Fabrication and Experimental Validation of a Sensitive and Robust Tactile Sensing Array with a Micro-Structured Porous Dielectric Layer

Abstract

1. Introduction

2. Methods and Fabrication

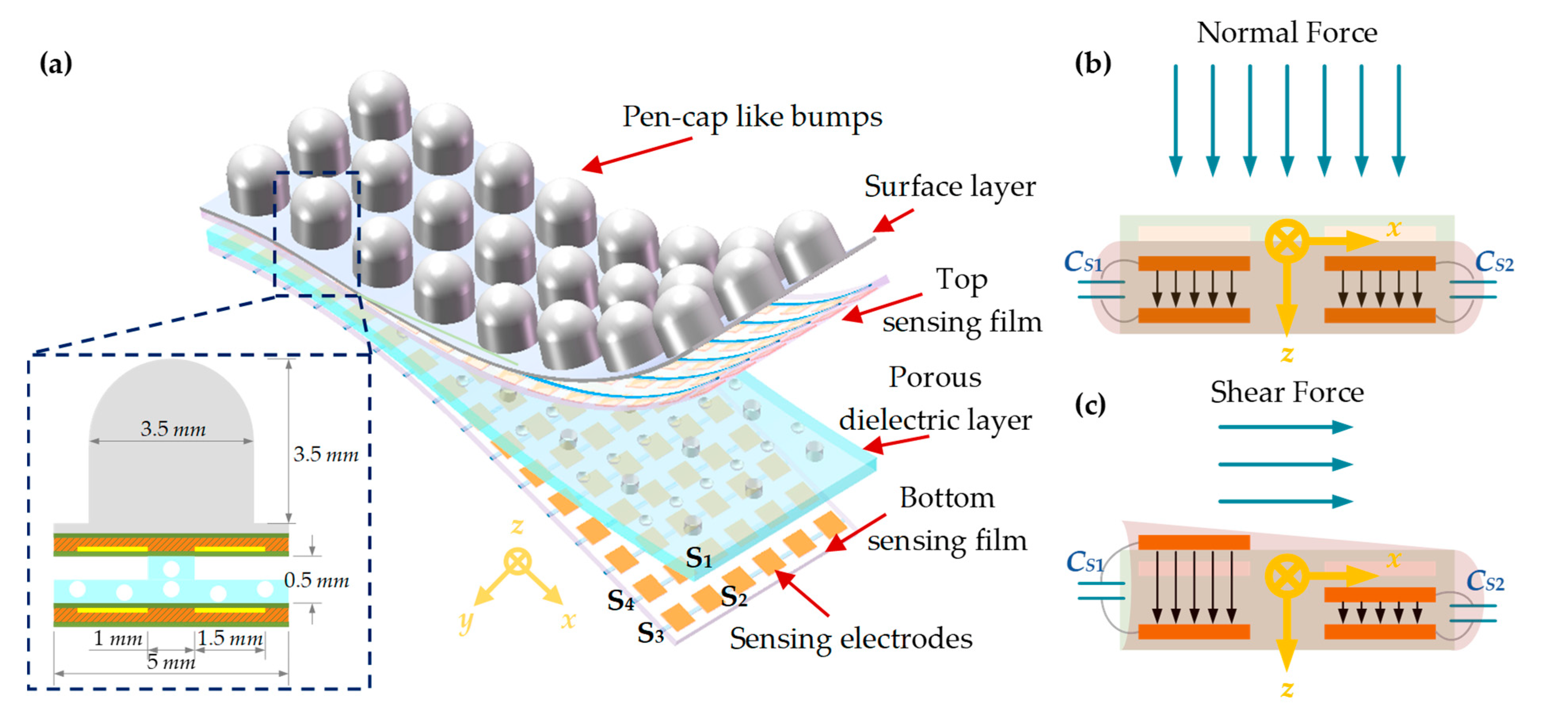

2.1. Design and Method of Three-Axial Tactile Sensing

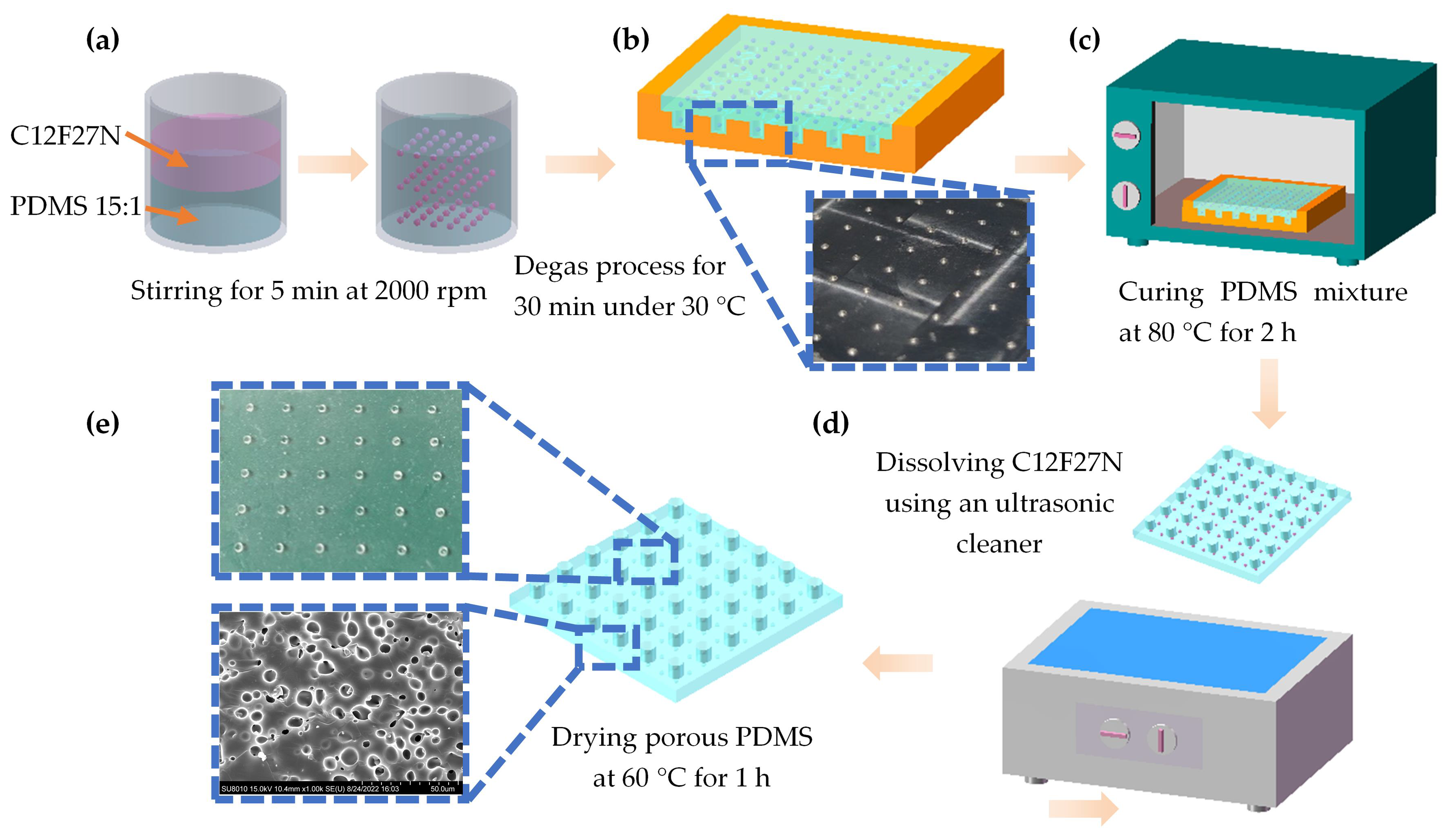

2.2. Preparation of Micro-Structructured Porous PDMS Dielectric Layer

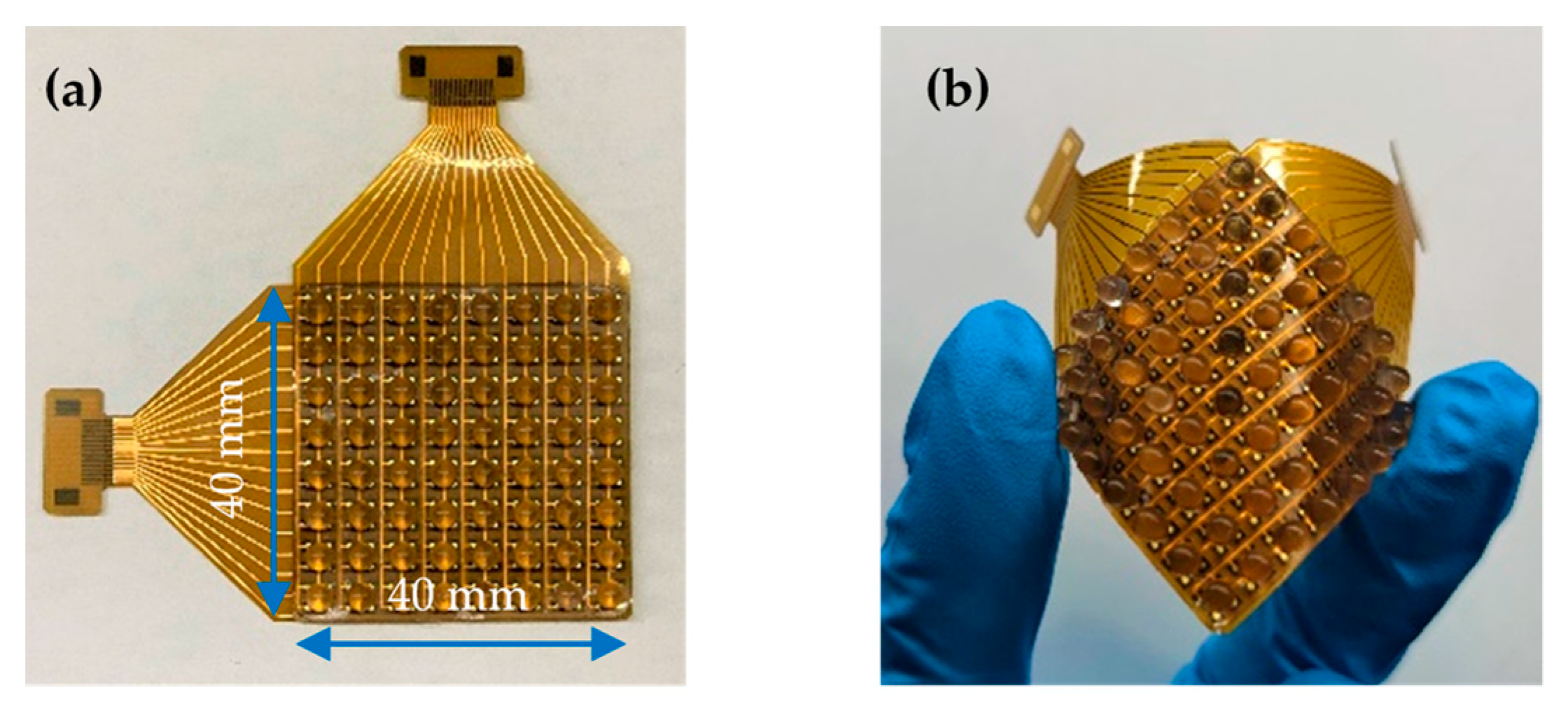

2.3. Fabrication of Capacitive Tactile Sensor

3. Results and Discussion

3.1. Experimental Setup

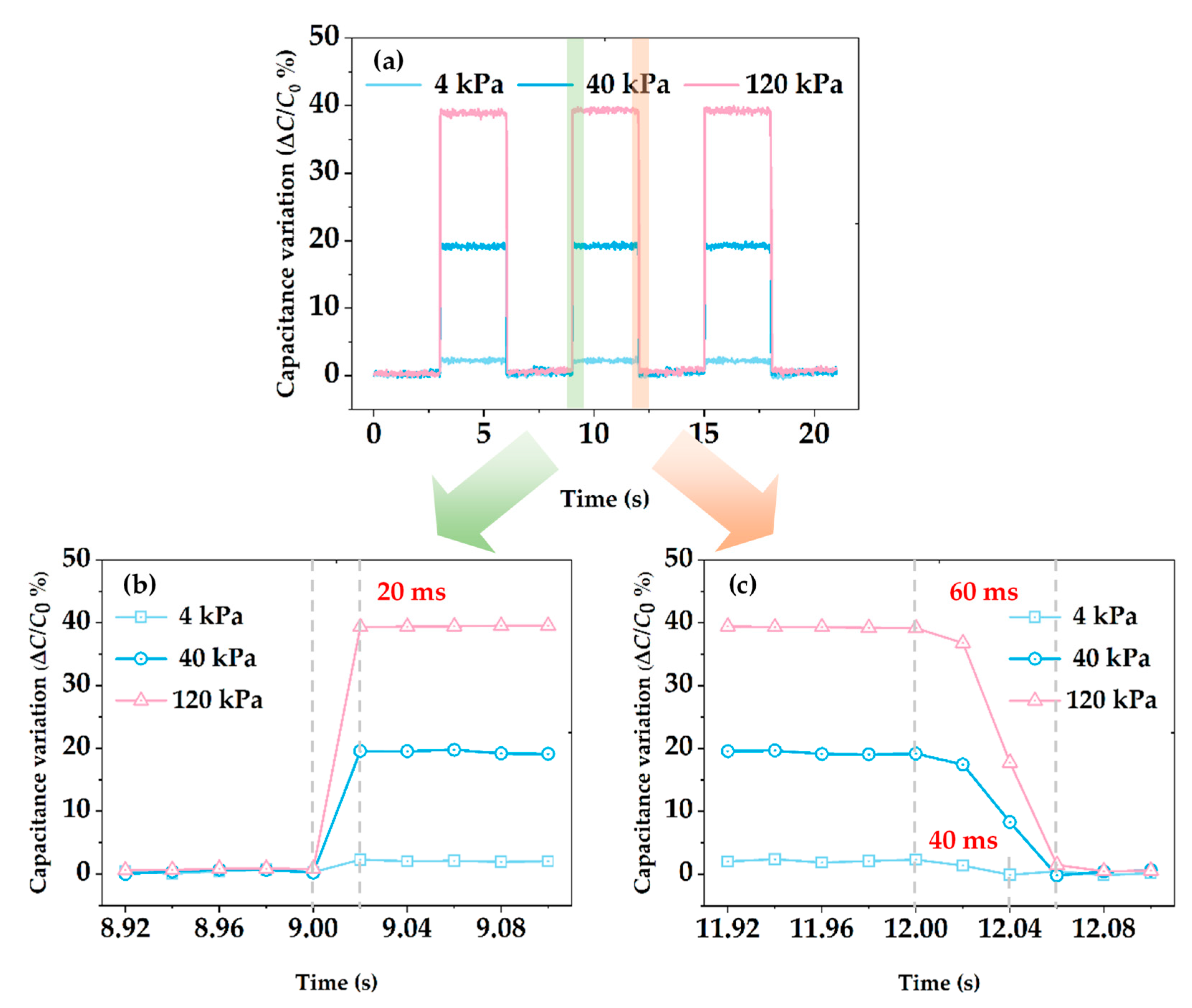

3.2. Sensing Array Calibration

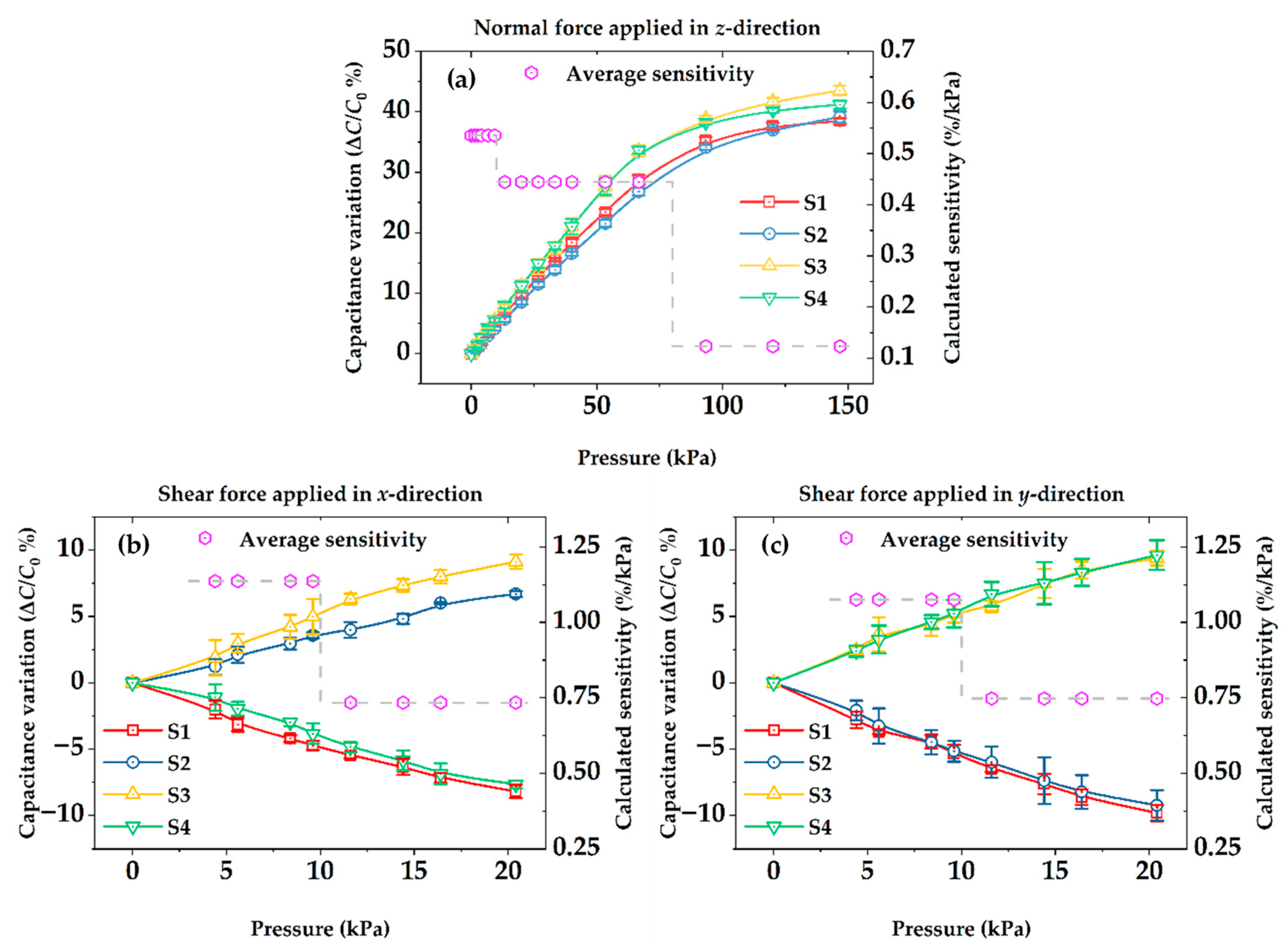

3.3. Three-Axial Force Sensing

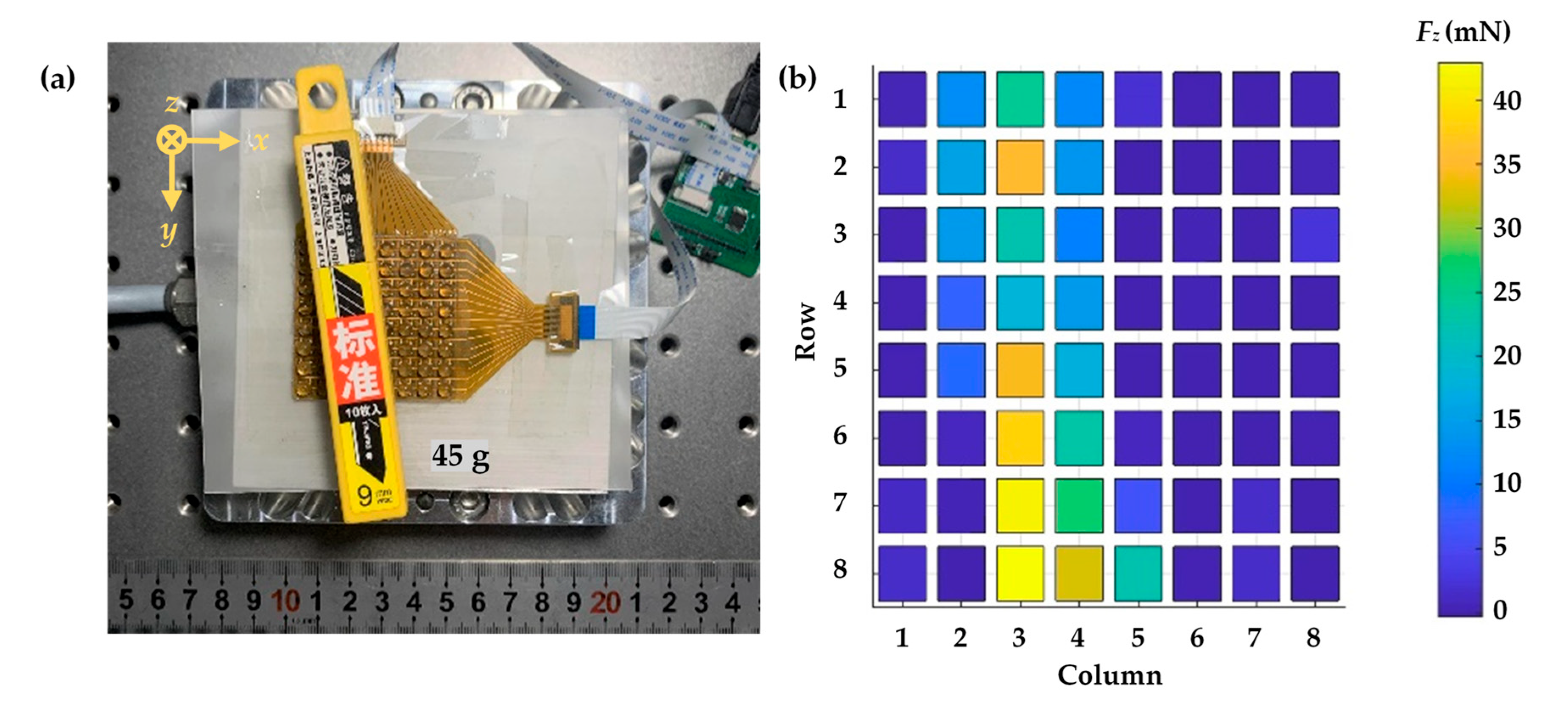

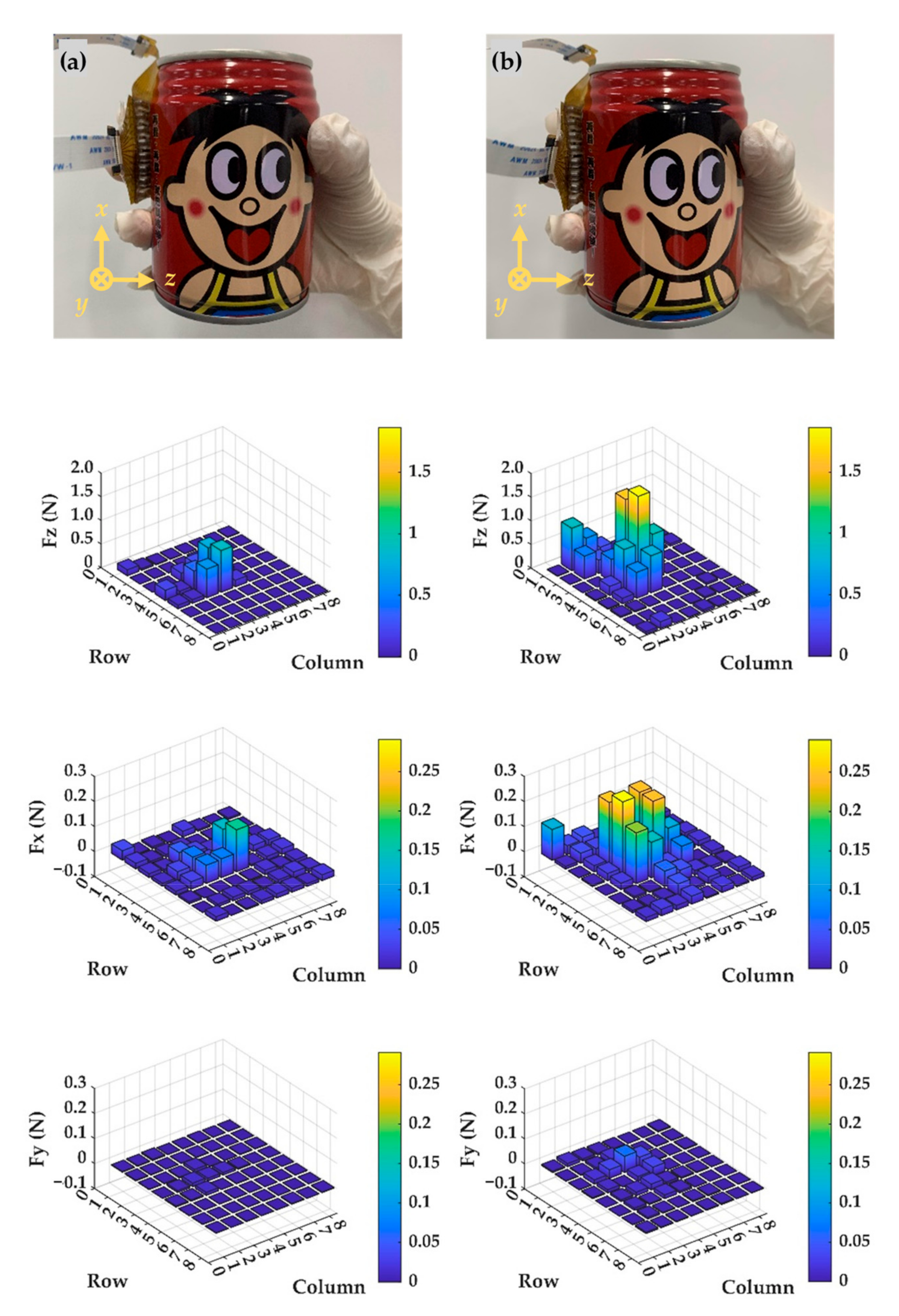

3.4. Distributed Contact Force Sensing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, Y.; Chortos, A.; Xu, W.; Liu, Y.; Oh, J.Y.; Son, D.; Kang, J.; Foudeh, A.M.; Zhu, C.; Lee, Y.; et al. A bioinspired flexible organic artificial afferent nerve. Science 2018, 360, 998–1003. [Google Scholar] [CrossRef]

- Mishra, R.B.; El-Atab, N.; Hussain, A.M.; Hussain, M.M. Recent progress on flexible capacitive pressure sensors: From design and materials to applications. Adv. Mater. Technol. 2021, 6, 2001023. [Google Scholar] [CrossRef]

- Claver, U.P.; Zhao, G. Recent progress in flexible pressure sensors based electronic skin. Adv. Eng. Mater. 2021, 23, 2001187. [Google Scholar] [CrossRef]

- Chang, S.; Geng, Y.; Yan, Y. Tip-based nanomachining on thin films: A mini review. Nanomanuf. Metrol. 2022, 5, 2–22. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Mei, D. Flexible tactile sensor array for slippage and grooved surface recognition in sliding movement. Micromachines 2019, 10, 579. [Google Scholar] [CrossRef]

- Park, M.; Park, Y.J.; Chen, X.; Park, Y.-K.; Kim, M.-S.; Ahn, J.-H. MoS2-based tactile sensor for electronic skin applications. Adv. Mater. 2016, 28, 2556–2562. [Google Scholar] [CrossRef]

- Metz, D.; Dietzel, A. 3-D isotropic tactile microprobe based on a silicon parallelogram kinematic: From concept to fabrication. J. Microelectromech. Syst. 2019, 28, 63–76. [Google Scholar] [CrossRef]

- Wang, L.Y.; Wang, Y.; Yang, S.; Tao, X.M.; Zi, Y.L.; Daoud, W.A. Solvent-free adhesive ionic elastomer for multifunctional stretchable electronics. Nano Energy 2022, 91, 106611. [Google Scholar] [CrossRef]

- Meng, H.; Zhu, W.; Zhou, L.; Qian, X.; Bao, G. A 3-D force sensor based on combination of magnetic and piezoresistive rransduction. IEEE Sens. J. 2022, 22, 3595–3604. [Google Scholar] [CrossRef]

- Zheng, Y.; Lin, T.; Zhao, N.; Huang, C.X.; Chen, W.; Xue, G.; Wang, Y.; Teng, C.; Wang, X.L.; Zhou, D.S. Highly sensitive electronic skin with a linear response based on the strategy of controlling the contact area. Nano Energy 2021, 85, 106013. [Google Scholar] [CrossRef]

- Ji, B.; Zhou, Q.; Lei, M.; Ding, S.; Song, Q.; Gao, Y.; Li, S.; Xu, Y.; Zhou, Y.; Zhou, B. Gradient architecture-enabled capacitive tactile sensor with high sensitivity and ultrabroad linearity range. Small 2021, 17, 2103312. [Google Scholar] [CrossRef]

- Liang, G.; Wang, Y.; Mei, D.; Xi, K.; Chen, Z. Flexible capacitive tactile sensor array with truncated pyramids as dielectric layer for three-Axis force measurement. J. Microelectromech. Syst. 2015, 24, 1510–1519. [Google Scholar] [CrossRef]

- Boutry, C.M.; Negre, M.; Jorda, M.; Vardoulis, O.; Chortos, A.; Khatib, O.; Bao, Z.N. A hierarchically patterned, bioinspired e-skin able to detect the direction of applied pressure for robotics. Sci. Robot. 2018, 3, eaau6914. [Google Scholar] [CrossRef] [PubMed]

- Ruth, S.R.A.; Feig, V.R.; Kim, M.G.; Khan, Y.; Phong, J.K.; Bao, Z.N. Flexible fringe effect capacitive sensors with simultaneous high-performance contact and non-contact sensing capabilities. Small Struct. 2021, 2, 2000079. [Google Scholar] [CrossRef]

- Guo, Z.; Mo, L.; Ding, Y.; Zhang, Q.; Meng, X.; Wu, Z.; Chen, Y.; Cao, M.; Wang, W.; Li, L. Printed and flexible capacitive pressure sensor with carbon nanotubes based composite dielectric layer. Micromachines 2019, 10, 715. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.H.; Lee, S.W.; Yu, S.; Kim, H.; Chang, S.; Kang, D.; Hwang, I.; Kang, H.S.; Jeong, B.; Kim, E.H.; et al. Micropatterned pyramidal ionic gels for sensing broad-range pressures with high sensitivity. ACS Appl. Mater. Interfaces 2017, 9, 10128–10135. [Google Scholar]

- Zhu, L.; Xiang, Y.; Liu, Y.; Geng, K.; Yao, R.; Li, B. Comparison of piezoelectric responses of flexible tactile sensors based on hydrothermally-grown ZnO nanorods on ZnO seed layers with different thicknesses. Sens. Actuators A Phys. 2022, 341, 113552. [Google Scholar] [CrossRef]

- Fan, X.; Lee, D.; Jackel, L.; Howard, R.; Isler, V. Enabling low-cost full surface tactile skin for human robot interaction. IEEE Robot. Autom. Lett. 2022, 7, 1800–1807. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, X.; Tang, X.Y.; Li, J.L.; Wei, D.C.; Tai, G.J.; Chen, Z.Y.; Liao, T.M.; Fu, J.T.; Wei, D.P.; et al. Microconformal electrode-dielectric integration for flexible ultrasensitive robotic tactile sensing. Nano Energy 2021, 80, 105580. [Google Scholar] [CrossRef]

- Shin, K.; Sim, M.; Choi, E.; Park, H.; Choi, J.W.; Cho, Y.; Sohn, J.I.; Cha, S.N.; Jang, J.E. Artificial tactile sensor structure for surface topography through sliding. IEEE ASME Trans. Mechatron. 2018, 23, 2638–2649. [Google Scholar]

- Bliss, J.C.; Katcher, M.H.; Rogers, C.H.; Shepard, R.P. Optical-to-tactile image conversion for the blind. IEEE Trans. Hum.-Mach. Syst. 1970, 11, 58–65. [Google Scholar] [CrossRef]

- Si, Z.; Yuan, W. Taxim: An example-based simulation model for gel sight tactile sensors. IEEE Robot. Autom. Lett. 2022, 7, 2361–2368. [Google Scholar] [CrossRef]

- Kajihara, Y.; Takahashi, R.; Yoshida, I.; Saito, S.; Sekine, N.; Nowatari, S.; Miyake, S. Measurement method of internal residual stress in plastic parts using terahertz spectroscopy. Nanomanuf. Metrol. 2021, 4, 46–52. [Google Scholar] [CrossRef]

- Morita, N.; Nogami, H.; Higurashi, E.; Sawada, R. Grasping force control for a robotic hand by slip detection using developed micro laser doppler velocimeter. Sensors 2018, 18, 326. [Google Scholar] [CrossRef]

- Kim, H.-K.; Lee, S.; Yun, K.-S. Capacitive tactile sensor array for touch screen application. Sens. Actuators A Phys. 2011, 165, 2–7. [Google Scholar] [CrossRef]

- Tsouti, V.; Filippidou, M.K.; Boutopoulos, C.; Broutas, P.; Zergioti, I.; Chatzandroulis, S. Self-aligned process for the development of surface stress capacitive biosensor arrays. Sens. Actuators B Chem. 2012, 166–167, 815–818. [Google Scholar] [CrossRef]

- Chuang, S.-T.; Chandra, M.; Chen, R.; Lo, C.-Y. Capacitive tactile sensor with asymmetric electrodes for angle-detection-error alleviation. Sens. Actuators A Phys. 2016, 250, 159–169. [Google Scholar] [CrossRef]

- Tang, X.; Gu, Q.; Gao, P.; Wen, W. Ultra-sensitive wide-range small capacitive pressure sensor based on porous CCTO-PDMS membrane. Sens. Actuators Rep. 2021, 3, 100027. [Google Scholar] [CrossRef]

- Kim, Y.; Yang, H.; Oh, J.H. Simple fabrication of highly sensitive capacitive pressure sensors using a porous dielectric layer with cone-shaped patterns. Mater. Des. 2021, 197, 109203. [Google Scholar] [CrossRef]

- Li, S.M.; Dong, K.; Li, R.Q.; Huang, X.Y.; Chen, T.J.; Xiao, X.L. Capacitive pressure sensor inlaid a porous dielectric layer of superelastic polydimethylsiloxane in conductive fabrics for detection of human motions. Sens. Actuators A Phys. 2020, 312, 112106. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, Y.; Mei, D.; Wu, X. Highly sensitive and flexible tactile sensor based on porous graphene sponges for distributed tactile sensing in monitoring human motions. J. Microelectromech. Syst. 2019, 28, 154–163. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, S.; Yu, J.; Jiang, X.; Xu, J.; Lan, K.; Yao, Z. Fabrication and Experimental Validation of a Sensitive and Robust Tactile Sensing Array with a Micro-Structured Porous Dielectric Layer. Micromachines 2022, 13, 1724. https://doi.org/10.3390/mi13101724

Yao S, Yu J, Jiang X, Xu J, Lan K, Yao Z. Fabrication and Experimental Validation of a Sensitive and Robust Tactile Sensing Array with a Micro-Structured Porous Dielectric Layer. Micromachines. 2022; 13(10):1724. https://doi.org/10.3390/mi13101724

Chicago/Turabian StyleYao, Shengjie, Jianping Yu, Xiaoliang Jiang, Junfei Xu, Kun Lan, and Zhehe Yao. 2022. "Fabrication and Experimental Validation of a Sensitive and Robust Tactile Sensing Array with a Micro-Structured Porous Dielectric Layer" Micromachines 13, no. 10: 1724. https://doi.org/10.3390/mi13101724

APA StyleYao, S., Yu, J., Jiang, X., Xu, J., Lan, K., & Yao, Z. (2022). Fabrication and Experimental Validation of a Sensitive and Robust Tactile Sensing Array with a Micro-Structured Porous Dielectric Layer. Micromachines, 13(10), 1724. https://doi.org/10.3390/mi13101724