Ring-Shaped Baffle Effect on Separation Performance of Lithium Carbonate Micro Particles in a Centrifugal Classifier

Abstract

:1. Introduction

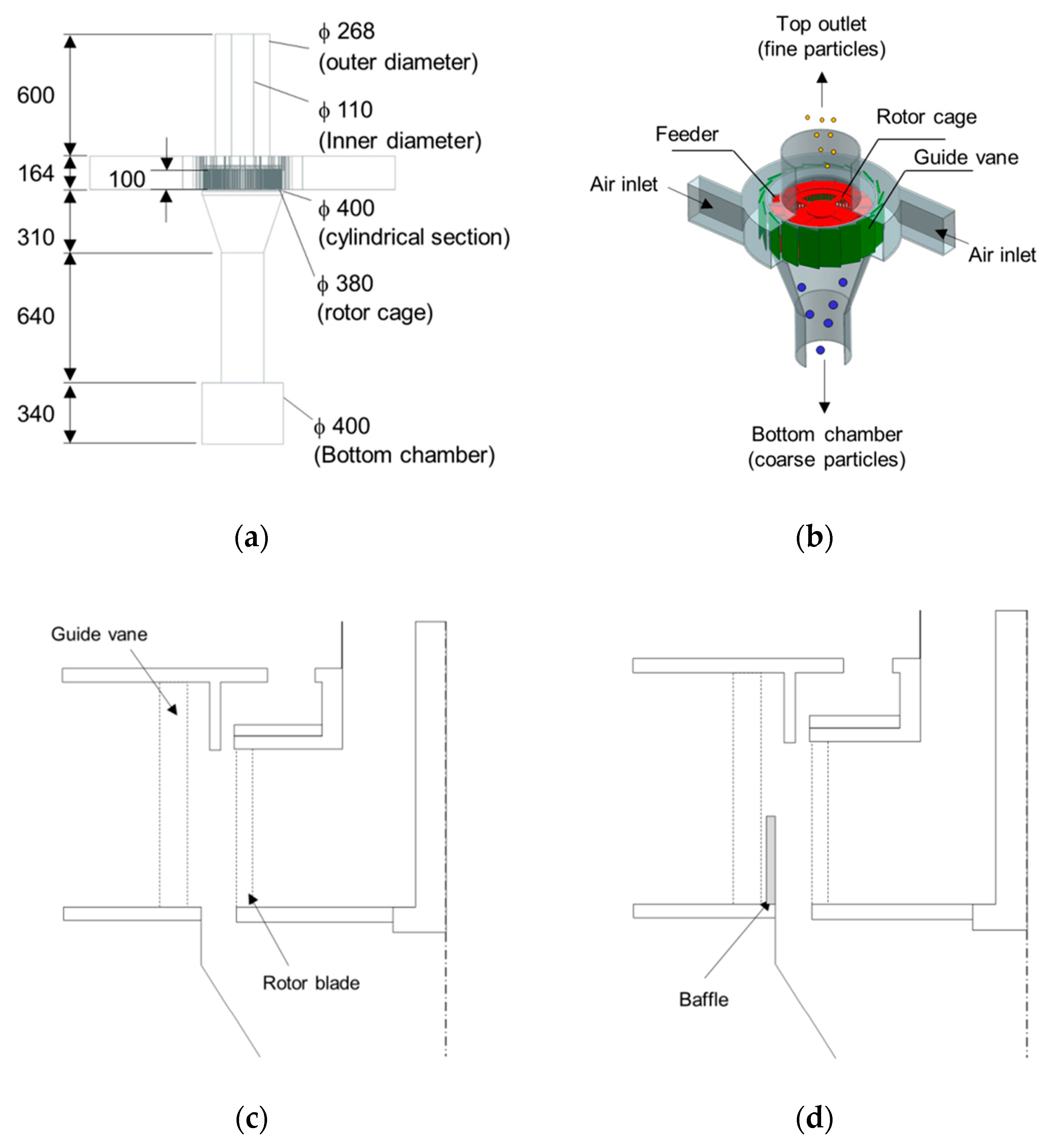

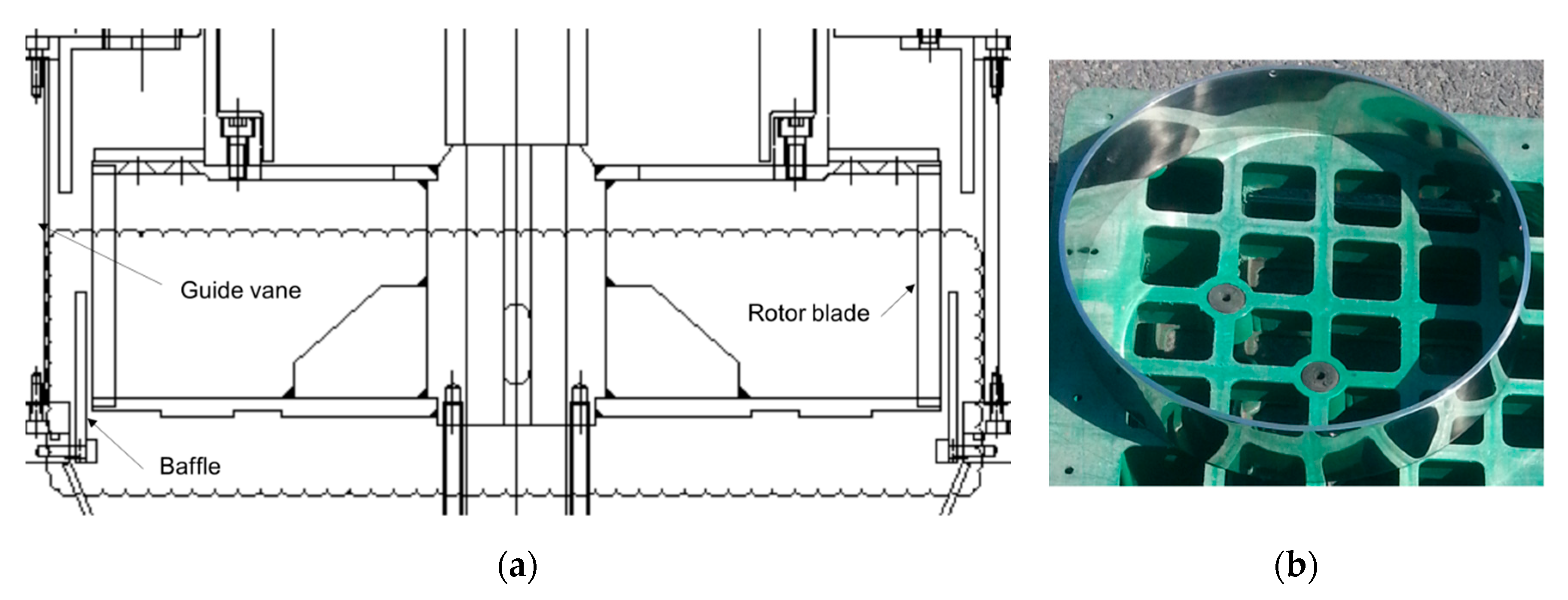

2. Centrifugal Classifier

- (1)

- The blower, which is connected at the top outlet, discharges air to the outside at a specific mass flow rate, and generates a negative pressure inside the classifier. Therefore, air is introduced through the inlet. Due to the cylindrical geometry and tangential velocity field, a high swirling flow is induced in the classifier.

- (2)

- The mixture particles are supplied from the feeder and fall onto the rotor cage. A rotor cage with 90 blades is rotated by the motor. The rotor cage is equipped with ribs for better distribution of particles. The particles are thrown towards the classifier wall by the rotation of the rotor cage.

- (3)

- The coarse particles are blocked by the blades and are not allowed to flow into the inner region. Therefore, most of them fall into the bottom chamber. As the rotational speed of the rotor cage increases, coarse particles collide more often with the blades.

- (4)

- Meanwhile, due to the low inertia, the fine particles move with the air flow and pass through the blades of the rotor cage and exit through the top outlet.

- (5)

- In this work, the effect of a ring-shaped baffle on the particle separation was investigated. As shown in Figure 1d, the baffle partially blocks this airflow from the guide vanes to the rotor cage. The baffle generates a strong velocity field locally in the direction of the rotor cage, allowing unseparated particles to flow back into the rotor cage.

3. Numerical Simulation

3.1. Air Flow Field

3.2. Particle Motion

3.3. Numerical Settings

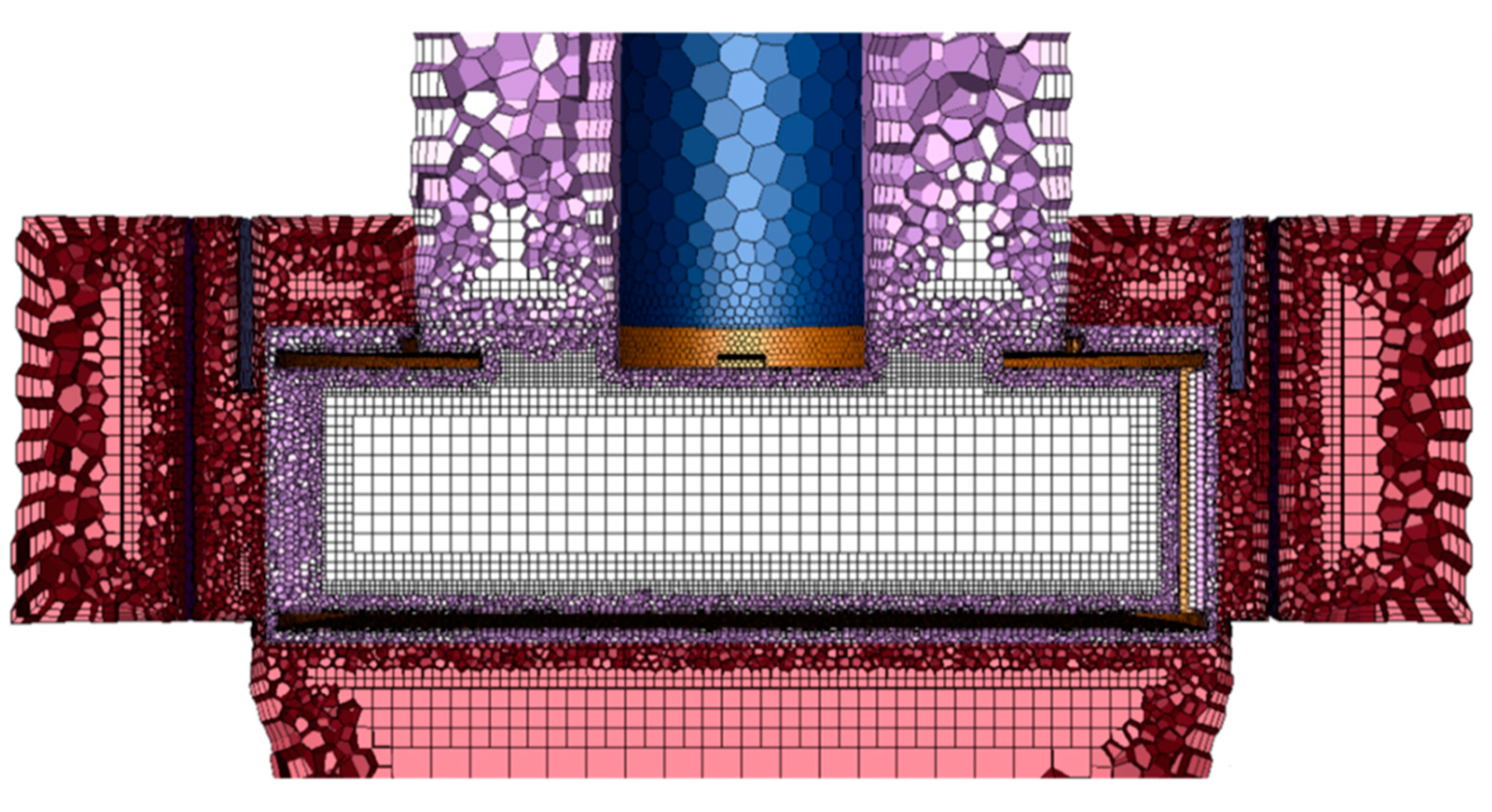

3.4. Numerical Domain

4. Particle Separation Performance

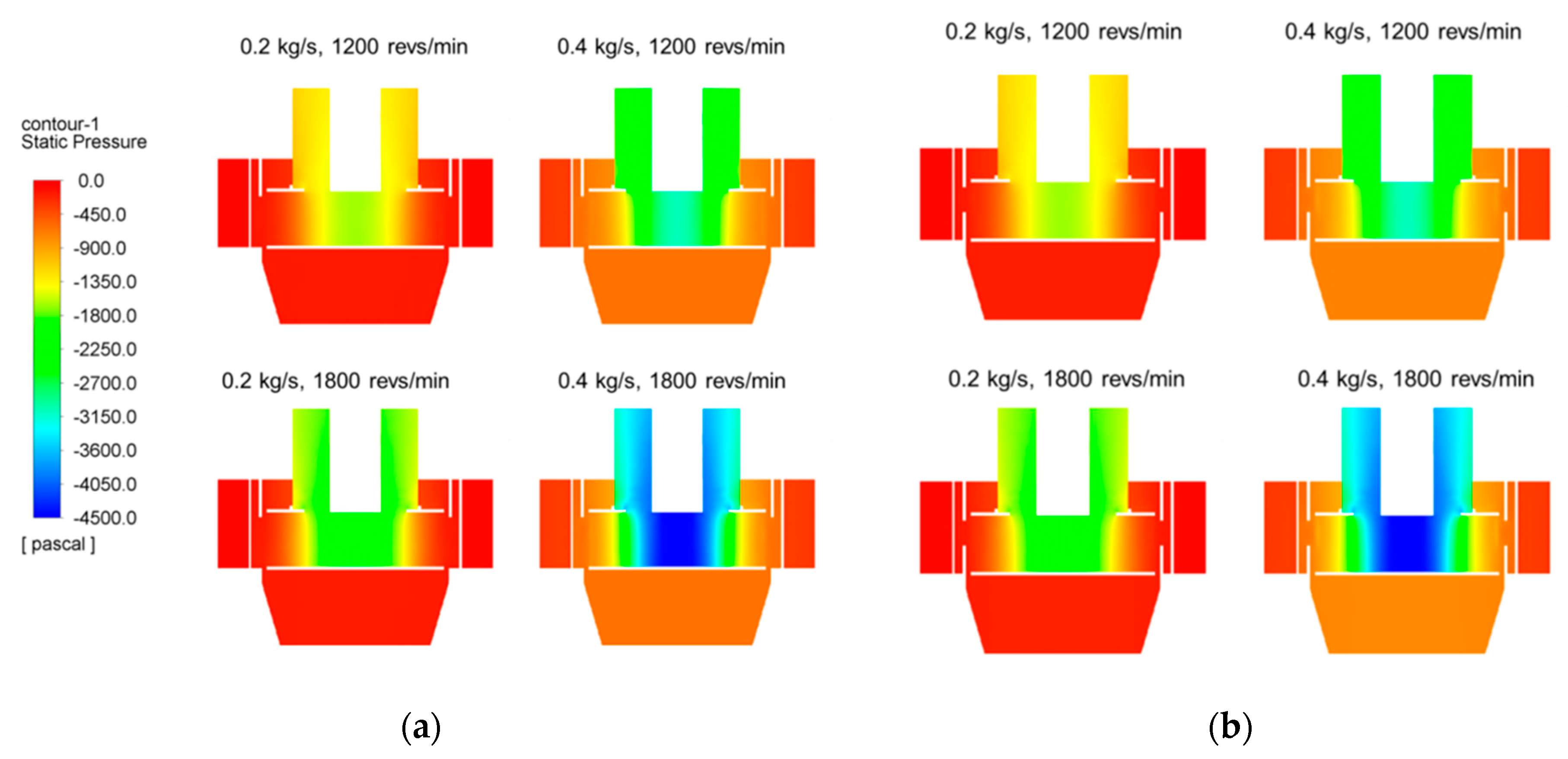

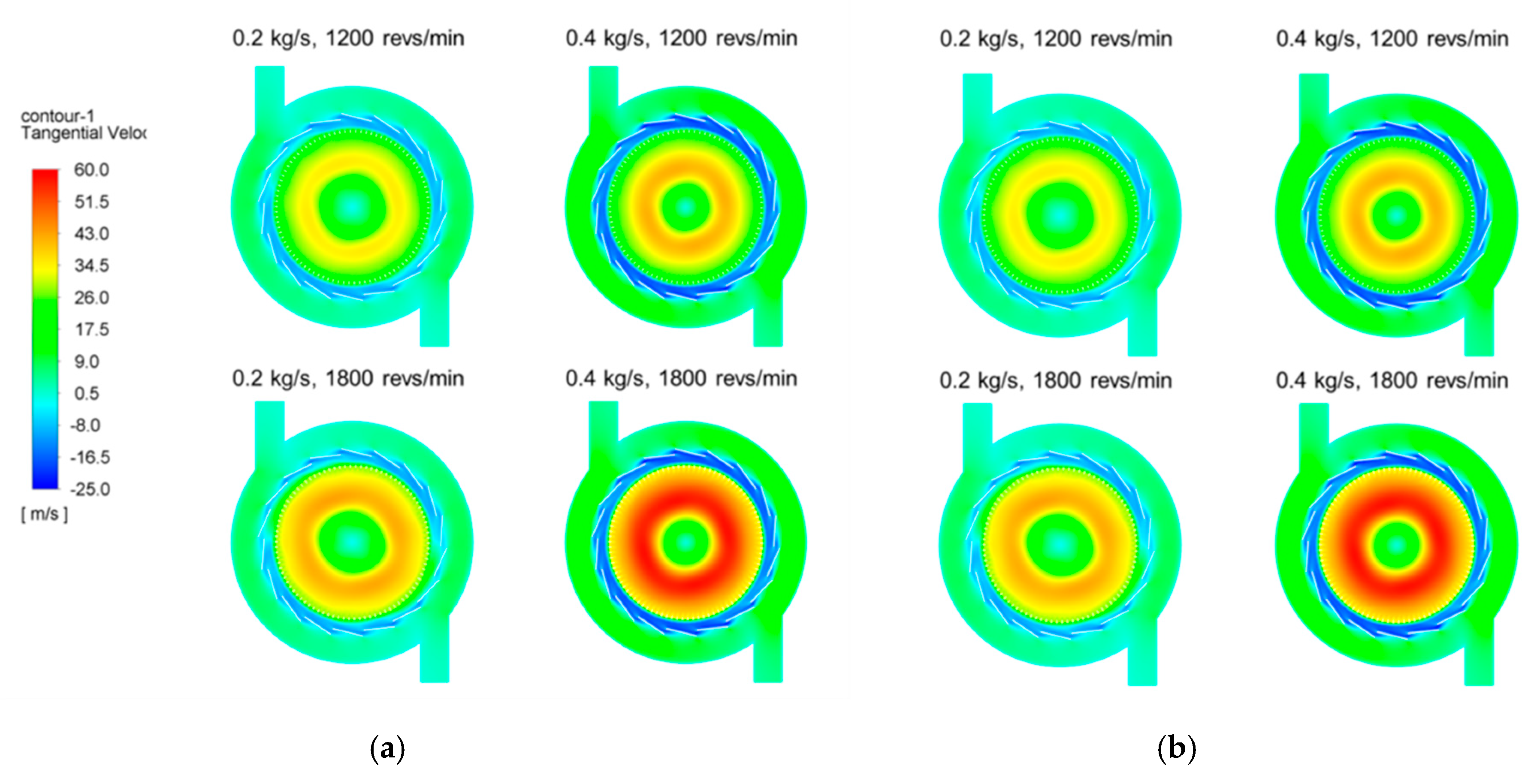

4.1. Pressure Field and Tangential Velocity Field

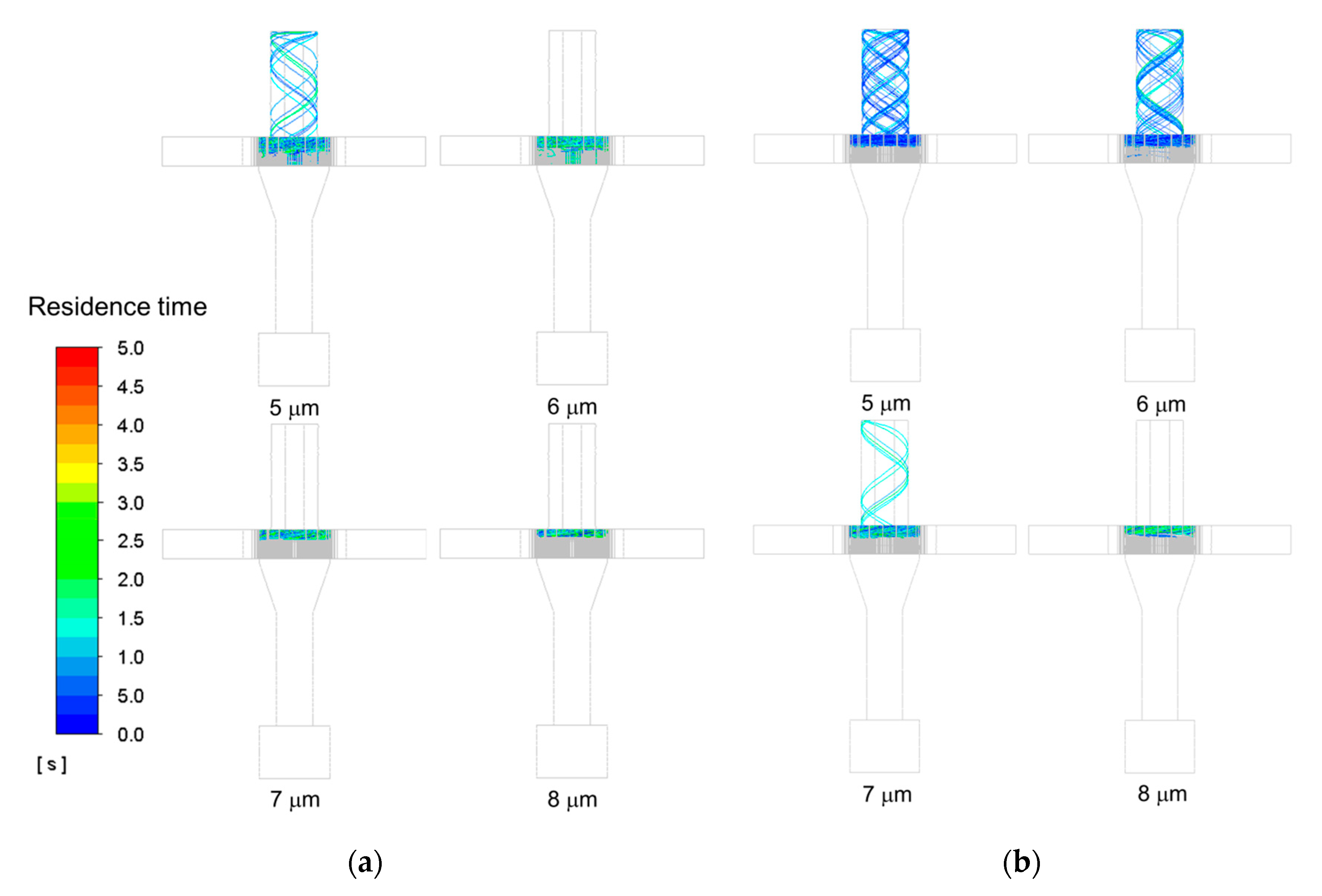

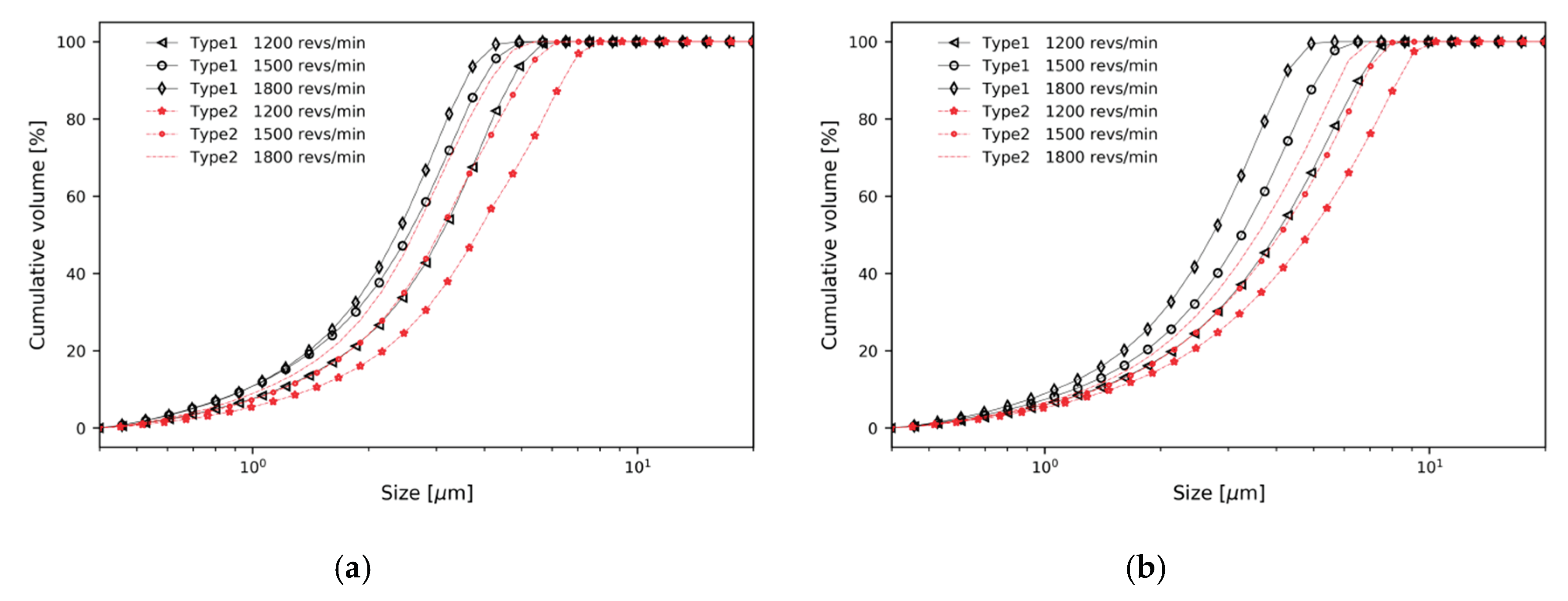

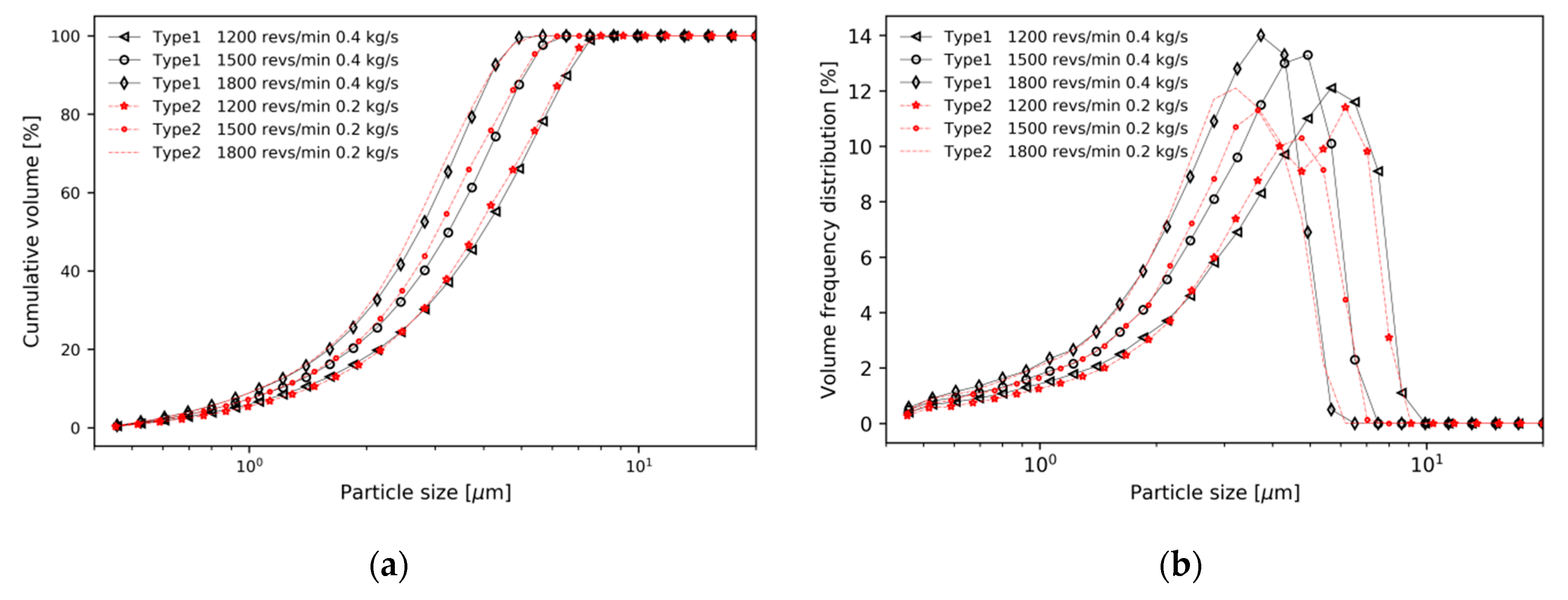

4.2. Particle Separation

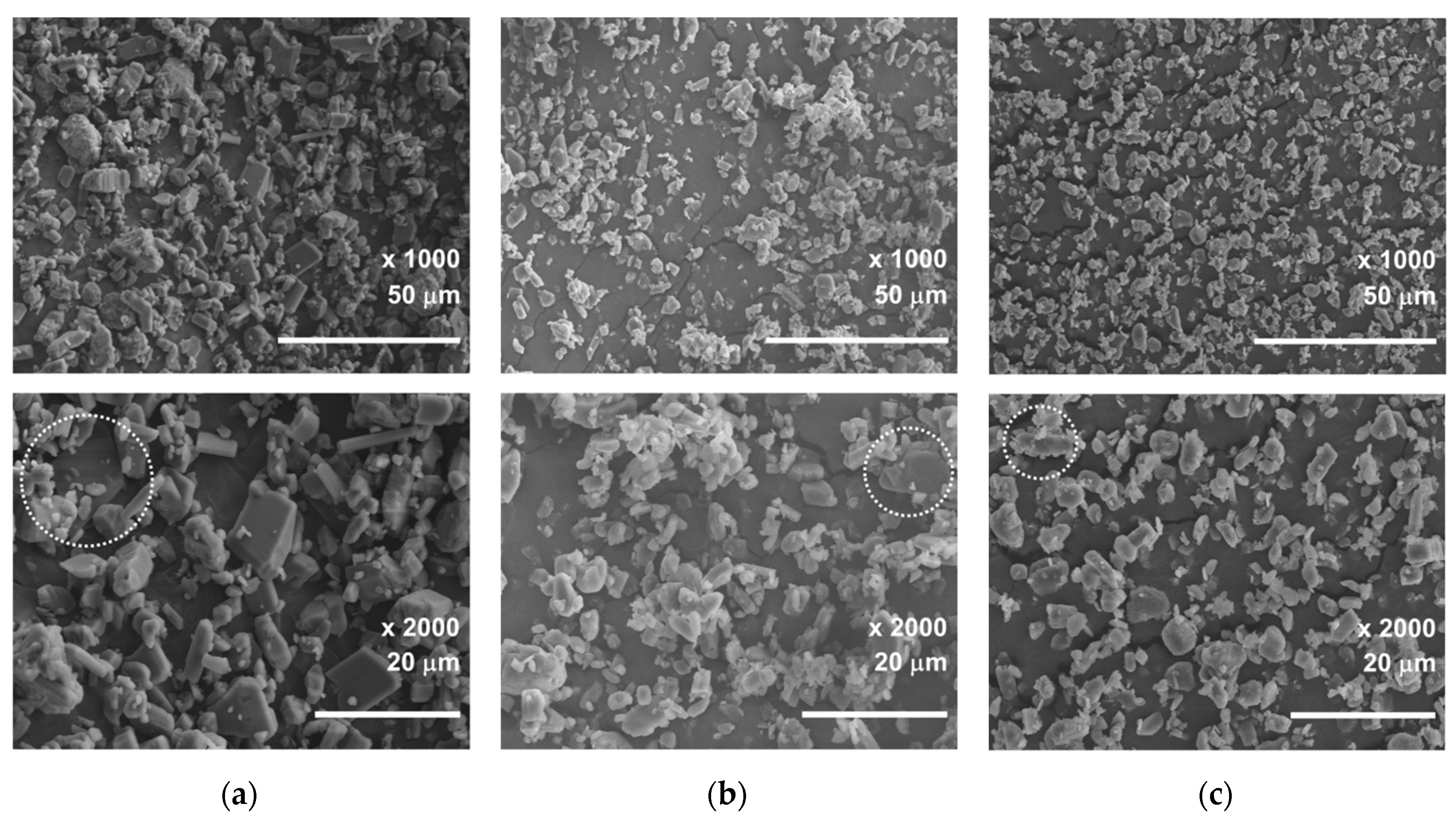

4.3. Experimental Settings

4.4. Experimental Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| p | Fluid Pressure [Pa] |

| g | Gravitational acceleration [m/s2] |

| FD | Drag force [N/m3] |

| CD | Drag coefficient of fluid [–] |

| Rep | Reynolds number of the particle |

| u | Fluid mean velocity [m/s] |

| u’ | Fluctuant fluid velocity [m/s] |

| ui | Fluid velocity to i-direction (i = x, y, z) [m/s] |

| uj | Fluid velocity to j-direction (i = x, y, z) [m/s] |

| up | Particle velocity [m/s] |

| t | Time [s] |

| Greek Letters | |

| δij | Kronecker delta [–] |

| μ | Fluid dynamic viscosity [kg-m/s] |

| ρa | Fluid density [kg/m3] |

| ρp | Particle density [kg/m3] |

Abbreviations

| PSD | Particle size distribution |

| CFD | Computational fluid dynamics |

| RSM | Reynolds stress model |

| LES | Large eddy simulation |

| DPM | Discrete phase model |

| LDV | Laser doppler velocimetry |

| PIV | Particle image velocimetry |

| MRF | Multiple reference frame |

| RANS | Reynolds averaged Navier–Stokes |

| FE-SEM | Field emission scanning electron microscope |

References

- Peng, C.; Liu, F.; Wang, Z.; Wilson, B.P.; Lundström, M. Selective extraction of lithium (Li) and preparation of battery grade lithium carbonate (Li2CO3) from spent Li-ion batteries in nitrate system. J. Power Sources 2019, 415, 179–188. [Google Scholar] [CrossRef]

- Bi, Y.; Wang, T.; Liu, M.; Du, R.; Yang, W.; Liu, Z.; Peng, Z.; Liu, Y.; Wang, D.; Sun, X. Stability of Li2CO3 in cathode of lithium ion battery and its influence on electrochemical performance. RSC Adv. 2016, 6, 19233–19237. [Google Scholar] [CrossRef]

- Shapiro, M.; Galperin, V. Air classification of solid particles: A review. Chem Eng Process. 2005, 44, 279–285. [Google Scholar] [CrossRef]

- Eswaraiah, C.; Angadi, S.I.; Mishra, B.K. Mechanism of particle separation and analysis of fish-hook phenomenon in a circulating air classifier. Powder Technol. 2012, 218, 57–63. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, J.; Zhang, K. Establishment of a prediction model for the cut size of turbo air classifiers. Powder Technol. 2014, 254, 274–280. [Google Scholar] [CrossRef]

- Denmud, N.; Baite, K.; Plookphol, T.; Janudom, S. Effects of Operating Parameters on the Cut Size of Turbo Air Classifier for Particle Size Classification of SAC305 Lead-Free Solder Powder. Processes 2019, 7, 427. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Y.; Zhang, S.; Zhou, Y.; Li, M. Numerical Simulation of a Flow Field in a Turbo Air Classifier and Optimization of the Process Parameters. Processes 2020, 8, 237. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Liu, J.; Yu, Y. Effects of axial inclined guide vanes on a turbo air classifier. Powder Technol. 2015, 280, 1–9. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, J.; Yu, Y. Turbo air classifier guide vane improvement and inner flow field numerical simulation. Powder Technol. 2012, 226, 10–15. [Google Scholar] [CrossRef]

- Karunakumari, L.; Eswaraiah, C.; Jayanti, S.; Narayanan, S.S. Experimental and Numerical Study of a Rotating Wheel Air Classifier. AIChE J. 2005, 51, 776–790. [Google Scholar] [CrossRef]

- Ren, W.; Liu, J.; Yu, Y. Design of a rotor cage with non-radial arc blades for turbo air classifiers. Powder Technol. 2016, 292, 46–53. [Google Scholar] [CrossRef]

- Sun, Z.; Sun, G.; Liu, J.; Yang, X. CFD simulation and optimization of the flow field in horizontal turbo air classifiers. Adv. Powder Technol. 2017, 28, 1474–1485. [Google Scholar] [CrossRef]

- Vakamalla, T.R.; Mangadoddy, N. Numerical simulation of industrial hydrocyclones performance: Role of turbulence modelling. Sep. Purif. Technol. 2017, 176, 23–39. [Google Scholar] [CrossRef]

- Durango-cogollo, M.; Garcia-bravo, J.; Newell, B.; Gonzalez-mancera, A. CFD Modeling of Hydrocyclones —A Study of E ffi ciency of Hydrodynamic Reservoirs. Fluids 2020, 5, 118. [Google Scholar] [CrossRef]

- Johansson, R.; Evertsson, M. CFD simulation of a centrifugal air classifier used in the aggregate industry. Miner. Eng. 2014, 63, 149–156. [Google Scholar] [CrossRef]

- Guo, L.; Liu, J.; Liu, S.; Wang, J. Velocity measurements and flow field characteristic analyses in a turbo air classifier. Powder Technol. 2007, 178, 10–16. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, J.; Liu, S. Effects of operating parameters on flow field in a turbo air classifier. Miner Eng. 2008, 21, 598–604. [Google Scholar] [CrossRef]

- Xing, W.; Wang, Y.; Zhang, Y.; Yamane, Y.; Saga, M.; Lu, J.; Zhang, H.; Jin, Y. Experimental study on velocity field between two adjacent blades and gas-solid separation of a turbo air classifier. Powder Technol. 2015, 286, 240–245. [Google Scholar] [CrossRef]

- Homann, H.; Bec, J.; Grauer, R. Effect of turbulent fluctuations on the drag and lift forces on a towed sphere and its boundary layer. J. Fluid Mech. 2013, 721, 155–179. [Google Scholar] [CrossRef] [Green Version]

- Schiller, L.; Naumann, A. Fundamental calculations in gravitational processing. Z. Des. Ver. Dtsch. Ing. 1933, 77, 318–320. [Google Scholar]

- Lee, J.W.; Yang, H.J.; Lee, D.Y. Effect of the cylinder shape of a long-coned cyclone on the stable flow-field establishment. Powder Technol. 2006, 165, 30–38. [Google Scholar] [CrossRef]

- Kaya, F.; Karagoz, I. Numerical investigation of performance characteristics of a cyclone prolonged with a dipleg. Chem. Eng. J. 2009, 151, 39–45. [Google Scholar] [CrossRef]

- Guizani, R.; Mokni, I.; Mhiri, H.; Bournot, P. CFD modeling and analysis of the fish-hook effect on the rotor separator’s efficiency. Powder Technol. 2014, 264, 149–157. [Google Scholar] [CrossRef]

- Galletti, C.; Rum, A.; Turchi, V.; Nicolella, C. Numerical analysis of flow field and particle motion in a dynamic cyclonic selector. Adv. Powder Technol. 2020, 31, 1264–1273. [Google Scholar] [CrossRef]

- Reeks, M.W. On model equations for particle dispersion in inhomogeneous turbulence. Int. J. Multiph. Flow. 2005, 31, 93–114. [Google Scholar] [CrossRef]

- Murthy, Y.R.; Bhaskar, K.U. Parametric CFD studies on hydrocyclone. Powder Technol. 2012, 230, 36–47. [Google Scholar] [CrossRef]

- Rosin, P.; Rammler, E. The laws governing the fineness of powdered coal. J. Inst. Fuel. 1933, 7, 29–36. [Google Scholar]

- Vesilind, P.A. The Rosin-Rammler particle size distribution. Resour Recover Conserv. 1980, 53, 275–277. [Google Scholar] [CrossRef]

- Munson, B.R.; Okiishi, T.H.; Huebsch, W.W.; Rothmayer, A.P. Fundamentals of Fluid Mechanics, 7th ed.; Welter, J., Ashenberg, W., Eds.; Don Fowley: Jefferson City, MO, USA, 2012; p. 120. [Google Scholar]

- Derksen, J.J.; Sundaresan, S.; Van den Akker, H.E.A. Simulation of mass-loading effects in gas-solid cyclone separators. Powder Technol. 2006, 163, 59–68. [Google Scholar] [CrossRef]

| Properties | Air | Density: ρ = 1.225 kg/m3 Viscosity: μ = 1.7894 × 10−5 kg/m/s |

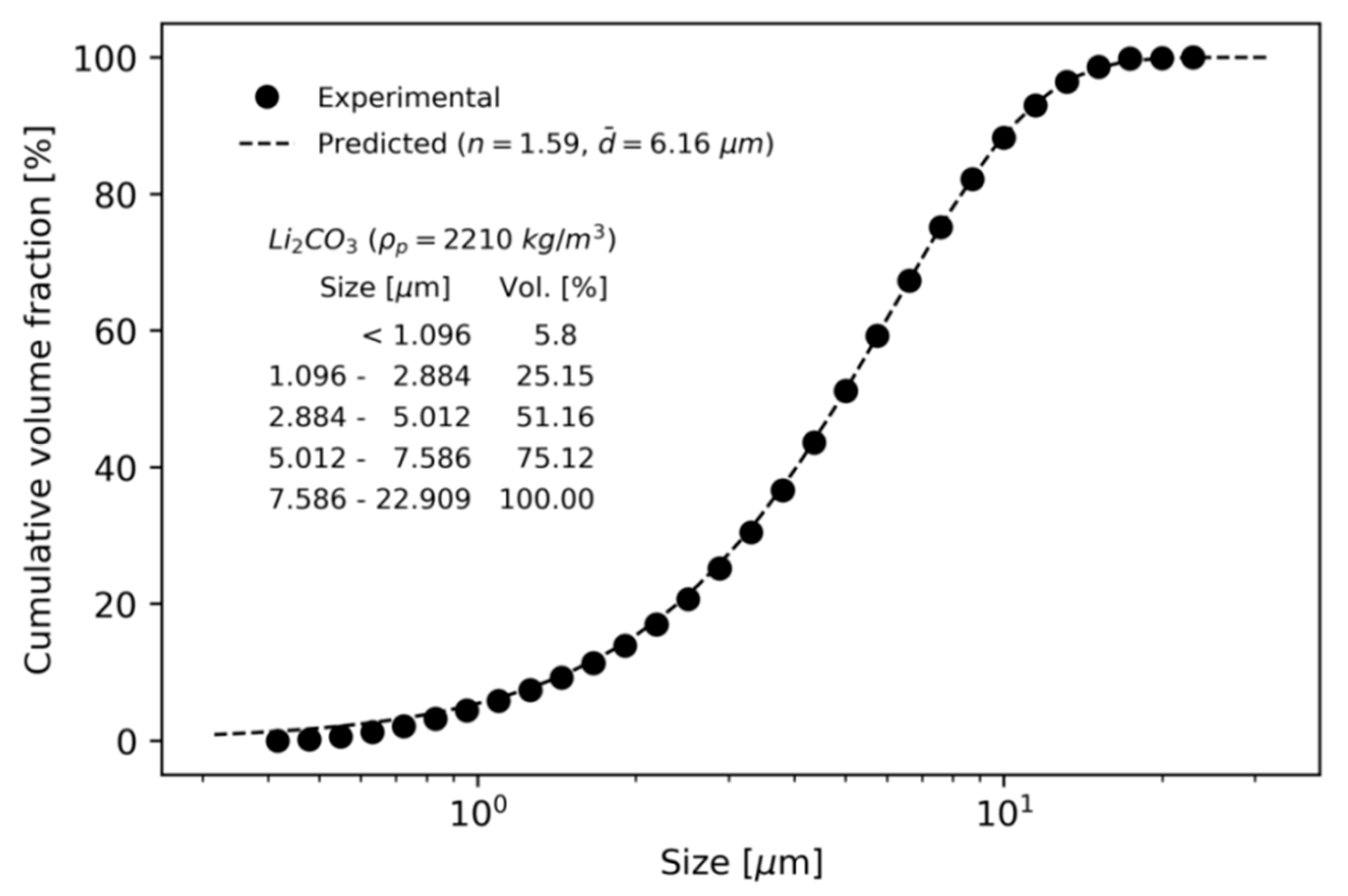

| Li2CO3 Particles | Density: ρp = 2110 kg/m3 Size Range: 0.407 to 22.909 μm Mass Flow Rate: 0.013 kg/s | |

| Boundary Conditions | Inlet | Pressure: 0 Pa Turbulence intensity: 3% Hydraulic diameter: 0.09812 m |

| Top outlet | Mass flow outlet: 0.2, 0.3, 0.4 kg/s | |

| Rotor cage | Rotor speed: 900, 1200, 1500, 1800 revs/min |

| No. | Mass Flow Rate [kg/s] | Rotor Speed [revs/min] | Type 1 | Type 2 | ||

|---|---|---|---|---|---|---|

| d50 [µm] | Throughput [–] | d50 [µm] | Throughput [–] | |||

| 1 | 0.2 | 900 | 4.3 | 99,122 | 5.7 | 117,096 |

| 2 | 0.2 | 1200 | 3.4 | 92,416 | 4.2 | 111,694 |

| 3 | 0.2 | 1500 | 2.8 | 93,085 | 3.3 | 102,189 |

| 4 | 0.2 | 1800 | 2.6 | 73,868 | 2.9 | 91,400 |

| 5 | 0.3 | 900 | 4.6 | 100,034 | 6.0 | 131,068 |

| 6 | 0.3 | 1200 | 3.9 | 110,097 | 5.0 | 121,348 |

| 7 | 0.3 | 1500 | 3.3 | 96,866 | 4.2 | 118,323 |

| 8 | 0.3 | 1800 | 2.8 | 78,432 | 3.5 | 109,714 |

| 9 | 0.4 | 900 | 5.4 | 131,287 | 6.4 | 136,131 |

| 10 | 0.4 | 1200 | 4.4 | 120,295 | 5.3 | 130,655 |

| 11 | 0.4 | 1500 | 3.6 | 115,356 | 4.5 | 124,680 |

| 12 | 0.4 | 1800 | 3.0 | 101,777 | 3.9 | 121,627 |

| Classifier N-20(Rotor) | Blower | |||

|---|---|---|---|---|

| INV[Hz] | Motor [rpm] | INV[Hz] | Motor [rpm] | Mass Flow Rate [kg/s] |

| 10 | 583 | 10 | 295 | 0.10 |

| 15 | 875 | 15 | 442 | 0.15 |

| 20 | 1167 | 20 | 590 | 0.21 |

| 25 | 1458 | 25 | 737 | 0.26 |

| 30 | 1750 | 30 | 884 | 0.31 |

| 35 | 2042 | 35 | 1032 | 0.36 |

| 40 | 2333 | 40 | 1179 | 0.41 |

| 45 | 2525 | 45 | 1327 | 0.46 |

| 50 | 2917 | 50 | 1474 | 0.51 |

| 55 | 3208 | 55 | 1622 | 0.56 |

| 60 | 3500 | 60 | 1769 | 0.62 |

| Type 1 | Type 2 | |||

|---|---|---|---|---|

| No. | Mass Flow Rate [kg/s] | Rotor Speed [revs/min] | d50 [µm] | d50 [µm] |

| 1 | 0.25 | 1800 | 4.04 | |

| 0.25 | 1800 | 4.73 | ||

| 2 | 0.55 | 3200 | 4.74 | |

| 0.25 | 3000 | 4.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.; Cha, J.; Go, J.S. Ring-Shaped Baffle Effect on Separation Performance of Lithium Carbonate Micro Particles in a Centrifugal Classifier. Micromachines 2020, 11, 980. https://doi.org/10.3390/mi11110980

Kim M, Cha J, Go JS. Ring-Shaped Baffle Effect on Separation Performance of Lithium Carbonate Micro Particles in a Centrifugal Classifier. Micromachines. 2020; 11(11):980. https://doi.org/10.3390/mi11110980

Chicago/Turabian StyleKim, Moonjeong, Jemyung Cha, and Jeung Sang Go. 2020. "Ring-Shaped Baffle Effect on Separation Performance of Lithium Carbonate Micro Particles in a Centrifugal Classifier" Micromachines 11, no. 11: 980. https://doi.org/10.3390/mi11110980

APA StyleKim, M., Cha, J., & Go, J. S. (2020). Ring-Shaped Baffle Effect on Separation Performance of Lithium Carbonate Micro Particles in a Centrifugal Classifier. Micromachines, 11(11), 980. https://doi.org/10.3390/mi11110980