Wafer-Level Vacuum-Packaged Translatory MEMS Actuator with Large Stroke for NIR-FT Spectrometers

Abstract

:1. Introduction

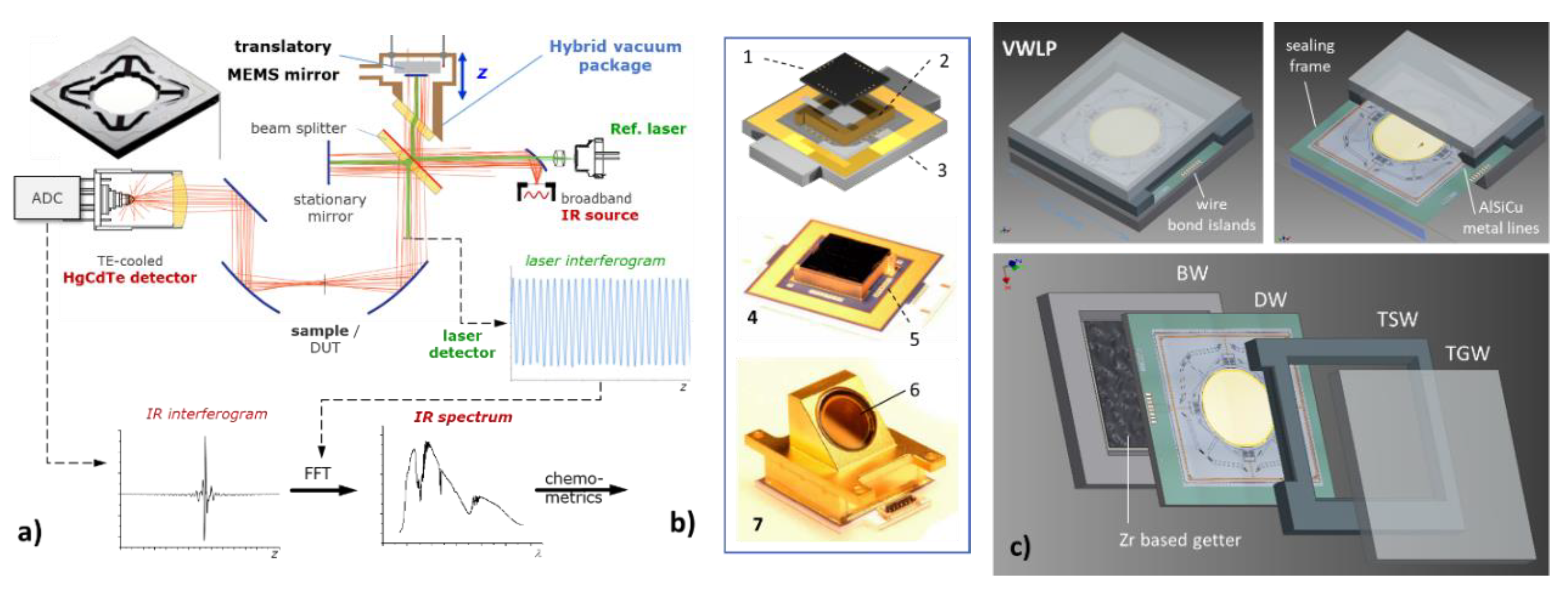

1.1. MEMS-Based Fourier-Transform (FT) Spectrometer

1.2. Motivation of This Study

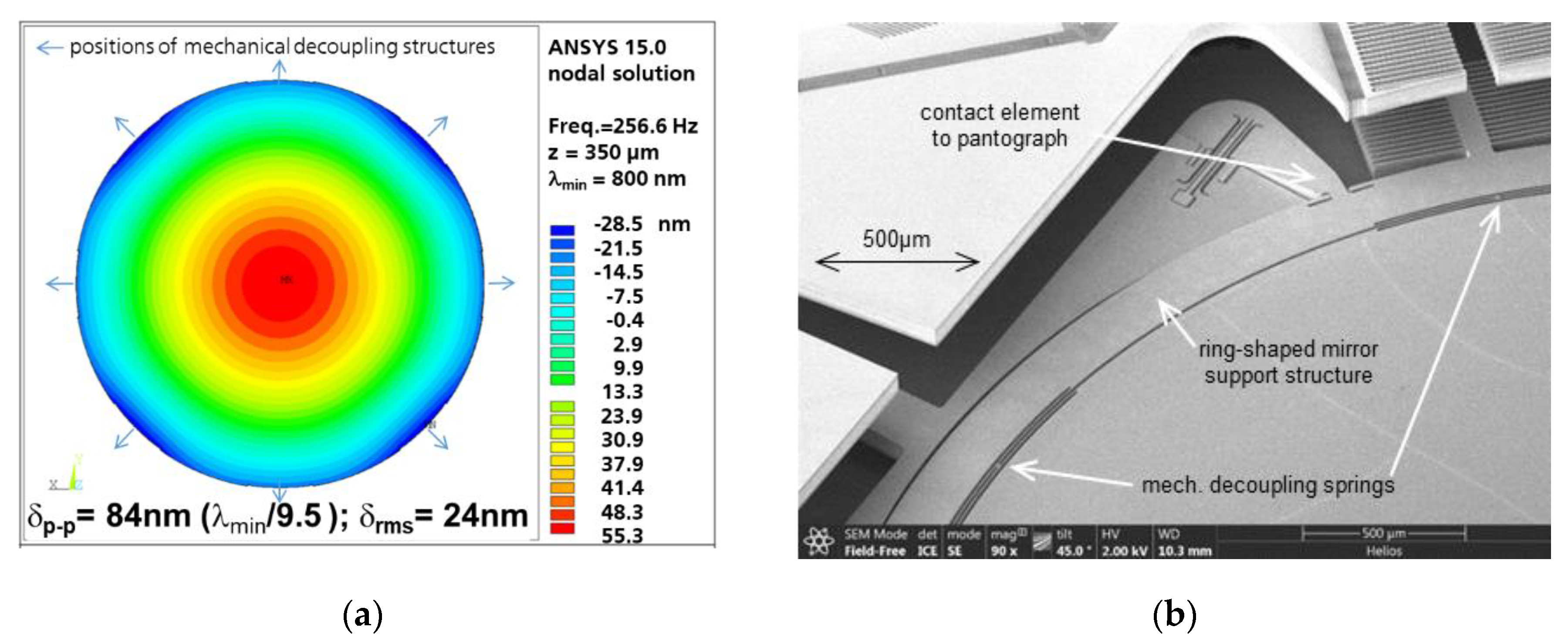

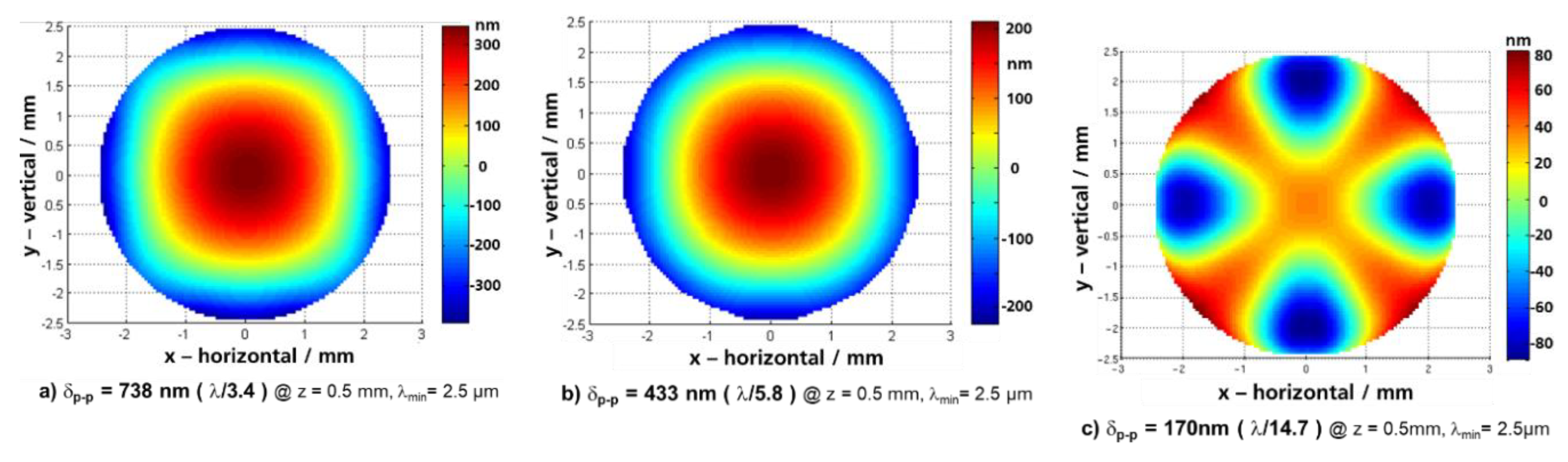

- NIR-FTS-specific design of a resonant large-stroke pantograph MEMS device with minimized dynamic mirror deformation of δp-p = 80 nm at 350 µm scan amplitude,

- development of a cost-effective optical (NIR) wafer-level vacuum package with process compatibility to the existing qualified MEMS scanner process AME75 of Fraunhofer IPMS,

- detailed characterization of new translatory MEMS devices with WLVP, investigation and elimination of failure mechanisms of WLVP (e.g., influence of process temperature on mirror planarity), and long-term stability of the desired vacuum pressure for ≥10 years lifetime.

- AlSiCu, which is used for metal signal lines and bond island45s (at the outer chip frame),

- high topography (≥2 µm due to metal lines) within the areas needed for hermetic sealing,

- ultrasonic Al wire bonding required for good electrical contact of AlSiCu,

- use of filled isolation trenches for electrostatic comb drives (also adding surface topography),

- CMOS compatibility of all in-line processes used for fabrication of MEMS device wafers.

2. Materials and Methods

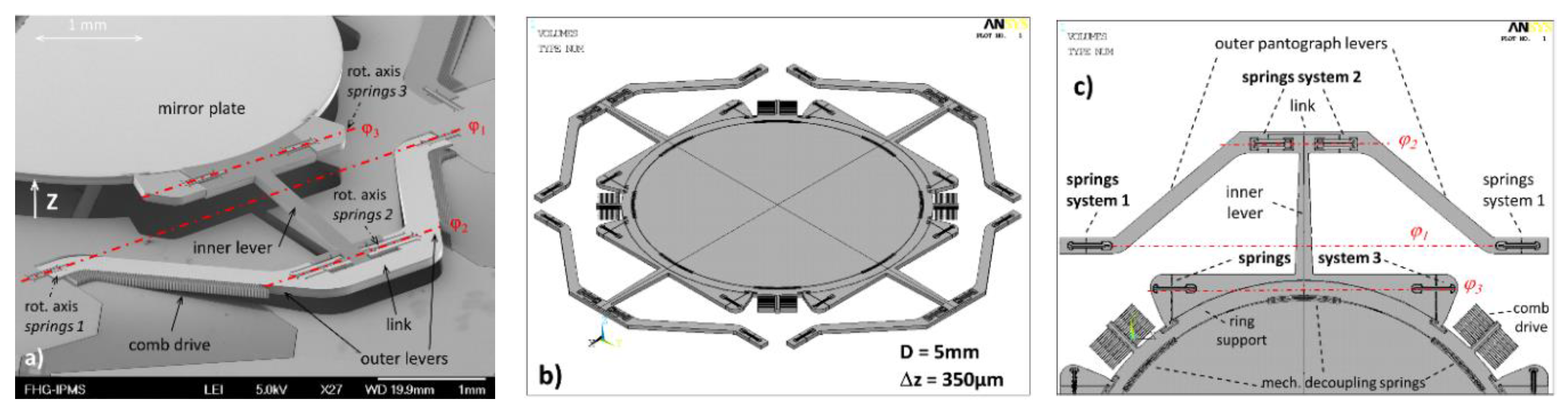

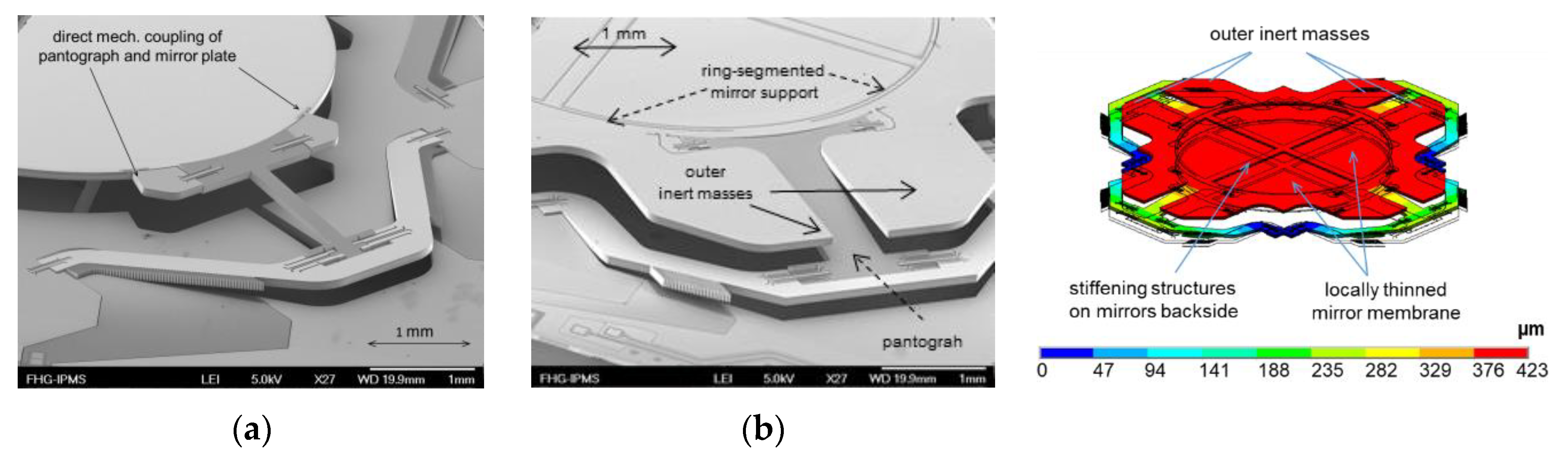

2.1. Translatory MEMS Design

- electrostatic resonant driving using vertical comb drives,

- use of 75 µm thick SOI (silicon-on-isolator) layer of monocrystalline silicon,

- no additional stiffening structures at mirrors backside.

2.1.1. Pantograph Mirror Suspension for Large Stroke

2.1.2. Reduction of Dynamic Mirror Deformation

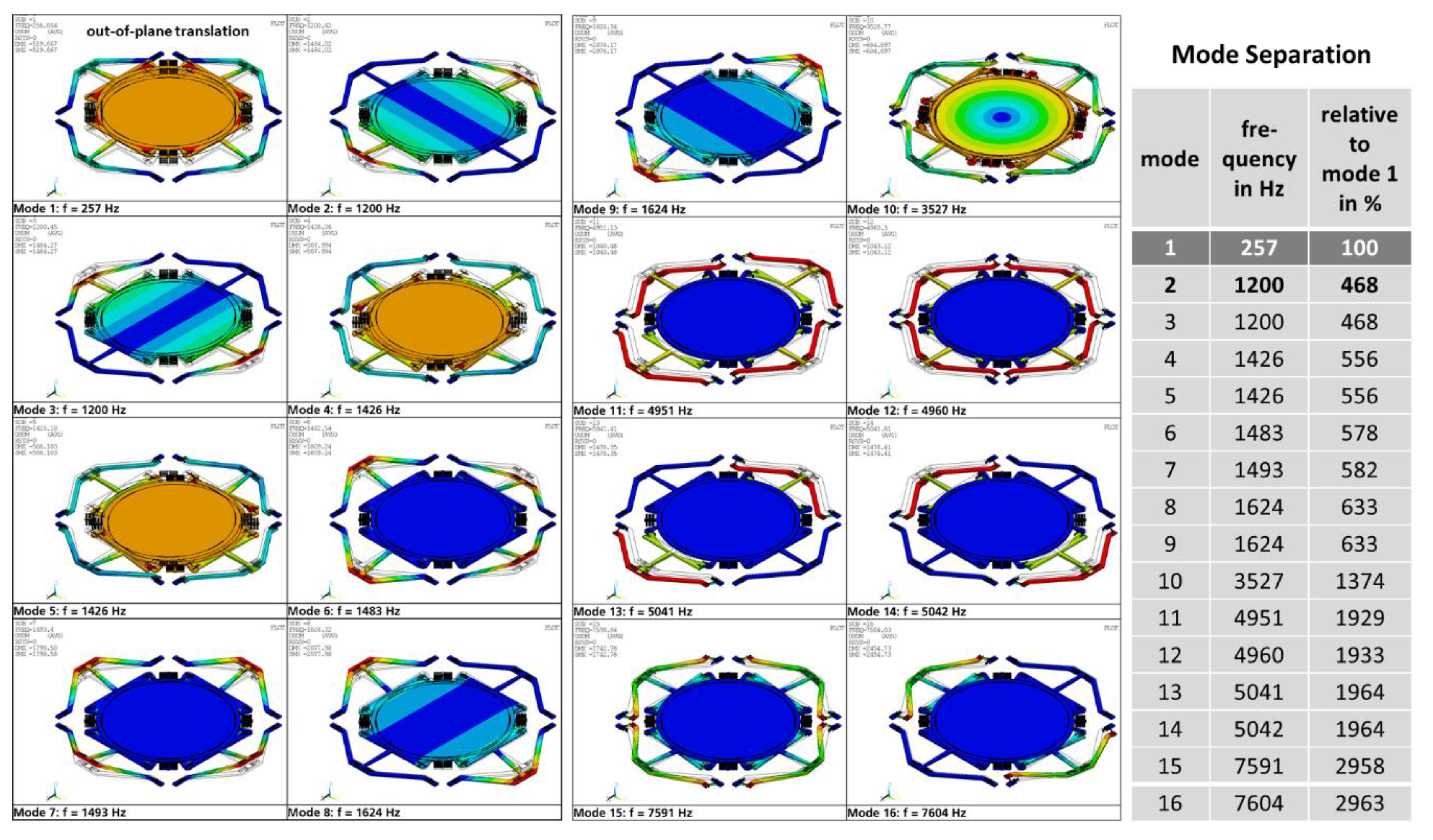

2.1.3. Modal Analysis

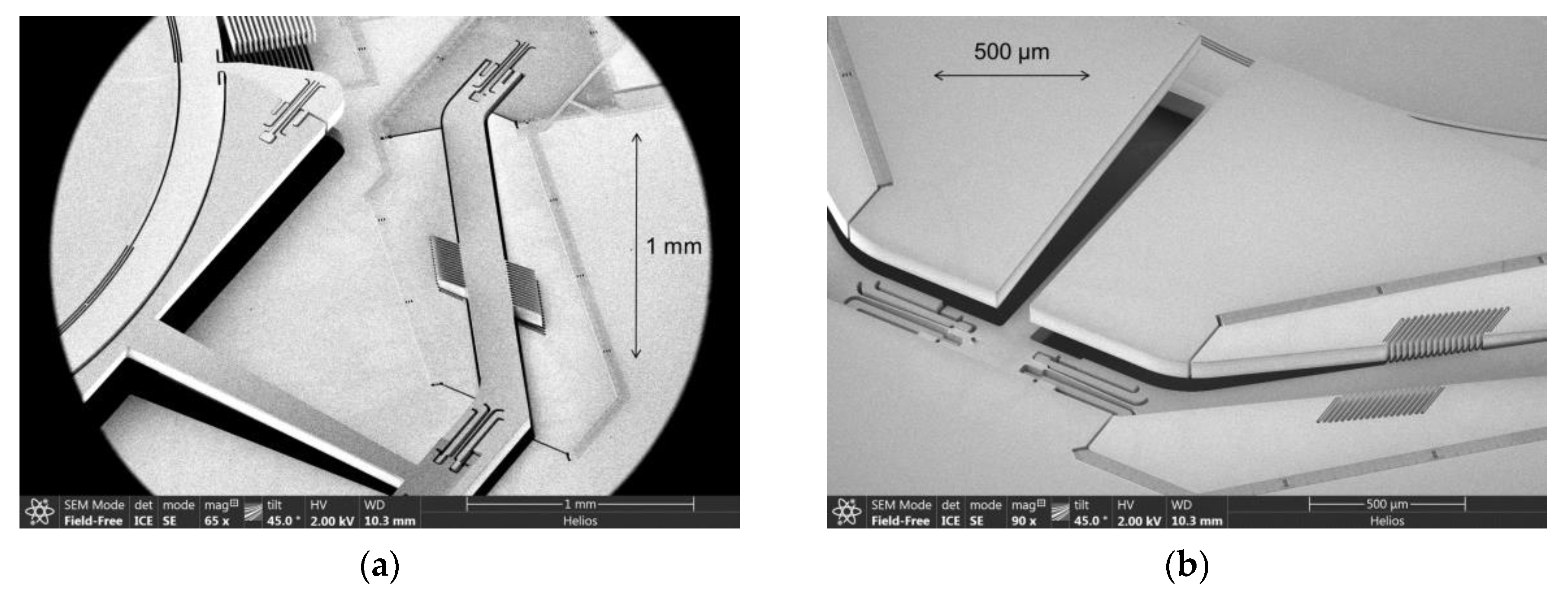

2.1.4. Electrostatic Comb Drives and Mechanical Reliability

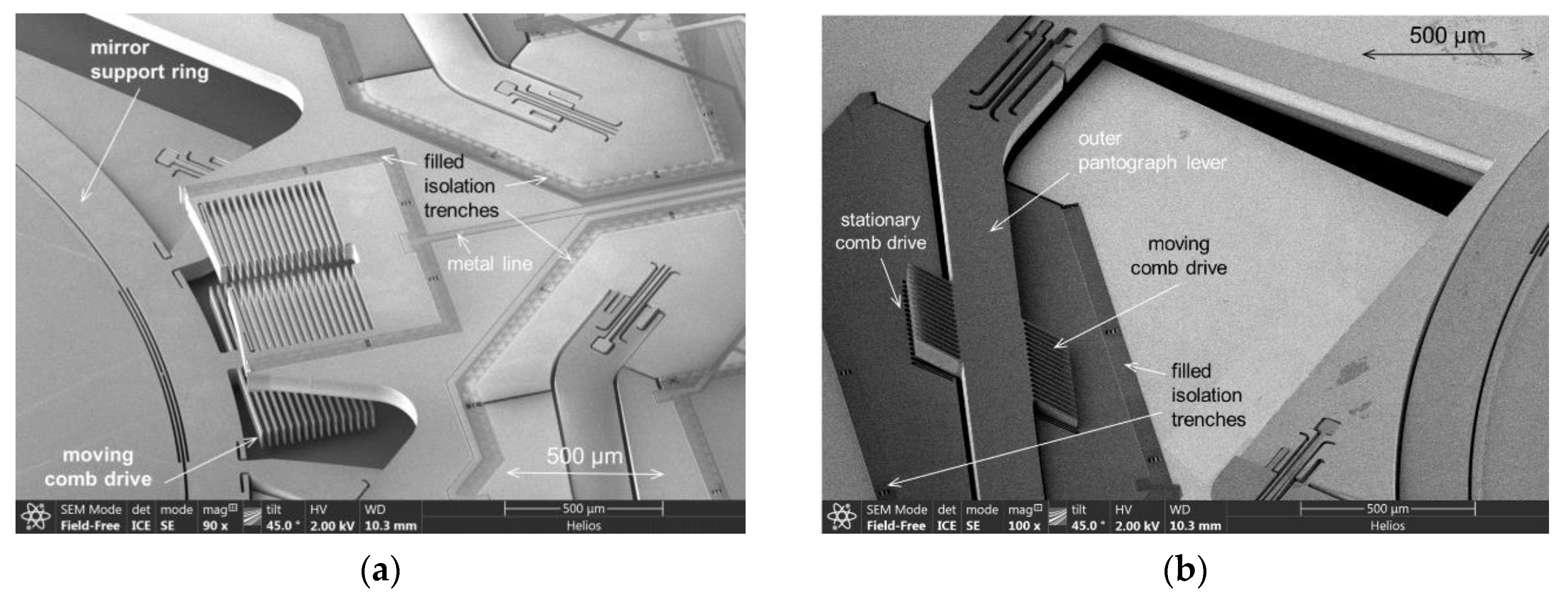

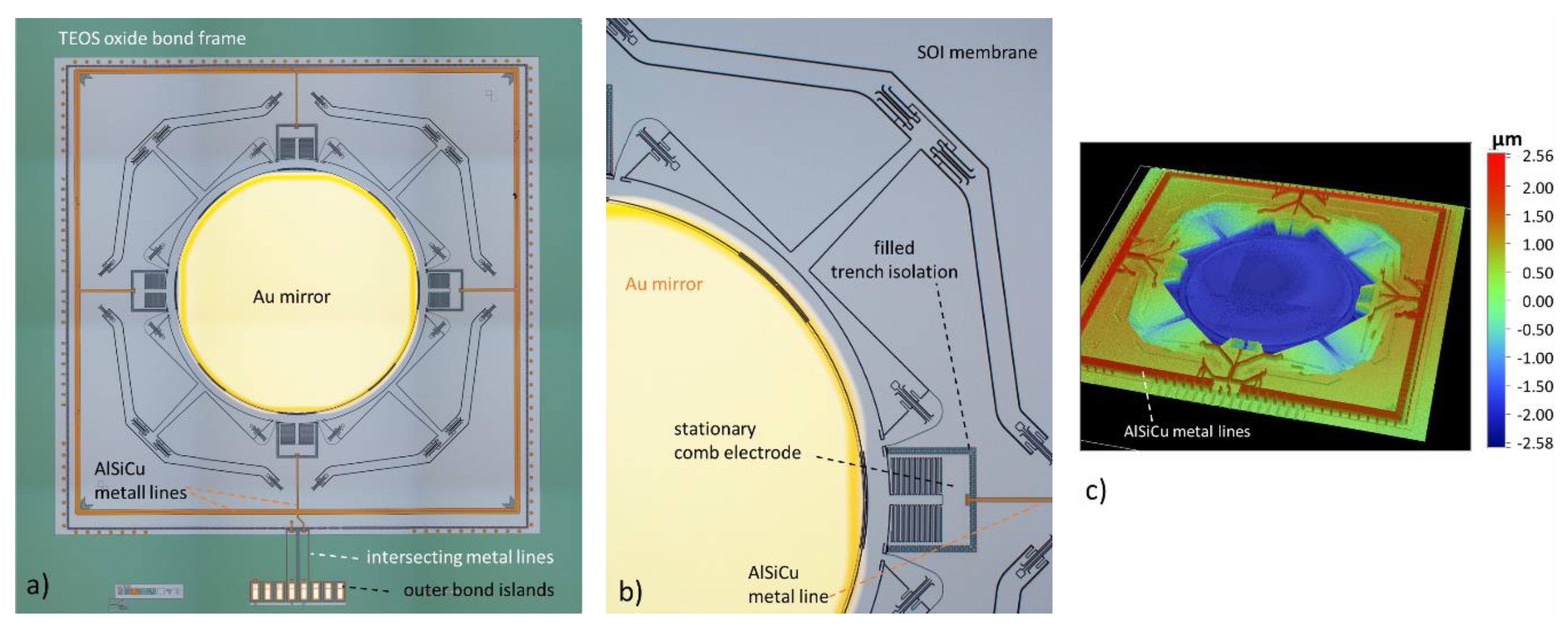

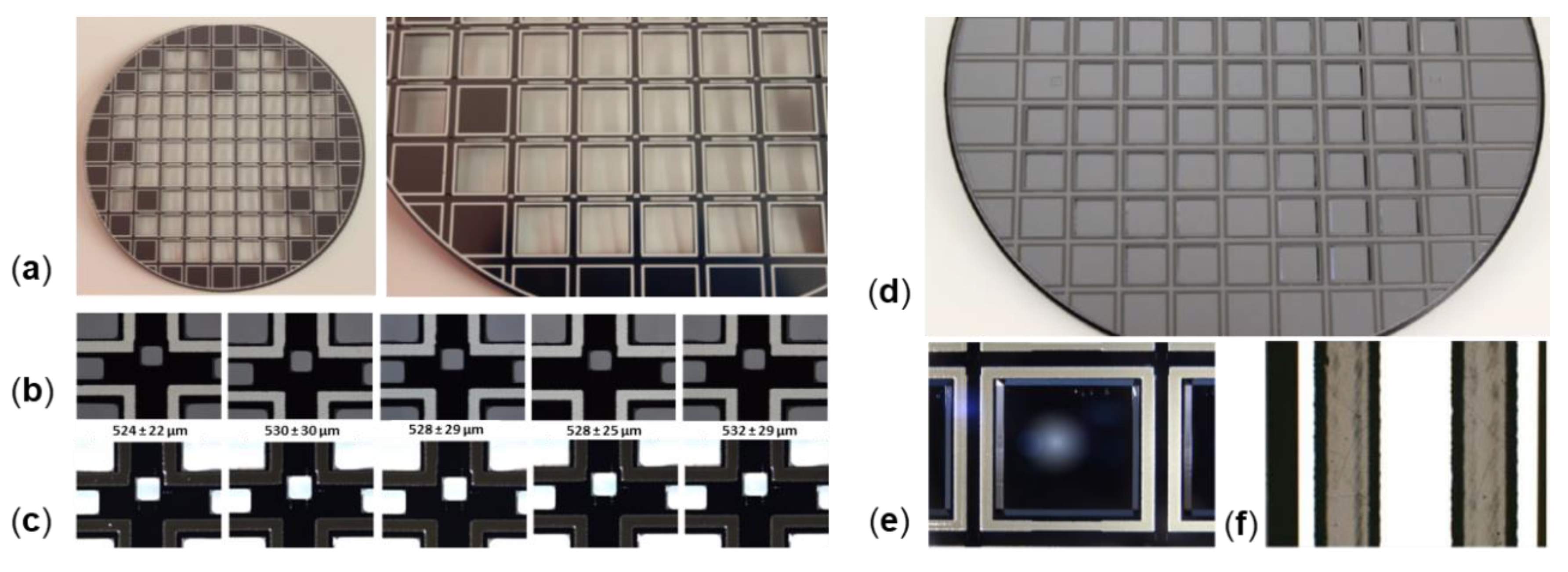

2.2. MEMS Device Wafer Fabrication

- Use of field isolation trenches (formed from DRIE-etched open trenches by thermal oxidation and refilling with polysilicon) to electrically isolate areas of different electrical potential within the same SOI layer needed to define the comb drives (Figure 10),

- Use of AlSiCu metal lines for electrical signal transmission from the bond islands at outer chip frame to the inner comb drive actuator (no VIA (vertical interconnect access) exists),

- Use of a thin protected aluminum layer as standard optical coating,

- CMOS (complementary metal–oxide–semiconductor) compatibility of all inline processes due to restrictions caused by in-house CMOS processes for highly integrated micro mirror arrays [57].

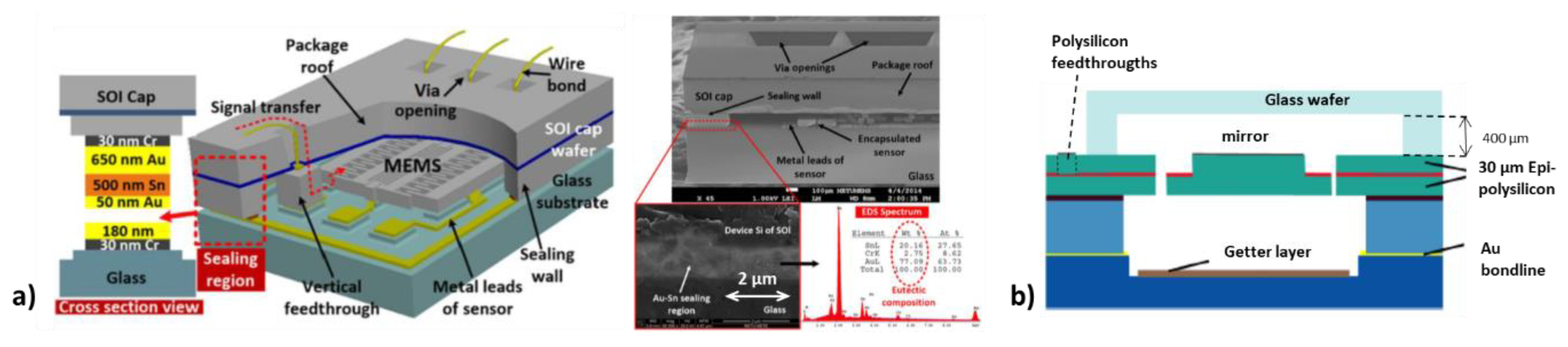

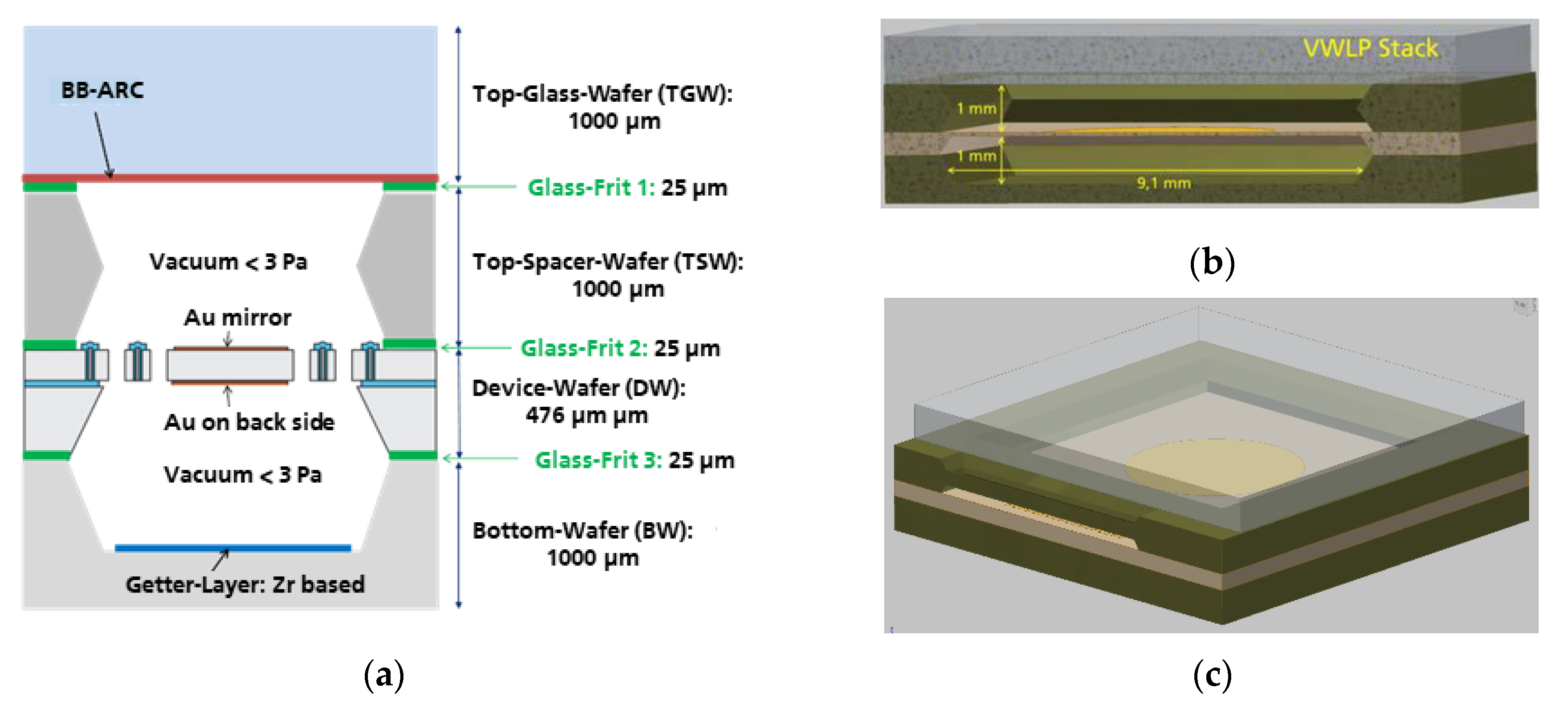

2.3. Wafer-Level Vacuum Package of Optical MEMS

2.3.1. Concept of WLVP for NIR-FTS

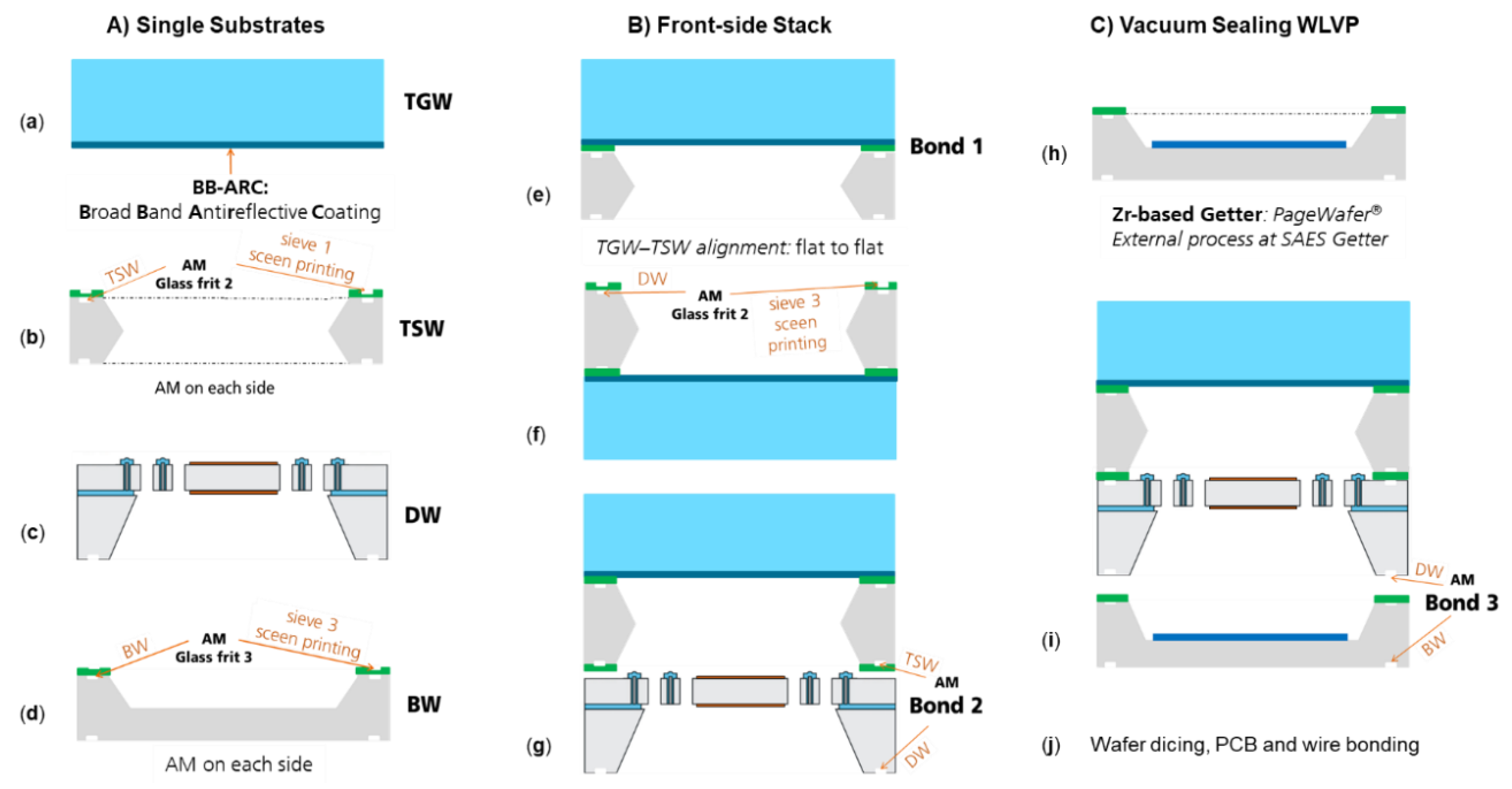

2.3.2. Process-Flow for NIR-WLVP

3. Results and Discussion

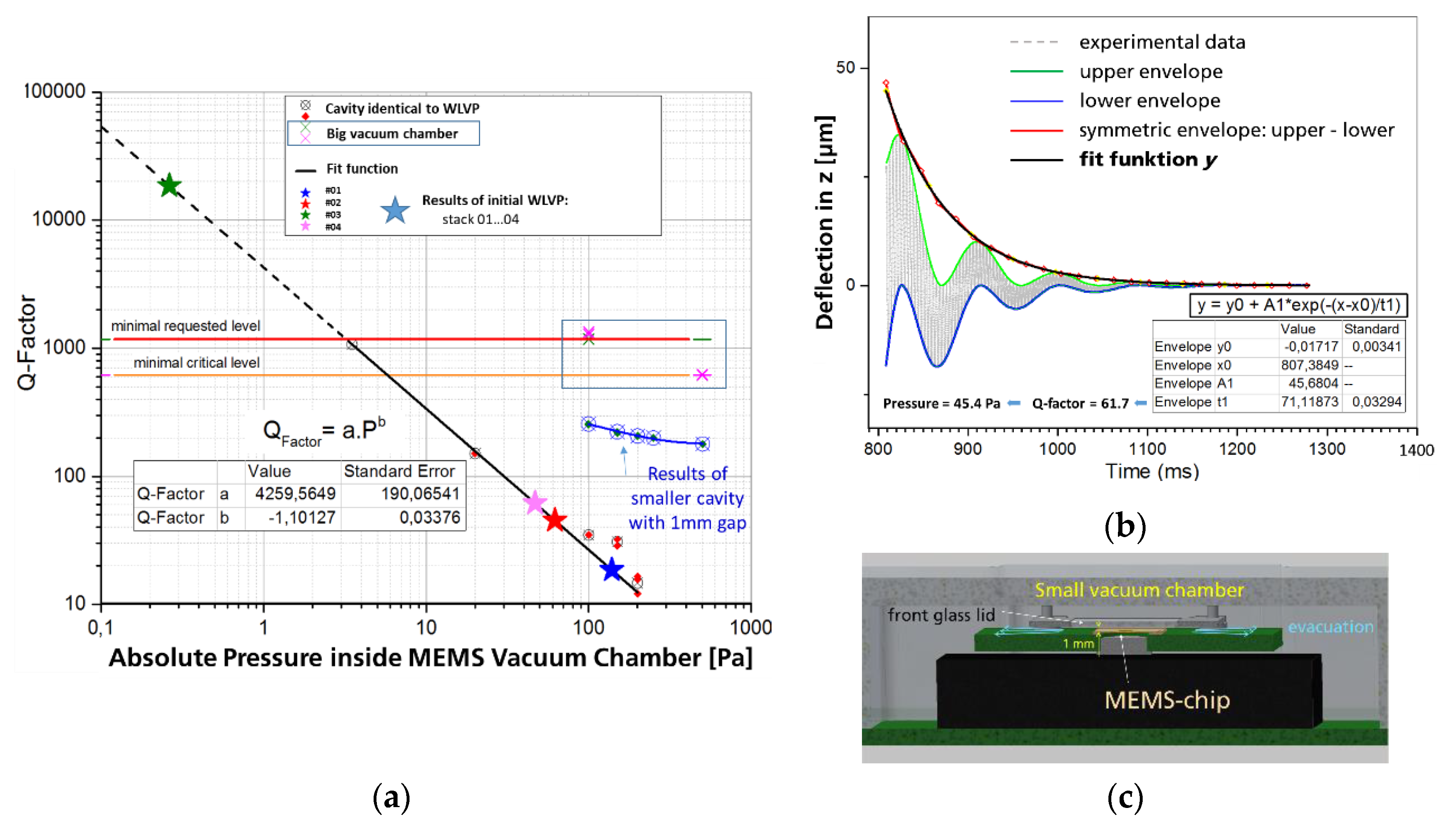

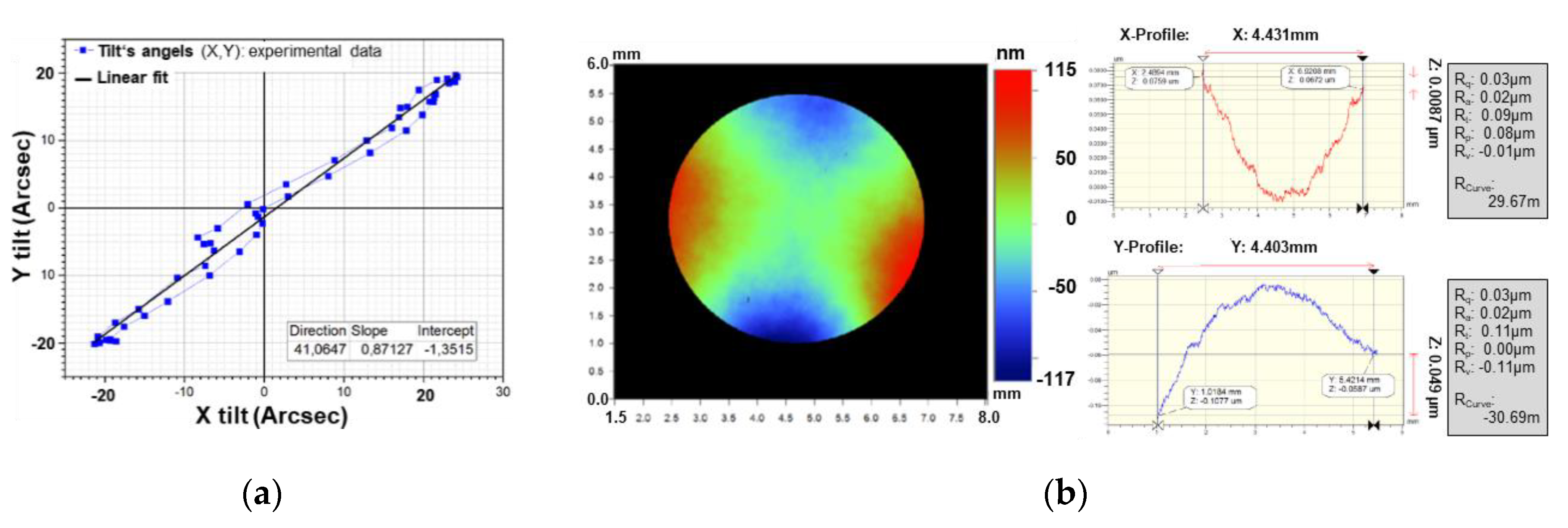

3.1. Basic MEMS Characteristics without WLVP

- maximal vacuum pressure: pmax = 3.21 Pa,

- minimum Q factor: Qmin = 1177,

- critical values (lower limits): Q = 600 and pmax = 5.5 Pa.

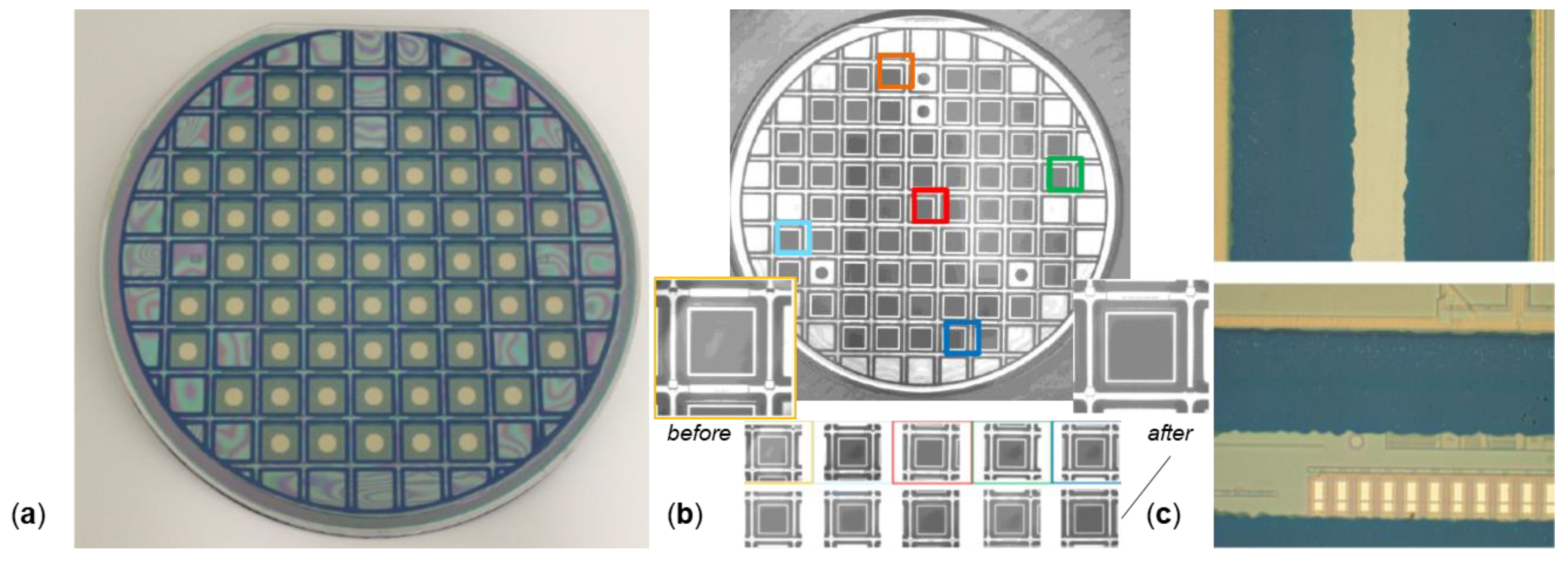

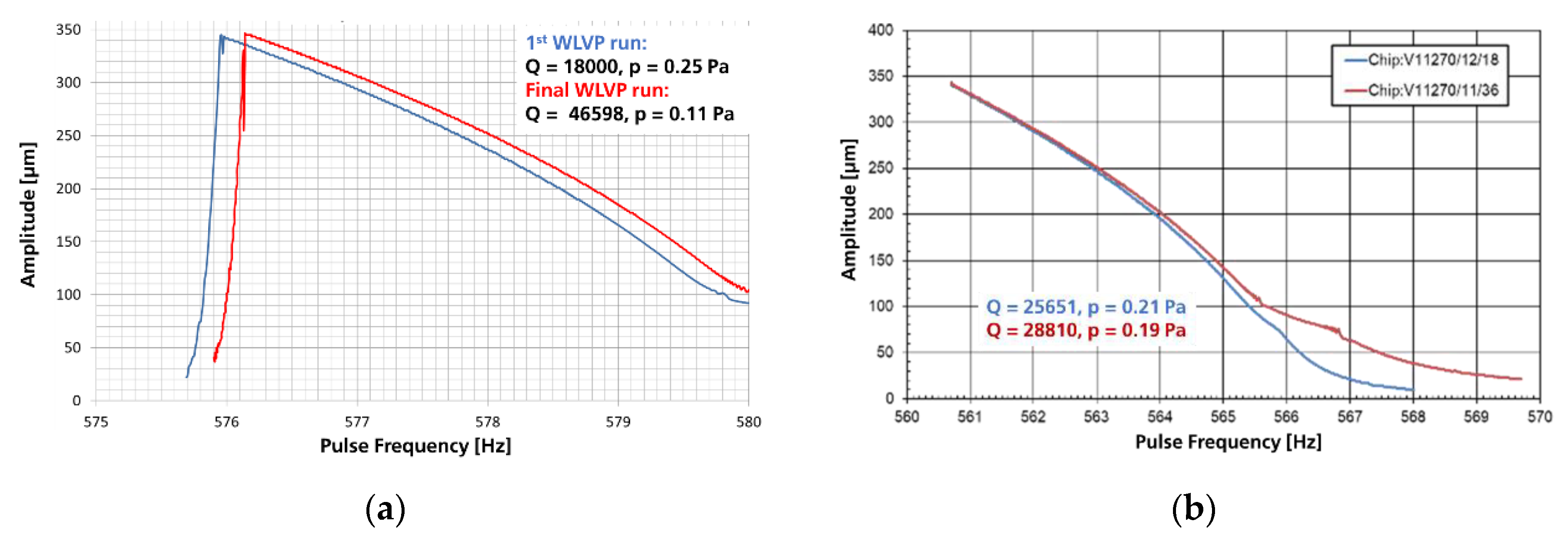

3.2. Characteristics of Initial MEMS WLVP Run

3.2.1. MEMS Characteristics with WLVP

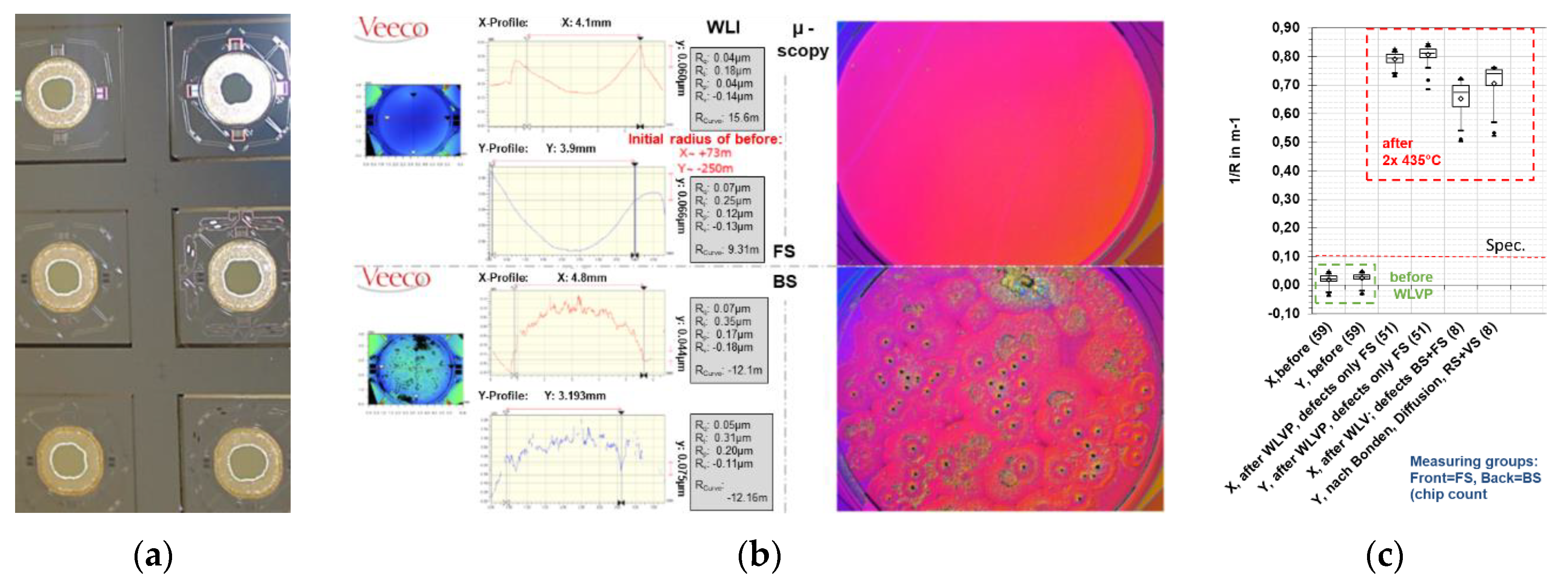

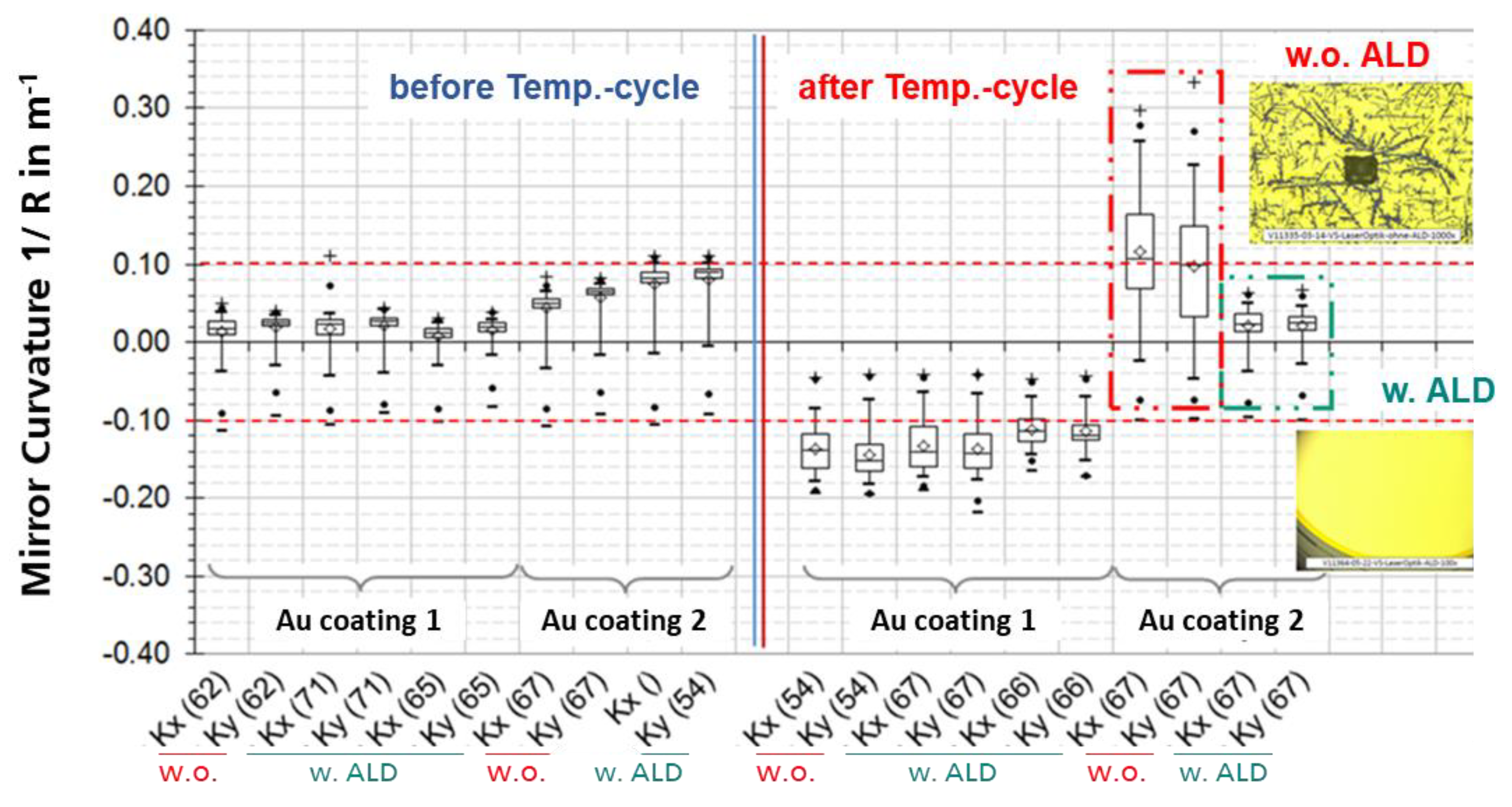

3.2.2. Influence of Process Temperature on Optical Coating

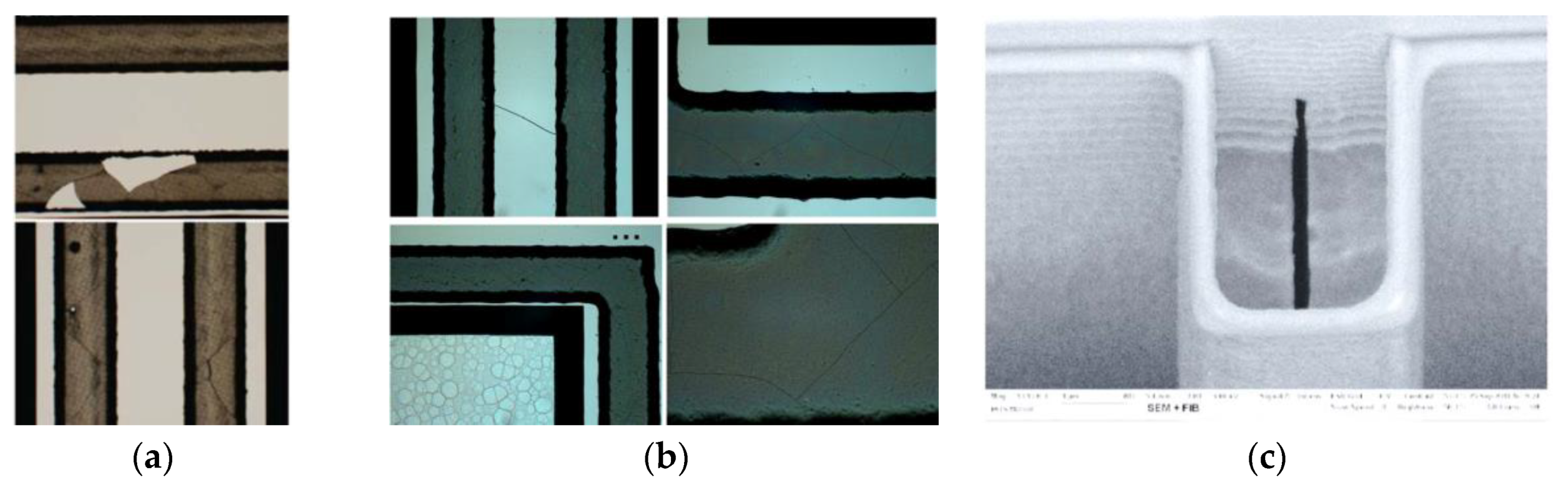

3.2.3. Discussion on Improvements of MEMS WLVP

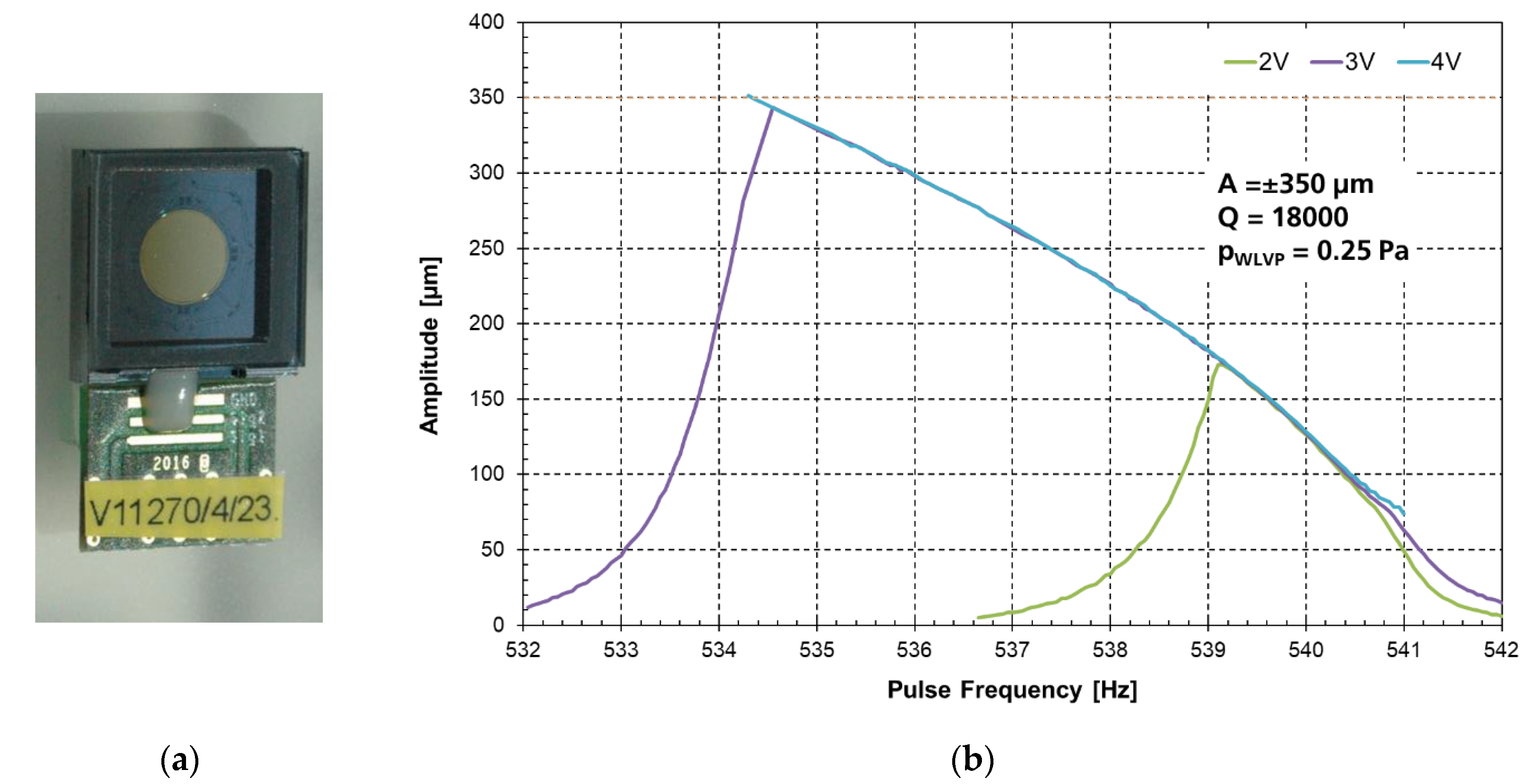

3.3. Final Characteristics of Improved MEMS WLVP

4. Conclusions

5. Summary and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Skoog, D.A.; Leary, J.J. Principles of Instrumental Analysis, 4th ed.; Saunders College Publishing: Orlando, FL, USA, 1992. [Google Scholar]

- Fischer, K. Neues Verfahren zur maßanalytischen Bestimmung des Wassergehaltes von Flüssigkeiten und festen Körpern. Angew. Chem. 1935, 48, 394–396. [Google Scholar] [CrossRef]

- Griffiths, P.R.; de Haseth, J.A. Fourier Transform Infrared Spectroscopy, 2nd ed.; John Willey & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Murayama, K.; Genkawa, T.; Ishikawa, D.; Komiyama, M.; Ozaki, Y. A polychromator-type near-infrared spectrometer with a high-sensitivity and high-resolution photodiode array detector for pharmaceutical process monitoring on the millisecond time scale. Rev. Sci. Instrum. 2013, 84, 23104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manzardo, O.; Herzig, H.P.; Marxer, C.R.; De Rooij, N.F. Miniaturized time-scanning Fourier transform spectrometer based on silicon technology. Opt. Lett. 1999, 24, 1705–1707. [Google Scholar] [CrossRef] [PubMed]

- Manzardo, O.; Michaely, R.; Schädelin, F.; Noell, W.; Overstolz, T.; De Rooij, N.; Herzig, H.P. Miniature lamellar grating interferometer based on silicon technology. Opt. Lett. 2004, 29, 1437–1439. [Google Scholar] [CrossRef] [Green Version]

- Kenda, A.; Drabe, C.; Schenk, H.; Frank, A.; Lenzhofer, M.; Scherf, W. Application of a micromachined translatory actuator to an optical FTIR spectrometer. In Proceedings of the SPIE 6186, MEMS, MOEMS, and Micromachining II, Strasbourg, France, 21 April 2006; p. 618609. [Google Scholar] [CrossRef]

- Ataman, Ç.; Urey, H.; Wolter, A. A Fourier transform spectrometer using resonant vertical comb actuators. J. Micromech. Microeng. 2006, 16, 2517–2523. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Liu, W.; Jia, K.; Liao, W.; Xie, H. A piezoelectric unimorph actuator based tip-tilt-piston micromirror with high fill factor and small tilt and lateral shift. Sens. Actuators A Phys. 2011, 167, 495–501. [Google Scholar] [CrossRef]

- Bakke, T.; Vogl, A.; Żero, O.; Tyholdt, F.; Johansen, I.-R.; Wang, D. A novel ultra-planar, long-stroke and low-voltage piezoelectric micromirror. J. Micromech. Microeng. 2010, 20, 064010. [Google Scholar] [CrossRef]

- Quenzer, H.-J.; Gu-Stoppel, S.; Stoppel, F.; Janes, J.; Hofmann, U.; Benecke, W. Piezoelectrically driven translatory optical MEMS actuator with 7 mm apertures and large displacements. In Proceedings of the SPIE 9375, MOEMS and Miniaturized Systems XIV, San Francisco, CA, USA, 9–12 February 2015. [Google Scholar] [CrossRef]

- Wallrabe, U.; Solf, C.; Mohr, J.; Korvink, J. Miniaturized Fourier Transform Spectrometer for the near infrared wavelength regime incorporating an electromagnetic linear actuator. Sens. Actuators A Phys. 2005, 123, 459–467. [Google Scholar] [CrossRef]

- Ataman, Ç.; Urey, H. Compact Fourier transform spectrometers using FR4 platform. Sens. Actuators A Phys. 2009, 151, 9–16. [Google Scholar] [CrossRef]

- Wang, S.; Yuan, X. The Designing of Magnetic-Driven Micromirror for Portable FTIRs. J. Sens. 2018, 2018, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Gu-Stoppel, S.; Timmermann, M.; Lisec, T.; Lofink, F. Magnetically Driven Actuators for Vector Scanning Mems Mirrors. In Proceedings of the Transducer 2019—Eurosensors XXXIII, Berlin, Germany, 23–27 June 2019; pp. 1507–1510. [Google Scholar]

- Jia, K.; Pal, S.; Xie, H. An Electrothermal Tip–Tilt–Piston Micromirror Based on Folded Dual S-Shaped Bimorphs. J. Microelectromech. Syst. 2009, 18, 1004–1015. [Google Scholar] [CrossRef]

- Samuelson, S.R.; Xie, H. A Large Piston Displacement MEMS Mirror with Electrothermal Ladder Actuator Arrays for Ultra-Low Tilt Applications. J. Microelectromech. Syst. 2014, 23, 39–49. [Google Scholar] [CrossRef]

- Wang, W.; Chen, J.; Zivkovic, A.S.; Xie, H. A Fourier Transform Spectrometer Based on an Electrothermal MEMS Mirror with Improved Linear Scan Range. Sensors 2016, 16, 1611. [Google Scholar] [CrossRef] [Green Version]

- Chai, J.; Jia, H.; Wang, D.; Liu, H.; Chen, Q.; Xie, H. A MEMS Based Fourier Transform Spectrometer and Its Scan Stability Study. ECS J. Solid State Sci. Technol. 2018, 7, Q3025–Q3031. [Google Scholar] [CrossRef]

- Wang, D.; Wang, P.; Liu, H.; Liu, H.; Zhang, J.; Liu, W.; Xie, H. Nondestructive On-Site Detection of Soybean Contents Based on An Electrothermal MEMS Fourier Transform Spectrometer. IEEE Photon. J. 2019, 11, 1–10. [Google Scholar] [CrossRef]

- Chen, H.; Li, M.; Zhang, Y.; Xie, H.; Chen, C.; Peng, Z.; Su, S. H∞ Robust Control of a Large-Piston MEMS Micromirror for Compact Fourier Transform Spectrometer Systems. Sensors 2018, 18, 508. [Google Scholar] [CrossRef] [Green Version]

- Hashimoto, M.; Taguchi, Y. Design and Fabrication of a Kirigami-Inspired Electrothermal MEMS Scanner with Large Displacement. Micromachines 2020, 11, 362. [Google Scholar] [CrossRef] [Green Version]

- Sandner, T.; Drabe, C.; Schenk, H.; Kenda, A.; Scherf, W. Translatory MEMS actuators for optical path length modulation in miniaturized Fourier-transform infrared spectrometers. J. Micro/NanoLithogr. MEMS MOEMS 2008, 7, 021006. [Google Scholar] [CrossRef]

- Sandner, T.; Grasshoff, T.; Schenk, H.; Kenda, A. Out-of-plane translatory MEMS actuator with extraordinary large stroke for optical path length modulation. In Proceedings of the SPIE 7930, MOEMS and Miniaturized Systems X, San Francisco, CA, USA, 22–27 January 2011; p. 79300I-1-9. [Google Scholar] [CrossRef] [Green Version]

- Sandner, T.; Grasshoff, T.; Gaumont, E.; Schenk, H.; Kenda, A. Translatory MOEMS actuator and system integration for miniaturized Fourier transform spectrometers. J. Micro/Nanolithogr. MEMS MOEMS 2014, 13, 11115. [Google Scholar] [CrossRef]

- Kenda, A.; Sandner, T.; Lüttjohann, S.; Kraft, M.; Tortschanoff, A.; Simon, A. Advances in performance and miniaturization of a FT-IR spectrometer system based on a large stroke MOEMS piston mirror. In Proceedings of the SPIE 8252, MOEMS and Miniaturized Systems XI, San Francisco, CA, USA, 16 March 2012; p. 82520D. [Google Scholar] [CrossRef]

- Kenda, A.; Kraft, M.; Tortschanoff, A.; Scherf, W.; Sandner, T.; Schenk, H.; Lüttjohann, S.; Simon, A. Development, characterization and application of compact spectrometers based on MEMS with in-plane capacitive drives. In Proceedings of the SPIE 9101, Next-Generation Spectroscopic Technologies VII, Baltimore, MD, USA, 5–6 May 2014; p. 910102. [Google Scholar] [CrossRef]

- Strong, J.; Vanasse, G.A. Lamellar Grating Far-Infrared Interferomer. J. Opt. Soc. Am. 1960, 50, 113. [Google Scholar] [CrossRef]

- Ferhanoğlu, O.; Seren, H.R.; Lüttjohann, S.; Urey, H. Lamellar grating optimization for miniaturized fourier transform spectrometers. Opt. Express 2009, 17, 21289–21301. [Google Scholar] [CrossRef] [PubMed]

- Seren, H.R.; Holmstrom, S.; Ayerden, N.P.; Sharma, J.; Urey, H. Lamellar-Grating-Based MEMS Fourier Transform Spectrometer. J. Microelectromech. Syst. 2012, 21, 331–339. [Google Scholar] [CrossRef]

- Ayerden, N.P.; Stehle, J.-L.; Holmström, S.; Urey, H. MEMS FTIR spectrometer and optical results. Proc. IEEE Opt. MEMS 2012. [Google Scholar] [CrossRef]

- Ayerden, N.P.; Aygun, U.; Holmstrom, S.T.S.; Olcer, S.; Can, B.; Stehle, J.-L.; Urey, H. High-speed broadband FTIR system using MEMS. Appl. Opt. 2014, 53, 7267–7272. [Google Scholar] [CrossRef] [PubMed]

- Kung, H.; Bhalotra, S.; Mansell, J.; Miller, D.; Harris, J. Standing-wave Fourier transform spectrometer based on integrated MEMS mirror and thin-film photodetector. IEEE J. Sel. Top. Quantum Electron. 2002, 8, 98–105. [Google Scholar] [CrossRef]

- Reyes, D.; Schildkraut, E.R.; Kim, J.; Connors, R.F.; Kotidis, P.; Cavicchio, D.J. A novel method of creating a surface micromachined 3D optical assembly for MEMS-based miniaturized FTIR spectrometers. In Proceedings of the SPIE Volume 6888, MEMS Adaptive Optics II, San Francisco, CA, USA, 12 February 2008; p. 68880. [Google Scholar] [CrossRef]

- Erfan, M.; Sabry, Y.M.; Sakr, M.; Mortada, B.; Medhat, M.; Khalil, D. On-Chip Micro–Electro–Mechanical System Fourier Transform Infrared (MEMS FT-IR) Spectrometer-Based Gas Sensing. Appl. Spectrosc. 2016, 70, 897–904. [Google Scholar] [CrossRef]

- Samir, I.; Sabry, Y.M.; Erfan, M.; Badra, N.; Khalil, D. MEMS FTIR spectrometer with enhanced resolution for low cost gas sensing in the NIR. In Proceedings of the SPIE 10545, MOEMS and Miniaturized Systems XVII, San Francisco, CA, USA, 30–31 January 2018; Volume 10545, p. 105450E. [Google Scholar]

- Fathy, A.; Sabry, Y.M.; Nazeer, S.; Bourouina, T.; Khalil, D.A. On-chip parallel Fourier transform spectrometer for broadband selective infrared spectral sensing. Microsyst. Nanoeng. 2020, 6, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Chai, J.; Zhang, K.; Xue, Y.; Liu, W.; Chen, T.; Lu, Y.; Zhao, G. Review of MEMS Based Fourier Transform Spectrometers. Micromachines 2020, 11, 214. [Google Scholar] [CrossRef] [Green Version]

- 44 Hilton, A.; Temple, D.S. Wafer-Level Vacuum Packaging of Smart Sensors. Sensors 2016, 16, 1819. [Google Scholar] [CrossRef]

- Oldsen, M.; Hofmann, U.; Quenzer, H.-J.; Wagner, B. A Novel Fabrication Technology for Waferlevel Vacuum Packaged Microscanning Mirrors. In Proceedings of the 2007 9th Electronics Packaging Technology Conference, Singapore, 10–12 December 2007; pp. 303–307. [Google Scholar]

- Hofmann, U.; Oldsen, M.; Quenzer, H.-J.; Janes, J.; Heller, M.; Weiss, M.; Fakas, G.; Ratzmann, L.; Marchetti, E.; D’Ascoli, F.; et al. Wafer-level vacuum packaged resonant micro-scanning mirrors for compact laser projection displays. In Proceedings of the SPIE 6887, MOEMS and Miniaturized Systems VII, San Francisco, CA, USA, 22 February 2008; p. 688706. [Google Scholar] [CrossRef]

- Hofmann, U.; Janes, J.; Quenzer, H.-J. High-Q MEMS Resonators for Laser Beam Scanning Displays. Micromachines 2012, 3, 509–528. [Google Scholar] [CrossRef]

- Stenchly, V.; Reinert, W.; Quenzer, H.-J. Modular packaging concept for MEMS and MOEMS. J. Phys. 2017, 922, 12015. [Google Scholar] [CrossRef]

- Wolffenbuttel, R.; Wise, K. Low-temperature silicon wafer-to-wafer bonding using gold at eutectic temperature. Sens. Actuators A Phys. 1994, 43, 223–229. [Google Scholar] [CrossRef] [Green Version]

- Schenk, H.; Sandner, T.; Drabe, C.; Klose, T.; Conrad, H. Single crystal silicon micro mirrors. Phys. Status Solidi 2009, 6, 728–735. [Google Scholar] [CrossRef]

- Ramm, P.; Lu, J.J.Q.; Taklo, M.M.V. Handbook of Wafer Bonding; Wieley-VCH Verlag &, Co. KGaA: Weinheim, Germany, 2012. [Google Scholar]

- Knechtel, R. Glass frit bonding: An universal technology for wafer level encapsulation and packaging. Microsyst. Technol. 2005, 12, 63–68. [Google Scholar] [CrossRef]

- Knechtel, R. Glass Frit Bonding. In Handbook of Silicon Based MEMS Materials and Technologies; Elsevier: Amsterdam, The Netherlands, 2010; pp. 521–531. [Google Scholar] [CrossRef]

- Knechtel, R.; Dempwolf, S.; Hering, S. Detailed Investigations of Inner Cavity Pressure of MEMS Devices Sealed by Wafer Bonding. ECS Trans. 2014, 64, 285–296. [Google Scholar] [CrossRef]

- Knechtel, R.; Zellmer, M.; Schikowski, M.; Behmueller, M.; Van Buggenhout, C.; Petropoulos, A. Glass Frit Wafer Bonding for Encapsulating Monolithic Integrated CMOS-MEMS Devices. ECS Trans. 2018, 86, 111–118. [Google Scholar] [CrossRef]

- Wu, G.; Xu, D.; Xiong, B.; Wang, Y.; Wang, Y.; Ma, Y. Wafer-Level Vacuum Packaging for MEMS Resonators Using Glass Frit Bonding. J. Microelectromech. Syst. 2012, 21, 1484–1491. [Google Scholar] [CrossRef]

- Langa, S.; Drabe, C.; Kunath, C.; Dreyhaupt, A.; Schenk, H. Wafer level vacuum packaging of scanning micro-mirrors using glass-frit and anodic bonding methods. In Proceedings of the SPIE 8614, Reliability, Packaging, Testing, and Characterization of MOEMS/MEMS and Nanodevices XII, San Francisco, CA, USA, 9 March 2013; p. 86140F. [Google Scholar] [CrossRef]

- Langa, S.; Utsumi, J.; Ludewig, T.; Drabe, C. Room temperature bonding for vacuum applications: Climatic and long time tests. Microsyst. Technol. 2013, 19, 681–687. [Google Scholar] [CrossRef]

- Sandner, T.; Gaumont, E.; Grasshoff, T.; Auboeck, G.; Kenda, A.; Gisler, T.; Grahmann, J.; Langa, S.; Herrmann, A. Translatory MEMS actuator with wafer level vacuum package for miniaturized NIR Fourier transform spectrometers. In Proceedings of the SPIE 10545, MOEMS and Miniaturized Systems XVII, San Francisco, CA, USA, 21 March 2018; p. 105450W. [Google Scholar] [CrossRef]

- Ataman, Ç.; Urey, H. Modeling and characterization of comb-actuated resonant microscanners. J. Micromech. Microeng. 2005, 16, 9–16. [Google Scholar] [CrossRef]

- Klose, T.; Conrad, H.; Sandner, T.; Schenk, H. Fluidmechanical damping analysis of resonant micromirrors with out-of-plane comb drive. In Proceedings of the COMSOL Conference, Hannover, Germany, 4–6 November 2008. [Google Scholar]

- Gehner, A.; Döring, S.; Rudloff, D.; Kunze, D.; Dürr, P.; González, S.F.; Hänsel, L.; Torlee, H.; Elgner, A.; Eckert, M.; et al. Novel CMOS-integrated 512x320 tip-tilt micro mirror array and related technology platform. In Proceedings of the MOEMS and Miniaturized Systems XIX, San Francisco, CA, USA, 1–3 February 2020; p. 1129302. [Google Scholar] [CrossRef]

- Kullberg, R.C.; Ramesham, R. Review of vacuum packaging and maintenance of MEMS and the use of getters therein. J. Micro/Nanolithogr. MEMS MOEMS 2009, 8, 031307. [Google Scholar] [CrossRef]

- Longoni, G.; Conte, A.; Amiotti, M.; Renzo, A.; Moraja, M.; Reinert, W. Q factor enhancement for MEMS devices: The role of the getter film. In Proceedings of the International Symposium on Microelectronics, IMAPS 2005, Philadelphia, PA, USA, 25–29 September2005; pp. 801–809. [Google Scholar]

- Longoni, G.; Conte, A.; Moraja, M.; Fourrier, A. Stable and Reliable Q-Factor in Resonant MEMS with Getter Film. In Proceedings of the IEEE 44th Annual International Reliability Physics Symposium, San Jose, CA, USA, 26–30 March 2006; pp. 416–420. [Google Scholar]

- Zhao, R.; Qiao, D.-Y.; Song, X.; You, Q. The Exploration for an Appropriate Vacuum Level for Performance Enhancement of a Comb-Drive Microscanner. Micromachines 2017, 8, 126. [Google Scholar] [CrossRef] [Green Version]

- Sandner, T.; Grasshoff, T.; Klose, T.; Schenk, H.; Massieu, J. MEMS based Laser Imager with Diagonal Progressive Scanning. In Proceedings of the 2009 IEEE 22nd International Conference on Micro Electro Mechanical Systems, Sorrento, Italy, 25–29 January 2009; pp. 951–954. [Google Scholar] [CrossRef]

- Reinert, W. Neon-Ultra-Feinlecktest zur Vorhersage der Vakuumerhaltung Resonanter Mikrosensoren. Ph.D. Thesis, Christian-Albrechts-Universität, Kiel, Germany, 2007. (In German). [Google Scholar]

- Suzuki, T.; Sugimoto, T.; Kotani, K.; Kuramoto, Y.; Shibayama, K. Compact FTIR engine made through MOEMS technology. In Proceedings of the SPIE MOEMS and Miniaturized Systems XVIII, San Francisco, CA, USA, 4 March 2019; Volume 10931. [Google Scholar] [CrossRef]

- Sandner, T.; Schmidt, J.U.; Schenk, H.; Lakner, H.; Yang, M.; Gatto, A.; Kaiser, N.; Braun, S.; Foltyn, T.; Leson, A. Highly reflective optical coatings for high-power applications of micro scanning mirrors in the UV-VIS-NIR spectral region. In Proceedings of the SPIE 6114, MOEMS Display, Imaging, and Miniaturized Microsystems IV, San Francisco, CA, USA, 23 January 2006; p. 61140H. [Google Scholar] [CrossRef]

- Hashimoto, K.; Ideguchi, T. Phase-controlled Fourier-transform spectroscopy. Nat. Commun. 2018, 9, 4448. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kita, D.; Lin, H.; Agarwal, A.; Richardson, K.; Luzinov, I.; Gu, T.; Hu, J. On-Chip Infrared Spectroscopic Sensing: Redefining the Benefits of Scaling. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 340–349. [Google Scholar] [CrossRef]

- Hiruma, A. Palm-sized FTIR engine capable of highly sensitive detection of near-infrared light at wavelengths ranging from 1.1 to 2.5 µm. News Release, 28 January 2020. [Google Scholar]

| FTS Specification | Value | MEMS Boundary Conditions | Value |

|---|---|---|---|

| Mirror aperture | 5 mm | Maximal mechanical stress s1 | ≤1.5 GPa |

| Resonance frequency | 250–300 Hz | Maximal shock acceleration | 2500 g |

| Mechanical amplitude | 350 µm | Mirror deformation δpp | 80 nm |

| Spectral range [λmin, λmax] | 800–2500 nm | Reflectance of mirror | ≥95% |

| Spectral resolution ∆ν | ≤15 cm−1 | Parasitic tilt angle | 20” |

| Lifetime | ≥10 years | Vacuum pressure in WLVP | ≤1 Pa |

| Bonding Approach | Bonding Temperature (°C) | Topo-Graphy Tolerance | Main Advantage | Main Disadvantage | Ref. | |

|---|---|---|---|---|---|---|

| Traditional approaches | Anodic Direct Glass-frit | 300–450 >800 430–450 | Low Very low High | Good for silicon–glass - Excellent hermetic sealing, possibility of incorporating metallic feedthroughs | High process voltage Poor CMOS compatibility Large seal area | [46] [46] [46,47,48] |

| Metal Bonding Approaches | Eutectic SLID (solid-liquid-inter-diffusion) Metal–to-metal | >200 >200 >200 | Medium Medium Low | Ductile seal Re-melting temperature is greater than bonding temperature Mature process | Complex deposition Lack of ductility in seal No collapse layer to absorb topology | [39,46] [39,46] [46] |

| Adhesive | BCB | >150 | High | Ductile seal | Non-hermetic | [46] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandner, T.; Gaumont, E.; Graßhoff, T.; Rieck, A.; Seifert, T.; Auböck, G.; Grahmann, J. Wafer-Level Vacuum-Packaged Translatory MEMS Actuator with Large Stroke for NIR-FT Spectrometers. Micromachines 2020, 11, 883. https://doi.org/10.3390/mi11100883

Sandner T, Gaumont E, Graßhoff T, Rieck A, Seifert T, Auböck G, Grahmann J. Wafer-Level Vacuum-Packaged Translatory MEMS Actuator with Large Stroke for NIR-FT Spectrometers. Micromachines. 2020; 11(10):883. https://doi.org/10.3390/mi11100883

Chicago/Turabian StyleSandner, Thilo, Eric Gaumont, Thomas Graßhoff, Andreas Rieck, Tobias Seifert, Gerald Auböck, and Jan Grahmann. 2020. "Wafer-Level Vacuum-Packaged Translatory MEMS Actuator with Large Stroke for NIR-FT Spectrometers" Micromachines 11, no. 10: 883. https://doi.org/10.3390/mi11100883

APA StyleSandner, T., Gaumont, E., Graßhoff, T., Rieck, A., Seifert, T., Auböck, G., & Grahmann, J. (2020). Wafer-Level Vacuum-Packaged Translatory MEMS Actuator with Large Stroke for NIR-FT Spectrometers. Micromachines, 11(10), 883. https://doi.org/10.3390/mi11100883