Technological Platform for Vertical Multi-Wafer Integration of Microscanners and Micro-Optical Components

Abstract

1. Introduction

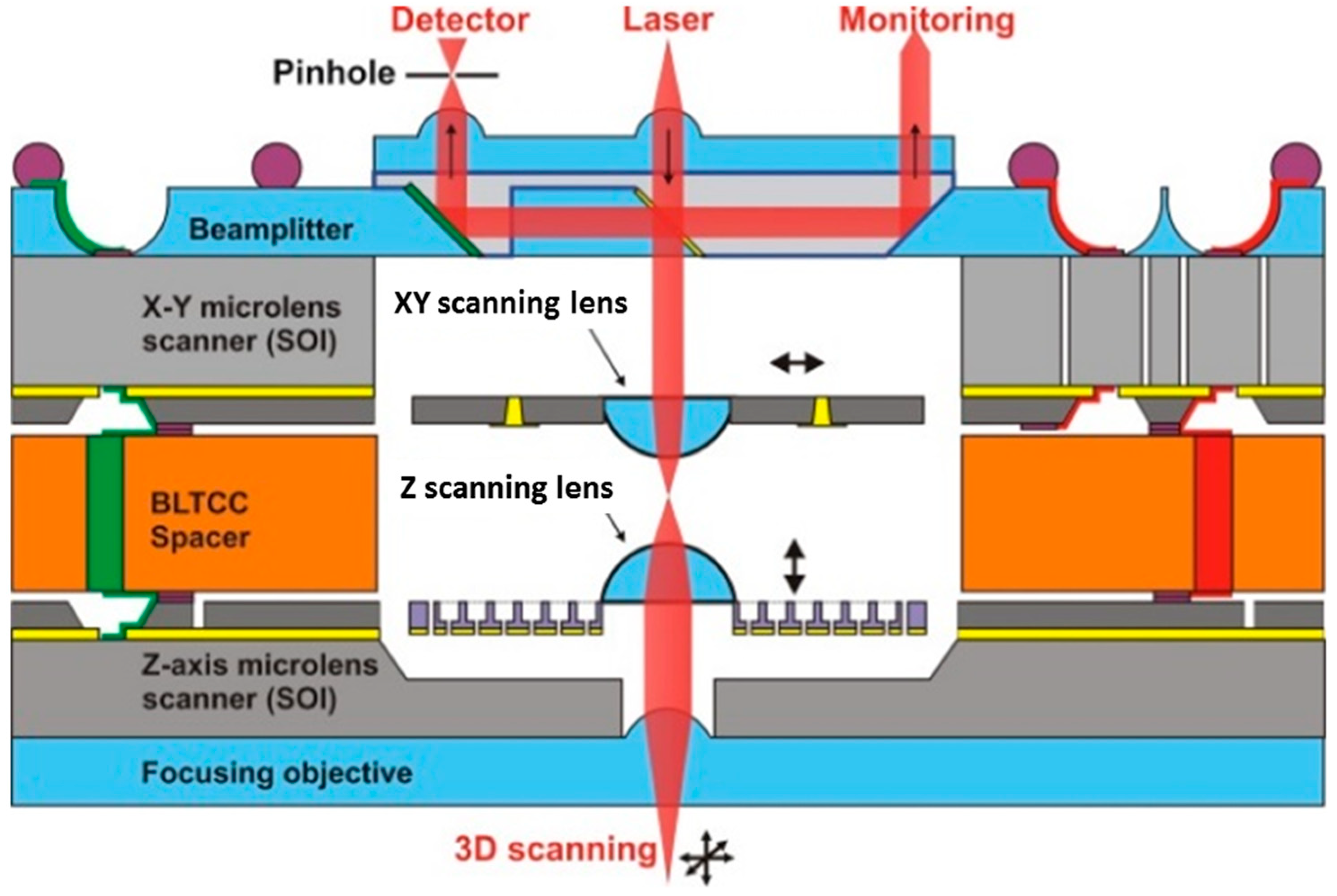

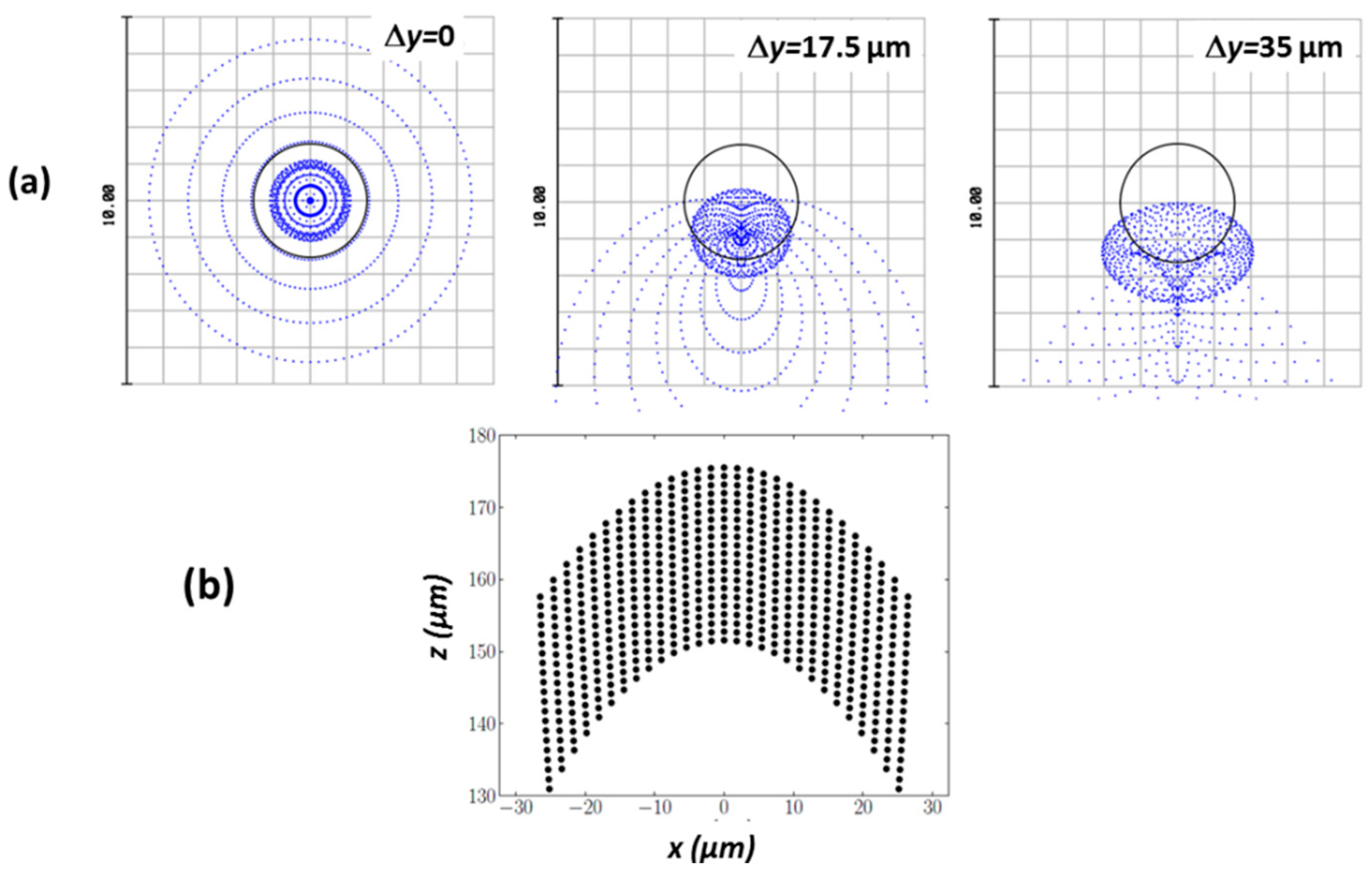

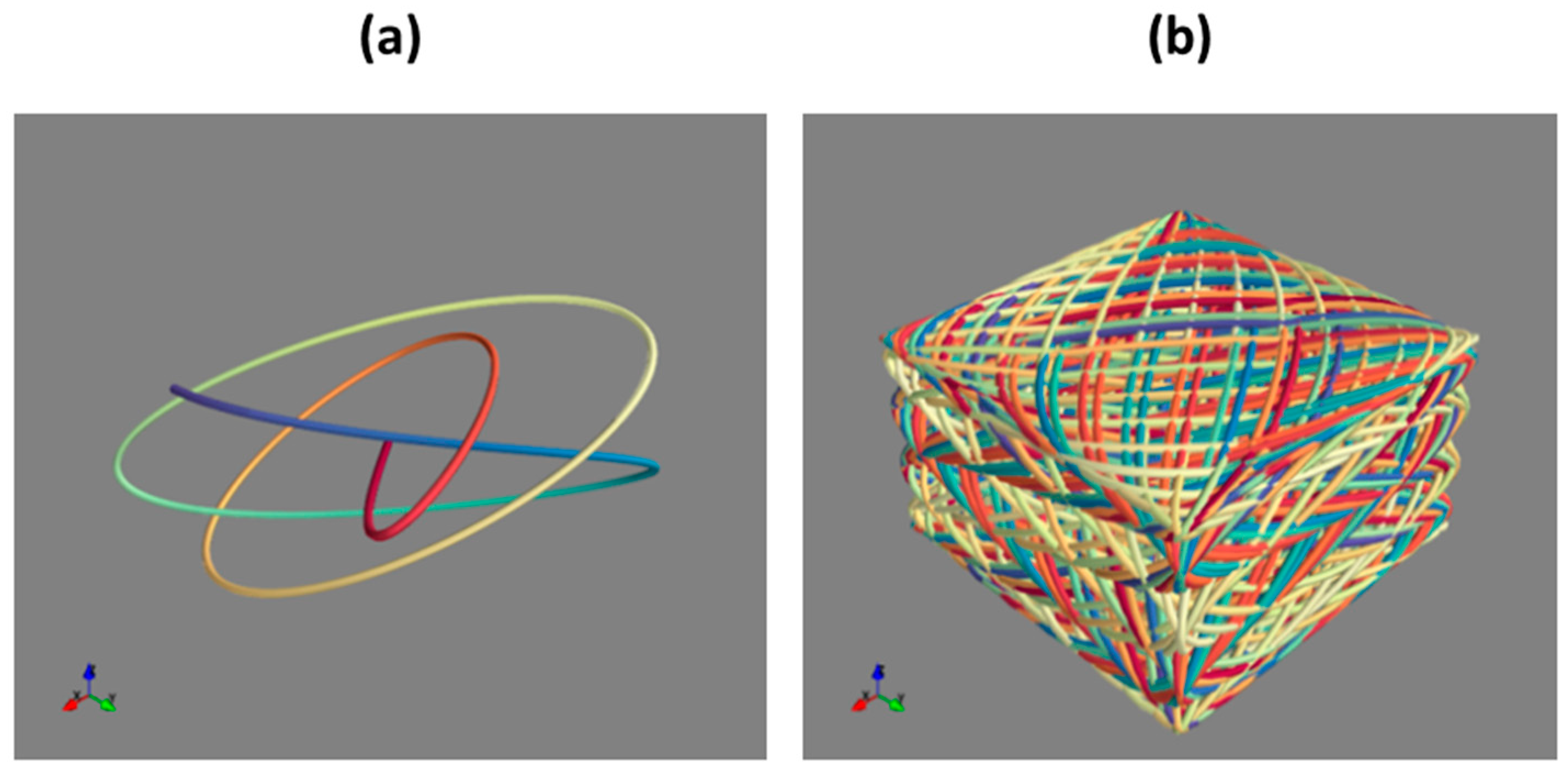

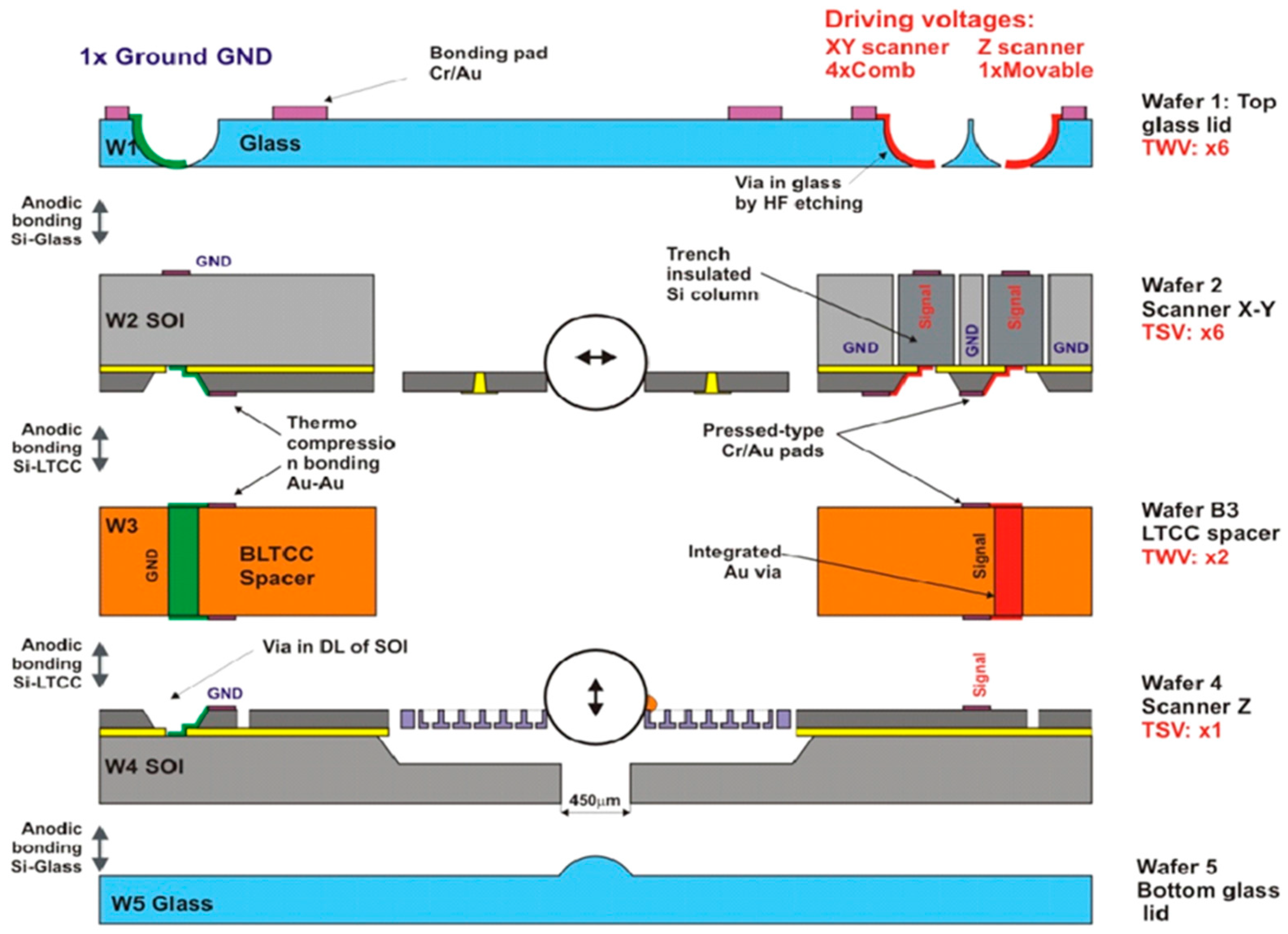

2. Method: The Optical Design of 3D Micro-optical Scanner

3. Results and Discussion

3.1. Glass Microoptical Components: Overview of Key Processes

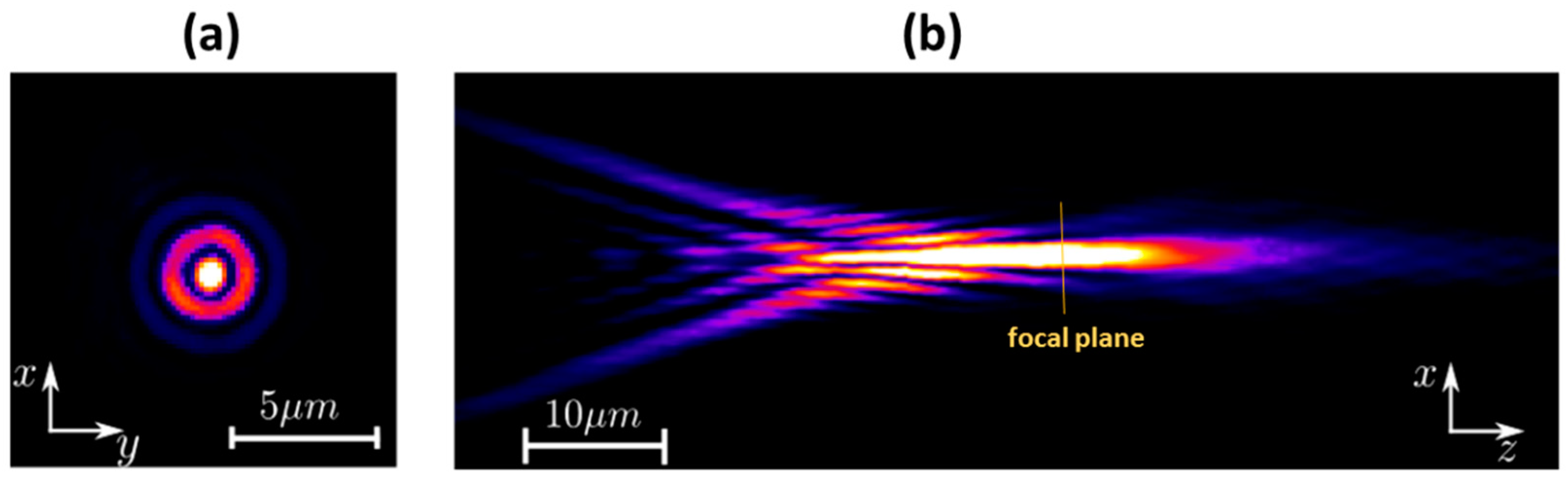

3.1.1. Characterization of Scanning Glass Ball Microlensess

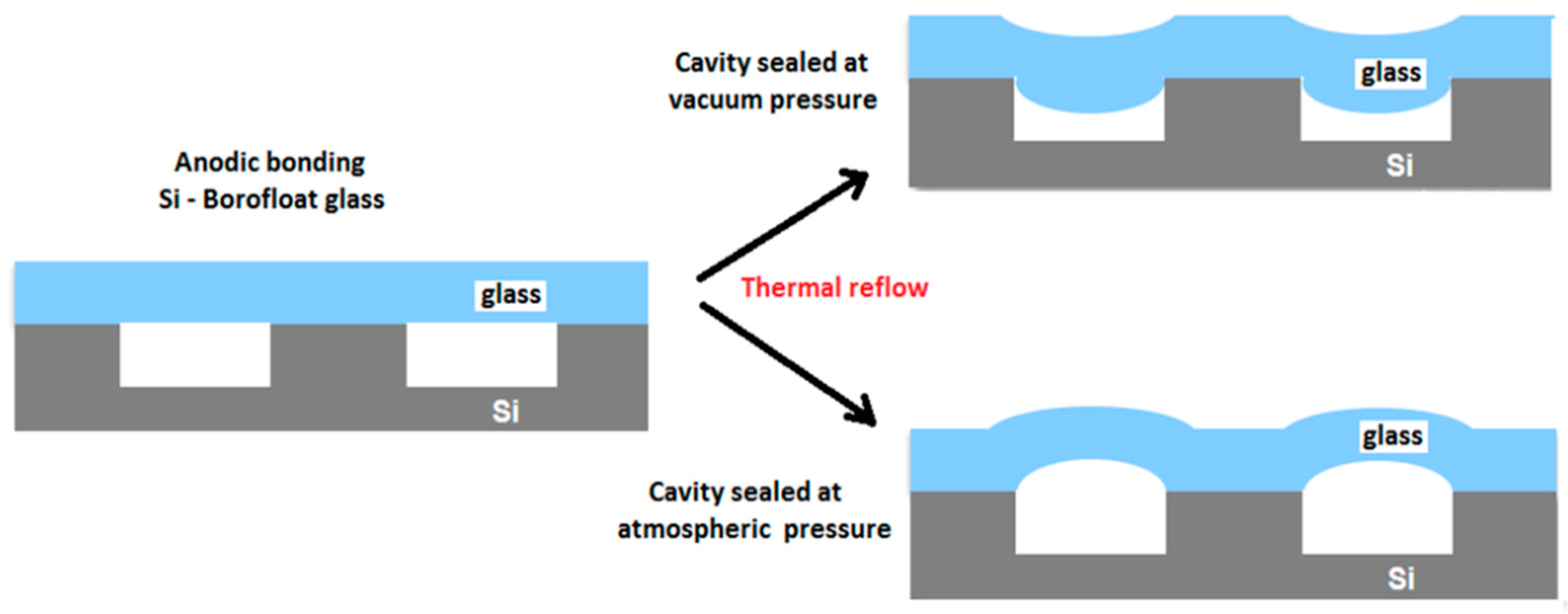

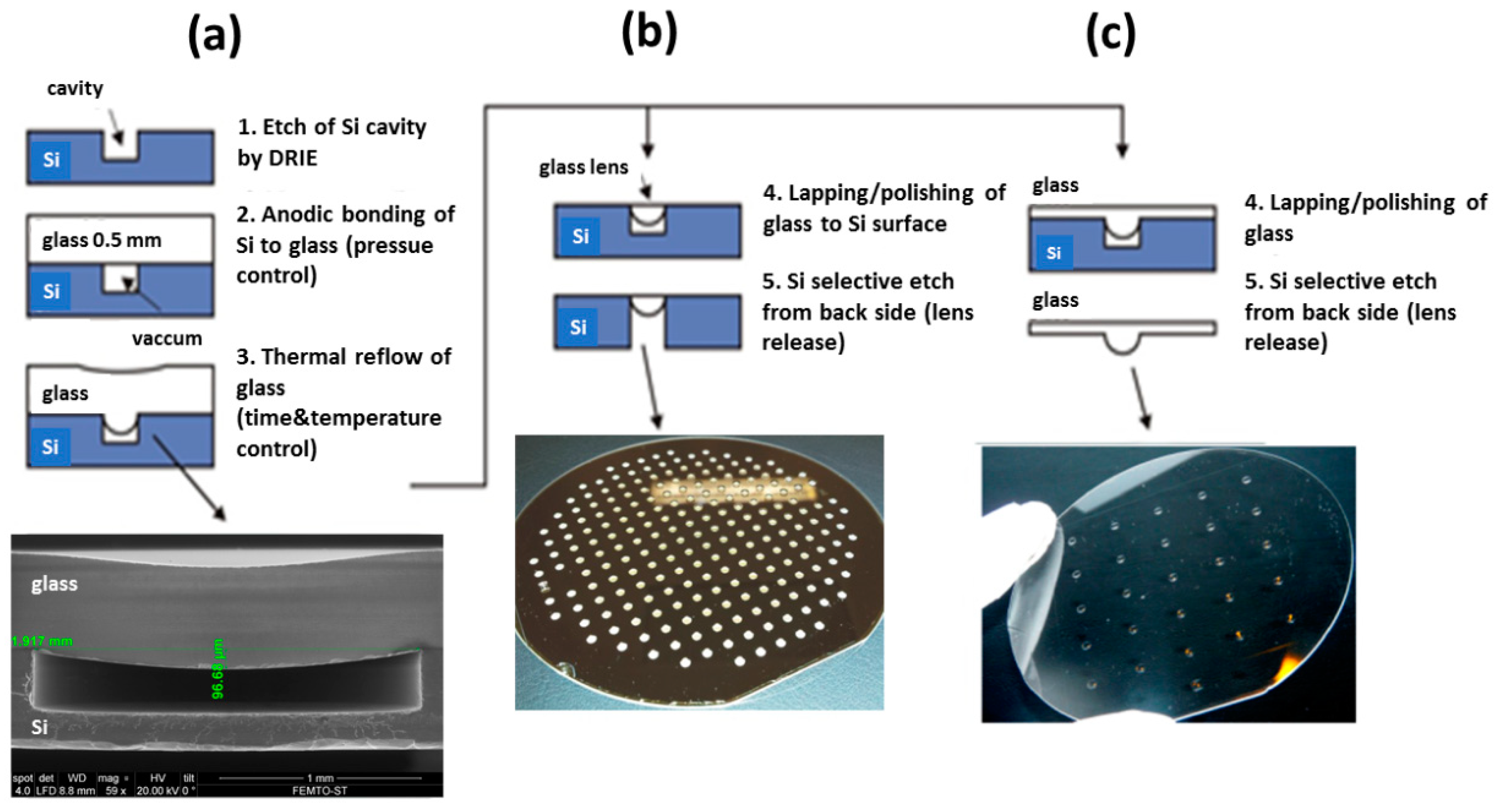

3.1.2. Fabrication of Focusing Plano-Convex Glass Microlenses by Micro-Blowing Process

3.1.3. Fabrication of Glass Micro Beam-Splitter by Saw Dicing

3.2. 3D MEMS Scanner with Integration of Glass Ball Microlens

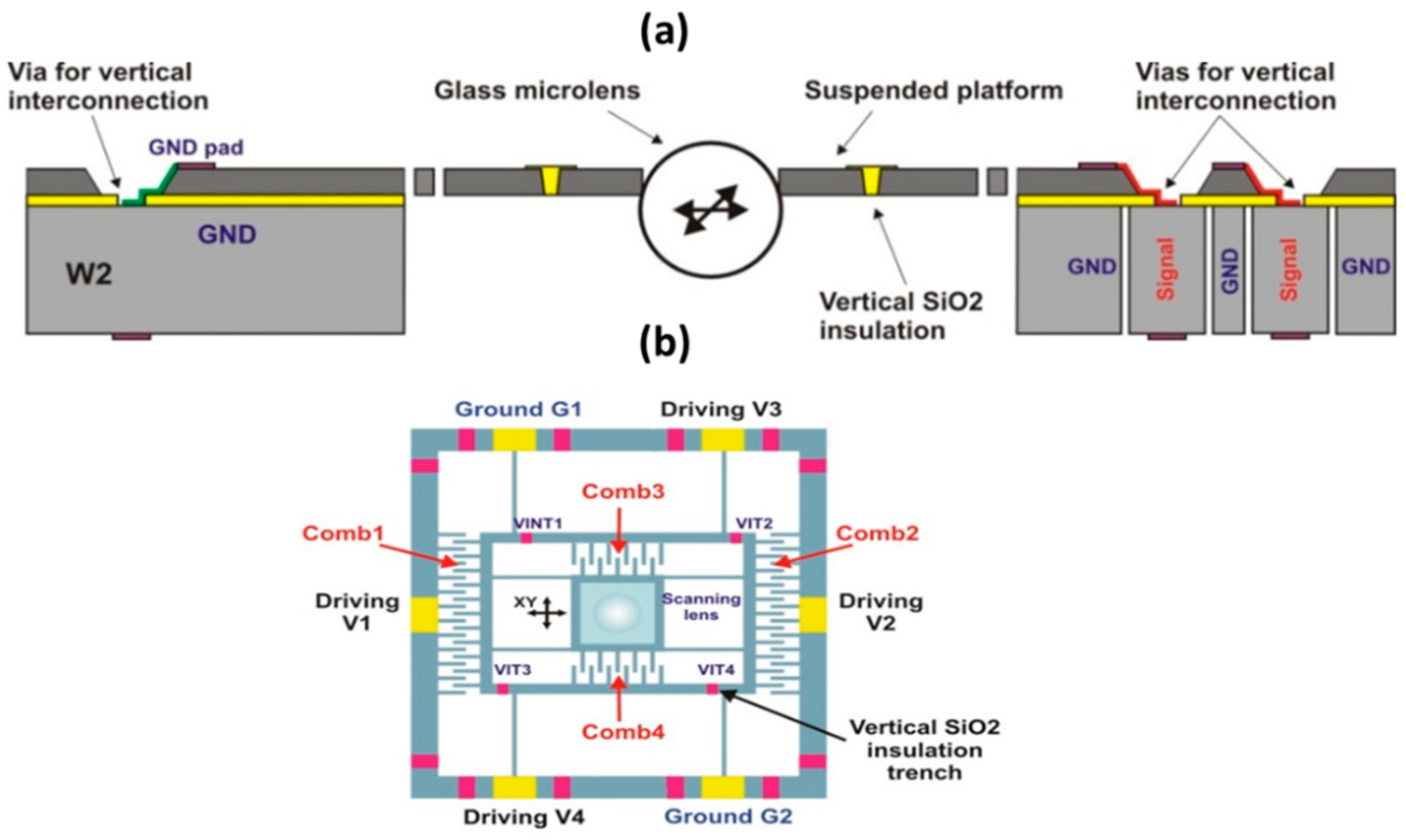

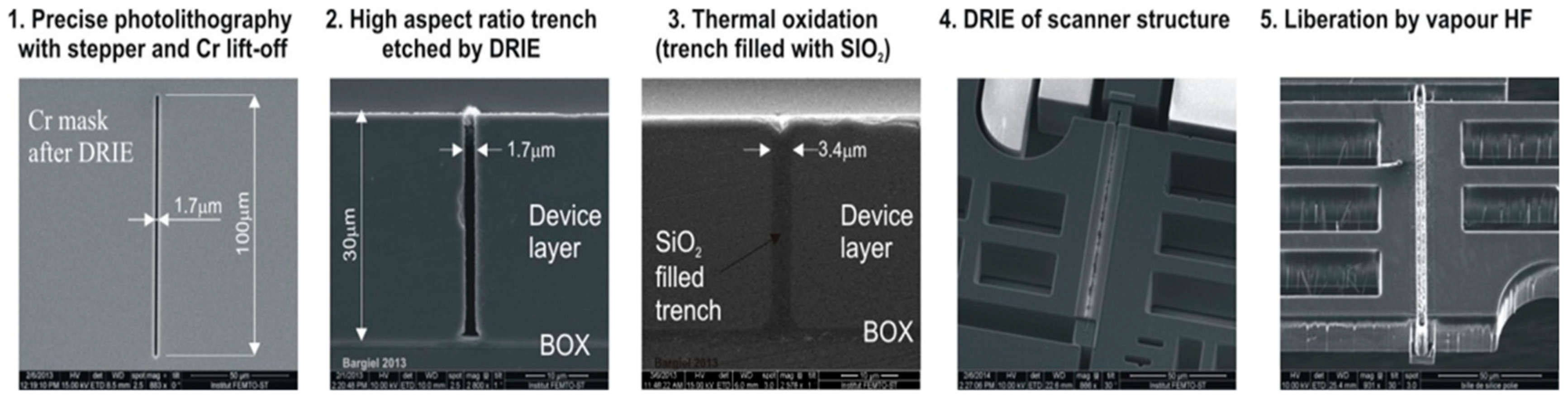

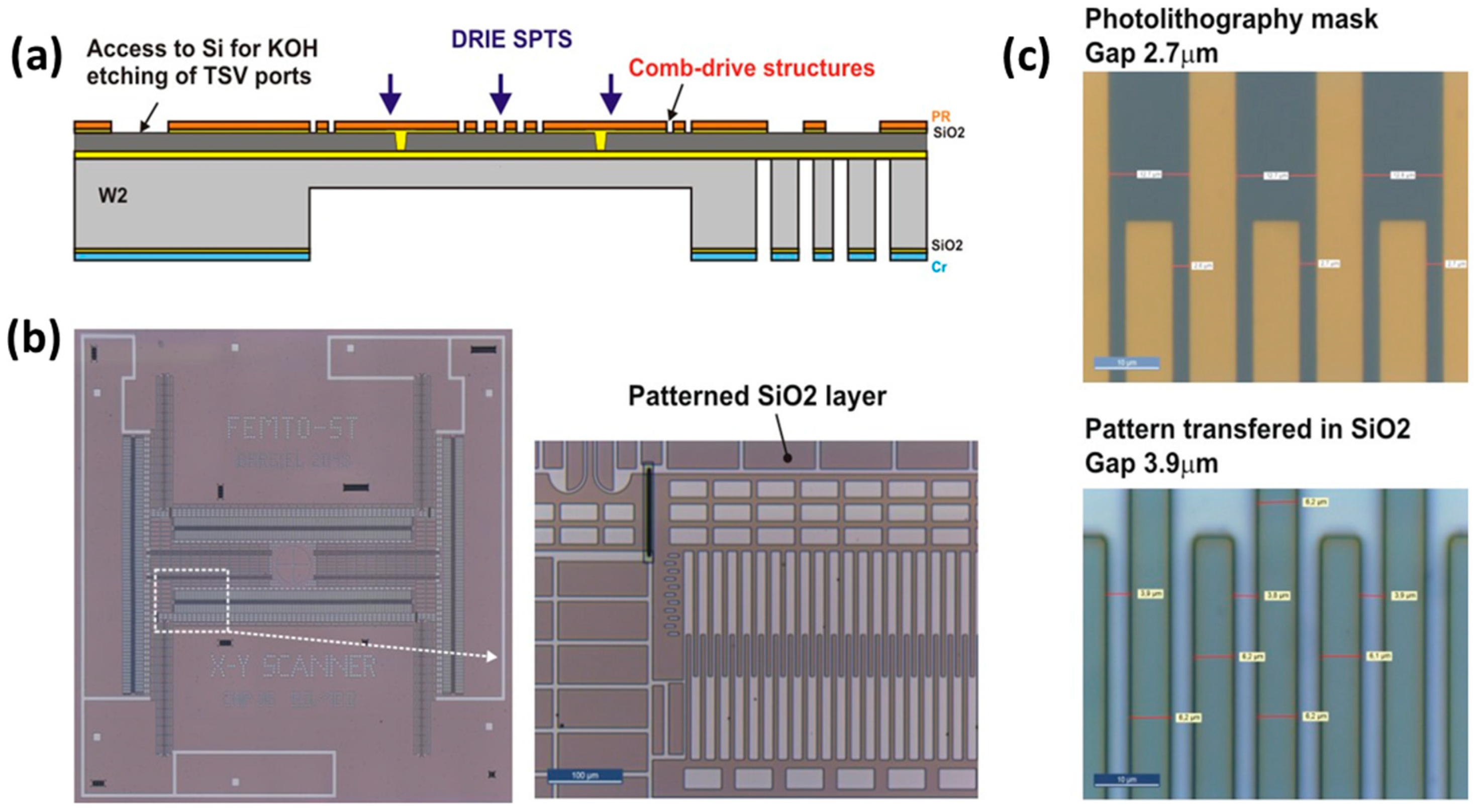

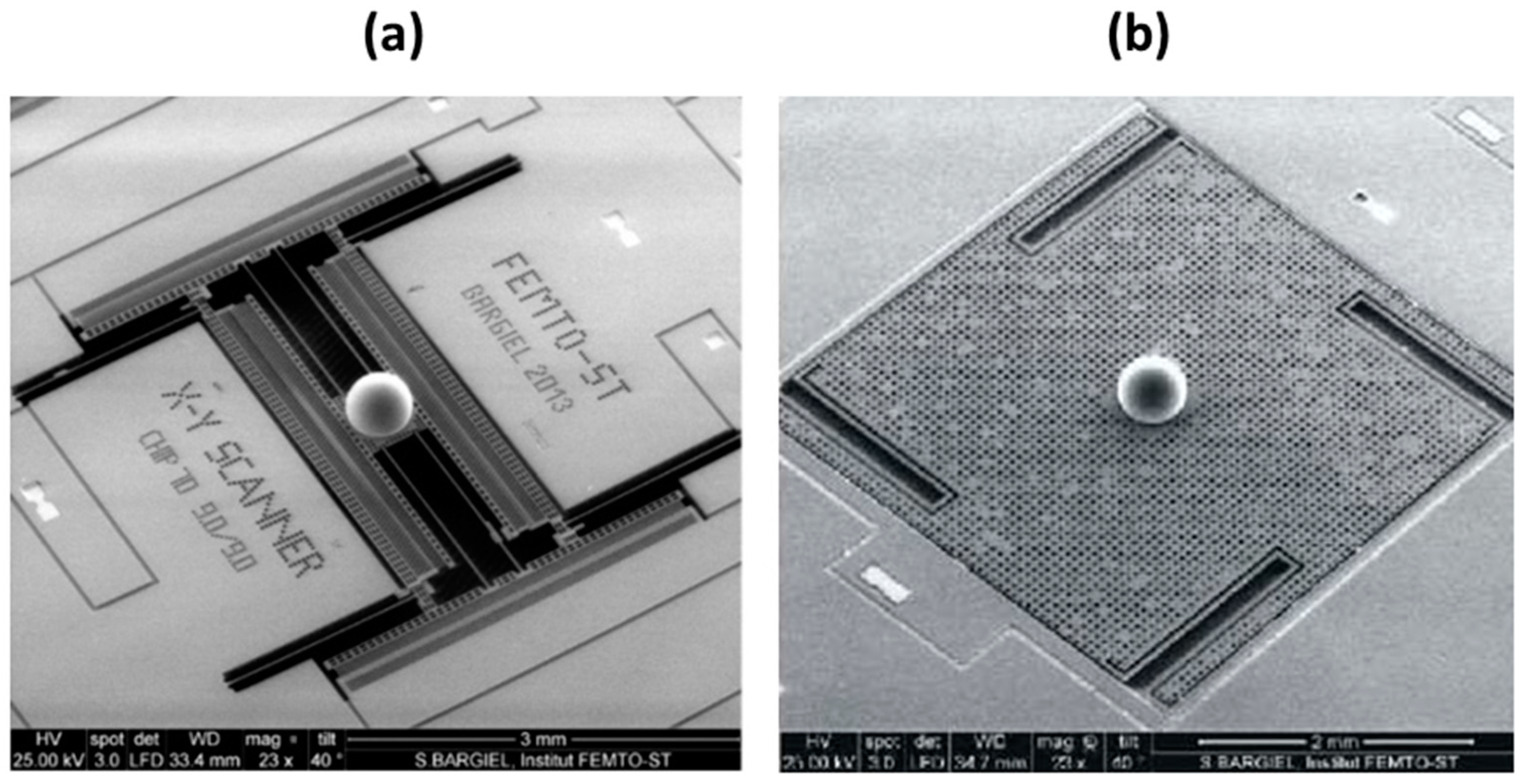

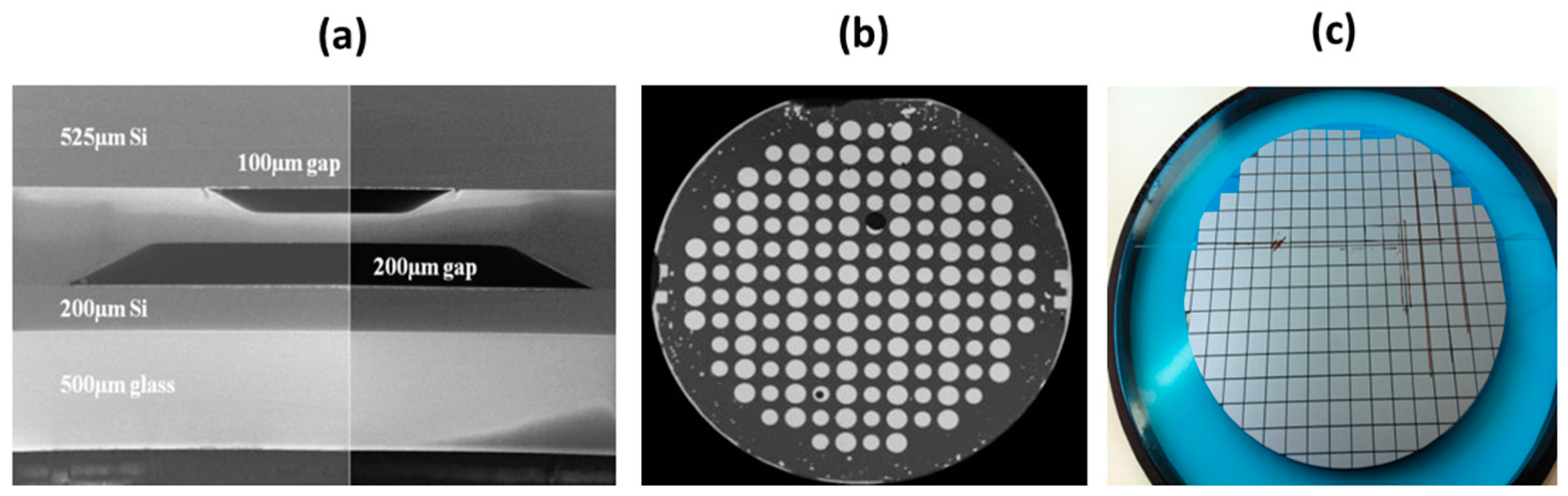

3.2.1. Electrostatic Microlens x-y Scanner

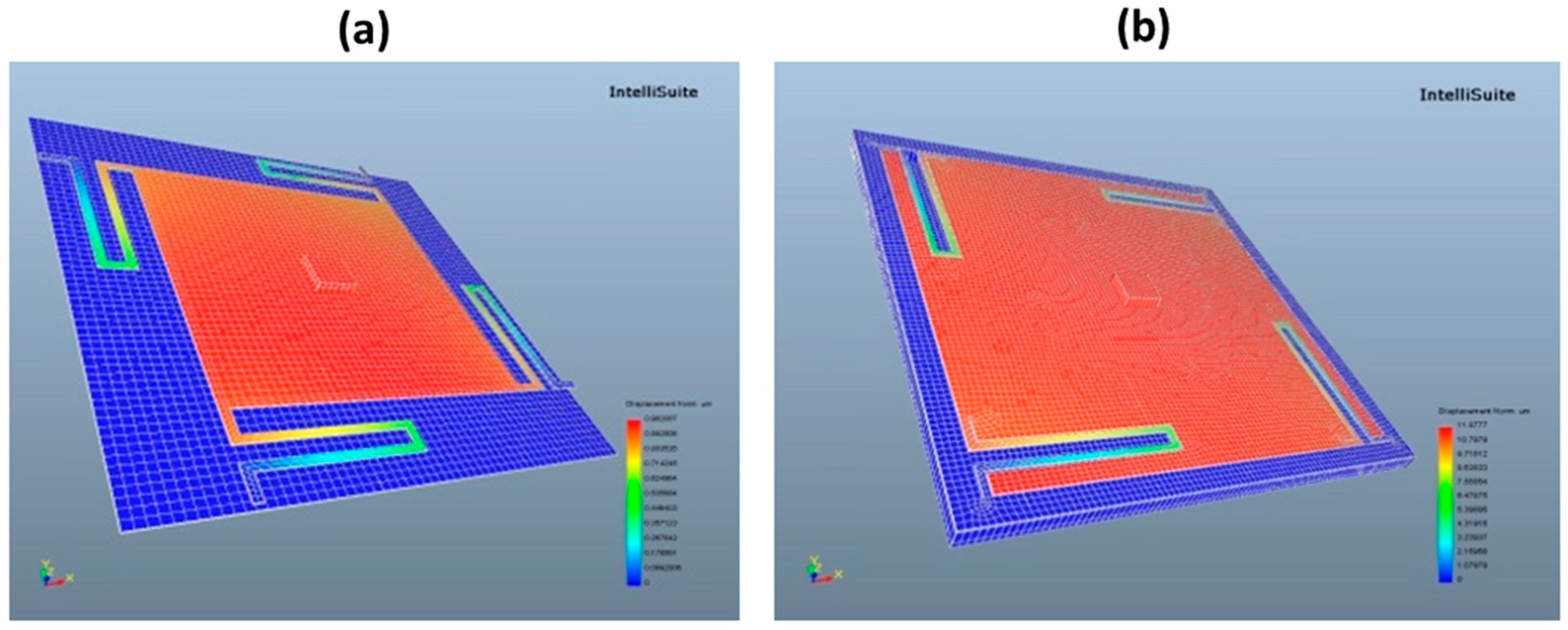

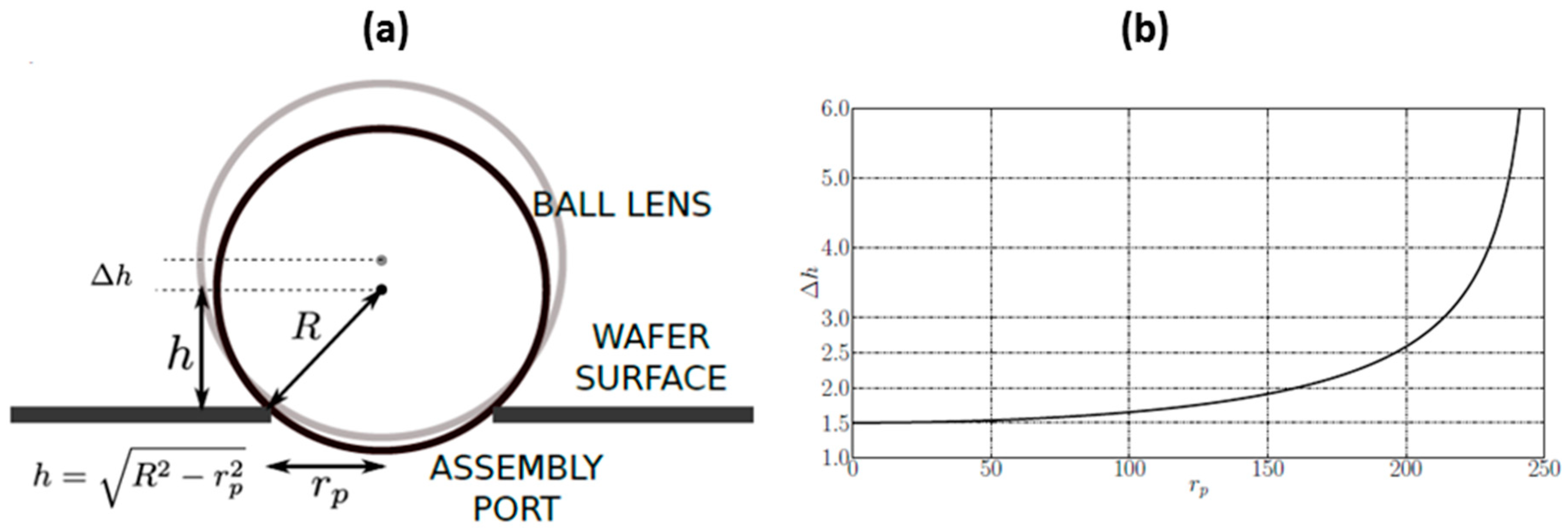

3.2.2. Electrostatic Microlens z-Scanner

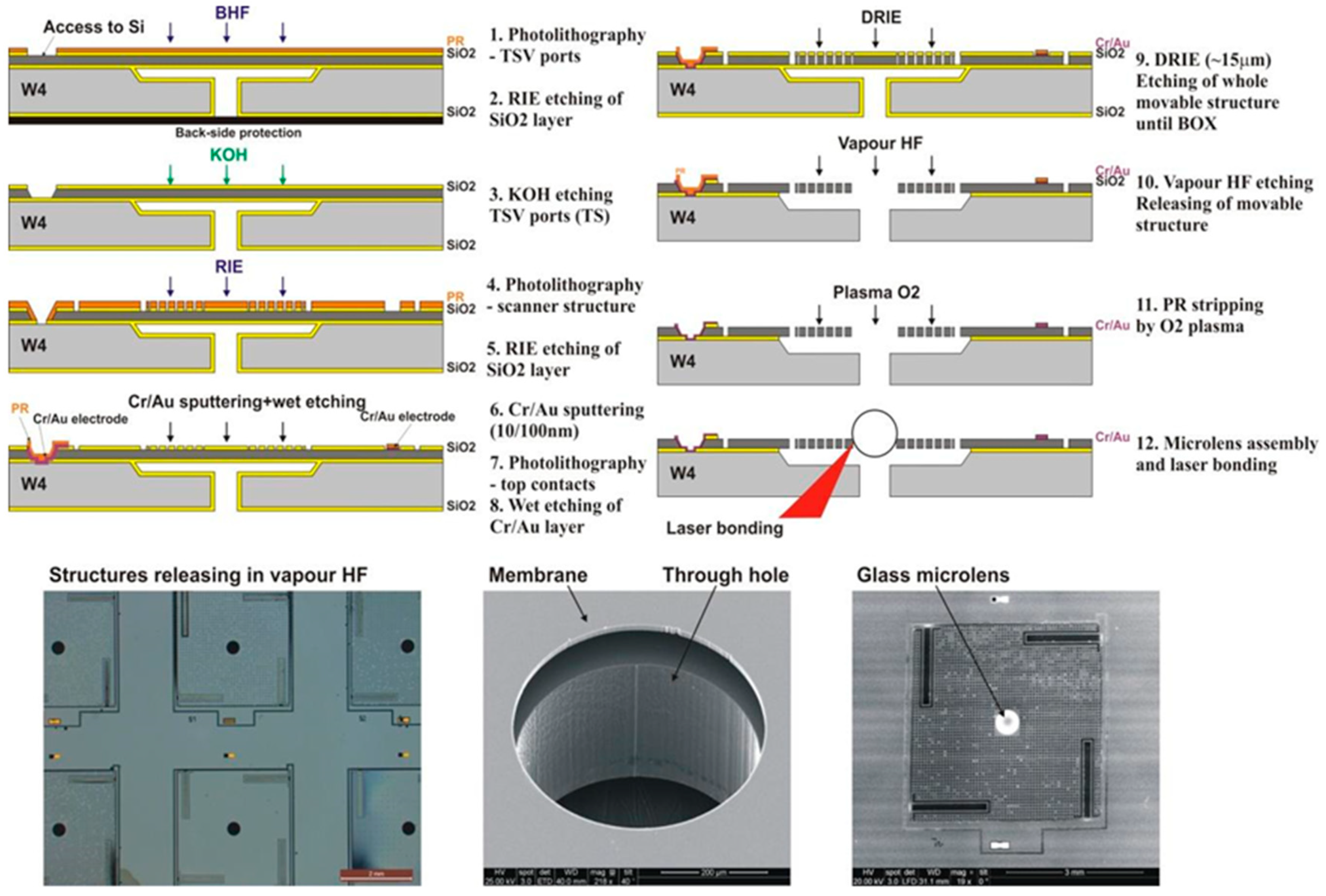

3.2.3. Hybrid Integration of Glass Ball Microlenses

- low temperature adhesive bonding,

- medium temperature bonding using intermediate glass frit material,

- high temperature direct thermal fusion of Si-glass (no intermediate materials), and

- laser-assisted local thermal fusion of Si-glass (no intermediate materials).

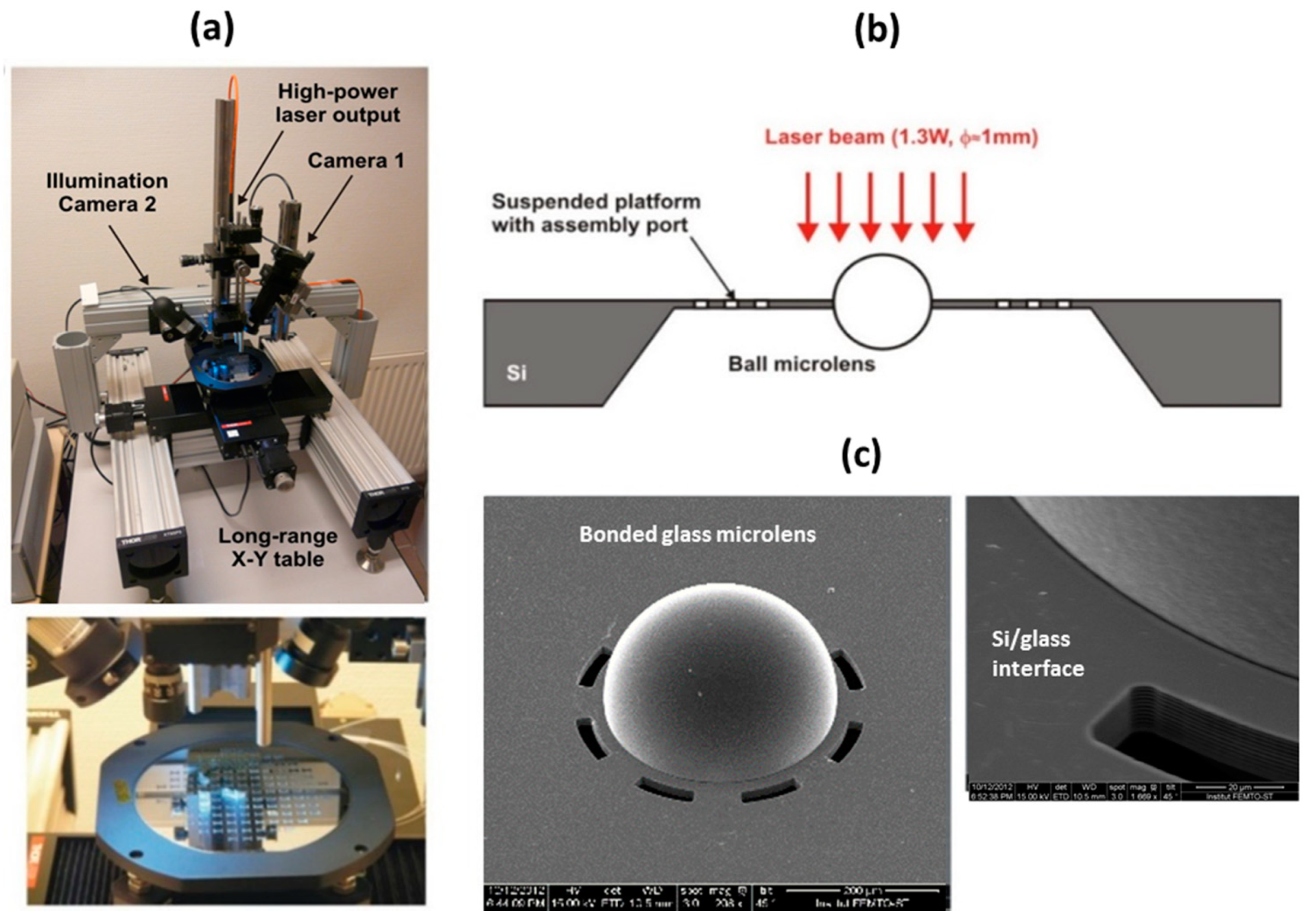

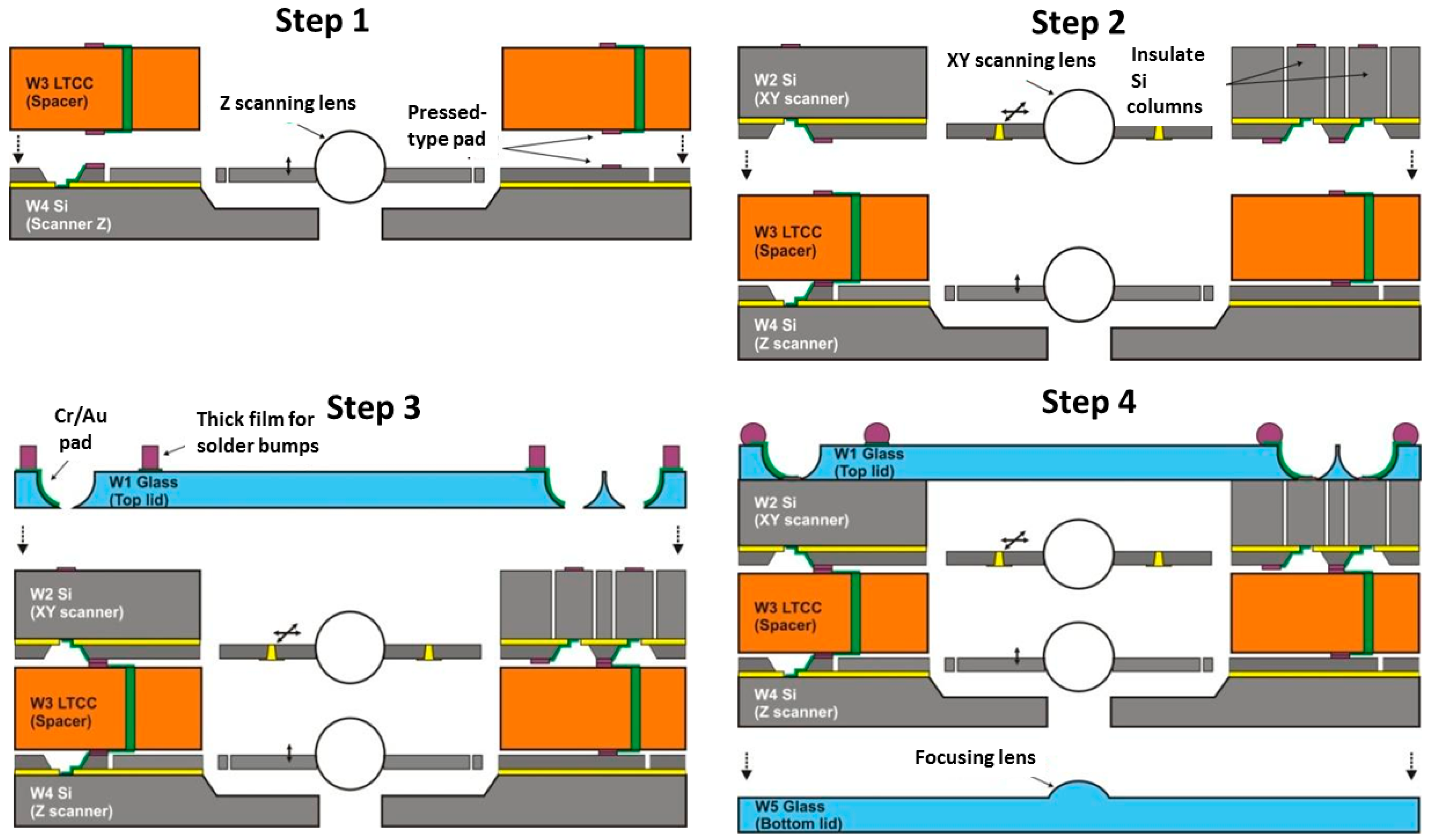

3.3. Assembly and Packaging of 3D Microlens Scanner

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Solgaard, O.; Godil, A.A.; Howe, R.T.; Lee, L.P.; Peter, Y.A.; Zappe, H. Optical MEMS: From Micromirrors to Complex Systems. J. Microelectromech. Syst. 2014, 23, 517–538. [Google Scholar] [CrossRef]

- Motamedi, M.E. Merging Micro-optics with Micromechanics: Micro-Opto-Electro-Mechanical (MOEM) devices. Proc. SPIE 1993, 10271, 102710G. [Google Scholar]

- Lapisa, M.; Stemme, G.; Niklaus, F. Wafer-level heterogeneous integration for MOEMS, MEMS, and NEMS. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 629–644. [Google Scholar] [CrossRef]

- Esashi, M. Wafer level packaging of MEMS. J. Micromech. Microeng. 2008, 18, 073001. [Google Scholar] [CrossRef]

- Albero, J.; Bargiel, S.; Passilly, N.; Gorecki, C. Micromachined array-type Mirau interferometer for parallel inspection of MEMS. J. Micromech. Microeng. 2011, 21, 065005. [Google Scholar] [CrossRef]

- Dickensheets, D.L.; Kino, G.S. Micromachined scanning confocal optical microscope. Opt. Lett. 1996, 21, 764–766. [Google Scholar] [CrossRef]

- Kumar, K.; Hoshino, K.; Zhang, X. Handheld subcellularresolution single-fiber confocal microscope using high-reflectivity two-axis vertical combdrive silicon microscanner. Biomed. Microdevices 2008, 10, 653–660. [Google Scholar] [CrossRef]

- Tang, S.; Jung, W.; McCormick, D.; Xie, T.; Su, J.; Ahn, Y.-C.; Tromberg, B.J.; Chen, Z. Design and implementation of fiber-based multiphoton endoscopy with microelectromechanical systems scanning. J. Biomed. Opt. 2009, 14, 034005. [Google Scholar] [CrossRef]

- Bargiel, S.; Gorecki, C.; Baranski, M.; Passilly, N.; Wiemer, M.; Jia, C.; Frömel, J. 3D micro-optical lens scanner made by multi-wafer bonding technology. Proc. SPIE 2013, 8616, 861605. [Google Scholar]

- Laszczyk, K.; Bargiel, S.; Gorecki, C.; Krężel, J.; Dziuban, P.; Kujawinska, M.; Callet, D.; Frank, S. A two directional electrostatic comb-drive X–Y micro-stage for MOEMS applications. Sens. Actuators A 2010, 163, 255–265. [Google Scholar] [CrossRef]

- Laszczyk, K.; Bargiel, S.; Krȩzel, J.; Gorecki, C.; Kujawińska, M. Silicon comb-drive X-Y microstage with frame-in-the-frame architecture for MOEMS applications. In Proceedings of the SPIE – Smart Sensors, Actuators, and MEMS IV, Dresden, Germany, 4–6 May 2009; Volume 7362. [Google Scholar]

- Wiemer, M.; Frömel, J.; Jia, C.; Bargiel, S.; Baranski, M.; Passilly, N.; Gorecki, C. Bonding and contacting of vertically integrated 3-D microscanners. In Proceedings of the 9th Annual International Wafer-Level Packaging Conference, San Jose, CA, USA, 5–8 November 2012; p. 5. [Google Scholar]

- Baranski, M.; Bargiel, S.; Passilly, N.; Gorecki, C.; Chenping, J.; Frömel, J.; Wiemer, M. Micro-optical design of a three-dimensional microlens scanner for vertically integrated micro-opto-electro-mechanical systems. Appl. Opt. 2015, 54, 6924–6934. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.T.C.; Mandella, M.J.; Loewke, N.O.; Haeberle, H.; Ra, H.; Piyawattanametha, W.; Solgaard, O.; Kino, G.S.; Contag, C.H. Micromirror-scanned dual-axis confocal microscope utilizing a gradient-index relay lens for image guidance during brain surgery. J. Biomed. Opt. 2010, 15, 026029. [Google Scholar] [CrossRef] [PubMed]

- Tuma, T.; Lygeros, J.; Kartik, V.; Sebastian, A.; Pantazi, A. High-speed multiresolution scanning probe microscopy based on Lissajous scan trajectories. Nanotechnology 2012, 23, 185501. [Google Scholar] [CrossRef] [PubMed]

- Perrin, S.; Baranski, M.; Froehly, L.; Albero, J.; Passilly, N.; Gorecki, C. Simple method based on intensity measurements for characterization of aberrations from micro-optical components. Appl. Opt. 2015, 54, 9060–9064. [Google Scholar] [CrossRef] [PubMed]

- Albero, J.; Perrin, S.; Bargiel, S.; Passilly, N.; Baranski, M.; Gauthier-Manuel, L.; Bernard, F.; Lullin, J.; Froehly, L.; Krauter, J.; et al. Dense arrays of millimeter-sized glass lenses fabricated at wafer-level. Opt. Express 2015, 23, 11702–11712. [Google Scholar] [CrossRef] [PubMed]

- Gorecki, C.; Carrion, J.V.; Passilly, N.; Bargiel, S. Micro Glass Blowing platform for microfabrication of microoptical components. Proc. SPIE 2018, 10678, 1067814. [Google Scholar]

- Bargiel, S.; Baranski, M.; Passilly, N.; Gorecki, C.; Wiemer, M.; Frömel, J.; Wünsch, W.; Wang, W.-S. Technological platform for vertical multi-wafer integration of miniature imaging instruments. In Proceedings of the MOEMS and Miniaturized Systems XIV, San Francisco, CA, USA, 7–12 February 2015. [Google Scholar]

- Lee, C.-H.; Chiu, Y.; Shieh, H.-P.D. High-extinction-ratio micro polarizing beam splitter for short wavelength optical storage applications. Opt. Express 2005, 13, 10292–10301. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Liu, F.; Adibi, A. 45 Degree Polymer Micromirror Integration for Board-Level Three-Dimensional Optical Interconnects. Opt. Express 2009, 17, 10514–10521. [Google Scholar] [CrossRef] [PubMed]

- Baranski, M.; Bargiel, S.; Passilly, N.; Guichardaz, B.; Herth, E.; Gorecki, C.; Jia, C.; Frömel, J.; Wiemer, M. Wafer-level fabrication of microcube-typed beam-splitters by saw-dicing of glass substrates. IEEE Photonics Technol. Lett. 2014, 26, 100–103. [Google Scholar] [CrossRef]

- Park, Y.; Moon, S.; Lee, J.; Kim, K.; Lee, S.J.; Lee, J.H. Gimbal-Less Two-Axis Electromagnetic Microscanner with Twist Mechanism. Micromachines 2018, 9, 219. [Google Scholar] [CrossRef] [PubMed]

- Zhao, R.; Qiao, D.; Song, X.; You, Q. The Exploration for an Appropriate Vacuum Level for Performance Enhancement of a Comb-Drive Microscanner. Micromachines 2017, 8, 126. [Google Scholar] [CrossRef]

- Mohri, M.; Kidani, N. Anodic Bondable Porcelain and Composition for the Porcelain. U.S. Patent 2011/0108931 A1, 12 May 2011. [Google Scholar]

- Wiemer, M.; Wuensch, D.; Frömel, J.; Gessner, T.; Bargiel, S.; Baranski, M.; Passilly, N. Multi-wafer bonding, stacking and interconnecting of integrated 3-D MEMS micro scanners. In Proceedings of the 14th International Symposium in Microwave and Optical Technology, Kuala Lumpur, Malaysia, 28–31 October 2013; p. 28. [Google Scholar]

| Parameter | |

|---|---|

| Numerical aperture | 0.45 |

| Volume of scanning volume, low aberration-level (lateral displacements Δxy = ±35 μm; Δz = ±20 μm) | 60 × 60 × 25 µm3 |

| Lateral resolution | 1.9–3.8 µm |

| Axial resolution | 13 µm |

| Parameter | Value | |

|---|---|---|

| x-axis | y-axis | |

| Resonance frequency (with 500-µm microlens) | 500 Hz @ 8 µm spring | 590 Hz @ 8 µm spring |

| 700 Hz @ 10 µm spring | 830 Hz @ 10 µm spring | |

| Displacement at resonance | min. ± 35 µm @ < 60 V | |

| Quality factor | ~50 | ~70 |

| Parameter | Value |

|---|---|

| Resonance frequency (with 500-µm microlens) | 570–600 Hz |

| Displacement x-axis at resonance | min. ± 20 µm @ < 70 V |

| Static critical voltage | 88 V |

| Dynamic critical voltage | 82 V |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bargiel, S.; Baranski, M.; Wiemer, M.; Frömel, J.; Wang, W.-S.; Gorecki, C. Technological Platform for Vertical Multi-Wafer Integration of Microscanners and Micro-Optical Components. Micromachines 2019, 10, 185. https://doi.org/10.3390/mi10030185

Bargiel S, Baranski M, Wiemer M, Frömel J, Wang W-S, Gorecki C. Technological Platform for Vertical Multi-Wafer Integration of Microscanners and Micro-Optical Components. Micromachines. 2019; 10(3):185. https://doi.org/10.3390/mi10030185

Chicago/Turabian StyleBargiel, Sylwester, Maciej Baranski, Maik Wiemer, Jörg Frömel, Wei-Shan Wang, and Christophe Gorecki. 2019. "Technological Platform for Vertical Multi-Wafer Integration of Microscanners and Micro-Optical Components" Micromachines 10, no. 3: 185. https://doi.org/10.3390/mi10030185

APA StyleBargiel, S., Baranski, M., Wiemer, M., Frömel, J., Wang, W.-S., & Gorecki, C. (2019). Technological Platform for Vertical Multi-Wafer Integration of Microscanners and Micro-Optical Components. Micromachines, 10(3), 185. https://doi.org/10.3390/mi10030185