Impact of Hydrogen Voiding in Chip-to-Chip Electroless All-Copper Interconnections

Abstract

1. Introduction

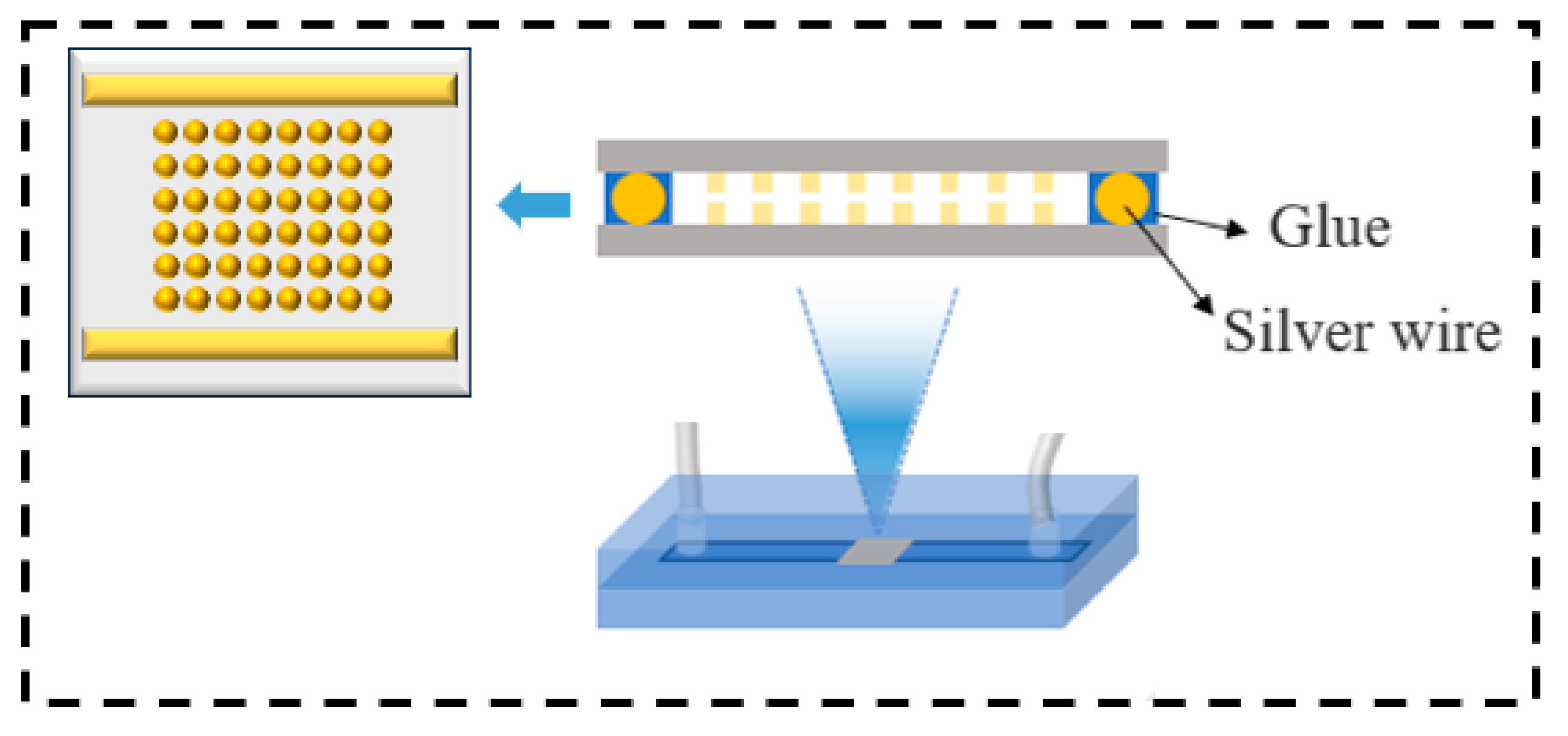

2. Materials and Methods

3. Results and Discussion

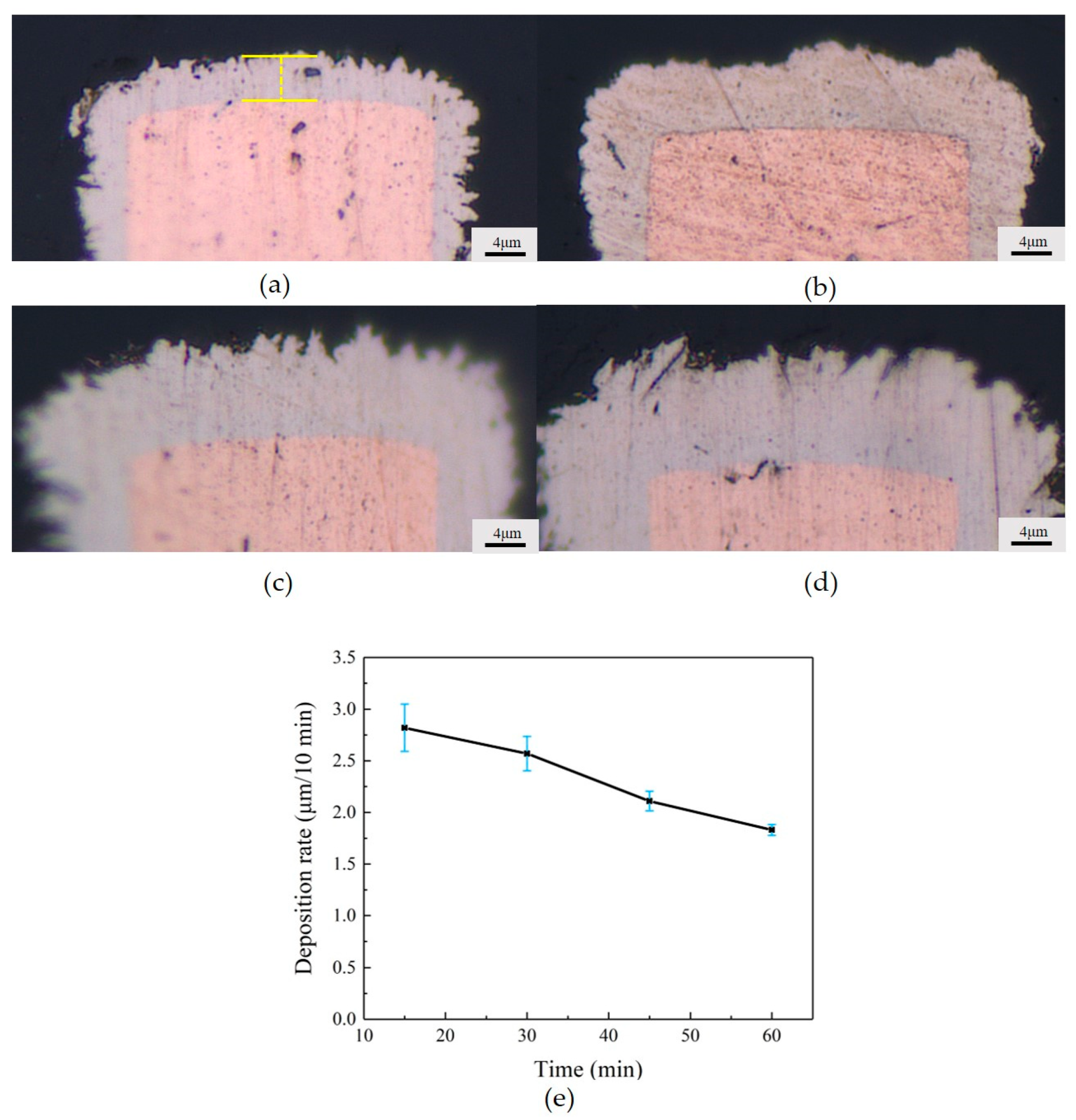

3.1. Three Stages of Electroless Copper Plating

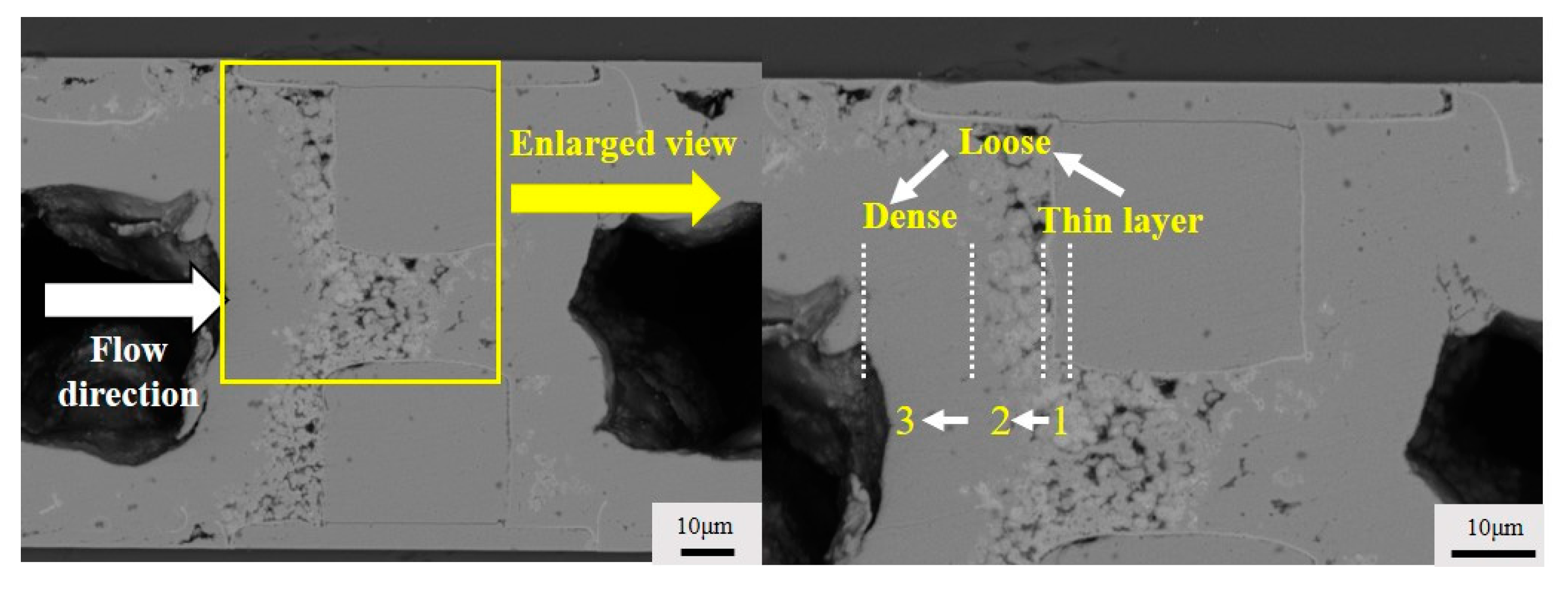

3.2. The Impact of the Interconnection Gap on the Formation of Voids

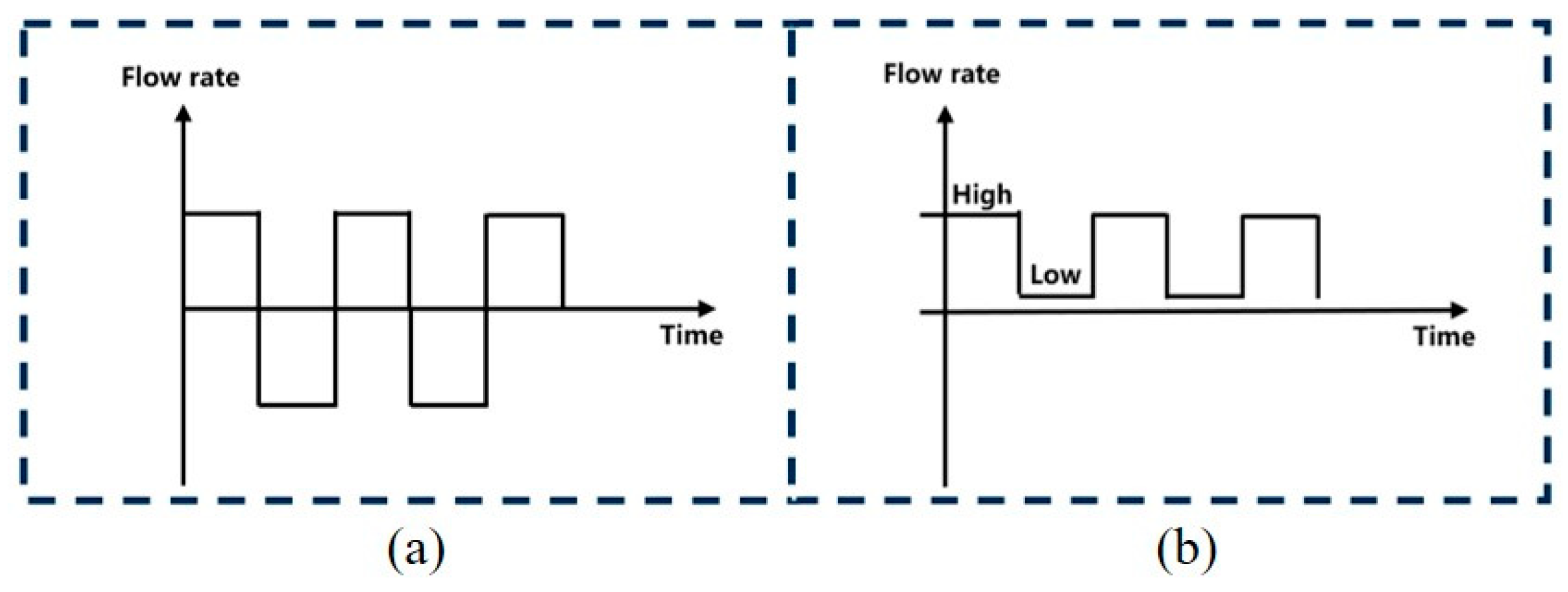

3.3. Optimization of the Flow Mode of the Plating Solution

3.4. Optimization of the Composition of the Plating Solution

4. Conclusions

- On the inflow side of the copper bumps, the chemical deposition of copper undergoes three stages, which are closely related to the activation of the copper bumps and the deposition rate of copper.

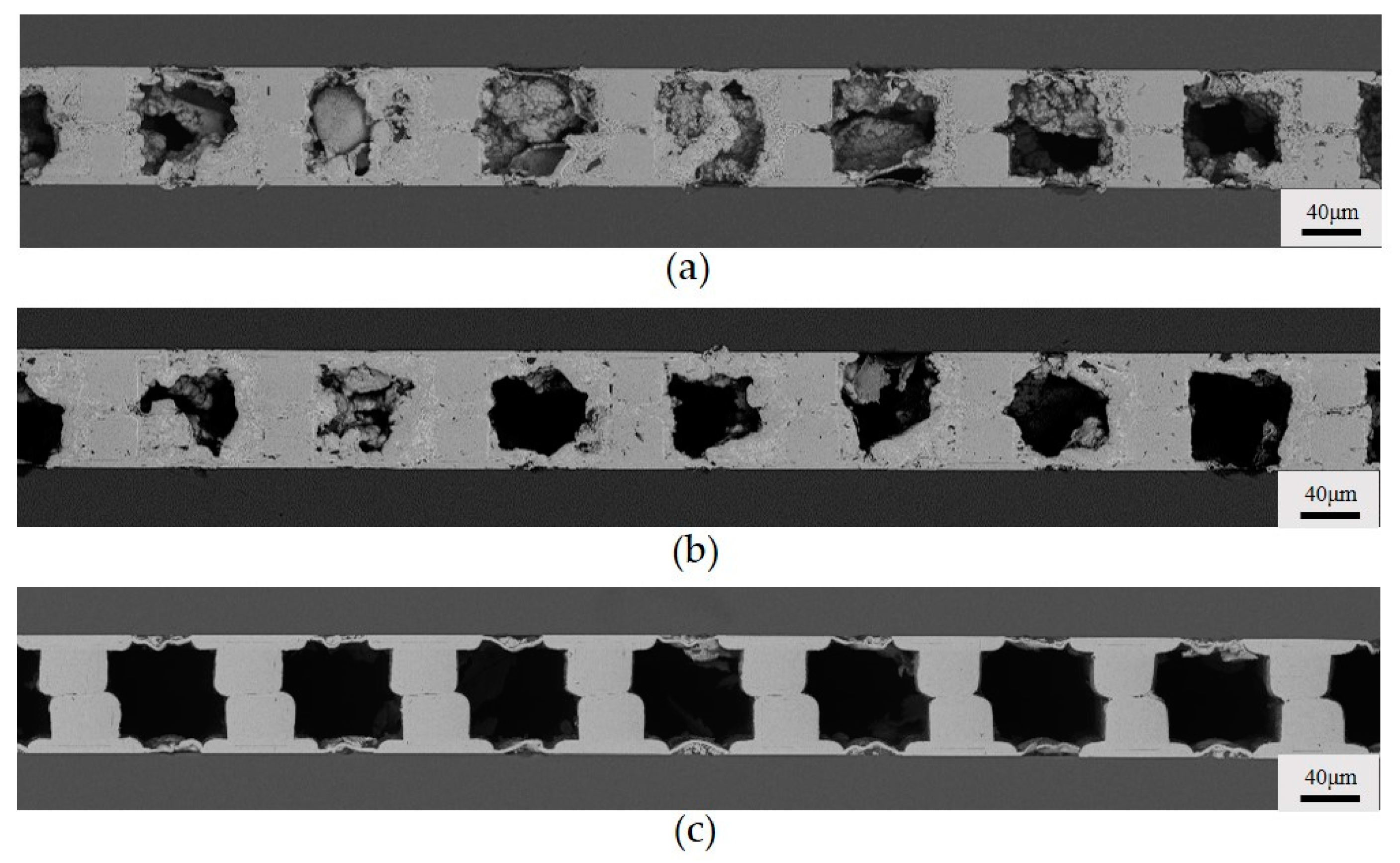

- When the interconnection gap decreases to 10 μm, extensive voids appear around the copper bumps. The formation of these voids is related to the direction of the plating solution flow, with voids being more prone to occur on the inflow side of the copper bumps rather than the outflow side.

- Improving the plating solution flow mode can only partially alleviate the generation of voids, and the root cause of void formation lies in the hydrogen gas that cannot be expelled in time. Extraneous deposition on the Si is only suppressed when the deposition is significantly suppressed.

- The addition of 2,2′-bipyridine can decelerate the generation of hydrogen gas, and when combined with the optimized plating solution flow mode, the quality of the interconnection can be improved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, S.; Hung, H.; Wu, P. Materials Merging Mechanism of Microfluidic Electroless Interconnection Process. J. Electrochem. Soc. 2018, 165, D273–D281. [Google Scholar] [CrossRef]

- Yu, A.; Lau, J. Fabrication of High Aspect Ratio TSV and Assembly with Fine-Pitch Low-Cost Solder Microbump for Si Interposer Technology with High-Density Interconnects. IEEE Trans. Compon. Packag. Manuf. 2011, 1, 1336–1344. [Google Scholar] [CrossRef]

- Braun, T.; Becker, K.; Hoelck, O. Fan-Out Wafer and Panel Level Packaging as Packaging Platform for Heterogeneous Integration. Micromachines 2019, 10, 342. [Google Scholar] [CrossRef] [PubMed]

- Song, R.; Chen, W.; Wang, Y. Enhancing mechanical strength of full intermetallic microbump via grain refinement by Zn in thermocompression bonding. Mater. Chem. Phys. 2022, 291, 126781–126789. [Google Scholar] [CrossRef]

- Huang, Y.; Tran, D.; Hsu, P. To suppress thermomigration of Cu-Sn intermetallic compounds in flip-chip solder joints. J. Mater. Res. Technol. 2023, 24, 7910–7924. [Google Scholar] [CrossRef]

- Jeong, H.; Jung, K.; Lee, C. Effect of epoxy mold compound and package dimensions on the thermomechanical properties of a fan-out package. J. Mater. Sci. Mater. Electron. 2020, 31, 6835–6842. [Google Scholar] [CrossRef]

- Guo, J.; Lin, Y.; Zhou, Z. Design and preparation of BaO–Al2O3–SiO2–B2O3/Quartz LTCC composites with tailored coefficient of thermal expansion. Ceram. Int. 2022, 48, 12065–12073. [Google Scholar] [CrossRef]

- Yang, Y.; Chou, T.; Yu, T. Low-Temperature Cu–Cu Direct Bonding Using Pillar–Concave Structure in Advanced 3-D Heterogeneous Integration. IEEE Trans. Compon. Packag. Manuf. 2017, 7, 1560–1566. [Google Scholar] [CrossRef]

- Utsumi, J.; Takigawa, R. Surface activated bonding of aluminum oxide films at room temperature. Scr. Mater. 2021, 191, 215–218. [Google Scholar] [CrossRef]

- Michitaka, Y.; Takashi, M.; Yuichi, K. Effect of Au Film Thickness and Surface Roughness on Room-Temperature Wafer Bonding and Wafer-Scale Vacuum Sealing by Au-Au Surface Activated Bonding. Micromachines 2020, 11, 454. [Google Scholar] [CrossRef]

- Yutaka, O.; Jianbo, L.; Naoteru, S. Chemical bonding at room temperature via surface activation to fabricate low-resistance GaAs/Si heterointerfaces. Appl. Surf. Sci. 2020, 525, 146610–146614. [Google Scholar]

- He, A.; Osborn, T.; Allen, S. Low-Temperature Bonding of Copper Pillars for All-Copper Chip-to-Substrate Interconnections. Electrochem. Solid-State Lett. 2006, 9, C192–C195. [Google Scholar] [CrossRef]

- Yang, S.; Hung, H.; Chen, Y. Low-Temperature, Pressureless Cu-to-Cu Bonding By Electroless Ni Plating. In Proceedings of the International Microsystems, Package, Assembly Conference, Taiwan, China, 26–28 October 2016. [Google Scholar]

- Hung, H.; Ma, Z.; Shih, P. Highly uniform microfluidic electroless interconnections for chip stacking applications. Electrochim. Acta 2021, 376, 138032–138041. [Google Scholar] [CrossRef]

- Yang, S.; Hung, H.; Kao, C. Development of Low-temperature, Presssureless Copper-to-Copper Bonding by Microfluidic Electroless Interconnection Process. In Proceedings of the Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2018. [Google Scholar]

- Yokoshim, T.; Yamaji, Y.; Oosato, H. Interconnection of Micropad Electrodes by Controlled “Extraneous” Deposition of Electroless NiB Film. Electrochem. Solid-State Lett. 2007, 10, D92–D94. [Google Scholar] [CrossRef]

- Weng, I.; Hung, H.; Huang, W. Vertical Interconnections by Electroless Au Deposition on Electroless Ni Immersion Au Surface Finish. J. Electron. Mater. 2020, 59, 5003–5008. [Google Scholar] [CrossRef]

- Weng, I.; Hung, H.; Yang, S. Self-assembly of reduced Au atoms for vertical interconnections in three dimensional integrated circuits. Scr. Mater. 2019, 159, 119–122. [Google Scholar] [CrossRef]

- Hung, H.; Yang, S.; Weng, I. Low Temperature and Pressureless Microfluidic Electroless Bonding Process for Vertical Interconnections. In Proceedings of the Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2019. [Google Scholar]

- Zhang, Y.; Yao, P.; Han, Y. Microfluidic electroless deposition for uniform stacking chip interconnection: Simulation framework and experimental validation. Chem. Eng. J. 2022, 434, 134684–138691. [Google Scholar] [CrossRef]

- Hung, H.; Yang, S.; Chen, Y. Chip-to-Chip Direct Interconnections by Using Controlled flow electroless Ni plating. J. Electron. Mater. 2017, 46, 4321–4325. [Google Scholar] [CrossRef]

- Koo, H.; Saha, R.; Kohl, P. Copper Electroless Bonding of Dome-Shaped Pillars for Chip to Package Interconnect. J. Electrochem. Soc. 2011, 158, D698–D703. [Google Scholar] [CrossRef]

- Xu, L.; Liao, J.; Huang, L. A new activation method for electroless metal plating: Palladium laden via bonding with self-assembly monolayers. Chin. Chem. Lett. 2002, 13, 687–688. [Google Scholar]

- Yang, B.; Yang, F.; Huang, L. Study on the role of 2,2′-bipyridine in electroless copper plating. Electrochem 2007, 13, 425–430. [Google Scholar]

- Martins, J.I.; Nunes, M.C. On the kinetics of copper electroless plating with hypophosphite reductant. Surf. Eng. 2016, 32, 363–371. [Google Scholar] [CrossRef]

| Composition of the Plating Solution | Concentration (g/L) |

|---|---|

| CuSO4 5H2O | 10 |

| NaH2PO2∙H2O | 30 |

| H3BO3 | 30 |

| NiSO4 6H2O | 2 |

| Na3C6H5O7 2H2O | 23.5 |

| PEG | 1.28 |

| 2,2′-bipyridine | 0.005, 0.01, 0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, N.; Zhang, Y.; Shu, W.; Lu, C.; Zhang, W.; Chen, Z.; Wang, F. Impact of Hydrogen Voiding in Chip-to-Chip Electroless All-Copper Interconnections. Micromachines 2024, 15, 612. https://doi.org/10.3390/mi15050612

Ren N, Zhang Y, Shu W, Lu C, Zhang W, Chen Z, Wang F. Impact of Hydrogen Voiding in Chip-to-Chip Electroless All-Copper Interconnections. Micromachines. 2024; 15(5):612. https://doi.org/10.3390/mi15050612

Chicago/Turabian StyleRen, Nana, Yuyi Zhang, Wenlong Shu, Chenxiao Lu, Wenjing Zhang, Zhuo Chen, and Fuliang Wang. 2024. "Impact of Hydrogen Voiding in Chip-to-Chip Electroless All-Copper Interconnections" Micromachines 15, no. 5: 612. https://doi.org/10.3390/mi15050612

APA StyleRen, N., Zhang, Y., Shu, W., Lu, C., Zhang, W., Chen, Z., & Wang, F. (2024). Impact of Hydrogen Voiding in Chip-to-Chip Electroless All-Copper Interconnections. Micromachines, 15(5), 612. https://doi.org/10.3390/mi15050612