Comparative Analysis and Strength Estimation of Fresh Concrete Based on Ultrasonic Wave Propagation and Maturity Using Smart Temperature and PZT Sensors

Abstract

1. Introduction

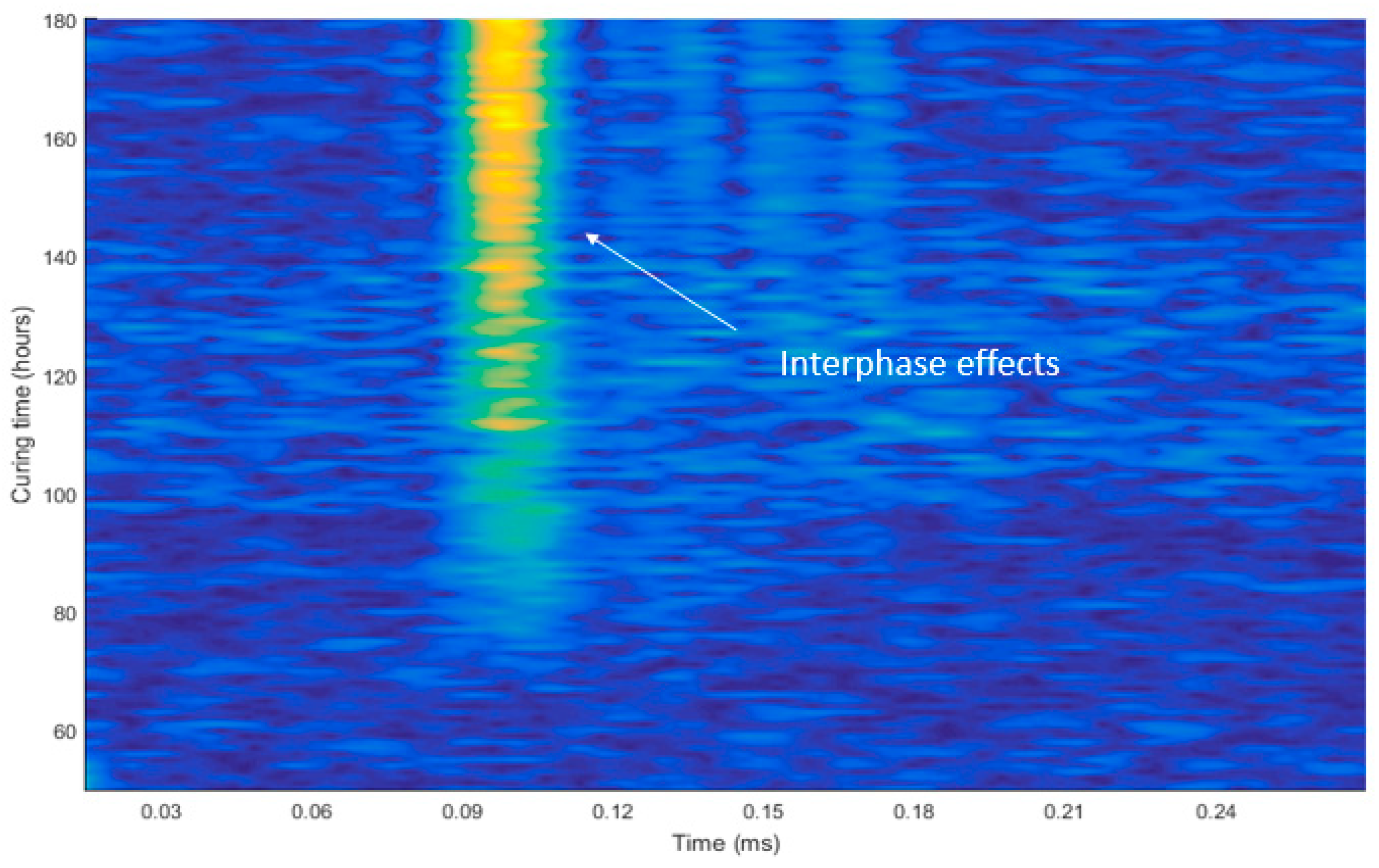

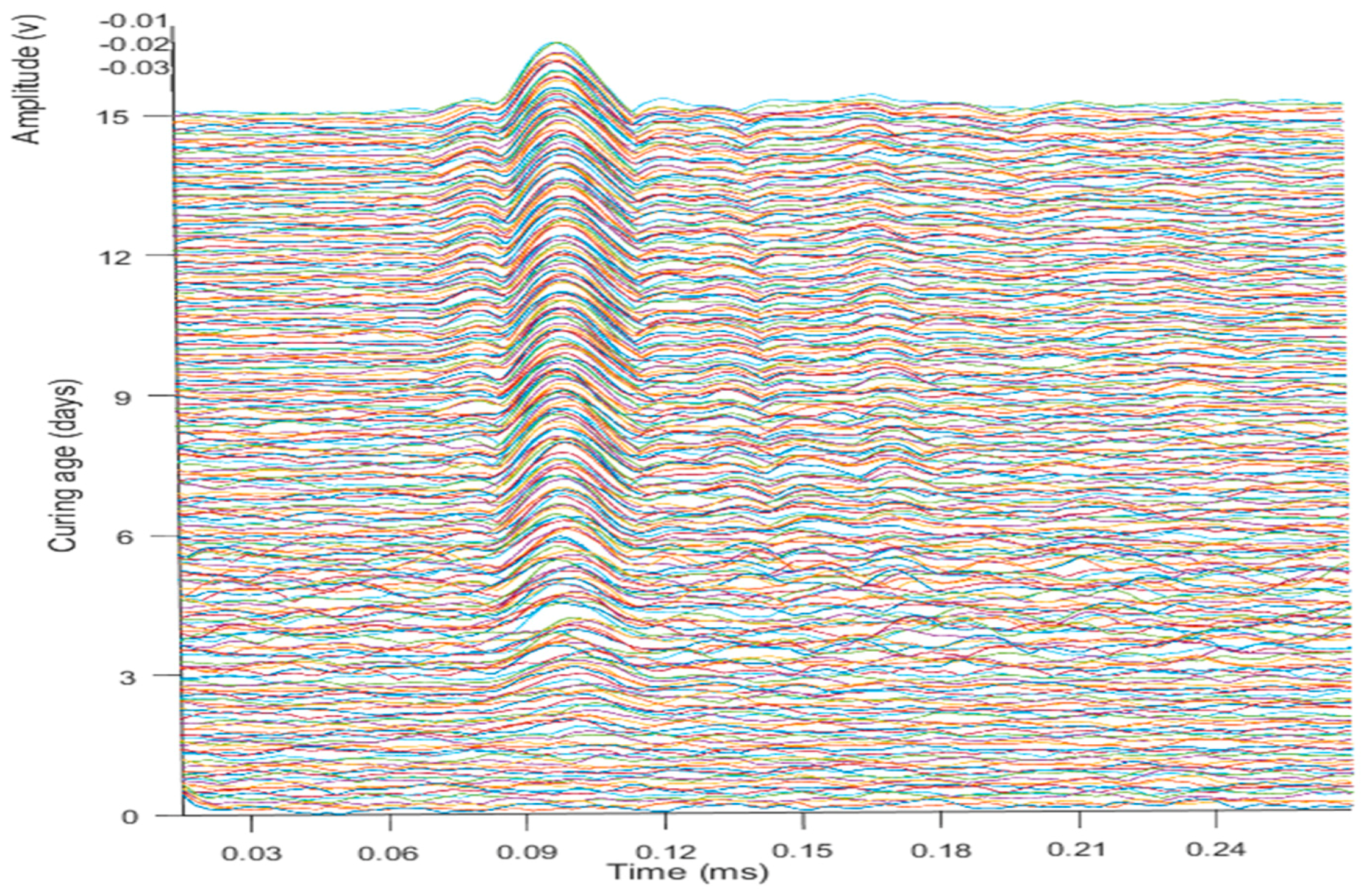

2. Transition of Pattern, Dissimilation of Signals

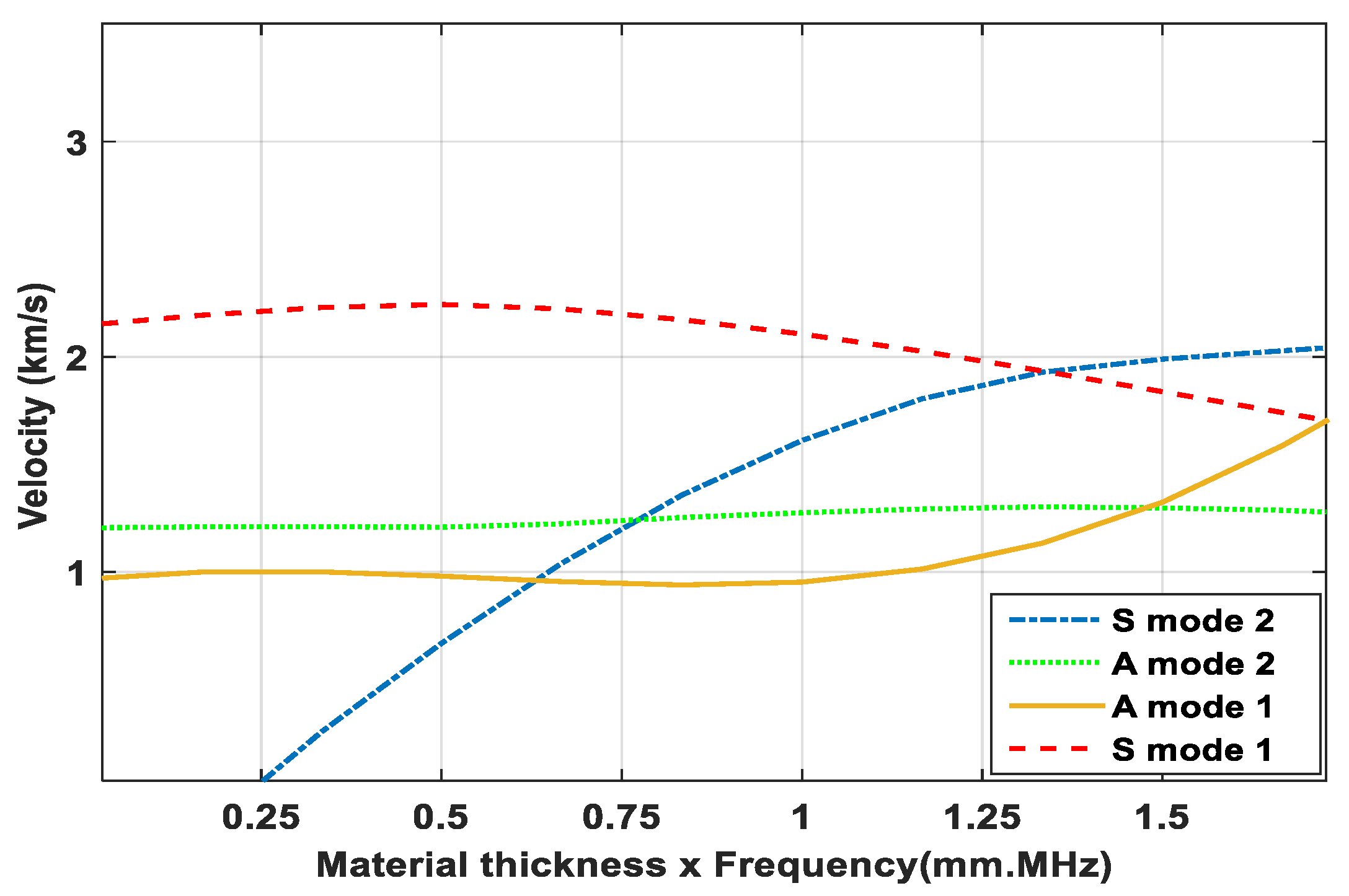

2.1. Waves Direct Velocities

2.2. Molded Variation

3. Experimental Setup

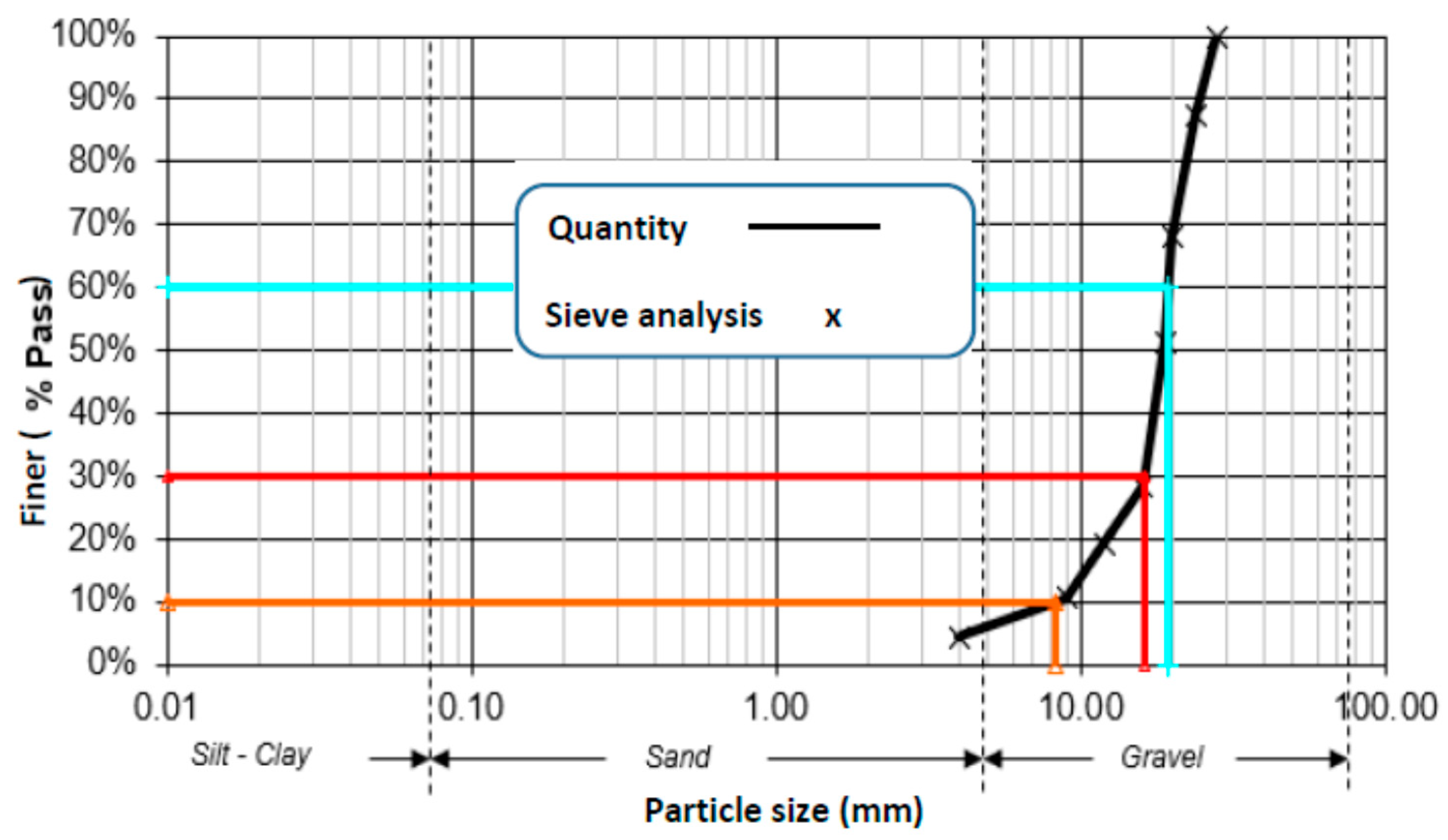

3.1. Mixture Composition and Material Gradations

3.2. Specimen Properties

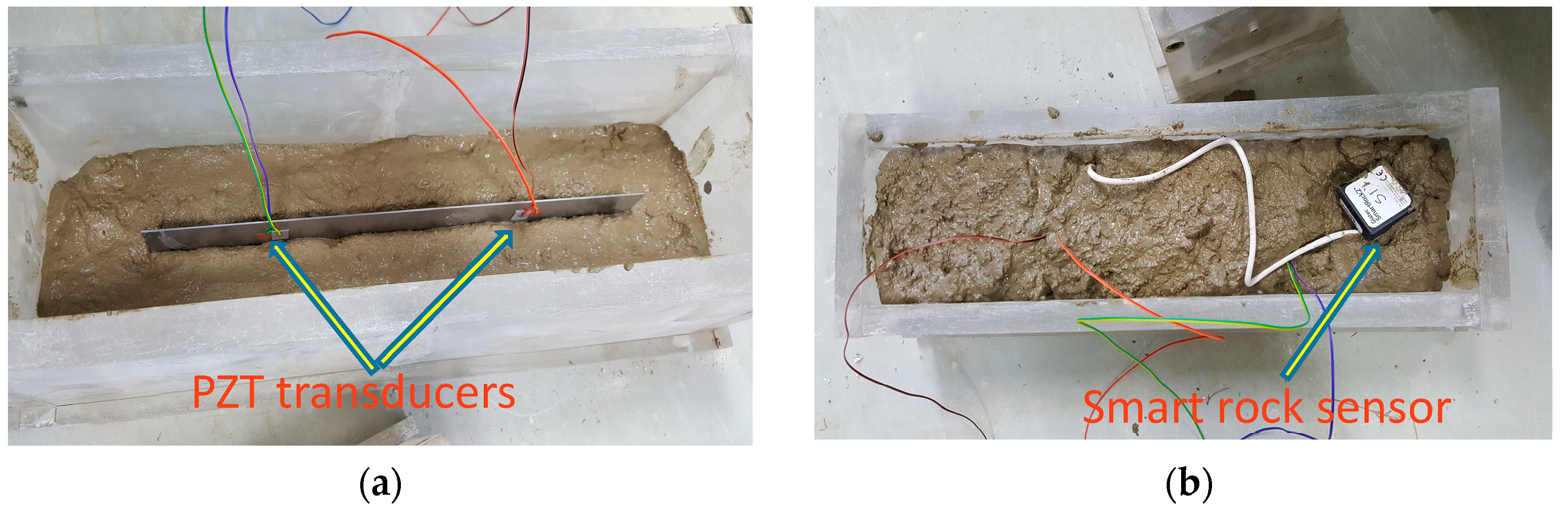

3.3. PZT Material as Sensors and Actuators

3.4. Sensors’ Preparation

3.5. Methodology Analysis for the Longitudinal Wave Variations

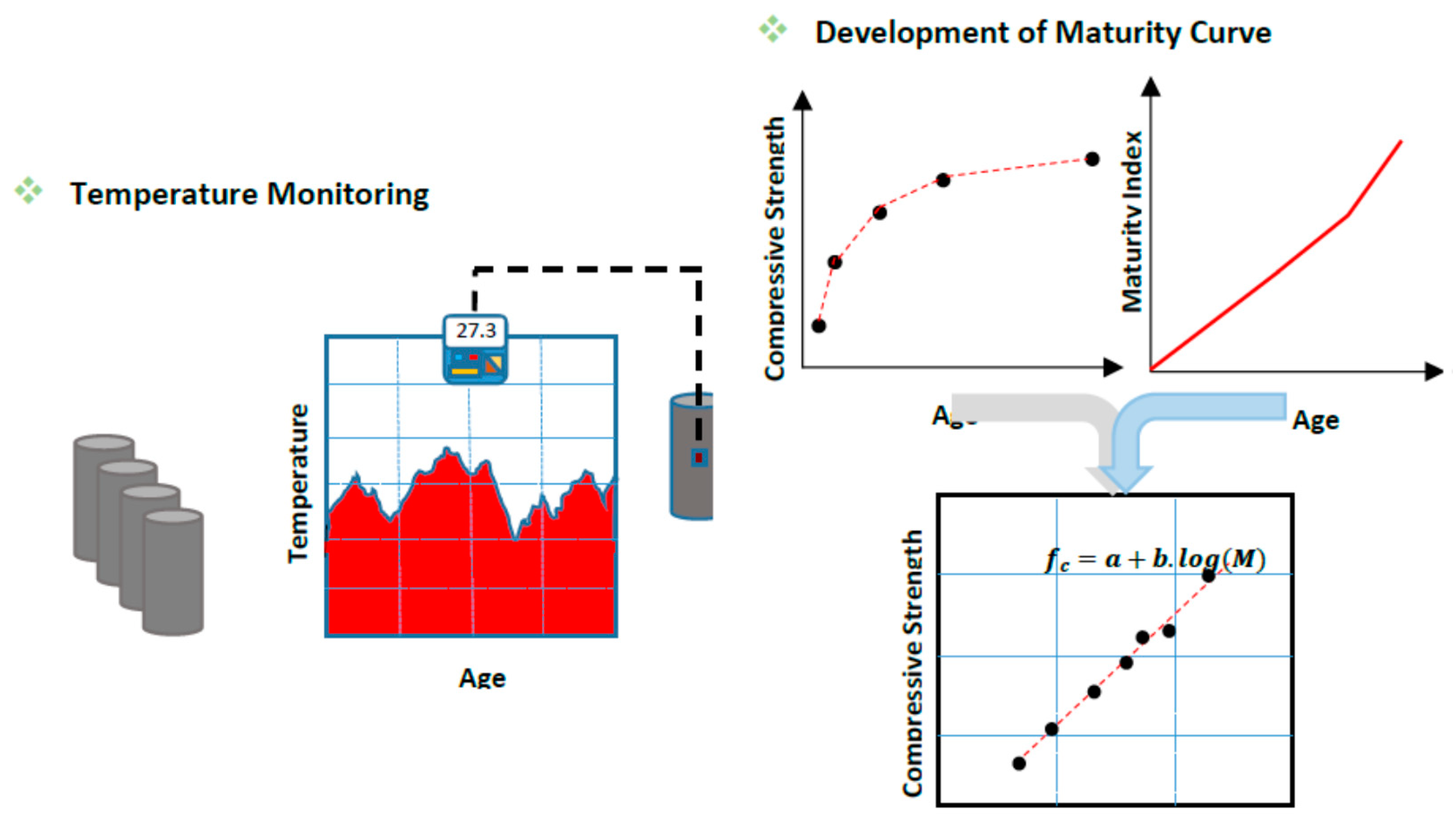

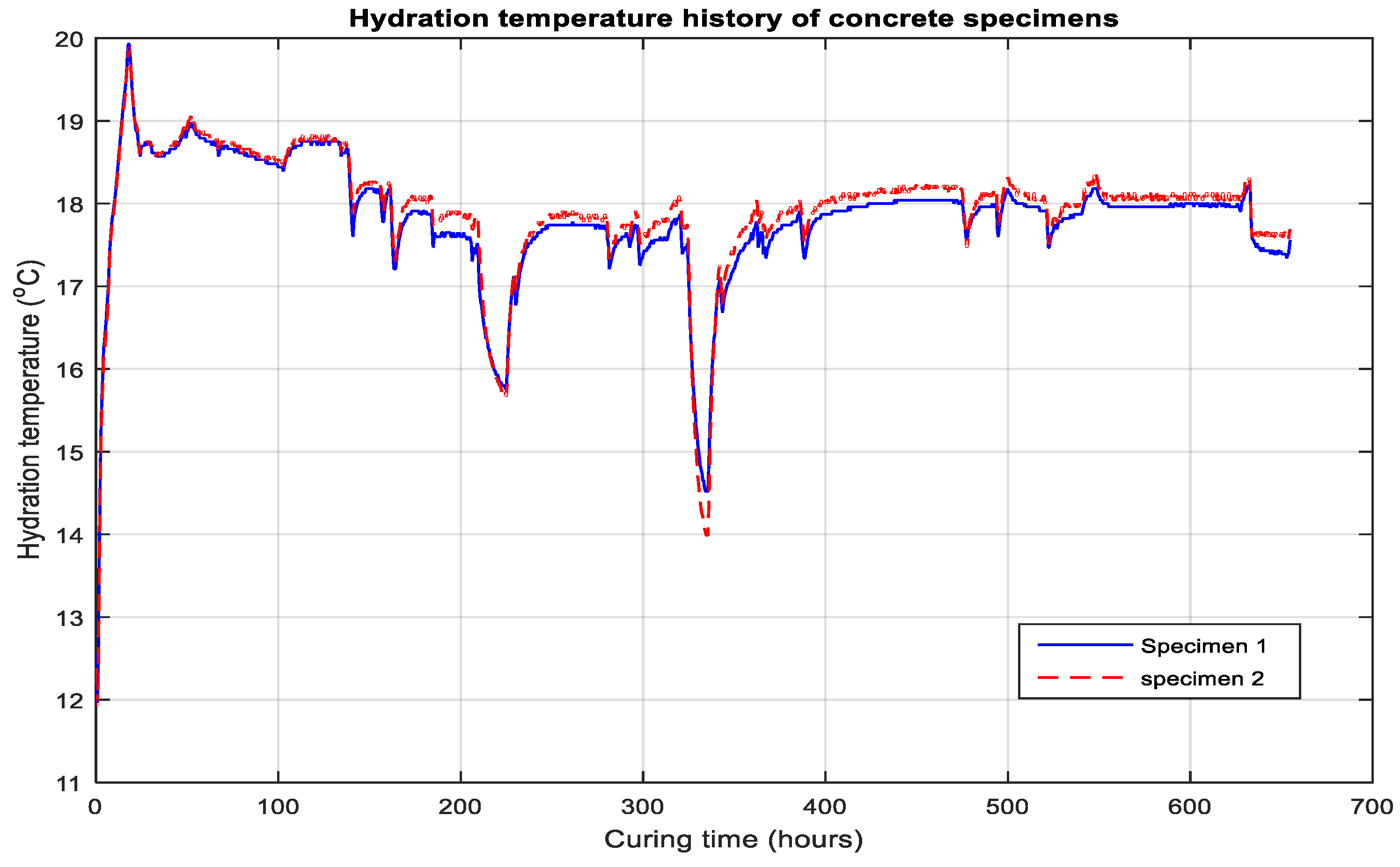

4. Hydration Temperature and Maturity Index

5. Discussion and Results

5.1. Phase Variation

5.2. Hydration Temperature and Maturity Index

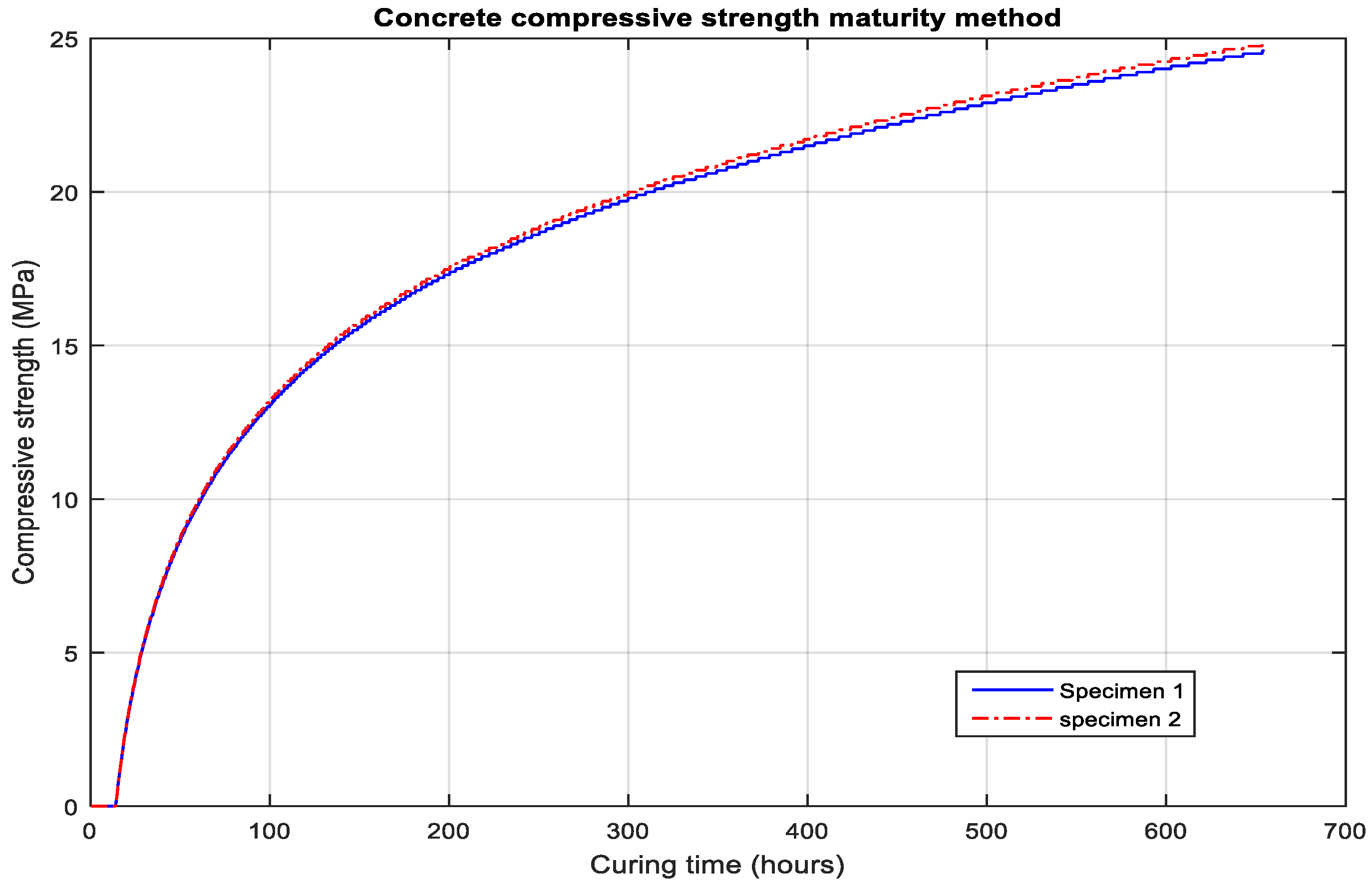

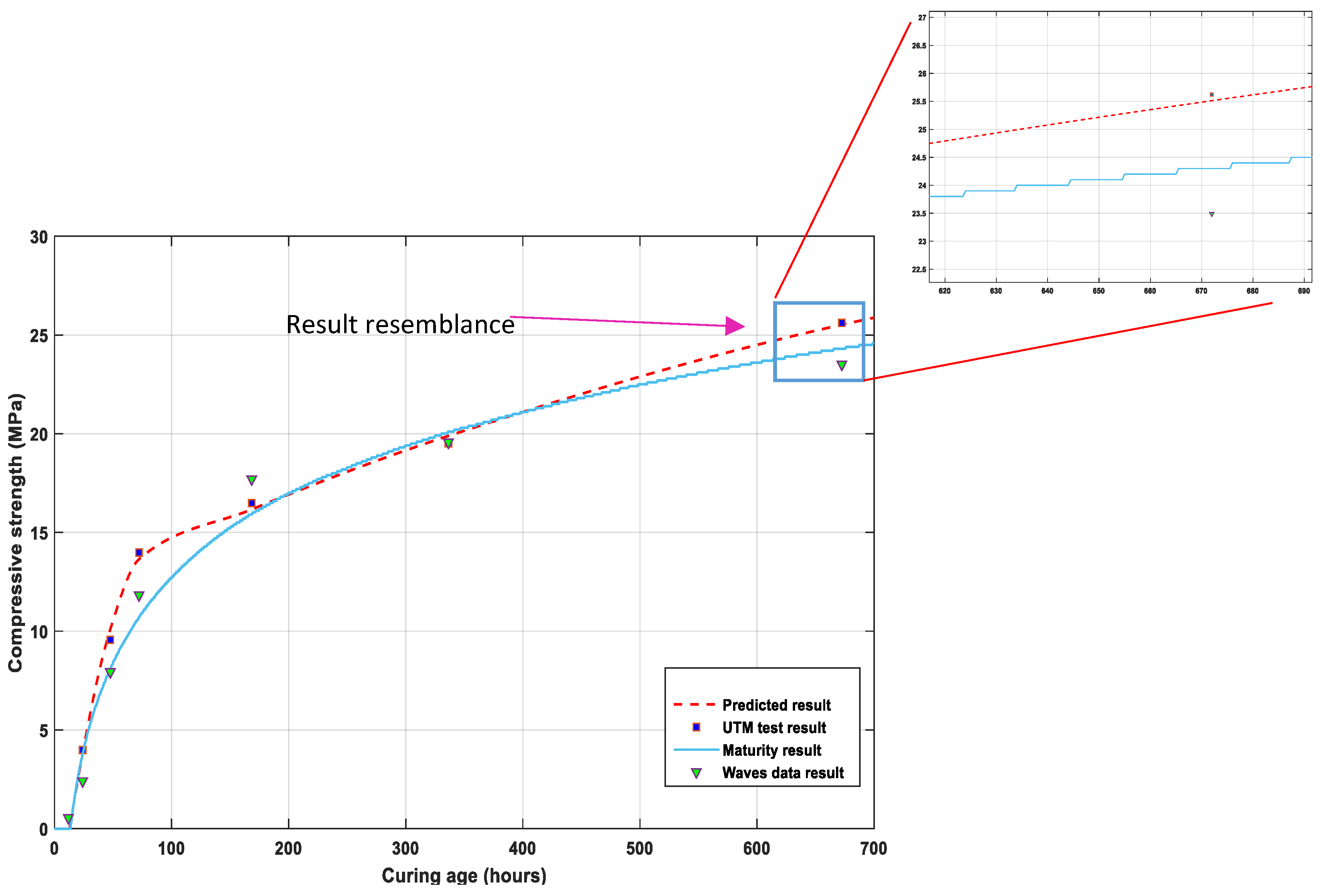

5.3. Comparative Data for the Strength Prediction

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| NDT | non-destructive testing |

| UTM | universal testing machine |

| RC | reinforced concrete |

| AWG | arbitrary waveform generator |

| MUX | multiplexer |

| SHM | structural health monitoring |

| PZT | piezoelectric |

| ASTM | American Society for Testing and Materials |

| APC | American Piezo Ceramics |

| IoT | Internet of Things |

References

- King, S.; Delatte, N.J. Collapse of 2000 Commonwealth Avenue: Punching shear case study. J. Perform. Constr. Facil. 2004, 18, 54–61. [Google Scholar] [CrossRef]

- Zinno, R.; Artese, S.; Clausi, G.; Magaro, F.; Meduri, S.; Miceli, A.; Venneri, A. Structural health monitoring (SHM). In The Internet of Things for Smart Urban Ecosystem; Springer: Cham, Switzerland, 2019; pp. 225–249. [Google Scholar]

- Sýkora, M.; Diamantidis, D.; Markova, J.; Rózsás, Á. Assessment of compressive strength of historic masonry using non-destructive and destructive techniques. Constr. Build. Mater. 2018, 193, 196–210. [Google Scholar] [CrossRef]

- James, H.; Massoud, S.; Priyan, M. Non-Destructive Testing of Concrete: A Review of Methods. Electron. J. Struct. Eng. 2015, 14, 97–105. [Google Scholar]

- Wahab, A.; Aziz, M.; Rahman, A.; Sam, M.; Qadir, A.; Kassim, K.; You, Y. Review on microwave nondestructive testing techniques and its applications in concrete technology. Constr. Build. Mater. 2019, 203, 135–146. [Google Scholar] [CrossRef]

- Gu, H.; Song, G.; Dhonde, H.; Mo, Y.L.; Yan, S. Concrete early-age strength monitoring using embedded piezoelectric transducers. Smart Mater. Struct. 2006, 15, 1837–1845. [Google Scholar] [CrossRef]

- Guidebook on Non-Destructive Testing of Concrete Structures; International Atomic Energy Agency: Vienna, Austria, 2002; Available online: https://www-pub.iaea.org/mtcd/publications/pdf/tcs-17_web.pdf (accessed on 21 August 2019).

- Lim, Y.Y.; Kwong, K.Z.; Liew, W.Y.H.; Chee, K.S. Non-destructive concrete strength evaluation using smart piezoelectric transducer—A comparative study. Smart Mater. Struct. 2016, 25, 085021. [Google Scholar] [CrossRef]

- Cédric, D.; Grigoris, K.; Jérôme, C.; Stéphanie, S.; Arnaud, D. Monitoring of the ultrasonic P-wave velocity in early-age concrete with embedded piezoelectric transducers. Smart Mater. Struct. 2012, 21, 047001. [Google Scholar]

- Sung, W.S.; Adeel, R.Q.; Jae, Y.L.; Chung, B.Y. Piezoelectric sensor based nondestructive active monitoring of strength gain in concrete. Smart Mater. Struct. 2008, 17, 055002. [Google Scholar]

- Kim, J.W.; Park, S.H. MFL sensing and ANN pattern recognition based automated damage detection and quantification for wire rope NDE. Sensors 2018, 18, 267–276. [Google Scholar]

- Kim, J.; Kim, J.W.; Lee, C.; Park, S. Development of Embedded EM Sensors for Estimating Tensile Forces of PSC Girder Bridges. Sensors 2017, 17, 1989. [Google Scholar] [CrossRef]

- Oh, T.K.; Kim, J.; Lee, C.; Park, S. Nondestructive Concrete Strength Estimation based on Electro-Mechanical Impedance with Artificial Neural Network. J. Adv. Concr. Technol. 2017, 15, 94–102. [Google Scholar] [CrossRef]

- Constantin, E.C.; Chris, G.K.; Georgia, M.A.; Nikos, A.P.; Maria, J.F.; Costas, P.P. Application of smart piezoelectric materials in a wireless admittance monitoring system. (WiAMS) to structure—Test in RC elements. Case Stud. Constr. Mater. 2016, 5, 1–18. [Google Scholar]

- Priya, B.; Thiyagarajan, J.; Monica, B.; Gopalakrishnan, N.; Rao, A. EMI based monitoring of early-age characteristics of concrete and comparison of serial/parallel multi-sensing technique. Constr. Build. Mater. 2018, 191, 1268–1284. [Google Scholar] [CrossRef]

- ASTM International. Standard Practice for Estimation Concrete Strength by the Maturity Method. ASTM C 2004, 1074, 1074–1093. [Google Scholar]

- Carino, N.J.; Lew, H.S. The maturity method: From theory to application. In Proceedings of the 2001 Structures Congress & Exposition, Washington, WA, USA, 21–23 May 2001; p. 19. Available online: https://ws680.nist.gov/publication/get_pdf.cfm?pub_id=860356 (accessed on 21 August 2019).

- Blaschke, J.H.V.; Torrico, F.A. Estimaing concrete strength using the correlation of the concrete maturity method applied to the mattrials of Cochabamba-Bolivia. Rev. Investig. Desarro. 2018, 18, 117–127. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete Second Edition; CRC Press: Florida, FL, USA, 2003; pp. 39–381. [Google Scholar]

- Bungey, J.H.; Grantham, M.G. Testing of Concrete in Structures; CRC Press: London, UK, 2014; pp. 18–331. [Google Scholar]

- Park, S.; Kim, J.-W.; Lee, C.; Park, S.-K. Impedance-based wireless Debonding condition monitoring of CFRP Laminated Concrete structure. NDT E Int. 2011, 44, 232–238. [Google Scholar] [CrossRef]

- Costas, P.P.; Stavros, E.T.; Evangelos, V.L. 2-D Statistical Damage Detection of Concrete Structures Combining Smart Piezoelectric Materials and Scanning Laser Doppler Vibrometry. SDHM 2018, 12, 257–279. [Google Scholar]

- Reinhardt, H.W.; Grosse, C.U. Continuous monitoring of setting and hardening of mortar and concrete. Constr. Build. Mater. 2004, 18, 145–154. [Google Scholar] [CrossRef]

- Bhalla, S.; Soh, C.K. Structural health monitoring by piezo-impedance transducers. J. Aerosp. Eng. 2004, 17, 154–165. [Google Scholar] [CrossRef]

- Hyejin, Y.; Kim, J.Y.; Kim, S.H.; Kang, W.J.; Hyun, K.M. Evaluation of Early-Age Concrete Compressive Strength with Ultrasonic Sensors. Sensors 2017, 17, 1817. [Google Scholar]

- Lim, Y.Y.; Tang, Z.S.; Smith, S. Piezoelectric based monitoring of structural adhesives curing: A novel experimental study. Smart Mater. Struct. 2018, 28, 015016. [Google Scholar] [CrossRef]

- Hudson, T.B.; Auwaijan, N.; Yuan, F.G. Guided wave-based system for real-time cure monitoring of composites using piezoelectric discs and phase-shifted fiber Bragg gratings. J. Compos. Mater. 2018, 53, 969–979. [Google Scholar] [CrossRef]

- Tavossi, H.M.; Tittmann, B.R.; Cohen, T.F. Ultrasonic characterization of cement and concrete. In Review of Progress in Quantitative Nondestructive Evolution; Springer Science & Business Media: Berlin, Germany, 1999; pp. 1943–1948. [Google Scholar]

- Marios, S.; Fragkoulis, K. The modified nurse-saul (MNS) maturity function for improved strength estimates at elevated curing temperatures. Case Stud. Constr. Mater. 2018, 9, 2214–5095. [Google Scholar]

- Marcus, P.; Gregorz, F.; Pawel, N.; Tim, R.; Jack, M. Wireless Concrete Strength Monitoring of Wind Turbine Foundations. Sensors 2017, 17, 2928. [Google Scholar]

- Ramachandran, V.S.; James, J.B. Handbook of Analytical Techniques in Concrete Science and Technology; Elsevier: Amsterdam, The Netherlands, 2000; pp. 672–713. [Google Scholar]

- Lee, Y.H.; Oh, T. The Measurement of P-, S-, and R-Wave Velocities to Evaluate the Condition of Reinforced and Prestressed Concrete Slabs. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Hall, K.S. Air-Coupled Ultrasonic Tomographic Imaging of Concrete Element. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, August 2011. [Google Scholar]

- Trtnik, G.; Kavcic, F.; Turk, G. Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics 2008, 49, 53–60. [Google Scholar] [CrossRef] [PubMed]

- Turgut, P. Evaluation of the ultrasonic pulse velocity data coming on the field. In Proceedings of the Fourth International Conference on NDE in Relation to Structural Integrity for Nuclear and Pressurized Components 2004, Session B, London, UK, 6–8 December 2004. [Google Scholar]

- Jian, H.Y.; Yuan, J.-X.; Liu, M.-G. Assessment of pil integrity by low strain stress wave method. HKIE Trans. 1999, 6, 42–49. [Google Scholar]

- David, R. Mechanical Properties of Materials. 2008. Available online: http://web.mit.edu/course/3/3.225/book.pdf (accessed on 21 August 2019).

- Kim, J.W.; Kim, J.K.; Park, S.H.; Oh, T.K. Integrating embedded piezoelectric sensors with continuous wavelet transforms for real-time concrete curing strength monitoring. Struct. Infrastruct. Eng. 2015, 11, 897–903. [Google Scholar] [CrossRef]

- Maeder, M.; Damjanovic, D.; Setter, N. Lead Free Piezoelectric Materials. J. Electroceram. 2004, 13, 385–392. [Google Scholar] [CrossRef]

- Elena, A.; Jacob, L.J. Advances in Lead-Free Piezoelectric Materials for Sensors and Actuators. Sensors 2010, 10, 1935–1954. [Google Scholar]

- Yunzhu, C.; Xingwei, X. Advances in the structural health monitoring of bridges using piezoelectric transducers. Sensors 2018, 12, 4312. [Google Scholar]

- Guoqi, Z.; Di, Z.; Lu, Z.; Ben, W. Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Nondestructive Evaluation with Piezoceramic Transducers and the Time Reversal Method. Sensors 2018, 12, 4176. [Google Scholar]

- Roa, R.G.; Aperador, W.; Delgado, A. Simulation of Non-destructive Testing Methods of Ultrasound in Concrete Columns. Int. J. Electrochem. Sci. 2013, 8, 12226–12237. [Google Scholar]

- Zailin, Y.; Hamada, M.E.; Yao, W. Damage Detection Using Lamb Waves (Review). Adv. Mater. Res. 2014, 1028, 161–166. [Google Scholar]

- Marilyne, P.; Constantinos, S.; Matthieu, G.; Kui, Y. Damage Detection in a Composite T-Joint Using Guided Lamb Waves. Aerospace 2018, 5, 40. [Google Scholar]

- Concrete in Practice. National Ready Mixed Concrete Association. 2018. Available online: https://www.nrmca.org/aboutconcrete/cips/39p.pdf (accessed on 21 August 2019).

- Taylor, P.C. Curing Concrete; CRC Press: Florida, FL, USA, 2013; pp. 2–22. [Google Scholar]

- Brown, T.L.; LeMay, H.E. Chemistry: The Central Science, 4th ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 1988; pp. 494–498. [Google Scholar]

- Rose, K.; Hope, B.B.; Ip, A.K.C. Factors affecting strength and durability of concrete made with various cements. Transp. Res. Rec. 1989, 1234, 13–23. [Google Scholar]

| Materials | Cement | Silica Fume | Silica Powder | Sand | Aggregates | Water | Fiber (Vol %) |

|---|---|---|---|---|---|---|---|

| Quantity | 330 | 0.165 (0.05%) | 2.310 (0.70%) | 873 | 916 | 165 | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tareen, N.; Kim, J.; Kim, W.-K.; Park, S. Comparative Analysis and Strength Estimation of Fresh Concrete Based on Ultrasonic Wave Propagation and Maturity Using Smart Temperature and PZT Sensors. Micromachines 2019, 10, 559. https://doi.org/10.3390/mi10090559

Tareen N, Kim J, Kim W-K, Park S. Comparative Analysis and Strength Estimation of Fresh Concrete Based on Ultrasonic Wave Propagation and Maturity Using Smart Temperature and PZT Sensors. Micromachines. 2019; 10(9):559. https://doi.org/10.3390/mi10090559

Chicago/Turabian StyleTareen, Najeebullah, Junkyeong Kim, Won-Kyu Kim, and Seunghee Park. 2019. "Comparative Analysis and Strength Estimation of Fresh Concrete Based on Ultrasonic Wave Propagation and Maturity Using Smart Temperature and PZT Sensors" Micromachines 10, no. 9: 559. https://doi.org/10.3390/mi10090559

APA StyleTareen, N., Kim, J., Kim, W.-K., & Park, S. (2019). Comparative Analysis and Strength Estimation of Fresh Concrete Based on Ultrasonic Wave Propagation and Maturity Using Smart Temperature and PZT Sensors. Micromachines, 10(9), 559. https://doi.org/10.3390/mi10090559