Efficient and Precise Grinding of Sapphire Glass Based on Dry Electrical Discharge Dressed Coarse Diamond Grinding Wheel

Abstract

:1. Introduction

2. Experiments and Methods

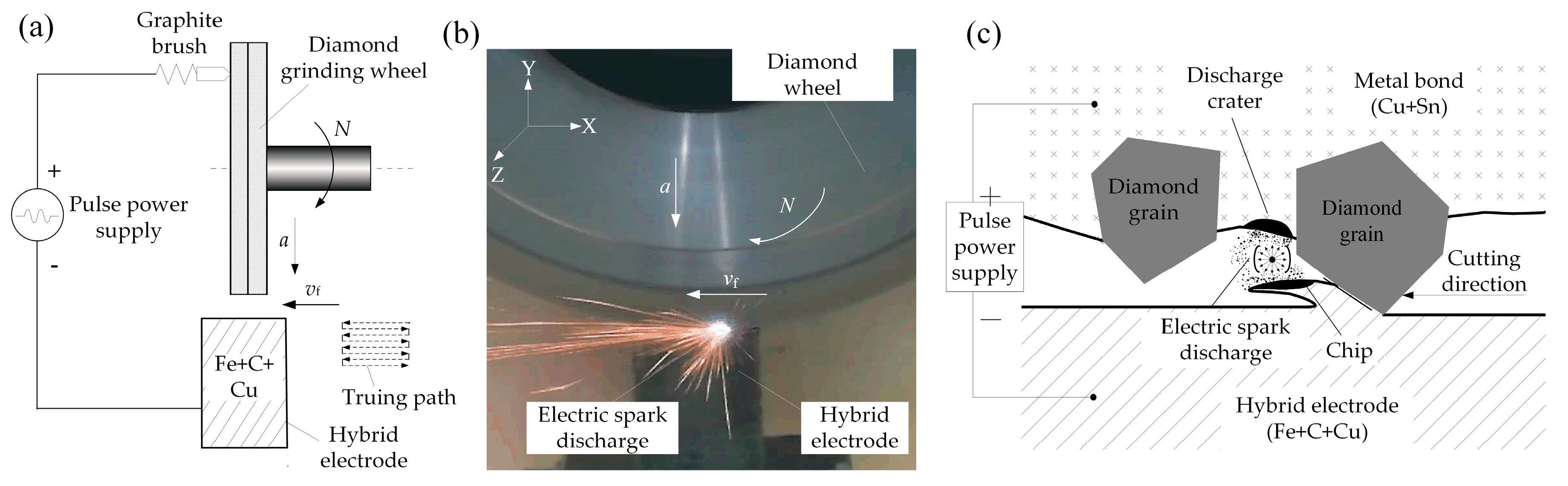

2.1. Dry Electrical Discharge Dressing of the Coarse Diamond Grinding Wheel

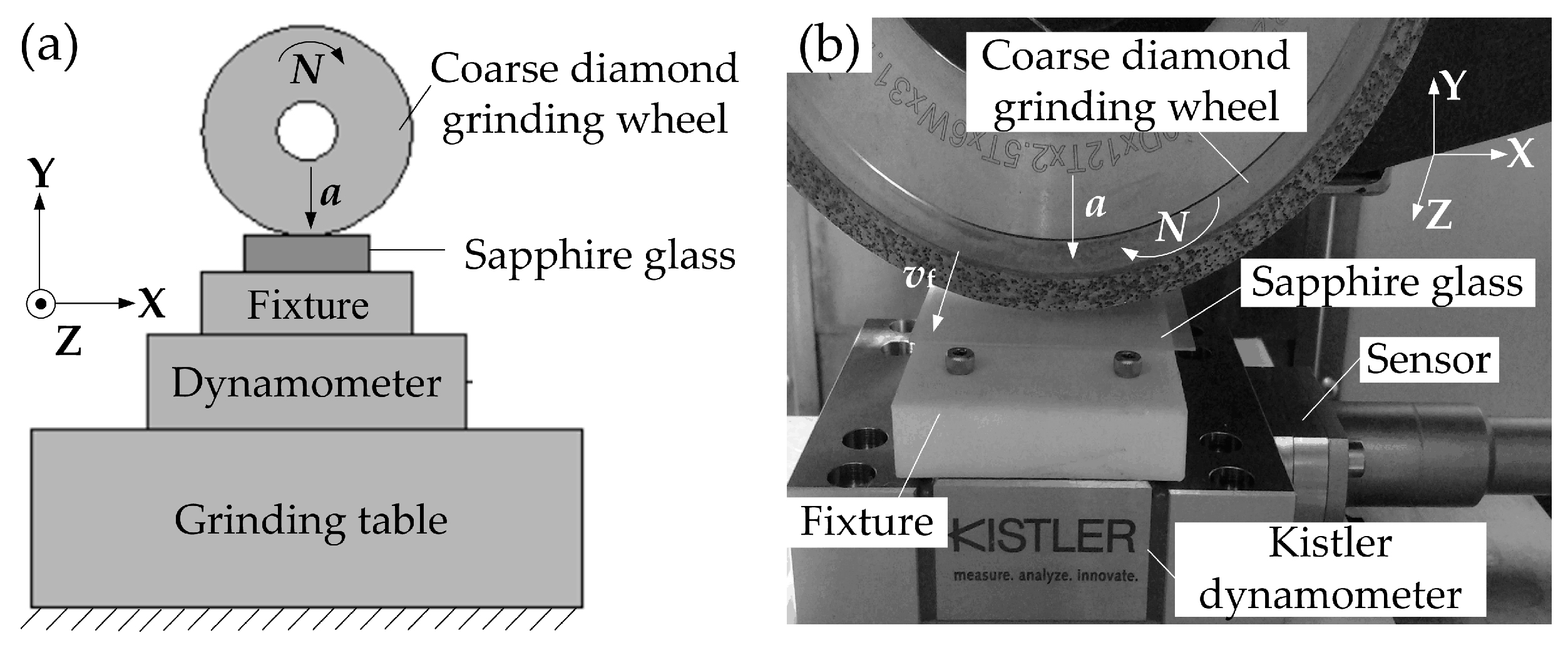

2.2. Axial Grinding Experiments of Sapphire Glass

2.3. Measurement

3. Results and Discussion

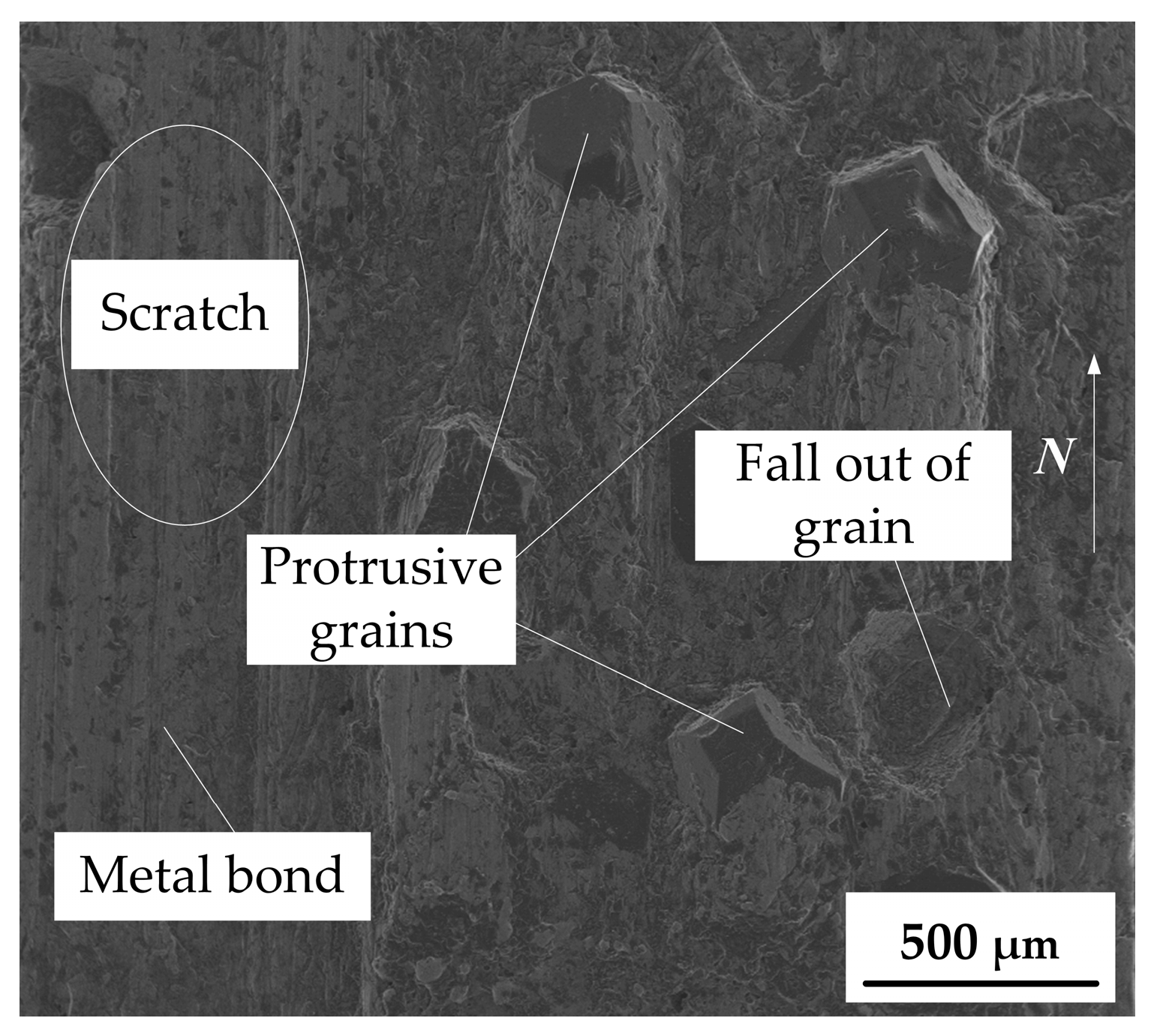

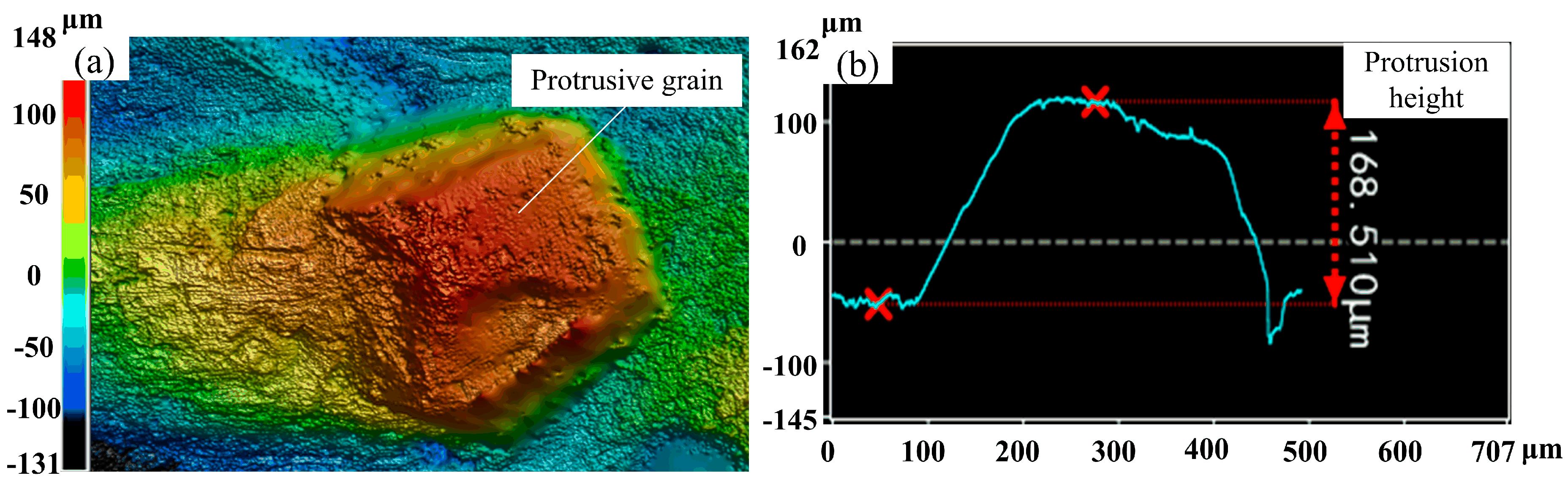

3.1. Grain Protrusion of the Coarse Diamond Grinding Wheel Surface

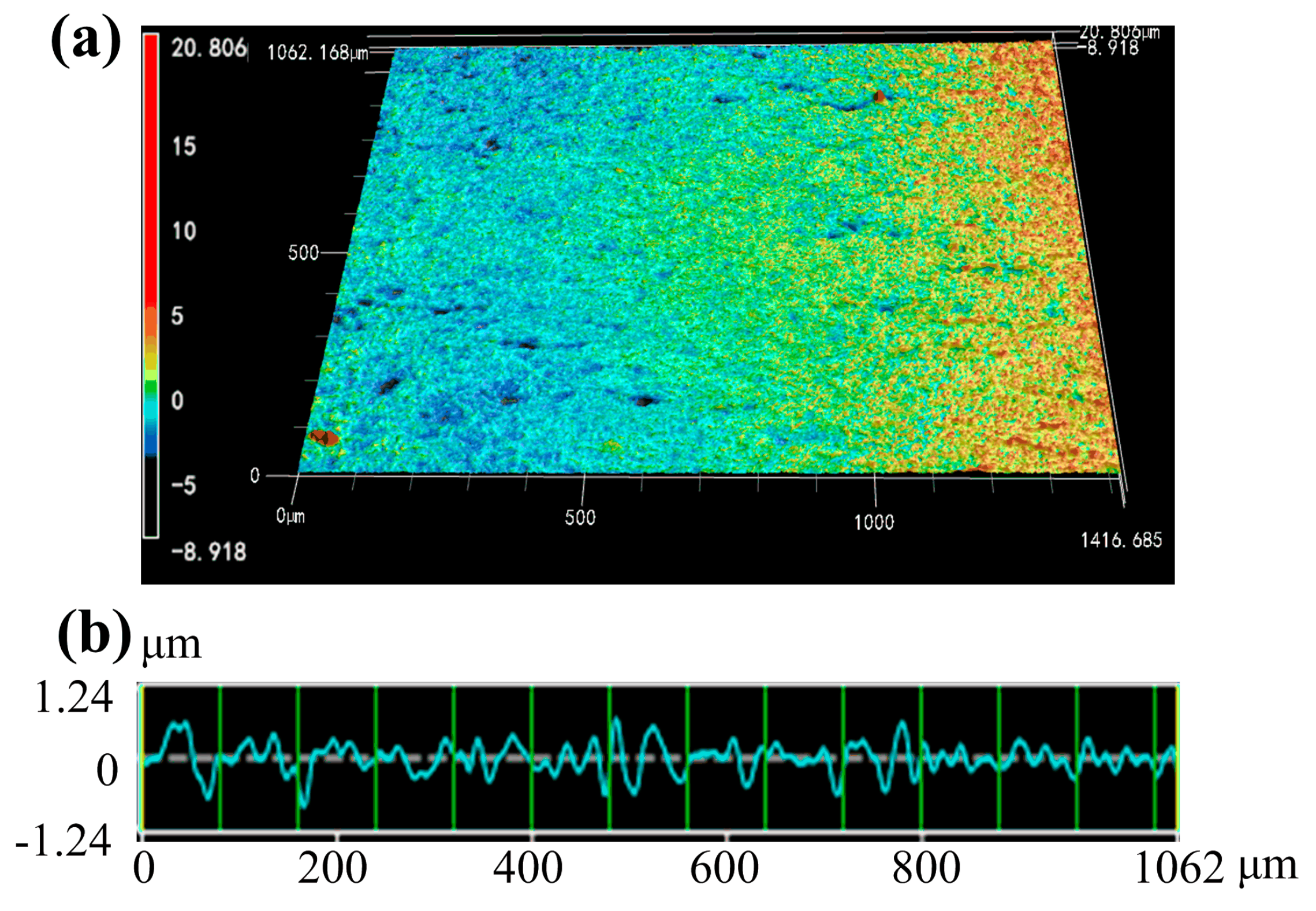

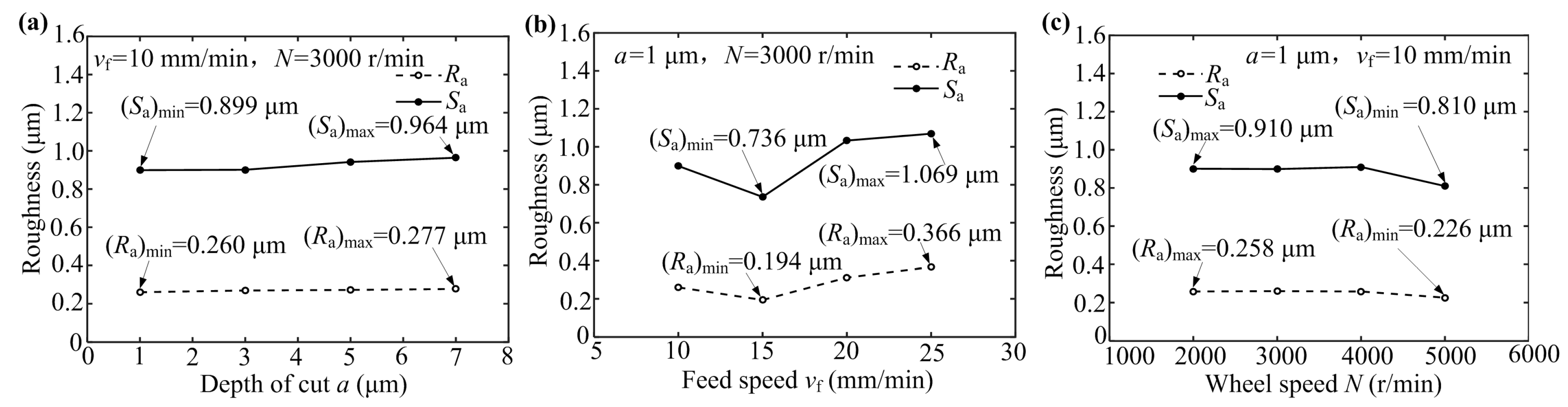

3.2. Surface Roughness of Ground Sapphire Glass

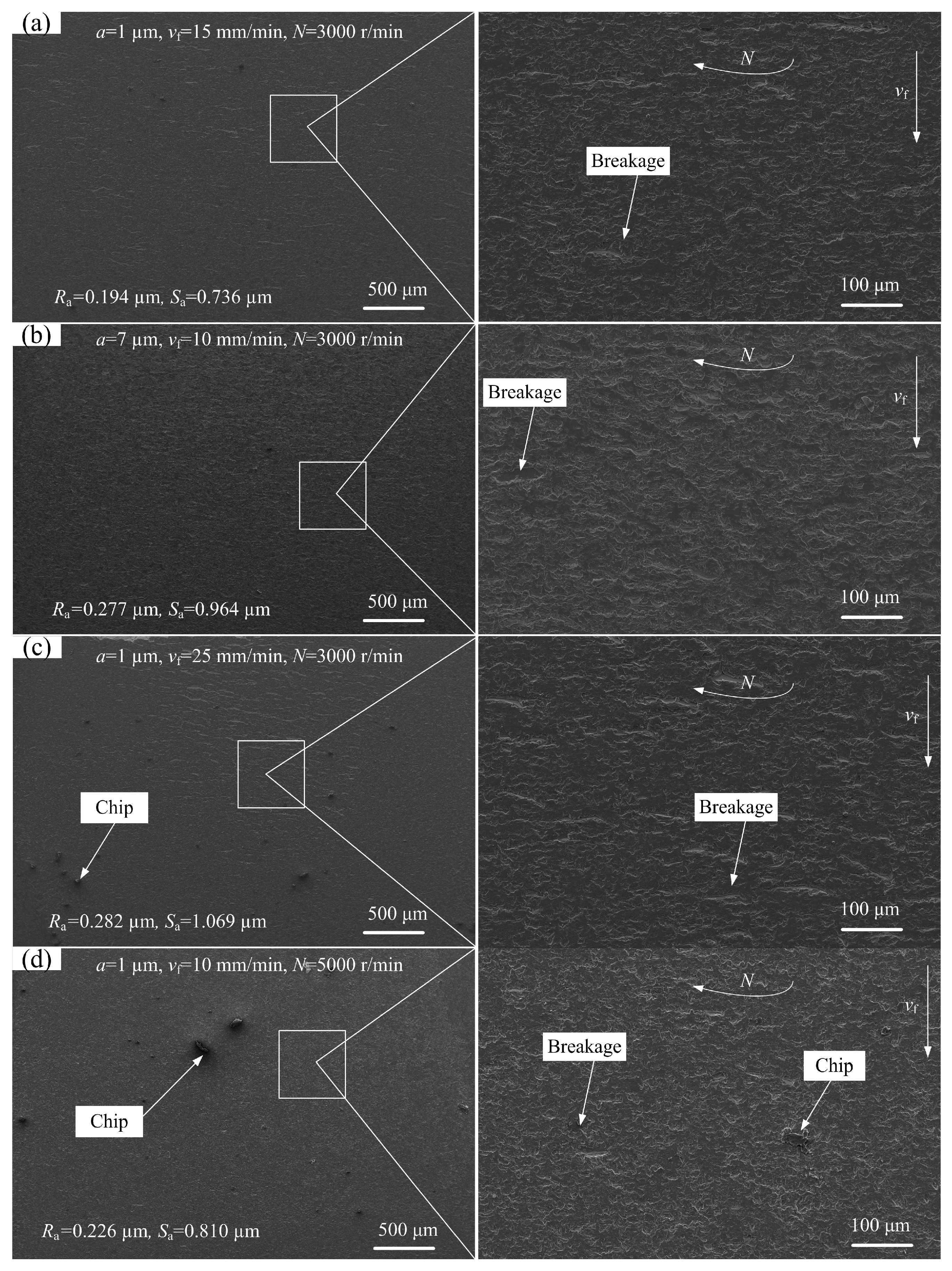

3.3. Surface Topographies of Ground Sapphire Glass

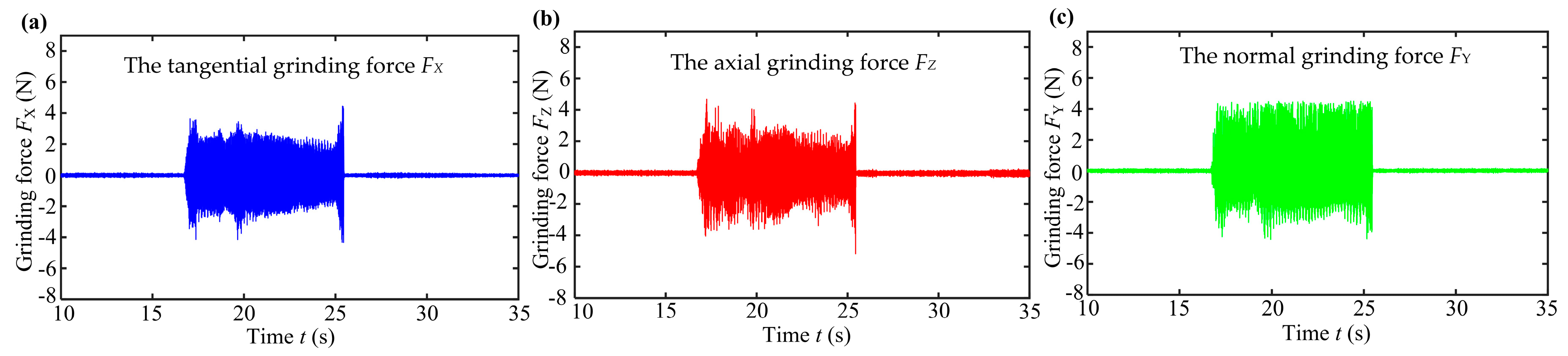

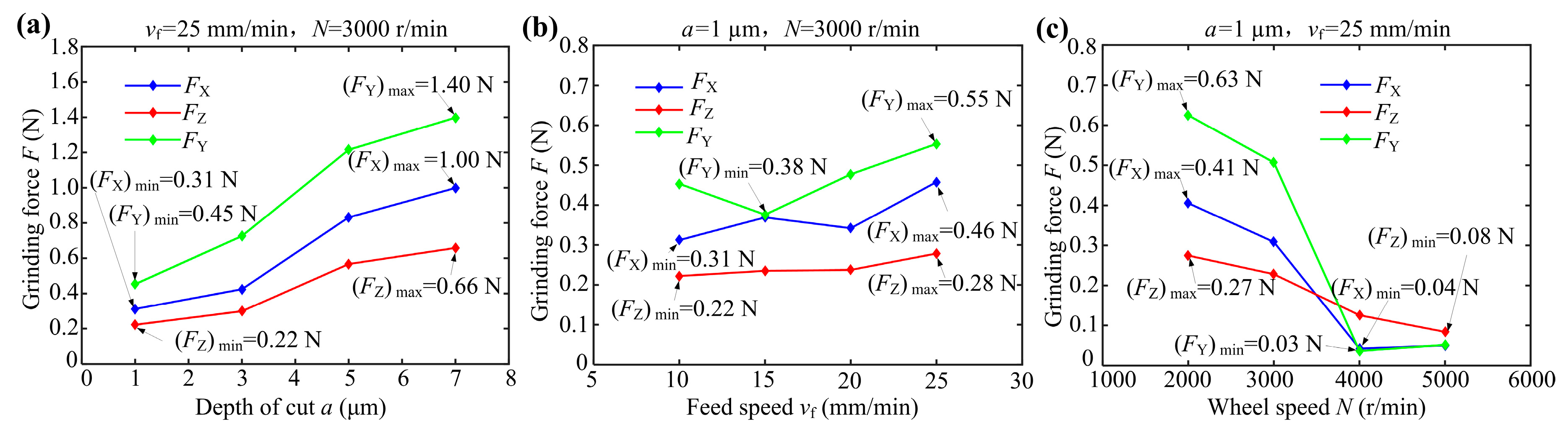

3.4. Grinding Force of Sapphire Glass Surface

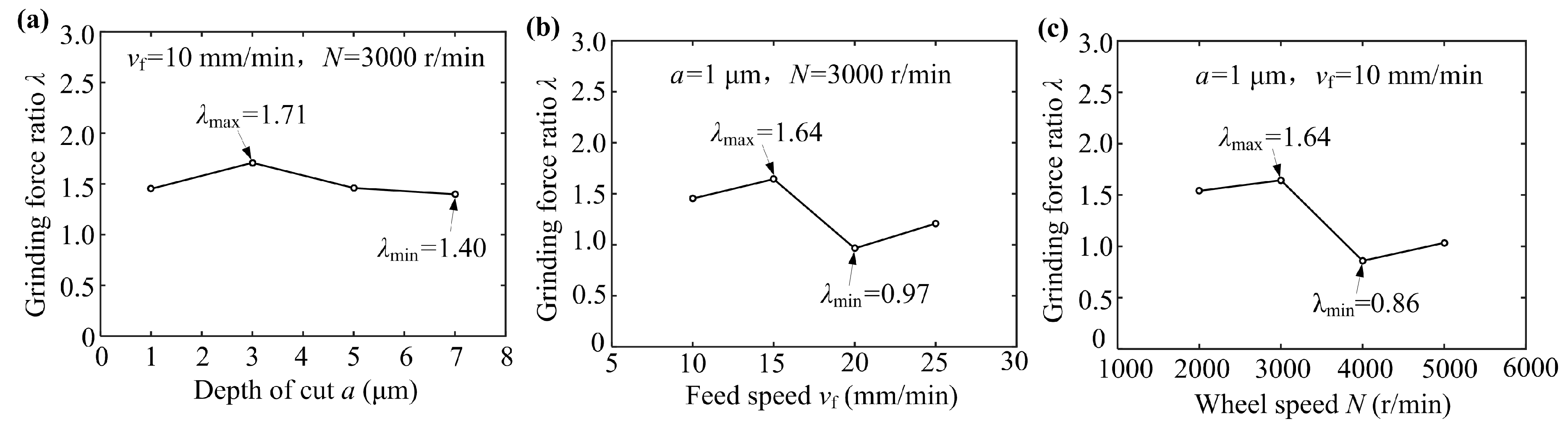

3.5. Grinding Force Ratio of Sapphire Glass Surface

4. Conclusions

- (1)

- Using the dry electrical discharge dressing technique, the grain protrusion height of #46 coarse diamond grinding wheel can reach 168.5 μm, which is about 48% of the theoretical diamond grain size. The large grain protrusion height and sharp micro-grain cutting edges can ensure efficient grinding machining for hard and brittle materials.

- (2)

- The minimum roughness Ra of ground sapphire glass surface is 0.194 μm using the proposed coarse diamond grinding method, which is much less than the obtained Ra of 0.392 μm using fine-grained diamond grinding wheels [5]. At this point, the normal grinding force reaches a minimum value of 0.38 N and the grinding force ratio achieves a maximum value of 1.64.

- (3)

- The depth of cut is controlled within 7 μm, and the wheel speed and feed speed are maintained between 3000–5000 r/min and 10–20 mm/min respectively, which can realize high efficiency and quality grinding of sapphire glass.

- (4)

- The change of the grinding process parameters will cause the changes of grinding force and grinding force ratio, thus affecting the ground surface quality of the workpiece. In the grinding of sapphire glass, the normal grinding force is the largest, followed by the tangential grinding force, and the axial grinding force is the smallest. The influences of the feed speed and wheel speed on the grinding force ratio are more significant, but the depth of cut has little effect.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cheng, J.; Wu, J.; Gong, Y.D.; Wen, X.L.; Wen, Q. Grinding forces in micro slot-grinding (MSG) of single crystal sapphire. Int. J. Mach. Tools Manuf. 2017, 112, 7–20. [Google Scholar] [CrossRef]

- Xu, Y.C.; Lu, J.; Xu, X.P. Pollution-free approaches for highly efficient sapphire substrate processing by mechanical chemical polishing. Catalysts 2019, 9, 594. [Google Scholar] [CrossRef]

- Lu, X.Z.; Jiang, F.; Lei, T.P.; Zhou, R.; Zhang, C.T.; Zheng, G.F.; Wen, Q.L.; Chen, Z. Laser-induced-plasma-assisted ablation and metallization on C-plane single crystal sapphire (c-Al2O3). Micromachines 2017, 8, 300. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.P.; Zhang, F.H.; Luo, X.C.; Guo, X.G.; Cai, Y.K.; Chang, W.L.; Sun, J.N. A new grinding force model for micro grinding RB-SiC ceramic with grinding wheel topography as an input. Micromachines 2018, 9, 368. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.J.; Hu, Z.W.; Fang, C.F.; Yu, Y.Q.; Xu, X.P. Study on the double-sided grinding of sapphire substrates with the trajectory method. Precis. Eng. 2018, 51, 308–318. [Google Scholar] [CrossRef]

- Luo, Q.F.; Lu, J.; Xu, X.P.; Feng, J. Removal mechanism of sapphire substrates (0001, 1120 and 1010) in mechanical planarization machining. Ceram. Int. 2018, 29, 1310–1315. [Google Scholar]

- Guo, L.; Zhang, X.R.; Chen, S.B.; Hui, J.Z. An experimental study on the precision abrasive machining process of hard and brittle materials with ultraviolet-resin bond diamond abrasive tools. Materials 2019, 12, 125. [Google Scholar] [CrossRef]

- Liang, Z.Q.; Wang, X.B.; Wu, Y.B.; Xie, L.J.; Liu, Z.B.; Zhao, W.X. An investigation on wear mechanism of resin-bonded diamond wheel in Elliptical Ultrasonic Assisted Grinding (EUAG) of monocrystal sapphire. J. Mater. Process. Technol. 2012, 212, 868–876. [Google Scholar] [CrossRef]

- Cheng, J.; Wu, J. Experimental investigation of fracture behaviors and subsurface cracks in micro-slot-grinding of monocrystalline sapphire. J. Mater. Process. Technol. 2017, 242, 60–181. [Google Scholar] [CrossRef]

- Lu, Y.J.; Chen, F.M.; Wu, X.Y.; Zhou, C.L.; Lou, Y.; Li, L.J. Fabrication of micro-structured polymer by micro injection molding based on precise micro-ground mold core. Micromachines 2019, 10, 253. [Google Scholar] [CrossRef]

- Guo, B.; Zhao, Q.L.; Fang, X.Y. Precision grinding of optical glass with laser micro-structured coarse-grained diamond wheels. J. Mater. Process. Technol. 2014, 214, 1045–1051. [Google Scholar] [CrossRef]

- Xie, J.; Wei, F.; Zheng, J.H.; Tamaki, J.; Kubo, A. 3D laser investigation on micron-scale grain protrusion topography of truncated diamond grinding wheel for precision grinding performance. Int. J. Mach. Tools Manuf. 2011, 51, 411–419. [Google Scholar] [CrossRef]

- Xie, J.; Xie, H.F.; Luo, M.J.; Tan, T.W.; Li, P. Dry electro-contact discharge mutual-wear truing of micro diamond wheel V-tip for precision micro-grinding. Int. J. Mach. Tools Manuf. 2012, 60, 44–51. [Google Scholar] [CrossRef]

- Yang, Z.B.; Zhang, S.Y.; Zhang, Z.; Zhang, Y.Q.; Hu, J.C.; Li, K.Q.; Zhao, B.; Zhang, Y.R. Experimental research on laser-ultrasonic vibration synergic dressing of diamond wheel. J. Mater. Process. Technol. 2019, 269, 182–189. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.J.; Hu, D.J. An experimental investigation of dry-electrical discharge assisted truing and dressing of metal bonded diamond wheel. Int. J. Mach. Tools Manuf. 2006, 46, 333–342. [Google Scholar] [CrossRef]

- Aurich, J.C. Electrolytic in-process dressing. In CIRP Encyclopedia of Production Engineering; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–5. [Google Scholar]

- Lu, Y.J.; Xie, J.; Si, X.H. Study on micro-topographical removals of diamond grain and metal bond in dry electro-contact discharge dressing of coarse diamond grinding wheel. Int. J. Mach. Tools Manuf. 2015, 88, 118–130. [Google Scholar] [CrossRef]

- Verdaasdonk, R.M.; Cross, F.W.; Borst, C. Physical properties of sapphire fibretips for laser angioplasty. Laser Med. Sci. 1987, 2, 183–188. [Google Scholar] [CrossRef]

- Vodenitcharova, T.; Zhang, L.C.; Zarudi, I.; Yin, Y.; Domyo, H.; Ho, T.; Sato, M. The effect of anisotropy on the deformation and fracture of sapphire wafers subjected to thermal shocks. J. Mater. Process. Technol. 2007, 194, 52–62. [Google Scholar] [CrossRef]

- Xie, J.; Xie, H.F.; Liu, X.R.; Tan, T.Y. Dry micro-grooving on Si wafer using a coarse diamond grinding. Int. J. Mach. Tools Manuf. 2012, 61, 1–8. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Y.X. Study on axial-feed mirror finish grinding of hard and brittle materials in relation to micron-scale grain protrusion parameters. Int. J. Mach. Tools Manuf. 2011, 51, 84–93. [Google Scholar] [CrossRef]

- Chen, J.; Shen, J.Y.; Huang, H.; Xu, X.P. Grinding characteristics in high speed grinding of engineering ceramics with brazed diamond wheels. J. Mater. Process. Technol. 2010, 210, 899–906. [Google Scholar] [CrossRef]

| Physical Characteristics | Sapphire Glass |

|---|---|

| Density, ρ (g/cm3) | 3.98 |

| Mohs’ scale of hardness, H | 9 |

| Poisson’s ratio, μ | 0.25–0.3 |

| Shear modulus, G (GPa) | 145 |

| Elastic modulus, E (GPa) | 431 |

| Fracture toughness, KIC (MPa·m1/2) | 2.5 |

| Term No. | Depth of Cut a (μm) | Feed Speed vf (mm/min) | Wheel Speed N (r/min) |

|---|---|---|---|

| 1 | 1 | 10 | 3000 |

| 2 | 3 | 10 | 3000 |

| 3 | 5 | 10 | 3000 |

| 4 | 7 | 10 | 3000 |

| 5 | 1 | 15 | 3000 |

| 6 | 1 | 20 | 3000 |

| 7 | 1 | 25 | 3000 |

| 8 | 1 | 10 | 2000 |

| 9 | 1 | 10 | 4000 |

| 10 | 1 | 10 | 5000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Luo, W.; Wu, X.; Zhou, C.; Xu, B.; Zhao, H.; Li, L. Efficient and Precise Grinding of Sapphire Glass Based on Dry Electrical Discharge Dressed Coarse Diamond Grinding Wheel. Micromachines 2019, 10, 625. https://doi.org/10.3390/mi10090625

Lu Y, Luo W, Wu X, Zhou C, Xu B, Zhao H, Li L. Efficient and Precise Grinding of Sapphire Glass Based on Dry Electrical Discharge Dressed Coarse Diamond Grinding Wheel. Micromachines. 2019; 10(9):625. https://doi.org/10.3390/mi10090625

Chicago/Turabian StyleLu, Yanjun, Wang Luo, Xiaoyu Wu, Chaolan Zhou, Bin Xu, Hang Zhao, and Liejun Li. 2019. "Efficient and Precise Grinding of Sapphire Glass Based on Dry Electrical Discharge Dressed Coarse Diamond Grinding Wheel" Micromachines 10, no. 9: 625. https://doi.org/10.3390/mi10090625

APA StyleLu, Y., Luo, W., Wu, X., Zhou, C., Xu, B., Zhao, H., & Li, L. (2019). Efficient and Precise Grinding of Sapphire Glass Based on Dry Electrical Discharge Dressed Coarse Diamond Grinding Wheel. Micromachines, 10(9), 625. https://doi.org/10.3390/mi10090625