Use of PtC Nanotips for Low-Voltage Quantum Tunneling Applications

Abstract

:1. Introduction

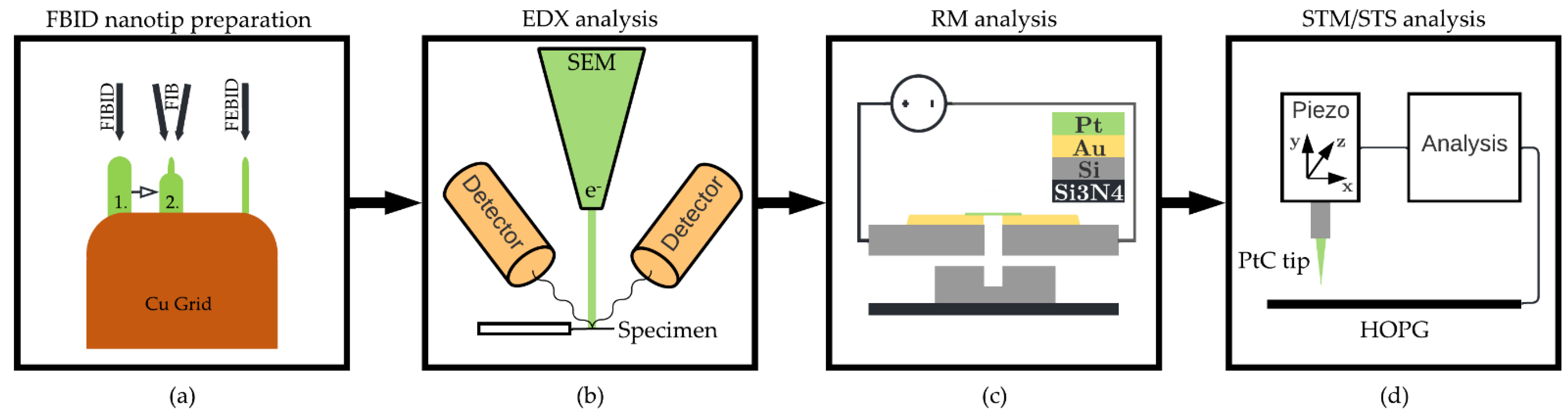

2. Materials and Methods

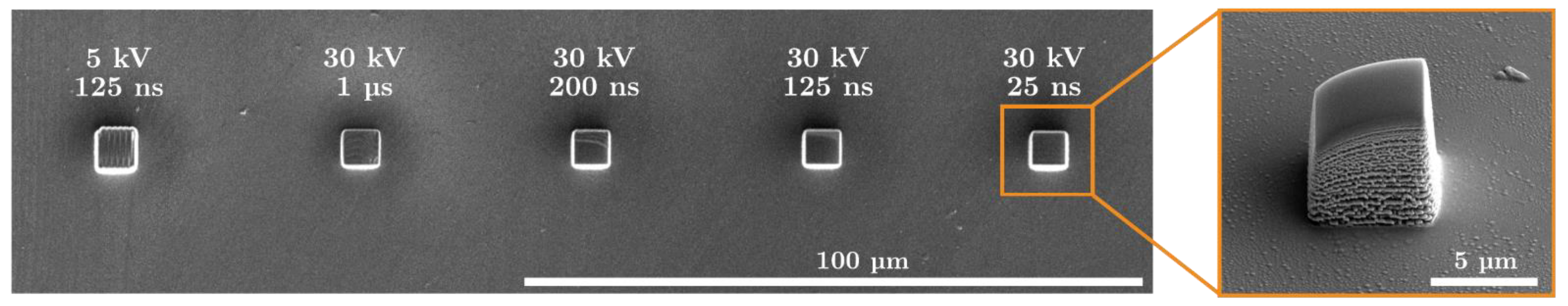

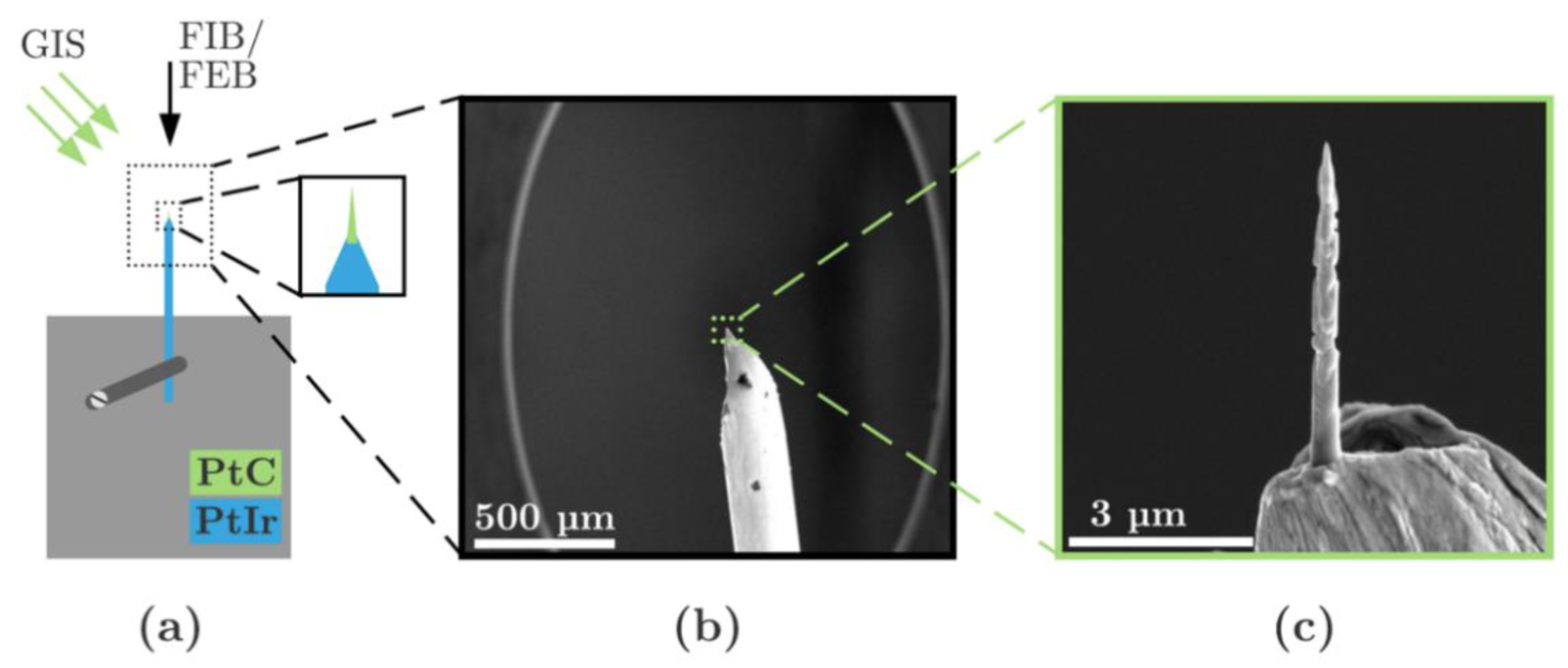

2.1. Platinum Carbon Composite

2.2. Energy Dispersive X-ray Spectroscopy

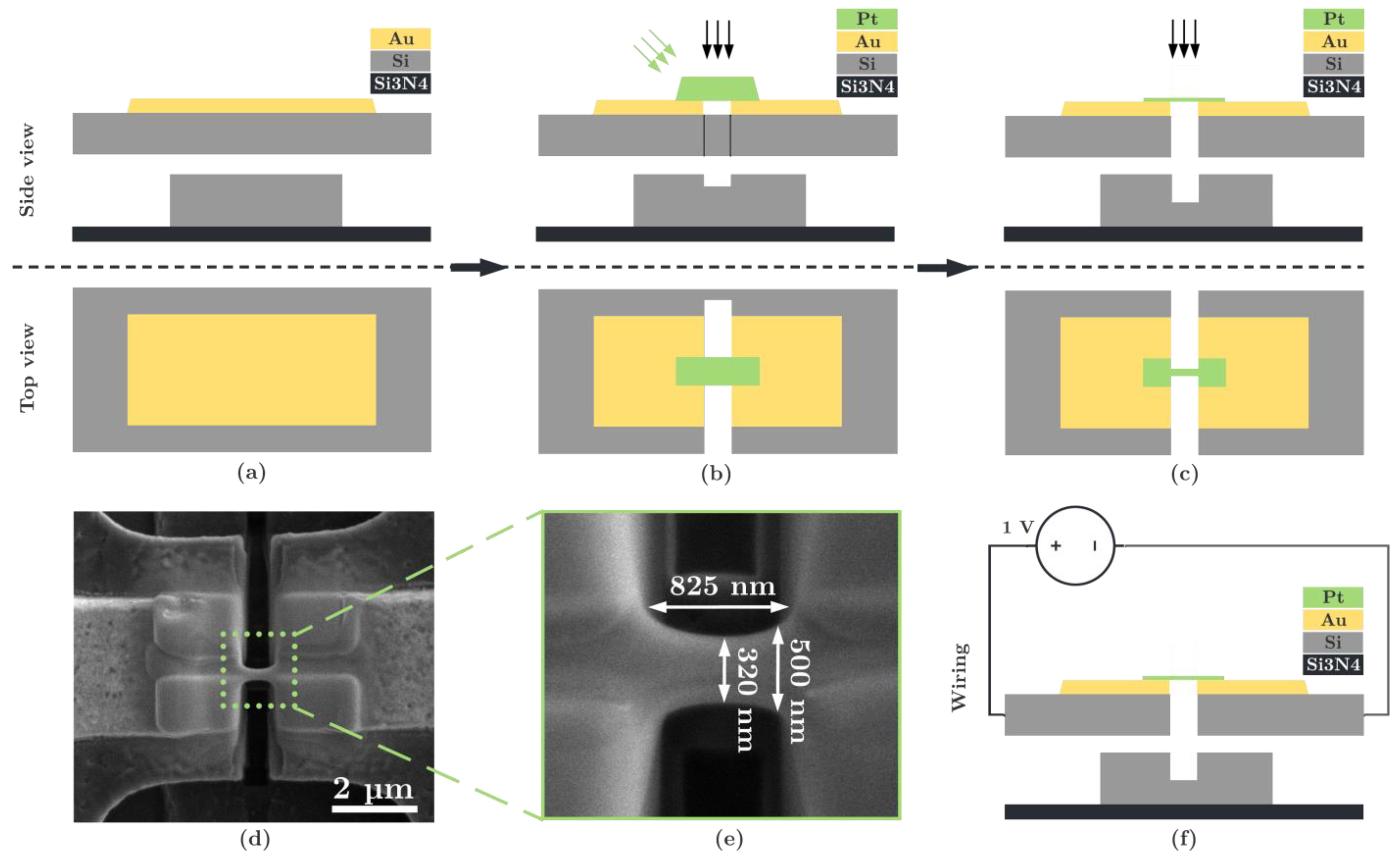

2.3. Resistivity Measurement

2.4. Scanning Tunneling Microscopy

3. Results

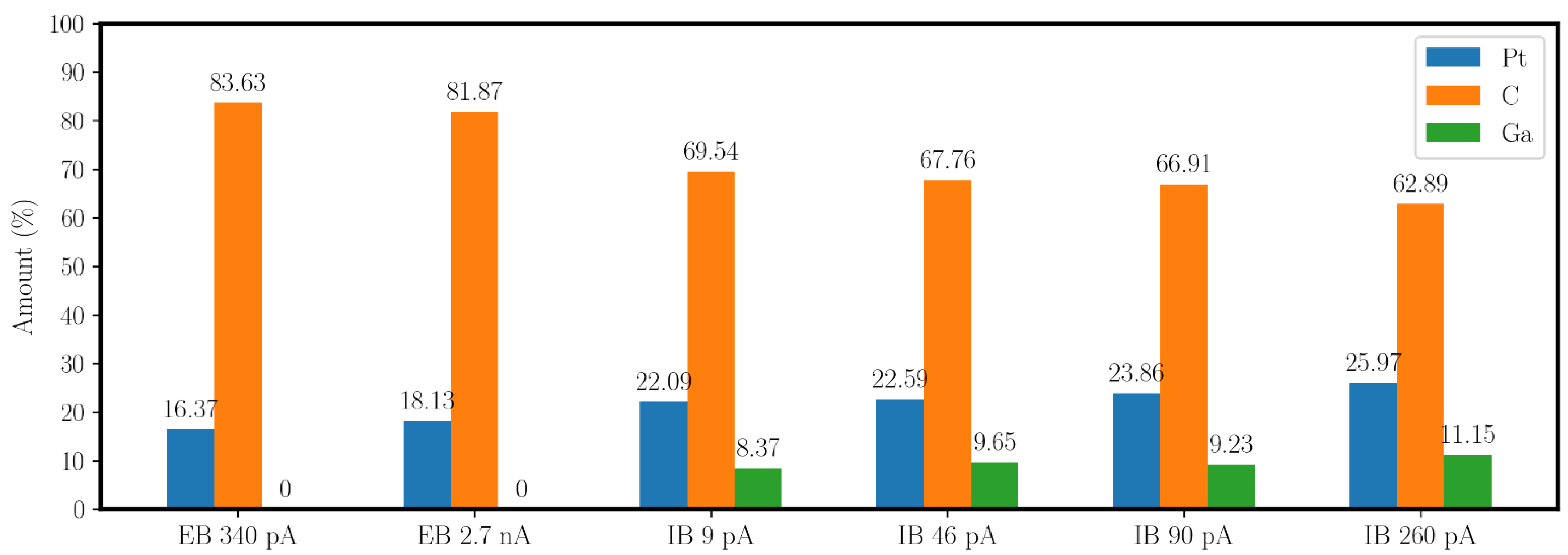

3.1. Energy Dispersive X-ray Spectroscopy

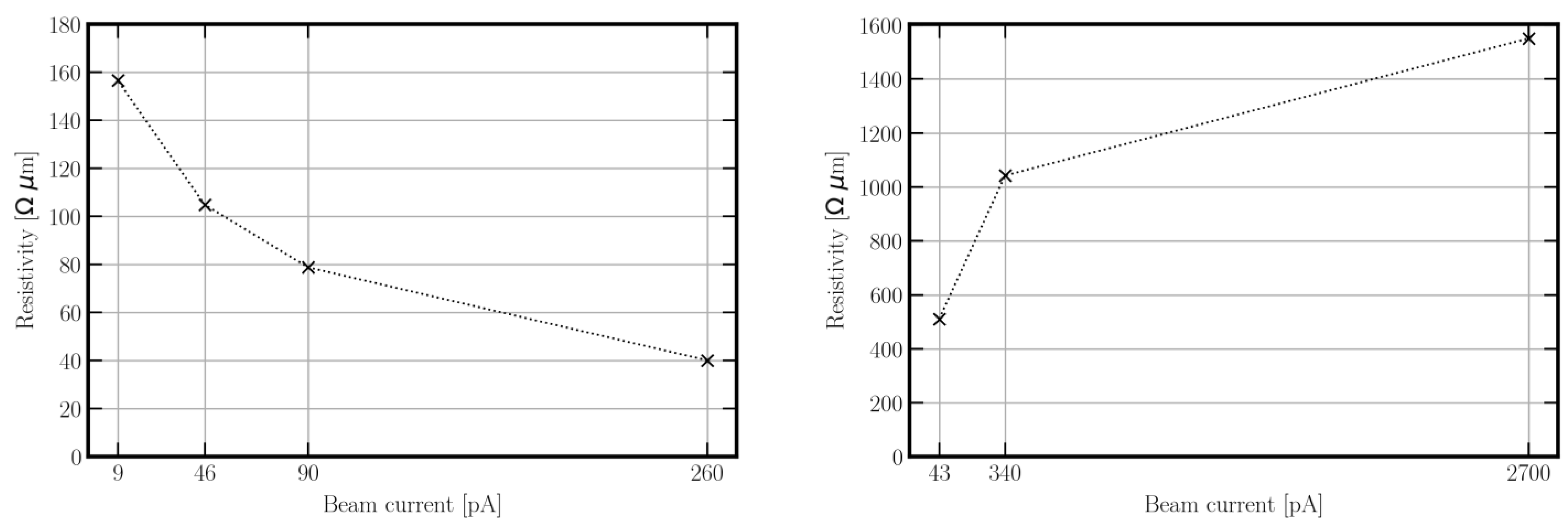

3.2. Resistivity Measurement

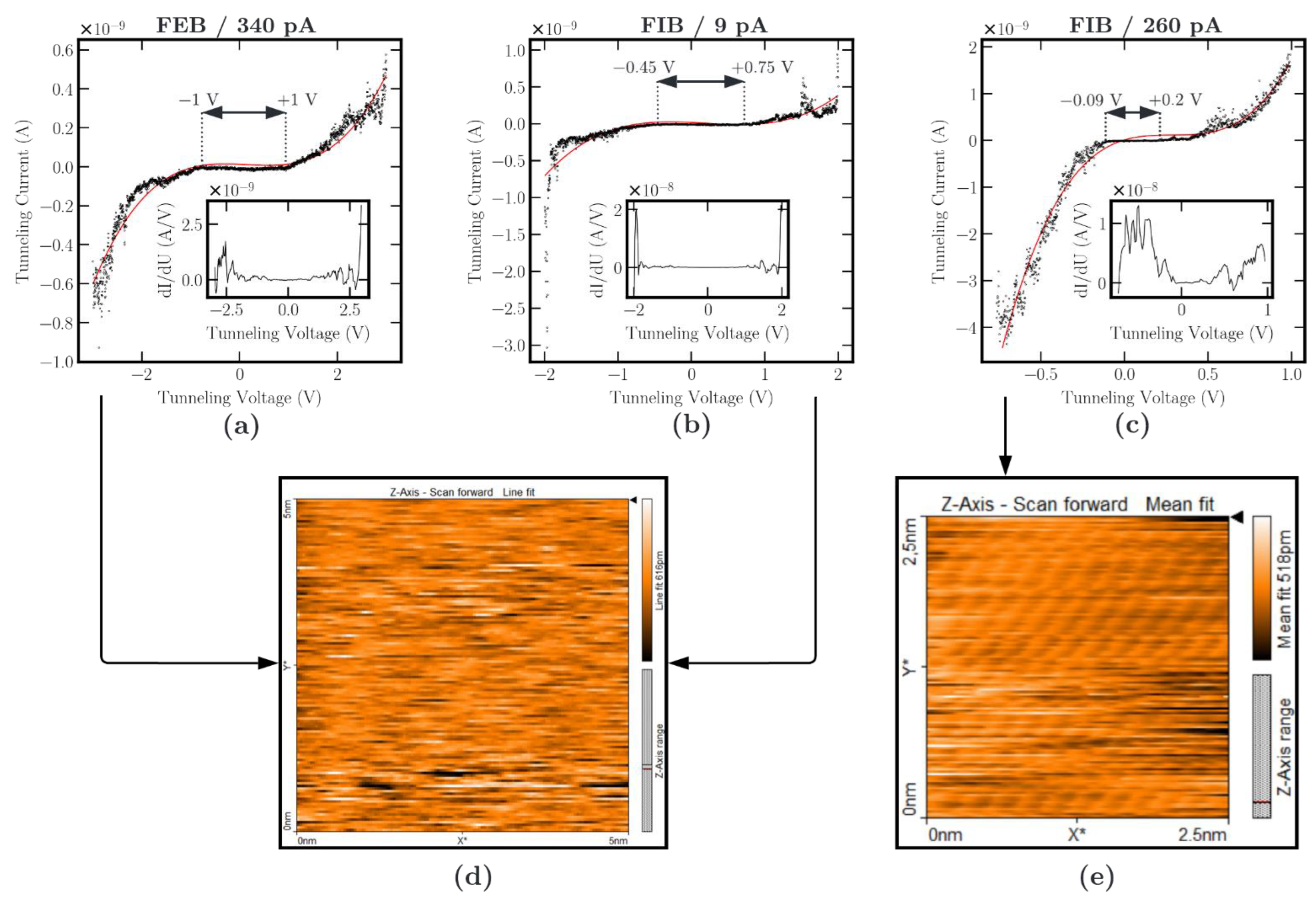

3.3. Scanning Tunneling Microscopy

- Increasing the metallic fraction according to the EDX (Figure 6) analysis;

4. Discussion

5. Summary

- The platinum content must be as high as possible (Figure 6).

- The platinum particles must have the smallest possible size and distance to each other. In the following, the distribution of the particles has a high density because large particles lead to larger spacings and thus higher material resistance. With a similar platinum content, according to EDX analysis (Figure 6), the PtC with smaller particle sizes, based on the HRTEM analysis (Figure 8), shows a lower resistivity.

- For the production of suitable PtC electrodes, the analyses show the following two essential requirements to decrease the electrode band gap (according to STS, Figure 9) and increase the tunneling suitability:

- ○

- The use of FIBID instead of FEBID;

- ○

- The use of the highest possible aperture current (260 pA) for FIBID.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| C | carbon |

| DLC | diamond-like carbon |

| EDX | energy dispersive X-ray spectroscopy |

| EELS | electron energy loss spectroscopy |

| FIB | focused ion beam |

| FEB | focused electron beam |

| FIBID | focused ion beam induced deposition |

| FEBID | focused electron beam induced deposition |

| GIS | gas injection system |

| Ga | gallium |

| HRTEM | high-resolution transmission electron microscopy |

| HOPG | highly oriented pyrolytic graphite |

| I/U | current/voltage |

| MEMS | microelectromechanical system |

| PCB | printed circuit board |

| Pt | platinum |

| PtIr | platinum iridium |

| PtC | platinum carbon |

| PolySi | polysilicon |

| RM | resistance measurement |

| SEM | scanning electron microscopy |

| SMU | source measuring unit |

| Si3N4 | silicon nitride |

| STM | scanning tunneling microscope |

| STS | scanning tunneling spectroscopy |

| TEM | transmission electron microscopy |

| XPS | X-ray photoelectron spectroscopy |

References

- Baski, A.A.; Albrecht, T.R.; Quate, C.F. Tunnelling accelerometer. J. Microsc. 1988, 152, 73–76. [Google Scholar] [CrossRef]

- Waltman, S.B.; Kaiser, W.J. An electron tunneling sensor. Sens. Actuators 1989, 19, 201–210. [Google Scholar] [CrossRef]

- Kenny, T.W.; Waltman, S.B.; Reynolds, J.K.; Kaiser, W.J. Micromachined silicon tunnel sensor for motion detection. Appl. Phys. Lett. 1991, 58, 100–102. [Google Scholar] [CrossRef]

- Kenny, T.W.; Kaiser, W.J.; Reynolds, J.K.; Podosek, J.A.; Rockstad, H.K.; Vote, E.C.; Waltman, S.B. Electron tunnel sensors. J. Vac. Sci. Technol. A Vac. Surf. Film. 1992, 10, 2114–2118. [Google Scholar] [CrossRef]

- Yeh, C.; Najafi, K. A low-voltage tunneling-based silicon microaccelerometer. IEEE Trans. Electron Devices 1997, 44, 1875–1882. [Google Scholar] [CrossRef]

- Strobelt, T. Hochauflösende Beschleunigungssensoren Mit Tunneleffekt; Hahn-Schickard-Gesellschaft für Angewandte Forschung e.v.: Villingen-Schwenningen, Germany, 2000. [Google Scholar]

- Dong, H.; Jia, Y.; Hao, Y.; Shen, S. A novel out-of-plane MEMS tunneling accelerometer. Sens. Actuators A Phys. 2005, 120, 360–364. [Google Scholar] [CrossRef]

- Miao, M.; Hu, Q.; Hao, Y.; Dong, H.; Zhang, H. A bulk micromachined Si-on-glass tunneling accelerometer. In Proceedings of the First International Conference on Integration and Commercialization of Micro and Nanosystems, Parts A and B, ASMEDC, Sanya, China, 10–13 January 2007; pp. 505–512. [Google Scholar]

- Rockstad, H.K.; Tang, T.K.; Reynolds, J.K.; Kenny, T.W.; Kaiser, W.J.; Gabrielson, T.B. A miniature, high-sensitivity, electron tunneling accelerometer. Sens. Actuators A Phys. 1996, 53, 227–231. [Google Scholar] [CrossRef]

- Hartwell, P.G.; Bertsch, F.M.; Miller, S.A.; Turner, K.L.; MacDonald, N.C. Single mask lateral tunneling accelerometer. In Proceedings of the Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS), Heidelburg, Germany, 25–29 January 1998; IEEE: New York, NY, USA, 2002; pp. 340–344. [Google Scholar]

- Burgner, C.; Yie, Z.; Kataria, N.; Oropeza, L.; Astrom, K.; Brewer, F.; Turner, K. Digital control of tunneling accelerometer. In Proceedings of the 2009 IEEE Sensors, Christchurch, New Zealand, 25–28 October 2009; IEEE: New York, NY, USA, 2010; pp. 1824–1827. [Google Scholar]

- Kubena, R.L.; Atkinson, G.M.; Robinson, W.P.; Stratton, F.P. A new miniaturized surface micromachined tunneling accelerometer. IEEE Electron Device Lett. 1996, 17, 306–308. [Google Scholar] [CrossRef]

- Haub, M.; Bogner, M.; Guenther, T.; Zimmermann, A.; Sandmaier, H. Development and proof of concept of a miniaturized mems quantum tunneling accelerometer based on PtC tips by focused ion beam 3D nano-patterning. Sensors 2021, 21, 3795. [Google Scholar] [CrossRef]

- Peñate-Quesada, L.; Mitra, J.; Dawson, P. Non-linear electronic transport in Pt nanowires deposited by focused ion beam. Nanotechnology 2007, 18, 215203. [Google Scholar] [CrossRef]

- Ballestar, A.; Esquinazi, P. Transport characteristics of focused beam deposited nanostructures. Nanofabrication 2015, 2, 1–18. [Google Scholar] [CrossRef]

- Fernández-Pacheco, A.; de Teresa, J.M.; Córdoba, R.; Ibarra, M.R. Metal-insulator transition in Pt-C nanowires grown by focused-ion-beam-induced deposition. Phys. Rev. B 2009, 79, 174204. [Google Scholar] [CrossRef]

- Rotkina, L.; Lin, J.-F.; Bird, J.P. Nonlinear current-voltage characteristics of pt nanowires and nanowire transistors fabricated by electron-beam deposition. Appl. Phys. Lett. 2003, 83, 4426–4428. [Google Scholar] [CrossRef]

- Fransson, J.; Lin, J.-F.; Rotkina, L.; Bird, J.P.; Bennett, P.A. Signatures of bandlike tunneling in granular nanowires. Phys. Rev. B 2005, 72, 113411. [Google Scholar] [CrossRef] [Green Version]

- Samanta, S.; Lee, M.; Kim, D.-S.; Kim, J.; Wang, L. High-pressure triggered quantum tunneling tuning through classical percolation in a single nanowire of a binary composite. Nano Res. 2019, 12, 1333–1338. [Google Scholar] [CrossRef]

- Kolb, F.; Schmoltner, K.; Huth, M.; Hohenau, A.; Krenn, J.; Klug, A.; List, E.J.W.; Plank, H. Variable tunneling barriers in FEBID based PtC metal-matrix nanocomposites as a transducing element for humidity sensing. Nanotechnology 2013, 24, 305501. [Google Scholar] [CrossRef]

- Schwalb, C.H.; Grimm, C.; Baranowski, M.; Sachser, R.; Porrati, F.; Reith, H.; Das, P.; Müller, J.; Völklein, F.; Kaya, A.; et al. A tunable strain sensor using nanogranular metals. Sensors 2010, 10, 9847–9856. [Google Scholar] [CrossRef]

- Haub, M.; Günther, T.; Bogner, M.; Zimmermann, A. Investigation of focused ion and electron beam platinum carbon nano-tips with transmission electron microscopy for quantum tunneling vacuum gap applications. Appl. Sci. 2021, 11, 11793. [Google Scholar] [CrossRef]

- Matsui, S.; Kaito, T.; Fujita, J.; Komuro, M.; Kanda, K.; Haruyama, Y. Three-dimensional nanostructure fabrication by focused-ion-beam chemical vapor deposition. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2000, 18, 3181–3184. [Google Scholar] [CrossRef]

- Kanda, K.; Igaki, J.; Kato, Y.; Kometani, R.; Saikubo, A.; Matsui, S. NEXAFS study on carbon-based material formed by focused-ion-beam chemical-vapor-deposition. Radiat. Phys. Chem. 2006, 75, 1850–1854. [Google Scholar] [CrossRef]

- Stanishevsky, A.; Khriachtchev, L. Modification of hydrogen-free amorphous carbon films by focused-ion-beam milling. J. Appl. Phys. 1999, 86, 7052–7058. [Google Scholar] [CrossRef]

- Frabboni, S.; Gazzadi, G.C.; Spessot, A. TEM study of annealed Pt nanostructures grown by electron beam-induced deposition. Phys. E: Low-Dimens. Syst. Nanostructures 2007, 37, 265–269. [Google Scholar] [CrossRef]

- Labille, J.; Pelinovskaya, N.; Botta, C.; Bottero, J.-Y.; Masion, A.; Joag, D.S.; Forbes, R.G.; Burger, S.; Pomplun, J.; Schmidt, F.; et al. Focused-ion-beam chemical-vapor-deposition (FIB-CVD). In Encyclopedia of Nanotechnology; Springer: Dordrecht, The Netherlands, 2012; pp. 866–876. [Google Scholar]

- Kometani, R.; Ichihashi, T.; Kanda, K.; Suzuki, T.; Niihara, K.; Ishihara, S.; Kaito, T.; Matsui, S. Resistivity change of the diamondlike carbon, deposited by focused-ion-beam chemical vapor deposition, induced by the annealing treatment. J. Vac. Sci. Technol. B: Microelectron. Nanometer Struct. 2008, 26, 2628–2631. [Google Scholar] [CrossRef]

- de Teresa, J.M.; Córdoba, R.; Fernández-Pacheco, A.; Montero, O.; Strichovanec, P.; Ibarra, M.R. Origin of the difference in the resistivity of as-grown focused-ion- and focused-electron-beam-induced Pt nanodeposits. J. Nanomater. 2009, 2009, 10. [Google Scholar] [CrossRef] [Green Version]

- Koops, H.W.P. Fabrication and characterization of platinum nanocrystalline material grown by electron-beam induced deposition. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1995, 13, 2400–2403. [Google Scholar] [CrossRef]

- van Dorp, W.F.; Hagen, C.W. A critical literature review of focused electron beam induced deposition. J. Appl. Phys. 2008, 104, 081301. [Google Scholar] [CrossRef] [Green Version]

- Utke, I.; Hoffmann, P.; Melngailis, J. Gas-assisted focused electron beam and ion beam processing and fabrication. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2008, 26, 1197–1276. [Google Scholar] [CrossRef] [Green Version]

- Wiedemair, J.; Menegazzo, N.; Pikarsky, J.; Booksh, K.S.; Mizaikoff, B.; Kranz, C. Novel electrode materials based on ion beam induced deposition of platinum carbon composites. Electrochim. Acta 2010, 55, 5725–5732. [Google Scholar] [CrossRef]

- Langford, R.M.; Wang, T.X.; Ozkaya, D. Reducing the resistivity of electron and ion beam assisted deposited Pt. Microelectron. Eng. 2007, 84, 784–788. [Google Scholar] [CrossRef]

- Lin, J.F.; Bird, J.P.; Rotkina, L.; Sergeev, A.; Mitin, V. Large Effects due to electron-phonon-impurity interference in the resistivity of Pt/C-Ga composite nanowires. Appl. Phys. Lett. 2004, 84, 3828–3830. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.-F.; Bird, J.P.; Rotkina, L.; Bennett, P.A. Classical and quantum transport in focused-ion-beam-deposited Pt nanointerconnects. Appl. Phys. Lett. 2003, 82, 802–804. [Google Scholar] [CrossRef]

- An, B.-S.; Kwon, Y.; Oh, J.-S.; Shin, Y.-J.; Ju, J.; Yang, C.-W. Evaluation of ion/electron beam induced deposition for electrical connection using a modern focused ion beam system. Appl. Microsc. 2019, 49, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tao, T. Focused ion beam induced deposition of platinum. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1990, 8, 1826–1829. [Google Scholar] [CrossRef]

- Melngailis, J. Focused ion beam induced deposition: A review. In Proceedings of the Electron-Beam, X-ray, and Ion-Beam Submicrometer Lithographies for Manufacturing, San Jose, CA, USA, 1 August 1991; Peckerar, M.C., Ed.; pp. 36–49. [Google Scholar]

- Faraby, H.; DiBattista, M.; Bandaru, P.R. Percolation of gallium dominates the electrical resistance of focused ion beam deposited metals. Appl. Phys. Lett. 2014, 104, 173107. [Google Scholar] [CrossRef] [Green Version]

- Utke, I.; Michler, J.; Winkler, R.; Plank, H. Mechanical properties of 3D nanostructures obtained by focused electron/ion beam-induced deposition: A review. Micromachines 2020, 11, 397. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reiser, A.; Koch, L.; Dunn, K.A.; Matsuura, T.; Iwata, F.; Fogel, O.; Kotler, Z.; Zhou, N.; Charipar, K.; Piqué, A.; et al. Metals by micro-scale additive manufacturing: Comparison of microstructure and mechanical properties. Adv. Funct. Mater. 2020, 30, 1910491. [Google Scholar] [CrossRef]

- Allen, F.I. Branched high aspect ratio nanostructures fabricated by focused helium ion beam induced deposition of an insulator. Micromachines 2021, 12, 232. [Google Scholar] [CrossRef] [PubMed]

- Belianinov, A.; Burch, M.J.; Ievlev, A.; Kim, S.; Stanford, M.G.; Mahady, K.; Lewis, B.B.; Fowlkes, J.D.; Rack, P.D.; Ovchinnikova, O.S. Direct write of 3D nanoscale mesh objects with platinum precursor via focused helium ion beam induced deposition. Micromachines 2020, 11, 527. [Google Scholar] [CrossRef] [PubMed]

- Alkemade, P.F.A.; Miro, H. Focused helium-ion-beam-induced deposition. Appl. Phys. A 2014, 117, 1727–1747. [Google Scholar] [CrossRef]

- Chen, P.; Veldhoven, E. van Sanford, C.A.; Salemink, H.W.M.; Maas, D.J.; Smith, D.A.; Rack, P.D.; Alkemade, P.F.A. Nanopillar growth by focused helium ion-beam-induced deposition. Nanotechnology 2010, 21, 455302. [Google Scholar] [CrossRef]

- Maas, D.; van Veldhoven, E.; Chen, P.; Sidorkin, V.; Salemink, H.; van der Drift, E.; Alkemade, P. Nanofabrication with a helium ion microscope. Proc. SPIE 2010, 7638, 763814. [Google Scholar]

- Haynes, W.M.; Lide, D.R.; Bruno, T.J. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Bhushan, B. (Ed.) Springer Handbook of Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 978-3-642-02524-2. [Google Scholar]

- NaioSTM Nanosurf. Available online: https://www.nanosurf.com/en/products/naiostm-stm-for-nanoeducation (accessed on 6 December 2021).

- Voigtländer, B. Scanning Probe Microscopy; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-662-45239-4. [Google Scholar]

- Pavlov, A.; Ihantola, H. A new method of scanning tunneling spectroscopy for study of the energy structure of semiconductors and free electron gas in metals. Scanning 1997, 19, 459–465. [Google Scholar] [CrossRef]

- Bardeen, J. Tunnelling from a many-particle point of view. Phys. Rev. Lett. 1961, 6, 57–59. [Google Scholar] [CrossRef]

- Olesen, L.; Brandbyge, M.; Sørensen, M.R.; Jacobsen, K.W.; Lægsgaard, E.; Stensgaard, I.; Besenbacher, F. Apparent barrier height in scanning tunneling microscopy revisited. Phys. Rev. Lett. 1996, 76, 1485–1488. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Current/Beam | Rw (Ω) | Rtotal (Ω) | Length (nm) | Width (nm) | Height (nm) | ρPtC (Ω·μm) | C (%) | Ga (%) | Pt (%) |

|---|---|---|---|---|---|---|---|---|---|

| 9 pA IB | 2547 | 2847 | 292 | 400 | 380 | 156.61 | 69.54 | 8.37 | 22.09 |

| 46 pA IB | 937 | 1090 | 390 | 557 | 480 | 104.93 | 67.76 | 9.65 | 22.59 |

| 90 pA IB | 667 | 785 | 440 | 570 | 516 | 78.86 | 66.91 | 9.23 | 23.86 |

| 260 pA IB | 454 | 555 | 607 | 650 | 370 | 40.15 | 62.89 | 11.15 | 25.97 |

| 43 pA EB | 1700 | 2962 | 428 | 330 | 525 | 510.69 | - | - | - |

| 340 pA EB | 743 | 3273 | 543 | 370 | 607 | 1042.57 | 83.63 | - | 16.37 |

| 2.7 nA EB | 1192 | 3433 | 393 | 400 | 680 | 1551.02 | 81.87 | - | 18.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haub, M.; Guenther, T.; Bogner, M.; Zimmermann, A. Use of PtC Nanotips for Low-Voltage Quantum Tunneling Applications. Micromachines 2022, 13, 1019. https://doi.org/10.3390/mi13071019

Haub M, Guenther T, Bogner M, Zimmermann A. Use of PtC Nanotips for Low-Voltage Quantum Tunneling Applications. Micromachines. 2022; 13(7):1019. https://doi.org/10.3390/mi13071019

Chicago/Turabian StyleHaub, Michael, Thomas Guenther, Martin Bogner, and André Zimmermann. 2022. "Use of PtC Nanotips for Low-Voltage Quantum Tunneling Applications" Micromachines 13, no. 7: 1019. https://doi.org/10.3390/mi13071019

APA StyleHaub, M., Guenther, T., Bogner, M., & Zimmermann, A. (2022). Use of PtC Nanotips for Low-Voltage Quantum Tunneling Applications. Micromachines, 13(7), 1019. https://doi.org/10.3390/mi13071019