Fabrication Process Research for Silicon-Waveguide-Integrated Cavity Optomechanical Devices Using Magnesium Fluoride Protection

Abstract

1. Introduction

2. Principle and Design

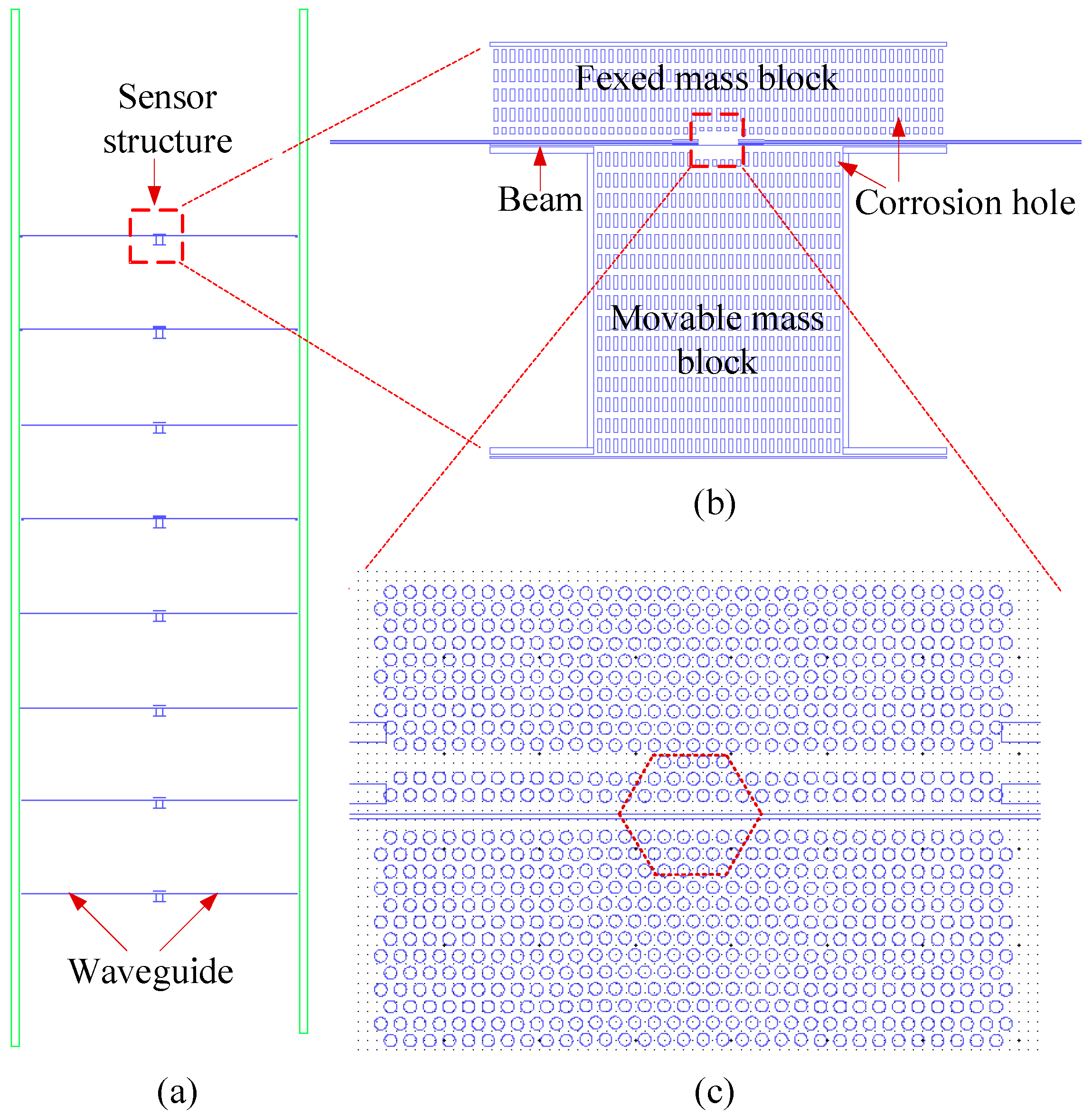

2.1. Chip Architecture and Operating Principle of the Integrated Silicon Waveguide Cavity Optomechanical Sensor

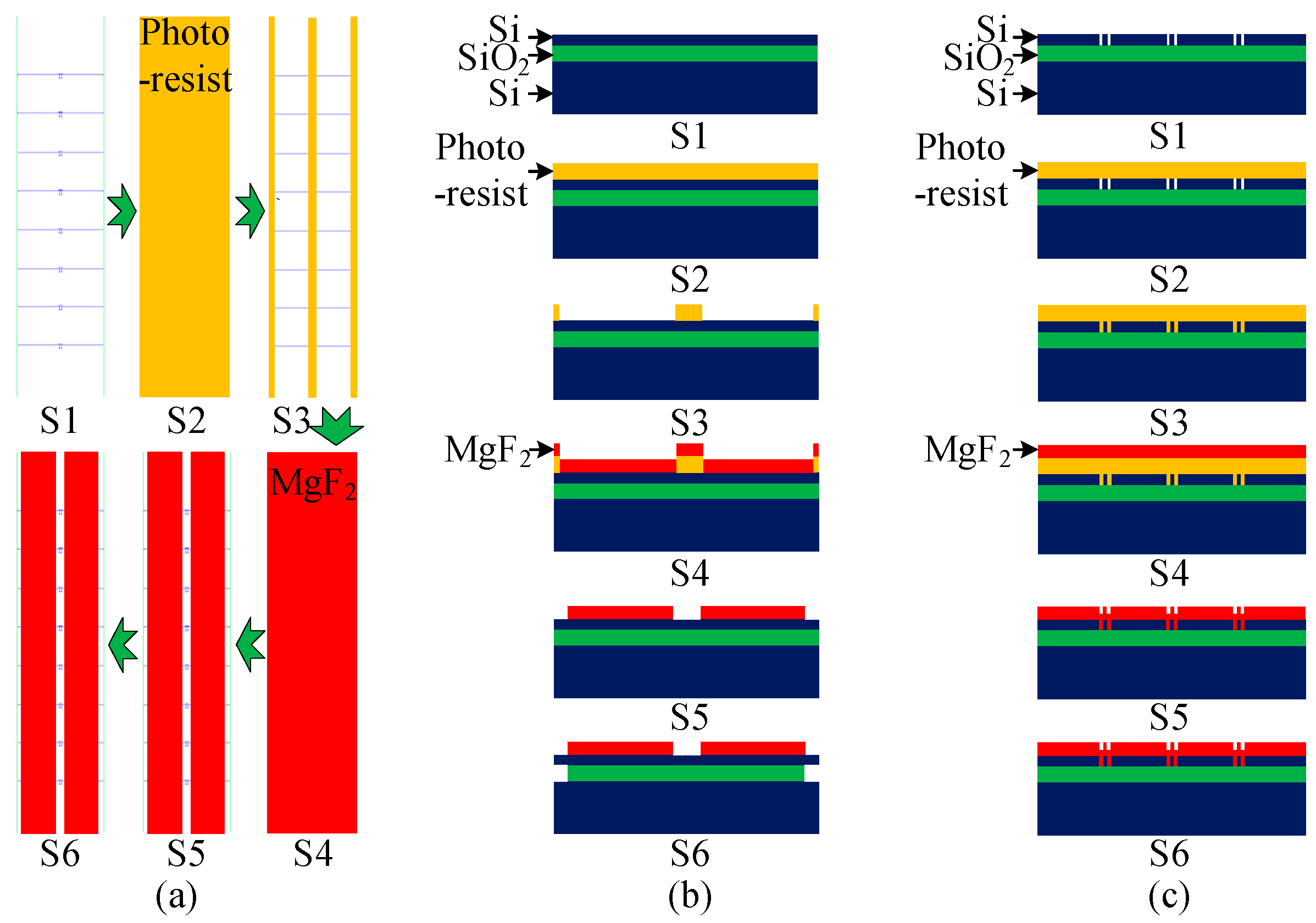

2.2. Process Flow Design for MgF2-Protected Vapor-Phase Release

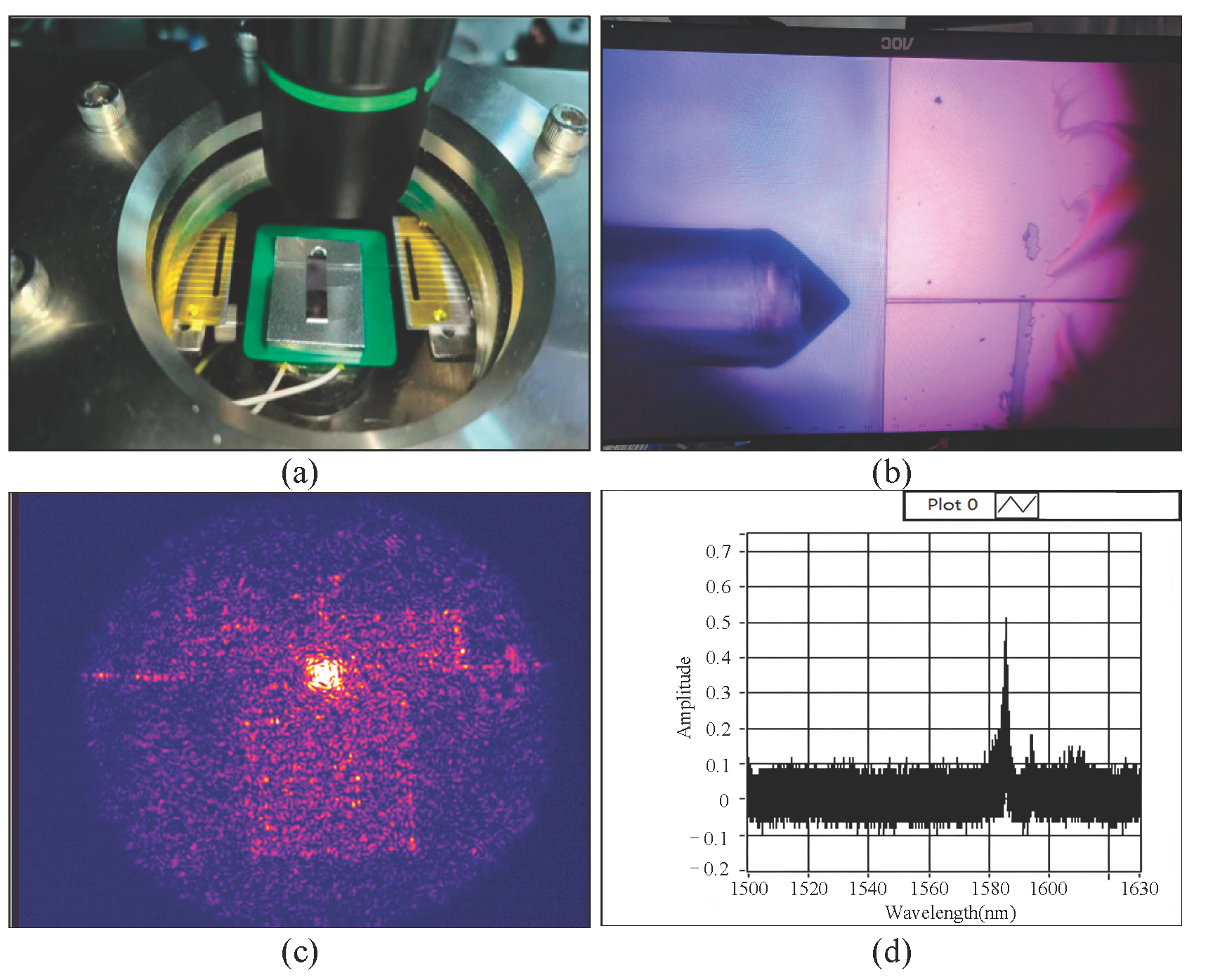

3. Test and Validation

4. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Malayappan, B.; Lakshmi, U.P.; Rao, B.P.; Ramaswamy, K.; Pattnaik, P.K. Sensing techniques and interrogation methods in optical MEMS accelerometers: A review. IEEE Sens. J. 2022, 22, 6232–6246. [Google Scholar] [CrossRef]

- French, P.J.; Muro, H.; Shinohara, T.; Nojiri, H.; Kaneko, H. SOI pressure sensor. Sens. Actuators A Phys. 1992, 35, 17–22. [Google Scholar] [CrossRef]

- Xue, H.; Li, X.; Lu, Y.; Xie, B.; Chen, D.; Wang, J.; Chen, J. A Method for Fabricating Cavity-SOI and Its Verification Using Resonant Pressure Sensors. Micromachines 2025, 16, 297. [Google Scholar] [CrossRef] [PubMed]

- Zandi, K.; Bélanger, J.A.; Peter, Y.A. Design and demonstration of an in-plane silicon-on-insulator optical MEMS Fabry–Pérot-based accelerometer integrated with channel waveguides. J. Microelectromech. Syst. 2012, 21, 1464–1470. [Google Scholar] [CrossRef]

- Chollet, F. Devices based on co-integrated MEMS actuators and optical waveguide: A review. Micromachines 2016, 7, 18. [Google Scholar] [CrossRef] [PubMed]

- TalebiFard, S.; Schmidt, S.; Shi, W.; Wu, W.; Jaeger, N.A.F.; Kwok, E.; Ratner, D.M.; Chrostowski, L. Optimized sensitivity of Silicon-on-Insulator (SOI) strip waveguide resonator sensor. Biomed. Opt. Express 2017, 8, 500–511. [Google Scholar] [CrossRef] [PubMed]

- Hoshino, T.; Nishioka, Y. Etching process of SiO2 by HF molecules. J. Chem. Phys. 1999, 111, 2109–2114. [Google Scholar] [CrossRef]

- Kiihamäki, J. Fabrication of SOI Micromechanical Devices; VTT Technical Research Centre of Finland: Espoo, Finland, 2005. [Google Scholar]

- Penadés, J.S.; Sánchez-Postigo, A.; Nedeljkovic, M.; Ortega-Moñux, A.; Wangüemert-Pérez, J.G.; Xu, Y.; Halir, R.; Qu, Z.; Khokhar, A.Z.; Osman, A.; et al. Suspended silicon waveguides for long-wave infrared wavelengths. Opt. Lett. 2018, 43, 795–798. [Google Scholar] [CrossRef] [PubMed]

- Jo, G.; Edinger, P.; Bleiker, S.J.; Wang, X.; Takabayashi, A.Y.; Sattari, H.; Quack, N.; Jezzini, M.; Lee, J.S.; Verheyen, P.; et al. Wafer-level hermetically sealed silicon photonic MEMS. Photonics Res. 2022, 10, A14–A21. [Google Scholar] [CrossRef]

- Romang, A.H.; Watkins, J.J. Supercritical fluids for the fabrication of semiconductor devices: Emerging or missed opportunities? Chem. Rev. 2010, 110, 459–478. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-I.; Park, K.-H.; Lee, J.; Lee, C.-S.; Yoo, H.; Kim, C.-J.; Yoon, Y.-S. Dry release for surface micromachining with HF vapor-phase etching. J. Microelectromech. Syst. 1997, 6, 226–233. [Google Scholar] [CrossRef]

- Ye, X.Y.; Chen, M.F.; Liu, D.B.; Yang, M.; Wei, J. Preparation and Properties of Fluoride-Coated Mg-Zn-Zr Alloy for Biodegradable Intravascular Stents. Adv. Mater. Res. 2011, 287–290, 1970–1975. [Google Scholar] [CrossRef]

- Huang, J.G. Corrosion action and passivation mechanism of magnesium alloy in fluoride solution. Trans. Nonferrous Met. Soc. China 2009, 19, 50–54. [Google Scholar] [CrossRef]

- Sun, P.; Jiang, C.; Jiang, Y.; Liu, D.; Sun, L.; Dun, S.; Li, Y.; Ji, Y.; Liu, H. Structural, infrared optical and mechanical properties of the magnesium fluoride films. Infrared Phys. Technol. 2024, 137, 105184. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, L.; Wang, C.; Li, C.; Lin, N.; Niu, S.; Han, Z.; Duan, J. Bioinspired Near-Full Transmittance MgF2 Window for Infrared Detection in Extremely Complex Environments. ACS Appl. Mater. Interfaces 2023, 15, 30985–30997. [Google Scholar] [CrossRef] [PubMed]

- Shakoury, R.; Willey, R.R. Ion assisted deposition of magnesium fluoride films at low temperature. Opt. Quantum Electron. 2018, 50, 322. [Google Scholar] [CrossRef]

- Niederwald, H. Low-temperature deposition of optical coatings using ion assistance. Thin Solid Film 2000, 377, 21–26. [Google Scholar] [CrossRef]

- Neelamraju, S.; Schön, J.C.; Jansen, M. Atomistic modeling of the low-temperature atom-beam deposition of magnesium fluoride. Inorg. Chem. 2015, 54, 782–791. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xian, C.; Kuang, P.; Fu, N.; Li, Z.; Wang, C.; Zhang, Y.; Zhou, R.; Wen, G.; Fan, B.; Huang, Y. Fabrication Process Research for Silicon-Waveguide-Integrated Cavity Optomechanical Devices Using Magnesium Fluoride Protection. Micromachines 2025, 16, 1217. https://doi.org/10.3390/mi16111217

Xian C, Kuang P, Fu N, Li Z, Wang C, Zhang Y, Zhou R, Wen G, Fan B, Huang Y. Fabrication Process Research for Silicon-Waveguide-Integrated Cavity Optomechanical Devices Using Magnesium Fluoride Protection. Micromachines. 2025; 16(11):1217. https://doi.org/10.3390/mi16111217

Chicago/Turabian StyleXian, Chengwei, Pengju Kuang, Ning Fu, Zhe Li, Changsong Wang, Yi Zhang, Rudi Zhou, Guangjun Wen, Boyu Fan, and Yongjun Huang. 2025. "Fabrication Process Research for Silicon-Waveguide-Integrated Cavity Optomechanical Devices Using Magnesium Fluoride Protection" Micromachines 16, no. 11: 1217. https://doi.org/10.3390/mi16111217

APA StyleXian, C., Kuang, P., Fu, N., Li, Z., Wang, C., Zhang, Y., Zhou, R., Wen, G., Fan, B., & Huang, Y. (2025). Fabrication Process Research for Silicon-Waveguide-Integrated Cavity Optomechanical Devices Using Magnesium Fluoride Protection. Micromachines, 16(11), 1217. https://doi.org/10.3390/mi16111217