Microparticle Acoustophoresis in Aluminum-Based Acoustofluidic Devices with PDMS Covers

Abstract

1. Introduction

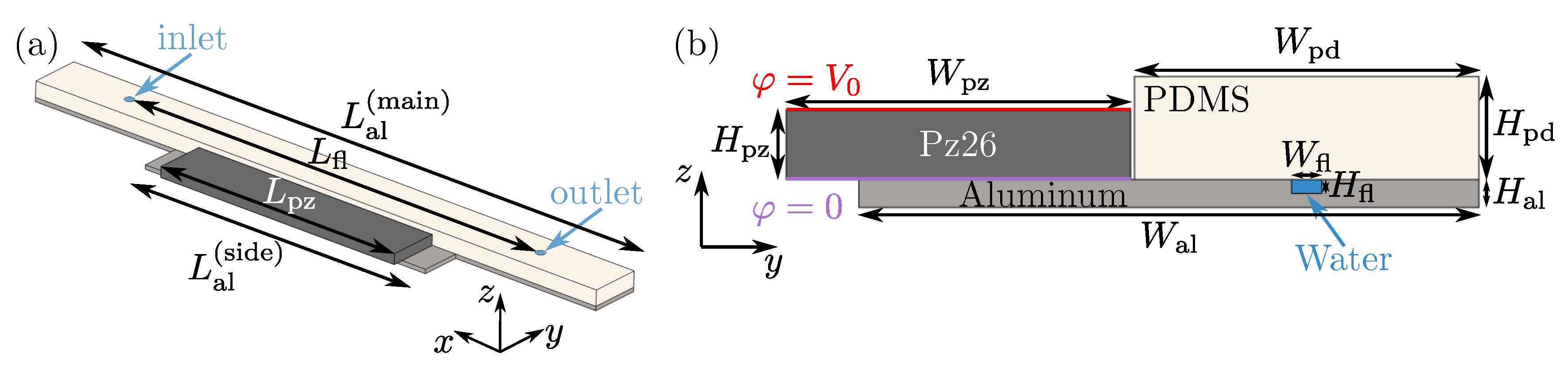

2. Theory: The Governing Equations and Boundary Conditions

2.1. The Piezoelectric Transducer

2.2. The Elastic Aluminum Base, PDMS Cover, and Silver Electrodes

2.3. Pressure Acoustics in the Water-Filled Microchannel

2.4. Acoustic Streaming in the Water-Filled Microchannel

2.5. The Acoustic Radiation and Drag Force on Suspended Microparticles

3. Numerical Implementation and Experimental Validation of the Single-PDMS-Cover Model

3.1. Model Implementation in COMSOL Multiphysics

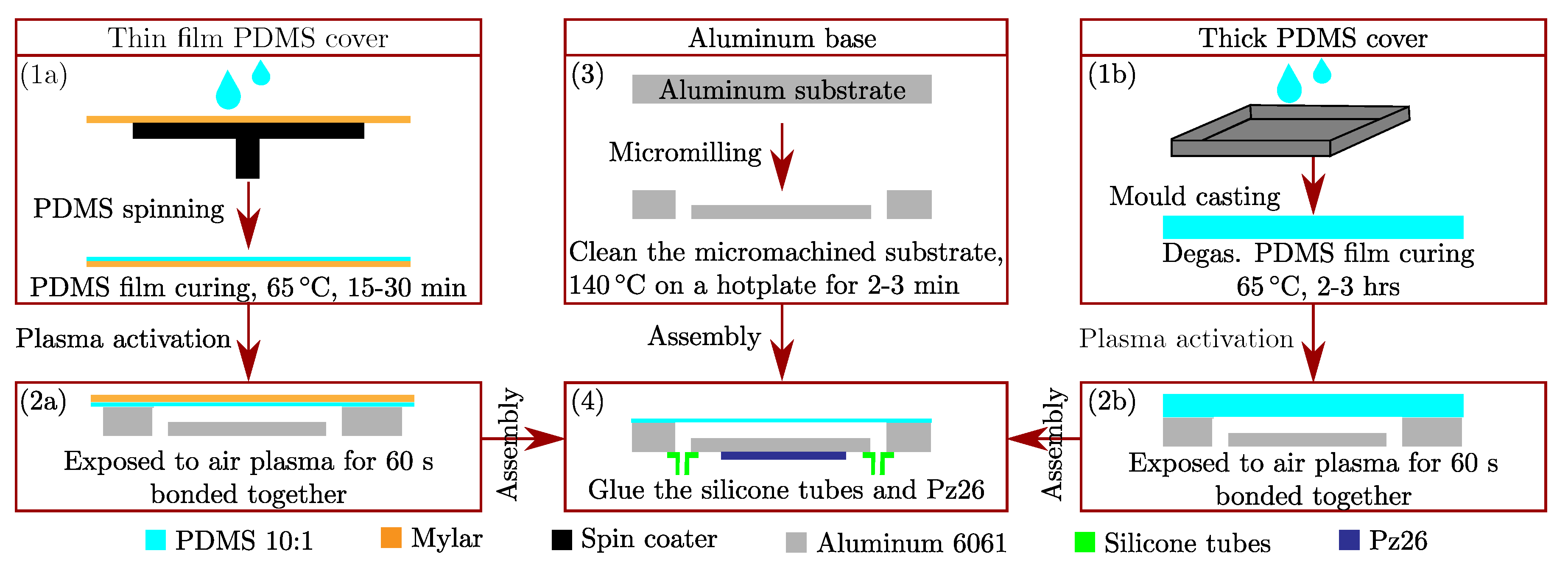

3.2. Manufacturing Method of the Chip for the Experimental Validation

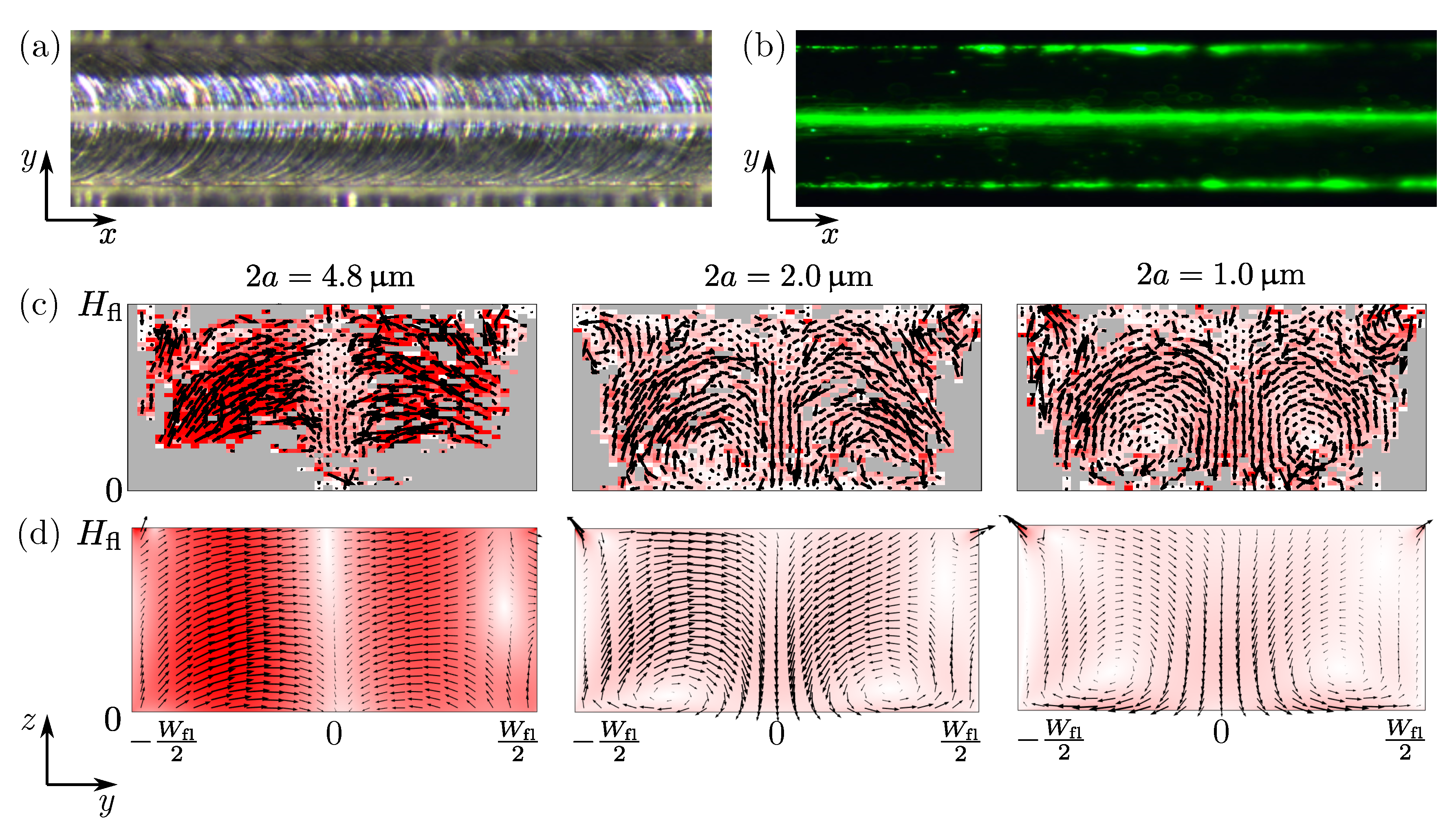

3.3. Experimental Validation of the Numerical Model

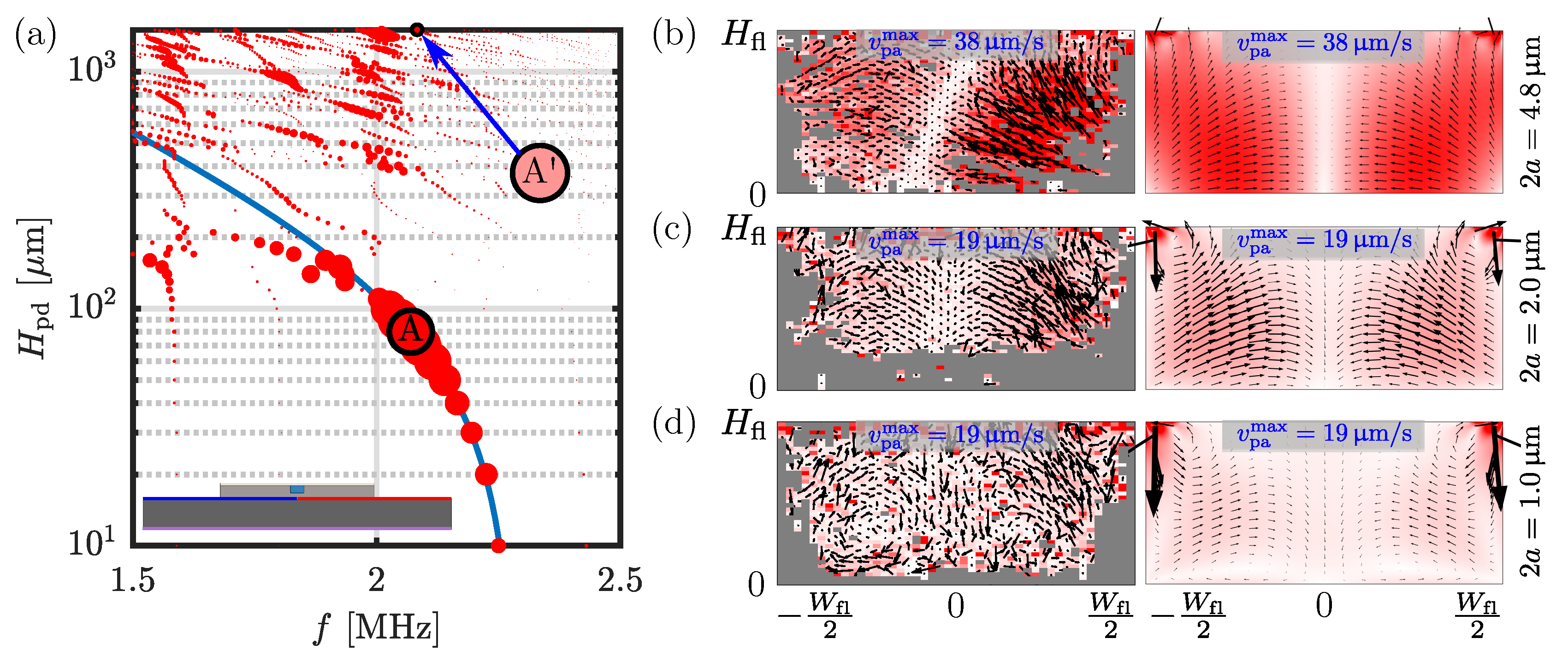

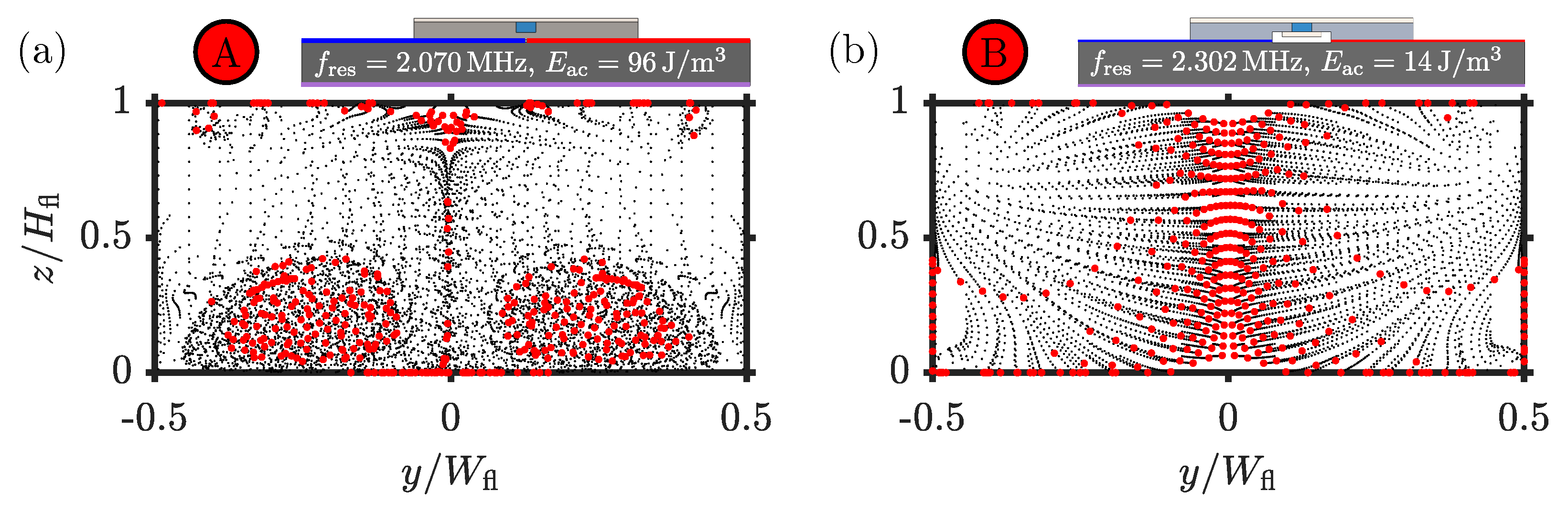

4. Modeling of Single-PDMS-Cover Devices with Anti-Symmetric Voltage Actuation

4.1. Numerical Optimization of the Thickness of the PDMS Cover

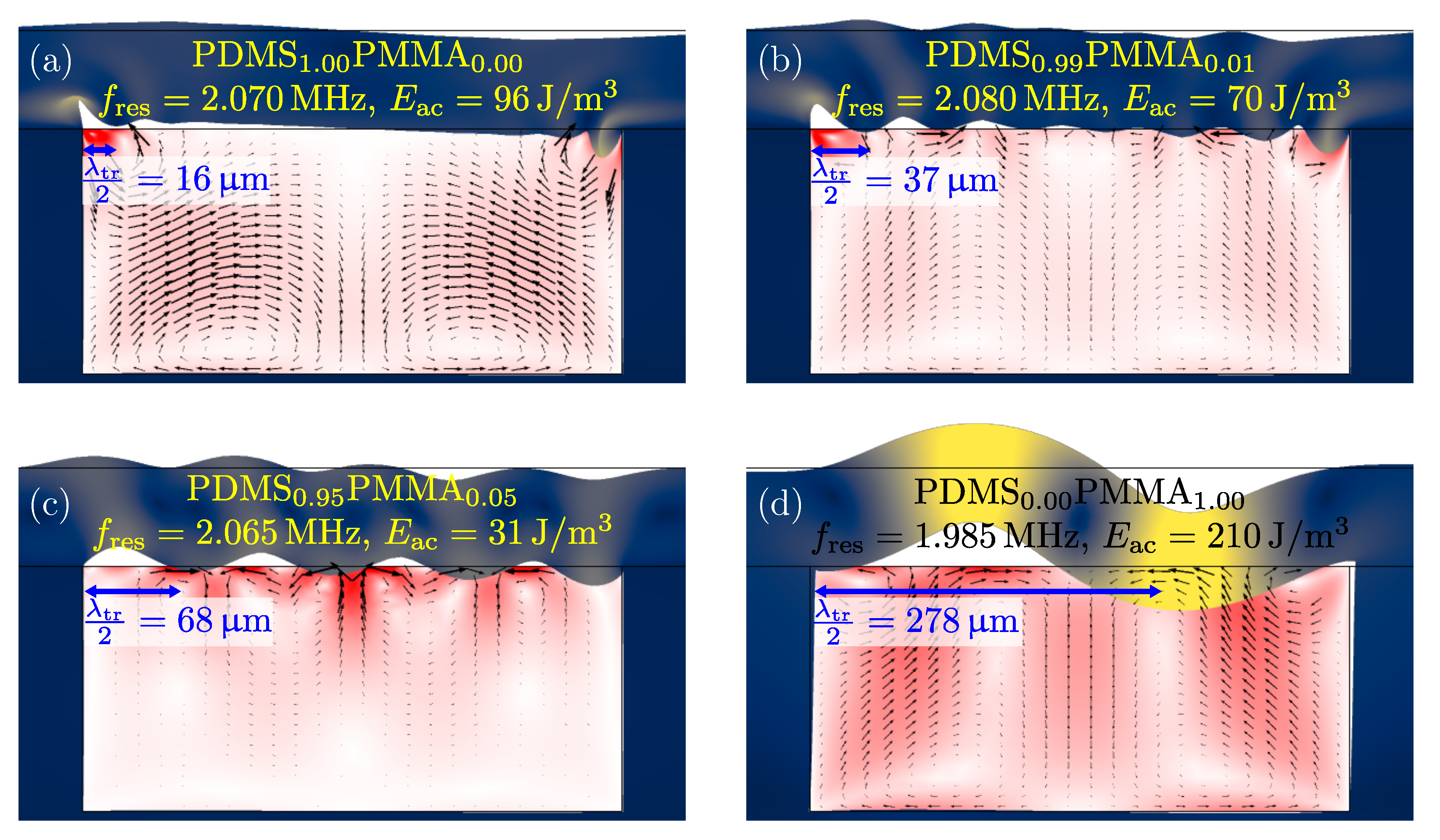

4.2. The Role of Variations in the PDMS Material Properties

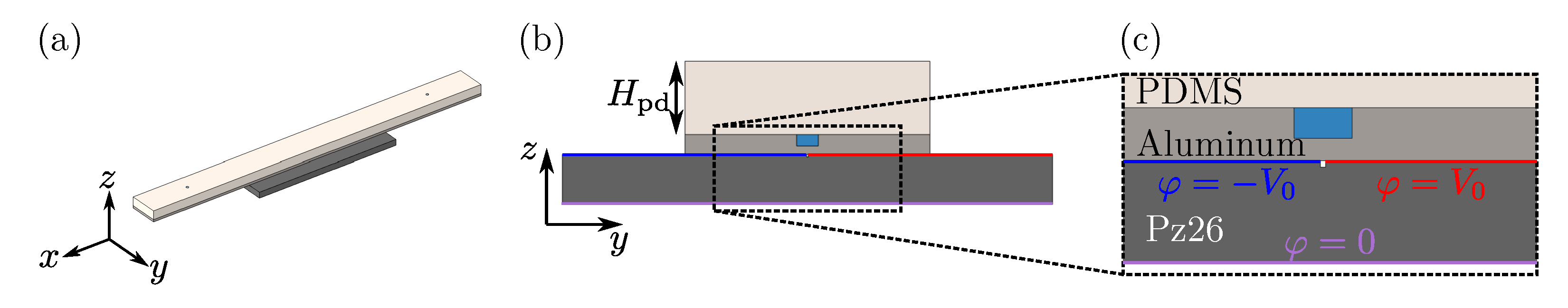

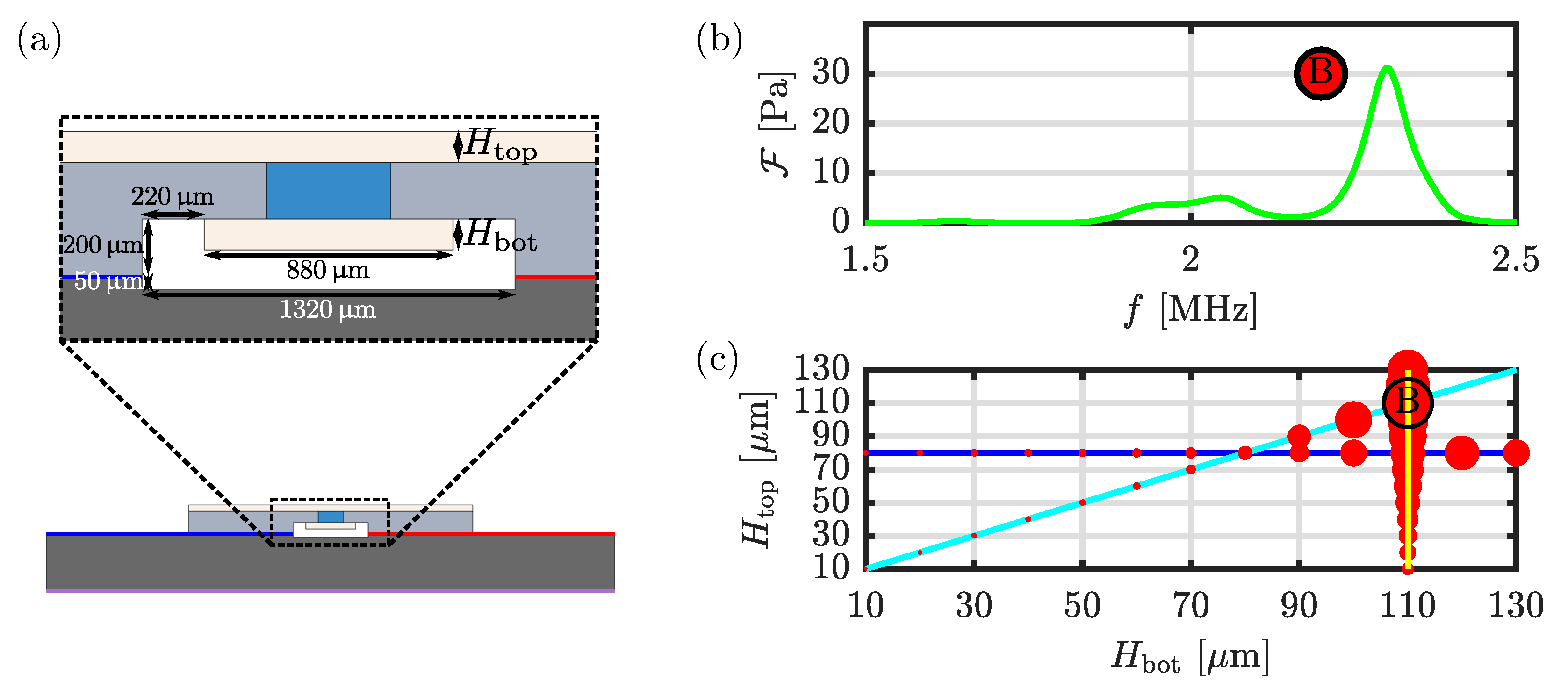

5. Modeling Dual-PDMS-Cover Aluminum Devices with Anti-symmetric Voltage Actuation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Material Parameters

| Parameter | Value | Parameter | Value | Parameter | Value | |||

|---|---|---|---|---|---|---|---|---|

| 7700 | kg/m | 828 | 700 | |||||

| 168 | GPa | 123 | GPa | C/m | ||||

| 110 | GPa | 30.1 | GPa | 14.7 | C/m | |||

| 99.9 | GPa | 29.0 | GPa | 9.86 | C/m | |||

| Aluminum | Silver | PDMS (10:1) | |||

|---|---|---|---|---|---|

| Parameter | Symbol | 6061 [29] | [30] | Cured at 65 C [31] | Unit |

| Mass density | 2700 | 10,485 | 1029 | kg/m | |

| Elastic modulus | GPa | ||||

| Elastic modulus | GPa | ||||

| Damping coefficient | 0.0013 | 0.0004 | – | – |

| Water [32] | Polystyrene Particles [33] | ||||

|---|---|---|---|---|---|

| Parameter | Symbol | Value | Parameter | Symbol | Value |

| Mass density | 997.05 kg/m | Mass density | 1050 kg/m | ||

| Compressibility | TPa | Compressibility | 238 TPa | ||

| Dynamic viscosity | 0.890 mPa·s | Monopole coefficient | 0.468 | ||

| Bulk viscosity | 2.485 mPa·s | Dipole coefficient | 0.034 | ||

| Speed of sound | 1496.7 m/s | Contrast factor | 0.173 | ||

References

- Lenshof, A.; Evander, M.; Laurell, T.; Nilsson, J. Acoustofluidics 5: Building microfluidic acoustic resonators. Lab Chip 2012, 12, 684–695. [Google Scholar] [CrossRef] [PubMed]

- Lilliehorn, T.; Simu, U.; Nilsson, M.; Almqvist, M.; Stepinski, T.; Laurell, T.; Nilsson, J.; Johansson, S. Trapping of microparticles in the near field of an ultrasonic transducer. Ultrasonics 2005, 43, 293–303. [Google Scholar] [CrossRef]

- Evander, M.; Johansson, L.; Lilliehorn, T.; Piskur, J.; Lindvall, M.; Johansson, S.; Almqvist, M.; Laurell, T.; Nilsson, J. Noninvasive acoustic cell trapping in a microfluidic perfusion system for online bioassays. Anal. Chem. 2007, 79, 2984–2991. [Google Scholar] [CrossRef]

- Hammarström, B.; Evander, M.; Barbeau, H.; Bruzelius, M.; Larsson, J.; Laurell, T.; Nillsson, J. Non-contact acoustic cell trapping in disposable glass capillaries. Lab Chip 2010, 10, 2251–2257. [Google Scholar] [CrossRef] [PubMed]

- Lei, J.; Glynne-Jones, P.; Hill, M. Acoustic streaming in the transducer plane in ultrasonic particle manipulation devices. Lab Chip 2013, 13, 2133–2143. [Google Scholar] [CrossRef] [PubMed]

- Mishra, P.; Hill, M.; Glynne-Jones, P. Deformation of red blood cells using acoustic radiation forces. Biomicrofluidics 2014, 8, 034109. [Google Scholar] [CrossRef]

- Gralinski, I.; Raymond, S.; Alan, T.; Neild, A. Continuous flow ultrasonic particle trapping in a glass capillary. J. Appl. Phys. 2014, 115, 054505. [Google Scholar] [CrossRef]

- Hammarström, B.; Laurell, T.; Nilsson, J. Seed particle enabled acoustic trapping of bacteria and nanoparticles in continuous flow systems. Lab Chip 2012, 12, 4296–4304. [Google Scholar] [CrossRef]

- Evander, M.; Gidlof, O.; Olde, B.; Erlinge, D.; Laurell, T. Non-contact acoustic capture of microparticles from small plasma volumes. Lab Chip 2015, 15, 2588–2596. [Google Scholar] [CrossRef]

- Harris, N.; Hill, M.; Keating, A.; Baylac-Choulet, P. A Lateral Mode Flow-through PMMA Ultrasonic Separator. Intl. J. Appl. Biomed. Eng. 2012, 5, 20–27. [Google Scholar]

- Mueller, A.; Lever, A.; Nguyen, T.V.; Comolli, J.; Fiering, J. Continuous acoustic separation in a thermoplastic microchannel. J. Micromech. Microeng. 2013, 23, 125006. [Google Scholar] [CrossRef]

- Gonzalez, I.; Tijero, M.; Martin, A.; Acosta, V.; Berganzo, J.; Castillejo, A.; Bouali, M.M.; Luis Soto, J. Optimizing Polymer Lab-on-Chip Platforms for Ultrasonic Manipulation: Influence of the Substrate. Micromachines 2015, 6, 574–591. [Google Scholar] [CrossRef]

- Yang, C.; Li, Z.; Li, P.; Shao, W.; Bai, P.; Cui, Y. Acoustic particle sorting by integrated micromachined ultrasound transducers on polymerbased microchips. In Proceedings of the IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 1–4. [Google Scholar]

- Savage, W.J.; Burns, J.R.; Fiering, J. Safety of acoustic separation in plastic devices for extracorporeal blood processing. Transfusion 2017, 57, 1818–1826. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.; Dow, P.; Dubay, R.; Lissandrello, C.; Holder, J.; Densmore, D.; Fiering, J. Rapid prototyping and parametric optimization of plastic acoustofluidic devices for blood-bacteria separation. Biomed. Microdevices 2017, 19, 70. [Google Scholar] [CrossRef]

- Lissandrello, C.; Dubay, R.; Kotz, K.T.; Fiering, J. Purification of Lymphocytes by Acoustic Separation in Plastic Microchannels. SLAS Technol. 2018, 23, 352–363. [Google Scholar] [CrossRef]

- Moiseyenko, R.P.; Bruus, H. Whole-System Ultrasound Resonances as the Basis for Acoustophoresis in All-Polymer Microfluidic Devices. Phys. Rev. Appl. 2019, 11, 014014. [Google Scholar] [CrossRef]

- Adams, J.D.; Ebbesen, C.L.; Barnkob, R.; Yang, A.H.J.; Soh, H.T.; Bruus, H. High-throughput, temperature-controlled microchannel acoustophoresis device made with rapid prototyping. J. Micromech. Microeng. 2012, 22, 075017. [Google Scholar] [CrossRef]

- Xu, K.; Clark, C.P.; Poe, B.L.; Lounsbury, J.A.; Nilsson, J.; Lauren, T.; Landers, J.P. Isolation of a Low Number of Sperm Cells from Female DNA in a Glass-PDMS-Glass Microchip via Bead-Assisted Acoustic Differential Extraction. Anal. Chem. 2019, 91, 2186–2191. [Google Scholar] [CrossRef]

- Gautam, G.P.; Burger, T.; Wilcox, A.; Cumbo, M.J.; Graves, S.W.; Piyasena, M.E. Simple and inexpensive micromachined aluminum microfluidic devices for acoustic focusing of particles and cells. Anal. Bioanal. Cham. 2018, 410, 3385–3394. [Google Scholar] [CrossRef]

- Skov, N.R.; Bach, J.S.; Winckelmann, B.G.; Bruus, H. 3D modeling of acoustofluidics in a liquid-filled cavity including streaming, viscous boundary layers, surrounding solids, and a piezoelectric transducer. AIMS Math. 2019, 4, 99–111. [Google Scholar] [CrossRef]

- Bach, J.S.; Bruus, H. Theory of pressure acoustics with viscous boundary layers and streaming in curved elastic cavities. J. Acoust. Soc. Am. 2018, 144, 766–784. [Google Scholar] [CrossRef] [PubMed]

- Settnes, M.; Bruus, H. Forces acting on a small particle in an acoustical field in a viscous fluid. Phys. Rev. E 2012, 85, 016327. [Google Scholar] [CrossRef] [PubMed]

- COMSOL Multiphysics 5.4. 2018. Available online: http://www.comsol.com (accessed on 3 February 2020).

- Barnkob, R.; Kähler, C.J.; Rossi, M. General defocusing particle tracking. Lab Chip 2015, 15, 3556–3560. [Google Scholar] [CrossRef] [PubMed]

- Institut für Strömungsmechanik und Aerodynamik, Univeristät der Bundeswher. GDTPlab—How to Get It. Available online: https://www.unibw.de/lrt7/gdpt-1/gdptlab-how_to_get_it (accessed on 17 February 2020).

- Meggit A/S, Porthusvej 4, DK-3490 Kvistgaard, Denmark. Ferroperm Matdat 2017. Available online: https://www.meggittferroperm.com/materials/ (accessed on 17 February 2020).

- Hahn, P.; Dual, J. A numerically efficient damping model for acoustic resonances in microfluidic cavities. Phys. Fluids 2015, 27, 062005. [Google Scholar] [CrossRef]

- ASM Aerospace Specification Metals Inc., Pompano Beach (Fl) USA. ASM Aluminum 6061. Available online: http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA6061T6, (accessed on 3 February 2020).

- AZO Materials, Manchester, UK. AZO—Applications and Properties of Silver. Available online: https://www.azom.com/properties.aspx?ArticleID=600 (accessed on 3 February 2020).

- Skov, N.R.; Sehgal, P.; Kirby, B.J.; Bruus, H. Three-Dimensional Numerical Modeling of Surface-Acoustic- Wave Devices: Acoustophoresis of Micro- and Nanoparticles Including Streaming. Phys. Rev. Appl. 2019, 12, 044028. [Google Scholar] [CrossRef]

- Muller, P.B.; Bruus, H. Numerical study of thermoviscous effects in ultrasound-induced acoustic streaming in microchannels. Phys. Rev. E 2014, 90, 043016. [Google Scholar] [CrossRef]

- Karlsen, J.T.; Bruus, H. Forces acting on a small particle in an acoustical field in a thermoviscous fluid. Phys. Rev. E 2015, 92, 043010. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bodé, W.N.; Jiang, L.; Laurell, T.; Bruus, H. Microparticle Acoustophoresis in Aluminum-Based Acoustofluidic Devices with PDMS Covers. Micromachines 2020, 11, 292. https://doi.org/10.3390/mi11030292

Bodé WN, Jiang L, Laurell T, Bruus H. Microparticle Acoustophoresis in Aluminum-Based Acoustofluidic Devices with PDMS Covers. Micromachines. 2020; 11(3):292. https://doi.org/10.3390/mi11030292

Chicago/Turabian StyleBodé, William Naundrup, Lei Jiang, Thomas Laurell, and Henrik Bruus. 2020. "Microparticle Acoustophoresis in Aluminum-Based Acoustofluidic Devices with PDMS Covers" Micromachines 11, no. 3: 292. https://doi.org/10.3390/mi11030292

APA StyleBodé, W. N., Jiang, L., Laurell, T., & Bruus, H. (2020). Microparticle Acoustophoresis in Aluminum-Based Acoustofluidic Devices with PDMS Covers. Micromachines, 11(3), 292. https://doi.org/10.3390/mi11030292