Bulge-Free and Homogeneous Metal Line Jet Printing with StarJet Technology

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Molten Metal Jet Generation

3.2. Printing Speed and Spherical Bulging (TC-A)

3.3. Standoff Distance (TC-B)

3.4. Reservoir Temperature (TC-C)

3.5. Substrate Temperature (TC-D)

3.6. Printing on Different Rough Substrate Materials

4. Conclusions

- The bulges in the printing lines grow after the liquid front passes its location, pointing towards a probable correlation with the internal pressure of the molten metal. The bulging behaviour remained for all the test cases in the investigated printing velocity range from 30 mm/s to 120 mm/s, with a 12 mm standoff distance.

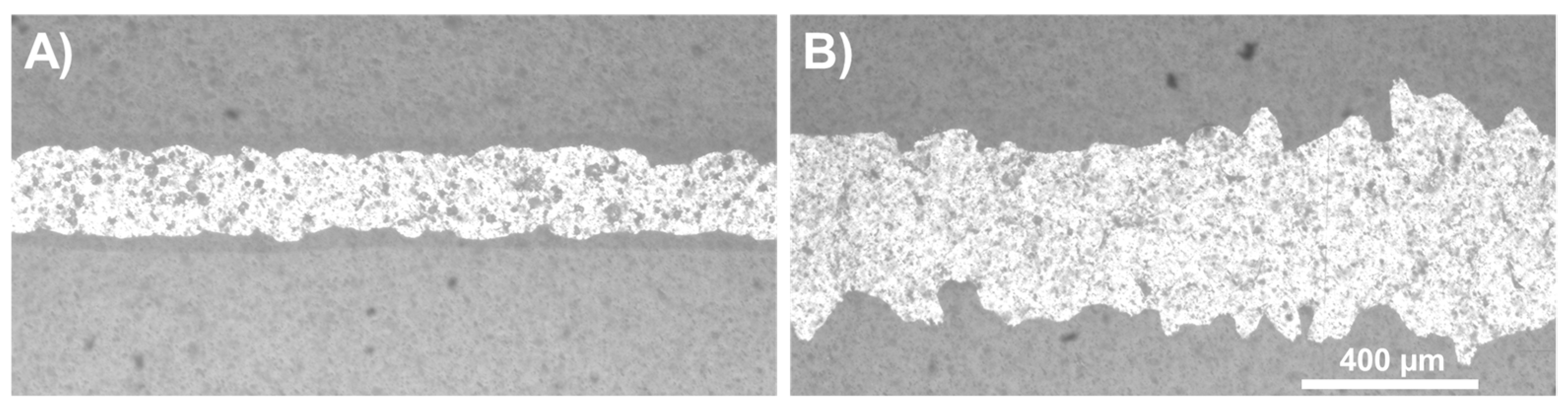

- The standoff distance is the critical parameter for line uniformity. Excessive distances can result in splashing behaviour where the lines are characterised by a higher width and non-uniformity.

- Closer standoff distance induce bulging of the lines. A uniform, bulge-free line can be realised on a PET sheet from the standoff distance of 16 mm for a reservoir temperature of 330 °C. The bulge-free standoff distance could be further reduced to 12 mm in the case of 400 °C elevated reservoir temperature.

- A standoff distance of 20 mm is recommended to realise bulge-free lines and avoid the splashing effect of the solder in the case of excessive distances.

- Substrate temperature and reservoir temperature have limited influence on line uniformity, but only induce slight linewidth deviation.

- The bulge-free metal lines can be printed from a metal jet via StarJet on rough polymer substrates from multiple materials (PETG, PA-GF, TPU, and PLA) using the optimised printing parameters from this study on PET sheets.

- Nevertheless, the elevated surface roughness posed challenges in the case of PA-GF and TPU materials, potentially causing disruptions in the metal line, such as necking or open connections at the edge between the printed polymer lines. The same parameter set also achieved a metal-on-metal structure with a high aspect ratio.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Corzo, D.; Tostado-Blázquez, G.; Baran, D. Flexible Electronics: Status, Challenges and Opportunities. Front. Electron. 2020, 1, 594003. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Industry 4.0 applications in medical field: A brief review. Curr. Med. Res. Pract. 2019, 9, 102–109. [Google Scholar] [CrossRef]

- Binyamin, S.S.; Hoque, M.R. Understanding the Drivers of Wearable Health Monitoring Technology: An Extension of the Unified Theory of Acceptance and Use of Technology. Sustainability 2020, 12, 9605. [Google Scholar] [CrossRef]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics toward Wearable Sensing. Acc. Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef]

- Khan, S.; Ali, S.; Bermak, A. Recent Developments in Printing Flexible and Wearable Sensing Electronics for Healthcare Applications. Sensors 2019, 19, 1230. [Google Scholar] [CrossRef]

- Tavakoli, M.; Lopes, P.A.; Hajalilou, A.; Silva, A.F.; Carneiro, M.R.; Carvalheiro, J.; Pereira, J.M.; de Almeida, A.T. 3R Electronics: Scalable Fabrication of Resilient, Repairable, and Recyclable Soft-Matter Electronics. Adv. Mater. 2022, 34, 2203266. [Google Scholar] [CrossRef]

- Farkas, C.; Gál, L.; Csiszár, A.; Grennerat, V.; Jeannin, P.-O.; Xavier, P.; Rigler, D.; Krammer, O.; Plachy, Z.; Dusek, K.; et al. Sustainable printed circuit board substrates based on flame-retarded PLA/flax composites to reduce environmental load of electronics: Quality, reliability, degradation and application tests. Sustain. Mater. Technol. 2024, 40, e00902. [Google Scholar] [CrossRef]

- Chen, S.; Wu, Z.; Chu, C.; Ni, Y.; Neisiany, R.E.; You, Z. Biodegradable Elastomers and Gels for Elastic Electronics. Adv. Sci. 2022, 9, 2105146. [Google Scholar] [CrossRef]

- Chiong, J.A.; Tran, H.; Lin, Y.; Zheng, Y.; Bao, Z. Integrating Emerging Polymer Chemistries for the Advancement of Recyclable, Biodegradable, and Biocompatible Electronics. Adv. Sci. 2021, 8, 2101233. [Google Scholar] [CrossRef]

- Marques, A.C.; Cabrera, J.-M.; de Fraga Malfatti, C. Printed circuit boards: A review on the perspective of sustainability. J. Environ. Manag. 2013, 131, 298–306. [Google Scholar] [CrossRef]

- JS-A102A Silver Nanoparticle Ink. NovaCentrix. Available online: https://www.novacentrix.com/product/js-a102a-silver-nanoparticles/ (accessed on 24 April 2024).

- Kao, Z.-K.; Hung, Y.-H.; Liao, Y.-C. Formation of conductive silver films via inkjet reaction system. J. Mater. Chem. 2011, 21, 18799. [Google Scholar] [CrossRef]

- Perelaer, J.; Smith, P.J.; Mager, D.; Soltman, D.; Volkman, S.K.; Subramanian, V.; Korvink, J.G.; Schubert, U.S. Printed electronics: The challenges involved in printing devices, interconnects, and contacts based on inorganic materials. J. Mater. Chem. 2010, 20, 8446. [Google Scholar] [CrossRef]

- Perelaer, J.; Abbel, R.; Wünscher, S.; Jani, R.; Van Lammeren, T.; Schubert, U.S. Roll-to-Roll Compatible Sintering of Inkjet Printed Features by Photonic and Microwave Exposure: From Non-Conductive Ink to 40% Bulk Silver Conductivity in Less Than 15 Seconds. Adv. Mater. 2012, 24, 2620–2625. [Google Scholar] [CrossRef]

- Du, X.; Zhong, Y.; Kang, G.; Jiang, J.; Wang, X.; Li, W.; Zheng, G. Low-Temperature Self-Stacking Ink for Electrohydrodynamic Direct Writing. ACS Appl. Polym. Mater. 2023, 5, 5314–5321. [Google Scholar] [CrossRef]

- Hirman, M.; Steiner, F. A comparison of the shear strength of conductive adhesives and soldering alloys. In Proceedings of the 2015 38th International Spring Seminar on Electronics Technology (ISSE), Eger, Hungary, 6–10 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 167–172. [Google Scholar] [CrossRef]

- Jager, J.; Buschkamp, S.; Werum, K.; Glaser, K.; Grozinger, T.; Eberhardt, W.; Zimmermann, A. Contacting Inkjet-Printed Silver Structures and SMD by ICA and Solder. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1232–1240. [Google Scholar] [CrossRef]

- Ermantraut, E.; Zimmermann, A.; Muller, H.; Wolf, M.; Eberhardt, W.; Ninz, P.; Kern, F.; Gadow, R. Laser Induced Selective Metallization of 3D Ceramic Interconnect Devices. In Proceedings of the 2018 13th International Congress Molded Interconnect Devices (MID), Würzburg, Germany, 25–26 September 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Sukhotskiy, V.; Karampelas, I.H.; Garg, G.; Verma, A.; Tong, M.; Vader, S.; Vader, Z.; Furlani, E.P. Magnetohydrodynamic Drop-on-Demand Liquid Metal 3D Printing. 2017. Available online: https://hdl.handle.net/2152/89984 (accessed on 26 March 2024).

- Neumann, T.V.; Dickey, M.D. Liquid Metal Direct Write and 3D Printing: A Review. Adv. Mater. Technol. 2020, 5, 2000070. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, X.; Mei, Z.; Chen, H.; Chen, J.; Wang, X.; Li, S.; Zhang, R.; Zheng, G.; Li, W. Review of Droplet Printing Technologies for Flexible Electronic Devices: Materials, Control, and Applications. Micromachines 2024, 15, 333. [Google Scholar] [CrossRef]

- Shu, Z.; Gerdes, B.; Fechtig, M.; Riegger, L.; Zengerle, R.; Koltay, P. Direct Printing of Conductive Metal Lines from Molten Solder Jets via StarJet Technology on Thin, Flexible Polymer Substrates. NIP Digit. Fabr. Conf. 2018, 2018, 72–75. [Google Scholar] [CrossRef]

- Lotdrähte & Lotpasten|Almit. Available online: https://www.almit.de/lotbarren-und-massivdraht.htm (accessed on 24 April 2024).

- ValCUN. Available online: https://www.valcun.be/ (accessed on 24 April 2024).

- Zakel, E.; Titerle, L.; Oppert, T.; Blankenhorn, R.G. High Speed Laser Solder Jetting Technology for Optoelectronics and MEMS Packaging. Available online: https://www.researchgate.net/profile/Thomas-Oppert/publication/228938320_High_Speed_Laser_Solder_Jetting_Technology_for_Optoelectronics_and_MEMS_Packaging/links/54240a950cf26120b7a71387/High-Speed-Laser-Solder-Jetting-Technology-for-Optoelectronics-and-MEMS-Packaging.pdf (accessed on 24 April 2024).

- Beckert, E.; Burkhardt, T.; Eberhardt, R.; Tünnermann, A. Solder Bumping—A Flexible Joining Approach for the Precision Assembly of Optoelectronical Systems. In Micro-Assembly Technologies and Applications; Ratchev, S., Koelemeijer, S., Eds.; Springer: Boston, MA, USA, 2008; pp. 139–147. [Google Scholar] [CrossRef]

- Aziz, S.D.; Chandra, S. Impact, recoil and splashing of molten metal droplets. Int. J. Heat. Mass. Transf. 2000, 43, 2841–2857. [Google Scholar] [CrossRef]

- Wang, C.-H.; Tsai, H.-L.; Wu, Y.-C.; Hwang, W.-S. Investigation of molten metal droplet deposition and solidification for 3D printing techniques. J. Micromech. Microeng. 2016, 26, 095012. [Google Scholar] [CrossRef]

- Yi, H.; Wang, Z.; Cao, H.; Liu, M.; Li, J. Metal Droplet Deposition: From Foundation to Engineering Manufacturing. Adv. Eng. Mater. 2023, 25, 2201003. [Google Scholar] [CrossRef]

- Huang, J.; Qi, L.; Luo, J.; Wang, Q. A study on the solidification shapes of molten metal droplet impacting at low weber number. Phys. Fluids 2023, 35, 092102. [Google Scholar] [CrossRef]

- Visser, C.W.; Pohl, R.; Sun, C.; Römer, G.-W.; Huis in ‘t Veld, B.; Lohse, D. Toward 3D Printing of Pure Metals by Laser-Induced Forward Transfer. Adv. Mater. 2015, 27, 4087–4092. [Google Scholar] [CrossRef]

- Pohl, R.; Visser, C.W.; Römer, G.-W.; Lohse, D.; Sun, C.; Veld, B.H.I. Ejection Regimes in Picosecond Laser-Induced Forward Transfer of Metals. Phys. Rev. Appl. 2015, 3, 024001. [Google Scholar] [CrossRef]

- Schiaffino, S.; Sonin, A.A. Molten droplet deposition and solidification at low Weber numbers. Phys. Fluids 1997, 9, 3172–3187. [Google Scholar] [CrossRef]

- Soltman, D.; Subramanian, V. Inkjet-Printed Line Morphologies and Temperature Control of the Coffee Ring Effect. Langmuir 2008, 24, 2224–2231. [Google Scholar] [CrossRef]

- Stringer, J.; Derby, B. Limits to feature size and resolution in ink jet printing. J. Eur. Ceram. Soc. 2009, 29, 913–918. [Google Scholar] [CrossRef]

- Yang, J.; Zheng, F.; Derby, B. Stability of Lines with Zero Receding Contact Angle Produced by Inkjet Printing at Small Drop Volume. Langmuir 2021, 37, 26–34. [Google Scholar] [CrossRef]

- Moon, Y.J.; Kang, H.; Lee, S.H.; Kang, K.; Cho, Y.J.; Hwang, J.Y.; Moon, S.J. Effect of contact angle and drop spacing on the bulging frequency of inkjet-printed silver lines on FC-coated glass. J. Mech. Sci. Technol. 2014, 28, 1441–1448. [Google Scholar] [CrossRef]

- Duineveld, P.C. The stability of ink-jet printed lines of liquid with zero receding contact angle on a homogeneous substrate. J. Fluid Mech. 2003, 477, 175–200. [Google Scholar] [CrossRef]

- Dang, M.C.; Dang, T.M.D.; Fribourg-Blanc, E. Silver nanoparticles ink synthesis for conductive patterns fabrication using inkjet printing technology. Adv. Nat. Sci. Nanosci. Nanotechnol. 2014, 6, 015003. [Google Scholar] [CrossRef]

- Rajan, K.; Roppolo, I.; Chiappone, A.; Bocchini, S.; Perrone, D.; Chiolerio, A. Silver nanoparticle ink technology: State of the art. Nanotechnol. Sci. Appl. 2016, 9, 1–13. [Google Scholar] [CrossRef]

- He, B.; Yang, S.; Qin, Z.; Wen, B.; Zhang, C. The roles of wettability and surface tension in droplet formation during inkjet printing. Sci. Rep. 2017, 7, 11841. [Google Scholar] [CrossRef]

- M’chaar, R.; Sabbar, A.; El Moudane, M. Temperature dependences of surface tension, density and viscosity study of Sn-Ag-Cu with Bi additions using theoretical models. Sci. Rep. 2019, 9, 14177. [Google Scholar] [CrossRef]

- Huang, B.; Dasgupta, A.; Lee, N. Effect of SnAgCu composition on soldering performance. Solder. Surf. Mt. Technol. 2005, 17, 9–19. [Google Scholar] [CrossRef]

- Gonçalves, C.; Leitão, H.; Lau, C.S.; Teixeira, J.C.; Ribas, L.; Teixeira, S.; Cerqueira, M.F.; Macedo, F.; Soares, D. Wetting behaviour of SAC305 solder on different substrates in high vacuum and inert atmosphere. J. Mater. Sci. Mater. Electron. 2015, 26, 5106–5112. [Google Scholar] [CrossRef]

- Shu, Z.; Fechtig, M.; Lombeck, F.; Breitwieser, M.; Zengerle, R.; Koltay, P. Direct Drop-on-Demand Printing of Molten Solder Bumps on ENIG Finishing at Ambient Conditions through StarJet Technology. IEEE Access 2020, 8, 210225–210233. [Google Scholar] [CrossRef]

- Géczy, A.; Csiszar, A.; Xavier, P.; Corrao, N.; Rauly, D.; Kovacs, R.; Feher, A.E.; Rozs, E.; Gal, L. Thermal and RF Characterization of Novel PLA/Flax Based Biodegradable Printed Circuit Boards. In Proceedings of the 2022 IEEE 24th Electronics Packaging Technology Conference (EPTC), Singapore, 7–9 December 2022; pp. 329–333. [Google Scholar] [CrossRef]

- Gerdes, B.; Breitwieser, M.; Kaltenbach, T.; Jehle, M.; Wilde, J.; Zengerle, R.; Koltay, P.; Riegger, L. Analysis of the metallic structure of microspheres produced by printing of aluminum alloys from the liquid melt. Mater. Res. Express 2018, 6, 036514. [Google Scholar] [CrossRef]

- Park, H.Y.; Kang, B.J.; Lee, D.; Oh, J.H. Control of surface wettability for inkjet printing by combining hydrophobic coating and plasma treatment. Thin Solid Films 2013, 546, 162–166. [Google Scholar] [CrossRef]

- McIlroy, C.; Harlen, O.G. Effects of drive amplitude on continuous jet break-up. Phys. Fluids 2019, 31, 064104. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Z.; Fu, J.; Huang, Y. Study of Pinch-Off Locations during Drop-on-Demand Inkjet Printing of Viscoelastic Alginate Solutions. Langmuir 2017, 33, 5037–5045. [Google Scholar] [CrossRef]

- Dobosz, A.; Gancarz, T. Reference Data for the Density, Viscosity, and Surface Tension of Liquid Al–Zn, Ag–Sn, Bi–Sn, Cu–Sn, and Sn–Zn Eutectic Alloys. J. Phys. Chem. Ref. Data 2018, 47, 013102. [Google Scholar] [CrossRef]

- CVAT. Available online: https://www.cvat.ai/ (accessed on 27 March 2024).

- Gerdes, B. StarJet Printheads for Printing Molten Solder Jets at 320 °C and Molten Aluminum Alloy Droplets at 950 °C. Doctoral Thesis, Albert-Ludwigs-Universität Freiburg, Freiburg im Breisgau, Germany, 2019. [Google Scholar] [CrossRef]

- Xiong, W.; Cheng, P. Numerical investigation of air entrapment in a molten droplet impacting and solidifying on a cold smooth substrate by 3D lattice Boltzmann method. Int. J. Heat Mass Transf. 2018, 124, 1262–1274. [Google Scholar] [CrossRef]

- Yi, H.; Qi, L.; Luo, J.; Jiang, Y.; Deng, W. Pinhole formation from liquid metal microdroplets impact on solid surfaces. Appl. Phys. Lett. 2016, 108, 041601. [Google Scholar] [CrossRef]

- Mao, T.; Kuhn, D.C.S.; Tran, H. Spread and rebound of liquid droplets upon impact on flat surfaces. AIChE J. 1997, 43, 2169–2179. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, P. Numerical Interpretation to the Roles of Liquid Viscosity in Droplet Spreading at Small Weber Numbers. Langmuir 2019, 35, 16164–16171. [Google Scholar] [CrossRef]

- Sklyarchuk, V.; Plevachuk, Y.; Novakovic, R.; Kaban, I. Surface properties and wetting characteristics of liquid Ag–Bi–Sn alloys. Monatshefte Für Chem.-Chem. Mon. 2012, 143, 1249–1254. [Google Scholar] [CrossRef]

- Golhin, A.P.; Tonello, R.; Frisvad, J.R.; Grammatikos, S.; Strandlie, A. Surface roughness of as-printed polymers: A comprehensive review. Int. J. Adv. Manuf. Technol. 2023, 127, 987–1043. [Google Scholar] [CrossRef]

- Chaidas, D.; Kitsakis, K.; Kechagias, J.; Maropoulos, S. The impact of temperature changing on surface roughness of FFF process. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012033. [Google Scholar] [CrossRef]

| Dimensionless Parameter | Expression 1 |

|---|---|

| Weber number | |

| Ohnesorge number | |

| Reynolds number |

| Test Case (TC) | [mm/s] | d [mm] | Tres [°C] | Tsub [°C] |

|---|---|---|---|---|

| Printing speed (A) | 35–120 | 12 | 330 | 20 |

| Standoff distance (B) | 30 | 6–30 | 330 | 20 |

| Reservoir temperature (C) | 30 | 6–20 | 400 | 20 |

| Substrate temperature (D) | 30 | 20 | 330 | 45–110 |

| Standoff Distance [mm] | 12 | 13 | 14 | 16 | 18 | 20 |

|---|---|---|---|---|---|---|

| Average line width @ 330 °C [µm] | Bulging | 185 | 216 | 228 | ||

| Average line width @ 330 °C [µm] | Bulging | 18.1 | 20.8 | 21.4 | ||

| Average line width @ 400 °C [µm] | 139 | 165 | 136 | 196 | 188 | 184 |

| Standard deviation @ 400 °C [µm] | 18 | 20 | 18 | 23 | 32 | 30.9 |

| Substrate Temperature [°C] | 45 | 55 | 65 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Average line width [µm] | 181 | 202 | 189 | 213 | 196 | 212 | 214 | 214 | 169 | 184 | 196 |

| Standard deviation [µm] | 13.2 | 13.2 | 14.8 | 15.5 | 13.6 | 13.0 | 16.0 | 16.0 | 25.3 | 29.0 | 18.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Straubinger, D.; Koltay, P.; Zengerle, R.; Kartmann, S.; Shu, Z. Bulge-Free and Homogeneous Metal Line Jet Printing with StarJet Technology. Micromachines 2024, 15, 743. https://doi.org/10.3390/mi15060743

Straubinger D, Koltay P, Zengerle R, Kartmann S, Shu Z. Bulge-Free and Homogeneous Metal Line Jet Printing with StarJet Technology. Micromachines. 2024; 15(6):743. https://doi.org/10.3390/mi15060743

Chicago/Turabian StyleStraubinger, Dániel, Peter Koltay, Roland Zengerle, Sabrina Kartmann, and Zhe Shu. 2024. "Bulge-Free and Homogeneous Metal Line Jet Printing with StarJet Technology" Micromachines 15, no. 6: 743. https://doi.org/10.3390/mi15060743

APA StyleStraubinger, D., Koltay, P., Zengerle, R., Kartmann, S., & Shu, Z. (2024). Bulge-Free and Homogeneous Metal Line Jet Printing with StarJet Technology. Micromachines, 15(6), 743. https://doi.org/10.3390/mi15060743