An Investigation into Laser-Assisted Electrochemical Discharge Machining of Transparent Insulating Hard-Brittle Material

Abstract

1. Introduction

2. Experimental Design

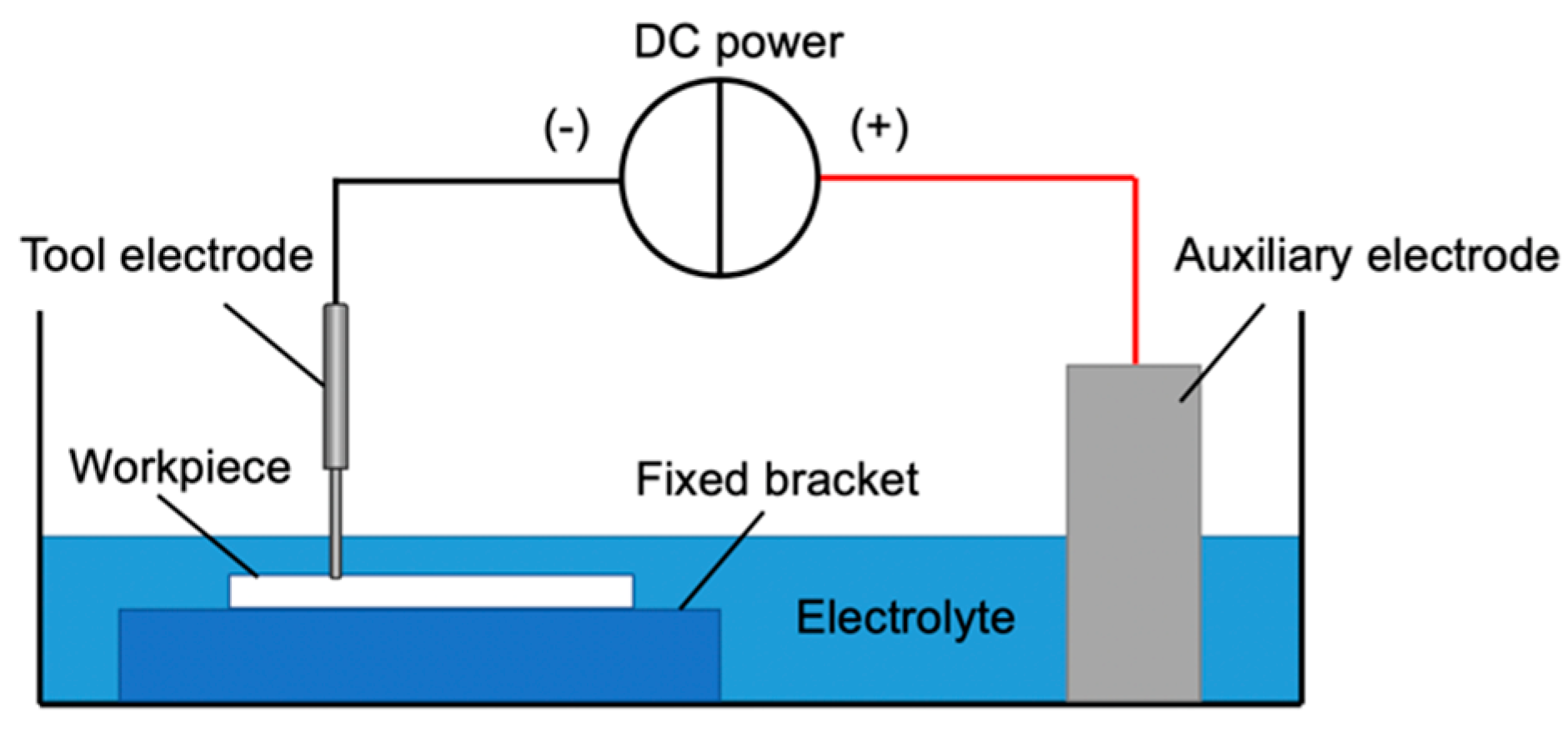

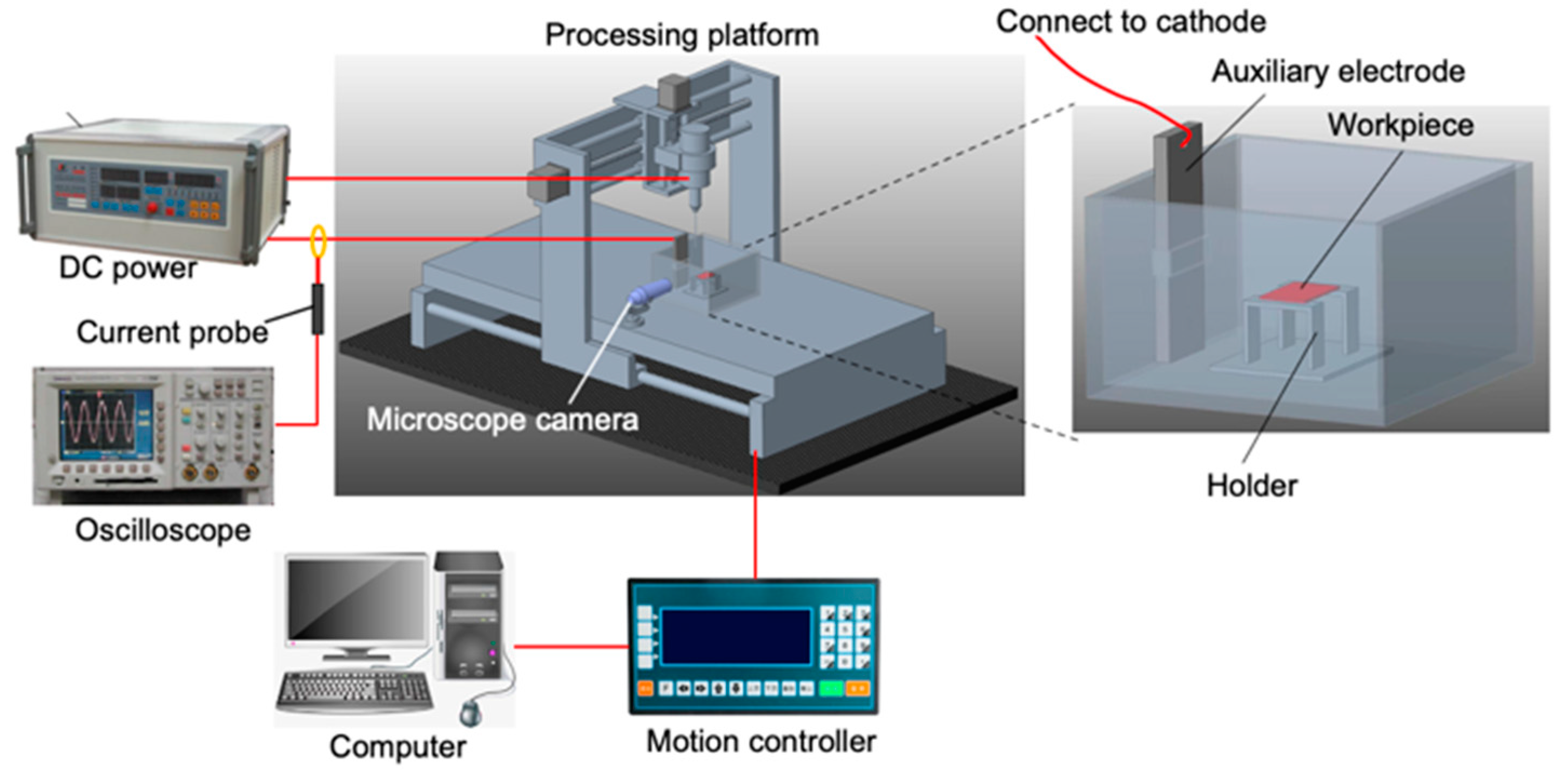

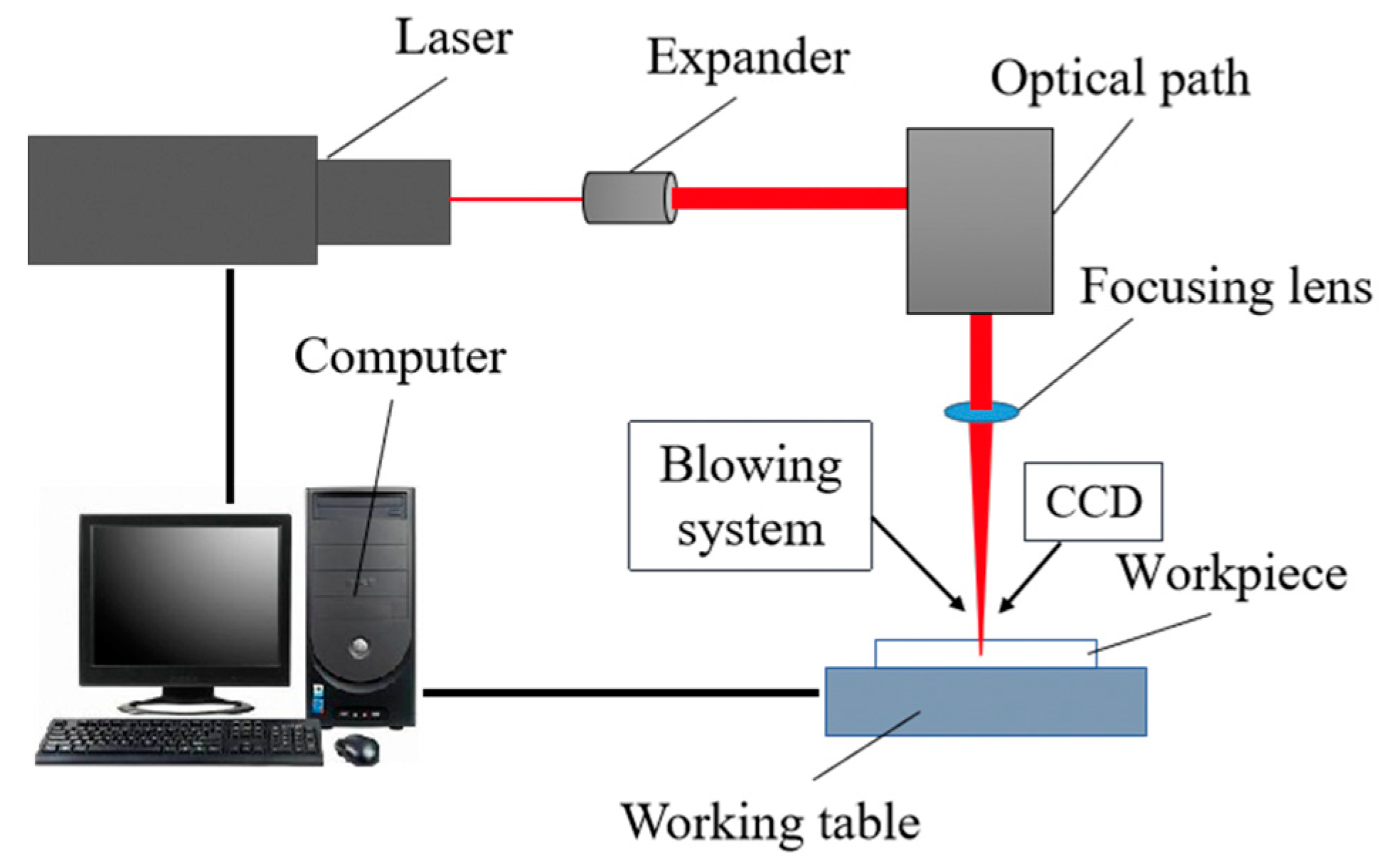

2.1. Experimental Setup

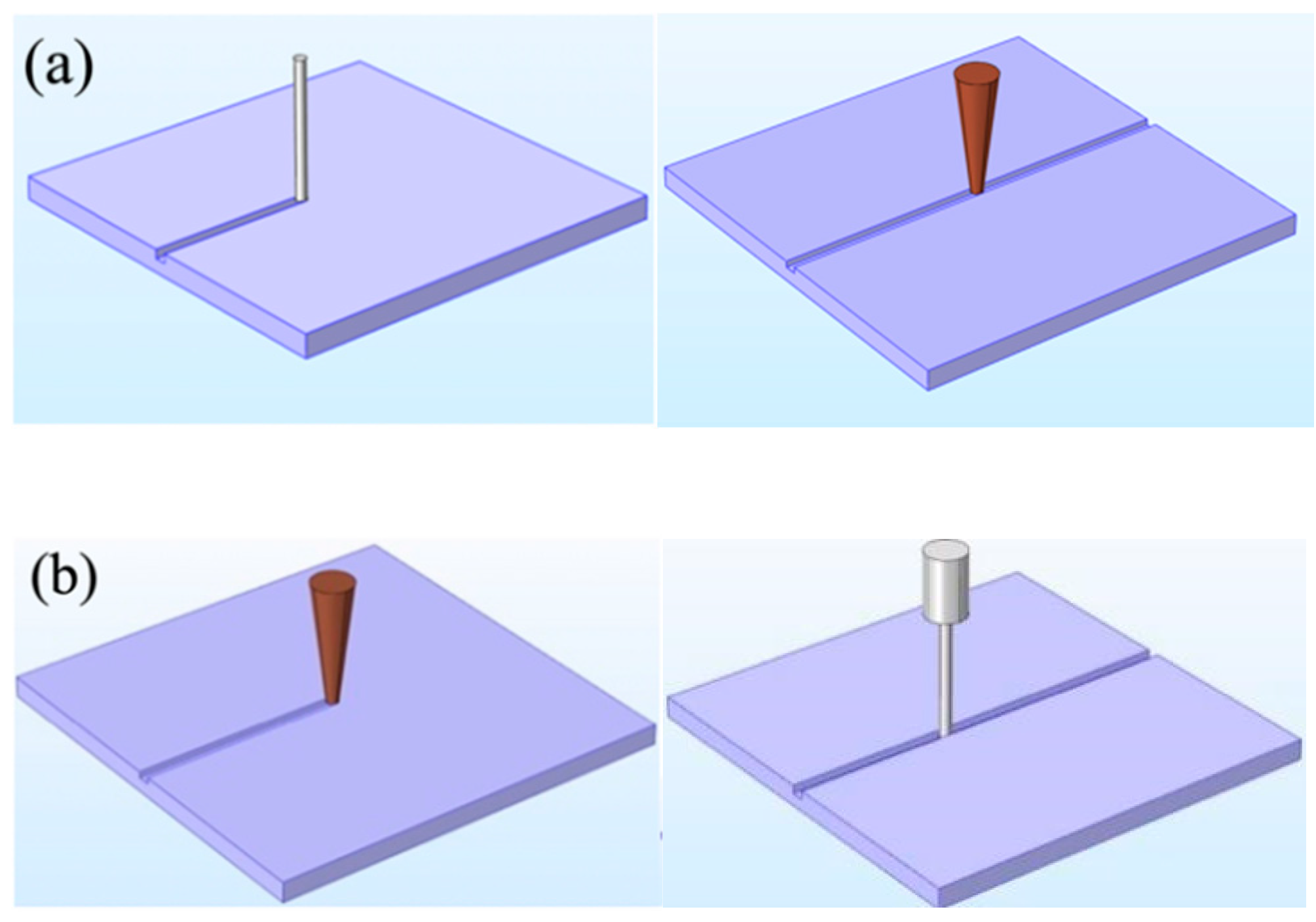

2.2. Machining Procedures

3. Results and Discussion

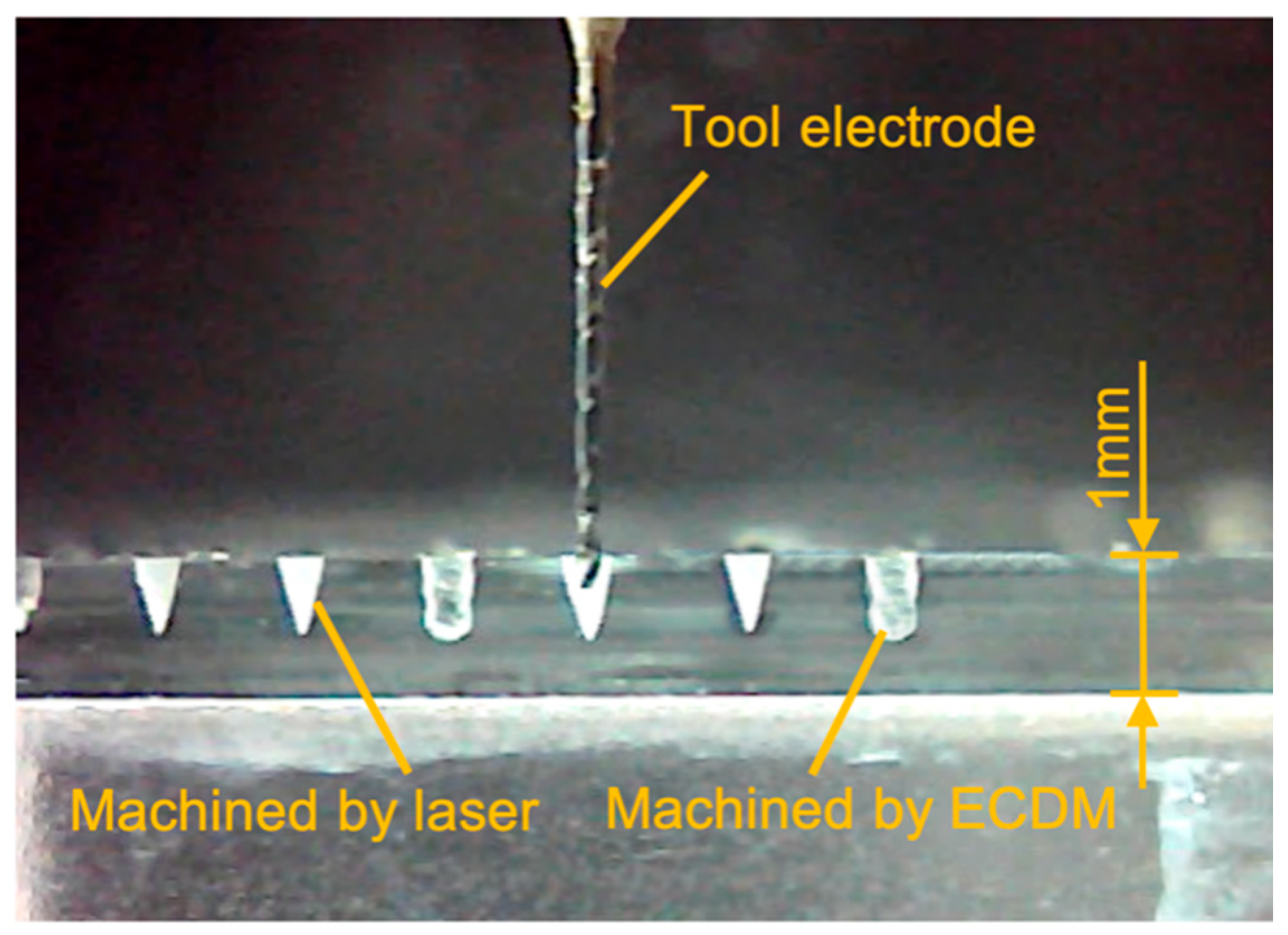

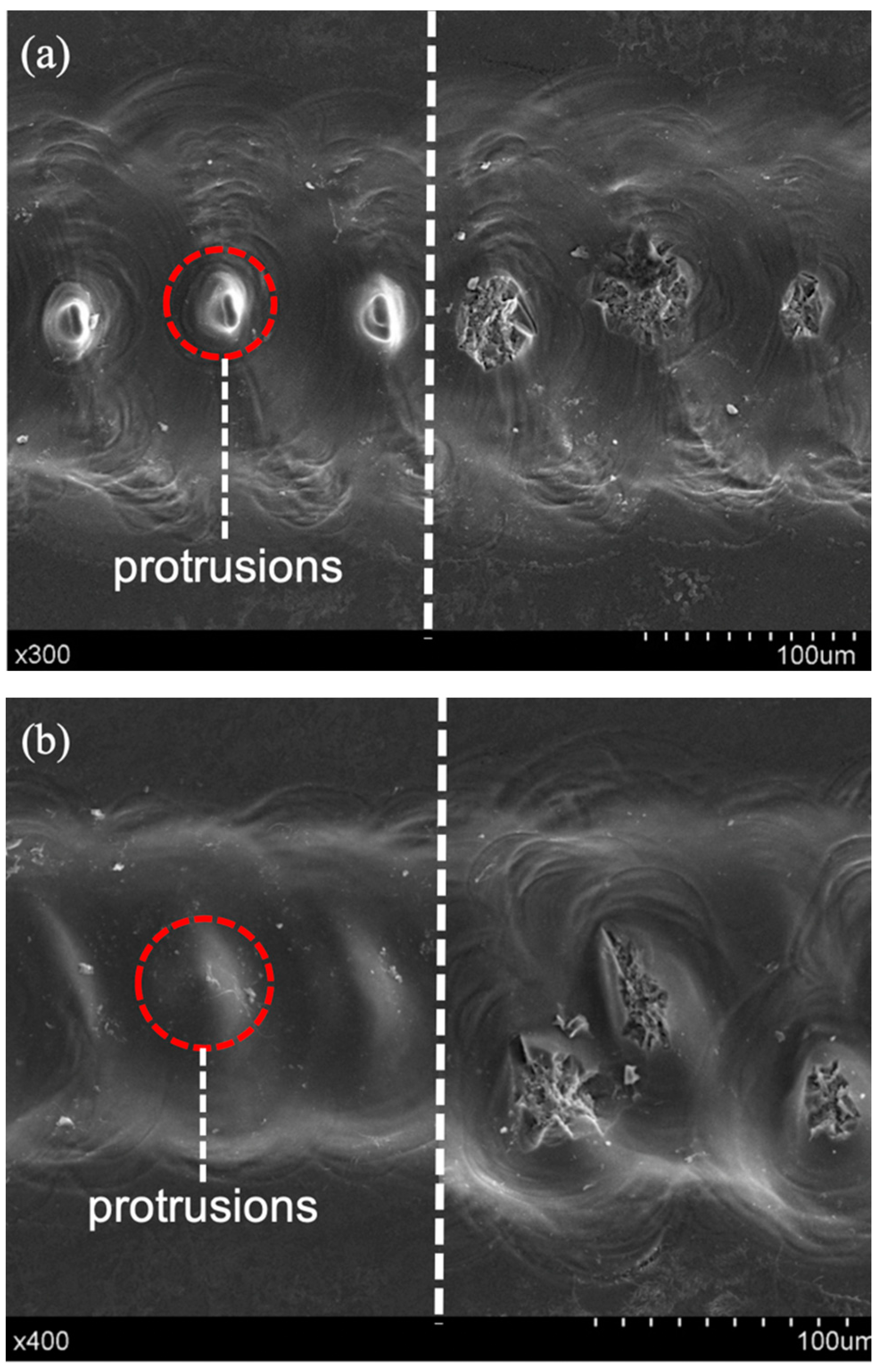

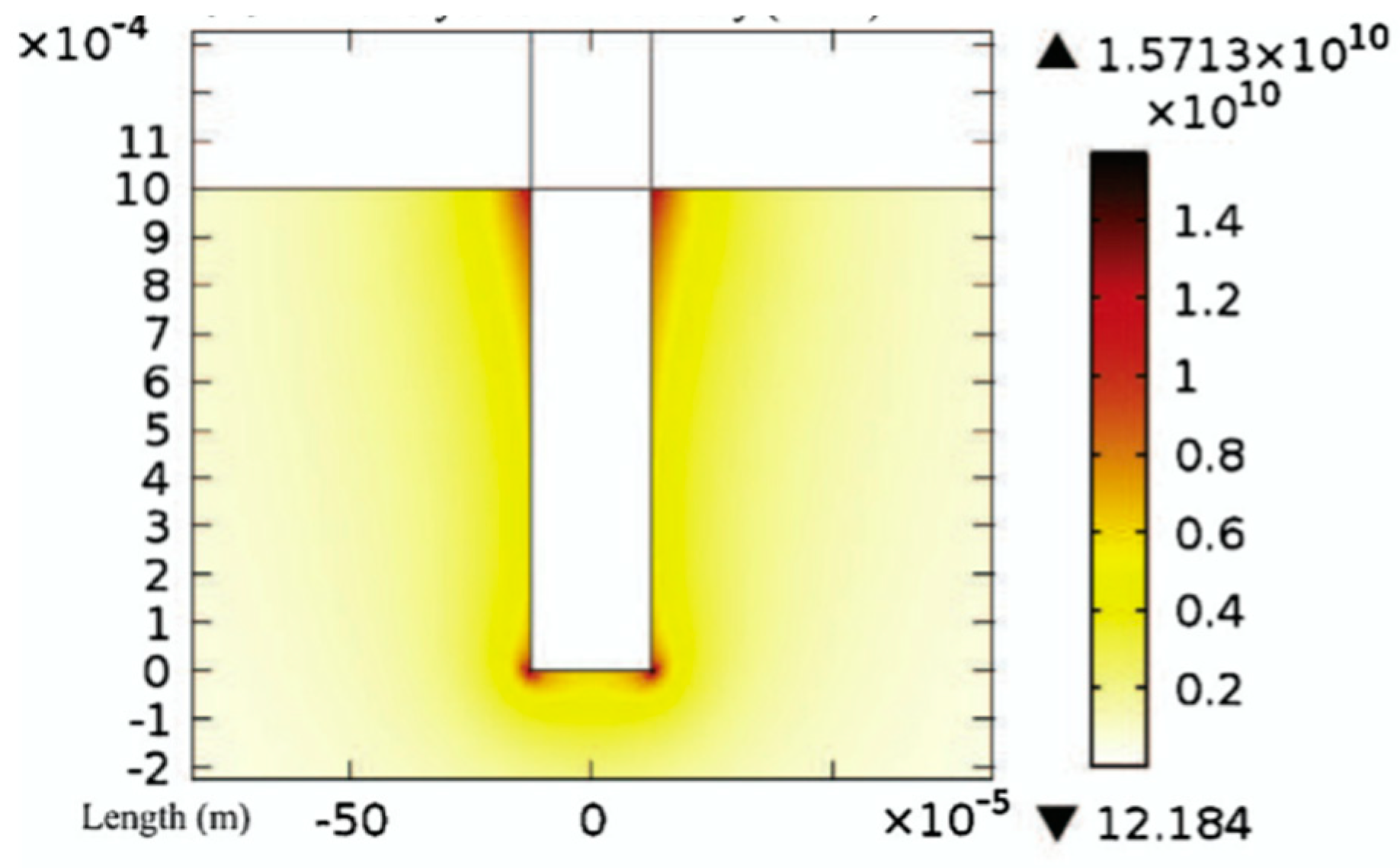

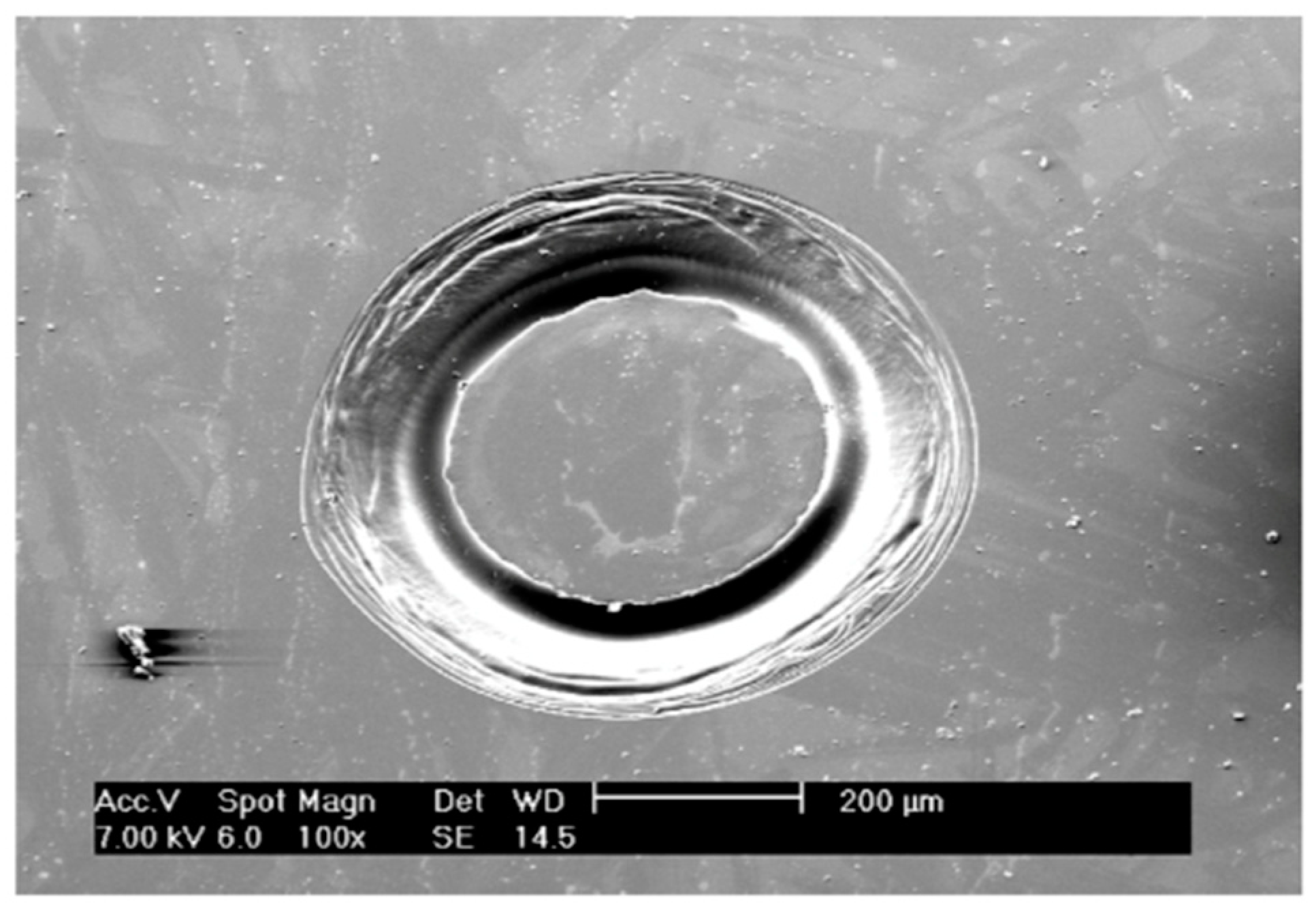

3.1. ECDM Preprocess

3.2. Laser Preprocess

4. Conclusions

- As a post-processing after ECDM, laser processing can effectively and selectively remove the protrusions at the bottom of the microgrooves. Because of the “cold processing” feature of the picosecond laser, there is no obvious heat-affected zone. Thus, the experiment obtained a more regular bottom structure of the microgrooves.

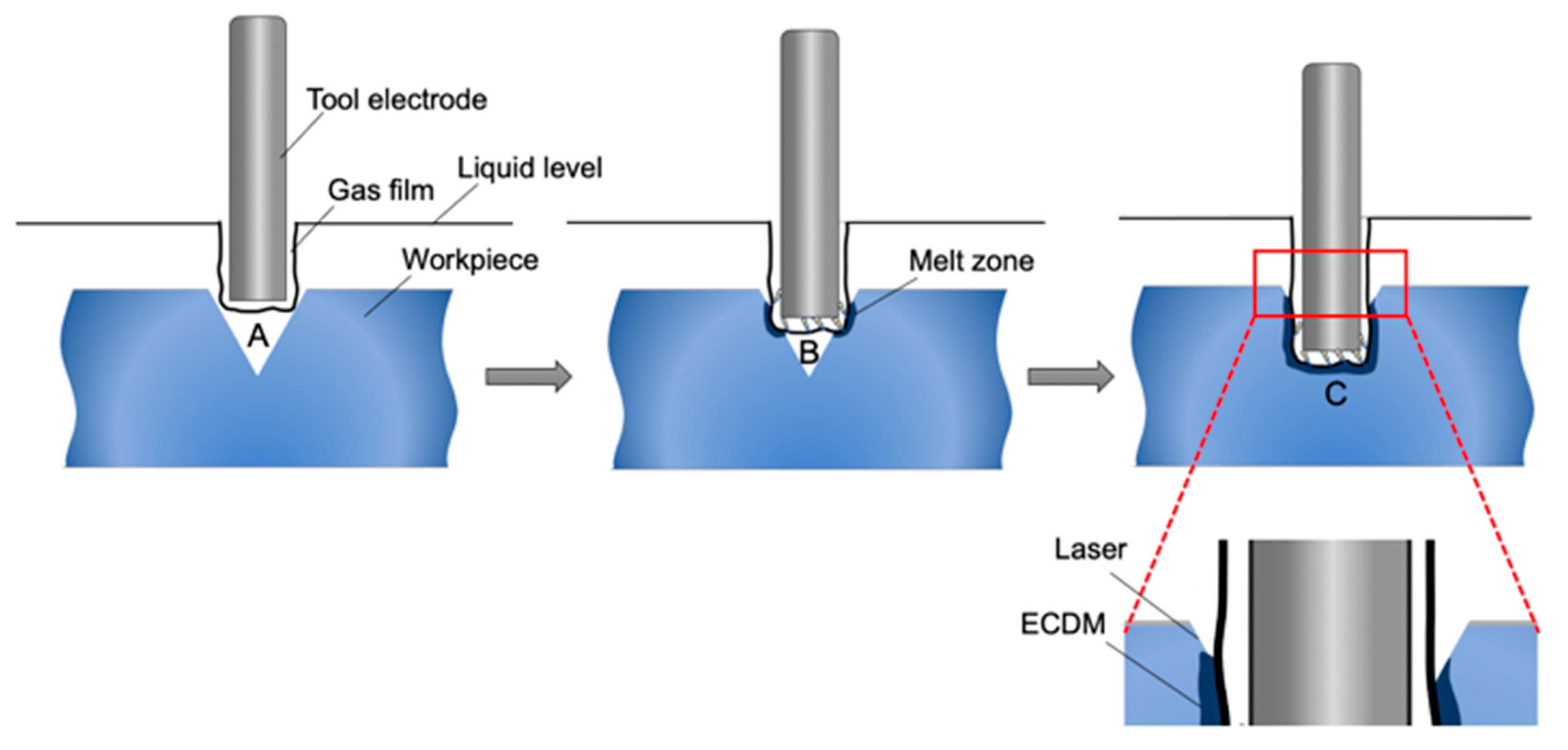

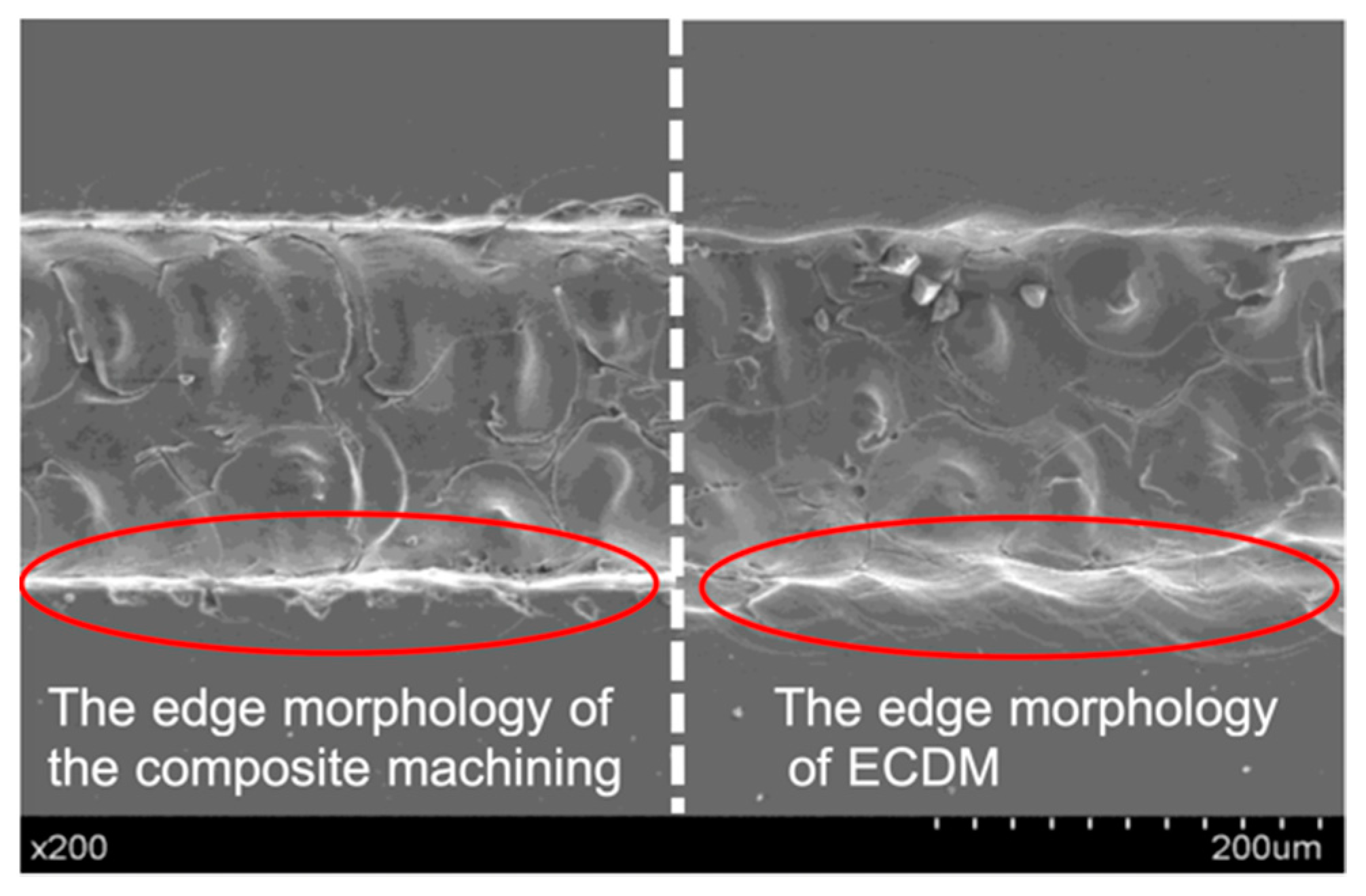

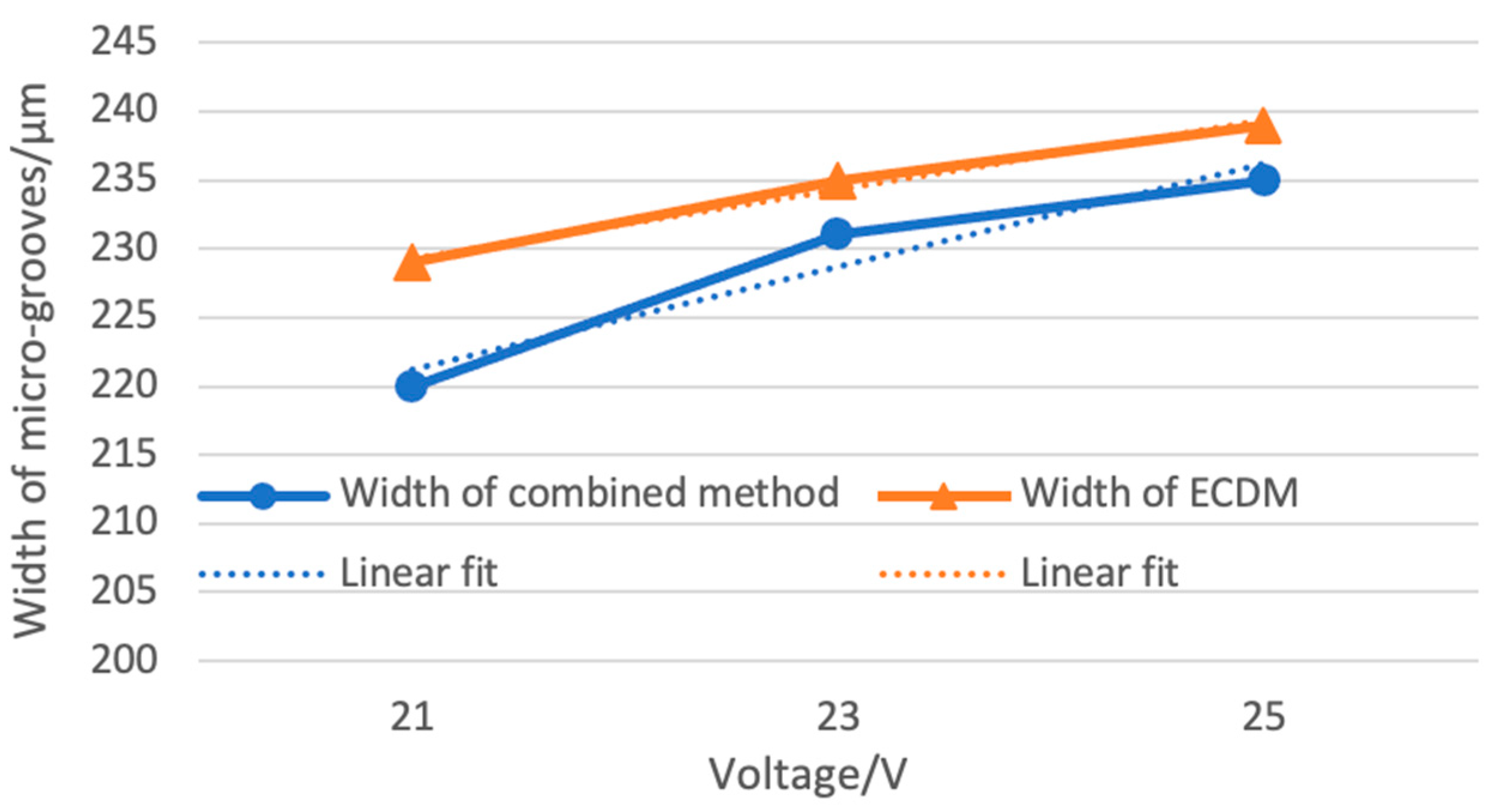

- In the laser preprocessing, the pre-etched microgrooves can reduce the thickness of the gas film, shorten the distance of the electrical discharge erosion, and achieve better quality. The results show the bottom of the microgroove presented an ECDM morphology, while the upper surface of the edge presented a laser morphology and there is no visible wave-shaped heat-affected zone. The combined processing method can improve the overcut phenomenon caused by ECDM.

- After the post-processing by ECDM, the V-shaped microgrooves gradually transform to the U-shape, and the taper of the microgrooves is reduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lucas, H.; Jana, A.Z. Micro-Hole Drilling on Glass Substrates—A Review. Micromachines 2017, 8, 53. [Google Scholar] [CrossRef]

- Sabahi, N.; Hajian, M.; Razfar, M.R. Experimental study on the heat-affected zone of glass substrate machined by electrochemical discharge machining (ECDM) process. Int. J. Adv. Manuf. Technol. 2018, 97, 1–8. [Google Scholar] [CrossRef]

- Schwartzentruber, J.; Papini, M. Abrasive waterjet micro-piercing of borosilicate glass. J. Mater. Proc. Technol. 2015, 219, 143–154. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, J.; Yao, P.; Huang, C. Heat transfer and material ablation in hybrid laser-waterjet microgrooving of single crystalline germanium. Int. J. Mach. Tools Manuf. 2017, 116, 25–39. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, C.; Wei, X.; Hu, W.; Ren, Q. Laser machining of transparent brittle materials: From machining strategies to applications. Opto Electron. Adv. 2019, 2, 11–23. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Z.Y.; Xu, J.L.; Xu, K.; Ren, Y. An experimental study of micro-machining of hydroxyapatite using an ultrashort picosecond laser. Precis. Eng. 2018, 54, 154–162. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Von Alvensleben, F.; Tunnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Ghosh, A. Electrochemical discharge machining: Principle and possibilities. Sadhana 1997, 22, 435–447. [Google Scholar] [CrossRef]

- Jain, V.K.; Dixit, P.M.; Pandey, P.M. On the analysis of the electrochemical spark machining process. Int. J. Mach. Tools Manuf. 1999, 39, 165–186. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Doloi, B.N.; Sorkhel, S.K. Experimental investigations into electrochemical discharge machining (ECDM) of non-conductive ceramic materials. J. Mater. Proc. Technol. 1999, 95, 145–154. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, S.W.; Lee, S.K.; Park, J.H. Through-glass copper via using the glass reflow and seedless electroplating processes for wafer-level RF MEMS packaging. J. Micromech. Microeng. 2013, 23, 085012. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Huang, L.; Jiang, Y.; Liu, G.; Nie, X.; Lu, H.; Zhuang, H. A study to explore the properties of electrochemical discharge effect based on pulse power supply. Int. J. Adv. Manuf. Technol. 2016, 85, 2107–2114. [Google Scholar] [CrossRef]

- Ahmmed, K.; Colin, G.; Anne-Marie, K. Fabrication of Micro/Nano Structures on Metals by Femtosecond Laser Micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Kovalenko, A.F.; Vorobev, A.A. Energy-Conserving Regimes for Laser Machining of Glass and Ceramic Materials. Glass Ceram. 2014, 71, 198–200. [Google Scholar] [CrossRef]

- Shin, J. Investigation of the surface morphology in glass scribing with a UV picosecond laser. Opt. Laser Technol. 2019, 111, 307–314. [Google Scholar] [CrossRef]

- Jawalkar, C.S.; Sharma, A.K.; Kumar, P. Investigations on performance of ECDM process using NaOH and NaNO3 electrolytes while micro machining soda lime glass. Int. J. Manuf. Technol. Manag. 2014, 28, 80–93. [Google Scholar] [CrossRef]

- Zheng, Z.P.; Cheng, W.H.; Huang, F.Y.; Yan, B.H. 3D microstructuring of Pyrex glass using the electrochemical discharge machining process. J. Micromech. Microeng. 2007, 17, 960–966. [Google Scholar] [CrossRef]

- Pawar, P.; Ballav, R.; Kumar, A. Revolutionary developments in ECDM process: An overview. Mater. Today Proc. 2015, 2, 3188–3195. [Google Scholar] [CrossRef]

- Xuan, D.C.; Bo, H.K.; Chong, N.C. Hybrid micromachining of glass using ECDM and micro grinding. Int. J. Prec. Eng. Manuf. 2013, 14, 5–10. [Google Scholar] [CrossRef]

- Nath, C.; Lim, G.C.; Zheng, H.Y. Influence of the material removal mechanisms on hole integrity in ultrasonic machining of structural ceramics. Ultrasonics 2012, 52, 605–613. [Google Scholar] [CrossRef]

- Ho, C.C.; Wu, D.S.; Chen, J.C. Flow-jet-assisted electrochemical discharge machining for quartz glass based on machine vision. Measurement 2018, 128, 71–83. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, J.; Jiang, B.; Liu, Y.; Ni, J. Experimental investigation of magnetohydrodynamic effect in electrochemical discharge machining. Int. J. Mech. Sci. 2018, 142, 86–96. [Google Scholar] [CrossRef]

- Jain, V.K.; Adhikary, S. On the mechanism of material removal in electrochemical spark machining of quartz under different polarity conditions. J. Mater. Proc. Tech. 2008, 200, 460–470. [Google Scholar] [CrossRef]

- Gaurav, S.; Alakesh, M. Amanpreet Singh Sethi, Investigations on performance of ECDM process using different tool electrode while machining e-glass fibre reinforced polymer composite. Mater. Today Proc. 2020, 28, 1622–1628. [Google Scholar] [CrossRef]

- Kim, D.J.; Ahn, Y.; Lee, S.H.; Kim, Y. Voltage pulse frequency and duty ratio effects in an electrochemical discharge microdrilling process of Pyrex glass. Int. J. Mach. Tools Manuf. 2006, 46, 1064–1067. [Google Scholar] [CrossRef]

- Jiang, B.; Lan, S.; Ni, J.; Zhang, Z. Experimental investigation of spark generation in electrochemical discharge machining of non-conducting materials. J. Mater. Proc. Tech. 2014, 214, 892–898. [Google Scholar] [CrossRef]

- Jiang, B.; Lan, S.; Wilt, K. Modeling and experimental investigation of gas film in micro electrochemical discharge machining process. Int. J. Mach. Tools Manuf. 2015, 90, 8–15. [Google Scholar] [CrossRef]

- Yang, C.K.; Wu, K.L.; Hung, J.C.; Lee, S.; Lin, J.; Yan, B. Enhancement of ECDM efficiency and accuracy by spherical tool electrode. Int. J. Mach. Tools Manuf. 2011, 51, 528–535. [Google Scholar] [CrossRef]

| Factors | Parameters |

|---|---|

| Tool electrode diameter (μm) | 200 |

| Voltage (V) | 25 |

| Peak current (A) | 0.3 |

| Duty factors (%) | 50 |

| Frequency (Hz) | 1000 |

| Rotating speed (RPM) | 3600 |

| Feed speed (μm/s) | 10 |

| Factors | Parameters |

|---|---|

| Layer | 10 |

| Number of elements | 20 |

| Scanning speed (mm/s) | 300 |

| Power (W) | 12 |

| Frequency (Hz) | 3 × 105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, D.; Zhang, Z.; Zhu, H.; Cao, Z.; Xu, K. An Investigation into Laser-Assisted Electrochemical Discharge Machining of Transparent Insulating Hard-Brittle Material. Micromachines 2021, 12, 22. https://doi.org/10.3390/mi12010022

Zhao D, Zhang Z, Zhu H, Cao Z, Xu K. An Investigation into Laser-Assisted Electrochemical Discharge Machining of Transparent Insulating Hard-Brittle Material. Micromachines. 2021; 12(1):22. https://doi.org/10.3390/mi12010022

Chicago/Turabian StyleZhao, Douyan, Zhaoyang Zhang, Hao Zhu, Zenghui Cao, and Kun Xu. 2021. "An Investigation into Laser-Assisted Electrochemical Discharge Machining of Transparent Insulating Hard-Brittle Material" Micromachines 12, no. 1: 22. https://doi.org/10.3390/mi12010022

APA StyleZhao, D., Zhang, Z., Zhu, H., Cao, Z., & Xu, K. (2021). An Investigation into Laser-Assisted Electrochemical Discharge Machining of Transparent Insulating Hard-Brittle Material. Micromachines, 12(1), 22. https://doi.org/10.3390/mi12010022