Chitosan-Based Flexible Memristors with Embedded Carbon Nanotubes for Neuromorphic Electronics

Abstract

:1. Introduction

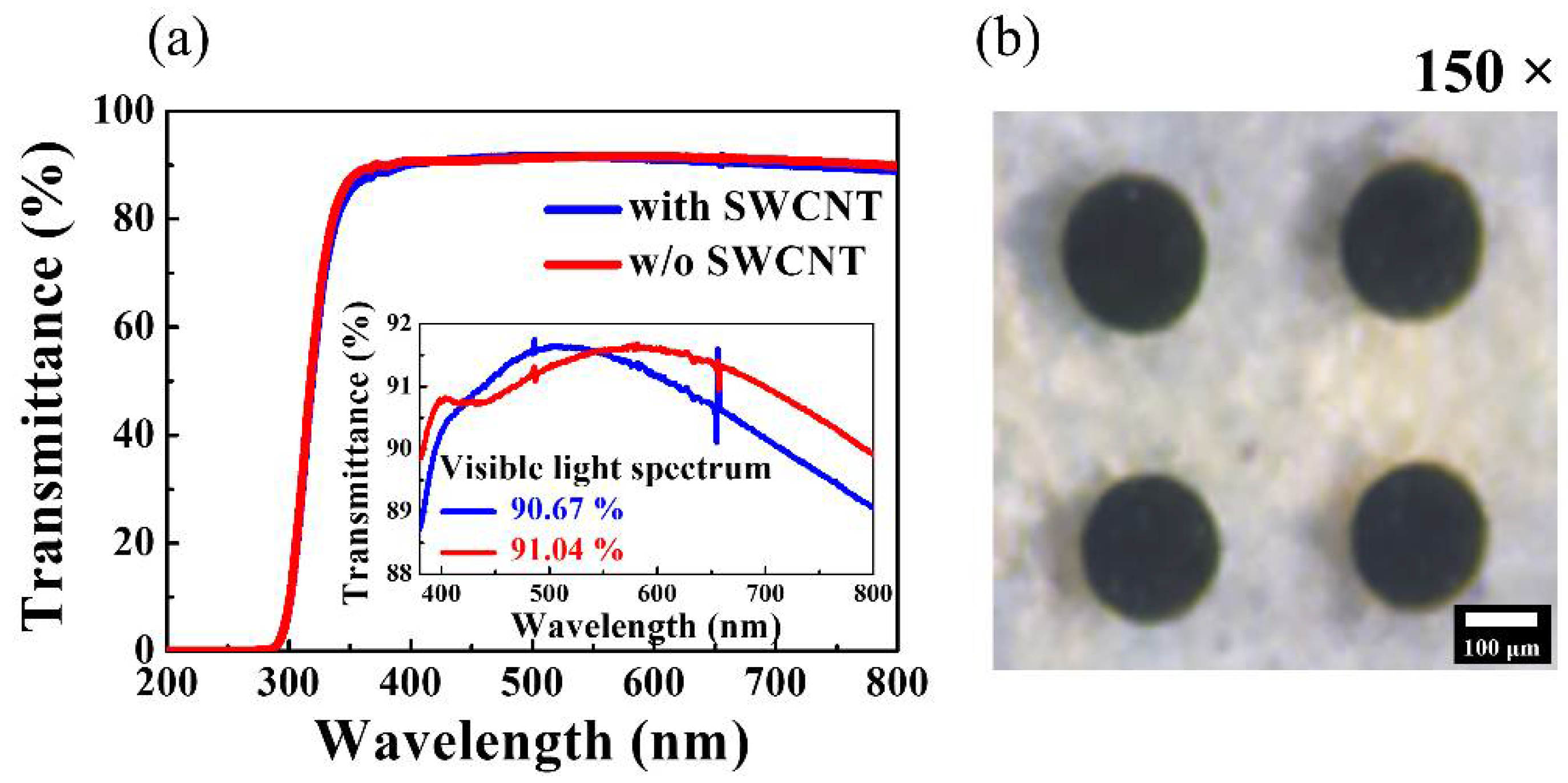

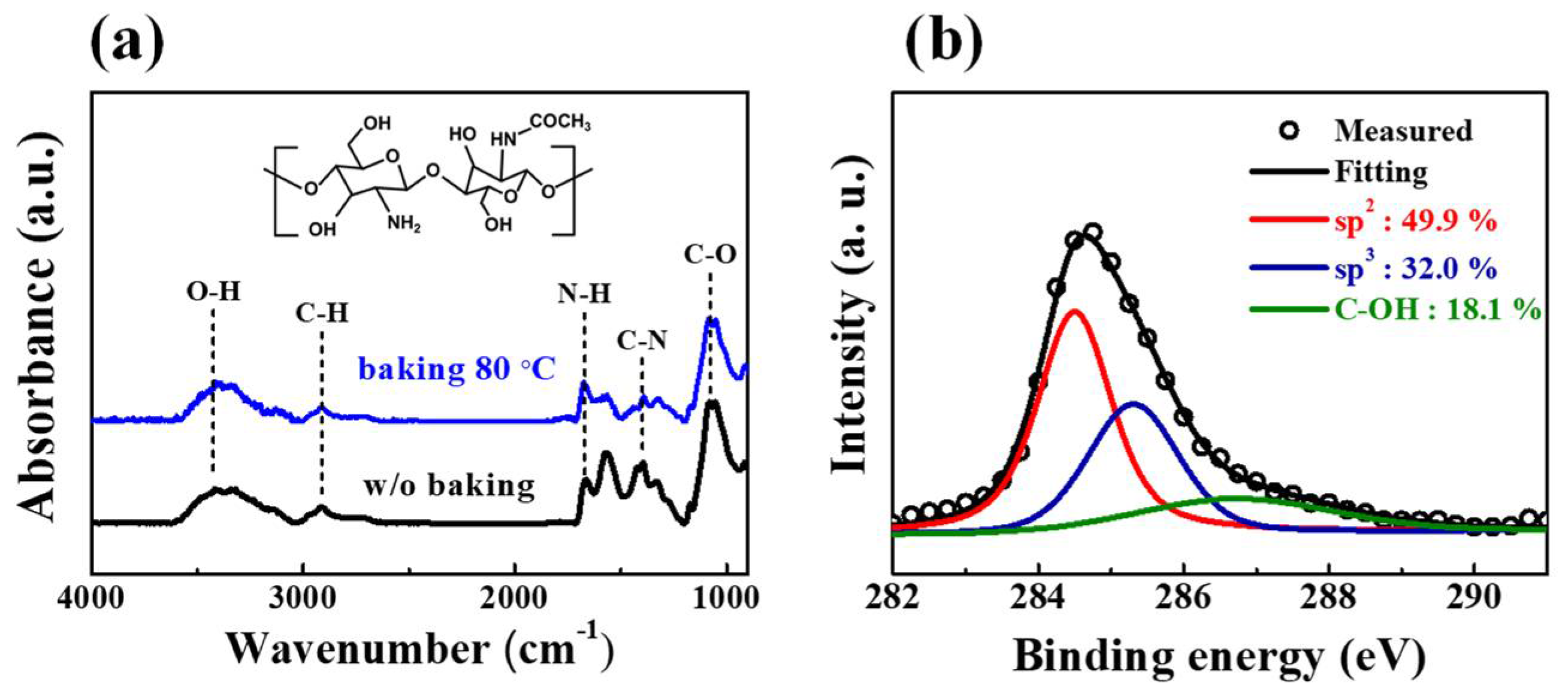

2. Experimental

2.1. Materials

2.2. Chitosan Solution Manufacturing Process

2.3. Fabrication of Flexible Transparent Memristors

2.4. Characterization Methods

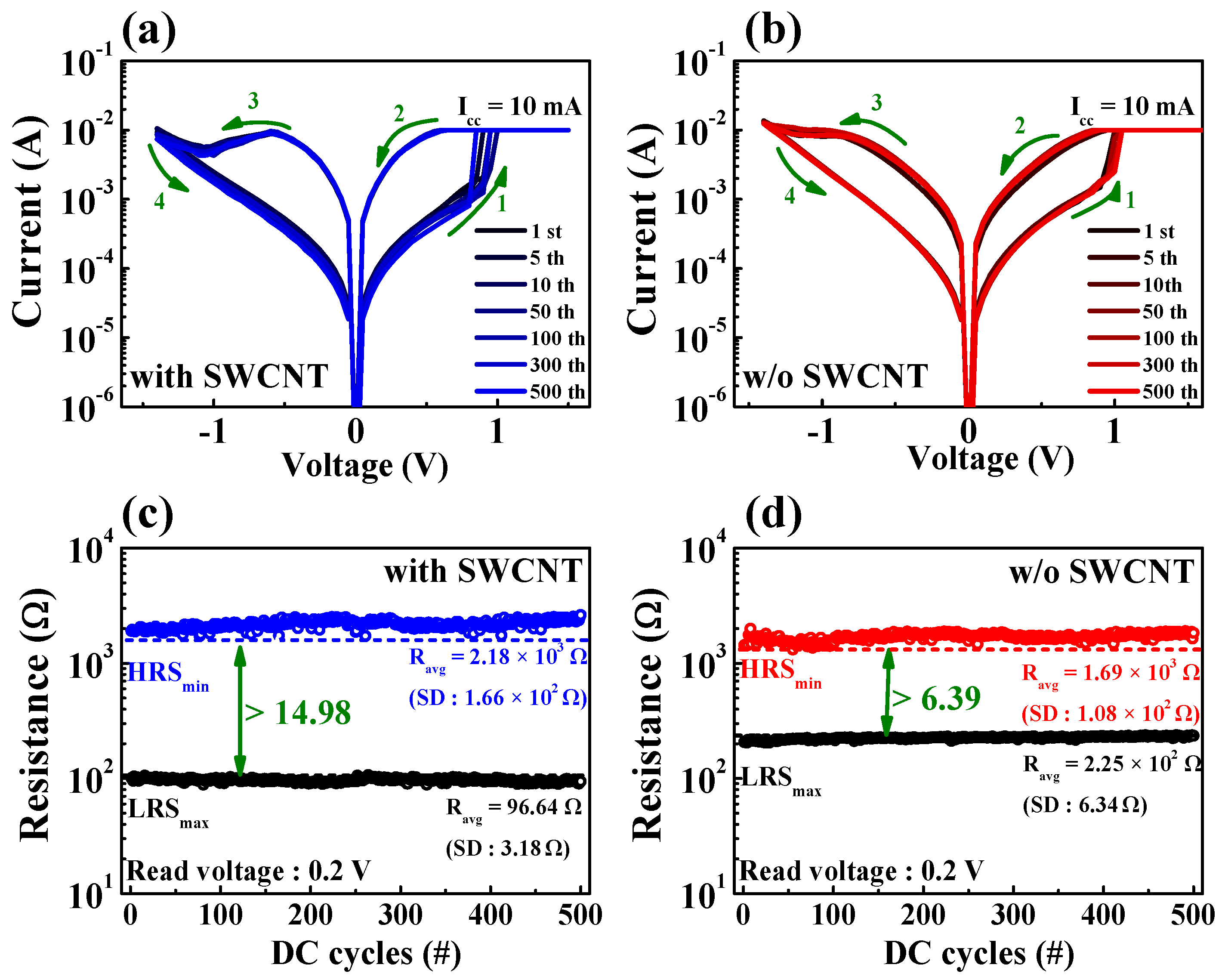

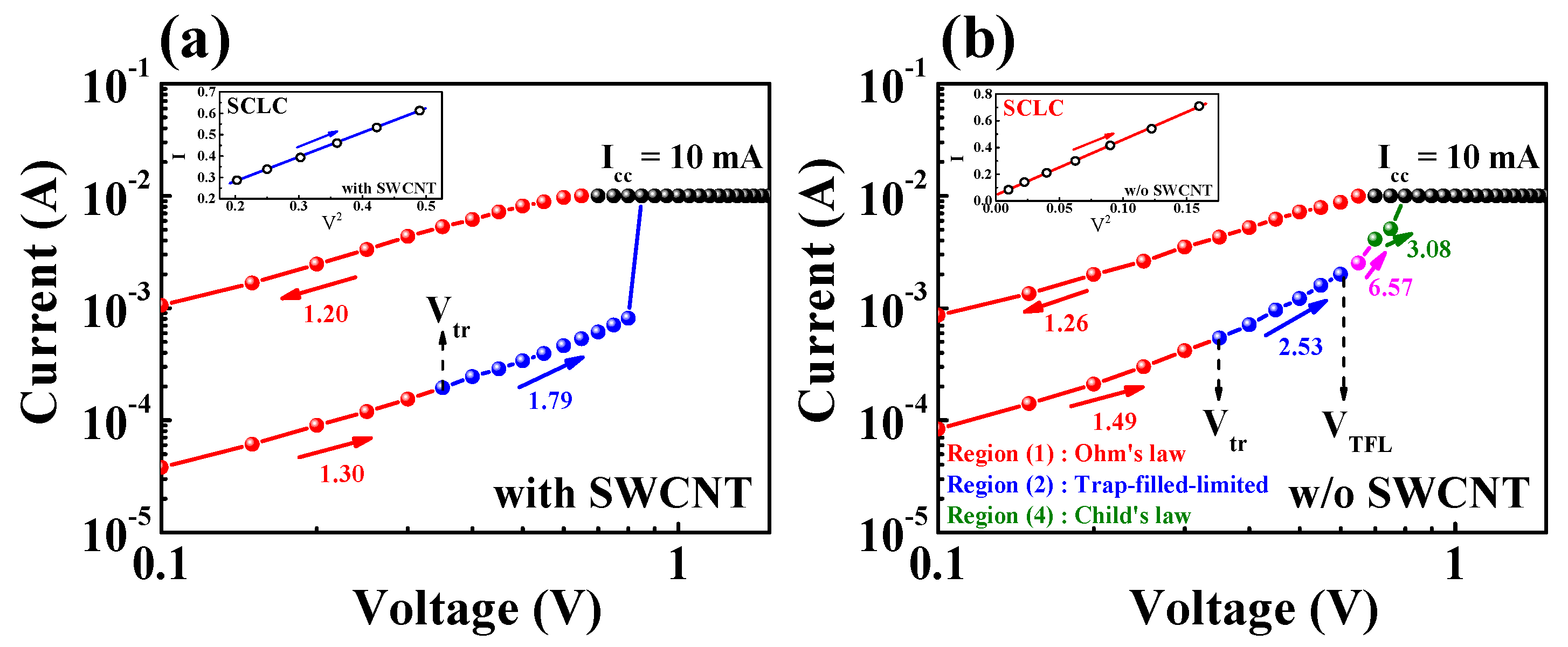

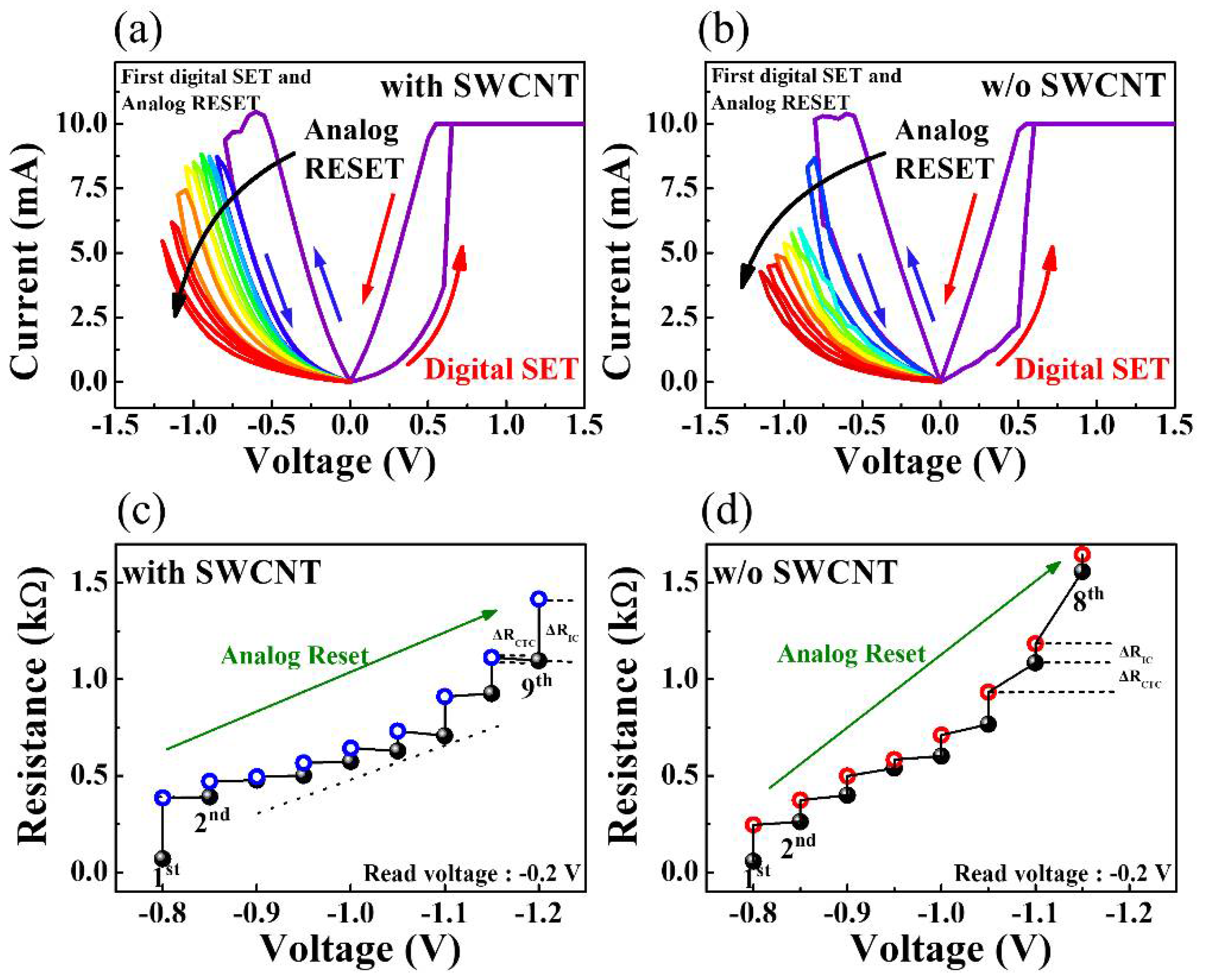

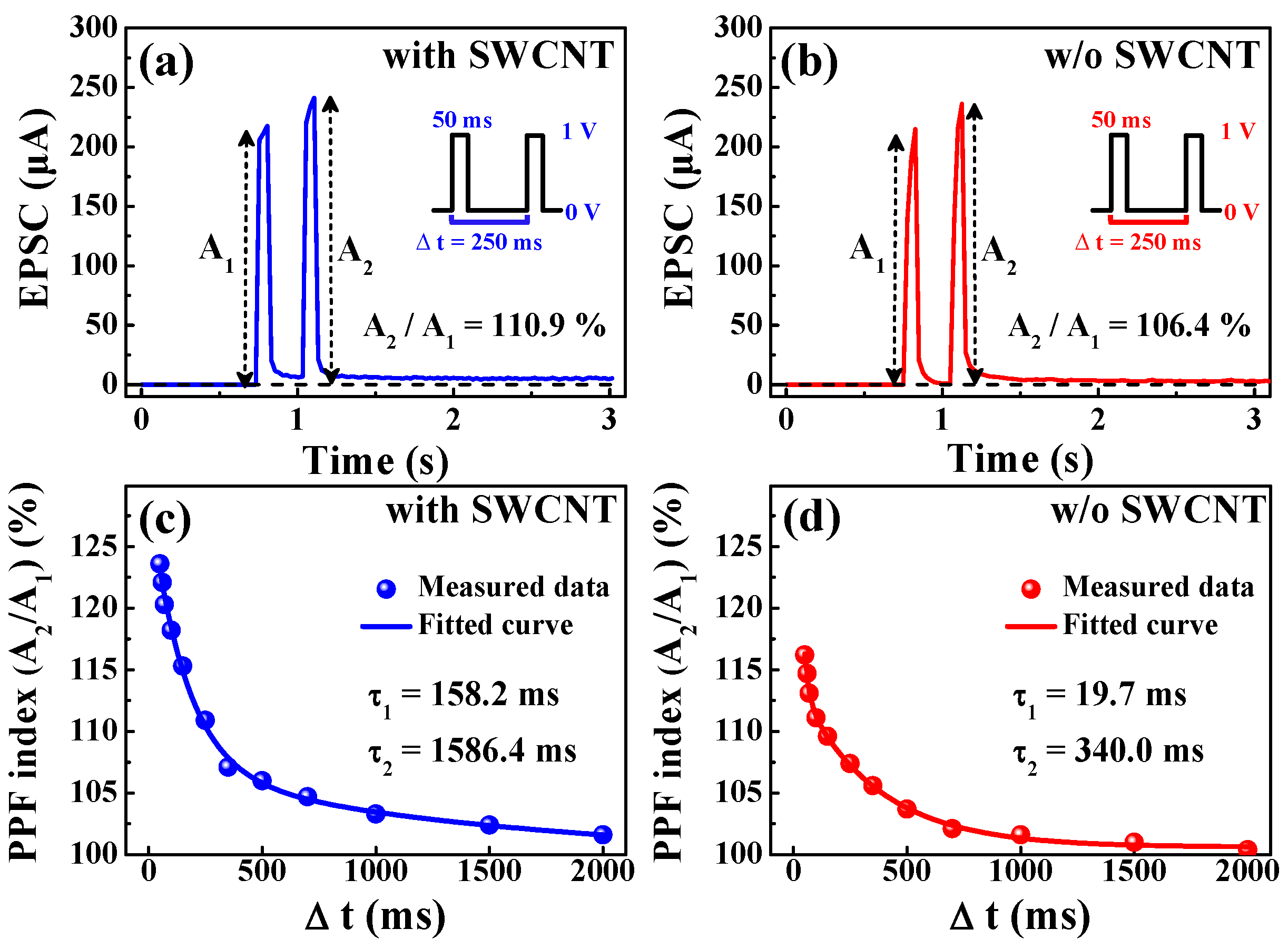

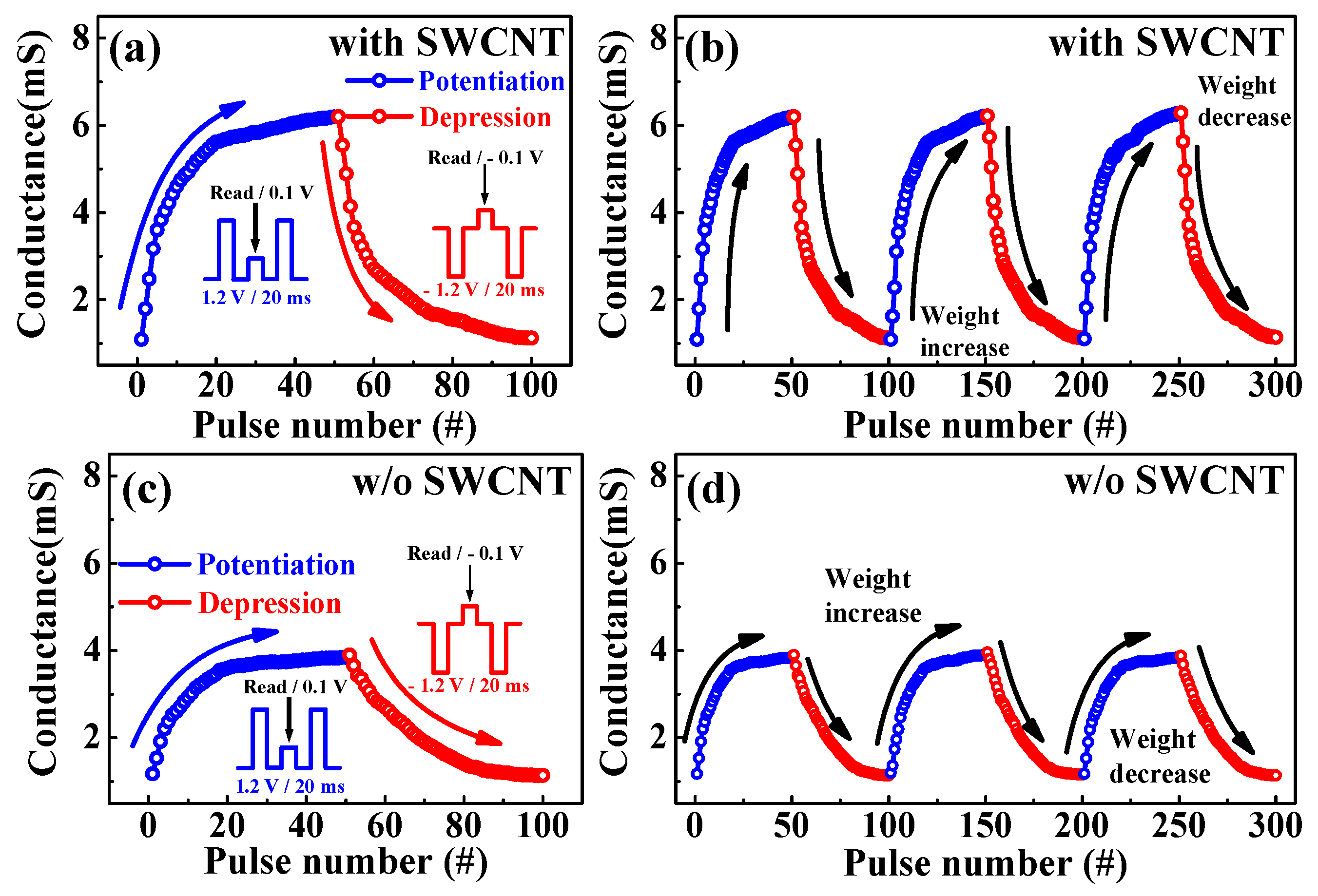

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zanotti, T.; Puglisi, F.M.; Pavan, P. Smart logic-in-memory architecture for low-power non-von Neumann computing. IEEE J. Electron Dev. Soc. 2020, 8, 757–764. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Z.; Shi, T.; Bi, C.; Rao, F.; Cai, Y.; Zhou, P. Memory materials and devices: From concept to application. InfoMat 2020, 2, 261–290. [Google Scholar] [CrossRef] [Green Version]

- Premsankar, G.; Di Francesco, M.; Taleb, T. Edge computing for the Internet of Things: A case study. IEEE Int. Things J. 2018, 5, 1275–1284. [Google Scholar] [CrossRef] [Green Version]

- Yanagida, T.; Nagashima, K.; Oka, K.; Kanai, M.; Klamchuen, A.; Park, B.H.; Kawai, T. Scaling effect on unipolar and bipolar resistive switching of metal oxides. Sci. Rep. 2013, 3, 1–6. [Google Scholar] [CrossRef]

- Waser, R.; Aono, M. Nanoscience and Technology: A Collection of Reviews from Nature Journals; World Scientific: Singapore, 2009. [Google Scholar]

- Khalid, M. Review on various memristor models, characteristics, potential applications, and future works. Trans. Electr. Electron. Mater. 2019, 20, 289–298. [Google Scholar] [CrossRef]

- Raeis Hosseini, N.; Lee, J.-S. Resistive switching memory using biomaterials. J. Electroceramics 2017, 39, 223–238. [Google Scholar] [CrossRef]

- Li, Y.; Qian, Q.; Zhu, X.; Li, Y.; Zhang, M.; Li, J.; Zhang, Q. Recent advances in organic-based materials for resistive memory applications. InfoMat 2020, 2, 995–1033. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Viventi, J.; Amsden, J.J.; Xiao, J.; Vigeland, L.; Kim, Y.S.; Blanco, J.A.; Panilaitis, B.; Frechette, E.S.; Contreras, D.; et al. Dissolvable films of silk fibroin for ultrathin conformal bio–integrated electronics. Nat. Mater. 2010, 9, 511–517. [Google Scholar] [CrossRef] [PubMed]

- Raeis Hosseini, N.; Lee, J.-S. Resistive switching memory based on bioinspired natural solid polymer electrolytes. ACS Nano 2015, 9, 419–426. [Google Scholar] [CrossRef]

- Hosseini, N.R.; Lee, J.-S. Biocompatible and flexible chitosan-based resistive switching memory with magnesium electrodes. Adv. Funct. Mater. 2015, 25, 5586–5592. [Google Scholar] [CrossRef]

- Jiang, J.; Kuroda, M.A.; Ahyi, A.C.; Isaacs-Smith, T.; Mirkhani, V.; Park, M.; Dhar, S. Chitosan solid electrolyte as electric double layer in multilayer MoS2 transistor for low-voltage operation. Phys. Status Solidi A 2015, 212, 2219–2225. [Google Scholar] [CrossRef]

- Liu, Y.H.; Zhu, L.Q.; Feng, P.; Shi, Y.; Wan, Q. Freestanding artificial synapses based on laterally proton-coupled transistors on chitosan membranes. Adv. Mater. 2015, 27, 5599–5604. [Google Scholar] [CrossRef] [PubMed]

- Ihara, K.; Numata, H.; Nihey, F.; Yuge, R.; Endoh, H. High purity semiconducting single-walled carbon nanotubes for printed electronics. ACS Appl. Nano Mater. 2019, 2, 4286–4292. [Google Scholar] [CrossRef]

- Hirotani, J.; Kishimoto, S.; Ohno, Y. Origins of the variability of the electrical characteristics of solution-processed carbon nanotube thin-film transistors and integrated circuits. Nanosc. Adv. 2019, 1, 636–642. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Seo, J.; Seong, N.; Kim, T.; Lee, S.; Hong, Y. P-29: Solution-processed single-walled carbon nanotube thin film transistors in-situ patterned by inkjet-printing of surface treatment material. SID Symp. Dig. Tech. Papers 2019, 50, 1321–1324. [Google Scholar] [CrossRef]

- Sun, Y.; Miao, F.; Li, R. Bistable electrical switching and nonvolatile memory effect based on the thin films of polyurethane-carbon nanotubes blends. Sens. Actuator A Phys. 2015, 234, 282–289. [Google Scholar] [CrossRef]

- Bose, S.; Khare, R.A.; Moldenaers, P. Assessing the strengths and weaknesses of various types of pre-treatments of carbon nanotubes on the properties of polymer/carbon nanotubes composites: A critical review. Polymer 2010, 51, 975–993. [Google Scholar] [CrossRef] [Green Version]

- Chaudhary, D.; Vankar, V.D.; Khare, N. Noble metal-free g-C3N4/TiO2/CNT ternary nanocomposite with enhanced photocatalytic performance under visible-light irradiation via multi-step charge transfer process. Sol. Energy 2017, 158, 132–139. [Google Scholar] [CrossRef]

- Shoukat, R.; Khan, M.I. Carbon nanotubes: A review on properties, synthesis methods and applications in micro and nanotechnology. Microsys. Tech. 2021, 1–10. [Google Scholar] [CrossRef]

- Janani, M.; Srikrishnarka, P.; Nair, S.V.; Nair, A.S. An in-depth review on the role of carbon nanostructures in dye-sensitized solar cells. J. Mater. Chem. A 2015, 3, 17914–17938. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polymer Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef] [Green Version]

- Berber, S.; Kwon, Y.K.; Tománek, D. Unusually high thermal conductivity of carbon nanotubes. Phys. Rev. Lett. 2000, 84, 4613–4616. [Google Scholar] [CrossRef] [Green Version]

- Strozzi, M.; Pellicano, F. Nonlinear resonance interaction between conjugate circumferential flexural modes in single-walled carbon nanotubes. Shock Vibr. 2019, 2019. [Google Scholar] [CrossRef]

- Strozzi, M.; Smirnov, V.V.; Manevitch, L.I.; Pellicano, F. Nonlinear normal modes, resonances and energy exchange in single-walled carbon nanotubes. Int. J. Non-Linear Mech. 2020, 120, 103398. [Google Scholar] [CrossRef]

- Wang, C.; Takei, K.; Takahashi, T.; Javey, A. Carbon nanotube electronics—Moving forward. Chem. Soc. Rev. 2013, 42, 2592–2609. [Google Scholar] [CrossRef]

- Jiang, S.; He, Y.; Liu, R.; Zhang, C.; Shi, Y.; Wan, Q. Synaptic metaplasticity emulation in a freestanding oxide-based neuromorphic transistor with dual in-plane gates. J. Phys. D 2021, 54, 185106. [Google Scholar] [CrossRef]

- Woranuch, S.; Yoksan, R. Preparation, characterization and antioxidant property of water-soluble ferulic acid grafted chitosan. Carbohydrate Polym. 2013, 96, 495–502. [Google Scholar] [CrossRef] [PubMed]

- Estrade-Szwarckopf, H. XPS photoemission in carbonaceous materials: A “defect” peak beside the graphitic asymmetric peak. Carbon 2004, 42, 1713–1721. [Google Scholar] [CrossRef]

- Yu, J. Carbon sp2-on-sp3 Technology: Graphene-on-Diamond Devices and Interconnects. Doctoral Dissertation, UC Riverside, Riverside, CA, USA, 2012. [Google Scholar]

- Wu, S.; Tsuruoka, T.; Terabe, K.; Hasegawa, T.; Hill, J.P.; Ariga, K.; Aono, M. A polymer-electrolyte-based atomic switch. Adv. Funct. Mater. 2011, 21, 93–99. [Google Scholar] [CrossRef]

- Waser, R.; Dittmann, R.; Staikov, G.; Szot, K. Redox-based resistive switching memories–nanoionic mechanisms, prospects, and challenges. Adv. Mater. 2009, 21, 2632–2663. [Google Scholar] [CrossRef]

- Belloni, F.; Kütahyali, C.; Rondinella, V.V.; Carbol, P.; Wiss, T.; Mangione, A. Can carbon nanotubes play a role in the field of nuclear waste management? Environ. Sci. Technol. 2009, 43, 1250–1255. [Google Scholar] [CrossRef] [Green Version]

- Min, S.Y.; Cho, W.J. Resistive switching characteristic improvement in a single-walled carbon nanotube random network embedded hydrogen silsesquioxane thin films for flexible memristors. Int. J. Mol. Sci. 2021, 22, 3390. [Google Scholar] [CrossRef]

- Chiu, F.C.; Pan, T.M.; Kundu, T.K.; Shih, C.H. Thin film applications in advanced electron devices. Adv. Mater. Sci. Eng. 2014, 2014. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.W.; Baek, I.J.; Cho, W.J. Resistive switching characteristics of solution-processed Al–Zn–Sn–O films annealed by microwave irradiation. Solid State Electron. 2018, 140, 122–128. [Google Scholar] [CrossRef]

- Kim, K.M.; Choi, B.J.; Shin, Y.C.; Choi, S.; Hwang, C.S. Anode-interface localized filamentary mechanism in resistive switching of TiO2 thin films. Appl. Phys. Lett. 2007, 91, 012907. [Google Scholar] [CrossRef]

- Tran, K.M.; Do, D.P.; Thi, K.H.T.; Pham, N.K. Influence of top electrode on resistive switching effect of chitosan thin films. J. Mater. Res. 2019, 34, 3899–3906. [Google Scholar] [CrossRef]

- Lin, W.P.; Liu, S.J.; Gong, T.; Zhao, Q.; Huang, W. Polymer-based resistive memory materials and devices. Adv. Mater. 2014, 26, 570–606. [Google Scholar] [CrossRef]

- Mondal, S.; Her, J.L.; Chen, F.H.; Shih, S.J.; Pan, T.M. Improved resistance switching characteristics in Ti–doped Yb2O3 for resistive nonvolatile memory devices. IEEE Electron Dev. Lett. 2012, 33, 1069–1071. [Google Scholar] [CrossRef]

- Feng, P.; Chen, C.; Wang, Z.S.; Yang, Y.C.; Yang, J.; Zeng, F. Nonvolatile resistive switching memories–characteristics, mechanisms and challenges. Prog. Nat. Sci. Mater. Int. 2010, 20, 1–15. [Google Scholar]

- Yu, F.; Zhu, L.Q.; Xiao, H.; Gao, W.T.; Guo, Y.B. Restickable oxide neuromorphic transistors with spike-timing-dependent plasticity and Pavlovian associative learning activities. Adv. Funct. Mater. 2018, 28, 1804025. [Google Scholar] [CrossRef]

- Majumdar, S.; Tan, H.; Qin, Q.H.; van Dijken, S. Energy-efficient organic ferroelectric tunnel junction memristors for neuromorphic computing. Adv. Electron. Mater. 2019, 5, 1800795. [Google Scholar] [CrossRef] [Green Version]

- Zhao, S.; Ni, Z.; Tan, H.; Wang, Y.; Jin, H.; Nie, T.; Yang, D. Electroluminescent synaptic devices with logic functions. Nano Energy 2018, 54, 383–389. [Google Scholar] [CrossRef]

- Sjostrom, P.J.; Rancz, E.A.; Roth, A.; Hausser, M. Dendritic excitability and synaptic plasticity. Physiol. Rev. 2008, 88, 769–840. [Google Scholar] [CrossRef] [PubMed]

- Zucker, R.S.; Regehr, W.G. Short-term synaptic plasticity. Ann. Rev. Physiol. 2002, 64, 355–405. [Google Scholar] [CrossRef] [Green Version]

- Bi, G.; Poo, M.M. Synaptic modifications in cultured hippocampal neurons: Dependence on spike timing, synaptic strength, and postsynaptic cell type. J. Neurosci. 1998, 18, 10464–10472. [Google Scholar] [CrossRef]

- Song, S.; Miller, K.D.; Abbott, L.F. Competitive Hebbian learning through spike-timing-dependent synaptic plasticity. Nat. Neurosci. 2000, 3, 919–926. [Google Scholar] [CrossRef]

- Kim, S.; Du, C.; Sheridan, P.; Ma, W.; Choi, S.; Lu, W.D. Experimental demonstration of a second-order memristor and its ability to biorealistically implement synaptic plasticity. Nano Lett. 2015, 15, 2203–2211. [Google Scholar] [CrossRef]

- Zhang, L.I.; Tao, H.W.; Holt, C.E.; Harris, W.A.; Poo, M. A critical window for cooperation and competition among developing retinotectal synapses. Nature 1998, 395, 37–44. [Google Scholar] [CrossRef]

- Markram, H.; Lübke, J.; Frotscher, M.; Sakmann, B. Regulation of synaptic efficacy by coincidence of postsynaptic APs and EPSPs. Science 1997, 275, 213–215. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Liu, S.; Zhao, X.; Wu, F.; Wu, Q.; Wang, W.; Cao, R.; Fang, Y.; Lv, H.; Long, S.; et al. Emulating short-term and long-term plasticity of bio-synapse based on Cu/a-Si/Pt memristor. IEEE Electron Dev. Lett. 2017, 38, 1208–1211. [Google Scholar] [CrossRef]

- Querlioz, D.; Bichler, O.; Vincent, A.F.; Gamrat, C. Bioinspired programming of memory devices for implementing an inference engine. Proc. IEEE 2015, 103, 1398–1416. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Saxena, V.; Zhu, K. Homogeneous spiking neuromorphic system for real-world pattern recognition. IEEE J. Emerg. Sel. Top. Circuits Syst. 2015, 5, 254–266. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, J.-G.; Cho, W.-J. Chitosan-Based Flexible Memristors with Embedded Carbon Nanotubes for Neuromorphic Electronics. Micromachines 2021, 12, 1259. https://doi.org/10.3390/mi12101259

Min J-G, Cho W-J. Chitosan-Based Flexible Memristors with Embedded Carbon Nanotubes for Neuromorphic Electronics. Micromachines. 2021; 12(10):1259. https://doi.org/10.3390/mi12101259

Chicago/Turabian StyleMin, Jin-Gi, and Won-Ju Cho. 2021. "Chitosan-Based Flexible Memristors with Embedded Carbon Nanotubes for Neuromorphic Electronics" Micromachines 12, no. 10: 1259. https://doi.org/10.3390/mi12101259

APA StyleMin, J.-G., & Cho, W.-J. (2021). Chitosan-Based Flexible Memristors with Embedded Carbon Nanotubes for Neuromorphic Electronics. Micromachines, 12(10), 1259. https://doi.org/10.3390/mi12101259