Development of a Microheater with a Large Heating Area and Low Thermal Stress in the Heating Area

Abstract

1. Introduction

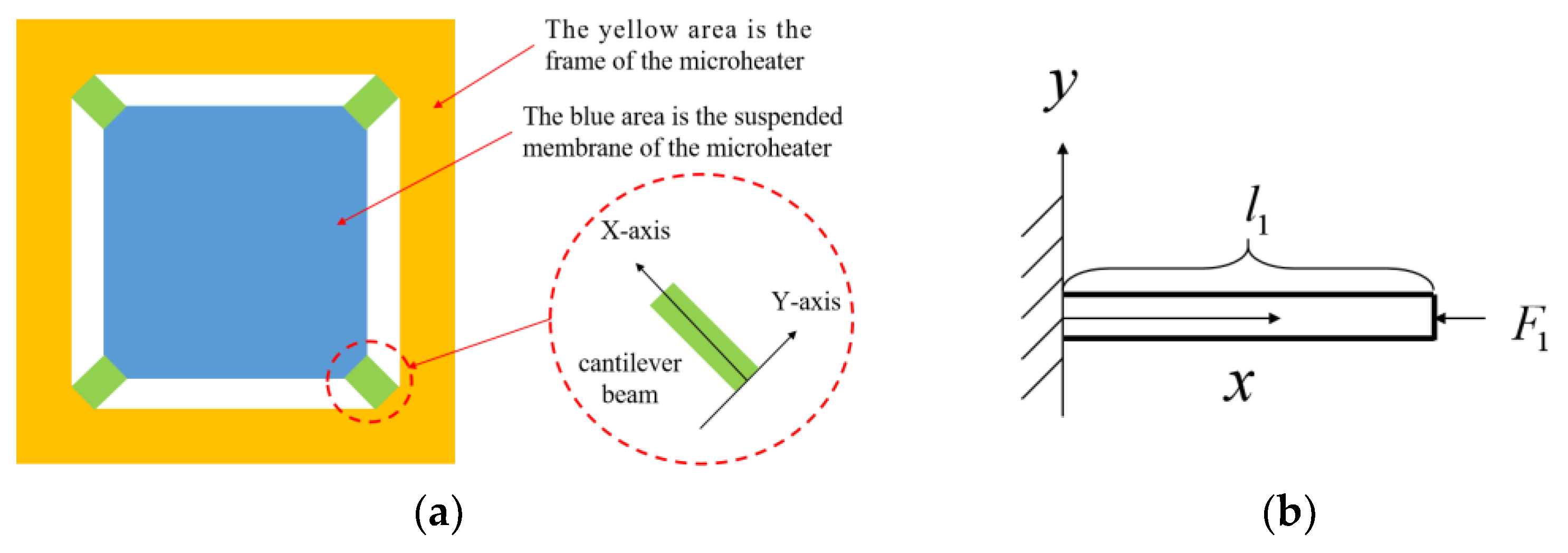

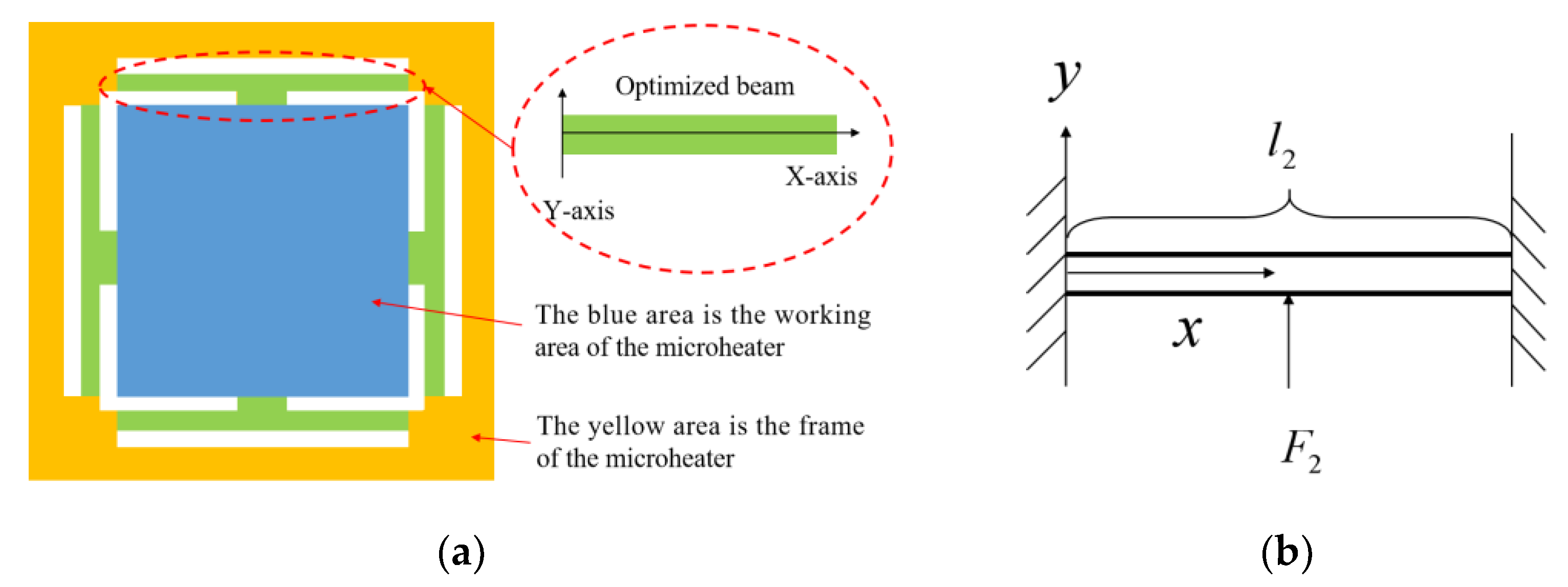

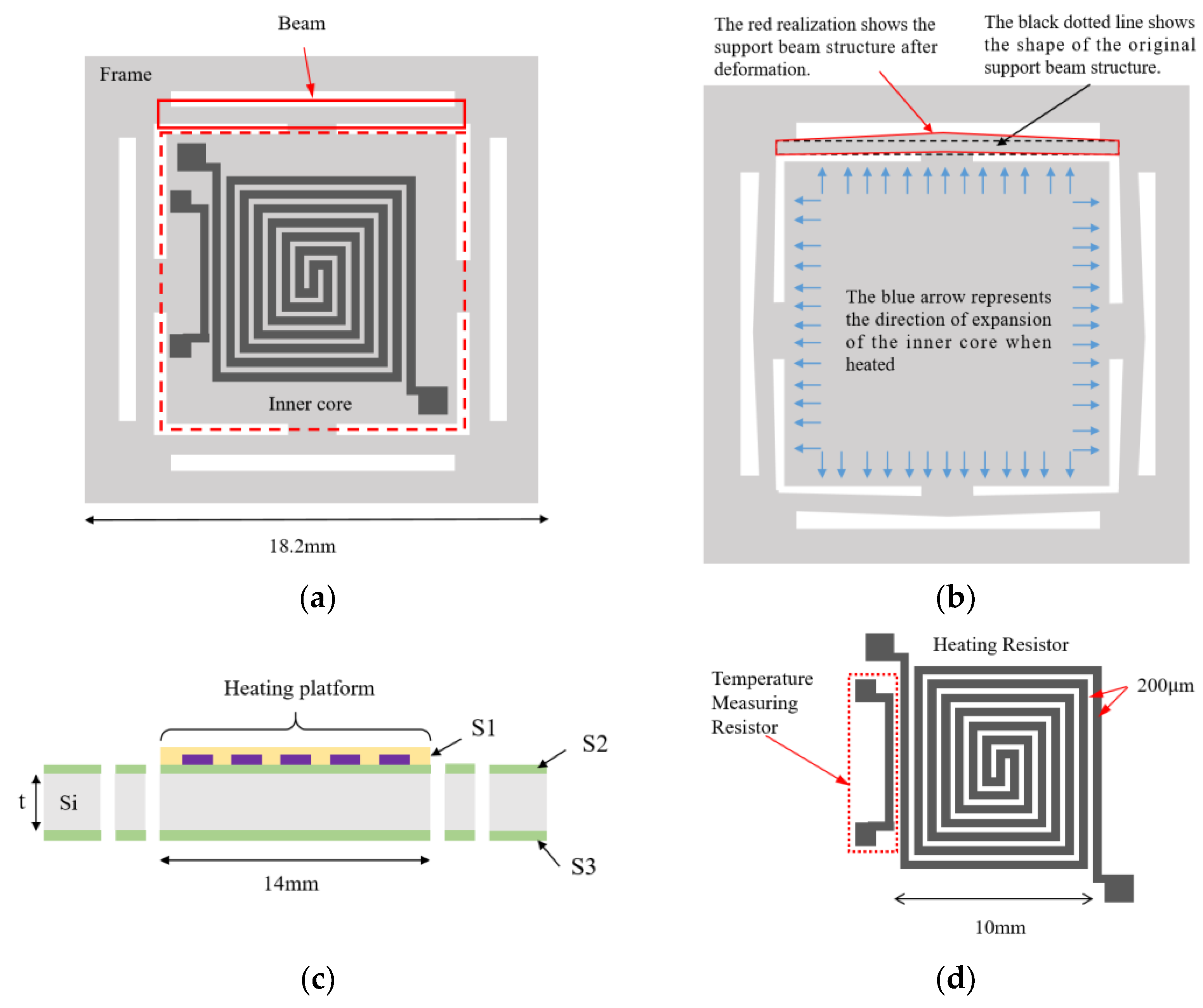

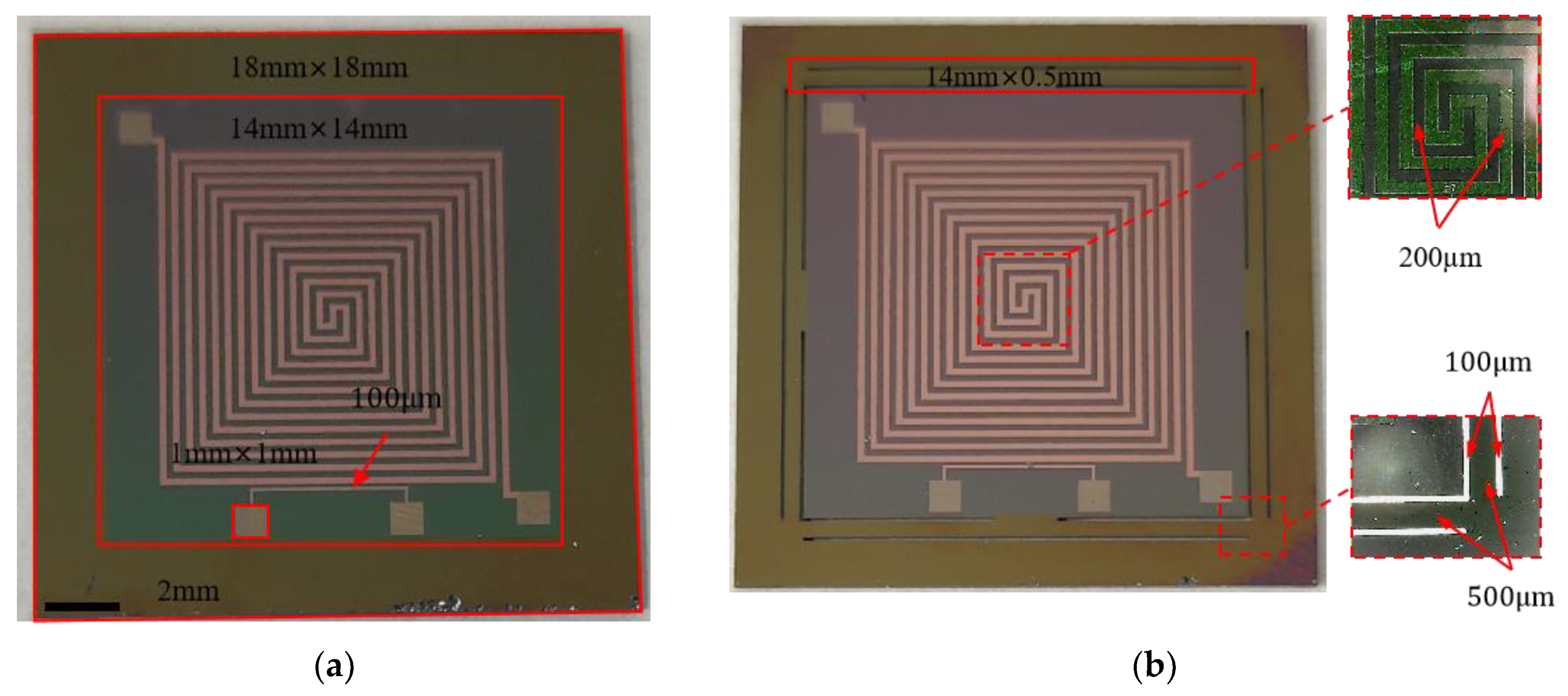

2. Structural Design and Process Flow of Microheater

2.1. Structural Design

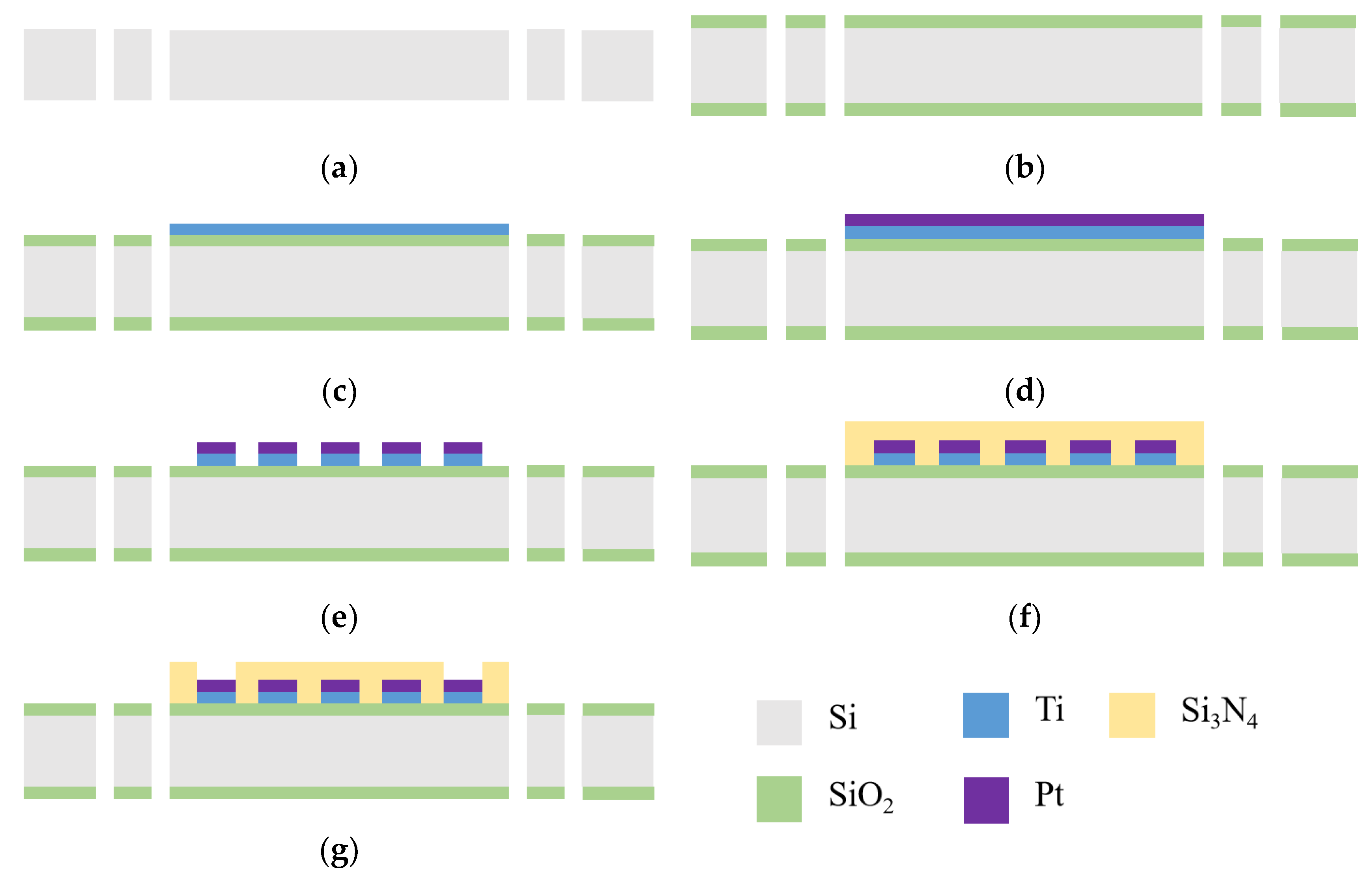

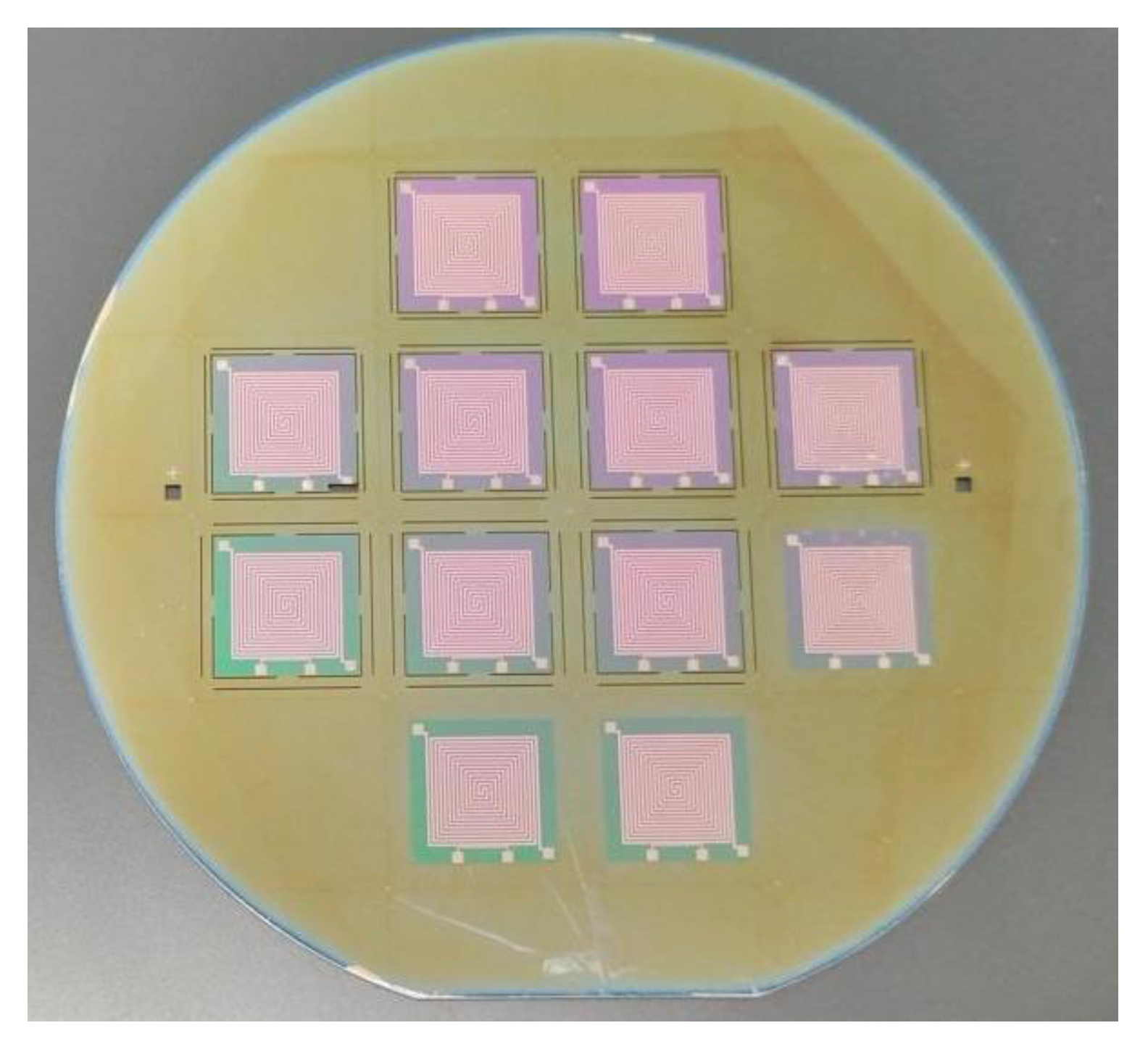

2.2. Process Flow

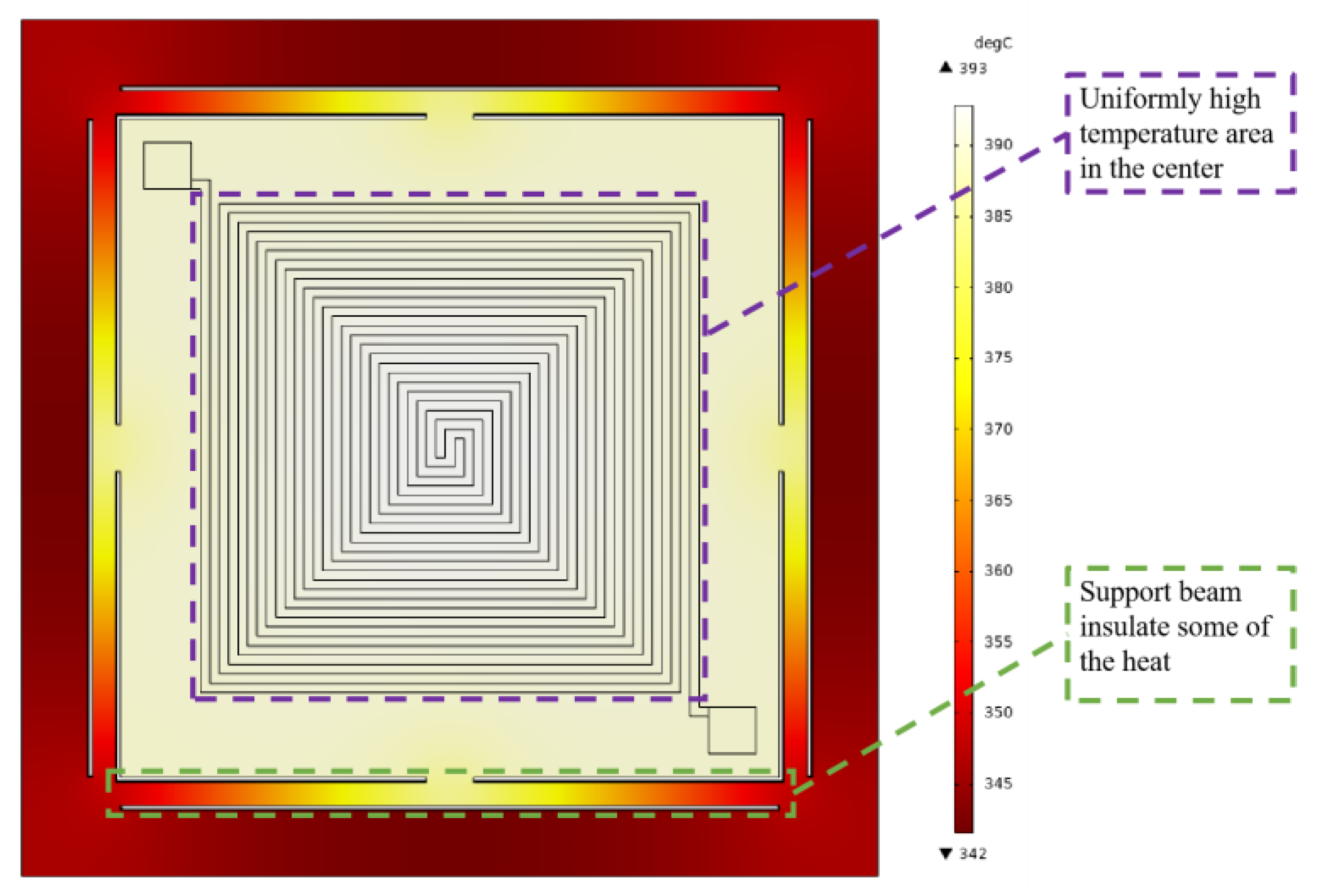

3. Electrical–Thermal–Mechanical Structural Characteristics of Microheater

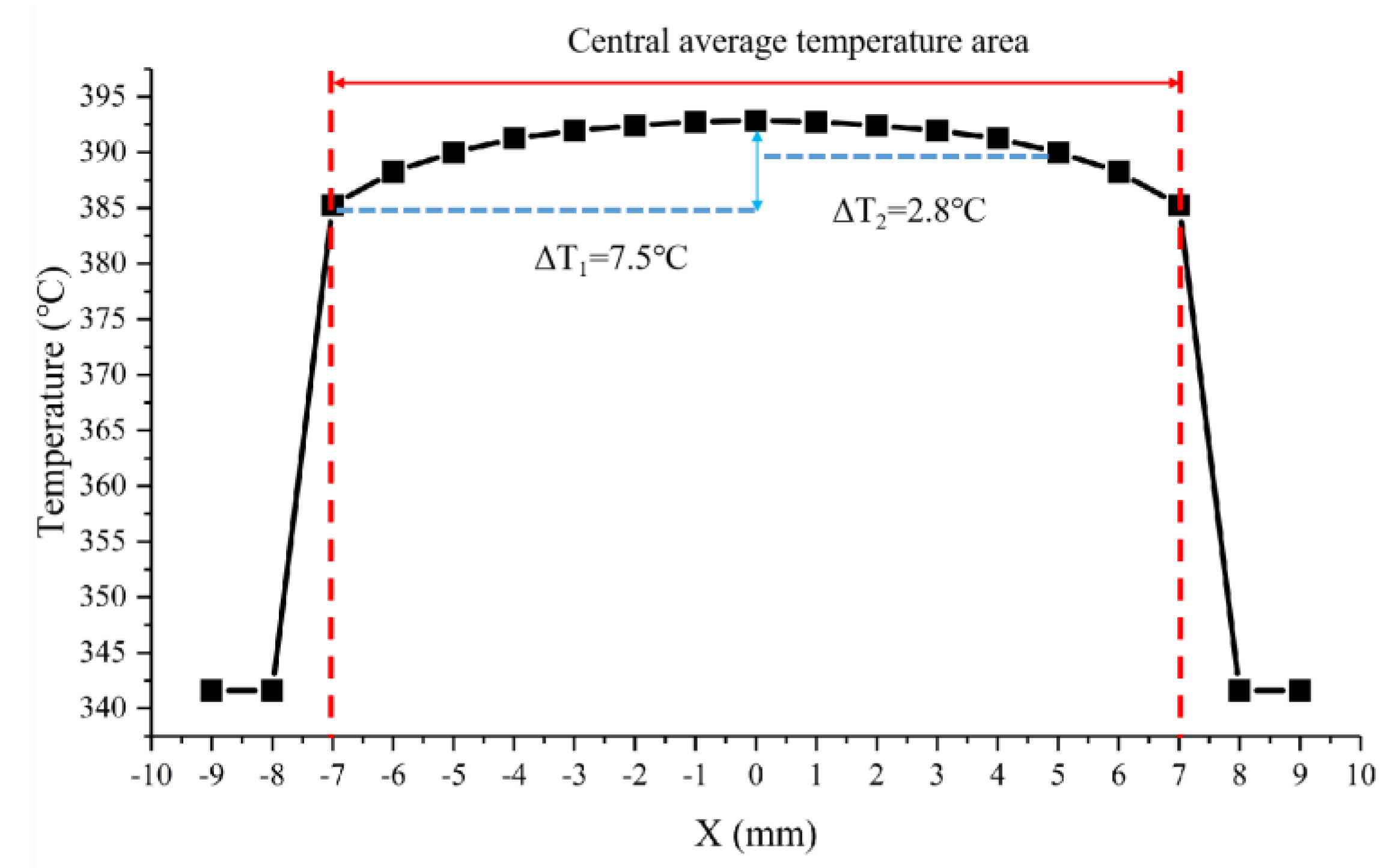

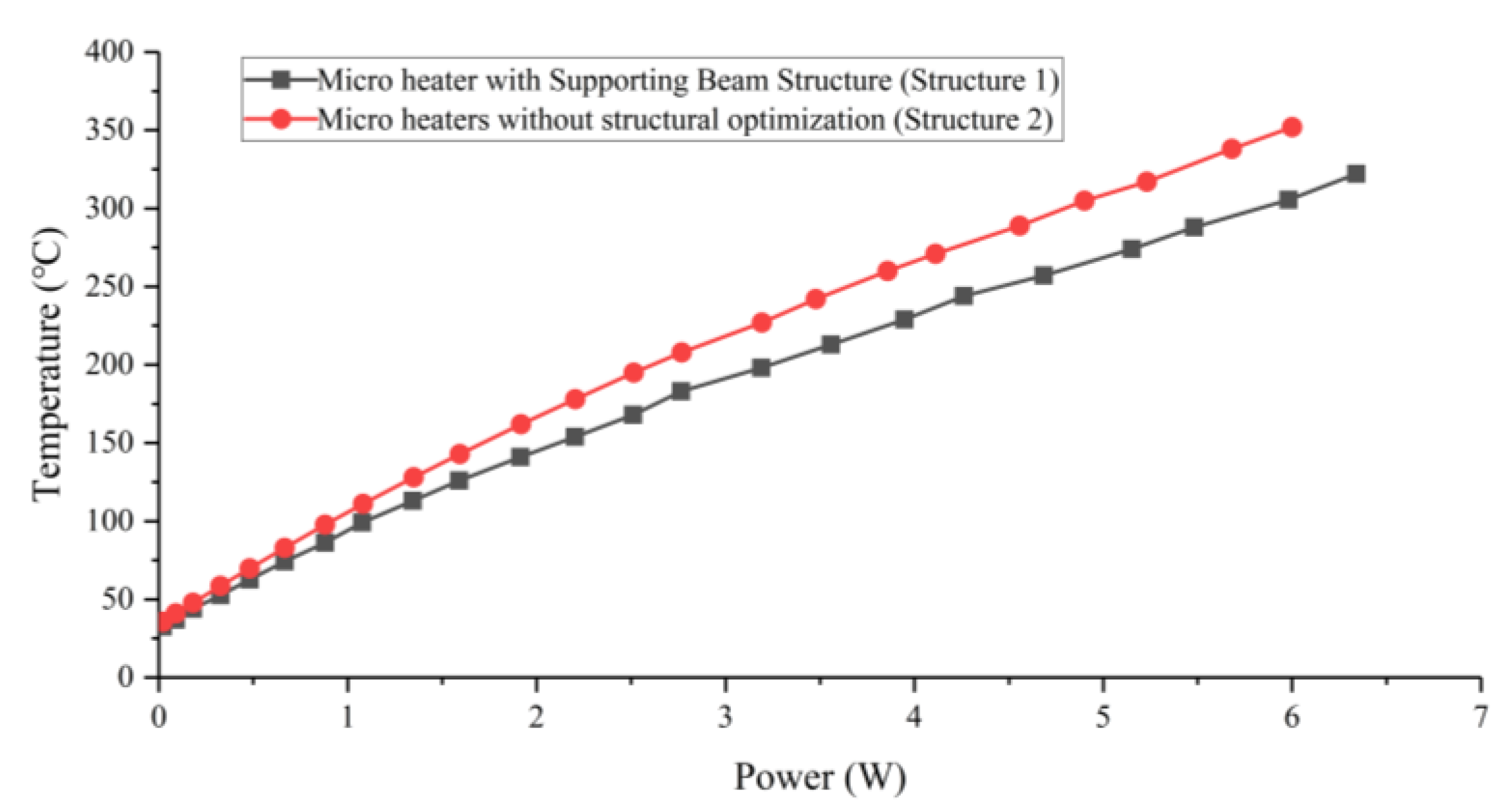

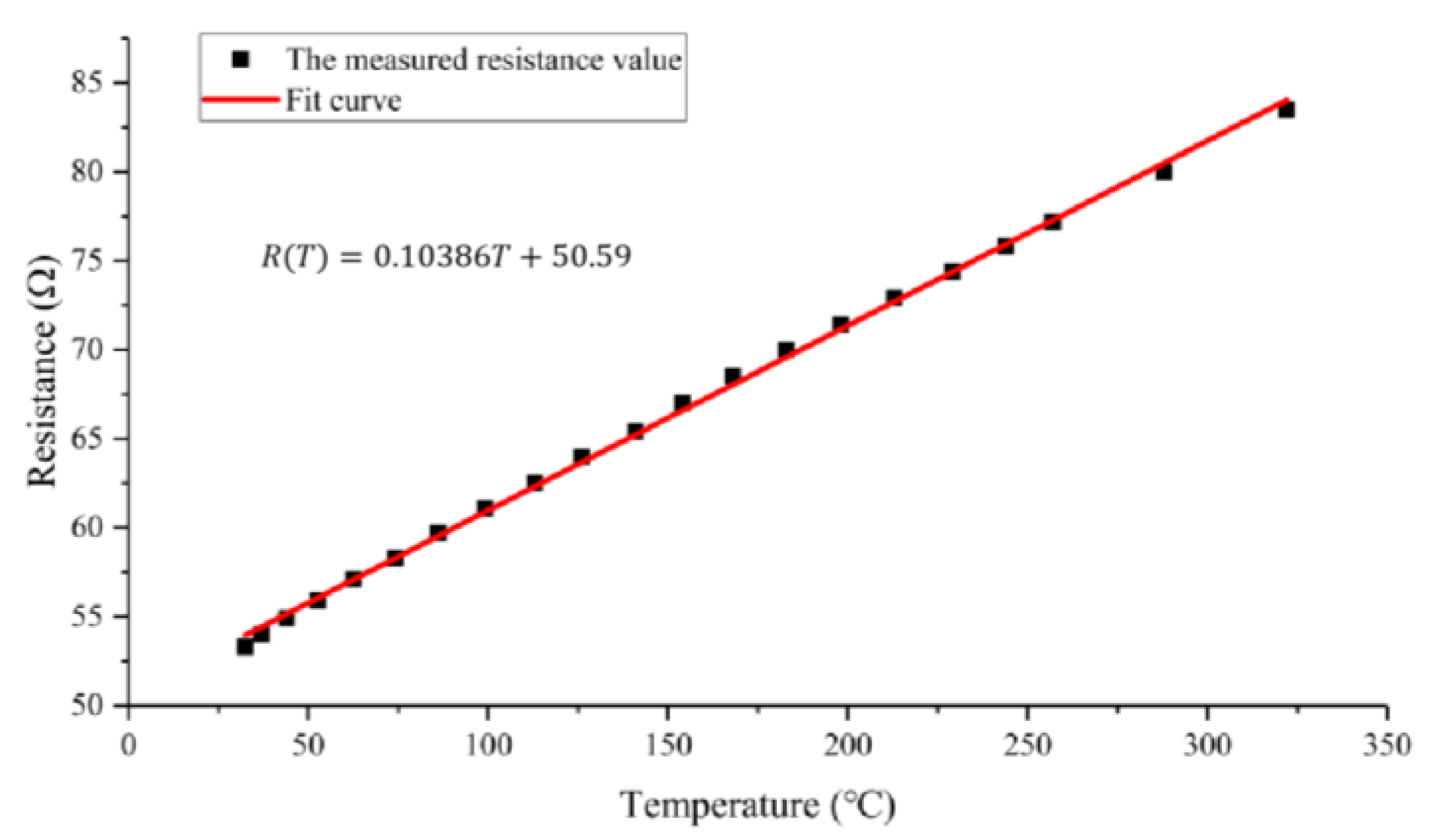

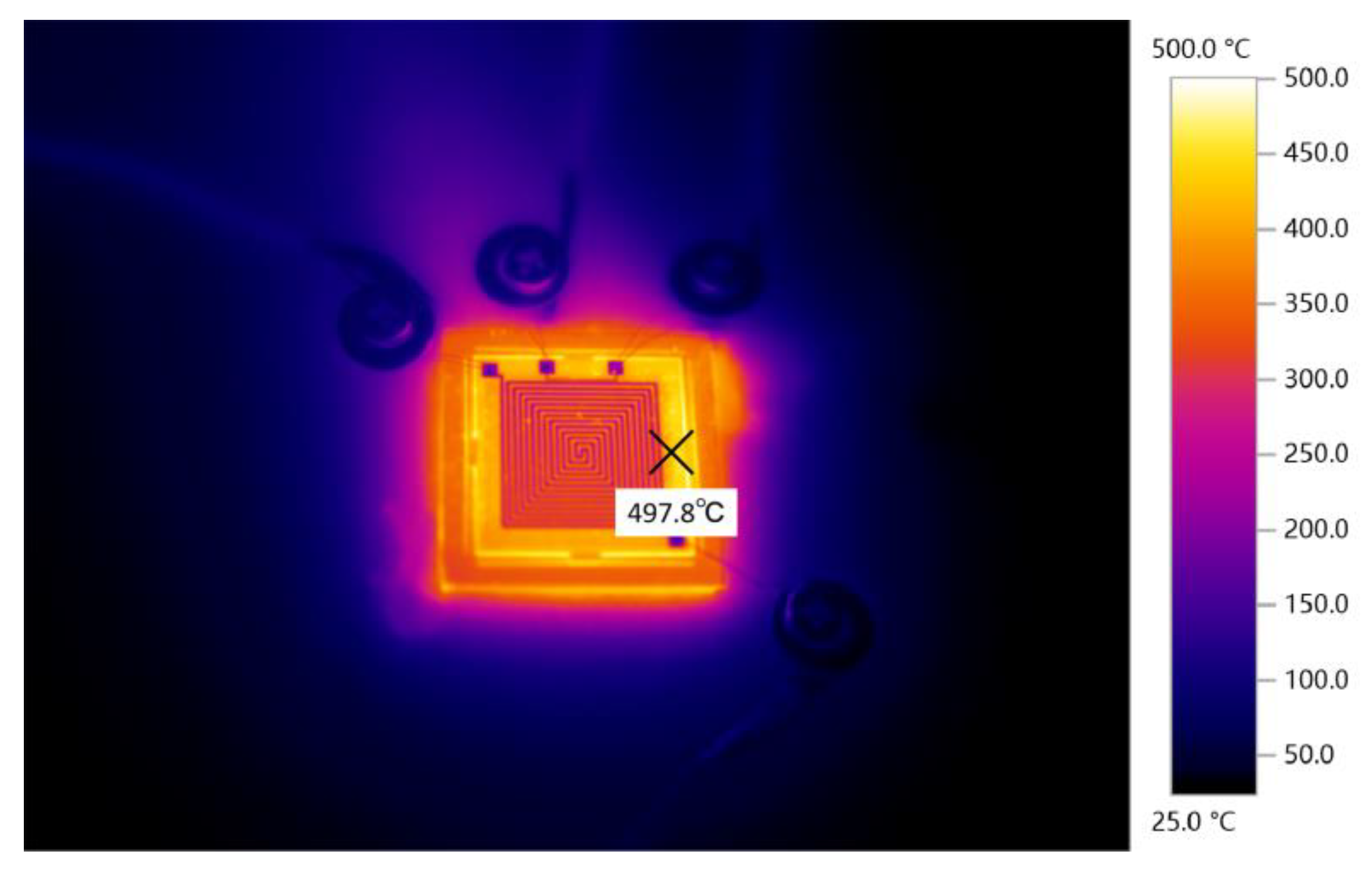

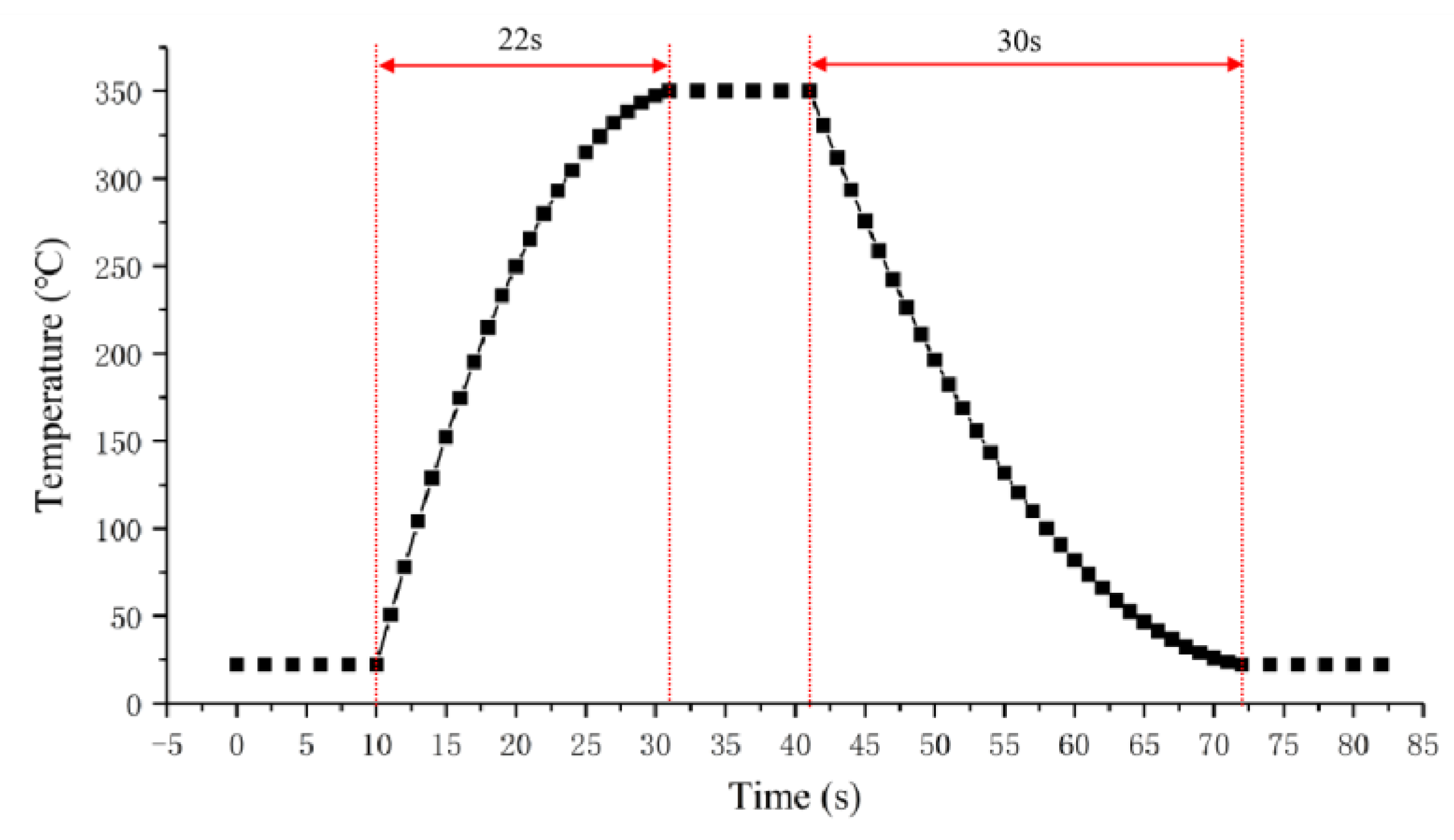

3.1. Electrical–Thermal Characteristics

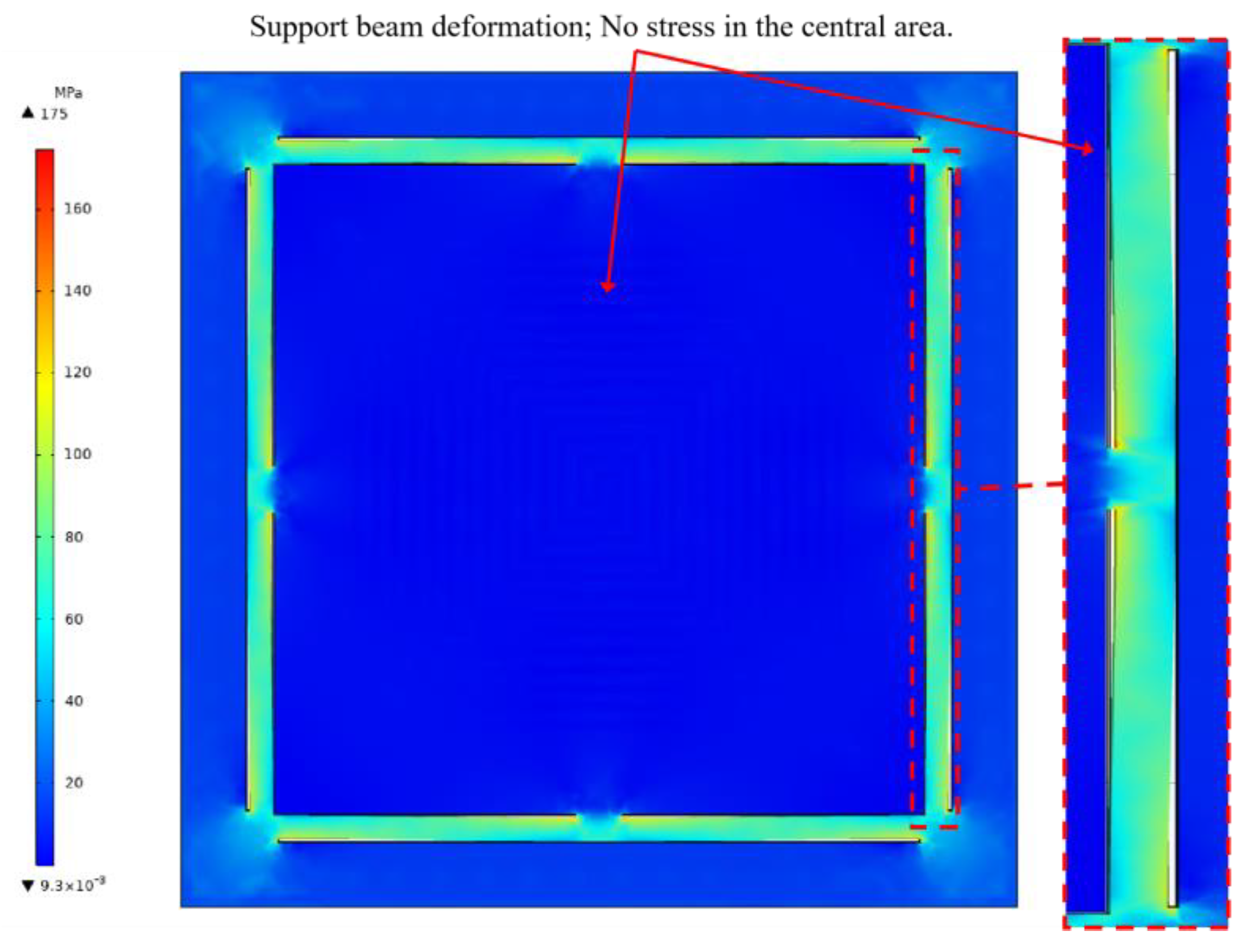

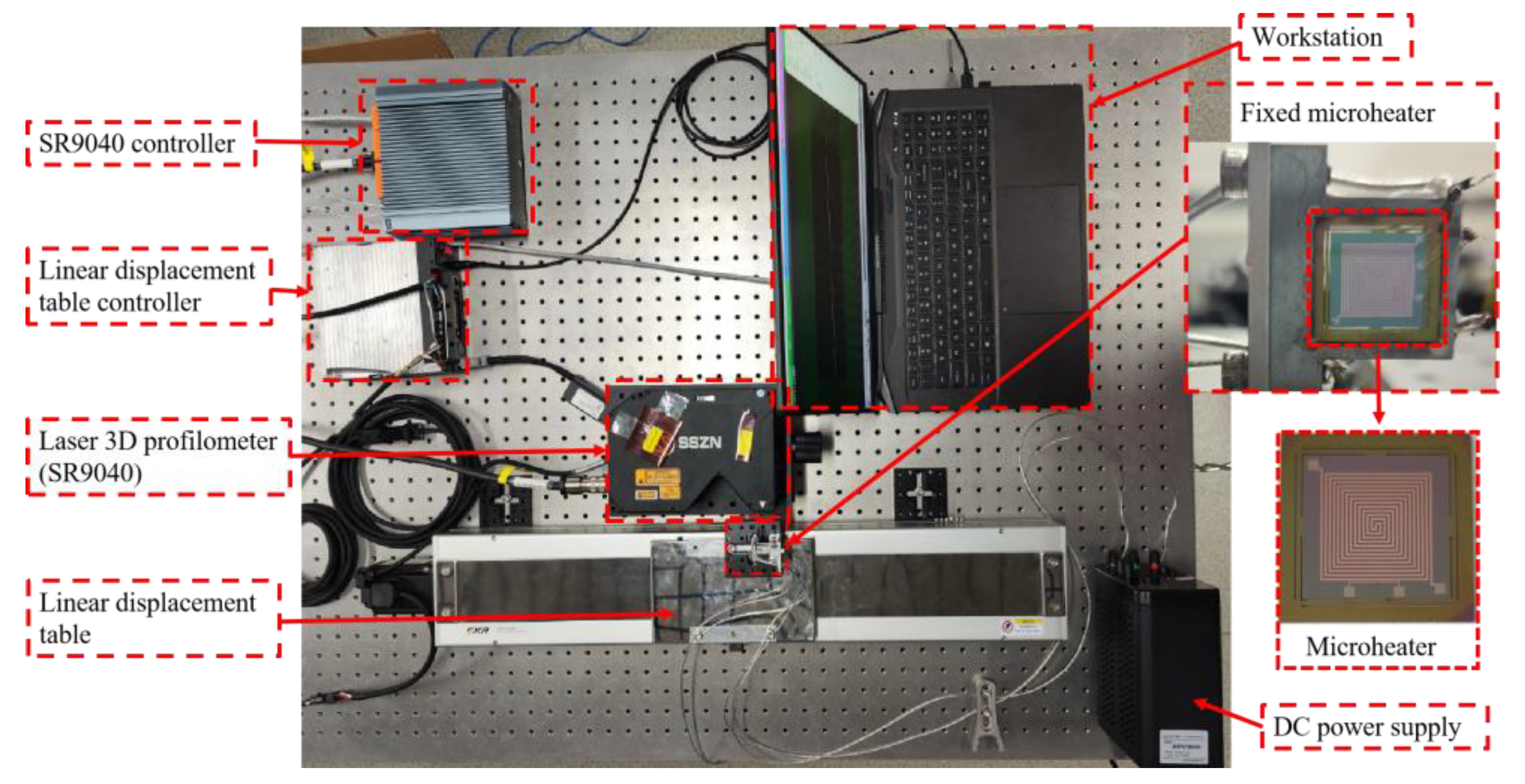

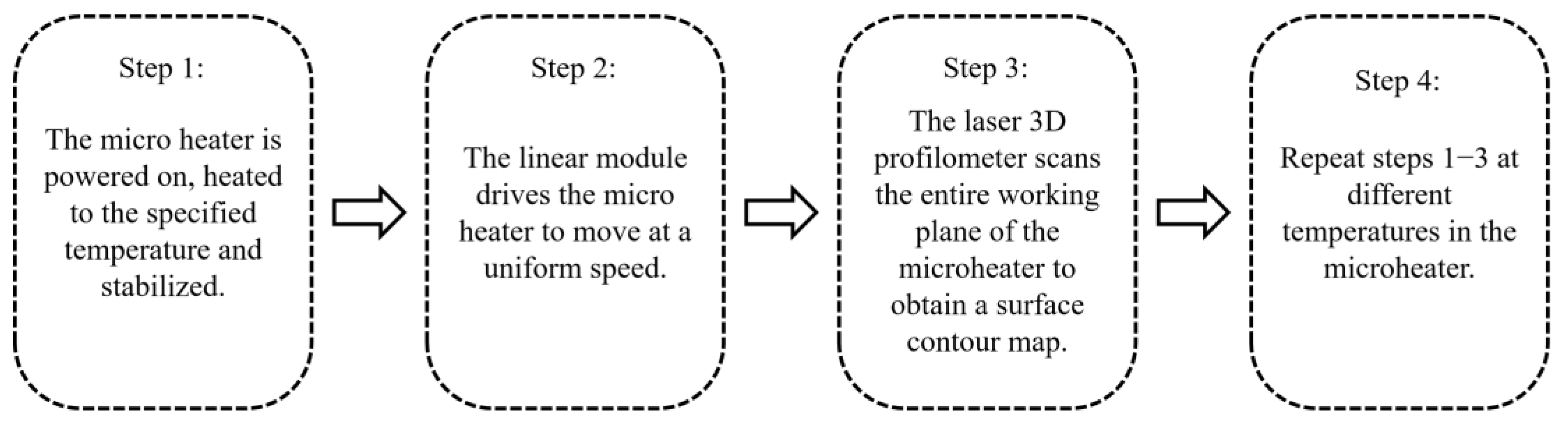

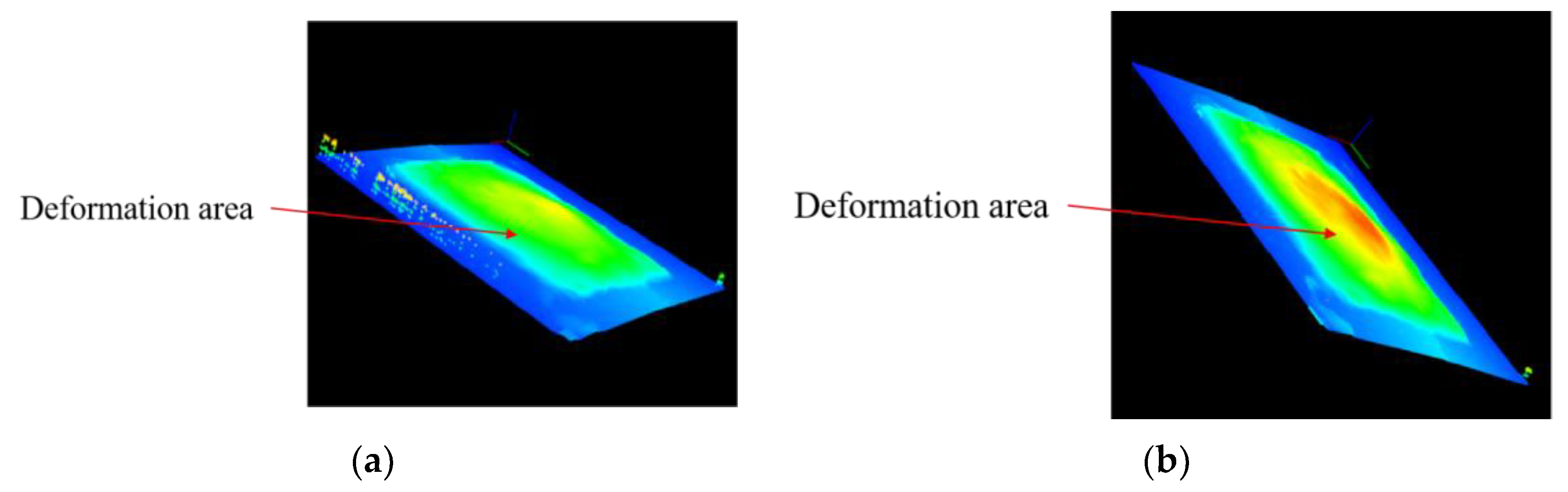

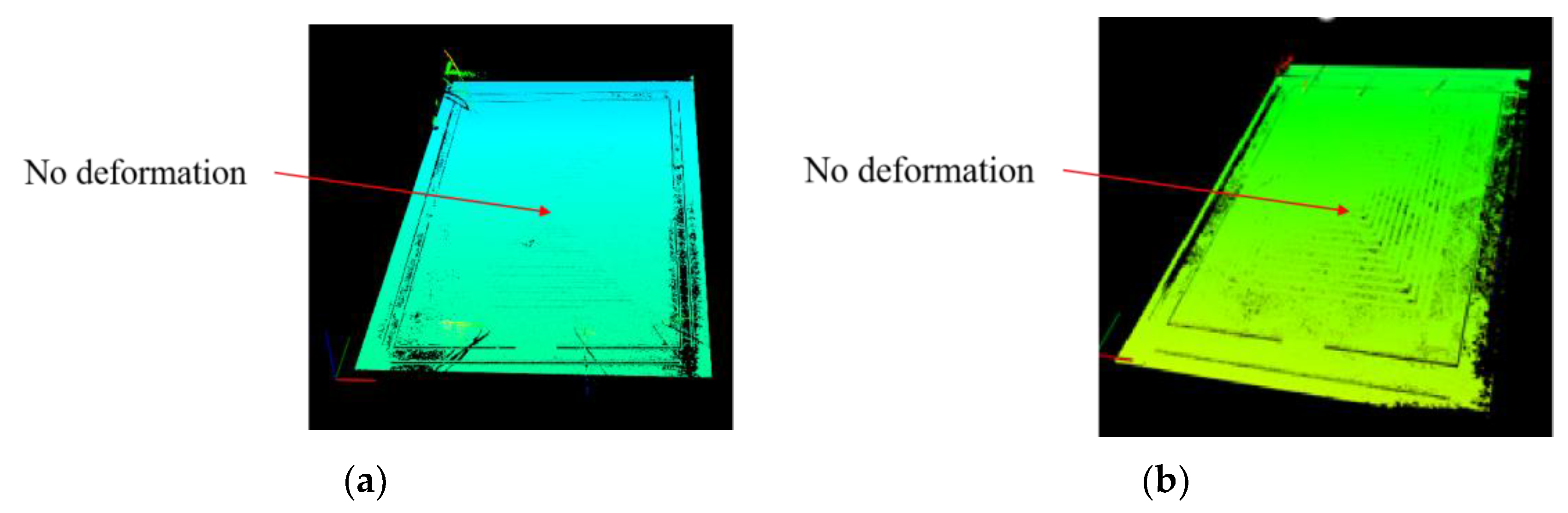

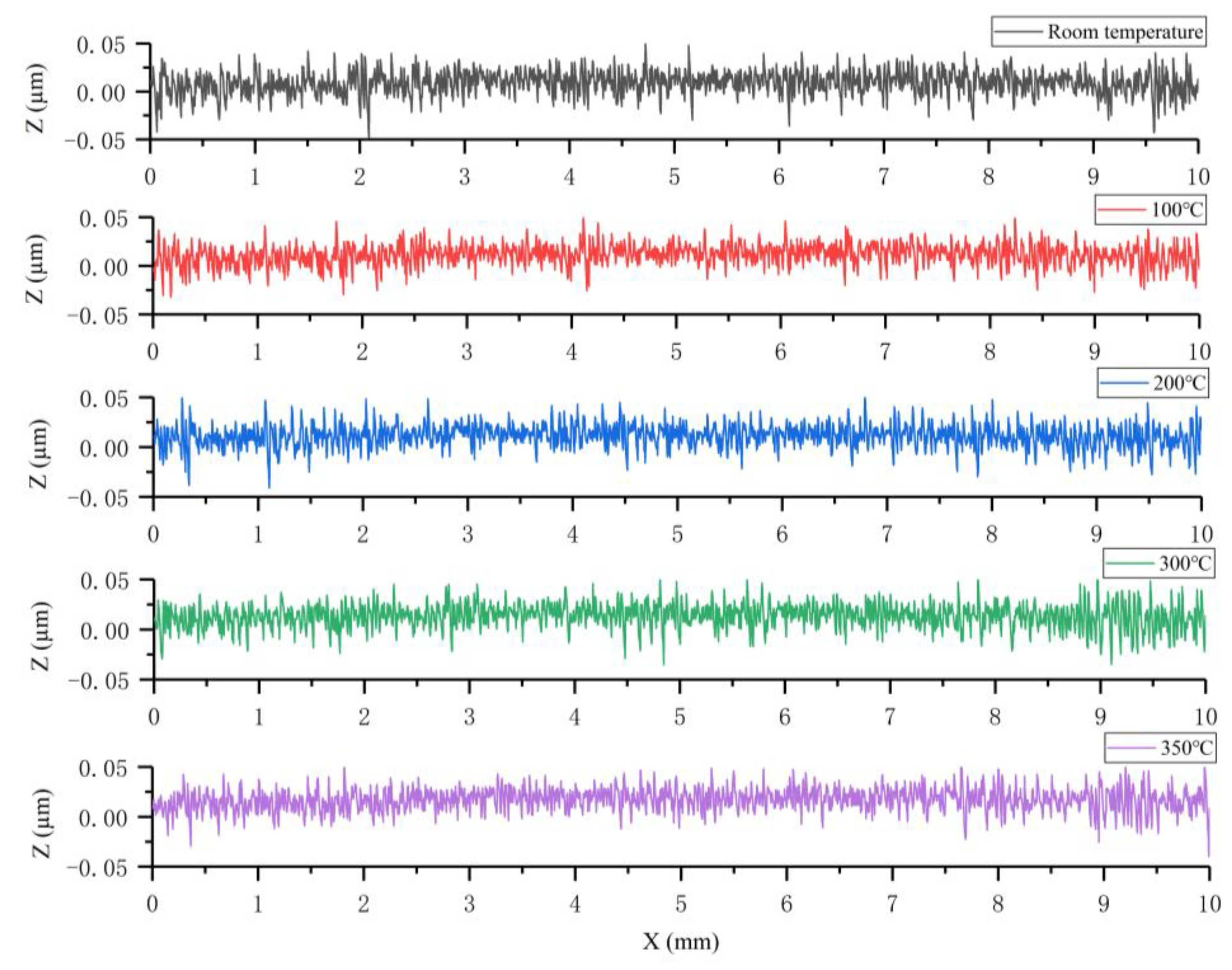

3.2. Electrical–Thermal Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, K.; Bu, Y.; Wang, H. Advances on in situ TEM mechanical testing techniques: A retrospective and perspective view. Front. Mater. 2023, 10, 1207024. [Google Scholar] [CrossRef]

- Gai, P.L.; Boyes, E.D.; Brydson, R.; Catlow, R. Dynamic in situ microscopy relating structure and function. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2020, 378, 20190596. [Google Scholar] [CrossRef] [PubMed]

- Gai, P.L.; Boyes, E.D. Advances in Atomic Resolution In Situ Environmental Transmission Electron Microscopy and 1Å Aberration Corrected In Situ Electron Microscopy. Microsc. Res. Tech. 2009, 72, 153–164. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Zhu, Y.; Ye, H.; He, Y.; Li, H.; Sun, Y.; Yang, F.; Wang, R. Atomic-Scale Structure Dynamics of Nanocrystals Revealed by In Situ and Environmental Transmission Electron Microscopy. Adv. Mater. 2023, 35, e2206911. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Zhao, H.; He, Y.; Wang, R. In-situ transmission electron microscopy for probing the dynamic processes in materials. J. Phys. D Appl. Phys. 2021, 54, 443002. [Google Scholar] [CrossRef]

- Zhou, W.H.; Li, X.Y.; Yao, F.L.; Zhang, H.Z.; Sun, K.; Chen, F.; Xu, P.C.; Li, X.X. Chip-Based MEMS Platform for Thermogravimetric/Differential Thermal Analysis (TG/DTA) Joint Characterization of Materials. Micromachines 2022, 13, 445. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Tian, J.; Lin, Z.; You, M.; Liu, J.; Wang, X. Development of a high throughput micro-heater array with controllable temperature for each heating unit. Microsyst. Technol. Micro-Nanosyst. Inf. Storage Process. Syst. 2020, 26, 787–792. [Google Scholar] [CrossRef]

- Gaulandris, F.; Simonsen, S.B.; Wagner, J.B.; Molhave, K.; Muto, S.; Kuhn, L.T. Methods for Calibration of Specimen Temperature During in situ Transmission Electron Microscopy Experiments. Microsc. Microanal. 2020, 26, 3–17. [Google Scholar] [CrossRef]

- Samaeifar, F.; Hajghassem, H.; Afifi, A.; Abdollahi, H. Implementation of high-performance MEMS platinum micro-hotplate. Sens. Rev. 2015, 35, 116–124. [Google Scholar] [CrossRef]

- Wang, B.; Haque, M.A. In Situ Microstructural Control and Mechanical Testing Inside the Transmission Electron Microscope at Elevated Temperatures. Jom 2015, 67, 1713–1720. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Lemaire, E.; Euphrasie, S.; Thiery, L.; Teyssieux, D.; Briand, D.; Vairac, P. Microfabricated high temperature sensing platform dedicated to scanning thermal microscopy (SThM). Sens. Actuators A Phys. 2018, 275, 109–118. [Google Scholar] [CrossRef]

- Hwang, W.-J.; Shin, K.-S.; Roh, J.-H.; Lee, D.-S.; Choa, S.-H. Development of Micro-Heaters with Optimized Temperature Compensation Design for Gas Sensors. Sensors 2011, 11, 2580–2591. [Google Scholar] [CrossRef]

- Xu, L.; Li, T.; Gao, X.; Wang, Y. Development of a Reliable Micro-Hotplate with Low Power Consumption. IEEE Sens. J. 2011, 11, 913–919. [Google Scholar] [CrossRef]

- Trawick, M.L.; Angelescu, D.E.; Chaikin, P.M.; Valenti, M.J.; Register, R.A. A replaceable, low thermal mass hot stage for scanning probe microscopy. Rev. Sci. Instrum. 2003, 74, 1390–1392. [Google Scholar] [CrossRef]

- van Omme, J.T.; Zakhozheva, M.; Spruit, R.G.; Sholkina, M.; Garza, H.H.P. Advanced microheater for in situ transmission electron microscopy; enabling unexplored analytical studies and extreme spatial stability. Ultramicroscopy 2018, 192, 14–20. [Google Scholar] [CrossRef] [PubMed]

- Allard, L.F.; Bigelow, W.C.; Jose-Yacaman, M.; Nackashi, D.P.; Damiano, J.; Mick, S.E. A New MEMS-Based System for Ultra-High-Resolution Imaging at Elevated Temperatures. Microsc. Res. Tech. 2009, 72, 208–215. [Google Scholar] [CrossRef] [PubMed]

- Rao, L.L.R.; Singha, M.K.; Subramaniam, K.M.; Jampana, N.; Asokan, S. Molybdenum Microheaters for MEMS-Based Gas Sensor Applications: Fabrication, Electro-Thermo-Mechanical and Response Characterization. IEEE Sens. J. 2017, 17, 22–29. [Google Scholar]

- Adedokun, G.; Geng, L.; Xie, D.; Xu, L. Low power perforated membrane microheater. Sens. Actuators A Phys. 2021, 322, 112607. [Google Scholar] [CrossRef]

- Hotovy, I.; Rehacek, V.; Mika, F.; Lalinsky, T.; Hascik, S.; Vanko, G.; Drzik, M. Gallium arsenide suspended microheater for MEMS sensor arrays. Microsyst. Technol. Micro-Nanosyst. Inf. Storage Process. Syst. 2008, 14, 629–635. [Google Scholar] [CrossRef]

- Lee, B.; Cho, I.; Kang, M.; Yang, D.; Park, I. Thermally/mechanically robust anodic aluminum oxide (AAO) microheater platform for low power chemoresistive gas sensor. J. Micromechanics Microengineering 2023, 33, 085011. [Google Scholar] [CrossRef]

- Singh, S.; Jejusaria, A.; Singh, J.; Vashishath, M.; Kumar, D. Comparative study of titanium, platinum, and titanium nitride thin films for micro-elecrto mechanical systems (MEMS) based micro-heaters. AIP Adv. 2022, 12, 095202. [Google Scholar] [CrossRef]

- Brunetti, G.; Marocco, G.; Di Benedetto, A.; Giorgio, A.; Armenise, M.N.; Ciminelli, C. Design of a large bandwidth 2 × 2 interferometric switching cell based on a sub-wavelength grating. J. Opt. 2021, 23, 085801. [Google Scholar] [CrossRef]

- Creemer, J.F.; Briand, D.; Zandbergen, H.W.; van der Vlist, W.; de Boer, C.R.; de Rooij, N.F.; Sarro, P.M. Microhotplates with TiN heaters. Sens. Actuators A Phys. 2008, 148, 416–421. [Google Scholar] [CrossRef]

- Jithin, M.A.; Ganapathi, K.L.; Vikram, G.; Udayashankar, N.K.; Mohan, S. Pulsed DC magnetron sputtered titanium nitride thin films for localized heating applications in MEMS devices. Sens. Actuators A Phys. 2018, 272, 199–205. [Google Scholar]

- Jeroish, Z.E.; Bhuvaneshwari, K.S.; Samsuri, F.; Narayanamurthy, V. Microheater: Material, design, fabrication, temperature control, and applications-a role in COVID-19. Biomed. Microdevices 2022, 24, 3. [Google Scholar] [CrossRef]

- Kim, H.J.K.; Kaplan, K.E.; Schindler, P.; Xu, S.; Winterkorn, M.M.; Heinz, D.B.; English, T.S.; Provine, J.; Prinz, F.B.; Kenny, T.W. Electrical Properties of Ultrathin Platinum Films by Plasma-Enhanced Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2019, 11, 9594–9599. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Y.; Wang, Q.; Kim, K.-H.; Kwon, S.-H. The Thermal Resistance Performance of WTi Alloy-Thin-Film Temperature Sensors Prepared by Magnetron Sputtering. Appl. Sci. 2023, 13, 4747. [Google Scholar] [CrossRef]

- Gaitas, A.; Zhu, W.; Gulari, N.; Covington, E.; Kurdak, C. Characterization of room temperature metal microbolometers near the metal-insulator transition regime for scanning thermal microscopy. Appl. Phys. Lett. 2009, 95, 153108. [Google Scholar] [CrossRef]

| Material | Thickness (nm) | |

|---|---|---|

| Membrane | Si3N4 (layer S1) | S1 = 300 |

| SiO2 (layer S2) | S2 = 500 | |

| SiO2 (layer S3) | S3 = 500 | |

| Heating resistor | Ti + Pt | 250 |

| Temperature measuring resistor | Ti + Pt | 250 |

| Chip | Si | t = 5 × 105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Pan, Z.; Zhang, C.; Xiong, L.; Yang, C.; Zhang, J.; Shi, M.; Wang, Y.; Qu, W. Development of a Microheater with a Large Heating Area and Low Thermal Stress in the Heating Area. Micromachines 2024, 15, 130. https://doi.org/10.3390/mi15010130

Zhang T, Pan Z, Zhang C, Xiong L, Yang C, Zhang J, Shi M, Wang Y, Qu W. Development of a Microheater with a Large Heating Area and Low Thermal Stress in the Heating Area. Micromachines. 2024; 15(1):130. https://doi.org/10.3390/mi15010130

Chicago/Turabian StyleZhang, Tao, Zequan Pan, Chunhua Zhang, Liuguang Xiong, Chunmei Yang, Jian Zhang, Mengjiao Shi, Yuhang Wang, and Wen Qu. 2024. "Development of a Microheater with a Large Heating Area and Low Thermal Stress in the Heating Area" Micromachines 15, no. 1: 130. https://doi.org/10.3390/mi15010130

APA StyleZhang, T., Pan, Z., Zhang, C., Xiong, L., Yang, C., Zhang, J., Shi, M., Wang, Y., & Qu, W. (2024). Development of a Microheater with a Large Heating Area and Low Thermal Stress in the Heating Area. Micromachines, 15(1), 130. https://doi.org/10.3390/mi15010130