Investigation on the Deformation and Surface Quality of a Bearing Outer Ring during Grinding Processing

Abstract

1. Introduction

2. Experimental Design and Simulation Modeling

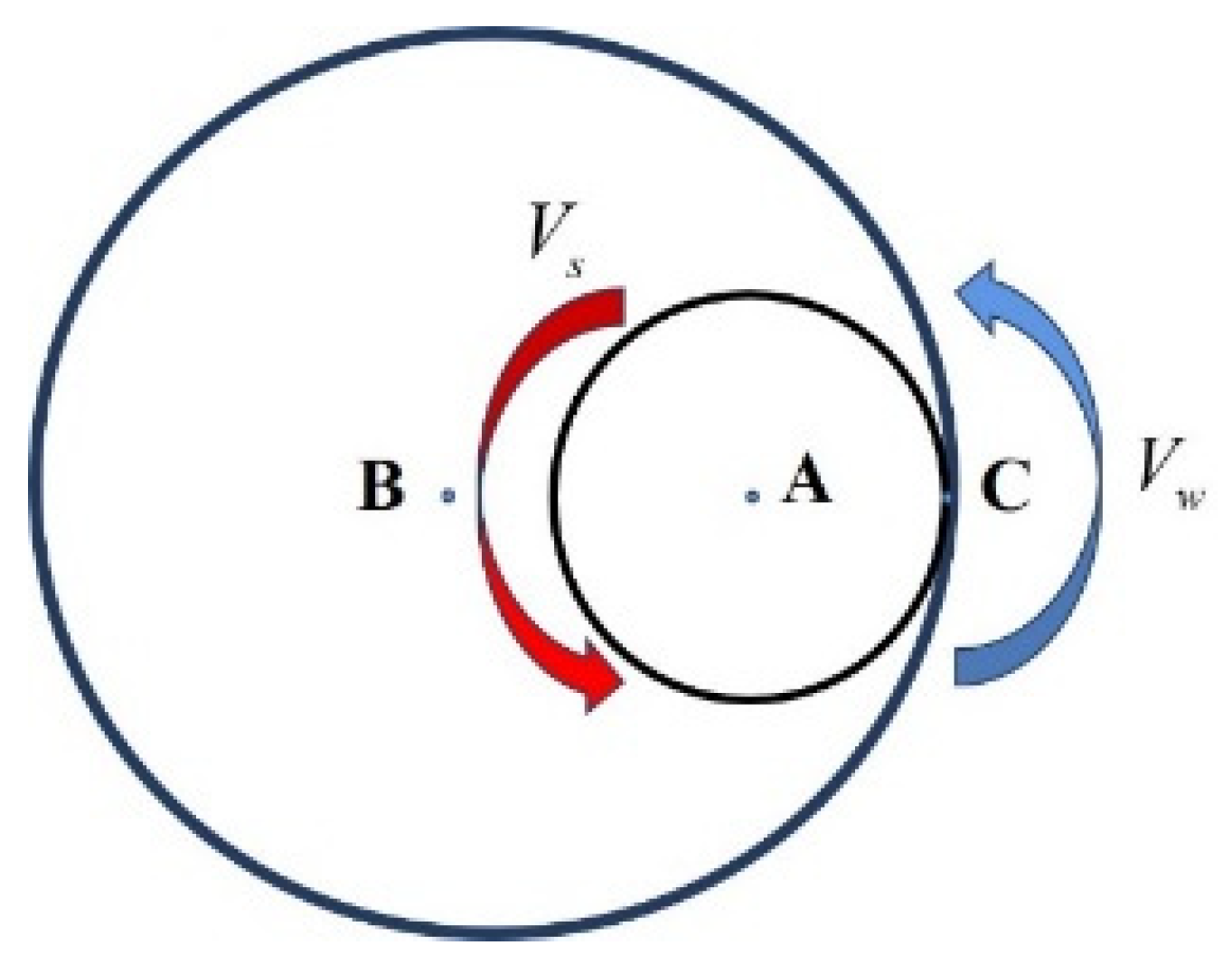

2.1. Experimental Setup

2.2. Experimental Design

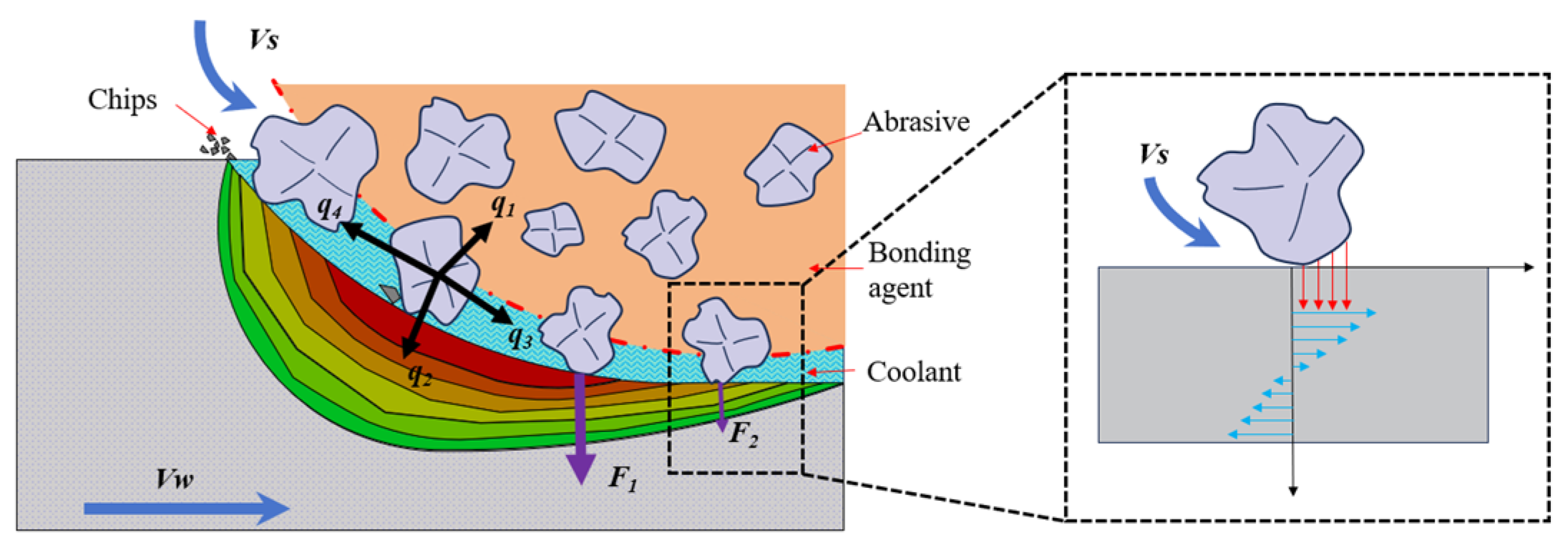

2.3. Numerical Simulation Modeling

3. Results and Discussion

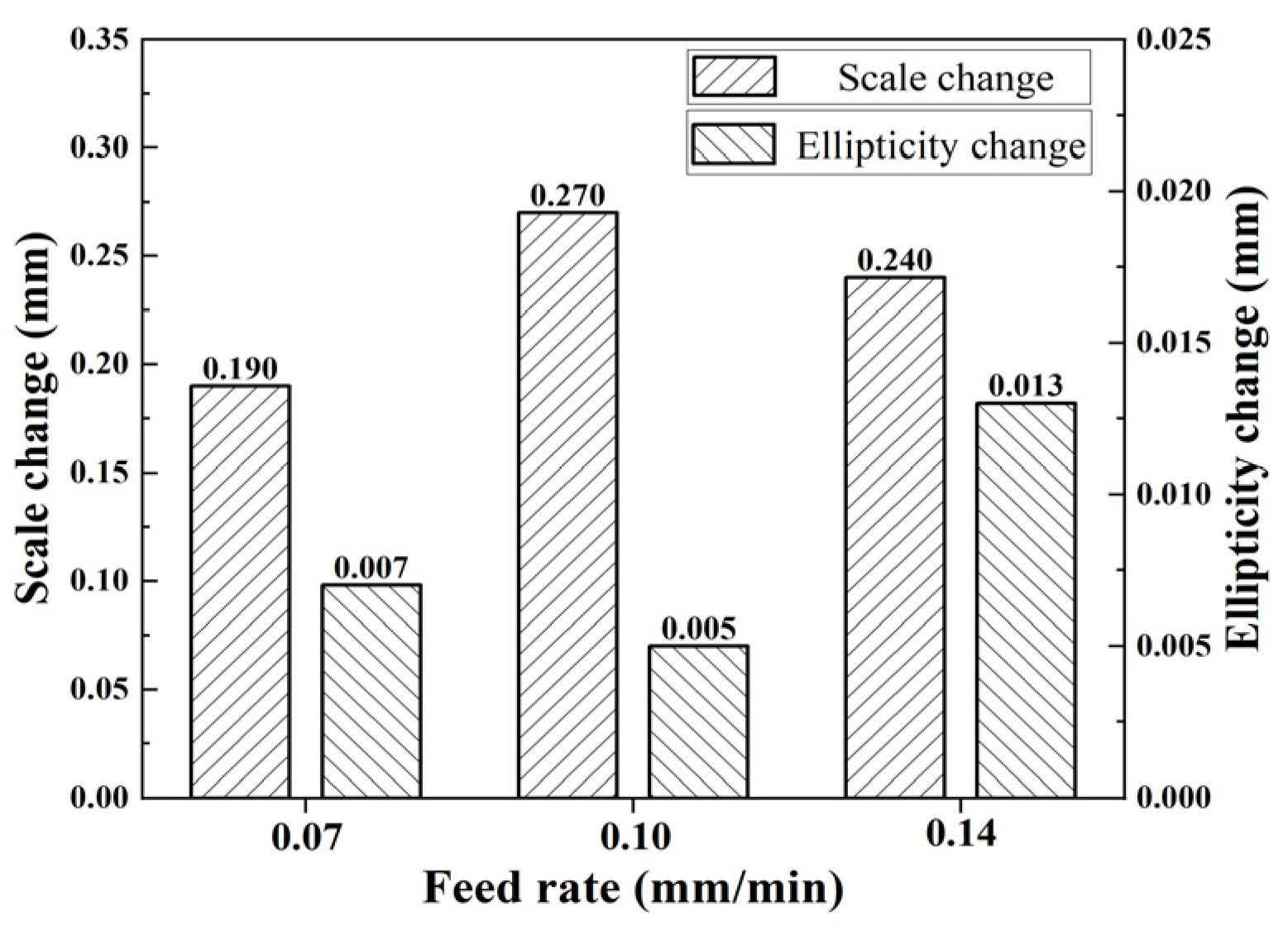

3.1. Relationship between Grinding Processing Parameters and Deformation

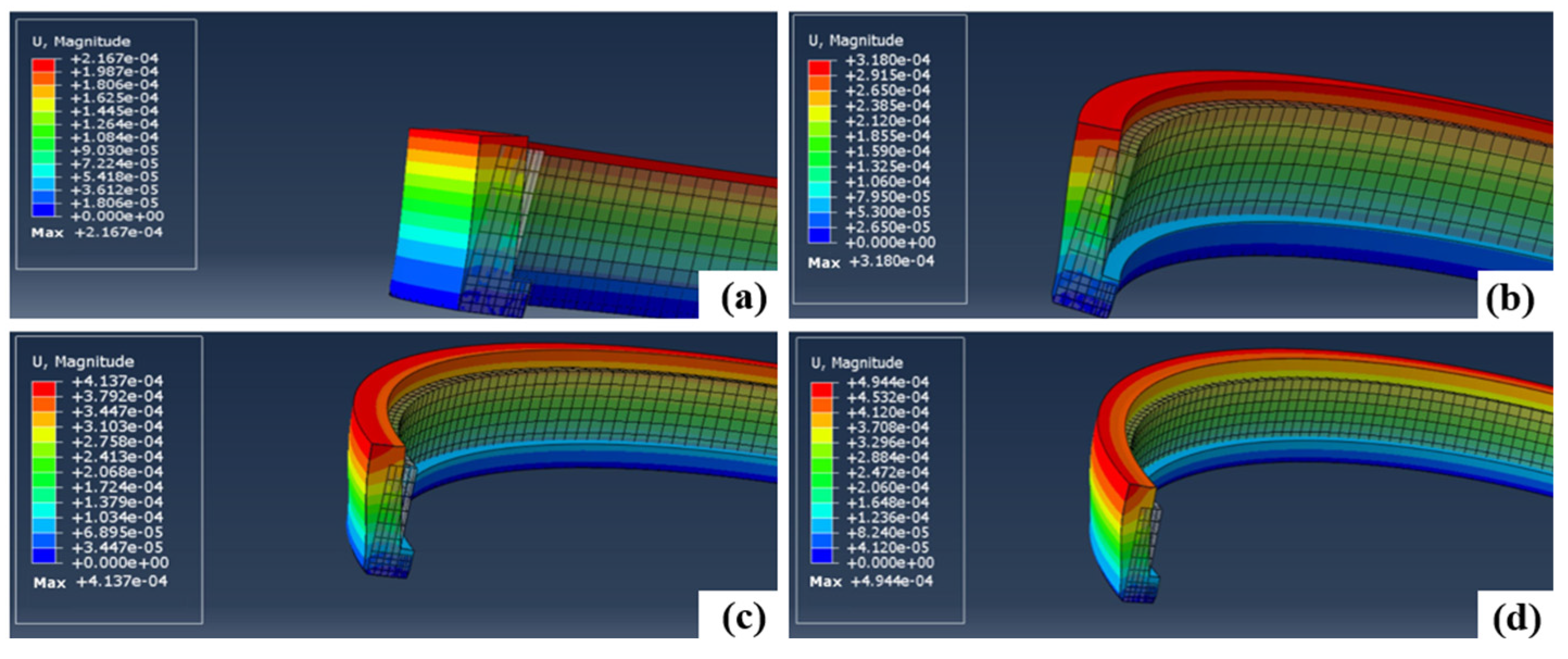

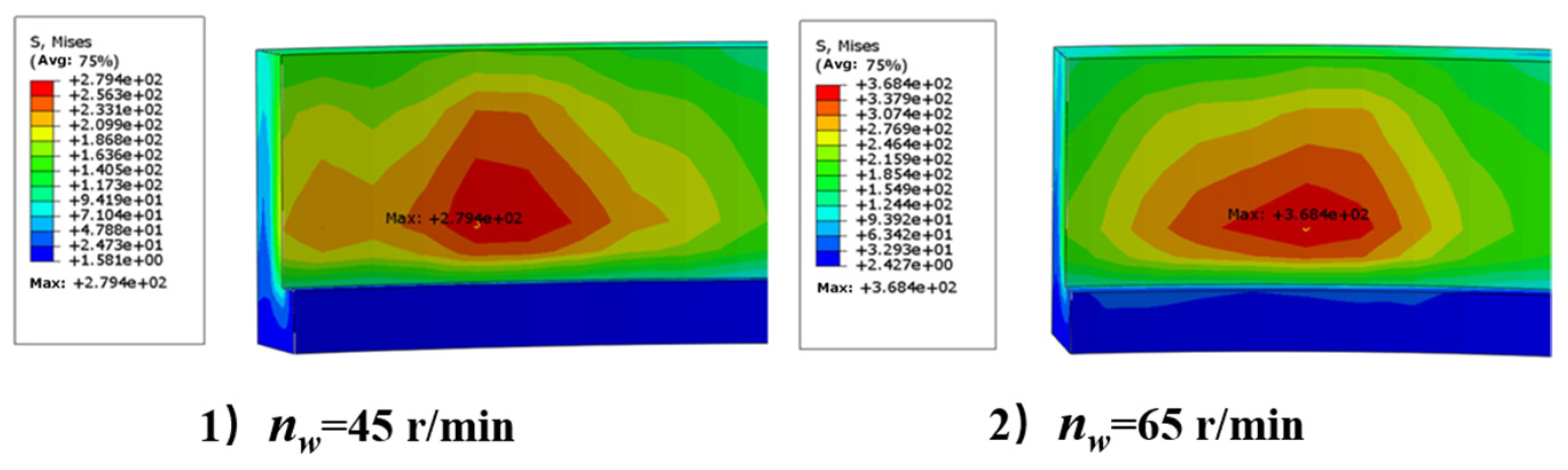

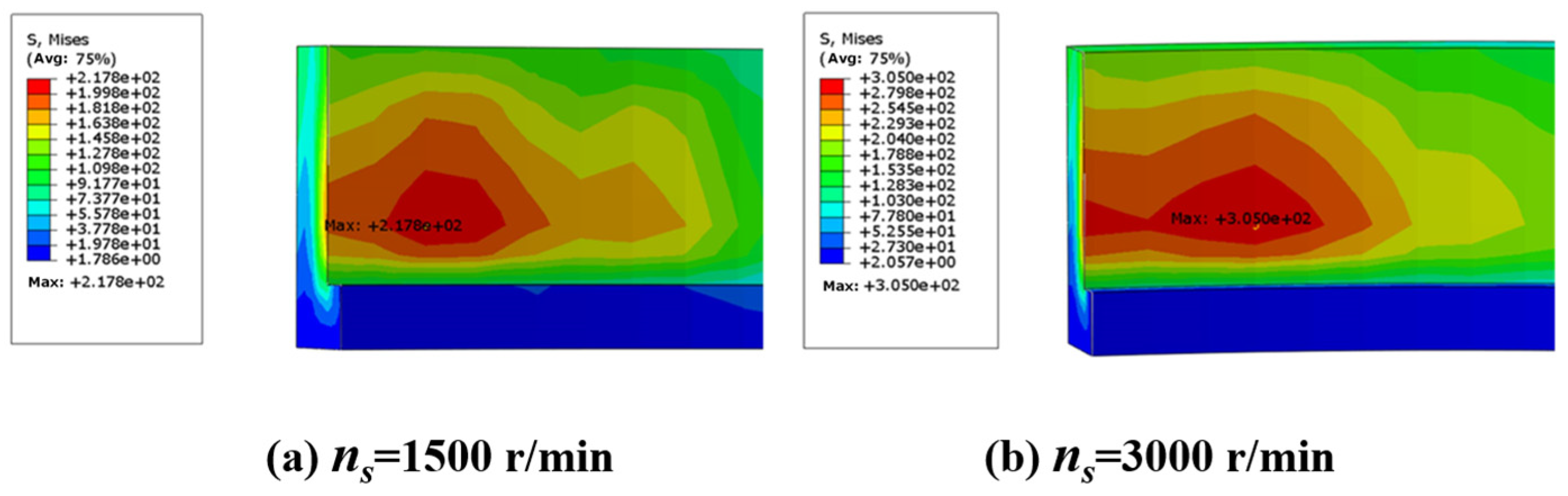

3.2. Simulation Analysis

3.3. Analysis of the Deformation Mechanism

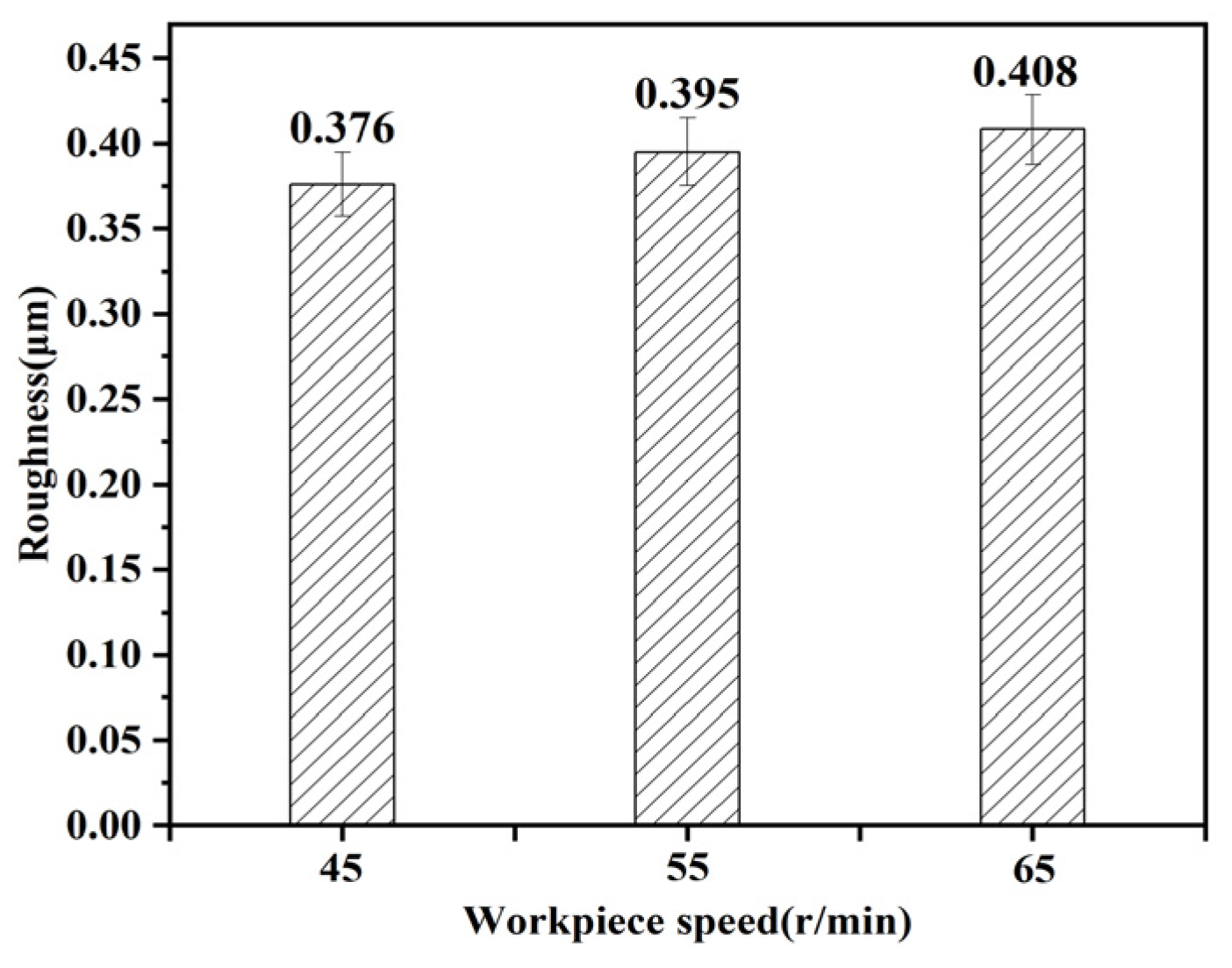

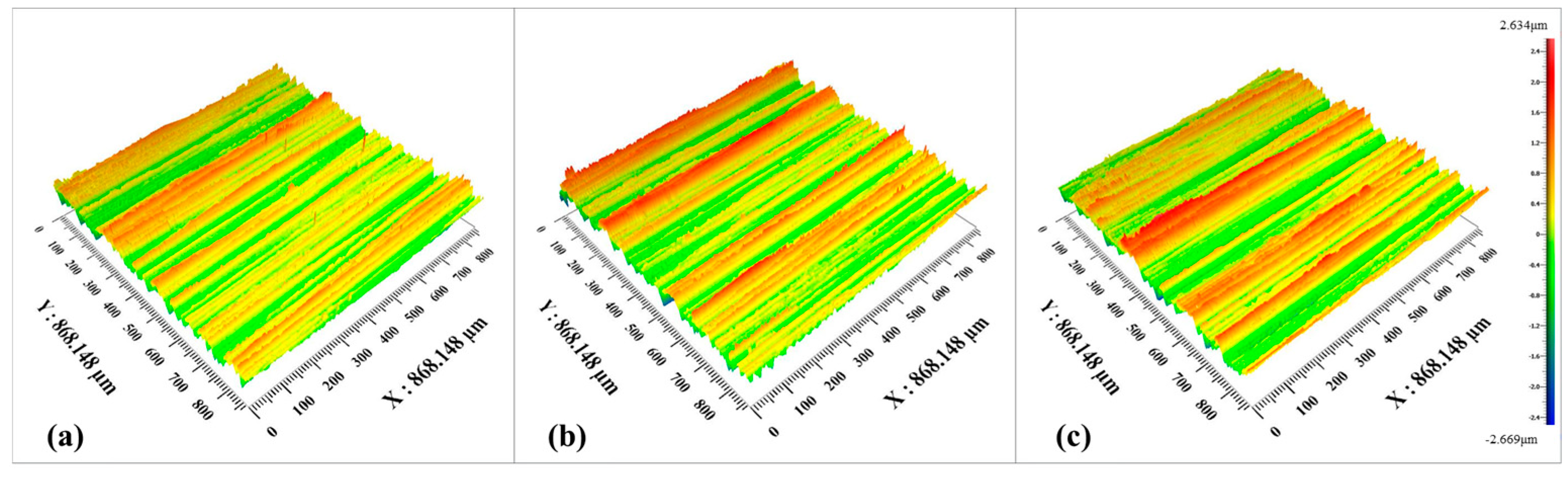

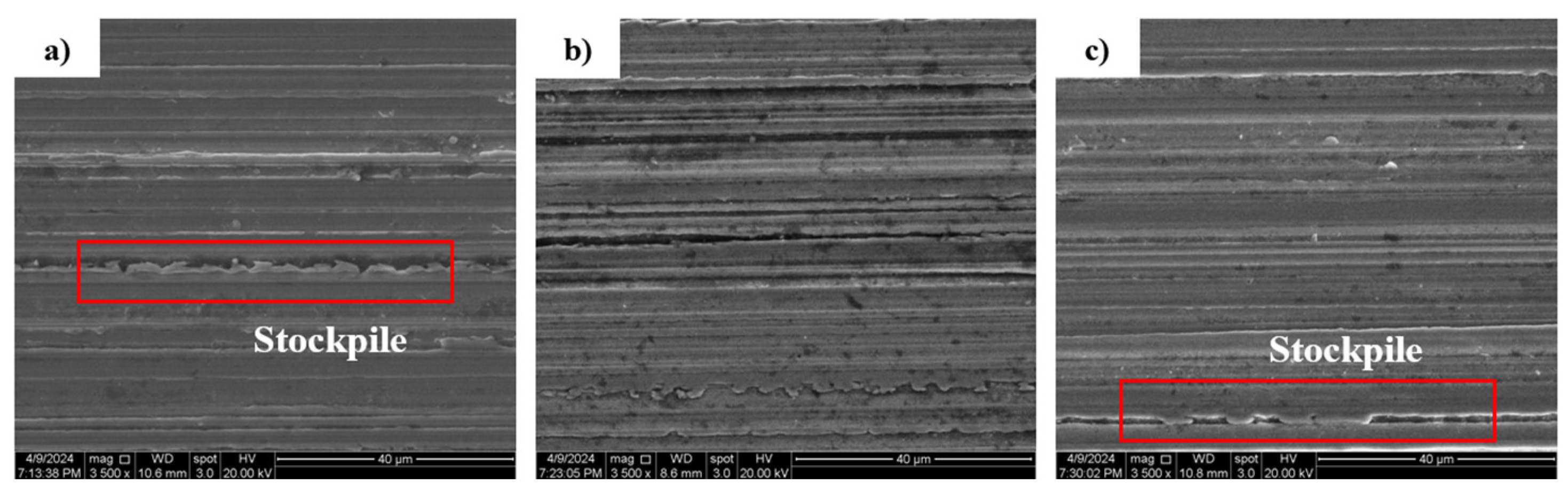

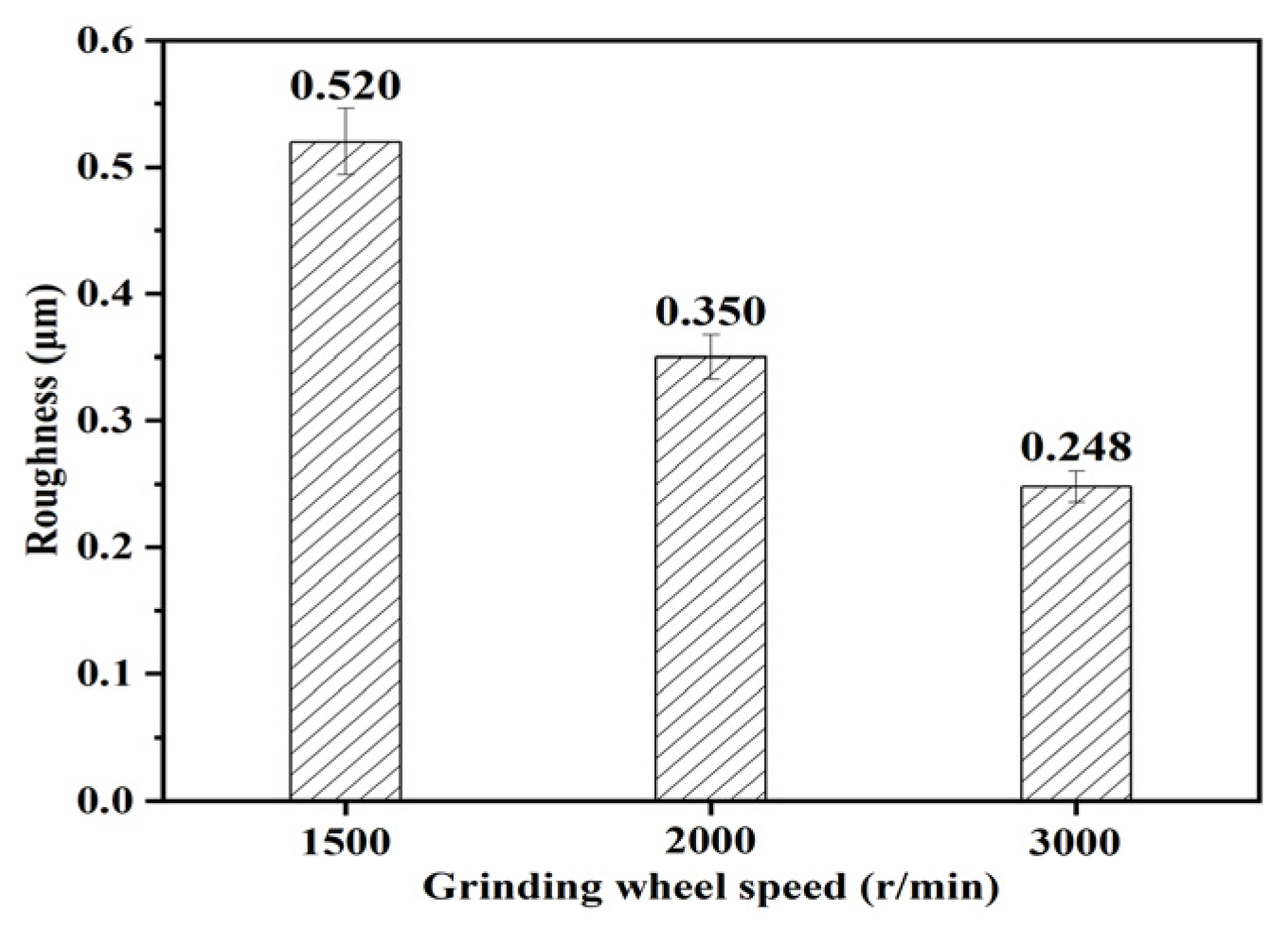

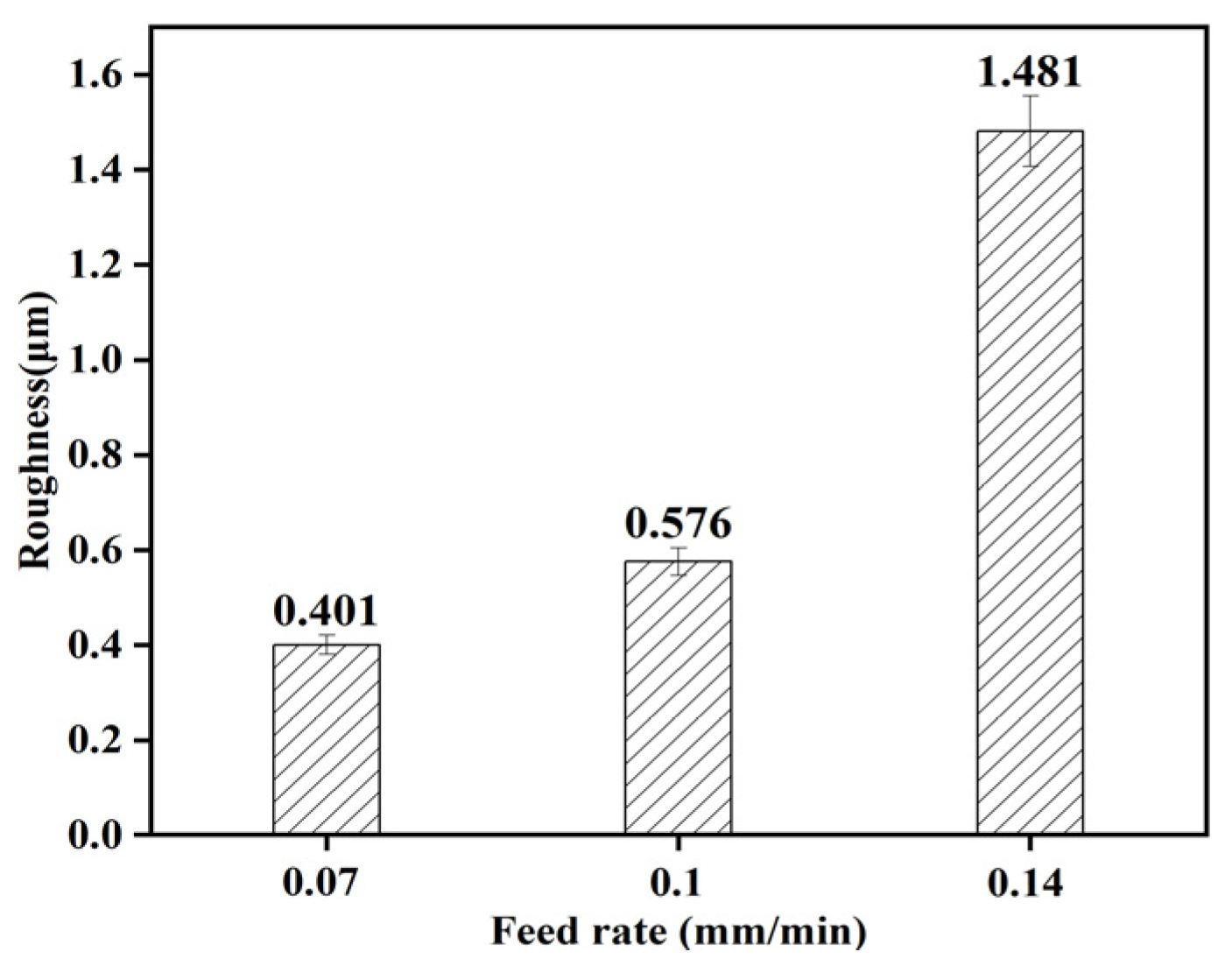

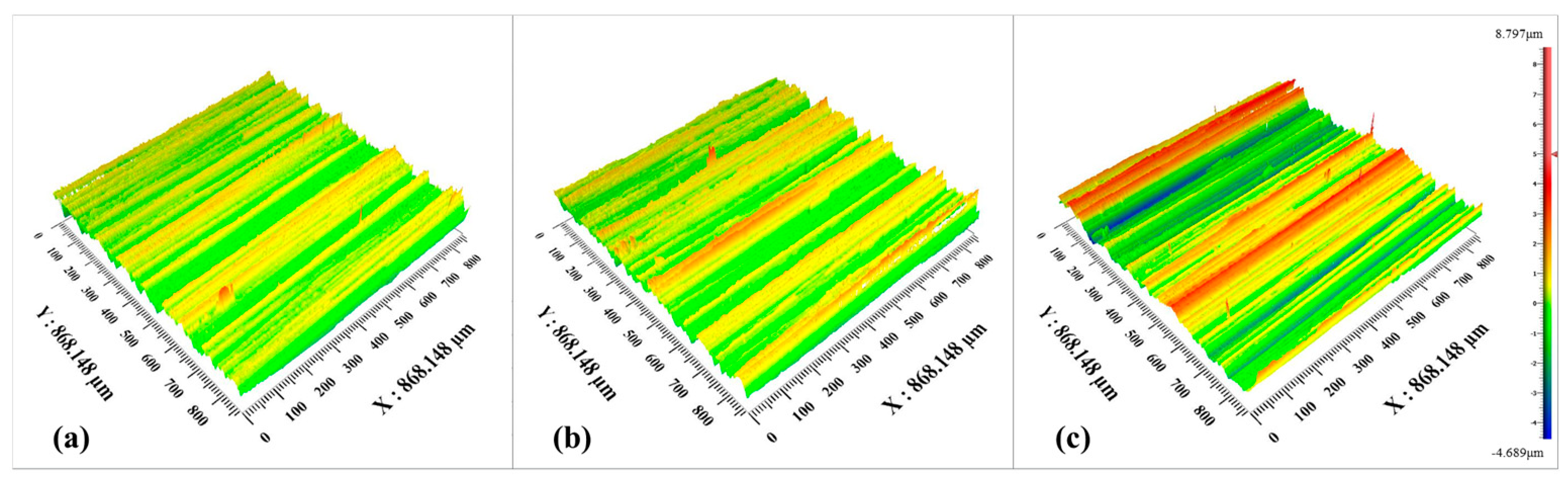

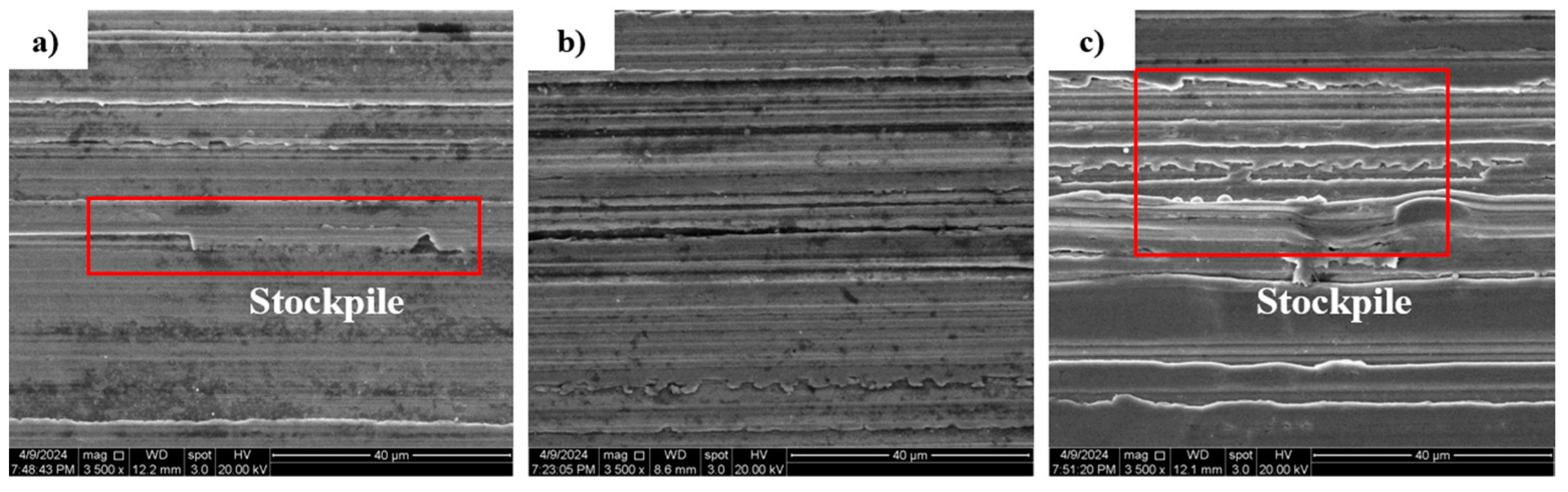

3.4. Relationship between Grinding Processing Parameters and Surface Quality

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, F.J.; Chen, J.L.; Han, T.; Xiao, G.; Li, S.C. Research on hardened bearing steel hard turning and grinding assisted machining technology. Bearing 2022, 6, 13–17. [Google Scholar]

- Cheng, S. Development and Analysis of Ultra-precision Machining Technology for High-precision Bearing Rings. China Equip. Eng. 2022, 1, 113–114. [Google Scholar]

- Guan, J.L.; Hu, Z.Y.; Zhang, Y. Current Situation and Development of Ultra-precision Machining Technology for High-precision Bearing Rings. Tool Technol. 2018, 52, 3–7. [Google Scholar]

- Fan, C.; Ren, L.; Zhang, Y.; Bao, S.; Yang, Z. Influence of Sodium Hexametaphosphate on Muscovite Grinding and Its Mechanism Analysis. Minerals 2023, 13, 457. [Google Scholar] [CrossRef]

- Fan, C.; Ren, L.; Zhang, Y.; Bao, S. Grinding effect of sodium silicate on muscovite and its mechanism analysis. Miner. Eng. 2023, 199, 108106. [Google Scholar] [CrossRef]

- Li, X.; Zhao, K.; Chen, G.; Ren, C.Z.; Zhang, Y.X.; Liu, Z.D. Optimization of ELID profile grinding process parameters for ball bearing outer ring grooves. Mech. Sci. Technol. 2021, 40, 1541–1548. [Google Scholar]

- Tang, S.J.; Guan, Y.P.; Liu, M.Y. Optimization of grinding process of outer ring of three-valve wave roller bearing. Bearing 2017, 5, 15–17. [Google Scholar]

- Yamamda, T.; Lee, H.S.; Miura, K. Effect of Contact Stiffness of Grinding Wheel on Ground Surface Roughness and Residual Stock Removal of Workpiece. Adv. Mater. Res. 2013, 797, 522–527. [Google Scholar] [CrossRef]

- Wen, J.M. Research on Mechanical Properties and Fatigue Life of Large Rolling Bearings. Bachelor’s Thesis, Dalian University of Technology, Dalian, China, 2013. [Google Scholar]

- Bhadeshia, H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Shihab, S.K.; Khan, Z.A.; Mohammad, A.; Siddiquee, A.N. A review of turning of hard steels used in bearing and automotive applications. Prod. Manuf. Res. 2014, 2, 24–49. [Google Scholar] [CrossRef]

- Nik, M.G.; Movahhedy, M.R.; Akbari, J. Ultrasonic-assisted Grinding of Ti6Al4V Alloy. Procedia CIRP 2012, 1, 353–358. [Google Scholar] [CrossRef]

- Chen, S.Q. Research on the Effect of Heat Treatment and Grinding Process on the Roundness of Outer Ring of Deep Groove Ball Bearings. Bachelor’s Thesis, Ningbo University, Ningbo, China, 2021. [Google Scholar]

- Tong, V.C.; Jung, E.W.; Hong, S.W. Modeling of Crossed Roller Bearings Considering Roller Roundness Deformation. J. Tribol.-Trans. Asme 2020, 142, 121201. [Google Scholar] [CrossRef]

- Lin, J.R. The Influence of Longitudinal Surface Roughness on Sub-critical and Super-critical Limit Cycles of Short Journal Bearings. Appl. Math. Model. 2014, 38, 392–402. [Google Scholar] [CrossRef]

- Nagarajub, T.; Sharmaa, S.C.; Jain, S.C. Influence of Surface Roughness Effects on The Performance of Non-recessed Hybrid Journal Bearings. Tribol. Int. 2002, 35, 467–487. [Google Scholar] [CrossRef]

- Shah, S.M.A. Prediction of Residual Stresses due to Grinding with Phase Transformation. Ph.D. Thesis, INSA, Lyon, France, 2011. [Google Scholar]

- Jin, G.D. Surface Roughness Prediction and Finite Element Simulation of Temperature Field in Tapered Roller Bearing Outer Raceway Grinding. Bachelor’s Thesis, Shandong University, Jinan, China, 2024. [Google Scholar]

- Tian, Y.; Shirinzadeh, B.; Zhang, D. Effects of the heat source profiles on the thermal distribution for ultraprecision grinding. Precis. Eng. 2009, 33, 447–458. [Google Scholar] [CrossRef]

- Rowe, W.; Black, S.; Mills, B. Grinding temperature and energy partitioning. Proceedings of the Royal Society of London. Ser. A Math. Phys. Eng. 1997, 453, 1083–1104. [Google Scholar]

- Wang, X.Z.; Yu, T.B.; Dai, Y.X. Kinematics modeling and simulating of grinding surface topography considering machining parameters and vibration characteristics. Int. J. Adv. Manuf. Technol. 2016, 87, 2459–2470. [Google Scholar] [CrossRef]

- Setti, D.; Kirsch, B.; Aurich, J.C. Experimental investigations and kinematic simulation of single grit scratched surfaces considering pile-up behaviour: Grinding perspective. Int. J. Adv. Manuf. Technol. 2019, 103, 471–485. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Z.W.; Zhao, Z.S. Effects of CBN Grinding Wheel Grinding Parameters on the Surface Roughness of Bearing Internal Circles. Diam. Abras. Eng. 2013, 33, 30–33. [Google Scholar]

| Material Properties | Unit | Numeric |

|---|---|---|

| Coefficient of thermal expansion | 1.5 × 10−5~8 × 10−5 | |

| Poisson’s ratio | 0.3 | |

| Modulus of elasticity | MPa | 2.06 × 10 × 105 |

| Tensile strength | MPa | ≥861.3 |

| Processing Parameters | Groups | Workpiece Speed | Grinding Wheel Speed | Feed Rate |

|---|---|---|---|---|

| Workpiece speed (r/min) | 1 | 45 | 2000 | 0.07 |

| 2 | 55 | 2000 | 0.07 | |

| 3 | 65 | 2000 | 0.07 | |

| Grinding wheel speed (r/min) | 1 | 55 | 1500 | 0.07 |

| 2 | 55 | 2000 | 0.07 | |

| 3 | 55 | 3000 | 0.07 | |

| Feed rate (mm/min) | 1 | 55 | 2000 | 0.07 |

| 2 | 55 | 2000 | 0.10 | |

| 3 | 55 | 2000 | 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Long, P.; Zhao, Y.; Xu, H.; Yang, Z.; Wang, J.; Li, T.; Tang, J. Investigation on the Deformation and Surface Quality of a Bearing Outer Ring during Grinding Processing. Micromachines 2024, 15, 614. https://doi.org/10.3390/mi15050614

Guo J, Long P, Zhao Y, Xu H, Yang Z, Wang J, Li T, Tang J. Investigation on the Deformation and Surface Quality of a Bearing Outer Ring during Grinding Processing. Micromachines. 2024; 15(5):614. https://doi.org/10.3390/mi15050614

Chicago/Turabian StyleGuo, Jiang, Pengyu Long, Yong Zhao, Haojie Xu, Zhaoyuan Yang, Jianjun Wang, Tingting Li, and Jiwu Tang. 2024. "Investigation on the Deformation and Surface Quality of a Bearing Outer Ring during Grinding Processing" Micromachines 15, no. 5: 614. https://doi.org/10.3390/mi15050614

APA StyleGuo, J., Long, P., Zhao, Y., Xu, H., Yang, Z., Wang, J., Li, T., & Tang, J. (2024). Investigation on the Deformation and Surface Quality of a Bearing Outer Ring during Grinding Processing. Micromachines, 15(5), 614. https://doi.org/10.3390/mi15050614