1. Introduction

The da Vinci surgical robotic system, introduced two decades ago, has given rise to a rapid paradigm-shift in minimally invasive surgery (MIS). Recently, flexible prototypes have been developed by emulating bio-inspired creatures for robot-assisted diagnostic, surgical, and therapeutic procedures [

1]. While robotic mechanisms with soft actuation and deformable joints are generally used in the context of flexible robotics, rigid serial-link robots have also been proposed and adapted to enhance MIS procedures that involve intrabody and intraluminal navigations [

2]. While the robots are capable of flexible intrabody movements in certain human cavities, links in the prototypes that have redundant parts can be utilized for effective obstacle and singularity avoidance by using operative kinodynamics model [

3,

4]. Some existing surgical robotic systems, such as Zeus and da Vinci robotic platforms, adopt parallel-link design mechanisms for flexible access during surgical interventions. While navigating the parallel mechanisms requires passive control systems, recent advances in flexible MIS have shown that serial-link prototypes, such the da Vinci

® Sp (Intuitive Surgical, Sunnyvale, CA, USA) and Flex Robotic (Medrobotics Corp., Raynham, MA, USA) surgical systems, can perform MIS. Flexible prototypes are designed for a fast, safe, and precise stratagem needed for intrabody navigation during surgery interventions in confined anatomical areas of the human body. Some recent advancements regarding MIS and single-port orifical surgery were documented in Simaan et al. [

4]. In addition, Simaan et al. [

5] discussed MIS robots that were designed with unique features for the elimination of abdominal or rectal wall aggression and a reduction of postoperative trauma. However, a major issue is the lack of motion and force constraints, which hinder the effective control of the multisegmented robots during flexible access surgery.

Applications of flexible robotic systems with snake-like parts is still in its infancy for MIS. The existing prototypes utilize discrete or continuous joint mechanisms for navigation. Hence, safe and efficient clinical procedures with a flexible robot requires precise constraint models for motion and teleoperation control [

6]. This involves the development of timely and accurate kinematics and dynamics models to enhance the precise point-to-point navigation of flexible robotic systems for intrabody manipulation [

7]. In teleoperated surgery, the transmission of force feedback between the surgeon and surgical room requires the availability of reliable force data and protocol communication. Su et al. [

8], proposed using a neural network for bilateral teleoperation with an enhanced robot tool identification and calibration. Constraints control modeling in flexible robotic mechanisms requires the intricate simultaneous analysis of the robot’s links and its workspace. The presence of multiple degrees of freedom (DoFs) in flexible robots enhances the dexterity of the robot’s links with snake-like navigation along flexible paths. However, this inordinateness leads to link or joint redundancy with the existence of more DoFs than what is needed to reach different manipulable areas in a low-dimensional space. Thus, developing a holistic motion control system is required for navigation using a flexible robotic mechanism in its operational work area. This involves designing timely and accurate kinematic and dynamic constraints with an effective path analysis for obstacle detection and avoidance during point-to-point navigation. Concerns are being raised regarding the acceptance and application of flexible robotic systems due to a lack of the appropriate and precise models required for the constraints control of flexible robots during MIS. Recently, Su et al. [

9] developed an improved constraint control system with a human–robot collaborative model for the teleoperation of a redundant MIS robot. The control system includes an integrated compensator models for the enhancement of surgical precision at the tooltip, and to guarantee motion constraints. Similarly, several methods have been proposed, developed, and adapted for modeling the kinematics, dynamics, and teleoperation constraints control in flexible snake-like robots [

1,

4,

5,

6]. Nonetheless, research into coherent methods that can intelligibly combine the individual constraints control for the navigation of flexible surgical robots during intrabody operations still displays paltry progress [

10]. To alleviate this, synergizing the kinematics and dynamics for modeling the required constraints control remains important open research. This is vital for the steady and consistent navigation of surgical robots along flexible and complex pathways.

Modeling kinematics and dynamic constraints without a loss of transparency and accuracy in master–slave surgical robots remains a challenging task and it has attracted research interests in recent years [

6,

11,

12]. In general, kinematics resolutions basically involve defining apt relationships between the joint and Cartesian spaces of a robot. Forward kinematics (FK) involves modeling the coordinates of a robot’s links and end-effector based on a given joint vector, while the idea in inverse kinematics (IK) is to obtain the joint angles with which an end-effector of the robot can move along via-points of a trajectory. Since snake-like robots are kinematically redundant [

6]; several methods have been proposed for achieving timely and accurate IK resolution [

13]. Similarly, developing dynamic control models involves analyzing the disparities that occur between the motion and respective generalized forces at each joint of a robot. Lagrangian and Newton–Euler formulations are two conventional methods developed for dynamics modeling in serial-link robotics [

14,

15]. Variations of both methods have been reported in several works. Nonetheless, the high complexity and computation cost of each variant are common cons when used for high-DoF flexible robots [

16,

17]. Since joint forces are dependent on the physical limits of their actuators [

18], the motion and force profiles of unique joints are investigated for point-to-point convergence of the robot during operation.

In this study, we designed a novel control system that could enhance both the motion and trajectory constraint control for the navigation of redundant snake-like robots along a flexible pathway during intraluminal surgery. To achieve this, a kinodynamics model was designed for solving the kinematics and dynamics of via-points established between the initial and target points on a surgical pathway, while a normalized cycloidal trajectory with boundary conditions was adapted for smooth and continuous point-to-option motion. Finally, the control system was enhanced with a switching method that decided alternative poses that were used to avoid collisions with obstacles. The main contributions of this study are:

- (a)

The computational modeling of motion constraints for snake-like robotic navigation during flexible surgical access. The model was based on a geometry-based inverse kinematics approach and it was also improved for dynamics resolution, trajectory planning, and obstacle avoidance.

- (b)

Development and implementation of the constraint models in motion and trajectory control software developed for the operation of flexible surgical robots.

The remainder of this paper is organized such that a brief review of studies on the design and control of flexible snake-like robots is presented in

Section 2 and the structural design of a new prototype proposed for radiosurgical interventions is discussed in

Section 3 along with the formulation of the kinodynamics and trajectory planning models proposed for the motion control of the flexible robot. The trajectory technique includes geometric modeling done for smooth and continuous navigation of the flexible robot and a collision avoidance scheme in cases of obstacle presence in the robot’s workspace. The simulation of the flexible robotic model and the implementation of the proposed control system are discussed along with the validation results from some case studies in

Section 4. Finally, a conclusion of the study and directions for future work are briefed in

Section 5.

2. Literature Review

Link flexibility and redundancy are vital features of continuum and snake-like robots, which makes them suitable in a wide range of surgical applications. A sizable number of flexible robotic prototypes have been designed following the introduction of the da Vinci robot and the recent advances in surgical interventions. In the earlier part of this millennium, a prototype for a highly dexterous snake-like robot was proposed for teleoperated surgery along the throat and upper airway, and it marked a vital point in adopting snake-like robots for flexible access surgery [

19]. The integrated robotic platform is characterized by three-armed distally dexterous mechanisms that are designed for the manipulation of surgical devices in a confined space. The motivations for the surgical application of flexible robotic systems in humans and clinical trials lead to the commercialization of the Viacath snake-like robotic system (EndoVia Medical Inc., Norwood, MA, USA). The flexible surgical tool consists of a control platform that surgeons use to remotely manipulate the surgical instruments deep inside a patient’s body. After the acquisition of the system by Hansen Medical (Mountain View, CA, USA) in 2005, the Viacath system became one of the few dexterous surgical robots commercialized for single-port intraluminal interventions [

20,

21]. Furthermore, the application of a flexible robotic platform, described as a highly articulated flexible robot, was proposed for less invasive cardiac surgery. The robot has astounding features that are uncommonly found in conventional MIS robots [

22]. As a proof of concept, models of the snake-like robot were developed for flexible percutaneous intra-pericardial interventions in Ota et al. [

23] and Thakkar et al. [

24]. Recently, Medrobotics Corp. (Raynham, MA, USA) developed a snake-like robotic system with flexible navigational access for hard-to-reach tissues in the mouth, throat, rectum, and colon during gynecological and thoracic procedures [

25].

Teleoperation is a common technique that is being adopted for the manipulation of flexible surgical robots during MIS procedures. The teleoperation control standard requires effective underlying models for the fast, safe, and accurate navigation of a robot’s multiple links during flexible access surgery. Currently, the follow-the-leader approach has been proposed for motion modeling and control of flexible robotic systems, especially ones based on concentric tube and snake-like mechanisms [

26]. The approach requires resolving kinematics of links in the robot’s lead module and transmitting the IK solution directly to subsequent modules for navigation via flexible pathways. Several IK models have been proposed for IK resolution in redundant robots [

13]. These can be categorized into analytical-based solutions wherein algebraic methods are used to solve closed-form and geometric systems of equations, and numerical-based solutions that involve iteratively minimizing kinematics errors. A more detailed review has been presented in Seah et al. [

6]. In general, algebraic methods involve the expansion of complex trigonometric equations due to high the transcendence in joint variables and symbolic expressions, while the existence of singular points in a robot’s workspace limits the latter. Precise motion control in multi-articulated robots requires consistent coordination of the different components driving the robotic links, camera(s) used for visualization, and surgical instruments. Dynamics control includes modeling timely and efficient methods for motion control, planning along a given trajectory, and computational analysis of the generalized forces acting on a flexible robotic system during surgery. In serial-link robots, Newton–Euler and Lagrangian formulations remain the basic techniques used for dynamics modeling [

16,

27], and several methods have been proposed based on them. For instance, in Saha [

15], Bernoulli–Euler beam theory was utilized to analyze the effects of generalized forces in modeling the dynamic motion and control of a flexible robot. Newton–Euler formulations are recursive methods used for modeling generalized forces acting on a robot. This involves analysis of the robot’s motion profile with respect to coordinates of frames at the fixed-base and free-moving ends of the robot. The recursive Newton–Euler system of equation proposed in Luh et al. [

14] was adapted in the efficient constraint models described for continuum robots in Ali [

28].

Flexible-joint robots are now commonly used in different fields, including healthcare services. For this, Dong et al. [

29] developed a force-free control model for a flexible-joint robot, and experiments were conducted to verify friction and gravitational force-free situations during human–robot interactions. Another study in a closer domain is the improved human–robot collaborative control scheme proposed for teleoperated MIS in Su et al. [

8]. However, this study either did not investigate the motion and force profiles during point-to-point navigation or did in domains that were different from flexible robotic surgery. Nonetheless, the underlying techniques, for instance in References [

14,

30], can be adapted with respect to a robot’s structure, required navigation, and desired trajectory with a degree of dynamic stability during surgical procedures. In a recent study, efficient dynamic constraint modeling was presented for the effective control and teleoperation of flexible snake-like robots in Omisore et al. [

30]. This model includes mapping the workspace of master and slave devices based on their kinematics resolution and adaptation of a higher other-motion profile for a direct analysis of the generalized forces acting on the robot’s joints. However, the IK approach can suffer from the singularity problem, and thus, the stability of the joint torques is not guaranteed. Furthermore, only the first two derivatives of the position data are utilized for the dynamic model. Generally, most studies on continuum and snake-like surgical robots do not give due attention to analyzing the motion/force interactions during flexible access surgery.

Besides kinematics and dynamics modeling, path and trajectory analyses are still open research points regarding the use of snake-like robots for flexible access surgery. This is said to be because link–obstacle interactions make it hard to generate an optimal trajectory in surgical areas cluttered with abdominal organs. Trajectory planning includes modeling smooth and shortest routes between two points in the robot’s workspace. In the last two decades, several algorithms have been proposed for trajectory analysis in robotics. Lozano-Perez [

31] proposed a primitive method of path planning using an object’s pose as single points in the robot’s workspace. If objects are deemed as via-points of an end-effector, its consecutive pose information is sufficient for motion and trajectory planning. Angeles et al. [

32] presented a trajectory planning method for motion along a continuous path in a robot’s configuration space. This requires specifying pose values of the robot’s end-effector using via-points as targets in the workspace. In Parsa et al. [

33], an interpolating polynomial was used for the trajectory planning of a three-DoF manipulator such that smooth and jerk-free motion is steadily produced. Similarly, Dasgupta et al. [

34] proposed a variational approach for path planning in hyper-redundant manipulators. Recently, Kuntz et al. [

35] presented a sampling-based motion planner for flexible surgical robots based on its manipulations outside the body. Typically, most mechanisms consist of serially-connected modules that are capable of bending in unique planes. Liu et al. [

36] designed an MIS pediatric surgical robot, with the latter having nine-DoF flexible robotic arms for dexterous interventions in a confined and narrow workspace. Another important aspect of the flexible robots designed for MIS is collision avoidance. Thus, Sun et al. [

37] presented a safe motion planning method for an imprecise flexible robot by minimizing the collision probability. Similarly, EMG-based analytics is being adapted for robotics motion control and related teleoperation procedures, such as tool identification and calibration [

38,

39,

40].

Similarly, artificial intelligence has been applied to solve motion constraints and trajectory planning problems in flexible robots. Agarwal [

8] applied fuzzy C-means, an AI-based approach, for planning the trajectory of a four-DOF redundant manipulator. The clustering model was based on weighted within-scatter and between-cluster metrics for the robot, with a manipulability index taken as the performance criteria. Aside from fuzzy methods, models based on a neural network (NN) and a genetic algorithm were utilized for the trajectory control and analysis of flexible robots. The network provides fast methods for trajectory and path control. Chen et al. [

41] designed a 3D neural model for a safety-enhanced trajectory in a workspace with the consideration of a minimum sweeping area. A memory neural network was used in Berni et al. [

42] for the path optimization of a three-DoF robotic arm. Furthermore, artificial neural network approaches [

6,

43] are used in trajectory planning. For instance, a method based on Hermite was recently proposed for the motion planning and obstacle avoidance of serially redundant robots. Models based on genetic algorithm have been applied for generating a cubic interpolation polynomial, such as that given in Chen et al. [

44]. The history of the task space trajectory was approximated and the interpolation points were obtained using the proposed genetic algorithm. Schmitz et al. [

4] combined a genetic algorithm with a recorded suturing and anatomical data to control the four distal DoFs of a flexible robot over a predefined trajectory. Modeling obstacle avoidance for flexible robots with multiple DoFs is challenging; yet, a deep recurrent NN-based model was developed and investigated for a redundant serial-link robot in Xu et al. [

45]. The recurrent network established the effective avoidance of static and dynamic obstacles. Recently, a vision-based obstacle avoidance approach was developed based on a sequential NN [

46]. The study was focused on an aerospace application but similar models can be adopted for flexible robotic surgery. Furthermore, a neural-learning-based control model was proposed for constraints control robotic systems with flexible joints in He et al. [

47]. A drawback of intelligent-based control systems is a requirement of training that hinders behavioral cloning. Since the control system is mainly used to navigate a robot under a planned motion sequence, such control systems might be impractical when used in a new setting. Furthermore, network-based techniques usually require objective methods for defining an optimal network topology. Thus, while designing and training a network takes time, learning requires a high amount of storage and control errors are unpredictable.

There is a great need to focus efforts on model-based motion and trajectory control models for the safe, precise, and collision-free navigation of snake-like robots. Harmonic potential functions were used to compute collision-free paths in redundant robots [

48,

49]; however, the approach may likely cause manipulators to be trapped in local minima. Parsa et al. [

34] extended the use of an interpolating polynomial to generate a smooth path between initial and final points such that robot–obstacle collisions were avoided. A general formulation of a trajectory planner includes collision avoidance as a sub-problem. Thus, a better method is to plan the trajectory with index measures taken to maximize the robot’s manipulable area. A pragmatic observation regarding the reviewed studies shows that the intrabody navigation of snake-like robots requires constraints modeling for efficient kinematic and dynamic control, optimal trajectory planning, redundancy resolution, and singularity and collision avoidance for safe intrabody navigation [

4]. While most authors usually focus on modeling each of those constraints individually, some groups of robotics researchers have developed control systems that include both kinematic and dynamic models. Similarly, stipulations for optimal trajectory analysis and collision avoidance have also been considered but there are only a few examples of this. Therefore, the development of motion control systems with modular interfaces for inclusiveness and the concurrent operability of each constraint model is still lacking across all existing studies.

4. Implementation and Validation Results

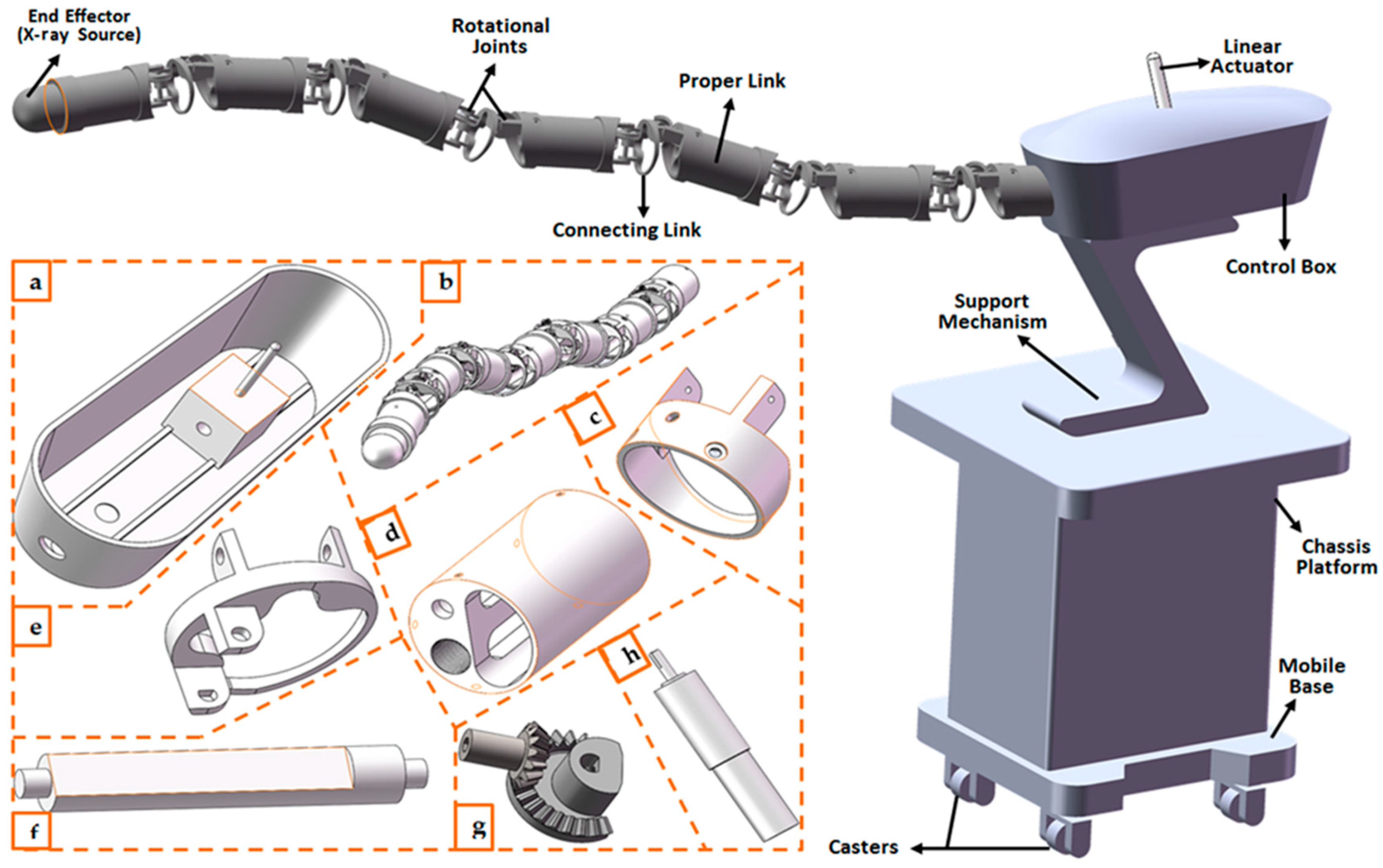

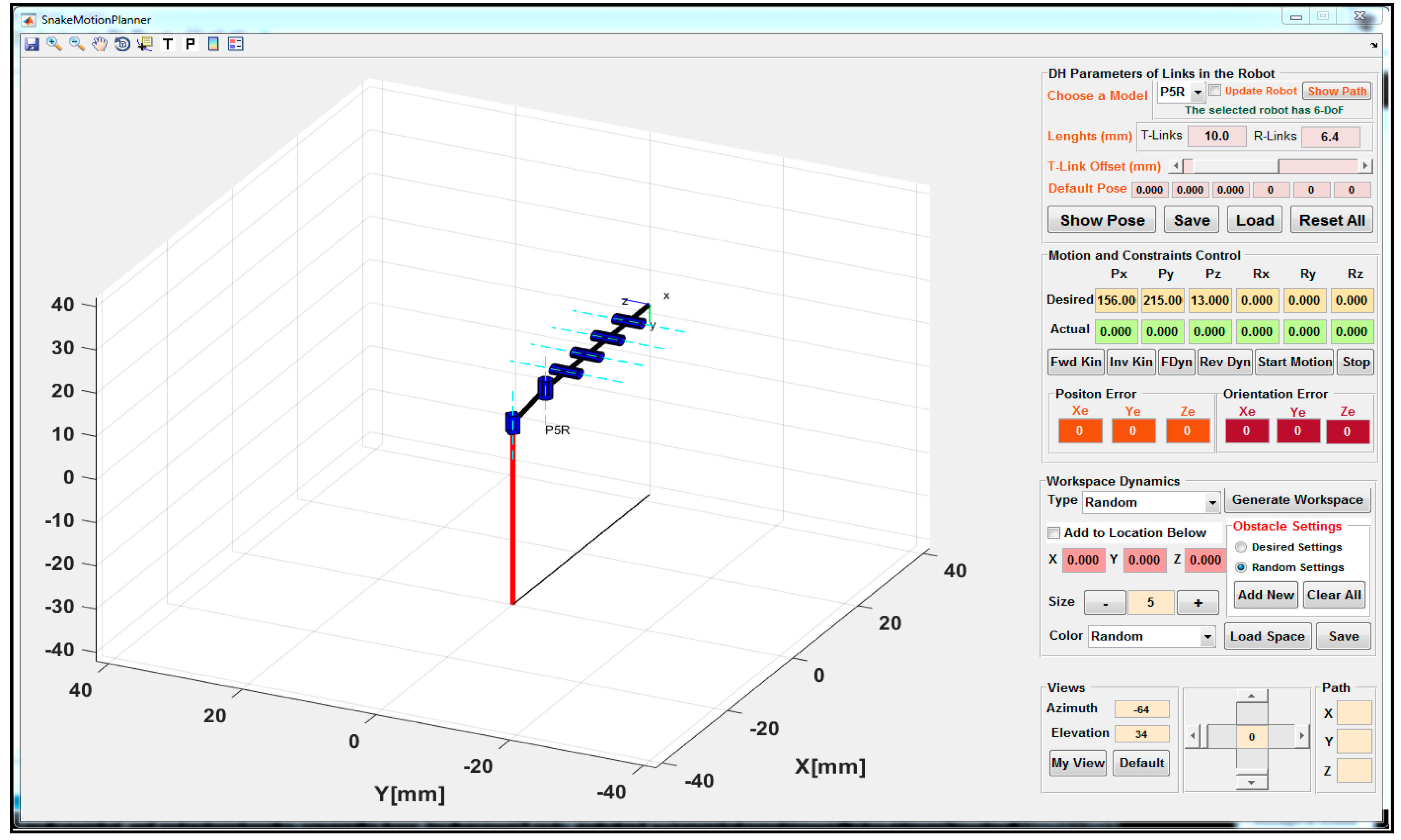

In this study, a typical

(n = 5) prototype of the snake-like robotic model in

Figure 1 was simulated with the Robotics Toolbox [

51] in Matlab (MathWorks, Inc., Natick, MA, USA). The flexible robot had six inter-connected links and was capable of spatially flexible and dexterous motion. The robotic model’s DH parameters were chosen such that the first link (connected via prismatic joint) had a length of 100 mm and a maximum joint offset

of 2 mm, while the remaining five links were connected via revolute joints. Each of the latter was made up of a proper link (53 mm in length) and an interconnecting link (11 mm in length) connected with a dummy joint; thus, a unique length of 64 mm in total. While only the first two links connected with a revolute joint had an orthogonal joint (thus, their rotation axes were perpendicular to those of the neighboring links), the last four links had a unique rotation axis. To validate the proposed control system using the

snake-like robot, each of the constraint models developed in

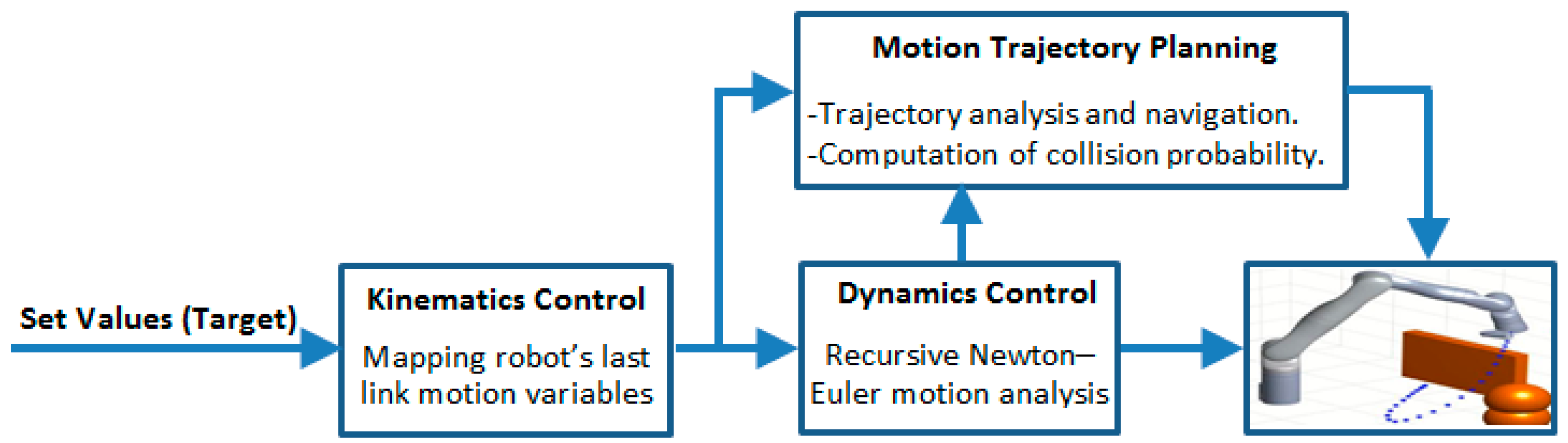

Section 3 was implemented as part of a motion and trajectory control software, as shown in

Figure 6. The control system had two basic modules, which were developed for motion and trajectory control of the flexible snake-like robot. The motion control module consisted of snippets that executed the kinematic and dynamic constraints control using the kinodynamic models in

Section 3.2. Furthermore, the trajectory control module included the pre-coded procedures for executing the motion trajectory planning and obstacle avoidance models in

Section 3.3. The software was built on the publicly available Robotics Toolbox [

44] and it had a separate module for configuring different models of the flexible snake-like robots. The modules were designed with several buttons and input boxes for user interaction and conducting in silico simulation studies for the flexible robot.

Simulation of the robotic prototype and implementation of the control system, including the constraints models, were carried out using the Robotics Toolbox in the Matlab environment installed on a PC with an Intel

® Core i3 duo processor (2.40 GHz each) and 2 GB RAM. An in silico experiment was set up to validate the control system based on vital objectives, such as navigation accuracy, execution time, and path reachability, when each of the constraints’ models were sequentially executed for path navigation exercise. In the study, the simulated

snake-like robot was to navigate along an arbitrary circular path that consisted of

n points that were equally spaced in an X-Y plane but tilted along a corresponding z-axis. Coordinates of each data point were parameterized using Equation (26):

The control study was followed with sequential execution of the models for kinodynamic constraints and trajectory tracking in an attempt to ensure a collision-free point-to-point navigation. The number of data points were varied over three different trials, and coordinates of the data points were iteratively set as the target point in each trial.

Finally, it was observed that the proposed control system navigated the flexible snake-like robot around the three circular paths with highly accurate kinematics and a fast dynamics resolution during the point-to-point navigation, and the collision-free potential of the control system was also guaranteed. Detailed results obtained from each of the kinematics, dynamics, trajectory planning, and collision avoidance algorithms are presented below.

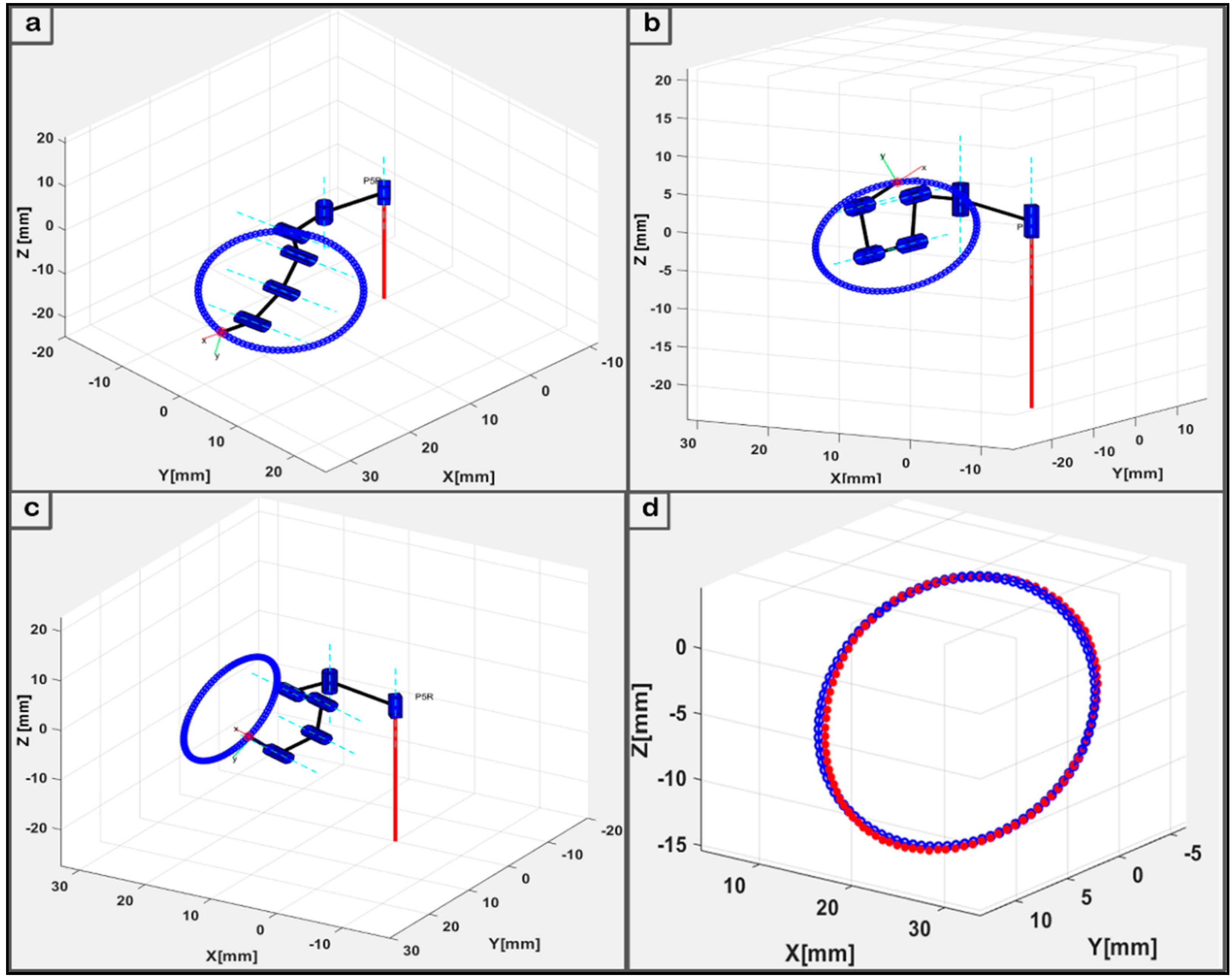

4.1. Results of the IK Model

The operation of the flexible snake-like robot used to navigate a desired trajectory started with setting coordinates of each via-point in the circular path as an input of the proposed geometric IK model. This part of the program computed appropriate joint angles with which the robot tip could be positioned at each via-point in the path. Each navigation scenario had different number (

n) of via-points, and the joint vectors obtained with the IK model were used to navigate the robot’s last link through the via-points. The poses obtained for the three scenarios (

n = 1, 10, and 20) are shown in

Figure 7a–c. A major objective was simultaneously solving the IK in a very accurate and fast manner for timely online motion control. For accuracy, limited axial offsets could be tolerated between the desired points along a path and the actual points the robot could reach when using the IK solution. The kinematic model was first validated with error offsets during each circular path tracking trial. The kinematic error values were obtained as the difference between the axial values of each data point and the corresponding actual point obtained using the IK model. We applied forward kinematics to determine the actual coordinates of the last link’s tip when the joint angles computed by our proposed method were set as the input.

A comparison between the desired via-points and the actual points obtained when the geometric IK technique was used during the circular path tracking is presented as

Figure 7d. The blue and red points are the desired via-points generated using Equation (11) and the actual points computed from the IK model, respectively. By analyzing the kinematic results obtained when the 3D circular paths were tracked by the flexible robot, it was observed that the IK model had accurately reached more than 90% of all points in the circular path with 100 via-points; that is,

n = 1. With a kinematics error threshold of 1 mm, an average kinematics error of 0.37 ± 0.36 mm was obtained from the 100 points with a 92% reachability. Besides the error offset analysis, the performance of the kinematic constraint model was also observed in terms of the model’s run-time taken to resolve the IK for each point. The run-time was the average execution time the model took to compute the IK of a single point over all the points in each circular movement. The geometric IK method had a maximum average response time of 0.061 s over all three trials. This was significantly close to zero relative to the time taken to reach each point in the six-link robot’s workspace. To the best of our knowledge, there exists no single method that has solved the IK of such a modular configuration with both a high accuracy and a short computational time simultaneously.

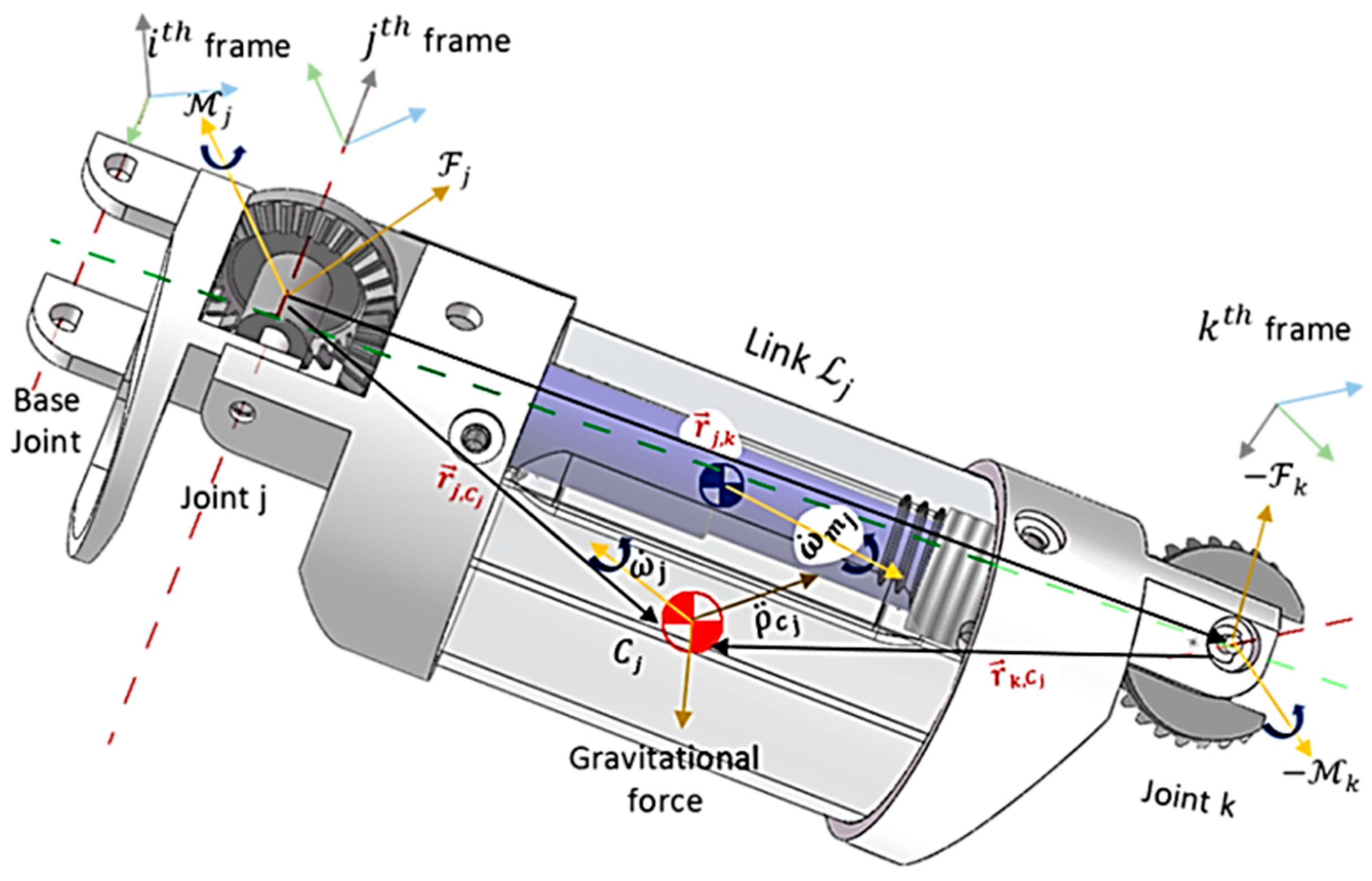

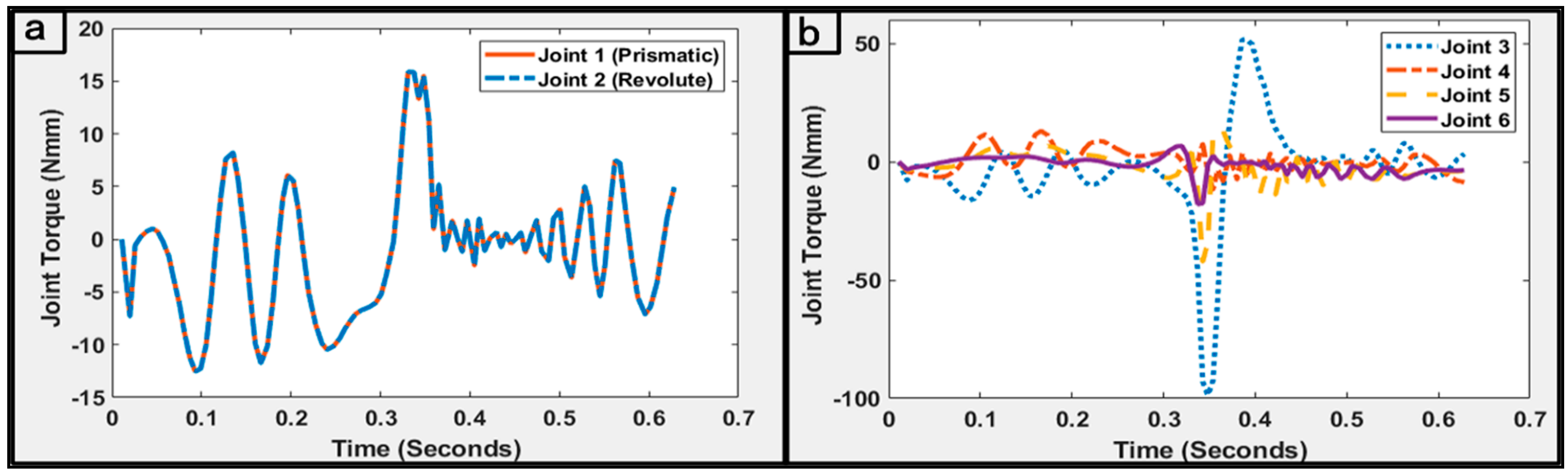

4.2. Result of the Dynamics Model

During the point-to-point navigation, the displacements of all joints in the robot were taken from the geometric IK model and set as the input of the recursive Newton–Euler model. The higher-order motion variables of the robots, namely velocities and accelerations, were computed and utilized in forward and backward recursions of the dynamics model to determine the generalized forces acting on the robot’s links. To ensure consistency between the simulated and real prototype of the robot, a compact and miniaturized design of the snake-like robot was parameterized using Solidworks

® 2016 (Dassault Systems Solidworks Corp., Waltham, MA, USA). This involved estimating the dynamic parameters of the cylindrical links with hollowed holes and pre-designed joints. The dynamic parameters, presented in

Table 1, were obtained and employed for the implementation and validation of the recursive Newton–Euler model. The values were obtained with the links’ center of mass aligned with their corresponding output coordinate system in the Solidworks

® environment. Furthermore, a constant mass density was assumed for each link, and their geometric centers were equally taken to be exactly each link’s center of mass. The joints of the robot were actuated using a Faulhaber

® DC (Clearwater, FL, USA) micromotor with a rotor inertia of 5.7 g·mm

2. With these, the simulated model of the robot’s links exhibited similar parameters as the proposed prototype. The computations started by deriving up to the second-order motion and force profiles using every consecutive joint position variable of the robot as it navigated the paths. For this purpose, the joint positions obtained during the execution of the kinematic model were differentiated to determine each joint’s velocity and acceleration while the corresponding forces at both terminal ends of the robot were obtained.

The latter was done by propagating zero initial velocities and acceleration outward from the stationary base link of the robot, while the terminal force and moment at the last link were set to zero. Thus, with other required parameters required by the dynamic model, the generalized forces acting at each joint of the robot during the point-to-point circular motion were computed as shown in

Figure 8. It can be observed that the consecutive transitions of the robot’s joints over all the consecutive via-points were relatively steady for the last four revolute joints. This could be attributed to the highly accurate IK constraints with the resolution achieved in a timely manner.

In addition, a mean execution time of 0.057 s was required for the iterative execution of the dynamic model. Thus, the model could enhance the real-time control of the robot. Similarly, analysis of the torque reflecting at the robot’s joints showed a high symmetry of the generalized forces amongst the four joints, except for the joint connecting the third link. This could be explained with respect to the role of the joint in enhancing the spatially flexible movement of the snake-like robot. The plot in

Figure 8b shows that comparably smaller torque inputs were required by the first two joints and the last link. Both links in the former had approximately similar generalized forces and this was because the prismatic joint had a limited offset and hardly moved during the trajectory. However, for the latter, the smaller torque was associated with the desired value set for the joint, and thus, the effects of gravity are reduced when the link was used for surgical contact. The peculiar structure of the kinematic and dynamic model was keenly exploited for implementation of the trajectory planning and collision avoidance techniques.

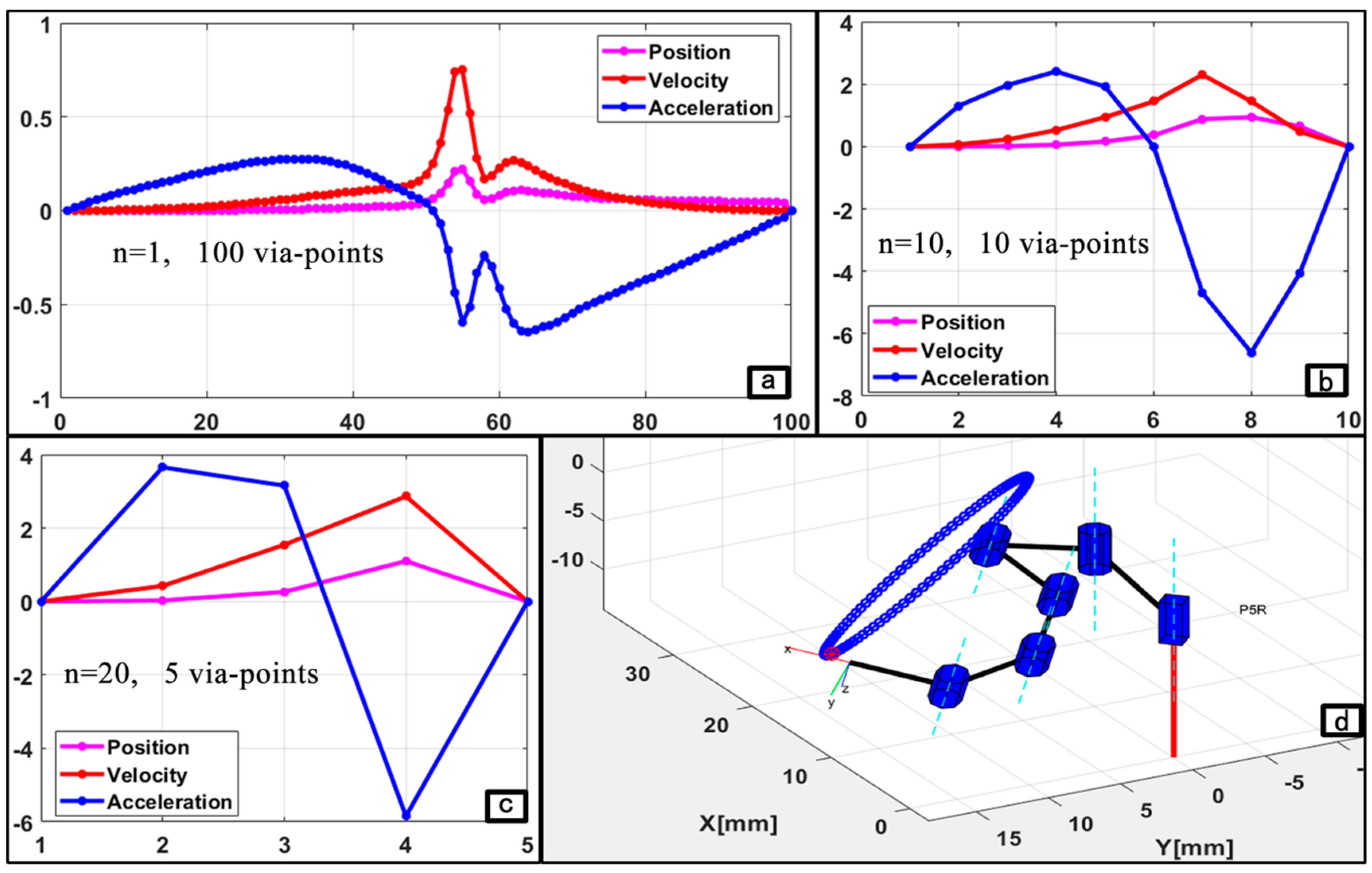

4.3. Motion Trajectory Model Results

As presented above, results from the kinematics and dynamics model were plausible for the navigation along the given paths. The points in each path were assigned as an admissible motion trajectory as computed by the planning strategy developed in

Section 3.3. The selection of the trajectory control basis was based on the flexibility of the robot’s structure and navigation along the circular path. Thus, sequences of the via-points were referenced in joint space for the trajectory planning, while the

robot tracked the circular path in a point-to-point manner. The three scenarios of

n via-points (i.e.,

n = 1, 10, and 20) were studied to validate the trajectory constraints model across the time splines. For convenience, the sequence of points obtained for each case was assigned and the corresponding joint variables computed in the workspace were followed for proper monitoring of the executed trajectories during navigation. The via-points were validated using the motion profile obtained when the cycloidal trajectory model in Equations (21)–(23) was implemented.

Table 2 shows the results obtained for the trajectory planning when executed for the case of

n = 20 via-points. This includes the coordinates of the last link, as well as the positions, velocities, and accelerations of all joints and their time splines during the point-wise movement. For each consecutive

movement in the three trajectory cases, the pose of the saddle points comprised a unit vector with orientation

=

defined along the normal of each via-point (

) in the flexible robot’s workspace. Plots in

Figure 6 show the poses of the robot along with an instance of the joint displacement during its navigations in the three scenarios. The motion was primed with values of variables

,

,

, and

set to be zero for all joints

j = 1, 2,…, 6. The robotic model was initialized to move along the circular path from rest and came to a full stop at the end of the trajectory. Joint displacements from the initial point through the desired via-points to the target point were computed in joint space by solving the robot’s IK. The model described for a normalized profile of the motion’s trajectory was implemented for the three cases of the circular path. For convenience, the sequence of points in each case was assigned and the corresponding joint variables computed in the workspace were followed for proper monitoring of the executed trajectories during navigation. Motion profiles for each of the three motion cases are presented in plots of

Figure 9a–c.

Figure 9 shows that the control system demonstrated geometrically and parametrically continuous motion with smooth trajectories in all the cases. Furthermore, the motion duration remained stable at approximately 0.623 s, and the workspace boundary and interior singularities were not encountered while navigating the circular pathways. Since trajectory error is an important metric for developing a motion control system for flexible robotic surgery, we further analyzed the point-to-point navigations to observe the error displacement for a given point in the trajectory. For instance,

Figure 7d shows the error details in the circular trajectory tracking with 100 via-points.

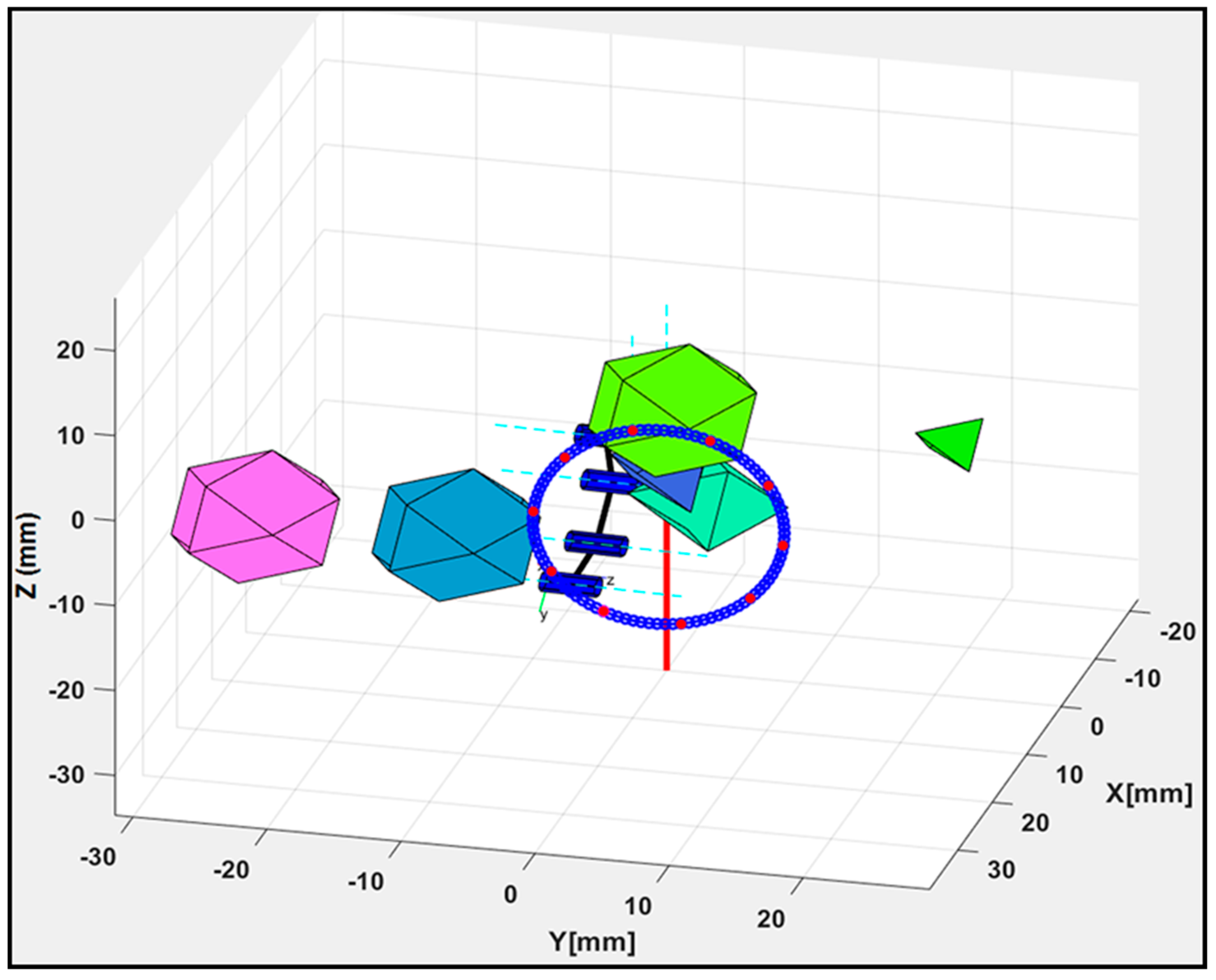

4.4. Results from the Obstacle Avoidance Model

Objects that are not of interest in a workspace or links making-up the flexible robot can be deemed as obstacles, and these can hinder the steady or continuous motion of a robotic mechanism when moving along a pathway with a pre-planned trajectory, which reduces the efficiency of the trajectory planning system. The avoidance of collision with obstacles in the workspace was initiated during the point-to-point navigation trials. For this purpose, polyhedral-shaped objects were randomly introduced as workspace obstacles while the trajectory model was executed. The interpolation of the robot’s links with each obstacle in the workspace was checked and the

for the potential collision points were calculated in accordance with

Section 3.3. Since each polygonal area was encircled, the algorithm checked for interpolation using the center and radius of both circles to decide whether a collision with an obstacle may occur and to trigger any necessary avoidance. Again, Equation (10) was used to generate a circular path while tracking scenarios with multiple obstacles were established to validate the avoidance model.

Figure 10 shows a scenario with five different obstacles in the robot’s workspace. Collision-free movement was obtained by using poses with the value of

PoC ≈ 0 from the pool of the robot’s poses generated using the IK scheme in

Section 3.2 as the robot moved along with the desired trajectory in the circular paths.

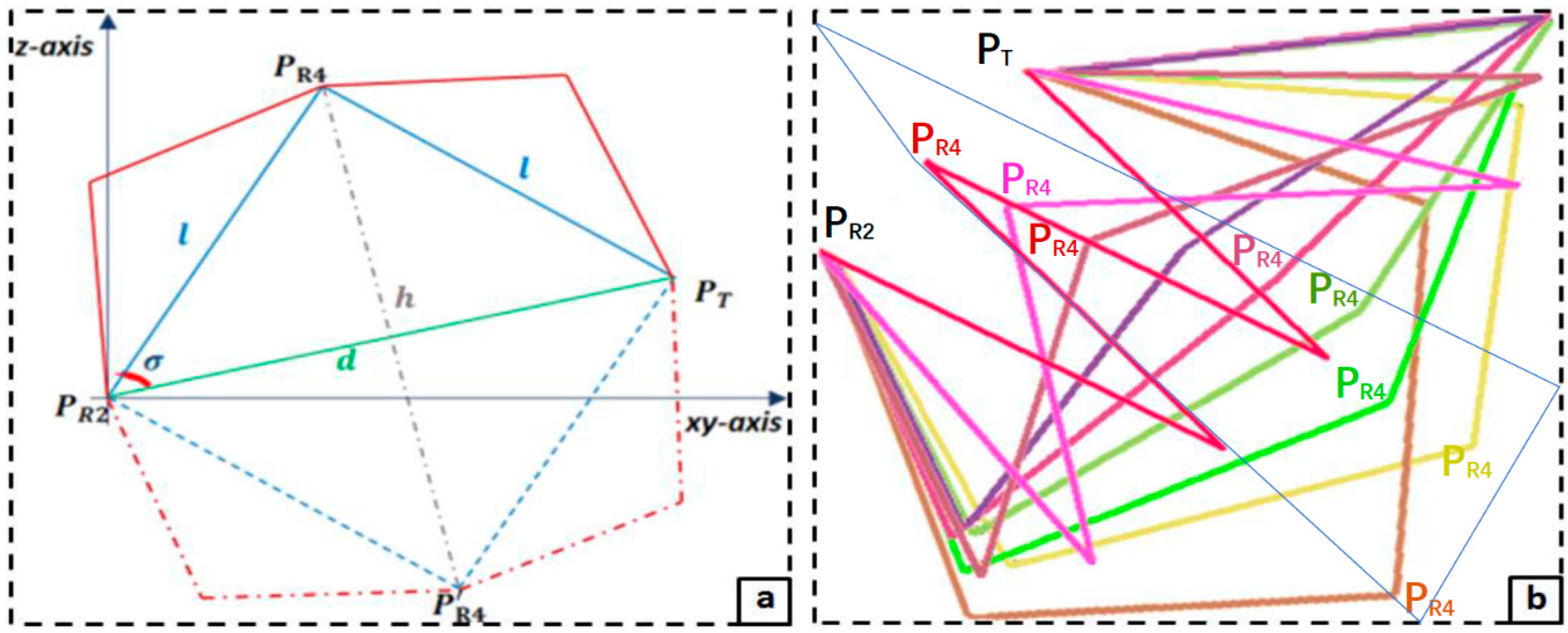

The detection algorithm of the model compiled

values for all link–obstacle pairs in the robot’s workspace, and the

value in

Figure 3a was changed to determine an IK solution that avoided collisions with obstacles during each point-to-point movement. Thus, the circular path was tracked and none of the trajectory movements were ensnared by an obstacle during the point-to-point navigation trials. The proposed system found optimized joint angles for all links to stably track the trajectory. Furthermore, components of the motion control system were evaluated to analyze the performance of the collision avoidance strategy. For this purpose, execution times when the control system was used with and without the collision avoidance strategy were compared and average execution times of 0.019 ± 0.008 s and 3.576 ± 1.688 s were obtained, respectively. Thus, the strategy used had a relatively high computational complexity; in fact, the time complexity directly depended on the number of interpolated points found when executing the obstacle detection and avoidance algorithm. Furthermore, the algorithm optimally maintained a safe distance between the robot’s links and the obstacles in the workspace.

5. Conclusions and Future Works

Recent developments in robotic surgery include designing flexible mechanisms that can enhance surgical interventions, such as suturing, tumor resection, and even radio-surgical interventions. In this study, a control system was proposed for the motion and trajectory tracking of flexible robots in this paper. This included a snake-like robotic mechanism designed for the navigation of a flexible surgical pathway, and the derivation of kinematic and dynamic constraint models for safe motion and trajectory control of the snake-like mechanism. Furthermore, the proposed surgical platform and control system were validated in silico. According to the implementation and validation results, the snake-like model was capable of navigating a flexible pathway, and the proposed motion and trajectory control system could quickly and accurately navigate the surgical robot. The IK resolution model in the control system was based on geometric analysis of the robot’s links and joints in Cartesian space, while the dynamic constraints modeling was focused on computing the generalized force acting at the robot’s links and joints during the path navigation. Both models demonstrated viably fast resolutions—6.1 ms for kinematics and 5.7 ms for dynamics—when the robotic mechanism was used to navigate three instances of a circular pathway. Kinematically, the proposed model demonstrated a 92% reachability when an error threshold of 1 mm was used. Thus, enhancement of the optimal trajectory tracking was achieved with the flexible snake-like robot in the circular-path-tracking study. The fast and efficient control system benefited from using simple Cartesian analytics for the model derivation. Hence, the control system can be ideally used for surgical robotic teleoperation.

In the future, another experimental validation will be performed using the same proposed robotic design. For this purpose, the proposed constraints control system will be enhanced to fit the complexity of the flexible snake-like robot such that each revolute joint will have a unique rotation axis, as in

Figure 1. Furthermore, the dynamics model, which is currently based on only the first two derivatives of the position data, will be improved and high-order generalized forces acting at the robot’s joints will also be considered. To avoid the noisy moment and torque values generated using the recursive Newton–Euler model, appropriate signal filtering model will be incorporated in a future study. Lastly, intelligence-based control methods will also be adapted for the kinematics and dynamics resolution, as well as the obstacle collision detection and avoidance schemes.