The Hybrid Fabrication Process of Metal/Silicon Composite Structure for MEMS S&A Device

Abstract

1. Introduction

2. The Hybrid Process

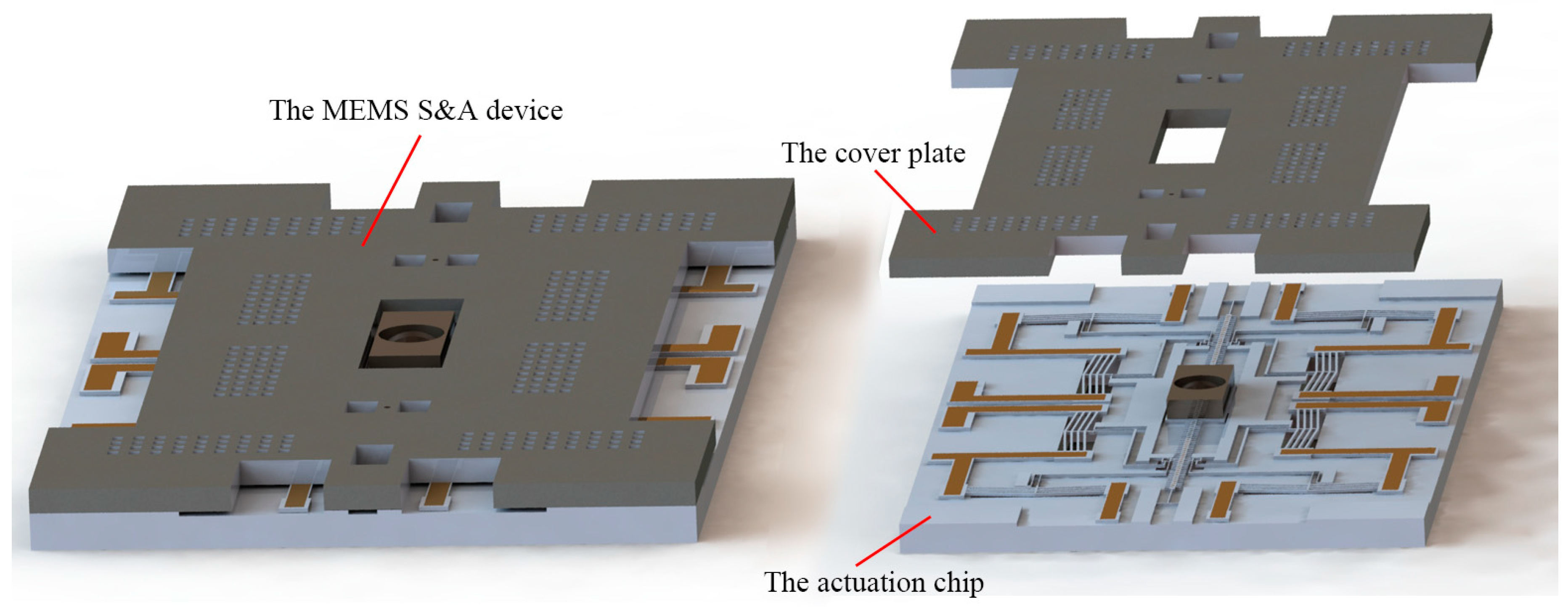

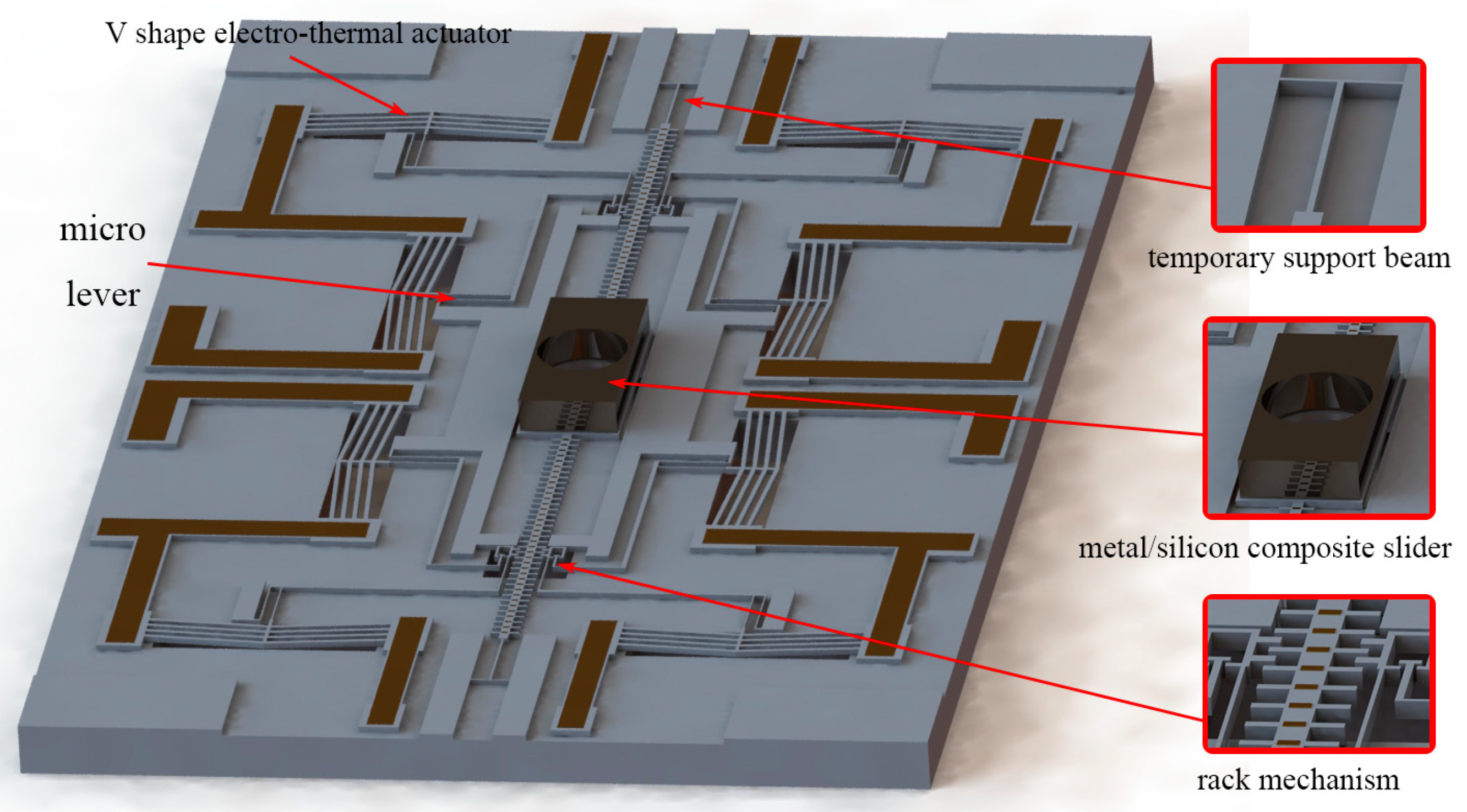

2.1. The Basic Structure of a MEMS S&A Device

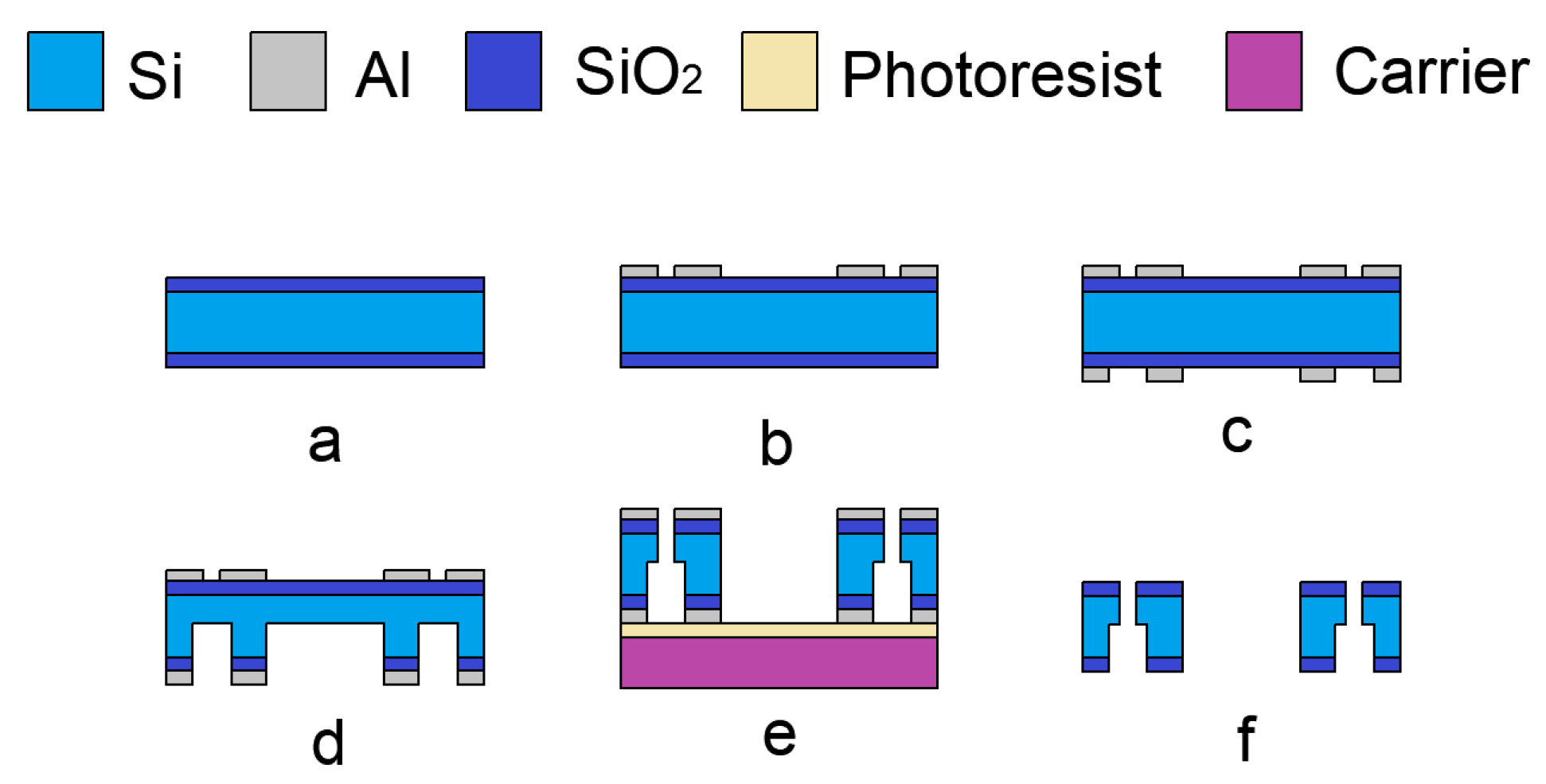

2.2. The Fabrication Flow

2.2.1. The Cover Plate

2.2.2. The Actuation Chip

3. Experimental Results and Discussion

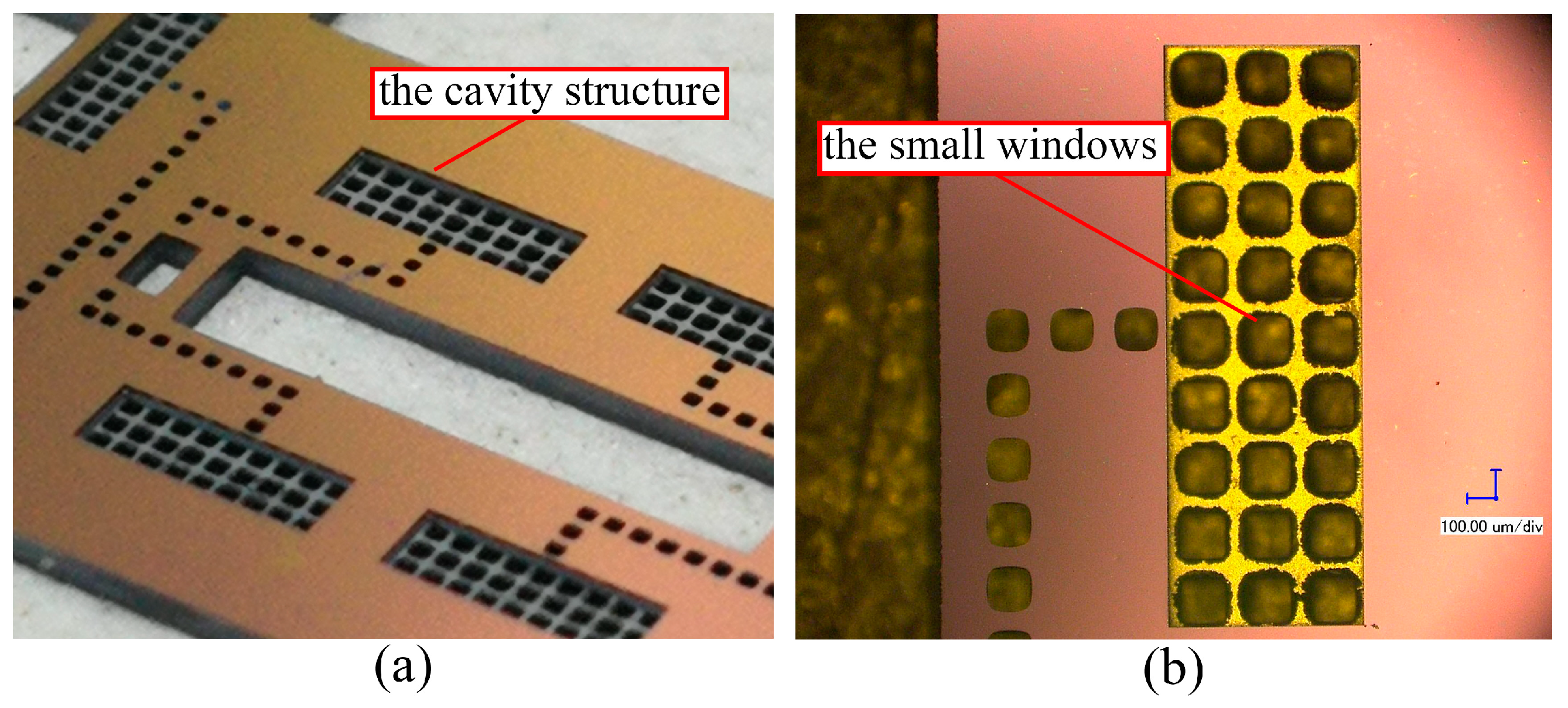

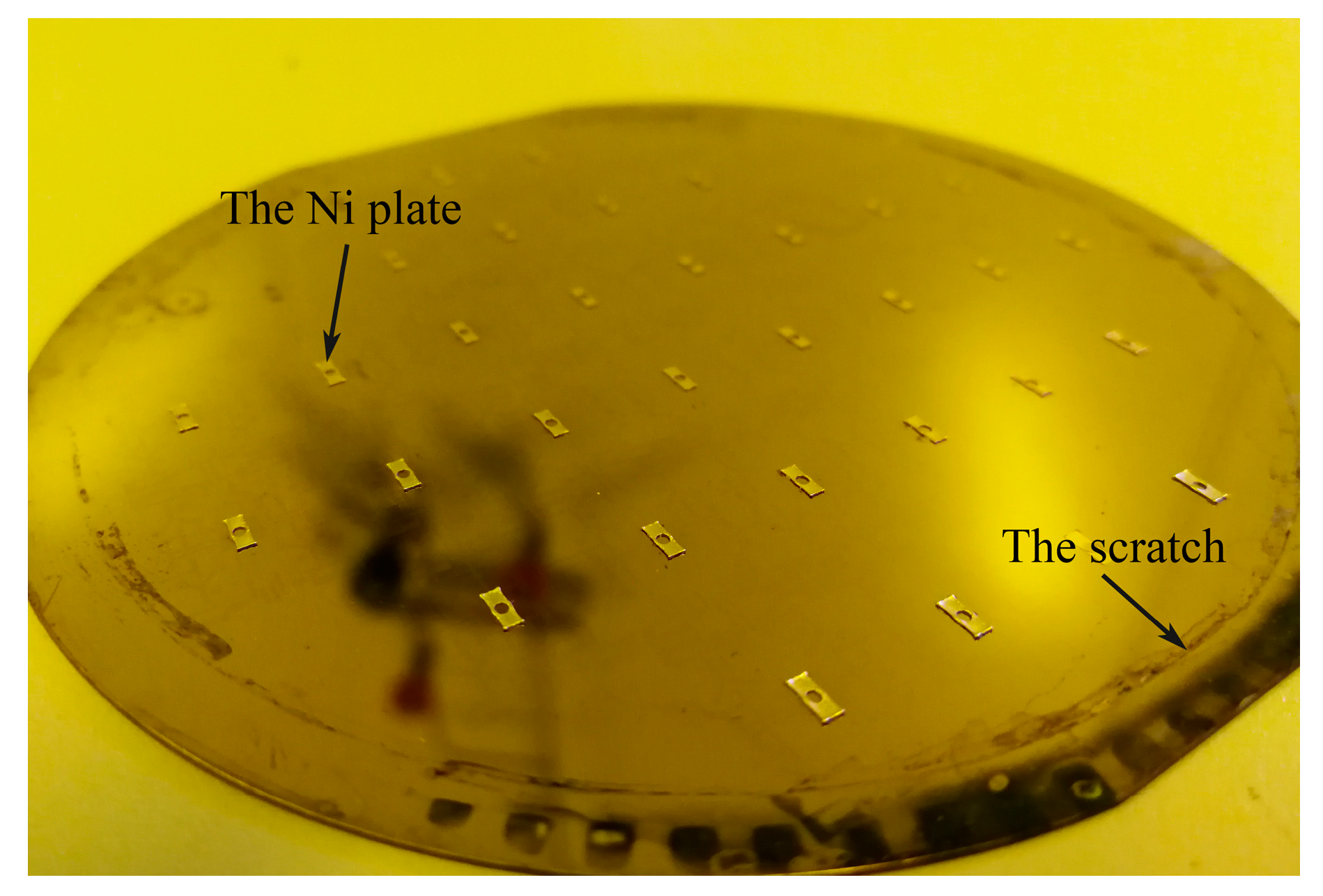

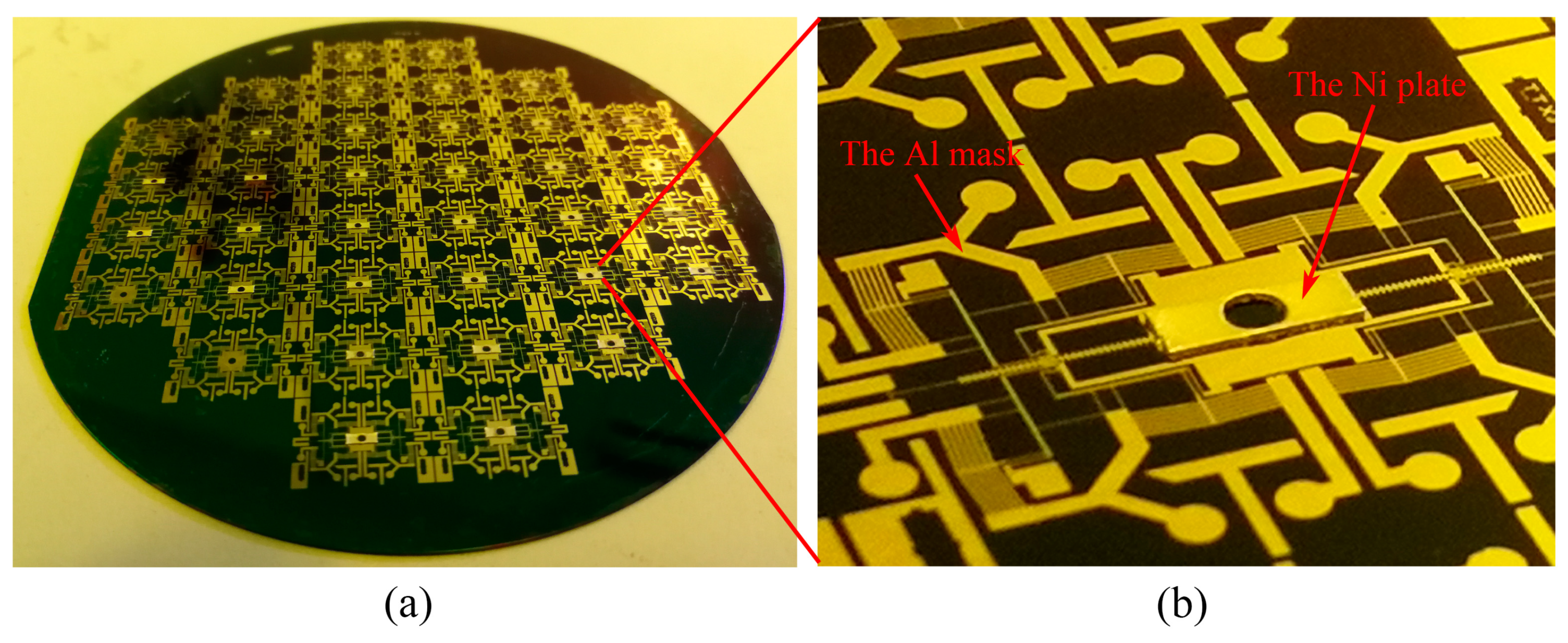

3.1. The Fabrication Result of the Cover Plate

3.2. The Fabrication Result of the Actuation Chip

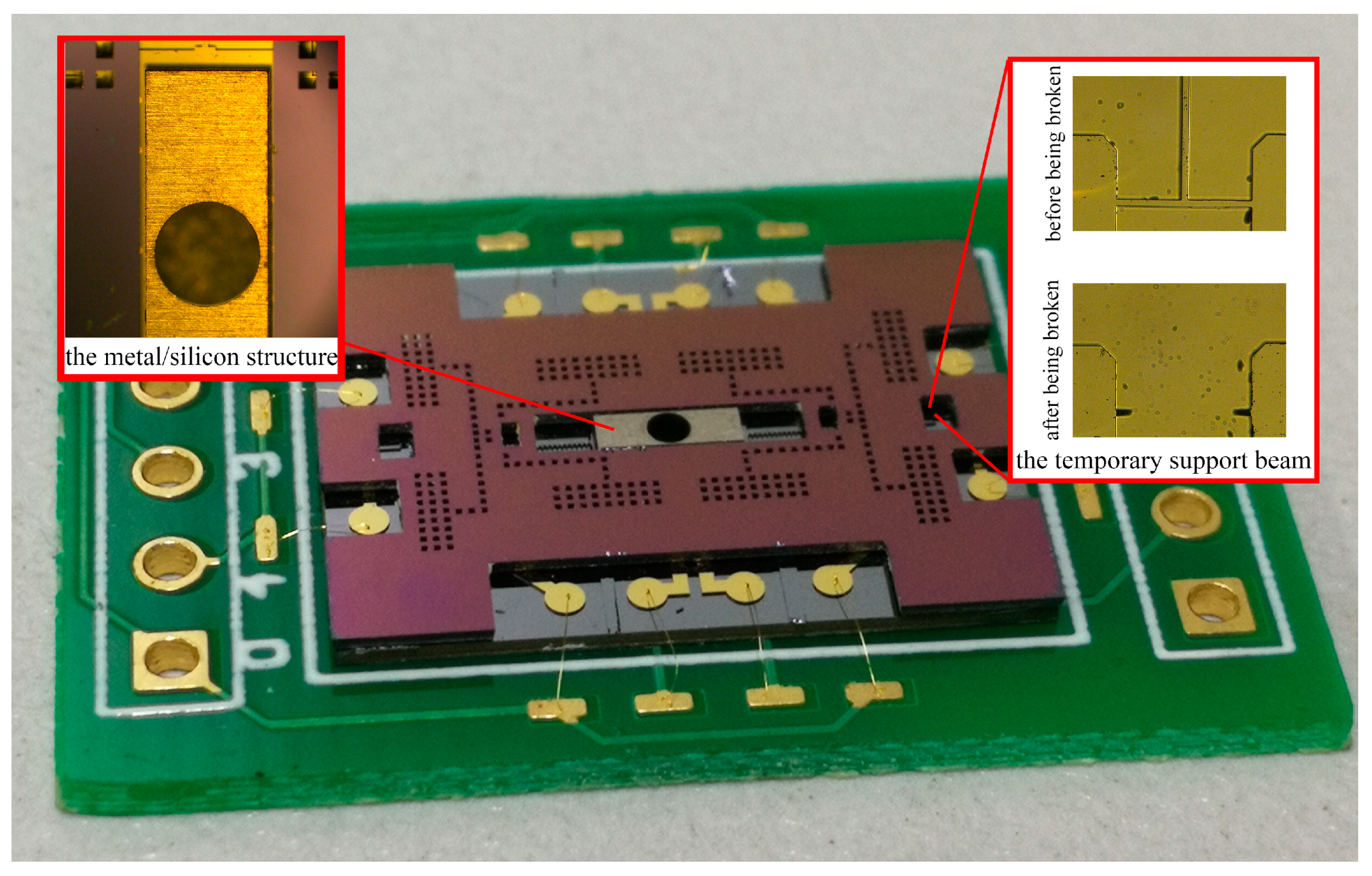

3.2.1. The Process of High Precision Metal/Silicon Structure

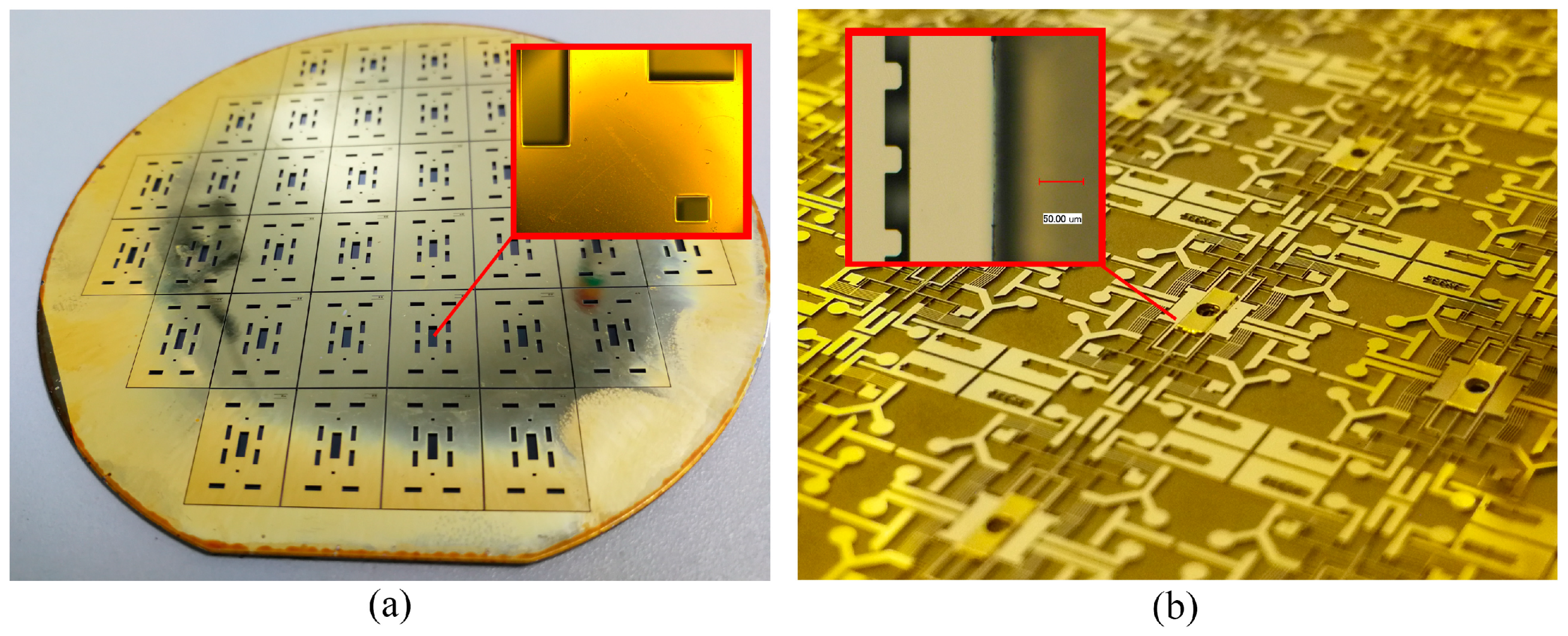

3.2.2. The Process of ICP Etching

3.2.3. The Process of Releasing

4. The Characterization of the MEMS S&A Device

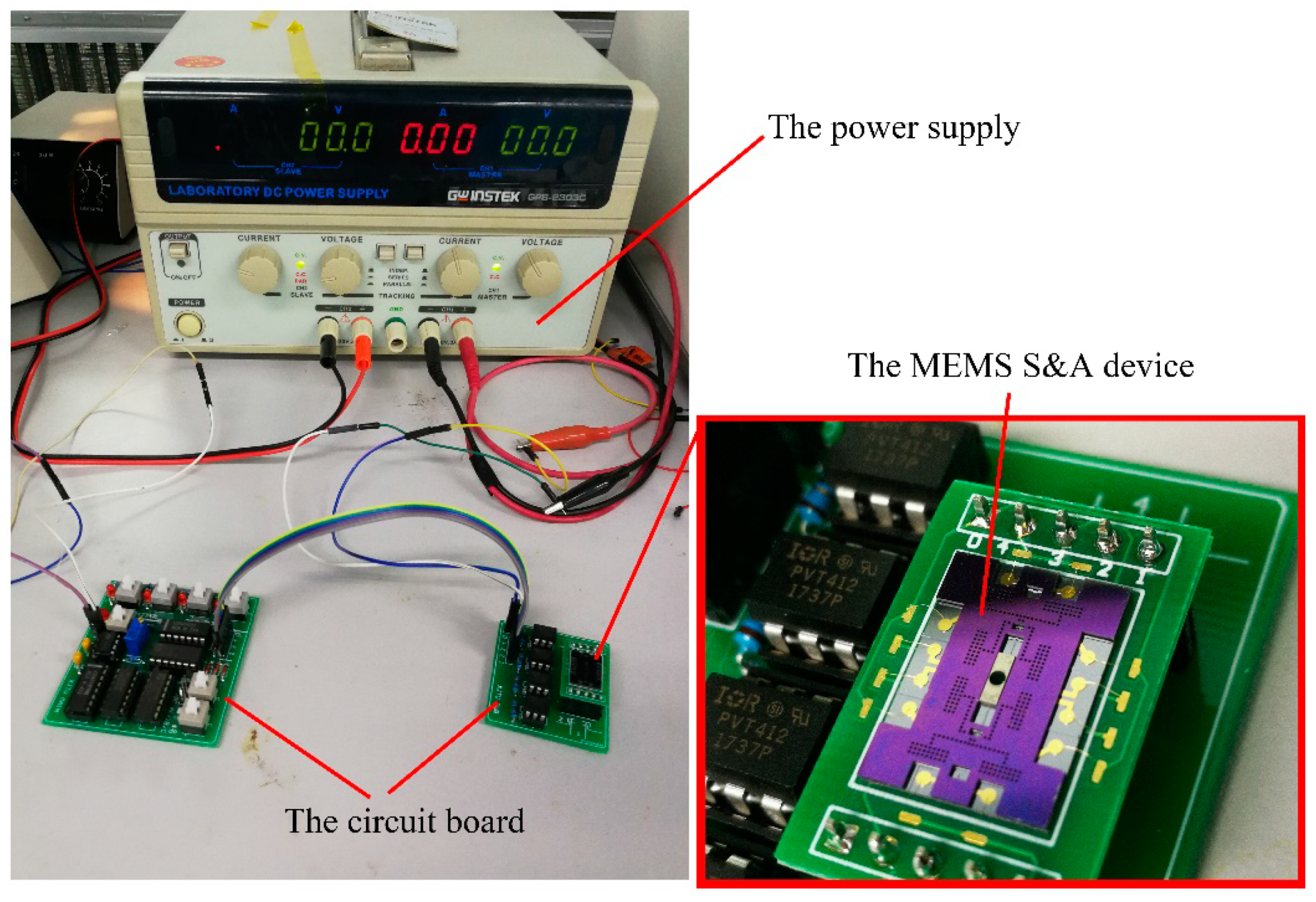

4.1. The Test Platform

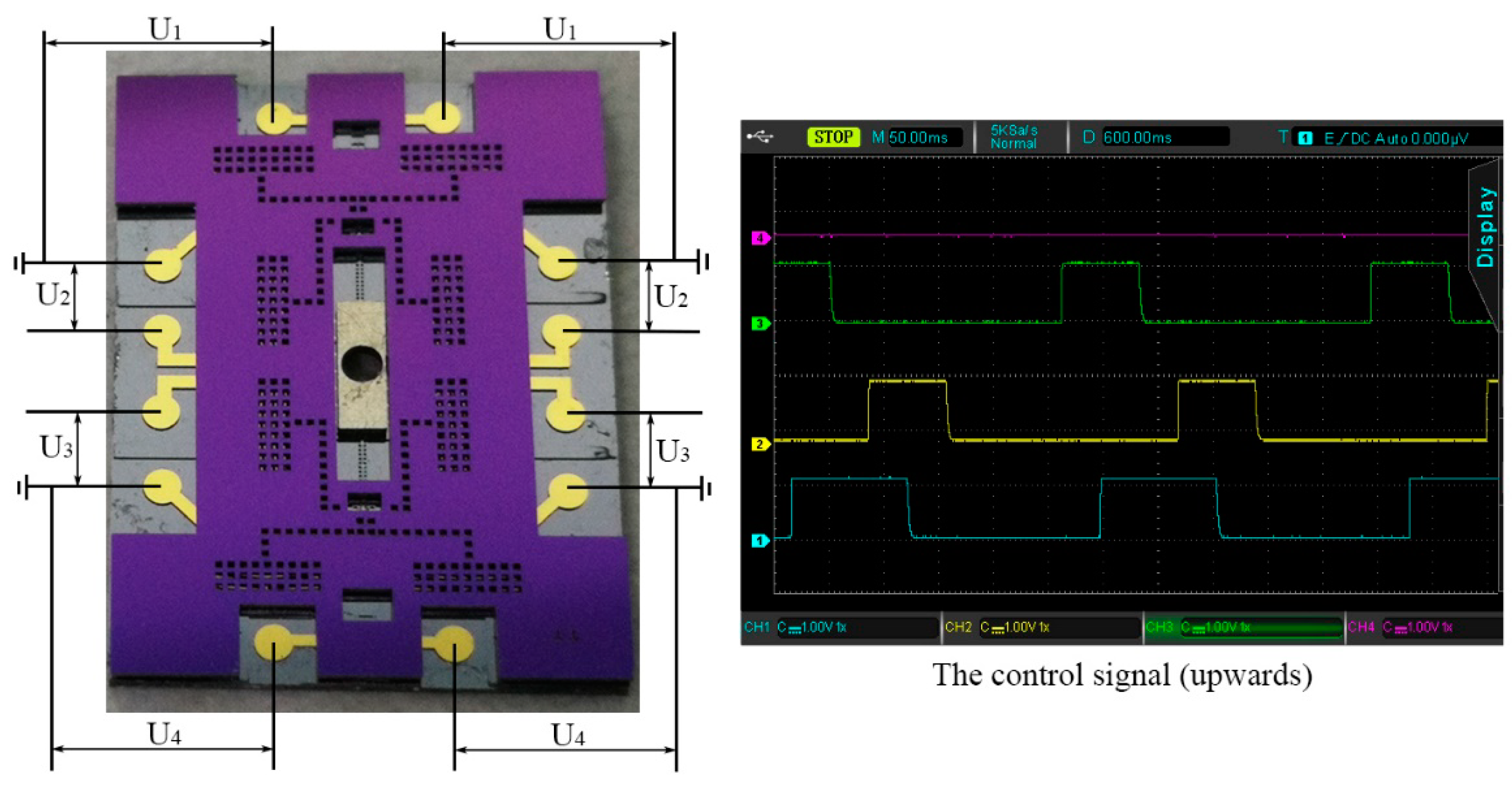

4.2. The Control Signal

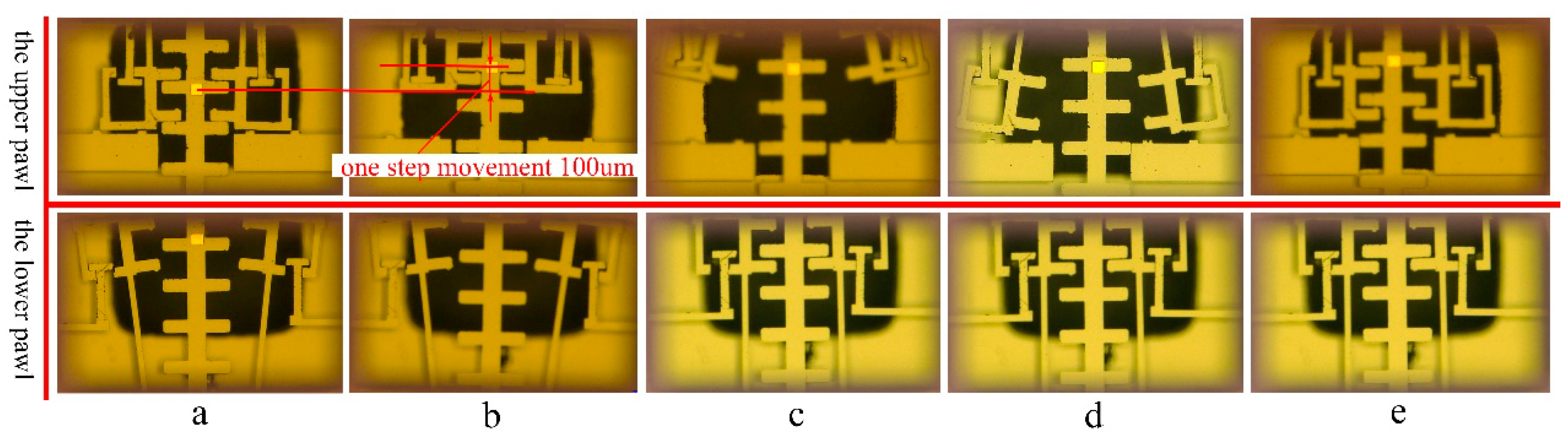

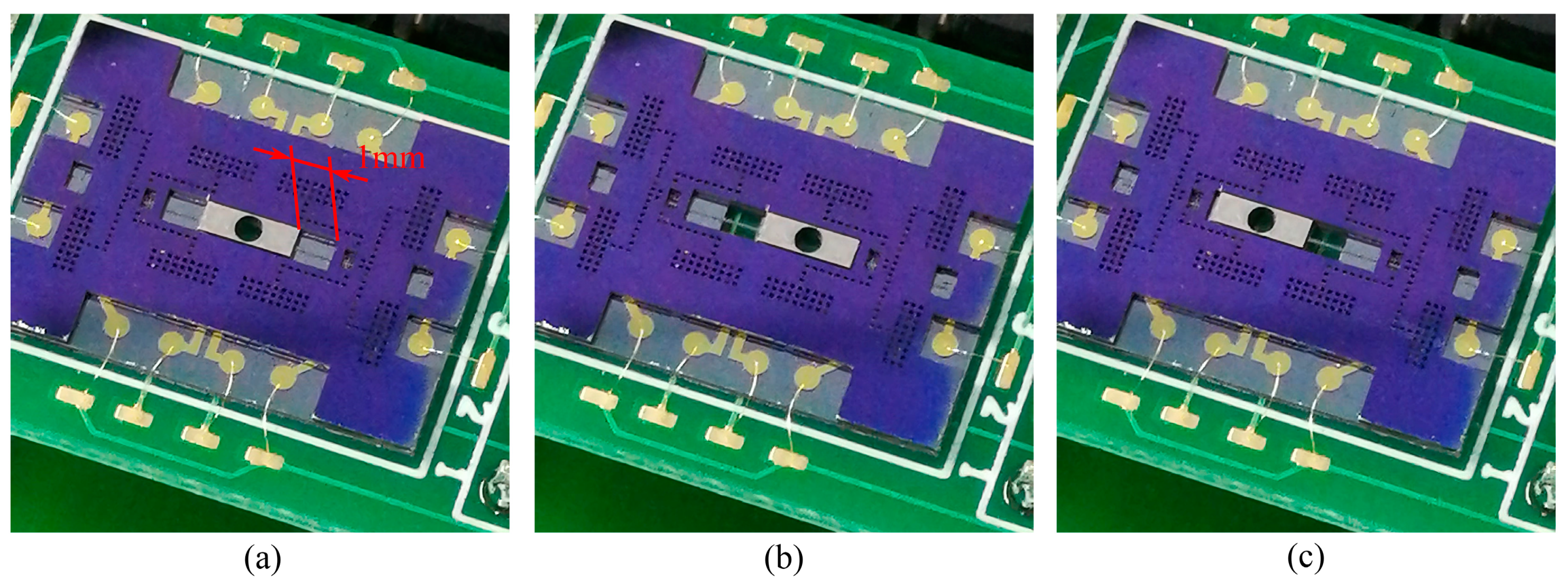

4.3. The Moving Tests

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pezous, H.; Rossi, C.; Sanchez, M.; Mathieu, F.; Dollat, X.; Charlot, S.; Salvagnac, L.; Conédéra, V. Integration of a MEMS based safe arm and fire device. Sens. Actuat. A Phys. 2010, 159, 157–167. [Google Scholar] [CrossRef]

- Zunino III, J.L.; Skelton, D.R.; Robinson, C. Reliability testing and analysis of safing and arming devices for army fuzes. Proc. SPIE 2008, 6884, 0C1–0C12. [Google Scholar]

- Du, L.; Jia, S.; Nie, W.; Wang, Q. Fabrication of Fuze Micro-electro-mechanical System Safety Device. Chin. J. Mechan. Eng. 2011, 5, 836–841. [Google Scholar] [CrossRef]

- Zhang, J.; Li, D. Failure analysis of set-back arming process of MEMS S&A device. Sens. Transd. 2014, 166, 66–72. [Google Scholar]

- Tu, H.; Lou, W.; Sun, Z.; Qian, Y. Structural reliability simulation for the latching mechanism in MEMS-based Safety and Arming device. Adv. Eng. Softw. 2017, 108, 48–56. [Google Scholar] [CrossRef]

- Seok, J.O.; Jeong, J.; Eom, J.; Lee, S.S.; Lee, C.J.; Ryu, S.M.; Oh, J.S. Ball driven type MEMS SAD for artillery fuse. J. Micromechan. Microeng. 2016, 27, 015032. [Google Scholar] [CrossRef]

- Robinson, C.H.; Wood, R.H.; Hoang, T.Q. Miniature MEMS-based Electromechanical Safety and Arming Device. US Patent No. 6964231, 15 November 2005. [Google Scholar]

- Jeong, J.H.; Eom, J.; Lee, S.S.; Lim, D.W.; Jang, Y.I.; Seo, K.W.; Choi, S.S.; Lee, C.J.; Oh, J.S. Miniature mechanical safety and arming device with runaway escapement arming delay mechanism for artillery fuze. Sens. Actuat. A Phys. 2018, 279, 518–524. [Google Scholar] [CrossRef]

- Mink, S.S. Microelectromechanical system (MEMS) interrupter for safe and arm devices. Dissertation, Air Force Institute of Technology, Dayton, OH, USA, 2006. [Google Scholar]

- Lake, R.A.; Starman, L.V.A.; Coutu, R.A. Electrothermal Actuators for Integrated MEMS Safe and Arming Devices. In Proceedings of the SEM Annual Conference, Indianapolis, IN, USA, June 7–10 2010. [Google Scholar]

- Ostrow, S.A.; Lake, R.A.; Lombardi III, J.P.; Coutu, R.A., Jr.; Starman, R.A. Fabrication Process Comparison and Dynamics Evaluation of Electrothermal Actuators for a Prototype MEMS Safe and Arming Devices. Experiment. Mechan. 2012, 52, 1229–1238. [Google Scholar] [CrossRef]

- Hu, T.; Zhao, Y.; Zhao, Y.; Ren, W. Integration design of a MEMS based fuze. Sens. Actuat. A Phys. 2017, 268, 193–200. [Google Scholar] [CrossRef]

- Kim, B.H.; Kim, J.B. Fabrication of a high aspect ratio thick silicon wafer mold and electroplating using flipchip bonding for MEMS applications. J. Micromechan. Microeng. 2009, 19, 065024. [Google Scholar] [CrossRef]

- Yang, Z.C.; Wei, Y.M.; Mao, X.; Yan, G.Z. A single-mask dry-release process for fabrication of high aspect ratio SOI MEMS devices. Sci. China Technol. Sci. 2013, 56, 387–391. [Google Scholar] [CrossRef]

- Xie, J.B.; Yuan, W.Z.; Chang, H.L. Design and Fabrication of MEMS Gyroscopes on the Silicon-on-insulator Substrate with Decoupled Oscillation Modes. Chin. J. Mechan. Eng. 2010, 23, 16–20. [Google Scholar] [CrossRef]

- Milanovic, V. Multilevel beam SOI-MEMS fabrication and applications. J. Microelectromechan. Syst. 2004, 13, 19–30. [Google Scholar] [CrossRef]

- Feng, H.; Lou, W.; Wang, D.; Zheng, F. Explosion Suppression Mechanism Characteristics of MEMS S&A Device With In Situ Synthetic Primer. Micromachines 2018, 9, 652. [Google Scholar]

- Hu, T.; Fang, K.; Zhang, Z.; Jiang, X.; Zhao, Y. Design and research on large displacement bidirectional MEMS stage with interlock mechanism. Sens. Actuat. A Phys. 2018, 283, 26–33. [Google Scholar] [CrossRef]

- Samuelson, S.R.; Xie, H. A Large Piston Displacement MEMS Mirror with Electrothermal Ladder Actuator Arrays for Ultra-Low Tilt Applications. J. Microelectromechan. Syst. 2014, 23, 39–49. [Google Scholar] [CrossRef]

- Williams, K.R.; Muller, R.S. Etch rates for micromachining processing. J. Microelectromechan. Syst. 1996, 5, 256–269. [Google Scholar] [CrossRef]

- Williams, K.R.; Gupta, K.; Wasilik, M. Etch rates for micromachining processing-Part II. J. Microelectromechan. Syst. 2003, 12, 761–778. [Google Scholar] [CrossRef]

- Hwang, I.H.; Lee, Y.G.; Lee, J.H. A micromachined friction meter for silicon sidewalls with consideration of contact surface shape. J. Micromechan. Microeng. 2006, 16, 2475–2481. [Google Scholar] [CrossRef]

- Lumbantobing, A.; Komvopoulos, K. Static friction in polysilicon surface micromachines. J. Microelectromechan. Syst. 2005, 14, 651–663. [Google Scholar] [CrossRef]

- Noguchi, K.; Fujita, H.; Suzuki, M.; Yoshimura, N. The measurements of friction on micromechatronics elements. In Proceedings of the IEEE Micro Electro Mechanical Systems, Nara, Japan, 30 December 1990–2 January 1991; pp. 148–153. [Google Scholar]

- Wang, W.; Wang, Y.; Bao, H.; Xiong, B.; Bao, M. Friction and wear properties in MEMS. Sens. Actuat. A Phys. 2002, 97, 486–491. [Google Scholar] [CrossRef]

| Item | Paramter |

|---|---|

| Power | 100 W |

| SiH4 | 200 sccm |

| N2O | 140 sccm |

| N2 | 140 sccm |

| Temperature | 350 °C |

| Time | 60 s |

| Item | Parameter | |

|---|---|---|

| Diameter | 100 mm | |

| Orientation | (100) | |

| Resistivity | Device layer | 0.01–0.02 Ω·cm |

| Handle layer | 1–20 Ω·cm | |

| Thickness | Device layer | 50 μm |

| Buried oxide layer | 3 μm | |

| Handle layer | 400 μm | |

| Material | Coating | Soft Bake | Expose | Post Bake | Develop | Hard Bake |

|---|---|---|---|---|---|---|

| Dry film SAF 2100 | Laminated three times | 65 °C 8 min | MA6 9.2 mW/cm2 6 s | 95 °C 55 s | NaCO3 2 wt% 6 min | 100 °C 2 min |

| PDMS | 500 rpm, 9 s 2000 rpm, 30 s | 80 °C 15 min | - | - | - | - |

| AZ 4620 (spray) | 500 rpm, 30 s | 85 °C 15 min | - | - | - | - |

| Item | Parameter |

|---|---|

| Ni(NH2SO3)2·4H2O | 550 g/L |

| NiCl2 | 10 g/L |

| H3BO3 | 35 g/L |

| Wetting agent | 0.15 g/L |

| PH | 3.9 |

| Current | 0.127 A |

| Temperature | 50 °C |

| Time | 20 h |

| Item | Parameter |

|---|---|

| Frequency | 300 kHz |

| Power | 1.8 W |

| Platform speed | 800 mm/s |

| Time delay of opening | 120 μs |

| Time delay of closing | 70 μs |

| Time delay of ending | 10 μs |

| Cycle | 30 |

| Object | Max | Min | Deviation |

|---|---|---|---|

| 0.075 mm | 0.0856 mm | 0.0751 mm | 0.0105 mm |

| ϕ 0.85 mm | 0.8546 mm | 0.8458 mm | 0.0088 mm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, T.; Fang, K.; Zhang, Z.; Jiang, X.; Zhao, Y. The Hybrid Fabrication Process of Metal/Silicon Composite Structure for MEMS S&A Device. Micromachines 2019, 10, 469. https://doi.org/10.3390/mi10070469

Hu T, Fang K, Zhang Z, Jiang X, Zhao Y. The Hybrid Fabrication Process of Metal/Silicon Composite Structure for MEMS S&A Device. Micromachines. 2019; 10(7):469. https://doi.org/10.3390/mi10070469

Chicago/Turabian StyleHu, Tengjiang, Kuang Fang, Zhiming Zhang, Xiaohua Jiang, and Yulong Zhao. 2019. "The Hybrid Fabrication Process of Metal/Silicon Composite Structure for MEMS S&A Device" Micromachines 10, no. 7: 469. https://doi.org/10.3390/mi10070469

APA StyleHu, T., Fang, K., Zhang, Z., Jiang, X., & Zhao, Y. (2019). The Hybrid Fabrication Process of Metal/Silicon Composite Structure for MEMS S&A Device. Micromachines, 10(7), 469. https://doi.org/10.3390/mi10070469