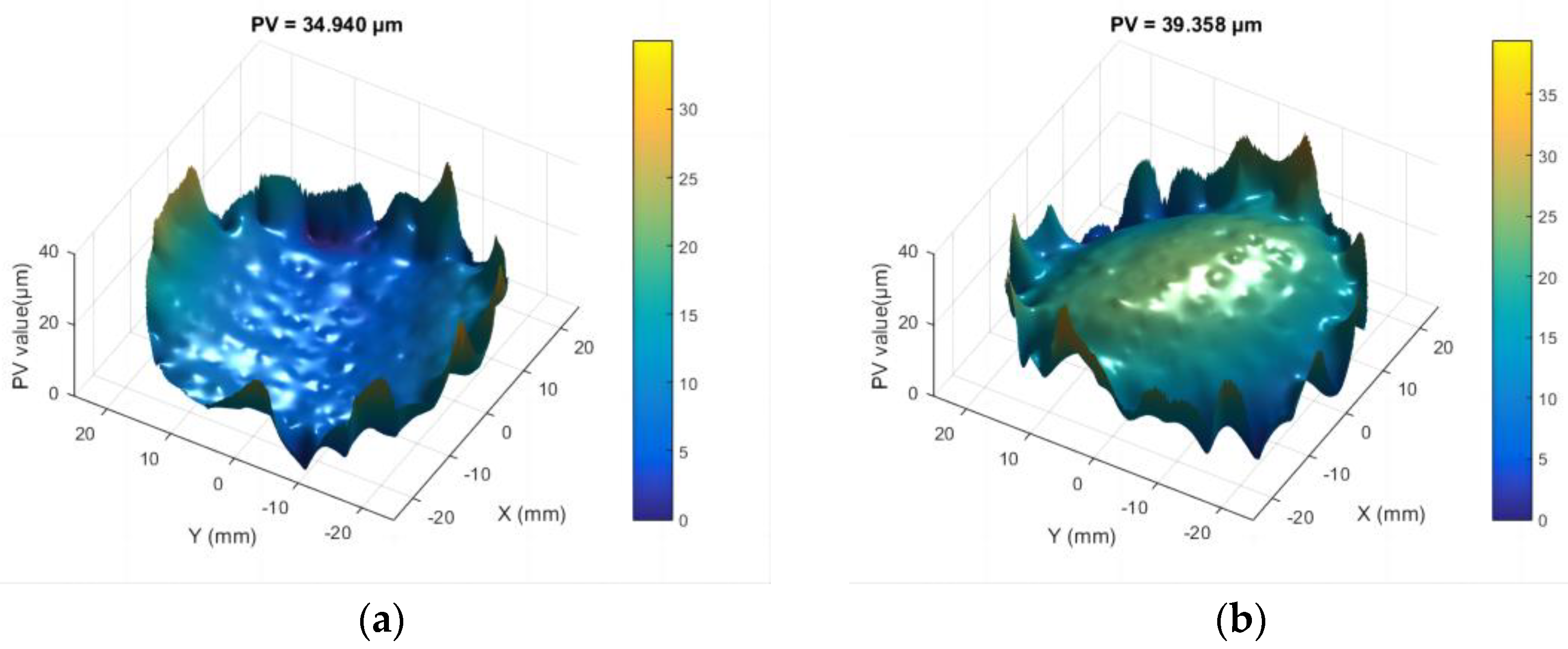

3.1. Influence of Laser Processing Parameters on Surface Profile of Fused Silica

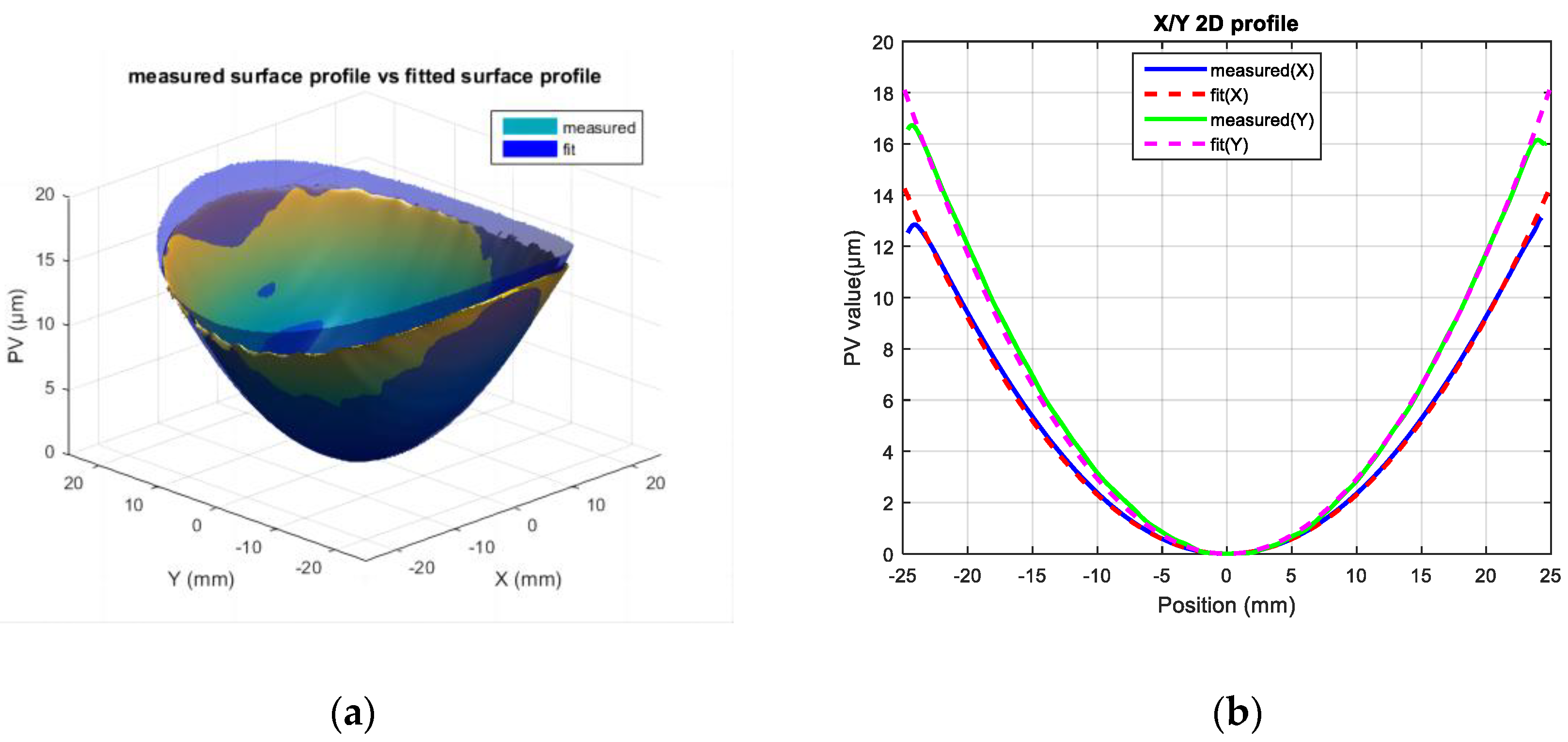

3.2. The Relationship Between Laser Processing Parameters and Surface Profile

3.3. Research on the Suppression Approach of Surface Profile Deformation

4. Conclusions

- (1)

- The upper surface of fused silica processed by a CW CO2 laser exhibited a concave morphology, whereas the bottom surface showed a convex shape. The PV value ranged between 10 and 30 μm when surface defects were fully fused. The PV value decreased with increasing scanning spacing and scanning speed but increased with higher laser power. Stress relief and cooling contraction of the hot-melt zone were the main causes of these surface profiles.

- (2)

- An empirical relationship for surface shape coefficients was proposed, providing an effective method to precisely control the surface profile of laser-processed fused silica.

- (3)

- Under annealing conditions of 1080 °C for 10 h, the low-frequency surface profile error of laser-processed fused silica was reduced by more than 50%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, L.; Huang, J.; Liu, H.; Wang, F.; Geng, F.; Jiang, X. Review of Research Progress on Damage Characteristics of Fused Silica Optics under Ultraviolet Pulsed Laser Irradiation. Acta Opt. Sin. 2022, 42, 1714004. (In Chinese) [Google Scholar]

- Tan, C.; Zhao, L.; Chen, M.; Cheng, J.; Wu, C.; Liu, Q.; Yang, H.; Yin, Z.; Liao, W. Experimental and theoretical investigation of localized CO2 laser interaction with fused silica during the process of surface damage mitigation. Results Phys. 2020, 16, 102936. [Google Scholar] [CrossRef]

- Ye, X.; Huang, J.; Liu, H.; Geng, F.; Sun, L.; Jiang, X.; Wu, W.; Qiao, L.; Zu, X.; Zheng, W. Advanced Mitigation Process (AMP) for Improving Laser Damage Threshold of Fused Silica Optics. Sci. Rep. 2016, 6, 31111. [Google Scholar] [CrossRef]

- Hsu, Y.-J.; Wu, H.-Y.; Chang, W.-C.; Nien, Y.-T. Machining fused silica surface by continuous-wave CO2 laser beams and their nanostructure characterizations. Mater. Chem. Phys. 2022, 306, 130960. [Google Scholar] [CrossRef]

- Tan, C.; Zhao, L.; Chen, M.; Cheng, J.; Yang, H.; Liu, Q.; Yin, Z.; Liao, W. Formation mechanism of surface morphology in the process of CO2 pulsed laser processing of fused silica optics. Opt. Laser Technol. 2021, 138, 106838. [Google Scholar] [CrossRef]

- Wlodarczyk, K.L.; Carter, R.M.; Jahanbakhsh, A.; Lopes, A.A.; Mackenzie, M.D.; Maier, R.R.; Hand, D.P.; Maroto-Valer, M.M. Rapid laser manufacturing of microfluidic devices from glass substrates. Micromachines 2018, 9, 409. [Google Scholar] [CrossRef]

- Xin, C.; Li, Z.; Hao, L.; Li, Y. A comprehensive review on additive manufacturing of glass: Recent progress and future outlook. Mater. Des. 2023, 227, 111736. [Google Scholar] [CrossRef]

- Hildebrand, J.; Hecht, K.; Bliedtner, J.; Müller, H. Advanced analysis of laser beam polishing of quartz glass surfaces. Phys. Procedia 2012, 39, 277–285. [Google Scholar] [CrossRef][Green Version]

- Temple, P.A.; Lowdermilk, W.H.; Milam, D. Carbon dioxide laser polishing of fused silica surfaces for increased laser-damage resistance at 1064 nm. Appl. Opt. 1982, 21, 3249–3255. [Google Scholar] [CrossRef]

- Dai, W.; Xiang, X.; Jiang, Y.; Wang, H.J.; Li, X.B.; Yuan, X.D.; Zheng, W.G.; Lv, H.B.; Zu, X.T. Surface evolution and laser damage resistance of CO2 laser irradiated area of fused silica. Opt. Lasers Eng. 2011, 49, 273–280. [Google Scholar] [CrossRef]

- Heidrich, S.; Willenborg, E.; Richmann, A. Development of a Laser Based Process Chain for Manufacturing Freeform Optics. Phys. Procedia 2011, 12, 519–528. [Google Scholar] [CrossRef]

- Zhang, C.; Liao, W.; Zhang, L.; Ye, Y.; Chen, J.; Wang, H.; Luan, X.; Yuan, X. Investigation of Control of Residual Stress Induced by CO2 Laser-Based Damage Mitigation of Fused Silica Optics. Condens. Matter Phys. 2014, 2014, 638045. [Google Scholar]

- Gallais, L.; Cormont, P.; Rullier, J.L. Investigation of stress induced by CO2 laser processing of fused silica optics for laser damage growth mitigation. Opt. Express 2009, 17, 23488–23501. [Google Scholar] [CrossRef]

- Toenshoff, H.-K. Microwave assisted thermal polishing of aspheric optical glass surfaces by CO2-laser. SPIE 2023, 10314, 25–27. [Google Scholar] [CrossRef]

- Liu, P.; Liu, W.; Li, Y.; Zhou, S. Influence Law of Scanning Velocity on Roughness in Laser Smoothing of Fused Silica Surface. Surf. Technol. 2019, 48, 316–322. (In Chinese) [Google Scholar]

- He, T. Theory and Experimental Research on CO2 Laser Polishing of Fused Silica Glass. Ph.D. Dissertation, University of Chinese Academy of Sciences, Beijing, China, 2019. (In Chinese). [Google Scholar]

- Wang, D.; Yu, M.; Yao, Y.; Wang, S.; Weng, Y.; Zhao, S.; Fan, F.; Goda, K.; Liu, S.; Zhao, Z.; et al. Dynamics of molten pool evolution and high-speed real-time optical measurement in laser polishing. Light Adv. Manuf. 2025, 5, 588–598. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, D.; Liu, J.; Yu, M.; Yan, R.; Cui, E.; Liu, S.; Lei, C. Analysis of molten pool dynamics and surface smoothing time scale in laser polishing alloy materials. Opt. Laser Technol. 2023, 161, 109183. [Google Scholar] [CrossRef]

- Zhao, S.; Yu, M.; Yan, R.; Zhai, Q.; Liu, J.; Dai, X.; Lei, C.; Wang, D. Surface roughness and microhardness improvement of laser cladding stainless-steel 316 by laser polishing based on multiple remelting. Opt. Laser Technol. 2024, 176, 110903. [Google Scholar] [CrossRef]

- Wang, D.; Fan, F.; Liu, M.; Tan, T.; Li, H.; Li, Y. Top-hat and Gaussian laser beam smoothing of ground fused silica surface. Opt. Laser Technol. 2020, 127, 106141. [Google Scholar] [CrossRef]

- Yu, M.; Mo, Z.; Yu, X.; Lei, C.; Wang, D. Effects of fictive temperature on mid-frequency waviness in laser polishing of glass. Appl. Opt. 2022, 61, 7315–7322. [Google Scholar] [CrossRef] [PubMed]

- Baisden, P.A.; Atherton, L.J.; Hawley, R.A.; Land, T.A.; Menapace, J.A.; Miller, P.E.; Runkel, M.J.; Spaeth, M.L.; Stolz, C.J.; Suratwala, T.I.; et al. Large Optics for the National Ignition Facility. Fusion Sci. Technol. 2016, 69, 295–351. [Google Scholar] [CrossRef]

- Doualle, T.; Gallais, L.; Cormont, P.; Donval, T.; Lamaignère, L.; Rullier, J.L. Effect of annealing on the laser induced damage of polished and CO2 laser-processed fused silica surfaces. J. Appl. Phys. 2016, 119, 213106. [Google Scholar] [CrossRef]

| Duty Cycle (%) | Scanning Speed (mm/s) | Scanning Spacing (mm) | PV Value (μm) | |

|---|---|---|---|---|

| 1 | 48 | 0.10 | 2 | 26.62 |

| 48 | 0.20 | 2 | 22.43 | |

| 48 | 0.25 | 2 | 19.60 | |

| 48 | 0.30 | 2 | 17.74 | |

| 48 | 0.40 | 2 | 15.62 | |

| 2 | 48 | 0.20 | 0.5 | 31.43 |

| 48 | 0.20 | 1.0 | 32.59 | |

| 48 | 0.20 | 1.25 | 26.66 | |

| 48 | 0.20 | 1.5 | 24.08 | |

| 48 | 0.20 | 2 | 22.43 | |

| 3 | 40 | 0.20 | 2 | 16.73 |

| 42 | 0.20 | 2 | 17.09 | |

| 45 | 0.20 | 2 | 21.39 | |

| 48 | 0.20 | 2 | 22.43 | |

| 51 | 0.20 | 2 | 24.91 |

| Heating | Heat Preservation | Slow Cooling | Fast Cooling I | Fast Cooling II |

|---|---|---|---|---|

| 43.2 °C/h | 950 °C-10 h | 15 °C/h | 35 °C/h | —— |

| 43.2 °C/h | 1080 °C-10 h | 15 °C/h | 35 °C/h | —— |

| 43.2 °C/h | 1150 °C-10 h | 15 °C/h | 35 °C/h | 300 °C/h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuo, J.; Wang, S.; Tan, T.; Jin, H.; Geng, F.; Wang, X.; Fan, F.; Zhang, Q.; Xu, Q. The Formation Law of Surface Profile in Fused Silica During Continuous-Wave CO2 Laser Processing. Micromachines 2025, 16, 1328. https://doi.org/10.3390/mi16121328

Zhuo J, Wang S, Tan T, Jin H, Geng F, Wang X, Fan F, Zhang Q, Xu Q. The Formation Law of Surface Profile in Fused Silica During Continuous-Wave CO2 Laser Processing. Micromachines. 2025; 16(12):1328. https://doi.org/10.3390/mi16121328

Chicago/Turabian StyleZhuo, Jin, Shengfei Wang, Ting Tan, Huiliang Jin, Feng Geng, Xiangfeng Wang, Fei Fan, Qinghua Zhang, and Qiao Xu. 2025. "The Formation Law of Surface Profile in Fused Silica During Continuous-Wave CO2 Laser Processing" Micromachines 16, no. 12: 1328. https://doi.org/10.3390/mi16121328

APA StyleZhuo, J., Wang, S., Tan, T., Jin, H., Geng, F., Wang, X., Fan, F., Zhang, Q., & Xu, Q. (2025). The Formation Law of Surface Profile in Fused Silica During Continuous-Wave CO2 Laser Processing. Micromachines, 16(12), 1328. https://doi.org/10.3390/mi16121328