Learning-Based Repetitive Control of a Bowden-Cable-Actuated Exoskeleton with Frictional Hysteresis

Abstract

1. Introduction

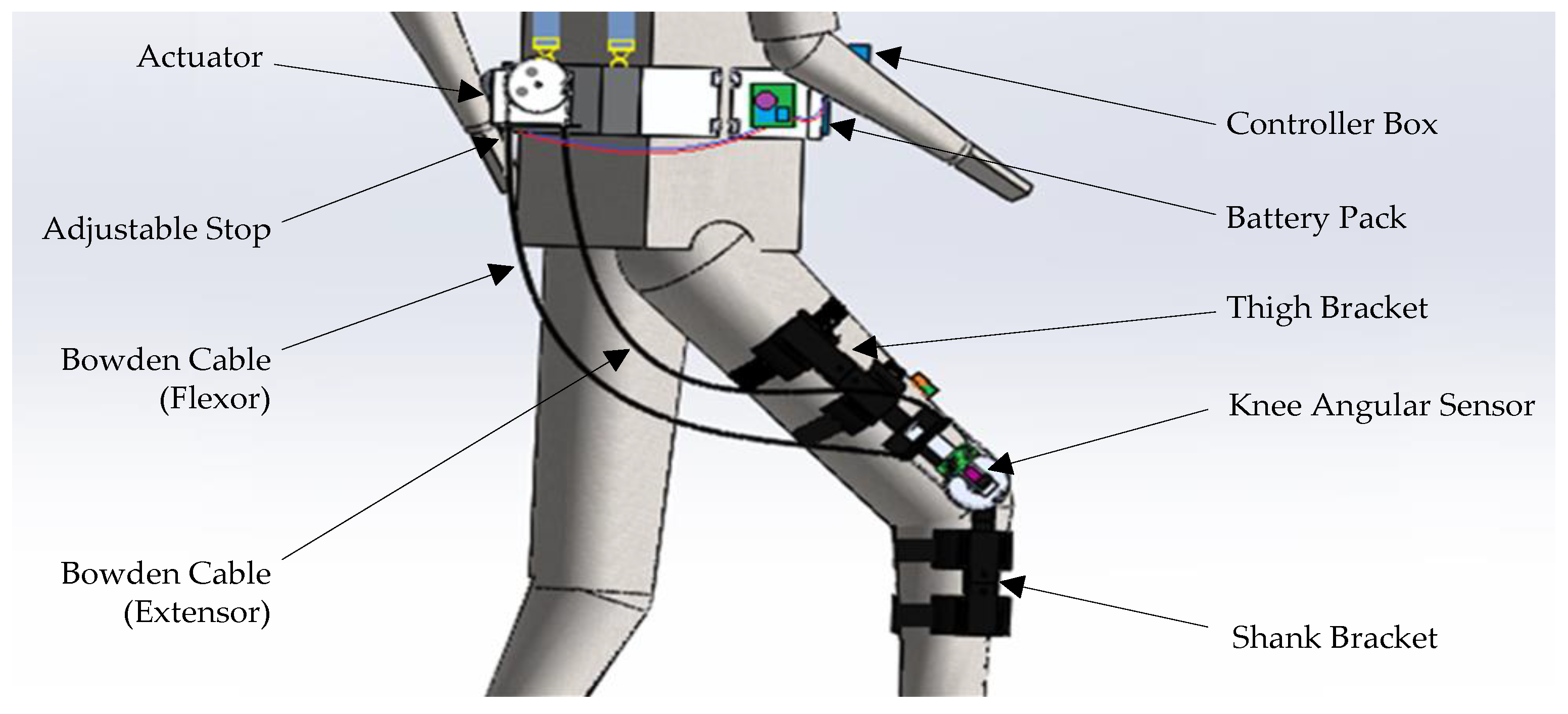

2. Soft Knee Exoskeleton and Actuator Design

2.1. Soft Knee Exoskeleton

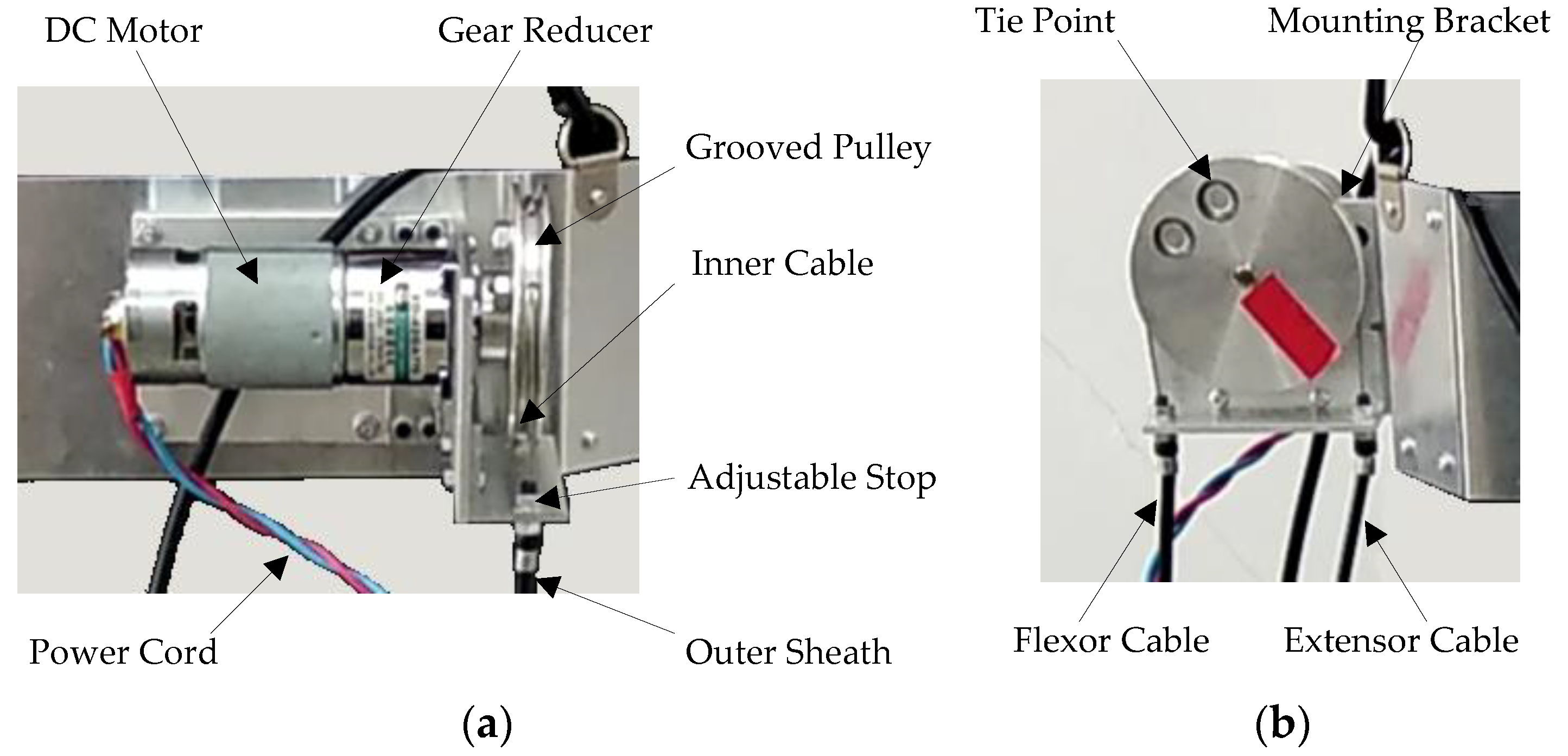

2.2. Actuator Design

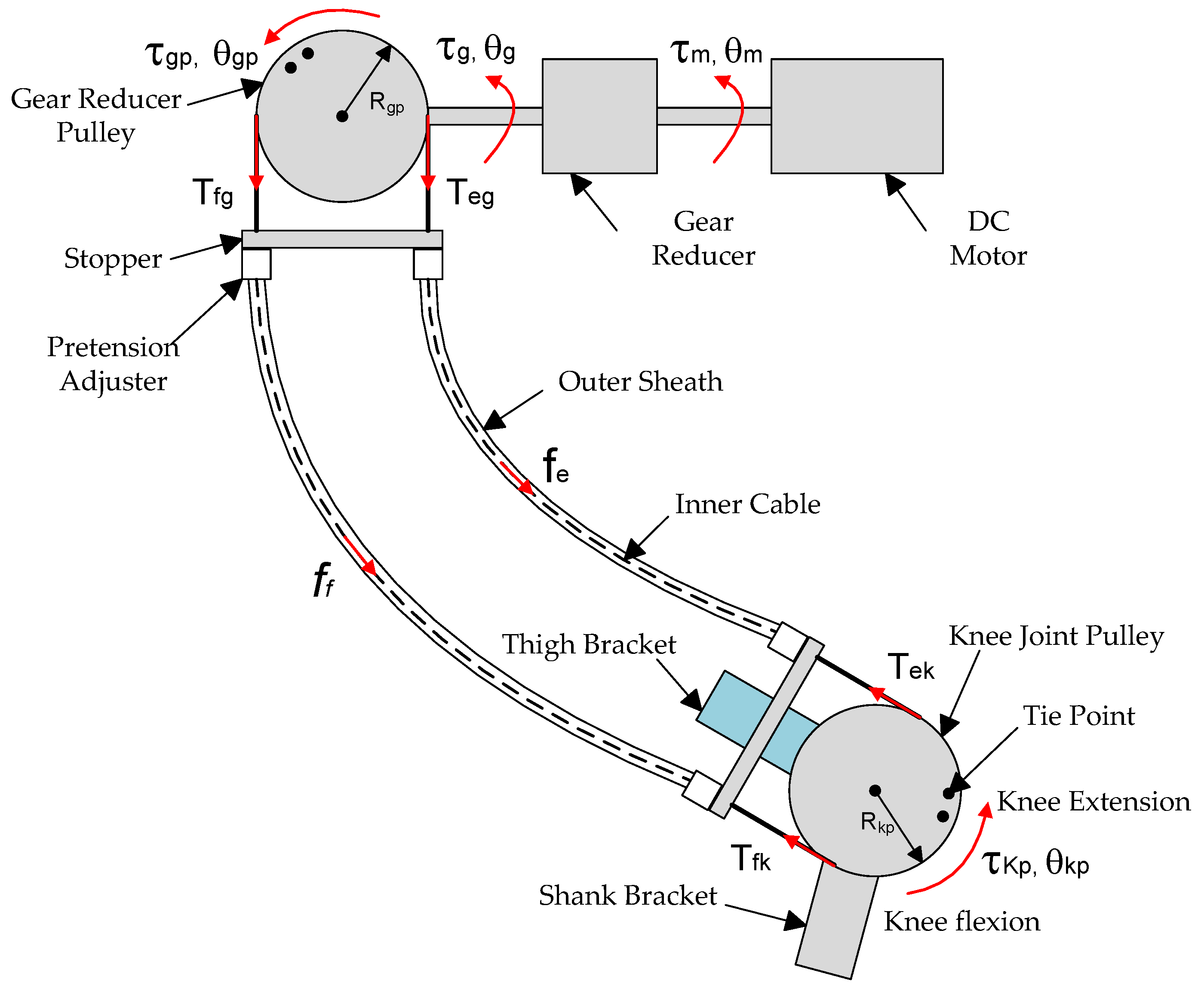

3. Mathematical Modeling of the Exoskeleton System

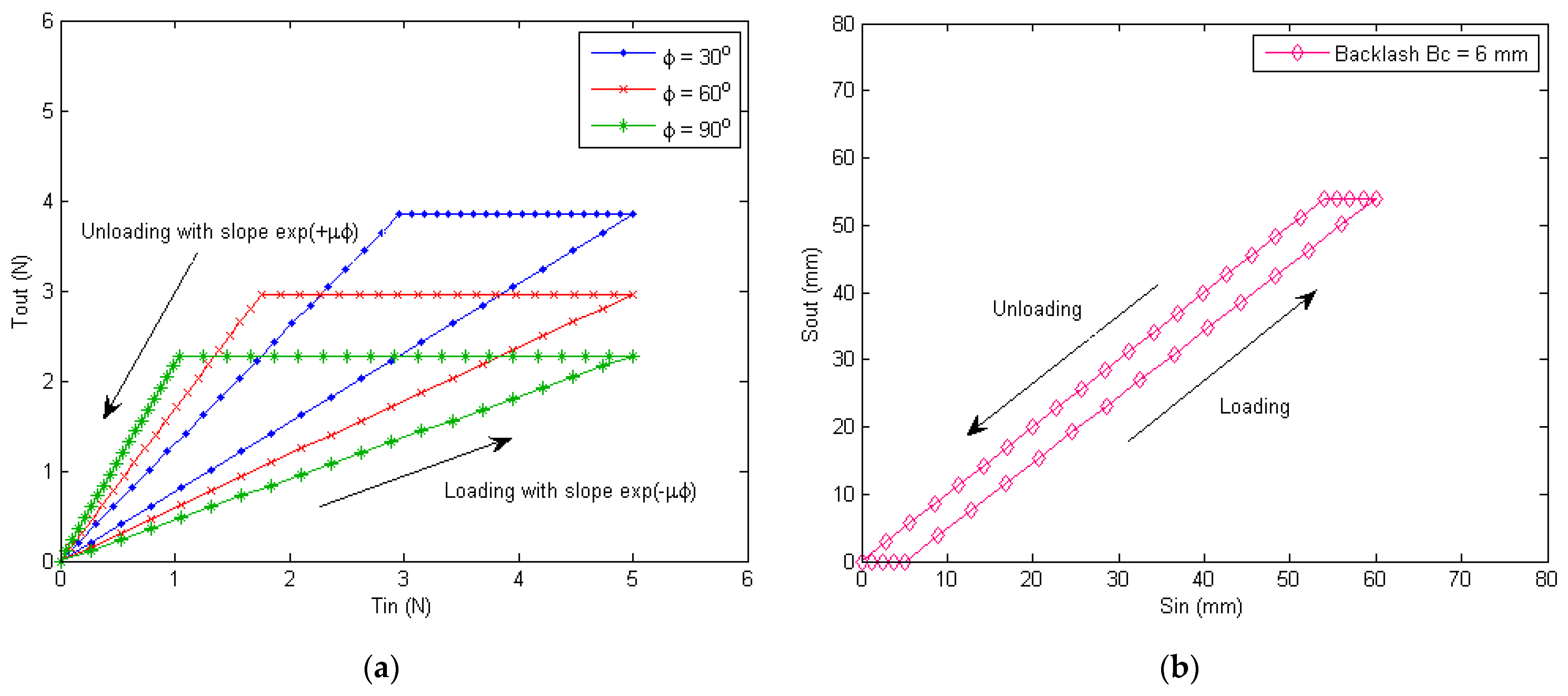

3.1. Nonlinear Friction in the Bowden Cable

3.2. Dynamics of the Soft Knee Exoskeleton System

4. Controller Design

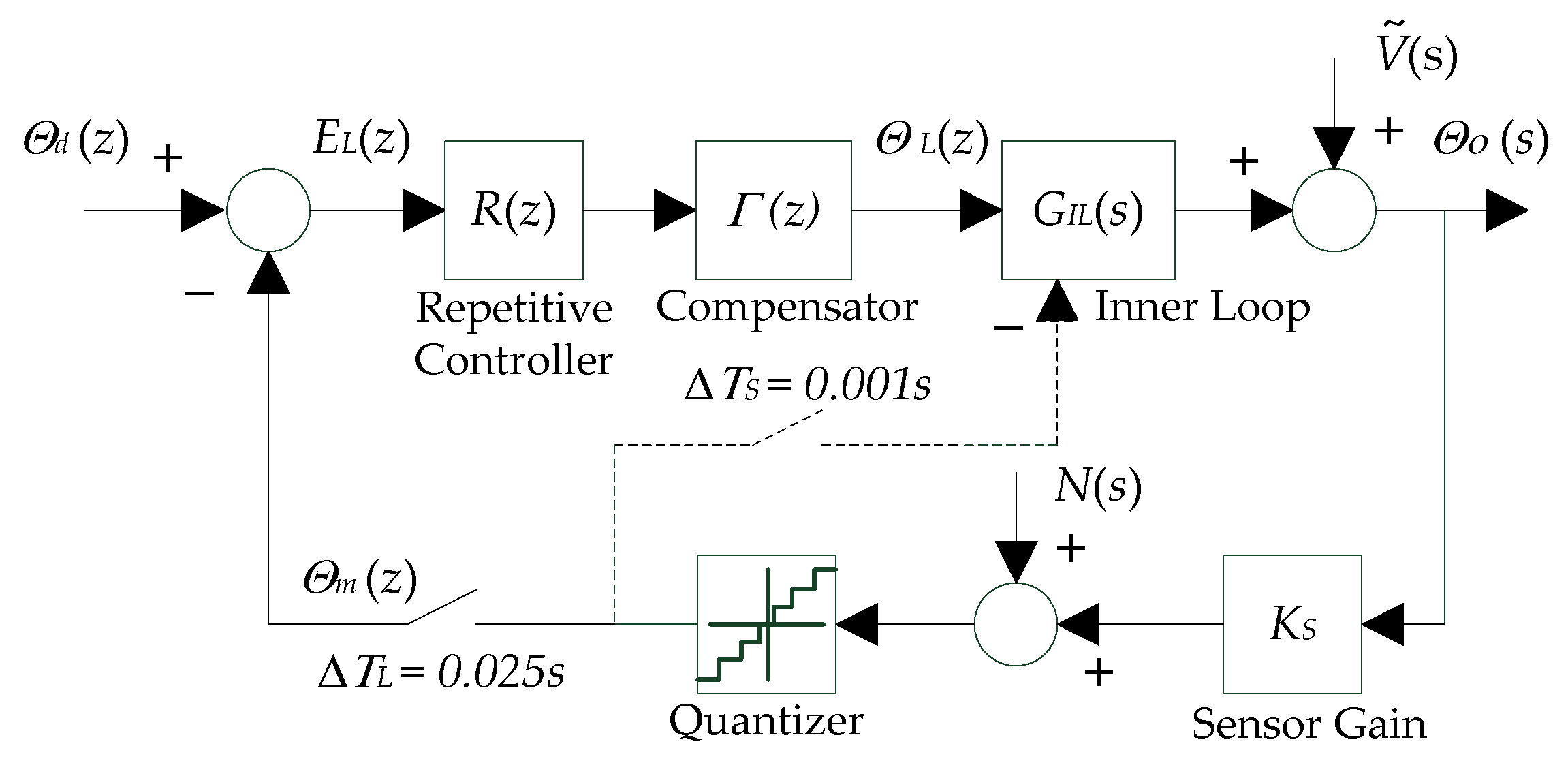

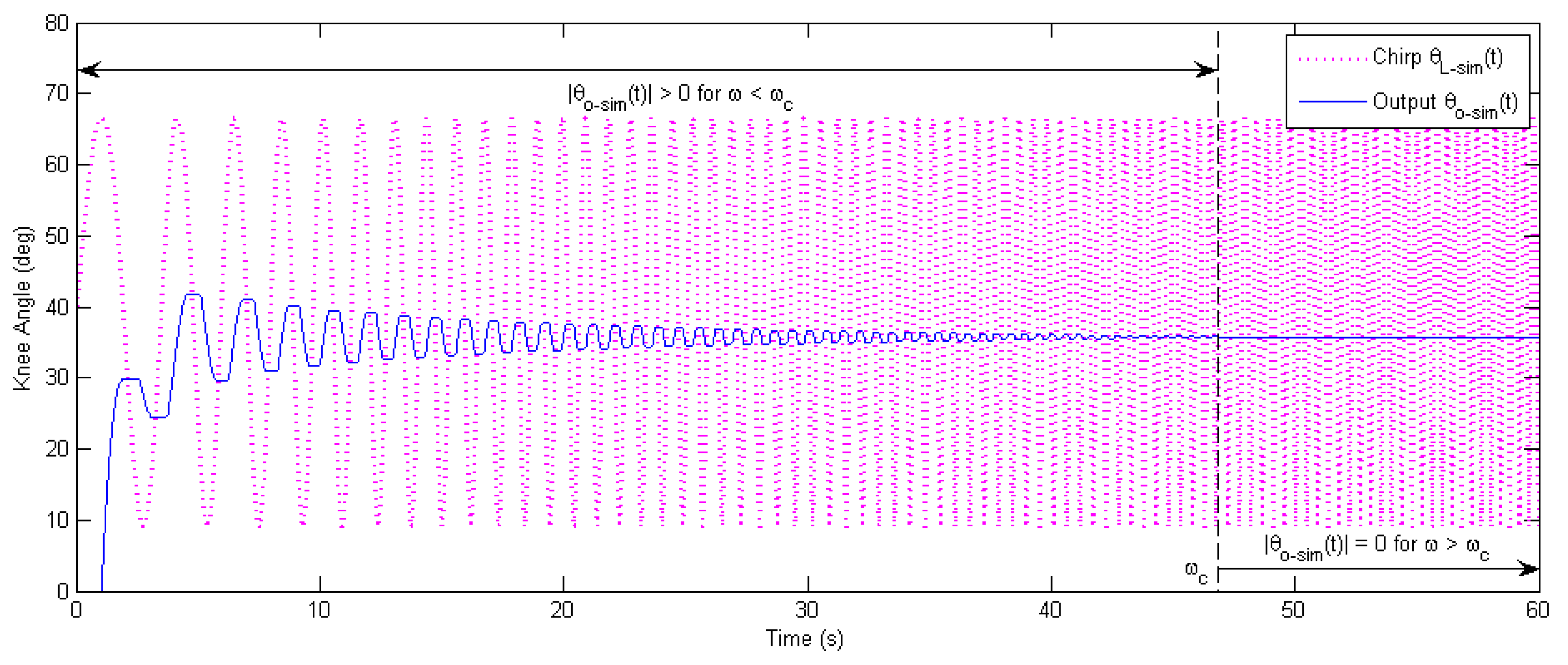

4.1. Design of Inner Loop Digital Servo Controller

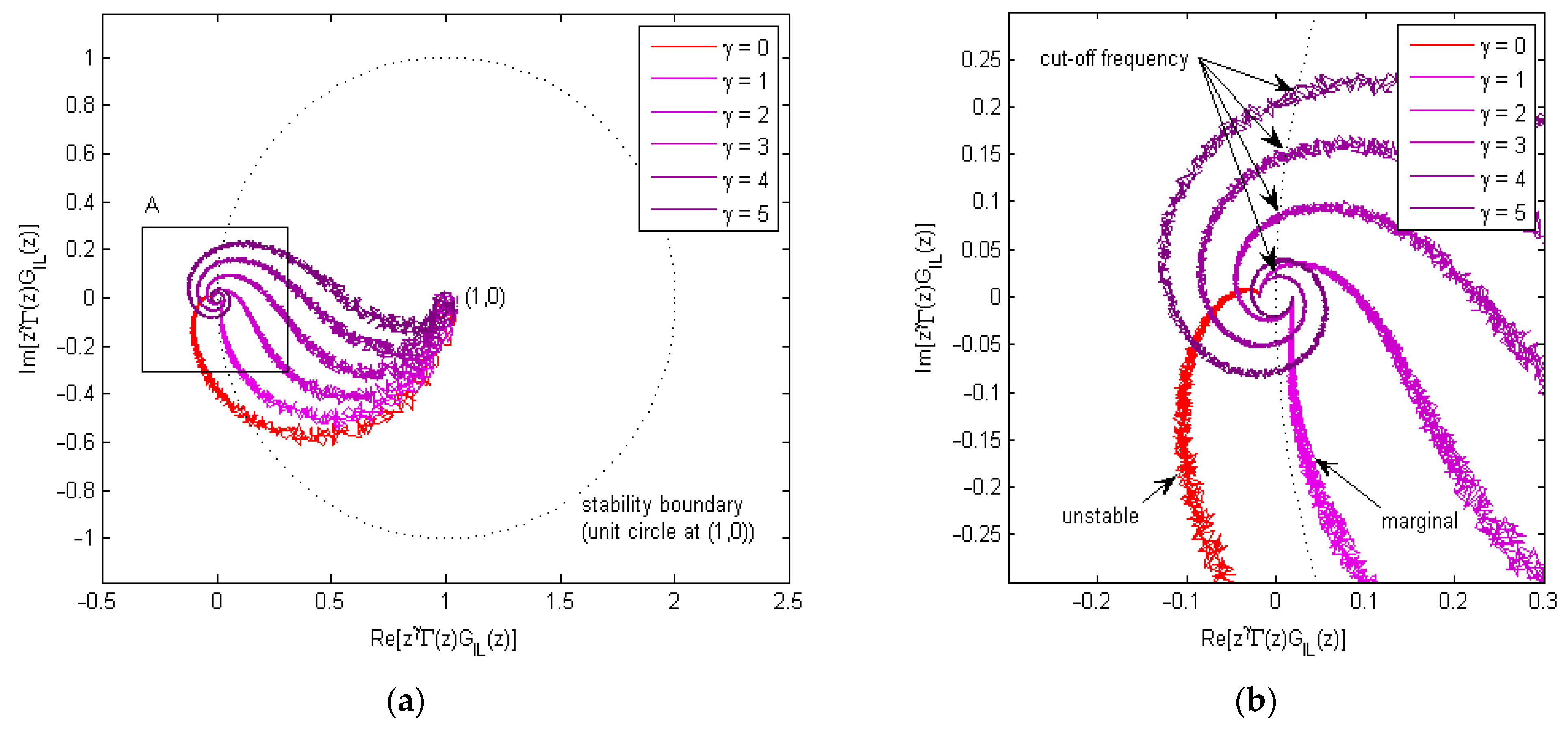

4.2. Design of Outer Loop Iterative Learning Controller

5. Experimental Verification

5.1. Test Setup

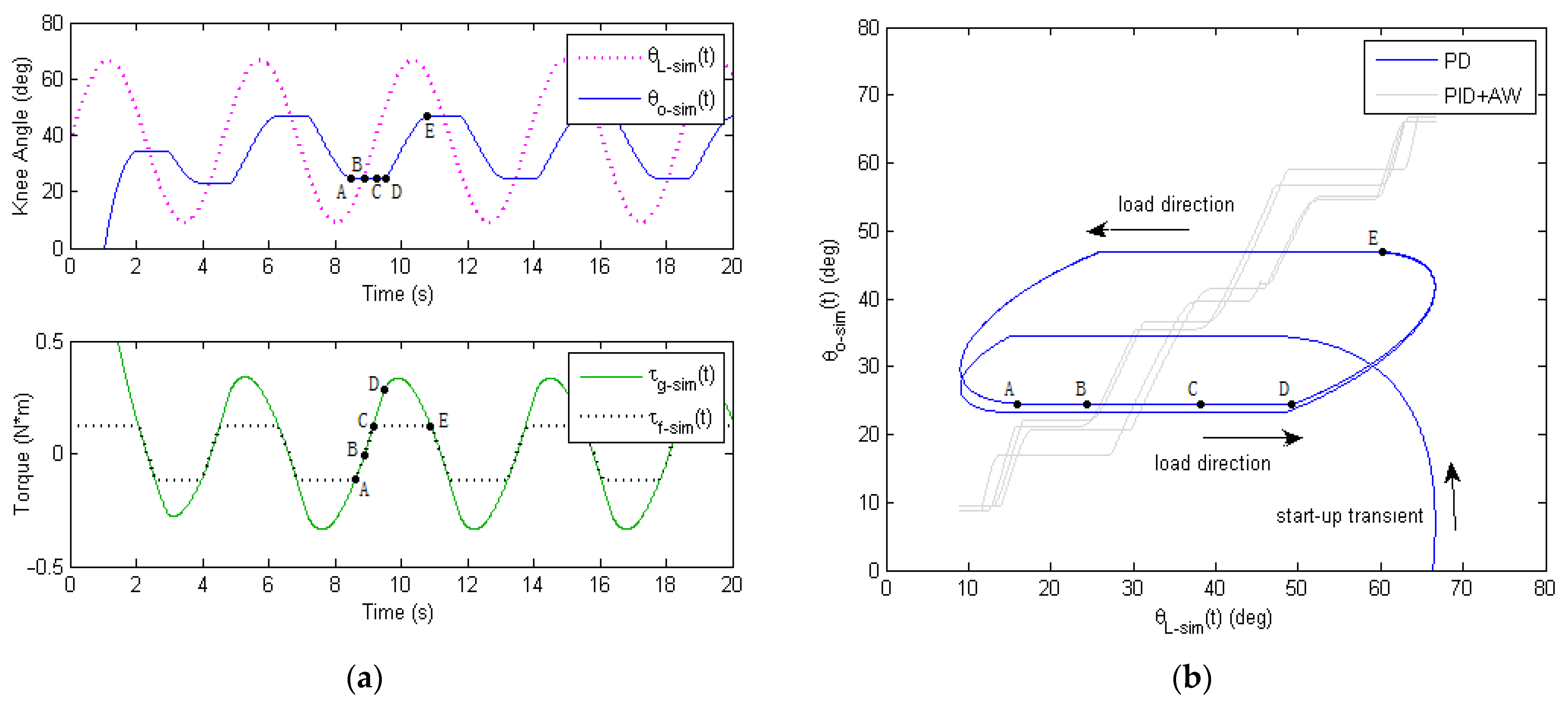

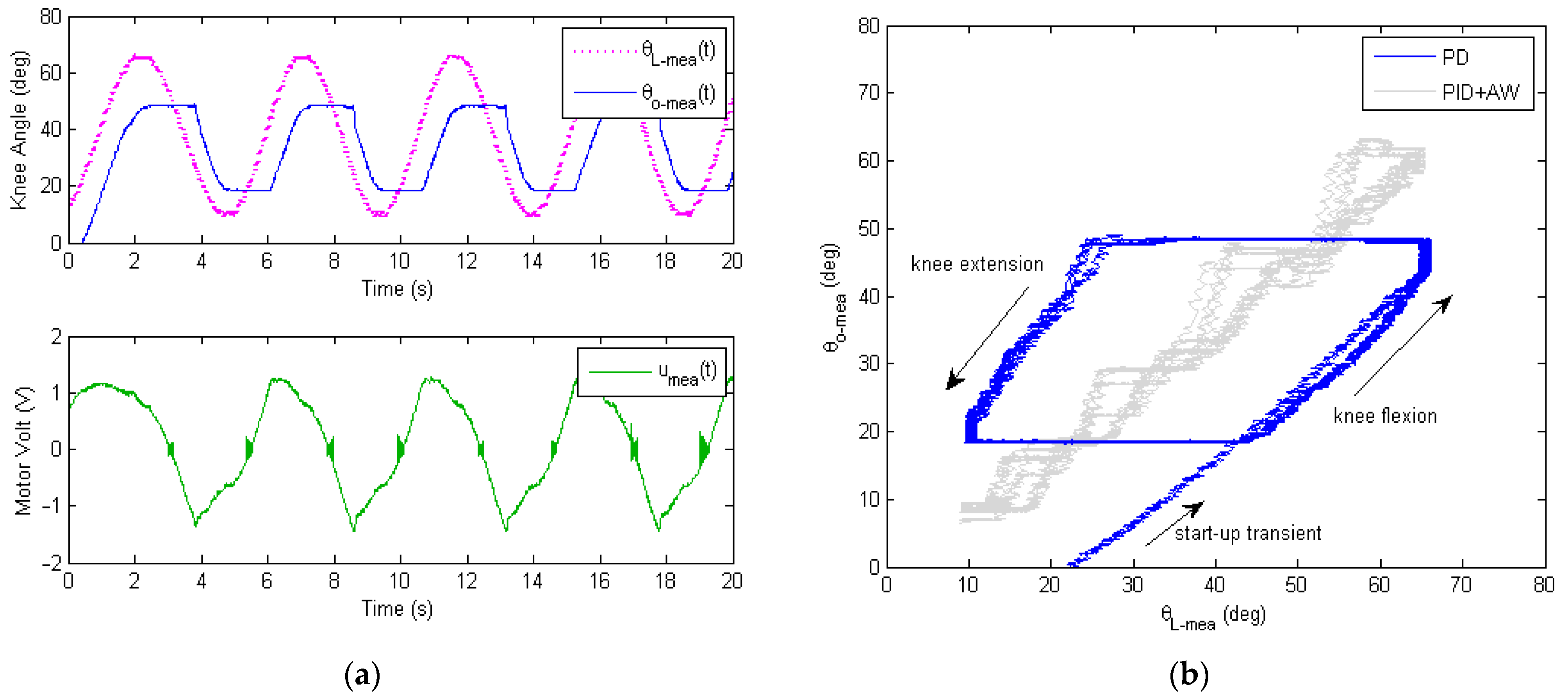

5.2. PD Control of the Inner Loopand Verification of Frictional Hysteresis

5.3. Phase-Lead Iterative Learning Control of the Outer Loop

5.3.1. Overall History of the Learning Process

5.3.2. Analysis of the Output Response

5.3.3. Mechanism of the Learning Compensation

5.3.4. Evaluation of the Tracking Error

5.3.5. Comparison of Different Control Methods

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, T.; Cempini, M.; Oddo, M.; Vitiello, N. Review of assistive strategies in powered lower-limb orthoses and exoskeletons. Robot. Auton. Syst. 2015, 64, 120–136. [Google Scholar] [CrossRef]

- Bogue, R. Exoskeletons and robotic prosthetics: A review of recent developments. Ind. Robot 2009, 36, 421–427. [Google Scholar] [CrossRef]

- Zoss, A.B.; Kazerooni, H.; Chu, A. On the mechanical design of the Berkeley Lower Extremity Exoskeleton (BLEEX). In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 3465–3472. [Google Scholar]

- Nilsson, A.; Vreede, K.S.; Häglund, V.; Kawamoto, H.; Sankai, Y.; Borg, J. Gait training early after stroke with a new exoskeleton—The hybrid assistive limb: A study of safety and feasibility. J. Neuroeng. Rehabil. 2014, 11, 92. [Google Scholar] [CrossRef] [PubMed]

- Zoss, A.B.; Kazerooni, H.; Chu, A. Hybrid control of the Berkeley Lower Extremity Exoskeleton (BLEEX). IEEE/ASME Trans. Mechatron. 2006, 11, 128–138. [Google Scholar] [CrossRef]

- He, Y.; Eguren, D.; Luu, T.P.; Contreras-Vidal, J.L. Risk and adverse events related to lower-limb exoskeletons. In Proceedings of the 2017 International Symposium on Wearable Robotics and Rehabilitation (WeRob), Houston, TX, USA, 5–8 November 2017; pp. 1–2. [Google Scholar]

- Xiloyannis, M.; Alicea, R.; Georgarakis, A.M.; Haufe, F.; Wolf, P.; Masia, L.; Riener, R. Soft robotic suits: State of the art, core technologies, and open challenges. IEEE Trans. Robot. 2022, 38, 1343–1362. [Google Scholar] [CrossRef]

- Tsagarakis, N.G.; Caldwell, D.G. Development and control of a soft-actuated exoskeleton for use in physiotherapy and training. Autonom. Robots 2003, 15, 21–33. [Google Scholar] [CrossRef]

- Zhang, J.F.; Yang, C.J.; Chen, Y.; Zhang, Y.; Dong, Y.M. Modeling and control of a curved pneumatic muscle actuator for wearable elbow exoskeleton. Mechatronics 2008, 18, 448–457. [Google Scholar] [CrossRef]

- Hocking, E.G.; Wereley, N.M. Analysis of nonlinear elastic behavior in miniature pneumatic artificial muscles. Smart Mater. Struct. 2013, 22, 014016. [Google Scholar] [CrossRef]

- Al-Fahaam, H.; Davis, S.; Nefti-Meziani, S. The design and mathematical modelling of novel extensor bending pneumatic artificial muscles (EBPAMS) for soft exoskeletons. Robot. Auton. Syst. 2018, 99, 63–74. [Google Scholar] [CrossRef]

- Veneman, J.F.; Ekkelenkamp, R.; Kruidhof, R.; Helm, R.; Kooij, H. A series elastic- and bowden-cable-based actuation system for use as torque actuator in exoskeleton-type robots. Int. J. Robot. Res. 2006, 25, 261–281. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, X. Design of a gravity balanced upper limb exoskeleton with bowden cable actuators. IFAC Proc. Vol. 2013, 46, 678–683. [Google Scholar]

- Asbeck, A.T.; DeRossi, S.M.M.; Holt, K.G.; Walsh, C.J. A biologically inspired soft exosuit for walking assistance. Int. J. Robot. Res. 2015, 34, 744–762. [Google Scholar] [CrossRef]

- Zhang, F.; Hua, L.; Fu, Y.; Chen, H.; Wang, S. Design and development of a hand exoskeleton for rehabilitation of hand injuries. Mech. Mach. Theory 2014, 73, 103–116. [Google Scholar] [CrossRef]

- Kuan, J.Y.; Pasch, K.A.; Herr, H.M. A high-performance cable-drive module for the development of wearable devices. IEEE/ASME Trans. Mechatron. 2018, 23, 1238–1248. [Google Scholar] [CrossRef]

- Yang, X.; Huang, T.H.; Hu, H.; Yu, S.; Zhang, S.; Zhou, X.; Carriero, A.; Yue, G.; Su, H. Spine-inspired continuum soft exoskeleton for stoop lifting assistance. IEEE Robot. Autom. Lett. 2019, 4, 4547–4554. [Google Scholar] [CrossRef]

- Zhong, B.; Guo, K.; Yu, H.; Zhang, M. Toward gait symmetry enhancement via a cable-driven exoskeleton powered by series elastic actuators. IEEE Robot. Autom. Lett. 2022, 7, 786–793. [Google Scholar] [CrossRef]

- Yin, M.; Wu, H.; Xu, Z.; Han, W.; Zhao, Z. Compliant control of single tendon-sheath actuators applied to a robotic manipulator. IEEE Access 2020, 8, 37361–37371. [Google Scholar] [CrossRef]

- Asbeck, A.T.; DeRossi, S.M.M.; Galiana, I.; Ding, Y.; Walsh, C.J. Stronger, smarter, softer: Next-generation wearable robots. IEEE Robot. Autom. Mag. 2014, 21, 22–33. [Google Scholar] [CrossRef]

- Chen, D.; Yun, Y.; Deshpande, A.D. Experimental characterization of Bowden cable friction. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 5927–5933. [Google Scholar]

- Jeong, U.; Cho, K.J. Feedforward friction compensation of Bowden-cable transmission via loop routing. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 5948–5953. [Google Scholar]

- Zhang, Q.; Wang, X.; Tian, M.; Shen, X.; Wu, Q. Modeling of novel compound tendon-sheath artificial muscle inspired by Hill muscle model. IEEE Trans. Ind. Electron. 2018, 65, 6372–6381. [Google Scholar] [CrossRef]

- Ikhouane, F.; Rodellar, J. On the hysteretic Bouc-Wen model—Part II: Robust parametric identification. Nonlinear Dyn. 2005, 42, 79–95. [Google Scholar] [CrossRef]

- Ikhouane, F.; Maosa, V.; Rodellar, J. Dynamic properties of the hysteretic Bouc-Wen model. Syst. Control Lett. 2007, 56, 197–205. [Google Scholar] [CrossRef]

- Dinh, B.K.; Xiloyannis, M.; Cappello, L.; Antuvan, C.W.; Yen, S.C.; Masia, L. Adaptive backlash compensation in upper limb soft wearable exoskeletons. Robot. Auton. Syst. 2017, 92, 173–186. [Google Scholar] [CrossRef]

- Jeong, U.; Cho, K.J. Control of a Bowden-cable actuation system with embedded BoASensor for soft wearable robots. IEEE Trans. Ind. Electron. 2020, 67, 7669–7680. [Google Scholar] [CrossRef]

- Jeong, U.; Cho, K.J. A novel low-cost, large curvature bend sensor based on a Bowden-cable. Sensors 2016, 16, 961. [Google Scholar] [CrossRef]

- Wang, Z.; Rho, S.; Yang, C.; Jiang, F.; Ding, Z.; Yi, C.; Wei, B. Active loading control design for a wearable exoskeleton with a bowden cable for transmission. Actuators 2021, 10, 108. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, Z. Iterative Learning Control for the Shank Part of Lower Limb Exoskeleton. In Proceedings of the 2019 Chinese Control Conference, Guangzhou, China, 27–30 July 2019; pp. 668–673. [Google Scholar]

- Cheng, L.; Chen, M.; Li, Z. Design and control of a wearable hand rehabilitation robot. IEEE Access 2018, 6, 74039–74050. [Google Scholar] [CrossRef]

- Meng, W.; Xie, S.Q.; Liu, Q.; Lu, C.Z.; Ai, Q. Robust iterative feedback tuning control of a compliant rehabilitation robot for repetitive ankle training. IEEE/ASME Trans. Mechatron. 2017, 22, 173–184. [Google Scholar] [CrossRef]

- Ajjanaromvat, N.; Parnichkun, M. Trajectory tracking using online learning LQR with adaptive learning control of a leg-exoskeleton for disorder gait rehabilitation. Mechatronics 2018, 51, 85–96. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.; Li, Y.; Wang, Z.; Liu, Y.; Cao, W.; Wu, X. Iterative learning control for a soft exoskeleton with hip and knee joint assistance. Sensors 2020, 20, 4333. [Google Scholar] [CrossRef]

- Chen, L.; Wang, X. Modeling of the tendon-sheath actuation system. In Proceedings of the 2012 International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 28–30 November 2012; pp. 489–494. [Google Scholar]

- Sun, Z.; Wang, Z.; Phee, S.J. Elongation modeling and compensation for the flexible tendon—Sheath system. IEEE/ASME Trans. Mechatron. 2014, 19, 1243–1250. [Google Scholar] [CrossRef]

- Jung, Y.; Bae, J. Torque control of a series elastic tendon-sheath actuation mechanism. IEEE/ASME Trans. Mechatron. 2020, 25, 2915–2926. [Google Scholar] [CrossRef]

- Bavdekar, V.A.; Deshpande, A.P.; Patwardhan, S.C. Identification of process and measurement noise covariance for state and parameter estimation using extended Kalman filter. J. Process Control 2011, 21, 585–601. [Google Scholar] [CrossRef]

- Panomruttanarug, B.; Longman, R.W. Using Kalman filter to attenuate noise in learning and repetitive control can easily degrade performance. In Proceedings of the 2008 SICE Annual Conference, Chofu, Japan, 20–22 August 2008; pp. 3453–3458. [Google Scholar]

- Francis, B.A.; Wonham, W.M. The internal model principle of control theory. Automatica 1976, 12, 457–465. [Google Scholar] [CrossRef]

- Costa-Castelló, R.; Nebot, J.; Griñó, R. Demonstration of the internal model principle by digital repetitive control of an educational laboratory plant. IEEE Trans. Educ. 2005, 48, 73–80. [Google Scholar] [CrossRef]

- Quan, Q.; Cai, K.Y. A new viewpoint on the internal model principle and its application to periodic signal tracking. In Proceedings of the 2010 World Congress on Intelligent Control and Automation, Jinan, China, 7–9 July 2010; pp. 1162–1167. [Google Scholar]

- Yamamoto, Y.; Hara, S. The internal model principle and stabilizability of repetitive control systems. Trans. Soc. Instrum. Control Eng. 2009, 22, 830–834. [Google Scholar] [CrossRef][Green Version]

- Shin, H.B.; Park, J.G. Anti-windup pid controller with integral state predictor for variable-speed motor drives. IEEE Trans. Ind. Electron. 2011, 59, 1509–1516. [Google Scholar] [CrossRef]

- Peng, Y.; Vrancic, D.; Hanus, R. Anti-windup, bumpless, and conditioned transfer techniques for pid controllers. IEEE Control Syst. 1996, 16, 48–57. [Google Scholar]

- Longman, R.W. On the theory and design of linear repetitive control systems. Eur. J. Control 2010, 16, 447–496. [Google Scholar] [CrossRef]

- Longman, R.W. Iterative learning control and repetitive control for engineering practice. Int. J. Control 2000, 73, 930–954. [Google Scholar] [CrossRef]

- Bristow, D.A.; Tharayil, M.; Alleyne, A.G. A survey of iterative learning. IEEE Control Syst. 2006, 26, 96–114. [Google Scholar]

- Williams, M. Biomechanics of human motion. Acad. Med. 1963, 38, 530. [Google Scholar]

- Stein, M. Biomechanics of human motion: Basics and beyond for the health professions. J. Sports Sci. Med. 2010, 9, 676. [Google Scholar]

| Exoskeleton Component | Weight (g) | Size 1 (mm) |

|---|---|---|

| Waist Bracket | 260 | 1000 (C) × 100 (W) × 1 (H) |

| Thigh Bracket | 321 | 300 ± 50 (L) × 75 (W) × 15 (H) |

| Shank Bracket | 254 | 250 ± 50 (L) × 75 (W) × 15 (H) |

| Back Strap | 12 × 2 | 800 ± 20 (L) × 25 (W) × 2 (H) |

| Actuator Module | 778 | 120 (L) × 80 (W) × 80 (H) |

| Battery Pack | 782 | 150 (L) × 90 (W) × 40 (H) |

| Controller Box | 316 | 150 (L) × 90 (W) × 60 (H) |

| Bowden Cable (Outer Sheath) | 20 × 2 | 600 (L) × 5 (D) |

| Bowden Cable (Inner Cord) | 8 × 2 | 1000 (L) × 2 (D) |

| Grooved Pulley | 136 × 2 | 80 (D) × 10 (H) |

| Control Method | RMS Error (Iteration #8) | RMS Error (Iteration #26) | RMS Error (Iteration #44) | Iterations for Convergence | Minimum RMS Error | Stability |

|---|---|---|---|---|---|---|

| PD | 15.512 | 15.351 | 15.454 | n/a | 15.312 | Yes |

| PID + AW | 3.478 | 3.411 | 3.499 | n/a | 3.235 | Yes |

| PD + ILC | 6.081 | 4.665 | 8.029 | n/a | 4.314 | No |

| PD + ILC + Lead () | 5.049 | 2.632 | 2.291 | 8 | 1.957 | Yes |

| PD + ILC + Lead () | 4.739 | 1.881 | 1.371 | 7 | 1.208 | Yes |

| PD + ILC + Lead () | 4.213 | 1.579 | 1.601 | 6 | 1.456 | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Guo, M.; Hui, C.; Li, S.; Ji, X.; Yang, Y.; Luo, X.; Xia, D. Learning-Based Repetitive Control of a Bowden-Cable-Actuated Exoskeleton with Frictional Hysteresis. Micromachines 2022, 13, 1674. https://doi.org/10.3390/mi13101674

Shi Y, Guo M, Hui C, Li S, Ji X, Yang Y, Luo X, Xia D. Learning-Based Repetitive Control of a Bowden-Cable-Actuated Exoskeleton with Frictional Hysteresis. Micromachines. 2022; 13(10):1674. https://doi.org/10.3390/mi13101674

Chicago/Turabian StyleShi, Yunde, Mingqiu Guo, Chang Hui, Shilin Li, Xiaoqiang Ji, Yuan Yang, Xiang Luo, and Dan Xia. 2022. "Learning-Based Repetitive Control of a Bowden-Cable-Actuated Exoskeleton with Frictional Hysteresis" Micromachines 13, no. 10: 1674. https://doi.org/10.3390/mi13101674

APA StyleShi, Y., Guo, M., Hui, C., Li, S., Ji, X., Yang, Y., Luo, X., & Xia, D. (2022). Learning-Based Repetitive Control of a Bowden-Cable-Actuated Exoskeleton with Frictional Hysteresis. Micromachines, 13(10), 1674. https://doi.org/10.3390/mi13101674