Analysis of the Downscaling Effect and Definition of the Process Fingerprints in Micro Injection of Spiral Geometries

Abstract

:1. Introduction

2. Materials and Methods

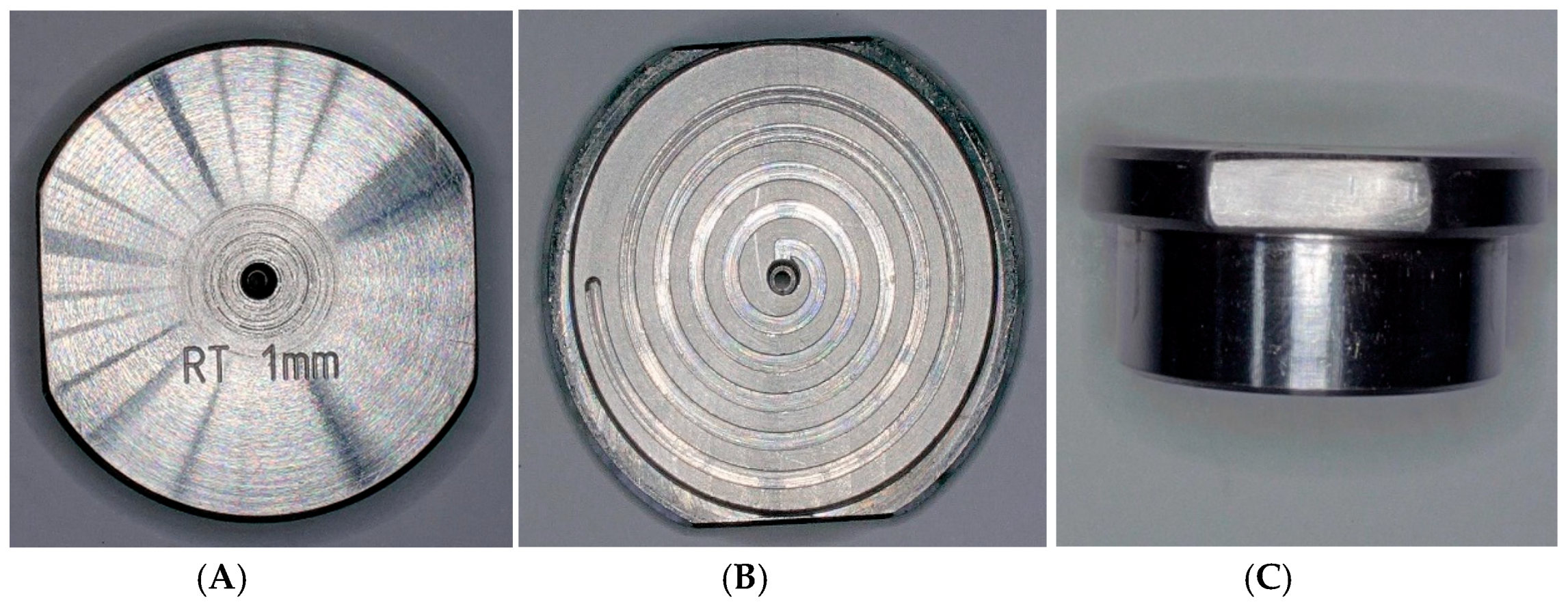

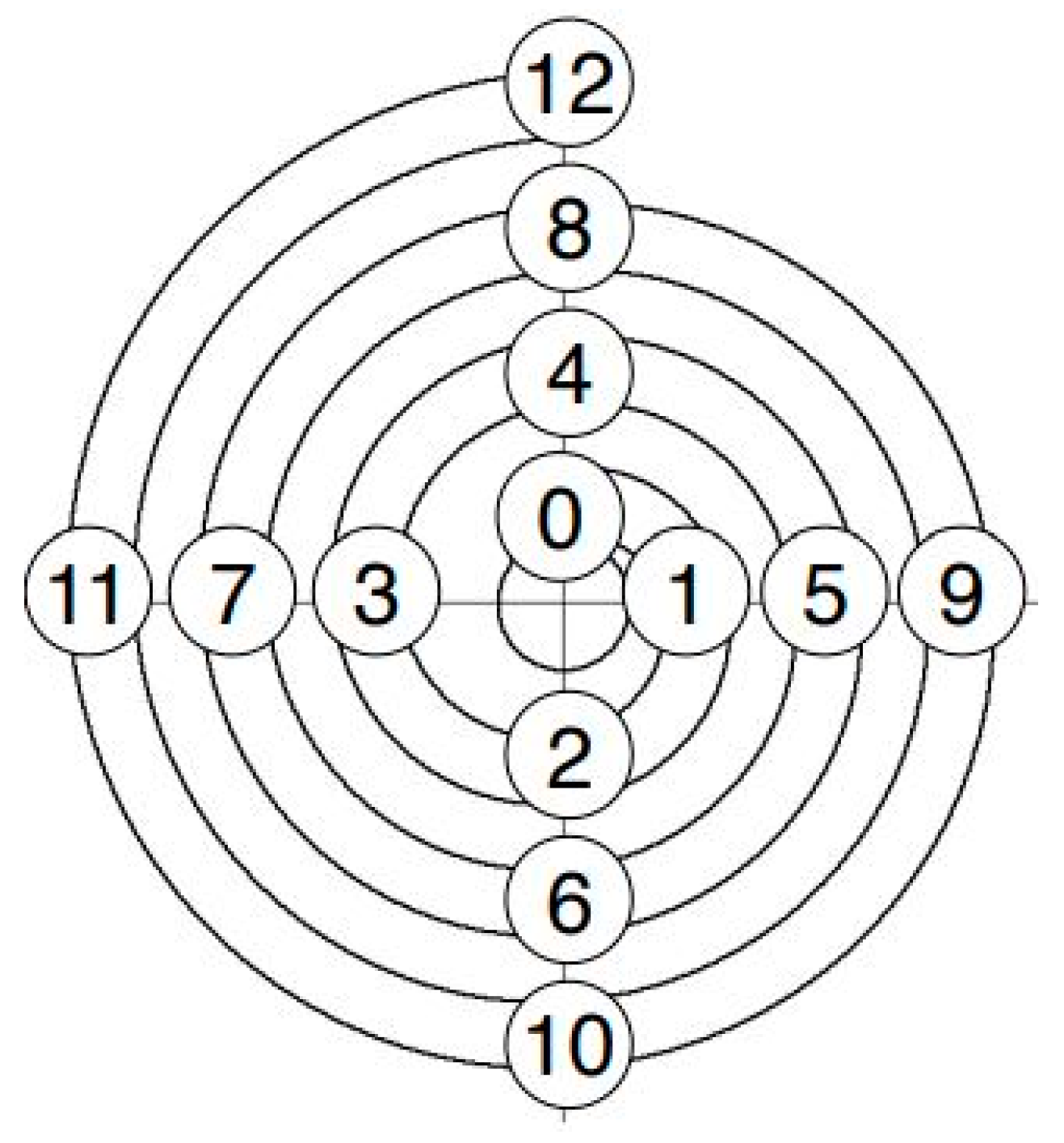

2.1. Spiral Geometry

2.2. Measurement Method

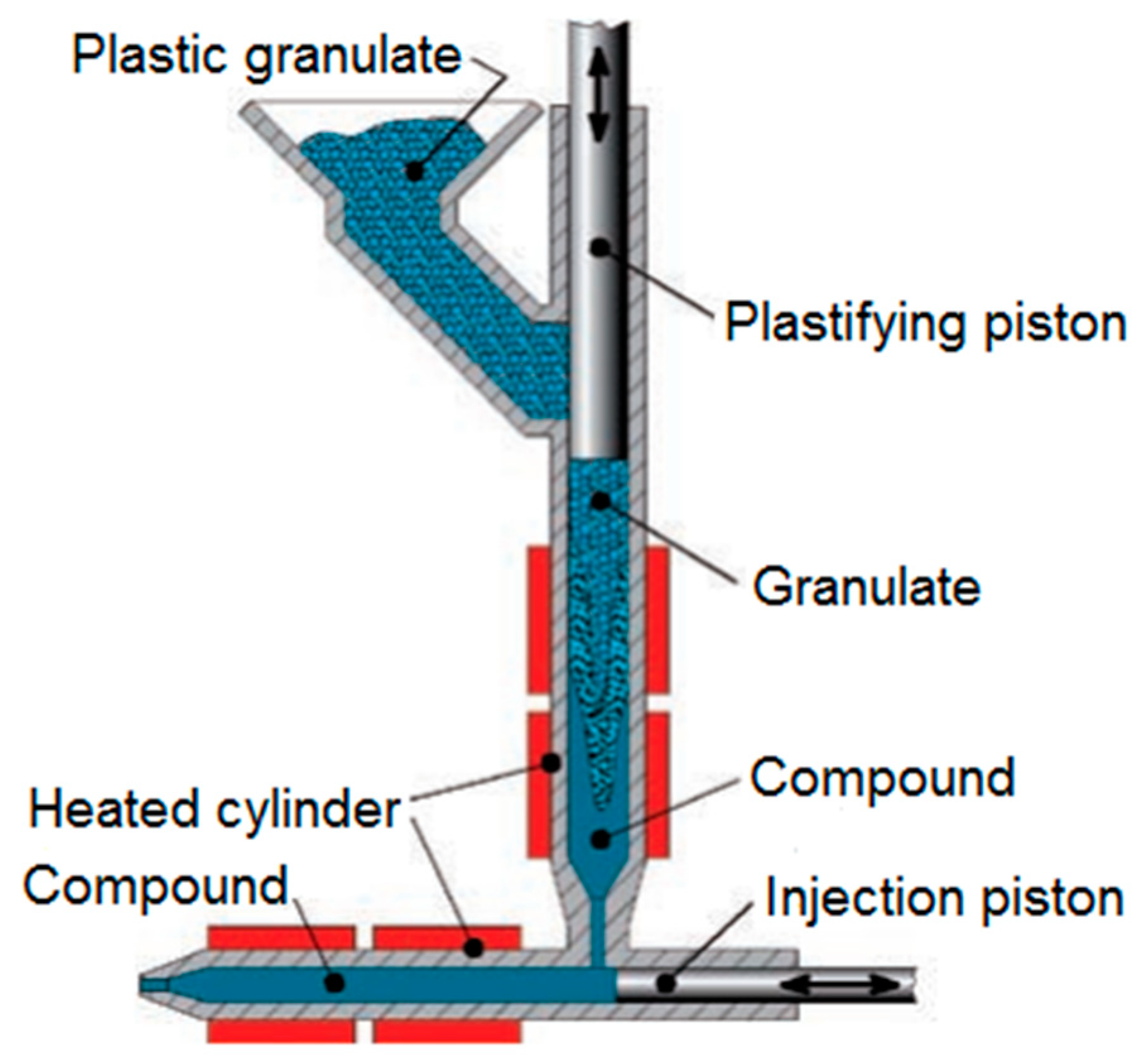

2.3. Microinjection Moulding Machine

2.4. Polymeric Material

2.5. Design of Experiments (DoE)

2.6. Process Monitoring

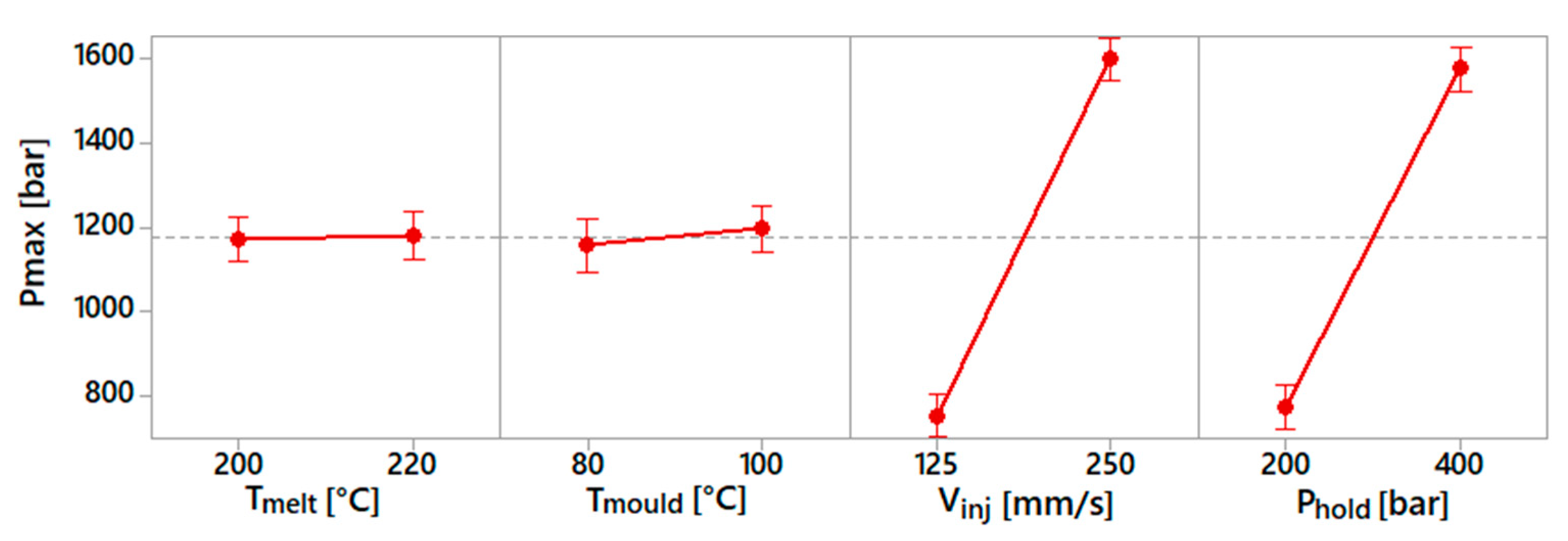

- Maximum injection pressure, Pmax: this value is defined as the maximum injection pressure recorded during each moulding cycle. This indicator is related to the filling behaviour of the cavity, since the pressure peak is increased by the small size of the channels.

- Mean injection pressure, Pmean: this quantity is calculated as the average of the pressure values recorded from the start to the end of the moulding cycle.

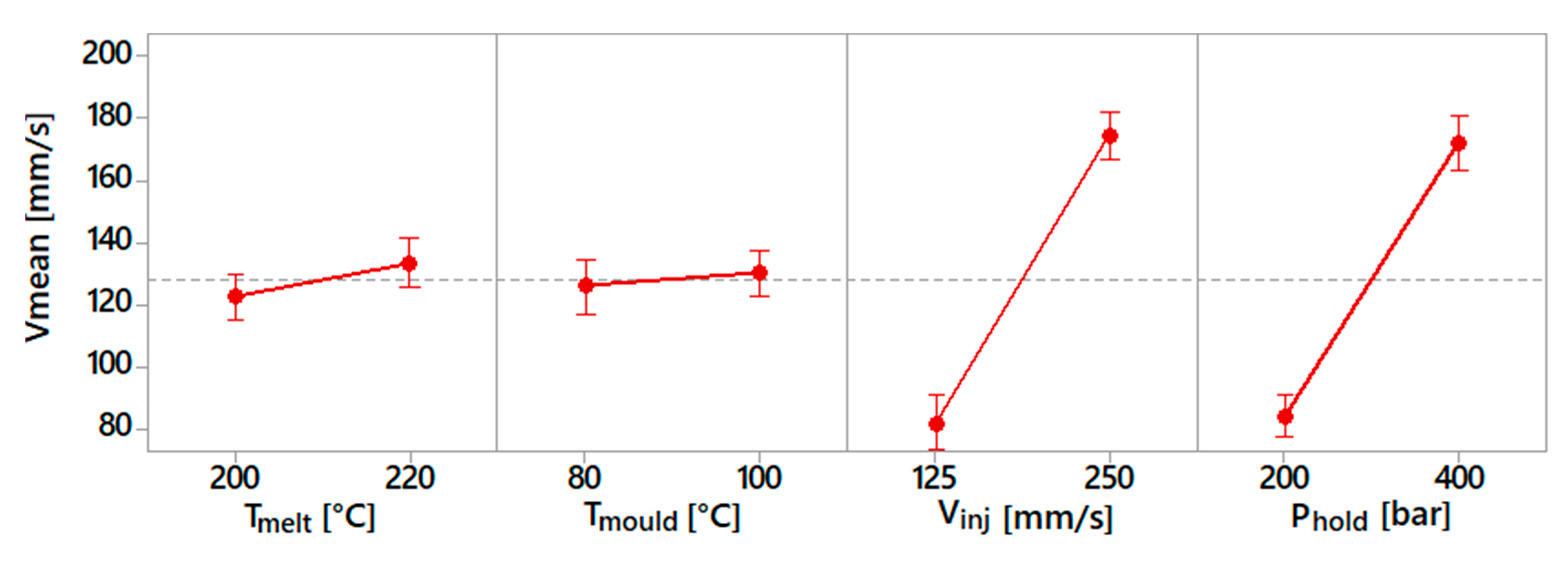

- Mean injection speed, Vmean: the mean injection speed is defined as the average velocity that characterises the filling phase. The speed values are recorded in the time interval between the start of the acceleration of the injection plunger and when it stops at the switch-over point.

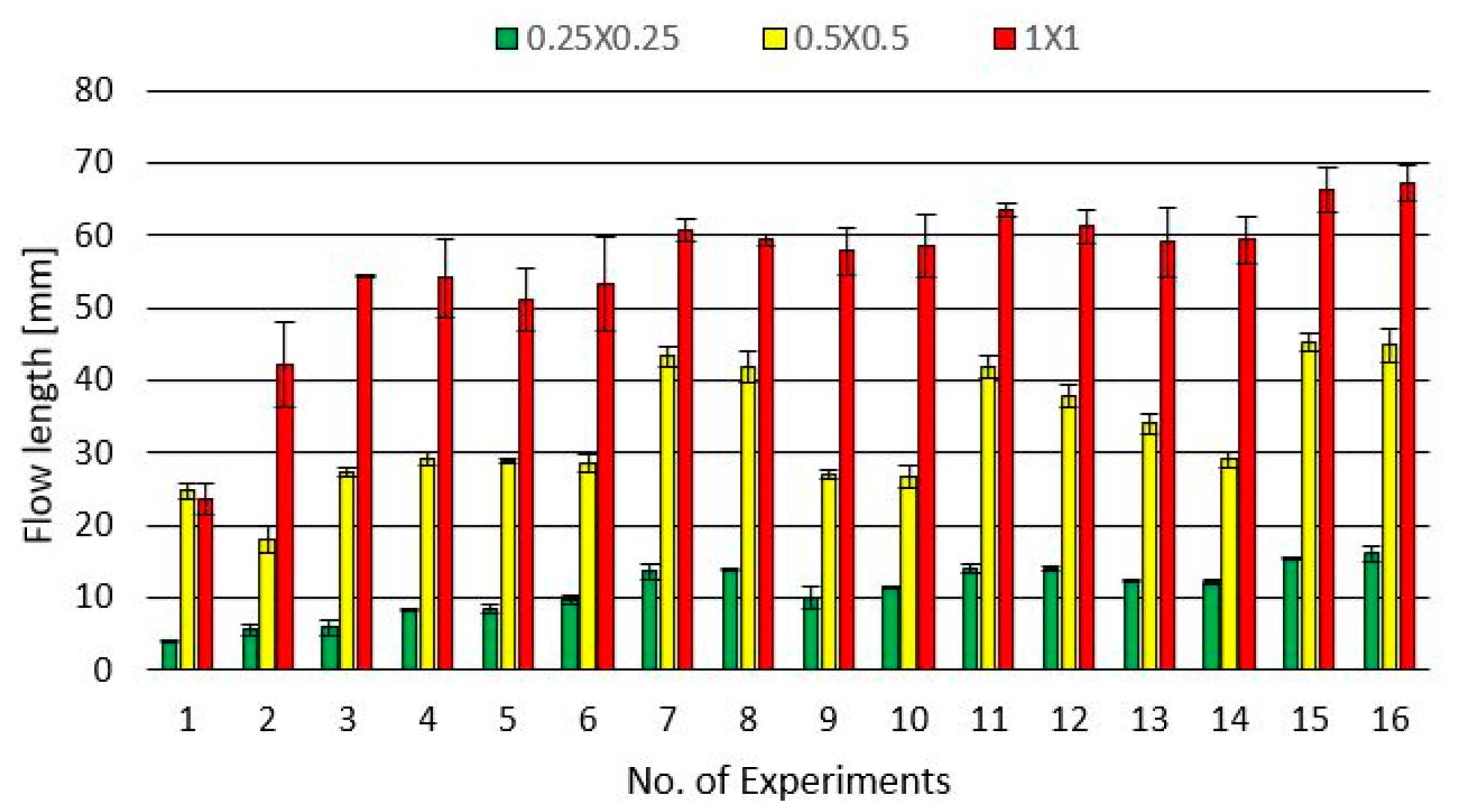

3. Results and Discussion

3.1. Achievable Flow Length

3.2. Process Fingerprint Analysis

3.3. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tosello, G. Micromanufacturing Engineering and Technology; Qin, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 201–238. [Google Scholar]

- Giboz, J.; Copponnex, T.; Mélé, P. Microinjection molding of thermoplastic polymers: A review. J. Micromech. Microeng. 2007, 17, R96–R109. [Google Scholar] [CrossRef]

- Whiteside, B.; Martyn, M.T.; Coates, P.D.; Greenway, G.; Allen, P.S.; Hornsby, P. Micromoulding: Process measurements, product morphology and properties. Plast. Rubber Compos. 2004, 33, 11–17. [Google Scholar] [CrossRef]

- Brousseau, E.B.; Dimov, S.; Pham, D.T. Some Recent Advances in Multi-Material Micro- And Nano-Manufacturing. Int. J. Adv. Manuf. Technol. 2010, 47, 161–180. [Google Scholar] [CrossRef]

- Lucchetta, G.; Ferraris, E.; Tristo, G.; Reynaerts, D. Influence of mould thermal properties on the replication of micro parts via injection moulding. Procedia CIRP 2012, 2, 113–117. [Google Scholar] [CrossRef]

- Meister, S.; Dietmar, D. Investigation on the Achievable Flow Length in Injection Moulding of Polymeric Materials with Dynamic Mould Tempering. Sci. World J. 2013, 3. [Google Scholar] [CrossRef]

- Sha, B.; Dimov, S.; Griffiths, C.; Packianather, M.S. Micro-injection moulding: Factors affecting the achievable aspect ratios. Int. J. Adv. Manuf. Technol. 2007, 33, 147–156. [Google Scholar] [CrossRef]

- Chen, Z.; Turng, L.S. A review of current developments in process and quality control for injection molding. Adv. Polym. Technol. 2005, 24, 165–182. [Google Scholar] [CrossRef]

- Michaeli, W.; Schreiber, A. Online control of the injection molding process based on process variables. Adv. Polym. Technol. 2009, 28, 65–76. [Google Scholar] [CrossRef]

- Speranza, V.; Vietri, U.; Pantani, R. Monitoring of injection moulding of thermoplastics: Adopting pressure transducers to estimate the solidification history and the shrinkage of moulded parts. Strojniški Vestnik J. Mech. Eng. 2013, 59, 677–682. [Google Scholar] [CrossRef]

- Tsai, K.-M.; Lan, J.-K. Correlation between runner pressure and cavity pressure within injection mold. Int. J. Adv. Manuf. Technol. 2015, 79, 14–23. [Google Scholar] [CrossRef]

- Mendibil, X.; Llanos, I.; Urreta, H.; Quintana, I. In process quality control on micro-injection moulding: The role of sensor location. Int. J. Adv. Manuf. Technol. 2017, 89, 3429–3438. [Google Scholar] [CrossRef]

- Griffiths, C.A.; Dimov, S.; Scholz, S.G.; Hirshy, H.; Tosello, G. Process Factors Influence on Cavity Pressure Behavior in Microinjection Moulding. J. Manuf. Sci. Eng. 2011, 133. [Google Scholar] [CrossRef]

- Griffiths, C.A.; Dimov, S.S.; Scholz, S.G.; Tosello, G.; Rees, A. Influence of Injection and Cavity Pressure on the Demoulding Force in Micro-Injection Moulding. J. Manuf. Sci. Eng. 2014, 136. [Google Scholar] [CrossRef]

- Griffiths, C.A.; Dimov, S.S.; Brousseau, E.B. Microinjection moulding: The influence of runner systems on flow behaviour and melt fill of multiple microcavities. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2008, 222, 1119–1130. [Google Scholar] [CrossRef]

- Desma Tec. Formicaplast—Micro Injection for the Smallest Shot Weights (100—200 mg). Available online: http://www.formicaplast.de/en/index.php (accessed on 21 May 2019).

| Quadrant | Radius (mm) | Max. Flow Length (mm) |

|---|---|---|

| 0 | 1.5 | 1.5 |

| 1 | 2 | 4.63 |

| 2 | 2.5 | 8.55 |

| 3 | 3 | 13.25 |

| 4 | 3.5 | 18.75 |

| Property | Test Method | Units | Value |

|---|---|---|---|

| Density | ISO 1183 | kg/m3 | 1400 |

| Melt volume rate (190 °C, 2.16 kg) | ISO 1133 | cm3/10 min | 7.5 |

| Melt temperature | ISO 11357-1/-3 | °C | 167 |

| Process Parameter | Low | High |

|---|---|---|

| Vinj (mm/s) | 125 | 250 |

| Tmelt (°C) | 200 | 220 |

| Tmould (°C) | 80 | 100 |

| Phold (bar) | 200 | 400 |

| Experiment | Tmelt (°C) | Tmould (°C) | Vinj (mm/s) | Phold (bar) |

|---|---|---|---|---|

| 1 | 200 | 80 | 125 | 400 |

| 2 | 200 | 80 | 125 | 200 |

| 3 | 200 | 80 | 250 | 400 |

| 4 | 200 | 80 | 250 | 200 |

| 5 | 200 | 100 | 125 | 400 |

| 6 | 200 | 100 | 125 | 200 |

| 7 | 200 | 100 | 250 | 400 |

| 8 | 200 | 100 | 250 | 200 |

| 9 | 220 | 80 | 125 | 400 |

| 10 | 220 | 80 | 125 | 200 |

| 11 | 220 | 80 | 250 | 400 |

| 12 | 220 | 80 | 250 | 200 |

| 13 | 220 | 100 | 125 | 400 |

| 14 | 220 | 100 | 125 | 200 |

| 15 | 220 | 100 | 250 | 400 |

| 16 | 220 | 100 | 250 | 200 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luca, A.; Riemer, O. Analysis of the Downscaling Effect and Definition of the Process Fingerprints in Micro Injection of Spiral Geometries. Micromachines 2019, 10, 335. https://doi.org/10.3390/mi10050335

Luca A, Riemer O. Analysis of the Downscaling Effect and Definition of the Process Fingerprints in Micro Injection of Spiral Geometries. Micromachines. 2019; 10(5):335. https://doi.org/10.3390/mi10050335

Chicago/Turabian StyleLuca, Antonio, and Oltmann Riemer. 2019. "Analysis of the Downscaling Effect and Definition of the Process Fingerprints in Micro Injection of Spiral Geometries" Micromachines 10, no. 5: 335. https://doi.org/10.3390/mi10050335

APA StyleLuca, A., & Riemer, O. (2019). Analysis of the Downscaling Effect and Definition of the Process Fingerprints in Micro Injection of Spiral Geometries. Micromachines, 10(5), 335. https://doi.org/10.3390/mi10050335