Assessment of Vehicle Dynamic Behavior Under Piezoelectric Actuation via Simcenter AMESim Modeling †

Abstract

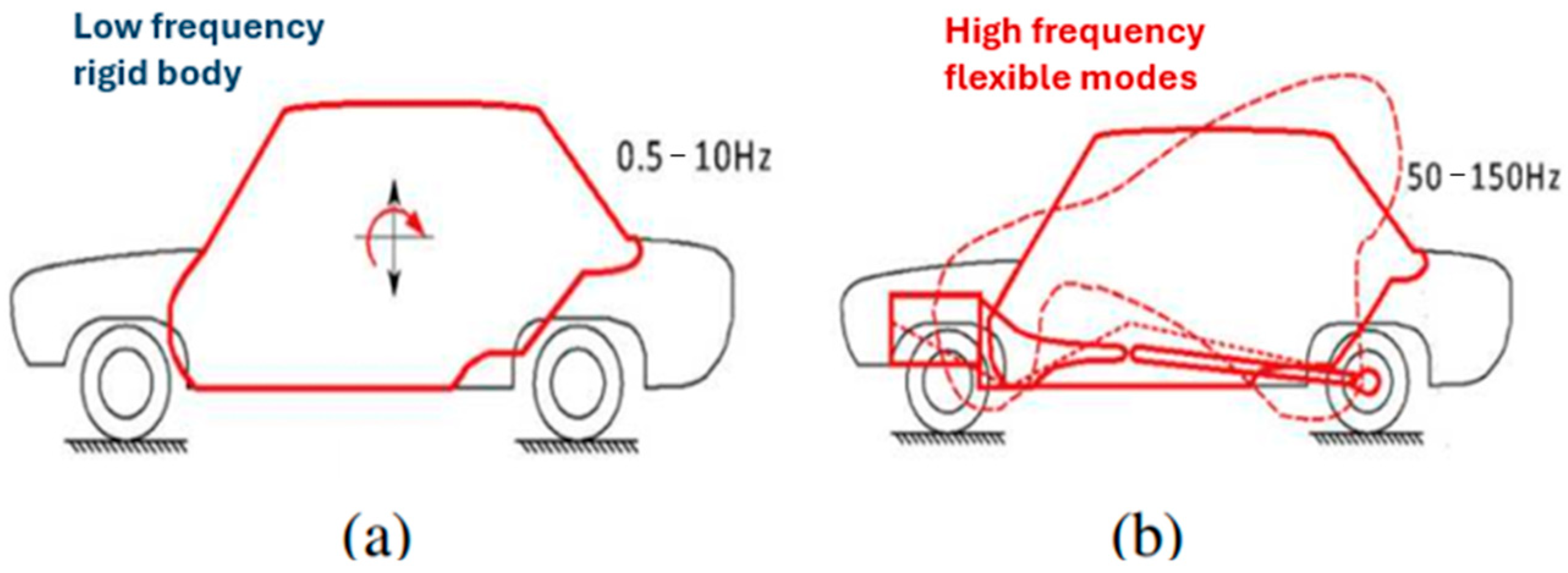

1. Introduction

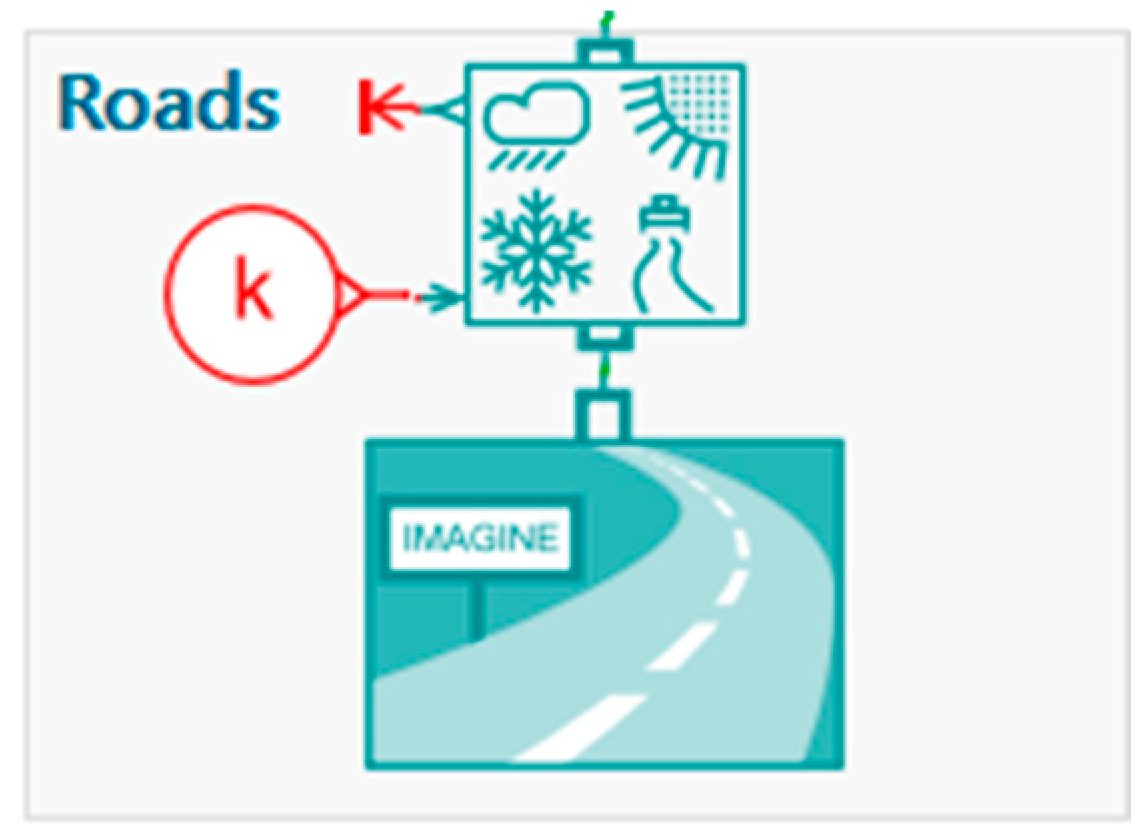

2. Model Description: Material and Effects

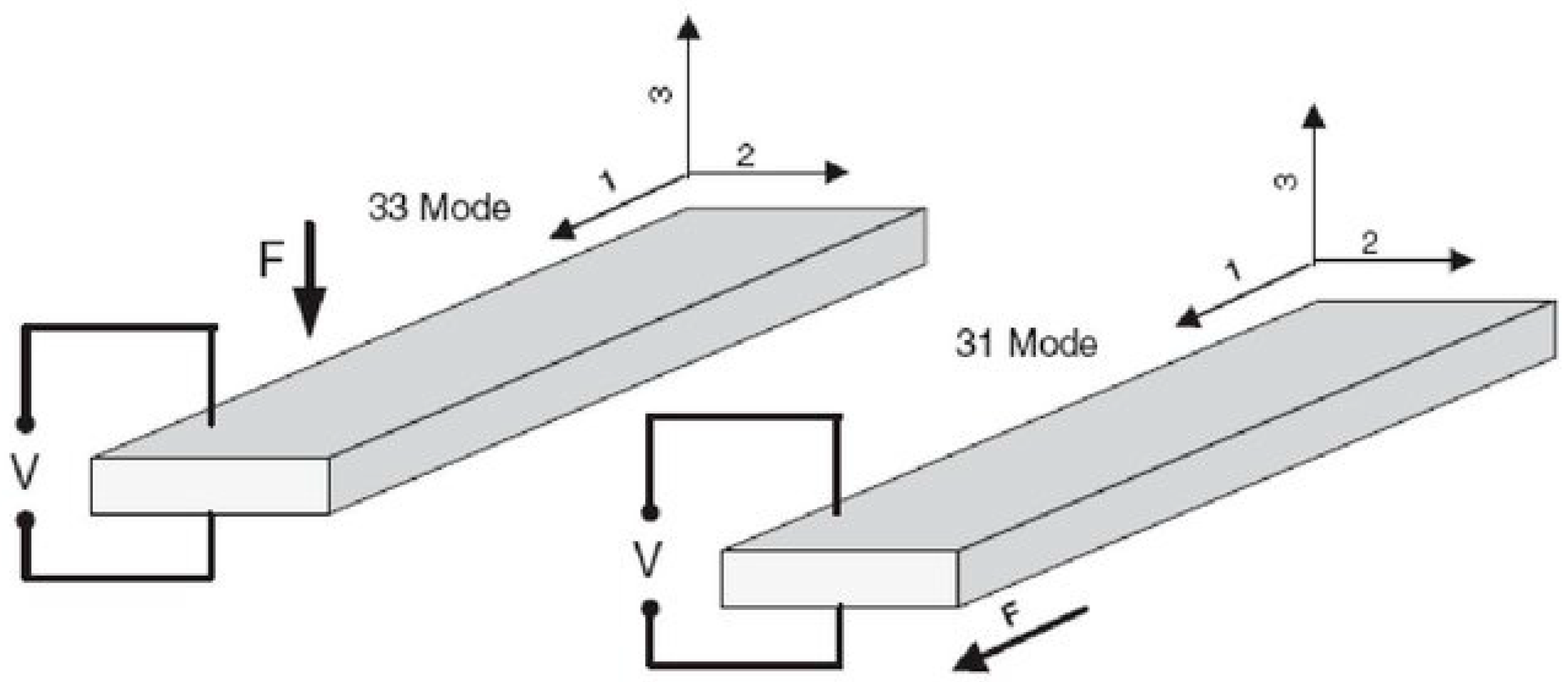

2.1. Piezoelectric Material

- i = 1, …, 6: components of the mechanical strain tensor;

- j = 1, 2, 3: components of the electric field vector.

- D: Electric charge density (C/m2),

- d: Piezoelectric charge constant (m/V or C/N),

- σ: Applied mechanical stress (N/m2),

- ε: Permittivity of the piezoelectric element (F/m),

- e: Electric field (N/C),

- δ: Mechanical strain,

- s: Elastic compliance coefficient of the piezoelectric element (m2/N).

- Qstack: Total charge generated by the piezoelectric stack (Coulombs C);

- nw: Number of wafers;

- d33: Direct piezoelectric coefficient (axis 3 in direction 3) (C/N);

- F: Longitudinally applied mechanical force (N);

- Cp: Electrical capacity of the stack (Farads F);

- V: Applied or generated electrical voltage Volts (V).

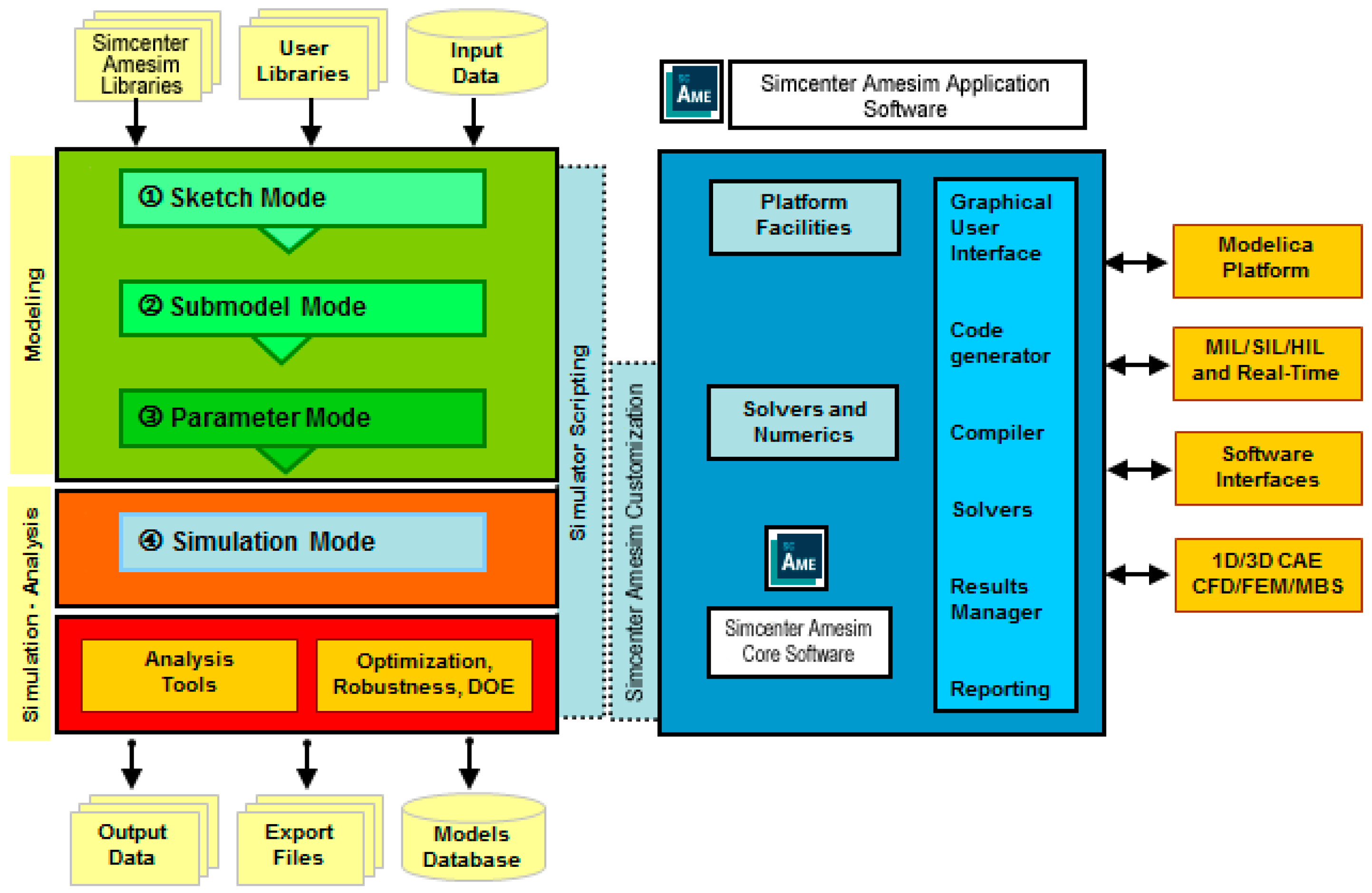

2.2. Modeling Approach Description

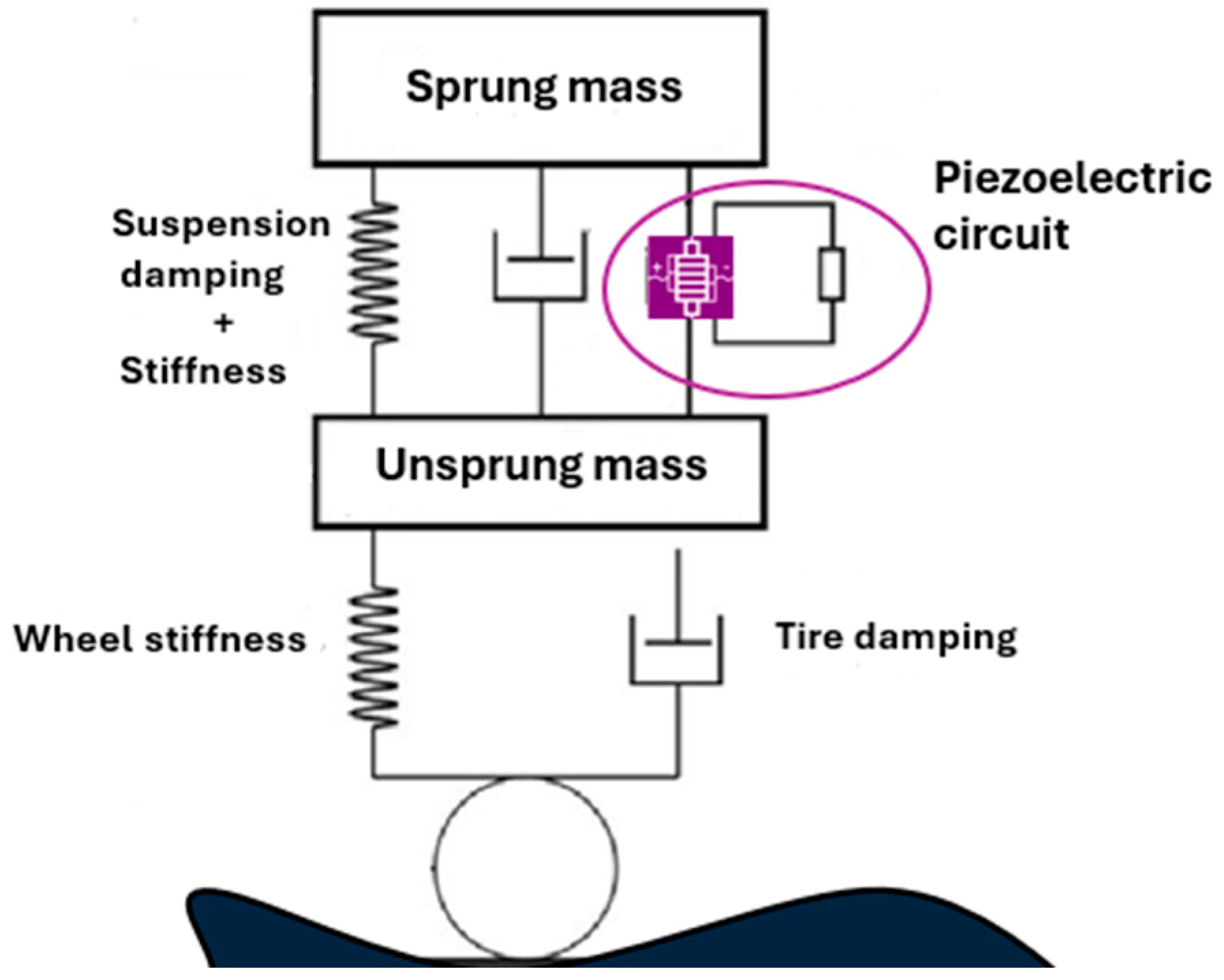

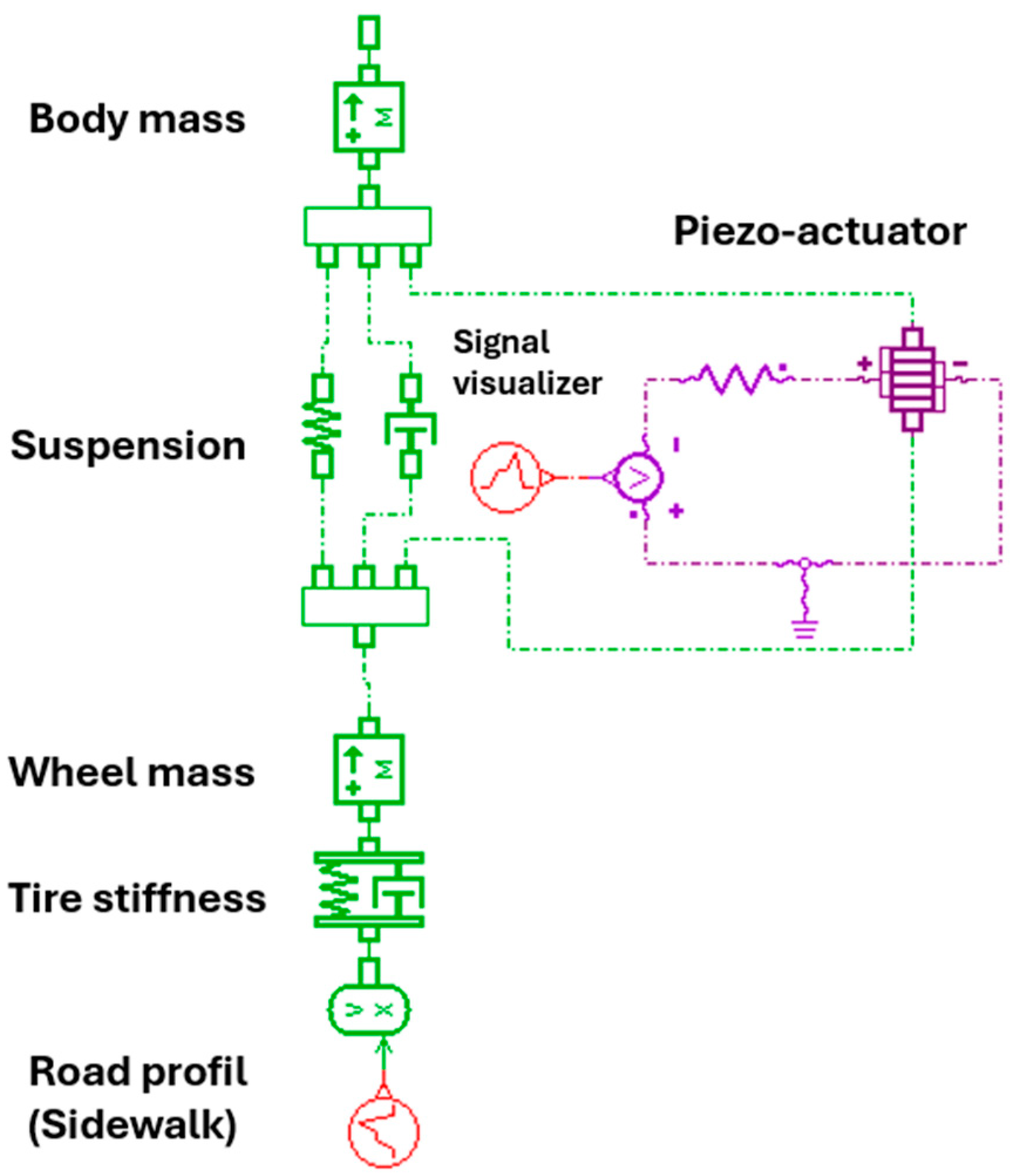

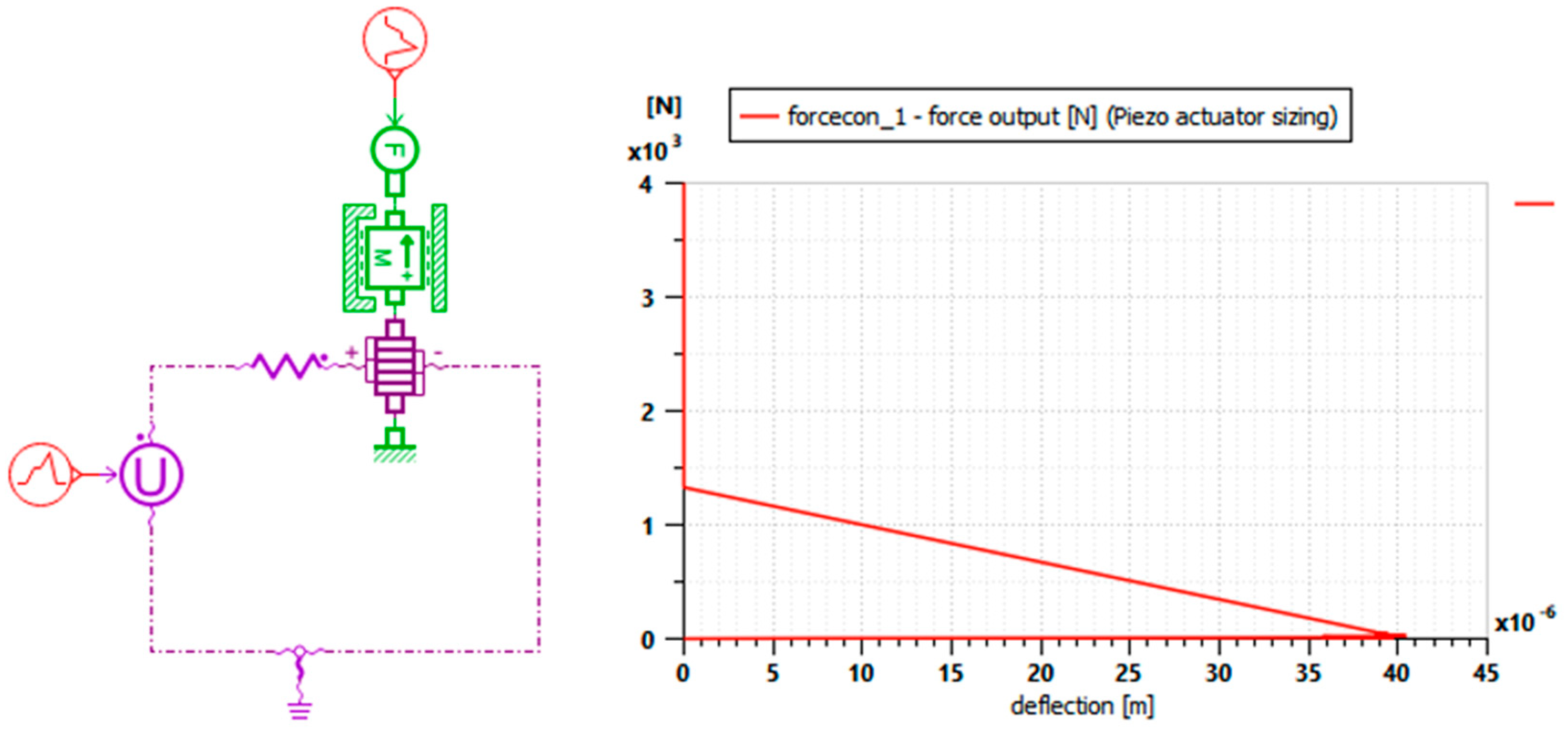

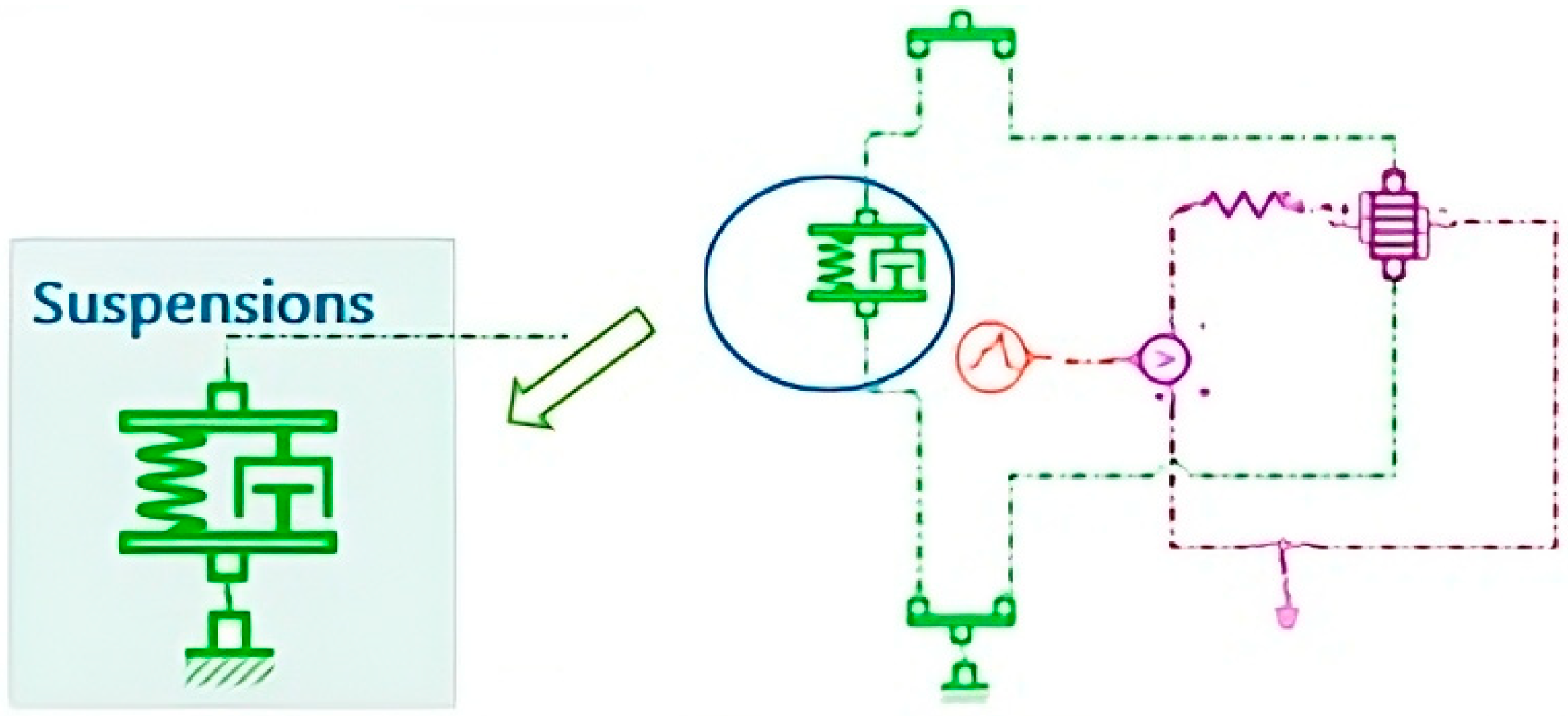

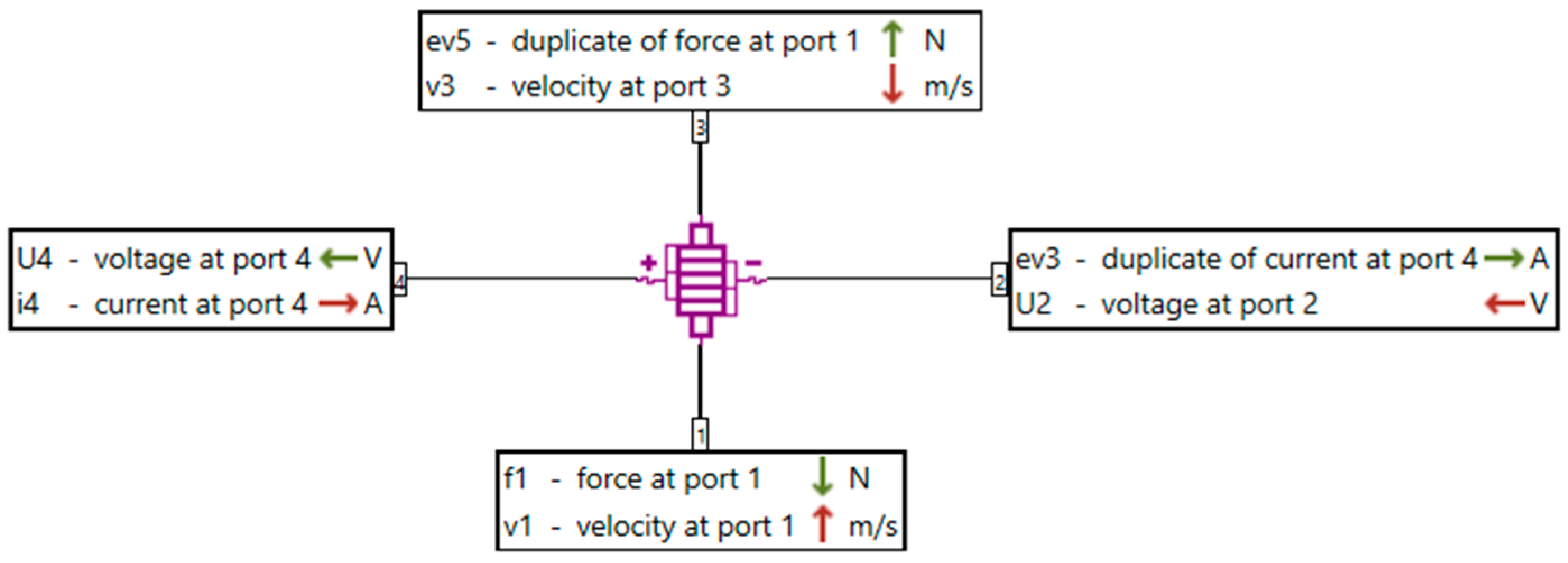

2.3. Quarter-Car Model with Piezo-Actuator

- m2/N: Elastic constant (reverse of Young modulus);

- nw: Number of wafers;

- tn: Thickness of a wafer;

- A: Area of a wafer;

- F: Input force;

- U: Input voltage;

- : Piezoelectric constant multiplied by the electromechanical coupling factor ;

- : Vacuum permittivity;

- : Relative permittivity.

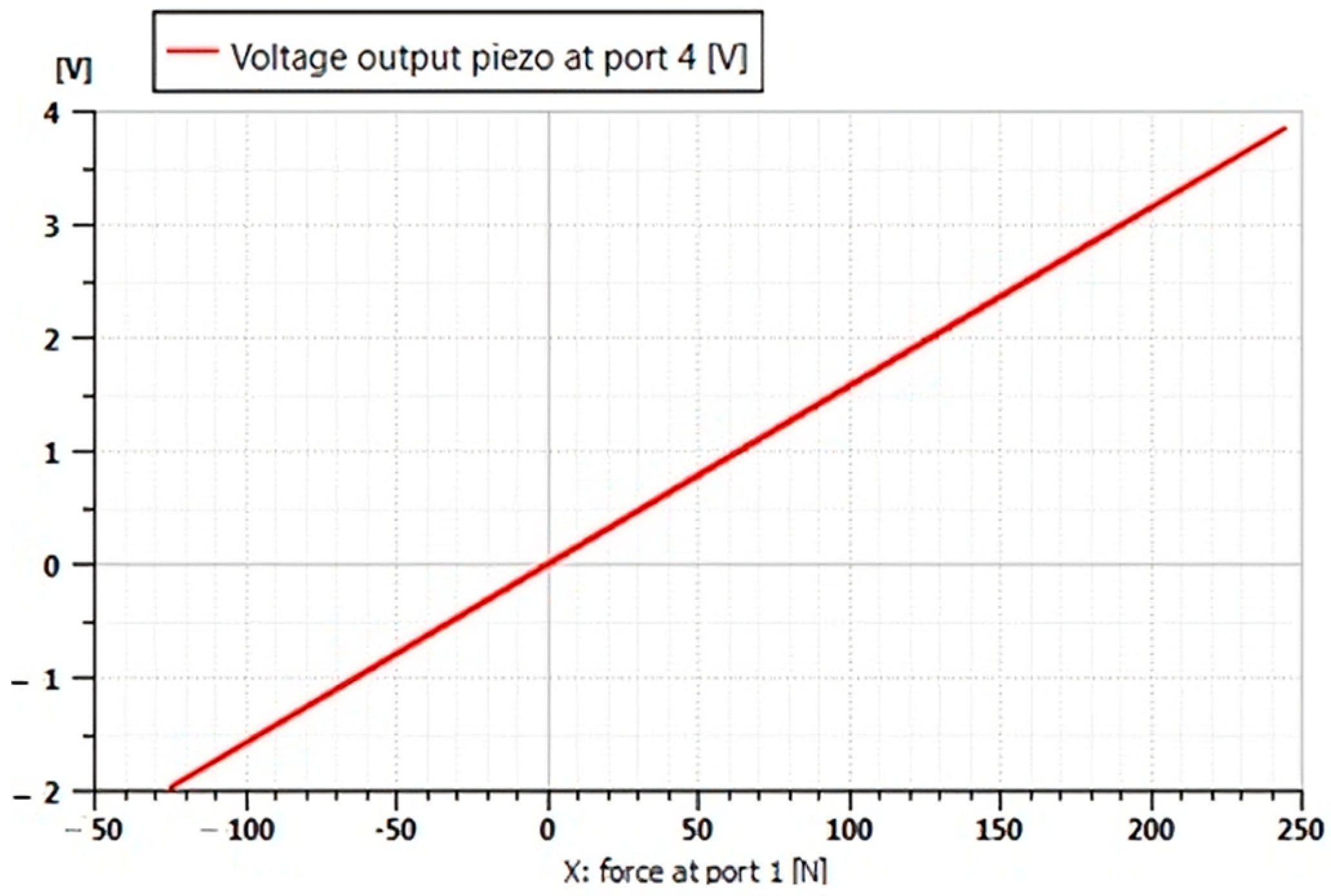

3. Multi-Physical Models and Simulation Result

3.1. Multiphysics Quarter-Car Model

- -

- Applied force (a): The graph shows the temporal evolution of the mechanical force exerted on the piezoelectric actuator. The waveforms reflect the dynamic disturbances induced by the road profile, with peaks corresponding to shocks and irregularities.

- -

- Simulated voltage (b): the graph shows the electrical output signal (in volts) generated by the piezoelectric actuator in response to the force applied to the mass. The curve shows a clear temporal proportion with the force graph: each force peak immediately produces a voltage peak, demonstrating the direct piezoelectric effect.

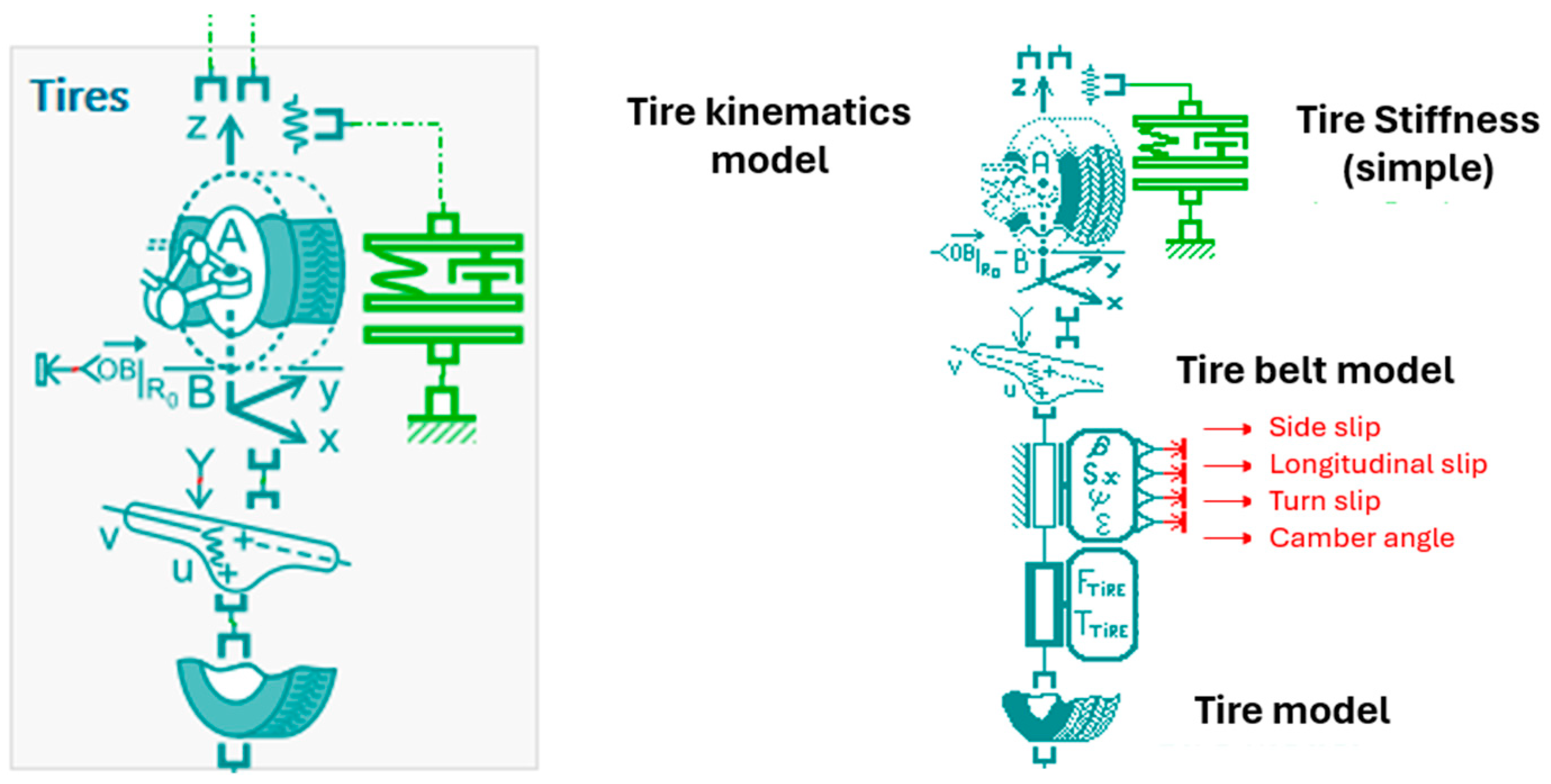

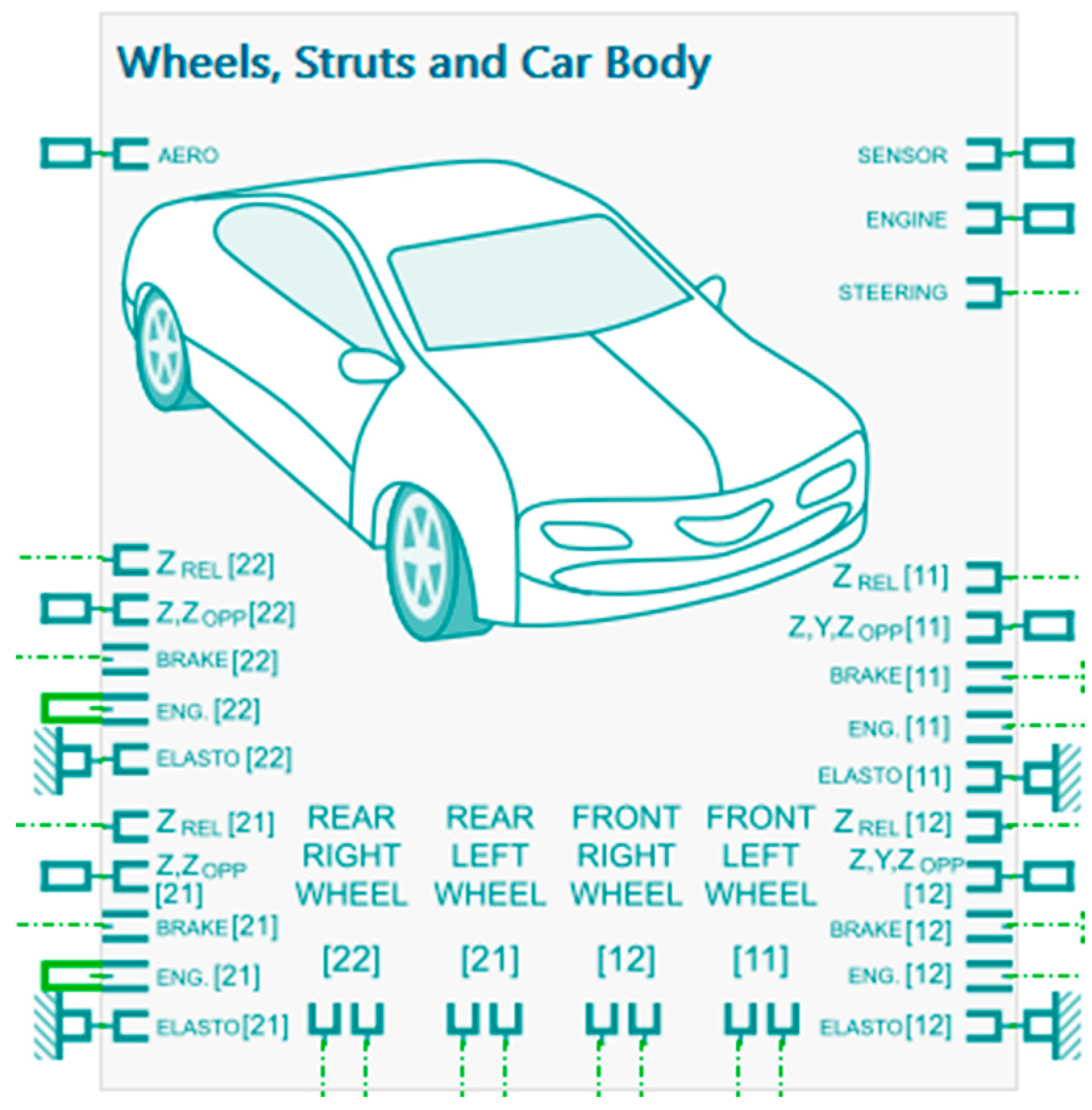

3.2. Global Model

- -

- The steered non-cambered frame RW, used to express contact forces and moments without camber;

- -

- The spindle frame R2, rigidly attached to the suspension system.

- -

- The camber angle εV, between the wheel and the ground normal;

- -

- The self-rotating angle ηRS, representing the wheel’s own rotation about its vertical axis.

- -

- Non-uniform distribution of deformations (for example, bending vs. axial loading).

- -

- Polarization bias in the piezoelectric material (common in PZT ceramics).

4. Towards Practical Implementation: Signal Conditioning and Energy Storage

4.1. Stability and Conditioning of Electrical Signals

4.2. Storage and Operational Feasibility

5. Experimental Perspectives

5.1. Instrumentation

5.2. Excitation Profiles According to ISO 8608

5.3. Measurement Protocols

5.4. Data Acquisition and Post-Processing

5.5. Limitations and Perspectives of Piezoelectric Energy Harvesting

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AMESim | Advanced Modelling Environment for performing Simulations |

| CSS | Car Suspension System |

| DAQ | Data Acquisition System |

| DOF | Degree of Freedom |

| FFT | Fast Fourier Transform |

| LVDT | Linear Variable Differential Transformer |

| MEMS | MicroElectroMechanical Systems |

| MPPT | Maximum Power Point Tracking |

| PE | Piezoelectric Element |

| PSD | Power Spectral Density |

| PZT | Plomb Zirconate Titanate |

| QCM | Quarter Car Model |

| SECE | Synchronous Electric Charge Extraction |

| SSHC | synchronized switch harvesting on capacitors |

References

- Zuo, L.; Tang, X. Large-scale vibration energy harvesting. J. Intell. Mater. Syst. Struct. 2013, 24, 1405–1430. [Google Scholar] [CrossRef]

- Sodano, H.A.; Inman, D.J.; Park, G. Comparison of Piezoelectric Energy Harvesting Devices for Recharging Batteries. J. Intell. Mater. Syst. Struct. 2005, 16, 799–807. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, G.; Wang, Y.; Lin, J.; Zhang, Q.; Hofmann, H.F. Active Piezoelectric Energy Harvesting: General Principle and Experimental Demonstration. J. Intell. Mater. Syst. Struct. 2009, 20, 575–585. [Google Scholar] [CrossRef]

- Caliò, R.; Rongala, U.B.; Camboni, D.; Milazzo, M.; Stefanini, C.; De Petris, G.; Oddo, C.M. Piezoelectric Energy Harvesting Solutions. Sensors 2014, 14, 4755–4790. [Google Scholar] [CrossRef]

- Balasubramaniam, M.; Fortin, J.B.; Smith, W.J.; Luo, H. Energy Harvesting System, Apparatus and Method. US7116036B2, 3 October 2006. Available online: https://patents.google.com/patent/US7116036B2/en (accessed on 29 June 2025).

- Roundy, S. Energy Harvesting for tire pressure monitoring systems: Design considerations. In Proceedings of the PowerMEMS2008+ microEMS 2008, Sendai, Japan, 9–12 November 2008. [Google Scholar]

- Oliver, J.R.; Neurgaonkar, R.R.; Moffatt, A.P.; Khoshnevisan, M.; Nelson, J.G. Piezoelectric Energy Harvester and Method. US6407484B1, 18 June 2002. Available online: https://patents.google.com/patent/US6407484B1/en (accessed on 29 June 2025).

- Tamboli, J.A.; Joshi, S.G. Optimum design of a passive suspension system of a vehicle subjected to actual random road excitations. J. Sound Vib. 1999, 219, 193–205. [Google Scholar] [CrossRef]

- Rustighi, E.; Elliott, S.J.; Finnveden, S.; Gulyás, K.; Mócsai, T.; Danti, M. Linear stochastic evaluation of tyre vibration due to tyre/road excitation. J. Sound Vib. 2008, 310, 1112–1127. [Google Scholar] [CrossRef]

- Jha, S.K. Characteristics and sources of noise and vibration and their control in motor cars. J. Sound Vib. 1976, 47, 543–558. [Google Scholar] [CrossRef]

- Uchino, K. Chapter 1—The Development of Piezoelectric Materials and the New Perspective. In Advanced Piezoelectric Materials, 2nd ed.; Uchino, K., Ed.; Woodhead Publishing in Materials; Woodhead Publishing: Cambridge, UK, 2017; pp. 1–92. [Google Scholar] [CrossRef]

- Anton, S.R.; Sodano, H.A. A review of power harvesting using piezoelectric materials (2003–2006). Smart Mater. Struct. 2007, 16, R1. [Google Scholar] [CrossRef]

- Tounsi, F. Microphone Électrodynamique MEMS en Technologie CMOS: Étude, Modélisation et Realization. Ph.D. Thesis, Institut National Polytechnique de Grenoble—INPG, Grenoble, France, 2010. [Google Scholar] [CrossRef]

- Goldfarb, M.; Jones, L.D. On the Efficiency of Electric Power Generation with Piezoelectric Ceramic. J. Dyn. Syst. Meas. Control 1999, 121, 566–571. [Google Scholar] [CrossRef]

- Leo, D.J. Engineering Analysis of Smart Material Systems; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Lafarge, B.; Grondel, S.; Delebarre, C.; Cattan, E. A validated simulation of energy harvesting with piezoelectric cantilever beams on a vehicle suspension using Bond Graph approach. Mechatronics 2018, 53, 202–214. [Google Scholar] [CrossRef]

- Siemens Digital Industries Software. Simcenter Amesim: Multidomain System Simulation Platform. Available online: https://plm.sw.siemens.com/en-US/simcenter/systems-simulation/amesim/ (accessed on 14 June 2025).

- Manvi, M.; Swamy, K.B.M. Comprehensive simulation study on AlN, ZnO, and PZT-5H piezoelectric materials for microcantilever-based MEMS energy harvesters: Mechanical and electrical insights. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241290635. [Google Scholar] [CrossRef]

- Wang, H.; Ma, M.; Xia, S.; Zhang, N.; Li, Z. Ultrahigh-performance [001]-oriented porous PZT-5H single crystal grown by the solid state crystal growth method. J. Eur. Ceram. Soc. 2023, 43, 5503–5510. [Google Scholar] [CrossRef]

- Vaishnav, A.; Sarvaiya, M.; Dhabaliya, P.; Rajguru, S. Mathematical modelling and comparison of two degree of freedom suspension system of quarter car. Imp. J. Interdiscip. Res. 2016, 2, 128–137. [Google Scholar]

- Sharma, P.; Saluja, N.; Saini, D.; Saini, P. Analysis of automotive passive suspension system with Matlab program generation. Int. J. Adv. Technol. 2013, 4, 115–119. [Google Scholar]

- Tabib-Azar, M. Microactuators: Electrical, Magnetic, Thermal, Optical, Mechanical, Chemical and Smart Structures; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Chater, N.; Mhaiti, N.; Radouani, M.; el Fahime, B. Dynamics Modeling of a Vehicle Including Piezoelectric Actuator. In Proceedings of the 6th IEEE Congress on Information Science and Technology (CiSt), Agadir, Morocco, 5–12 June 2021. [Google Scholar] [CrossRef]

- A State-of-the-Art Review of Car Suspension-Based Piezoelectric Energy Harvesting Systems. Available online: https://www.mdpi.com/1996-1073/13/9/2336 (accessed on 14 September 2025).

- Alhumaid, S.; Hess, D.; Guldiken, R. A Noncontact Magneto–Piezo Harvester-Based Vehicle Regenerative Suspension System: An Experimental Study. Energies 2022, 15, 4476. [Google Scholar] [CrossRef]

- Al Ghazi, A.; Ouslimani, A.; Kasbari, A.-E. Advances in Interface Circuits for Self-Powered Piezoelectric Energy Harvesting Systems: A Comprehensive Review. Sensors 2025, 25, 4029. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Ye, Y.; Wang, Y. A hybrid rectifier with dual-modes SECE method for piezoelectric energy harvesting. IEICE Electron. Express 2025, 22, 20250086. [Google Scholar] [CrossRef]

- Selleri, G.; Poli, F.; Neri, R.; Gasperini, L.; Gualandi, C.; Soavi, F.; Fabiani, D. Energy harvesting and storage with ceramic piezoelectric transducers coupled with an ionic liquid-based supercapacitor. J. Energy Storage 2023, 60, 106660. [Google Scholar] [CrossRef]

- Ali, A.K.; Abdulrazzaq, A.A.; Mohsin, A.H. A Dynamic Simulation of a Piezoelectric Energy Harvesting System Integrated with a Closed-Loop Voltage Source Converter for Sustainable Power Generation. Preprint 2024. [Google Scholar] [CrossRef]

- Muscalu, G.; Firtat, B.; Anghelescu, A.; Moldovan, C.; Dinulescu, S.; Brasoveanu, C.; Ekwinska, M.; Szmigiel, D.; Zaborowski, M.; Zajac, J.; et al. Piezoelectric MEMS Energy Harvester for Low-Power Applications. Electronics 2024, 13, 2087. [Google Scholar] [CrossRef]

- Sodano, H.; Inman, D. A Review of Power Harvesting from Vibration Using Piezoelectric Materials. Shock Vib. Dig. 2004, 36, 197–205. [Google Scholar] [CrossRef]

- Priya, S.; Inman, D.J. (Eds.) Energy Harvesting Technologies; Springer: Boston, MA, USA, 2009. [Google Scholar] [CrossRef]

- Preumont, A. Vibration Control of Active Structures: An Introduction. In Meccanica; Springer: Berlin/Heidelberg, Germany, 1999; Volume 96. [Google Scholar] [CrossRef]

| Characteristic | Value |

|---|---|

| Number of wafers | 250 |

| Area of wafer | 10 × 10 mm2 |

| Thickness of a wafer | 0.07 mm |

| ) | 2900 |

| Electromechanical coupling factor (k33) | 0.772 |

| ) | 2.18 × 10−11 m2/N |

| Mechanical Data | Unit | Value |

|---|---|---|

| Dimensions (L × W × H) | mm | 10 × 10 × 18 |

| Compressive Strength | N/m2 | 8.8 × 108 |

| Tensile Strength | N/m2 | 4.9 × 106 |

| Young’s Modulus | N/m2 | 4.4 × 1010 |

| Poisson Ratio | (–) | 0.34 |

| Density | kg/m3 | 7900 |

| Weight | grams | 16 |

| Electrical Data | Unit | Value |

|---|---|---|

| Rated voltage (positive only) | VDC | +100 |

| Capacitance | nF | 6500 |

| Free deflection | µm | 4.9 × 106 |

| Blocked force | N | 4.4 × 1010 |

| Response time | µs | 0.34 |

| Variable | Unit | Value |

|---|---|---|

| Unsprung mass | kg | 30 |

| Sprung mass | kg | 300 |

| Tire elastic coefficient | N/m | 180,000 |

| Passive spring coefficient | N/m | 15,000 |

| Tire damping coefficient | Ns/m | 100 |

| Passive damping coefficient | Ns/m | 1000 |

| Variable | Unit | Value |

|---|---|---|

| Car body initial velocity | 5 | m/s |

| Wheel mass (front axle) | 18 | kg |

| Wheel mass (rear axle) | 14 | kg |

| Suspension stiffness (front axle) | 21,000 | N/m |

| Suspension stiffness (rear axle) | 21,000 | N/m |

| Suspension damping (front axle) | 2000 | Ns/m |

| Suspension damping (rear axle) | 1500 | Ns/m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chater, N.; Benmoussa, A.; El Fahime, B.; Radouani, M. Assessment of Vehicle Dynamic Behavior Under Piezoelectric Actuation via Simcenter AMESim Modeling. Micromachines 2025, 16, 1087. https://doi.org/10.3390/mi16101087

Chater N, Benmoussa A, El Fahime B, Radouani M. Assessment of Vehicle Dynamic Behavior Under Piezoelectric Actuation via Simcenter AMESim Modeling. Micromachines. 2025; 16(10):1087. https://doi.org/10.3390/mi16101087

Chicago/Turabian StyleChater, Nezha, Ali Benmoussa, Benaissa El Fahime, and Mohammed Radouani. 2025. "Assessment of Vehicle Dynamic Behavior Under Piezoelectric Actuation via Simcenter AMESim Modeling" Micromachines 16, no. 10: 1087. https://doi.org/10.3390/mi16101087

APA StyleChater, N., Benmoussa, A., El Fahime, B., & Radouani, M. (2025). Assessment of Vehicle Dynamic Behavior Under Piezoelectric Actuation via Simcenter AMESim Modeling. Micromachines, 16(10), 1087. https://doi.org/10.3390/mi16101087