A Review on Analytical Modeling for Collapse Mode Capacitive Micromachined Ultrasonic Transducer of the Collapse Voltage and the Static Membrane Deflections

Abstract

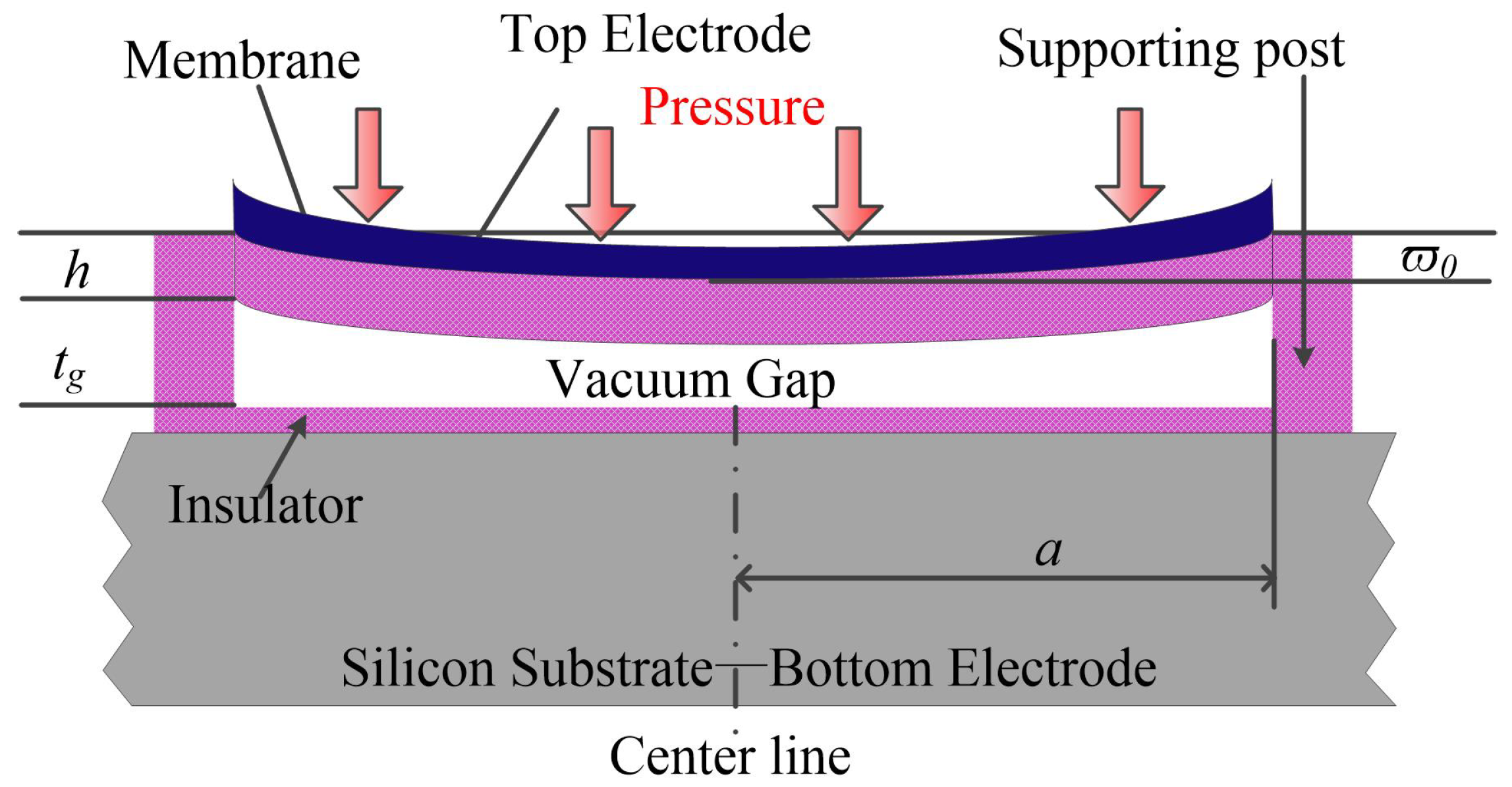

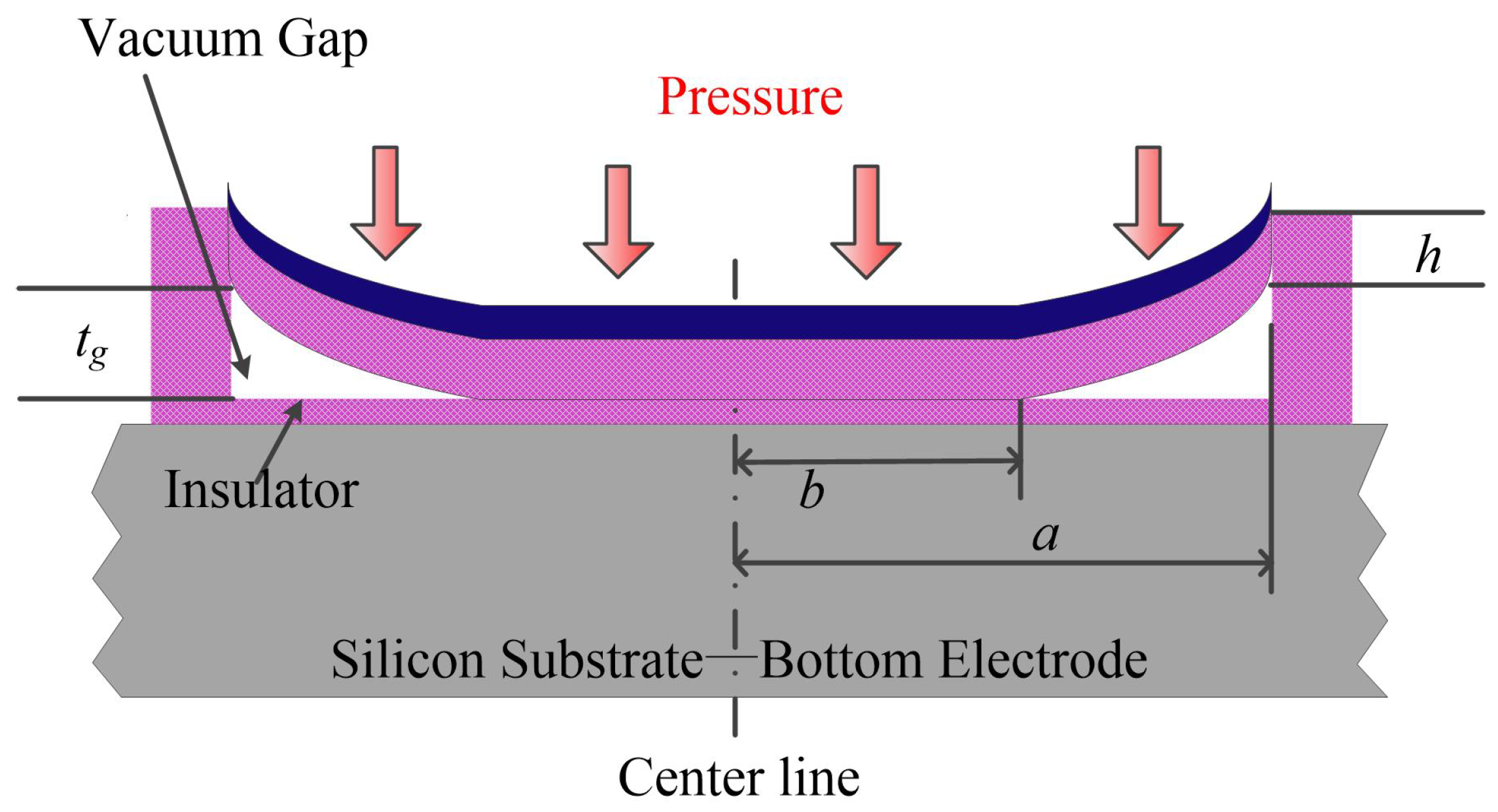

1. Introduction

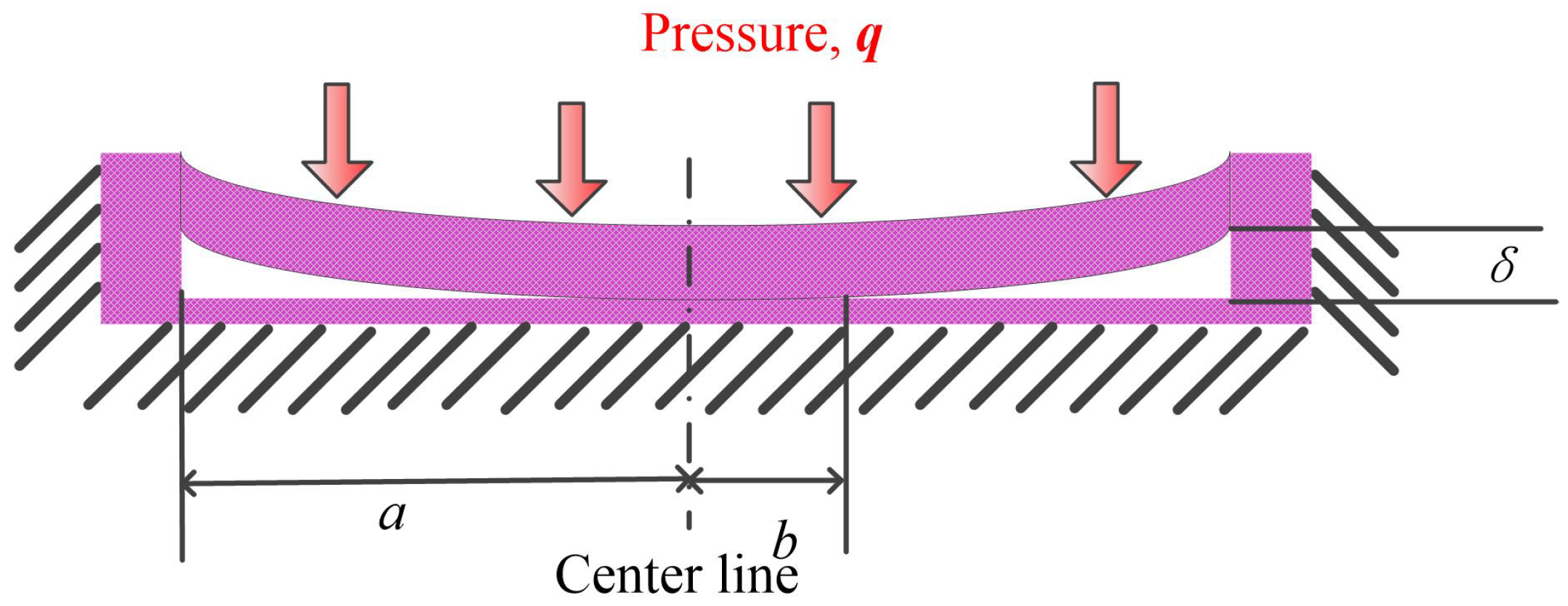

2. Collapse Voltage Models

3. Static Membrane Deflection Models

- Small deflection, /h ≤ 0.2;

- Nonlinear deflection, 0.2 < /h < 1;

- Large deflection, /h ≈ 1.

4. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Ladabaum, I.; Jin, X.; Soh, H.T.; Atalar, A.; Khuri-Yakub, B.T. Surface micromachined capacitive ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 678–690. [Google Scholar] [CrossRef]

- Caronti, A.; Caliano, G.; Iula, A.; Pappalardo, M. An accurate model for capacitive micromachined ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 159–168. [Google Scholar] [CrossRef] [PubMed]

- Olcum, S.; Senlik, M.N.; Atalar, A. Optimization of the gain-bandwidth product of capacitive micromachined ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2211–2219. [Google Scholar] [CrossRef]

- Oralkan, Ö.; Ergun, A.S.; Cheng, C.H.; Johnson, J.A.; Karaman, M.; Lee, T.H.; Khuri-Yakub, B.T. Volumetric ultrasound imaging using 2-D CMUT arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 1581–1594. [Google Scholar] [CrossRef] [PubMed]

- Wygant, I.; Zhuang, X.; Yeh, D.; Oralkan, Ö.; Ergun, A.S.; Karaman, M.; Khuri-Yakub, B.T. Integration of 2D CMUT arrays with front-end electronics for volumetric ultrasound imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 327–342. [Google Scholar] [CrossRef]

- Johnson, J.; Oralkan, Ö.; Demirci, U.; Ergun, S.; Karaman, M.; Khuri-Yakub, B.T. Medical imaging using capacitive micromachined ultrasonic transducer arrays. Ultrasonics 2002, 40, 471–476. [Google Scholar] [CrossRef]

- Oralkan, Ö.; Ergun, A.S.; Johnson, J.A.; Karaman, M.; Demirci, U.; Kaviani, K.; Lee, T.H.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers: Next-generation arrays for acoustic imaging? IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 1596–1610. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, M.; Cheng, J.; Wang, Y.; Li, P.; Cheng, X. A photoacoustic imager with light illumination through an infrared-transparent silicon CMUT array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 766–775. [Google Scholar] [CrossRef]

- Jang, J.H.; Chang, C.; Rasmussen, M.; Moini, A.; Brenner, K.; Stephens, D.; Oralkan, O.; Khuri-Yakub, B.T. Integration of a dual-mode catheter for ultrasound image guidance and HIFU ablation using a 2-D CMUT array. In Proceedings of the IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 1–4. [Google Scholar]

- Wong, S.H.; Kupnik, M.; Watkins, R.D.; Butts-Pauly, K.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers for therapeutic ultrasound applications. IEEE. Trans. Biomed. Eng. 2010, 57, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Khuri-Yakub, B.T.; Park, K.K.; Lee, H.J.; Yaralioglu, G.G.; Ergun, A.S.; Oralkan, Ö.; Kupnik, M.; Quate, C.F.; Braun, T.; Lang, H.P.; et al. 6D-1 The Capacitive Micromachined Ultrasonic Transducer (CMUT) as a Chem/Bio Sensor. In Proceedings of the IEEE Ultrasonics Symposium, New York, NY, USA, 28–31 October 2007; pp. 472–475. [Google Scholar]

- Park, K.K.; Lee, H.J.; Yaralioglu, G.G.; Ergun, A.S.; Oralkan, Ö.; Kupnik, M.; Quate, C.F.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers for chemical detection in nitrogen. Appl. Phys. Lett. 2007, 91, 094102. [Google Scholar] [CrossRef]

- Nazemi, H.; Emadi, A. A New Advanced Analytical Model for Bi-Layer Circular CMUT-Based Gas Sensors. In Proceedings of the IEEE SENSORS, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4. [Google Scholar]

- Cristman, P.; Oralkan, Ö.; Zhuang, X.; Ma, T.J.; Vaithilingam, S.; Carver, T.; Wygant, I.; Khuri-Yakub, B.T. A 2D CMUT hydrophone array: Characterization results. In Proceedings of the 2009 IEEE International Ultrasonics Symposium, Roma, Italy, 20–23 September 2009; pp. 992–995. [Google Scholar]

- Shahiri-Tabarestani, M.; Ganji, B.A.; Sabbaghi-Nadooshan, R. Design and simulation of high sensitive capacitive pressure sensor with slotted diaphragm. In Proceedings of the 2012 International Conference on Biomedical Engineering (ICoBE), Penang, Malaysia, 27–28 February 2012; pp. 484–489. [Google Scholar]

- Shin, K.S.; Jang, C.I.; Kim, M.J.; Yun, K.S.; Park, K.H.; Kang, J.Y.; Lee, S.H. Development of Novel Implantable Intraocular Pressure Sensors to Enhance the Performance in Tests. J. Microelectromech. Syst. 2015, 24, 1896–1905. [Google Scholar] [CrossRef]

- Stedman, Q.; Park, K.K.; Khuri-Yakub, B.T. CMUT chip with integrated temperature and pressure sensors. In Proceedings of the IEEE International Ultrasonics Symposium(IUS), Tours, France, 18–21 September 2016; pp. 1–4. [Google Scholar]

- Shin, M.; Krause, J.S.; Debitetto, P.; White, R.D. Acoustic doppler velocity measurement system using capacitive micromachined ultrasound transducer array technology. J. Acoust. Soc. Am. 2013, 134, 1011–1020. [Google Scholar] [CrossRef] [PubMed]

- Savoia, A.; Caliano, G.; Iula, A.; Longo, C.; Caronti, A.; Carotenuto, R.; Pappalardo, M. Design and fabrication of a cMUT probe for ultrasound imaging of fingerprints. In Proceedings of the IEEE Ultrasonics Symposium, San Diego, CA, USA, 11–14 October 2010; pp. 1877–1880. [Google Scholar]

- Kwak, Y.S.; Choi, W.Y.; Park, K.K. Fingerprint imaging using CMUT impediography with glass waveguide. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 1–4. [Google Scholar]

- Ergun, A.; Yaralioglu, G.G.; Khuri-Yakub, B.T. Capacitive Micromachined Ultrasonic Transducers: Theory and Technology. J. Aerosp. Eng. 2003, 16, 76–84. [Google Scholar] [CrossRef]

- Yaralioglu, G.; Ergun, S.; Khuri-Yakub, B.T. Finite-element analysis of capacitive micromachined ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2185–2198. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Y.; Pun, S.H.; Gao, Y.; Che, U.K.; Mak, P.U. An accurate design to calculate and measure the capacitance of CMUT for pressure sensors. In Proceedings of the 2016 IEEE International Conference on Consumer Electronics-China (ICCE-China), Guangzhou, China, 19–21 December 2016; pp. 1–4. [Google Scholar]

- Jin, X.; Oralkan, Ö.; Degertekin, F.; Khuri-Yakub, B.T. Characterization of one-dimensional capacitive micromachined ultrasonic immersion transducer arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2001, 48, 750–760. [Google Scholar]

- Olcum, S.; Yamaner, F.Y.; Bozkurt, A.; Atalar, A. Deep-collapse operation of capacitive micromachined ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 2475–2483. [Google Scholar] [CrossRef] [PubMed]

- Brenner, K.; Ergun, A.S.; Firouzi, K.; Rasmussen, M.F.; Stedman, Q.; Khuri–Yakub, B.T. Advances in Capacitive Micromachined Ultrasonic Transducers. Micromachines 2019, 10, 152. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Chen, H.; Ding, H.; Xie, J. High-Accuracy Ultrasonic Rangefinders via pMUTs Arrays Using Multi-Frequency Continuous Waves. J. Microelectromech. Syst. 2019, 28, 634–642. [Google Scholar] [CrossRef]

- Sun, C.; Shi, Q.; Yazici, M.S.; Kobayashi, T.; Liu, Y.; Lee, C. Investigation of Broadband Characteristics of Multi-Frequency Piezoelectric Micromachined Ultrasonic Transducer (MF-pMUT). IEEE Sens. J. 2019, 19, 860–867. [Google Scholar] [CrossRef]

- Ledesma, E.; Zamora, I.; Uranga, A.; Barniol, N. Tent-Plate AlN PMUT With a Piston-Like Shape Under Liquid Operation. IEEE Sens. J. 2020, 20, 11128–11137. [Google Scholar] [CrossRef]

- Mills, D.M.; Smith, L.S. Real-time imaging with capacitive micromachined ultrasound transducer (cMUT) linear arrays. In Proceedings of the IEEE Symposium on Ultrasonics, Honolulu, HI, USA, 5–8 October 2003; pp. 568–571. [Google Scholar]

- Bayram, B.; Haeggstrom, E.; Yaralioglu, G.G.; Khuri-Yakub, B.T. A new regime for operating capacitive micromachined ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 1184–1190. [Google Scholar] [CrossRef]

- Oralkan, Ö.; Bayram, B.; Yaralioglu, G.G.; Ergun, A.S.; Kupnik, M.; Yeh, D.T.; Wygant, I.O.; Khuri-Yakub, B.T. Experimental characterization of collapse-mode CMUT operation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 1513–1523. [Google Scholar] [CrossRef] [PubMed]

- Park, K.K.; Oralkan, O.; Khuri-Yakub, B.T. A comparison between conventional and collapse-mode capacitive micromachined ultrasonic transducers in 10-MHz 1-D arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1245–1255. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Pun, S.H.; Mak, P.U.; Cheng, C.H.; Wang, J.; Mak, P.I.; Vai, M.I. Design of a Collapse-Mode CMUT With an Embossed Membrane for Improving Output Pressure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 854–863. [Google Scholar] [CrossRef]

- Sénégond, N.; Boulmé, A.; Plag, C.; Teston, F.; Certon, D. Fast time-domain modeling of fluid-coupled cMUT cells: From the single cell to the 1-D linear array element. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1505–1518. [Google Scholar] [CrossRef] [PubMed]

- Park, K.K.; Oralkan, Ö.; Khuri-Yakub, B.T. Comparison of conventional and collapse-mode CMUT in 1-D array configuration. In Proceedings of the IEEE International Ultrasonics Symposium, Orlando, FL, USA, 18–21 October 2011; pp. 1000–1003. [Google Scholar]

- Midtbo, K.; Ronnekleiv, A. Analysis of charge effects in high frequency CMUTs. In Proceedings of the 2008 IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 379–382. [Google Scholar]

- Olcum, S.; Yamaner, F.Y.; Bozkurt, A.; Koymen, H.; Atalar, A. CMUT array element in deep-collapse mode. In Proceedings of the IEEE International Ultrasonics Symposium, Orlando, FL, USA, 18–21 October 2011; pp. 108–111. [Google Scholar]

- Oguz, H.K.; Olcum, S.; Senlik, M.N.; Atalar, A.; Koymen, H. Nonlinear modeling of an immersed transmitting capacitive micromachined ultrasonic transducer for harmonic balance analysis. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 438–447. [Google Scholar] [CrossRef]

- Cour, M.F.l.; Christiansen, T.L.; Jensen, A.; Thomsen, E.V. Electrostatic and small-signal analysis of CMUTs with circular and square anisotropic plates. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 1563–1579. [Google Scholar] [CrossRef]

- Ceroici, C.; Zemp, R.J. Large-Scale Nonlinear Lumped and Integrated Field Simulations of Top-Orthogonal-to-Bottom-Electrode CMUT Architectures. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 64, 1087–1091. [Google Scholar] [CrossRef]

- Koymen, H.; Senlik, M.N.; Atalar, A.; Olcum, S. Parametric linear modeling of circular cMUT membranes in vacuum. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 1229–1239. [Google Scholar] [CrossRef] [PubMed]

- Eccardt, P.C.; Wagner, P.; Hansen, S. 5F-1 Analytical Models for Micromachined Transducers—An Overview (Invited). In Proceedings of the 2006 IEEE Ultrasonics Symposium, Vancouver, BC, Canada, 2–6 October 2006; pp. 572–581. [Google Scholar]

- Wygant, I.O.; Kupnik, M.; Khuri-Yakub, B.T. CMUT design equations for optimizing noise figure and source pressure. In Proceedings of the IEEE International Ultrasonics Symposium(IUS), Tours, France, 18–21 September 2016; pp. 1–4. [Google Scholar]

- Li, Z.; Zhao, L.; Zhao, Y.; Li, J.; Xu, T.; Hu, K.; Liu, Z.; Yang, P.; Luo, G.; Lin, Q.; et al. Closed-form expressions on CMUTs with layered anisotropic microplates under residual stress and pressure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 1828–1843. [Google Scholar] [CrossRef]

- Bozkurt, A.; Ladabaum, I.; Atalar, A.; Khuri-Yakub, B.T. Theory and analysis of electrode size optimization for capacitive microfabricated ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1999, 46, 1364–1374. [Google Scholar] [CrossRef] [PubMed]

- Yaralioglu, G.G.; Ergun, A.S.; Bayram, B.; Haeggstrom, E.; Khuri-Yakub, B.T. Calculation and measurement of electromechanical coupling coefficient of capacitive micromachined ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 449–456. [Google Scholar] [CrossRef]

- Nikoozadeh, A.; Bayram, B.; Yaralioglu, G.; Khuri-Yakub, B.T. Analytical calculation of collapse voltage of CMUT membrane. In Proceedings of the IEEE Ultrasonics Symposium, Montreal, QC, Canada, 23–27 August 2004; Volume 1, pp. 256–259. [Google Scholar]

- Timoshenko, S.; Woinowsky-krieger, S. Theory of Plates and Shells; McGraw-Hill: New York, NY, USA, 1959; pp. 64–65, 308–310. [Google Scholar]

- Wygant, I.O.; Kupnik, M.; Khuri-Yakub, B.T. Analytically Calculating Membrane Displacement and the Equivalent Circuit Model of a Circular CMUT Cell. In Proceedings of the IEEE International Ultrasonics Symposium (IUS), Beijing, China, 2–5 November 2008; pp. 2111–2114. [Google Scholar]

- Nemirovsky, Y.; Bochobza-Degani, Y. A methodology and model for the pull-in parameters of electrostatic actuators. J. Microelectromech. Syst. 2001, 10, 601–615. [Google Scholar] [CrossRef]

- Ahmad, B.; Pratap, R. Elasto-electrostatic analysis of circular microplates used in capacitive micromachined ultrasonic transducers. IEEE Sens. J. 2010, 10, 1767–1773. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, L.; Zhao, Y.; Jiang, Z.; Ye, Z. Zhao, Y. An Improved Method for the Mechanical Behavior Analysis of Electrostatically Actuated Microplates Under Uniform Hydrostatic Pressure. J. Microelectromech. Syst. 2015, 24, 474–485. [Google Scholar] [CrossRef]

- Ventsel, E.; Krauthammer, T. Thin Plates and Shells Theory: Analysis, and Applications; CRC Press: Boca Raton, FL, USA, 2001; pp. 215–216. [Google Scholar]

- Zheng, X. Theory and Applications of Large Deflections of Thin Circular Membranes; Jilin Science and Technology Press: Changchun, China, 1990; p. 11. (In Chinese) [Google Scholar]

- Logan, A.; Yeow, J.T.W. Fabricating capacitive micromachined ultrasonic transducers with a novel silicon-nitride-Based wafer bonding process. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1074–1084. [Google Scholar] [CrossRef]

- Aydogdu, E.; Ozgurluk, A.; Atalar, A.; Koymen, H. Parametric nonlinear lumped element model for circular CMUTs in collapsed mode. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 173–181. [Google Scholar] [CrossRef]

- Khan, M.; Khan, T.M.; Tadelen, S.; Yilmaz, M.; Atalar, A.; Koymen, H. Optimization of a collapsed mode CMUT receiver for maximum off-resonance sensitivity. J. Microelectromech. Syst. 2018, 27, 921–930. [Google Scholar] [CrossRef]

- Liew, K.M.; Xiang, Y.; Wang, C.; Kitipornchai, S. Vibration of Mindlin Plates: Programming the p-Version Ritz Method; Elsevier Science: Amsterdam, The Nederland, 1998; pp. 5–8. [Google Scholar]

- Olcum, S.; Yamaner, F.Y.; Bozkurt, A.; Koymen, H.; Atalar, A. An equivalent circuit model for transmitting capacitive micromachined ultrasonic transducers in collapse mode. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 1468–1477. [Google Scholar] [CrossRef]

- Aydogdu, E.; Ozgurluk, A.; Oguz, H.K.; Atalar, A.; Koymen, H. Lumped Element Model of Single CMUT in Collapsed Mode. In Proceedings of the IEEE International Ultrasonics Symposium (IUS), Prague, Czech Republic, 21–25 July 2013; pp. 283–286. [Google Scholar]

- Aydogdu, E.; Ozgurluk, A.; Oguz, H.K.; Atalar, A.; Kocabas, C.; Koymen, H. Nonlinear equivalent circuit model for circular CMUTs in uncollapsed and collapsed mode. In Proceedings of the IEEE International Ultrasonics Symposium (IUS), Dresden, Germany, 7–10 October 2012. pp. 987–990.

- Aydogdu, E.; Ozgurluk, A.; Atalar, A.; Koymen, H. Lumped element modeling of cmut arrays in collapsed mode. In Proceedings of the 2014 IEEE International Ultrasonics Symposium, Chicago, IL, USA, 3–6 September 2014; pp. 309–312. [Google Scholar]

- Pekar, M.; Nispen, S.H.M.V.; Fey, R.H.B.; Shulepov, S.; Mihajlovic, N.; Nijmeijer, H. A fluid-coupled transmitting CMUT operated in collapse mode: Semi-analytic modeling and experiments. Sens. Actuators Phys. 2017, 267, 474–484. [Google Scholar] [CrossRef]

- Kupnik, M.; Wygant, I.O.; Khuri-Yakub, B.T. Finite element analysis of stress stiffening effects in CMUTS. In Proceedings of the 2008 IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 487–490. [Google Scholar]

- Vogl, G.W. Nonlinear Dynamics of Circular Plates under Electrical Loadings for Capacitive Micromachined Ultrasonic Transducers (CMUTs). Ph.D Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2006. [Google Scholar]

- Wang, J.; Pun, S.H.; Mak, P.U.; Cheng, C.-H.; Yu, Y.; Mak, P.-I.; Vai, M.I. Improved Analytical Modeling of Membrane Large Deflection With Lateral Force for the Underwater CMUT Based on Von Kármán Equations. IEEE Sens. J. 2016, 16, 6633–6640. [Google Scholar] [CrossRef]

| Parameters | Collapse Mode | References |

|---|---|---|

| Output pressure sensitivity | 26.4 kPa/V, while 12.7 kPa/V for conventional | [33] |

| Receive sensitivity | higher than conventional | [33] |

| Mechanical coupling coefficient | higher than conventional | [31] |

| Center frequency | variable for collapse while fixed for conventional | [32] |

| Charging effect | more severe, but can be decreased | [37,38] |

| Second harmonic distortion | about 10 dB higher than conventional, but can be decreased | [33] |

| Method and Parameter Source | Equations (1) and (3) | Equation (6) | Equation (12) | Equation (13) |

|---|---|---|---|---|

| Parallel plate theory [47] | 56.27 V | 39.39 V | 20.42 V | 40.74 V |

| Semi-analytical algorithm [48] | 218.75 V | 153.13 V | 124.16 V | 158.35 V |

| Expansion of electrostatic force [52] | 170.65 V | 119.45 V | 96.93 V | 123.53 V |

| Expansion of electrostatic force [52] | 2013.03 | 1409.12 | 326.75 | 1457.23 |

| Analytical Modeling Methods | Application Scenarios | Reference |

|---|---|---|

| Solution Equation (17) | For small deflections | [60] |

| Governing Equation (18) and its variations | For small deflections | [62] |

| 2D plate equation | For small deflections, no analytical expression | [35] |

| von Kármán equations | For small and large deflections | [67] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liu, X.; Yu, Y.; Li, Y.; Cheng, C.; Zhang, S.; Mak, P.; Vai, M.; Pun, S. A Review on Analytical Modeling for Collapse Mode Capacitive Micromachined Ultrasonic Transducer of the Collapse Voltage and the Static Membrane Deflections. Micromachines 2021, 12, 714. https://doi.org/10.3390/mi12060714

Wang J, Liu X, Yu Y, Li Y, Cheng C, Zhang S, Mak P, Vai M, Pun S. A Review on Analytical Modeling for Collapse Mode Capacitive Micromachined Ultrasonic Transducer of the Collapse Voltage and the Static Membrane Deflections. Micromachines. 2021; 12(6):714. https://doi.org/10.3390/mi12060714

Chicago/Turabian StyleWang, JiuJiang, Xin Liu, YuanYu Yu, Yao Li, ChingHsiang Cheng, Shuang Zhang, PengUn Mak, MangI Vai, and SioHang Pun. 2021. "A Review on Analytical Modeling for Collapse Mode Capacitive Micromachined Ultrasonic Transducer of the Collapse Voltage and the Static Membrane Deflections" Micromachines 12, no. 6: 714. https://doi.org/10.3390/mi12060714

APA StyleWang, J., Liu, X., Yu, Y., Li, Y., Cheng, C., Zhang, S., Mak, P., Vai, M., & Pun, S. (2021). A Review on Analytical Modeling for Collapse Mode Capacitive Micromachined Ultrasonic Transducer of the Collapse Voltage and the Static Membrane Deflections. Micromachines, 12(6), 714. https://doi.org/10.3390/mi12060714