Residual Stress in Lithium Niobate Film Layer of LNOI/Si Hybrid Wafer Fabricated Using Low-Temperature Bonding Method

Abstract

1. Introduction

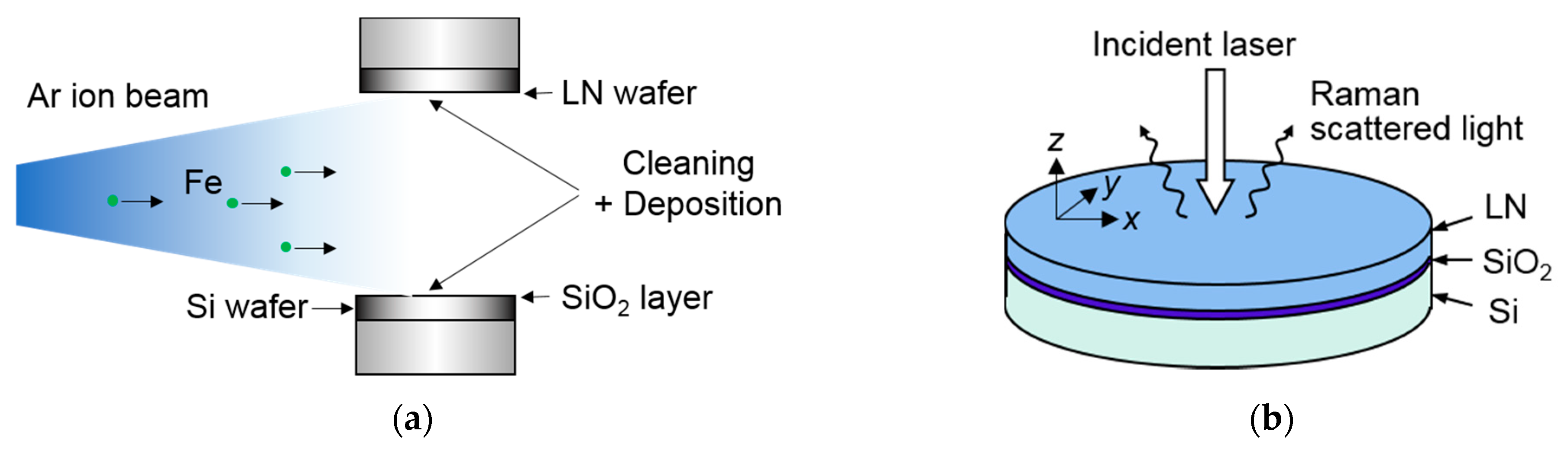

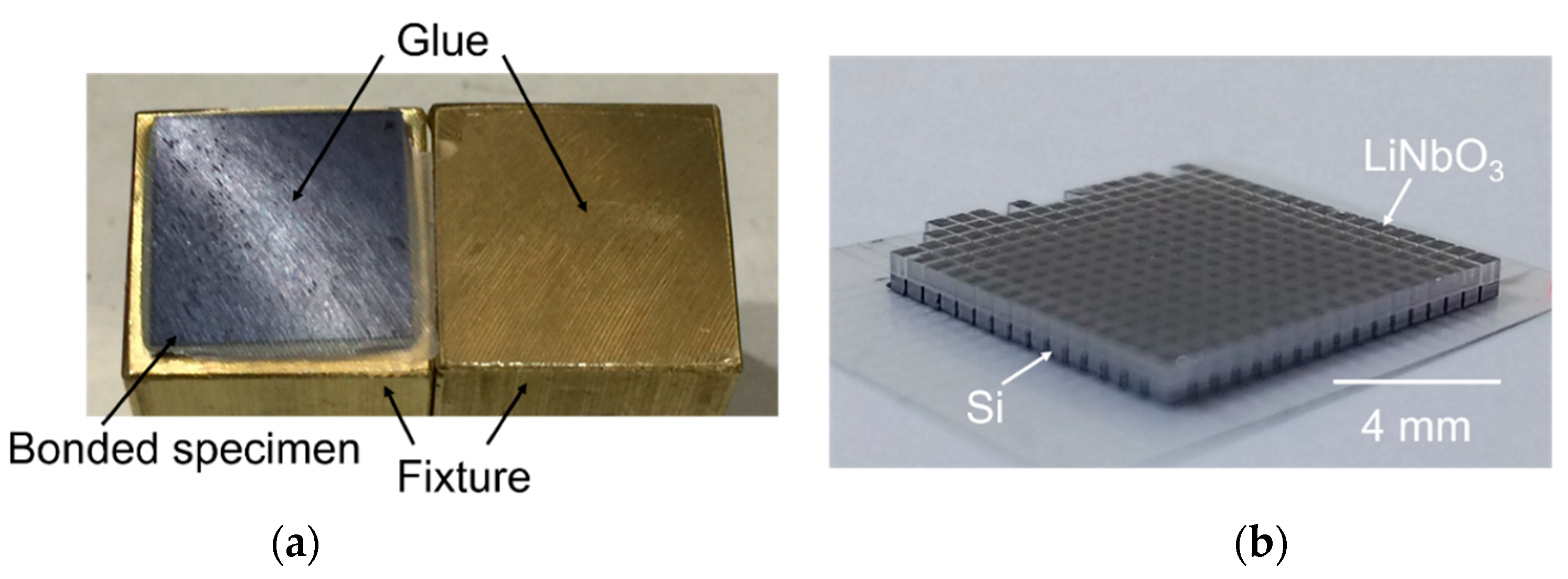

2. Experimental Procedure

3. Results and Discussion

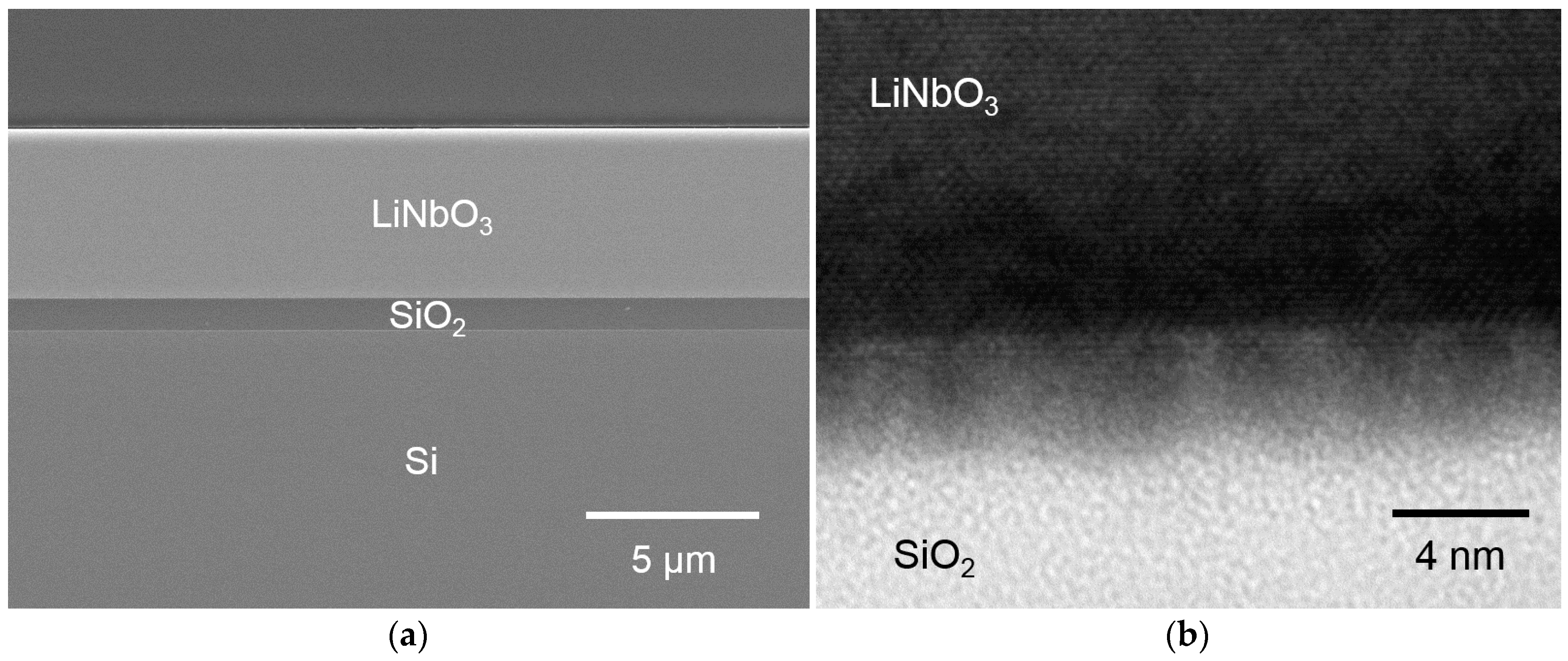

3.1. Thin-Film LNOI/Si Hybrid Wafer

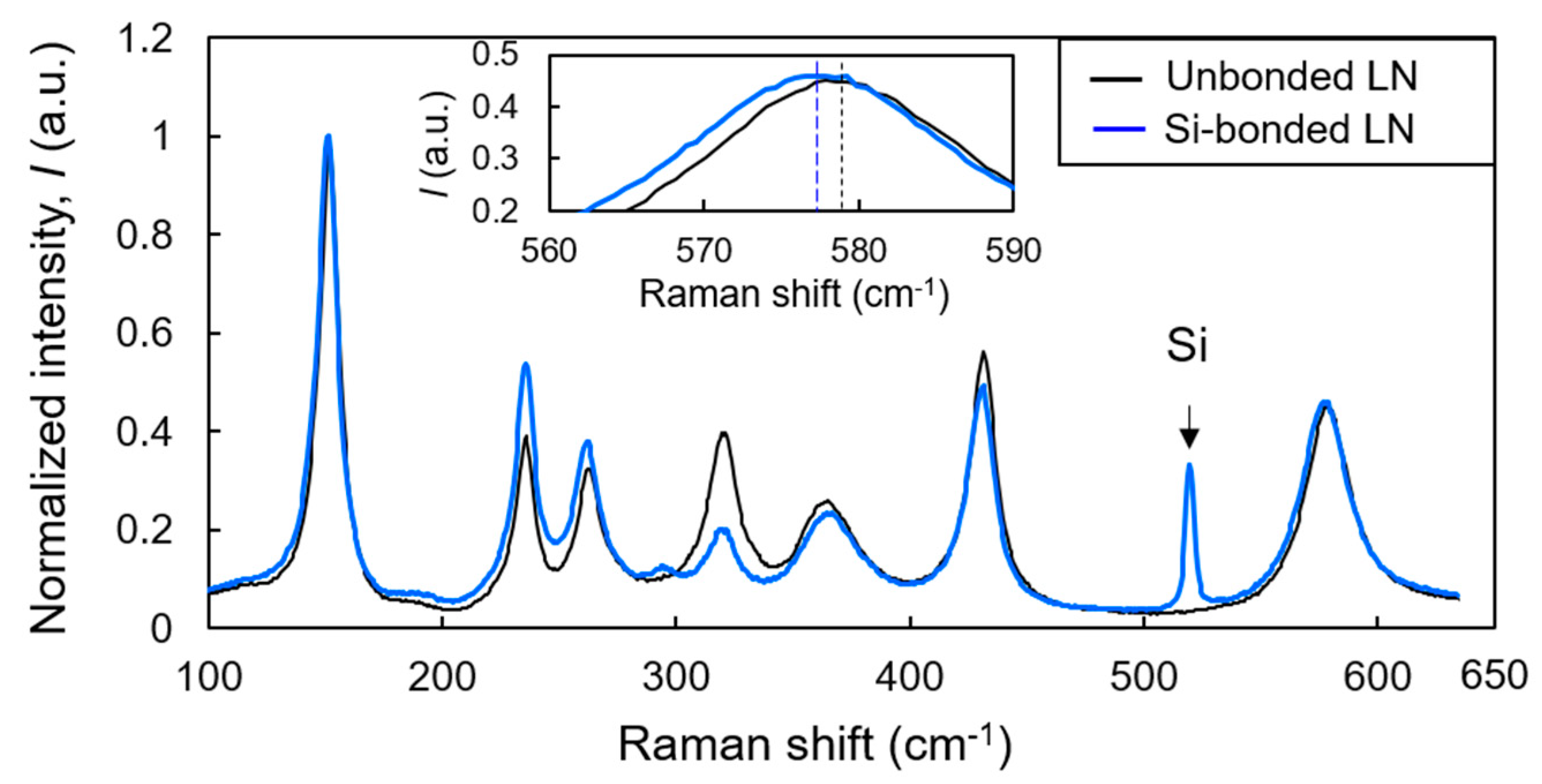

3.2. Residual Stress in LN Film Layer

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Poberaj, G.; Hu, H.; Sohler, W.; Guenter, P. Lithium niobate on insulator (LNOI) for microphotonics devices. Laser Photon. Rev. 2012, 6, 488–503. [Google Scholar] [CrossRef]

- Boes, A.; Corcoran, B.; Chang, L.; Bowers, J.; Mitchell, A. Status and Potential of Lithium Niobate on Insulator (LNOI) for Photon Integrated Circuits. Laser Photon. Rev. 2018, 12, 1700256. [Google Scholar] [CrossRef]

- Rabiei, P.; Gunter, P. Optical and electro-optical properties of submicrometer lithium niobate slab waveguides prepared by crystal ion slicing and wafer bonding. Appl. Phys. Lett. 2004, 85, 4603–4605. [Google Scholar] [CrossRef]

- Guarino, A.; Poberaj, G.; Rezzonico, D.; Degl’Innocenti, R.; Gunter, P. Electro-optically tunable microring resonators. Nat. Photon. 2007, 1, 407–410. [Google Scholar] [CrossRef]

- Mercante, A.J.; Yao, P.; Shi, S.; Schneider, G.; Murakowski, J.; Prather, D.W. 110 GHz CMOS compatible thin film LiNbO3 modulator on Silicon. Opt. Express 2016, 24, 15590–15595. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhang, M.; Chen, X.; Bertrand, M.; Ansari, A.S.; Chandrasekher, S.; Wintzer, P.; Loncar, M. Integrated lithium niobate electro-optic modulators operating at CMOS-compatible voltage. Nature 2018, 1, 101–104. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.B.; Min, B.; Vahala, K.J.; Atwater, H.A. Integration of single-crystal LiNbO3 thin film on silicon by laser irradiation and ion implantation-induced layer transfer. Adv. Mater. 2006, 18, 1533–1536. [Google Scholar] [CrossRef]

- Takagi, H.; Maeda, R.; Suga, T. Room-temperature wafer bonding of Si to LiNbO3, LiTaO3 and Gd3Ga5O12 by Ar-beam surface activation. J. Micromech. Microeng. 2001, 11, 348–351. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Shinada, S.; Kawanishi, T. Low-temperature Au-Au bonding for LiNbO3/Si structure achieved in ambient air. IEICE Trans. Electron. 2007, 90, 145–146. [Google Scholar] [CrossRef]

- Takigawa, R.; Kawano, H.; Ikenoue, H.; Asano, T. Investigation of the interface between LiNbO3 and Si wafers bonded by laser irradiation. Jpn. J. Appl. Phys. 2017, 56, 088002. [Google Scholar] [CrossRef]

- Wu, C.C.; Horng, R.H.; Wuu, D.S.; Chen, T.N.; Ho, S.S.; Ting, C.J.; Tsai, H.Y. Thinning technology for lithium niobate wafer by surface activated bonding and chemical mechanical polishing. Jpn. J. App. Phys. 2006, 45, 3822–3828. [Google Scholar] [CrossRef]

- Pasquariello, D.; Hjort, K. Plasma-assisted InP-to-Si low temperature wafer bonding. IEEE J. Sel. Top. Quant. Electron. 2002, 8, 118–131. [Google Scholar] [CrossRef]

- Takagi, H.; Maeda, R.; Hosoda, N.; Suga, T. Room-temperature bonding of lithium niobate and silicon wafers by argon-beam surface activation. Appl. Phys. Lett. 1999, 74, 2387–2389. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Sawada, R. Room-temperature bonding of vertical-cavity surface-emitting laser diode chips on Si substrates in ambient air. Appl. Phys. Exp. 2008, 1, 112201. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Kawanishi, T. Passive alignment and mounting of LiNbO3 waveguide chips on Si substrates by low-temperature solid-state bonding of Au. IEEE J. Sel. Top. Quant. Electron. 2011, 17, 652–658. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Kawanishi, T. Air-gap structure between integrated LiNbO3 optical modulators and micromachined Si substrates. Opt. Express 2011, 19, 15739–15749. [Google Scholar] [CrossRef] [PubMed]

- Takigawa, R.; Higurashi, E.; Suga, T.; Kawanishi, T. Room-temperature transfer bonding of Lithium niobate thin film on micromachined silicon substrates with Au microbumps. Sens. Actuators A. 2017, 264, 274–281. [Google Scholar] [CrossRef]

- Takagi, H.; Maeda, R.; Chung, T.R.; Suga, T. Low-temperature direct bonding of silicon and silicon oxide by the surface activation method. Sens. Actuators A 1998, 70, 164–170. [Google Scholar] [CrossRef]

- Howlader, M.M.R.; Okada, H.; Kim, T.H.; Itoh, T.; Suga, T. Wafer level surface activated bonding tool for MEMS packaging. J. Electrochem. Soc. 2004, 151, G461–G467. [Google Scholar] [CrossRef]

- Howlader, M.M.R.; Suga, T.; Kim, M.J. Room temperature bonding of silicon and lithium niobate. Appl. Phys. Lett. 2006, 89, 031914. [Google Scholar] [CrossRef]

- Kondou, R.; Wang, C.; Shigetou, A.; Suga, T. Nanoadhesion layer for enhanced Si-Si and Si-SiN wafer bonding. Microelectron. Reliab. 2012, 52, 342–346. [Google Scholar] [CrossRef]

- Suga, T.; Mu, F.; Fujino, M.; Takahashi, Y.; Nakazawa, H.; Iguchi, K. Silicon carbide wafer bonding by modified surface activated bonding method. Jpn. J. Appl. Phys. 2015, 54, 030214. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Asano, T. Surface activated wafer bonding of LiNbO3 and SiO2/Si for LNOI on Si. In Proceedings of the 2017 5th International Workshop on Low Temperature Bonding for 3D Integration (LTB-3D), Tokyo, Japan, 16–18 May 2017; p. 47. [Google Scholar]

- Takigawa, R.; Higurashi, E.; Asano, T. Room-temperature wafer bonding of LiNbO3 and SiO2 using surface activated bonding method. Jpn. J. Appl. Phys. 2018, 57, 06HJ12. [Google Scholar] [CrossRef]

- Shimatsu, T.; Uomoto, M. Atomic diffusion bonding of wafers with thin nanocrystalline metal films. J. Vac. Sci. Technol. B 2010, 28, 706–714. [Google Scholar] [CrossRef]

- Utsumi, J.; Ide, K.; Ichiyanagi, Y. Room-temperature bonding of SiO2 and SiO2 by surface activated bonding method using Si ultrathin films. Jpn. J. Appl. Phys. 2016, 55, 026503. [Google Scholar] [CrossRef]

- Takigawa, R.; Asano, T. Thin-film lithium niobate-on-insulator waveguides fabricated on silicon wafer by room-temperature bonding method with silicon nanoadhesive layer. Opt. Express 2018, 26, 24413–24421. [Google Scholar] [CrossRef] [PubMed]

- Fontana, M.D.; Bourson, P. Microstructure and defects probed by Raman spectroscopy in lithium niobate crystals and devices. Appl. Phys. Rev. 2015, 2, 040602. [Google Scholar] [CrossRef]

- Suchocki, A.; Paszkowicz, W.; Kamińska, A.; Durygin, A.; Saxena, S.K.; Arizmendi, L.; Bermudez, V. Influence of stoichiometry on phase transition pressure of LiNbO3. Appl. Phys. Lett. 2006, 89, 261908. [Google Scholar] [CrossRef]

- Pezzotti, G.; Hagihara, H.; Zhu, W. Quantitative investigation of Raman selection rules and validation of the secular equation for trigonal LiNbO3. J. Phys. D: Appl. Phys. 2013, 46, 145103. [Google Scholar] [CrossRef]

- Hsueh, C.H.; Lee, S. Modeling of elastic thermal stresses in two materials joined by a graded layer. Composites: Part B 2003, 34, 747–752. [Google Scholar] [CrossRef]

- Smith, R.T.; Welsh, F.S. Temperature Dependence of the Elastic, Piezoelectric, and Dielectric Constants of Lithium Tantalate and Lithium Niobate. J. Appl. Phys. 1971, 42, 2219–2230. [Google Scholar] [CrossRef]

- Pignatiello, F.; De Rosa, M.; Ferraro, P.; Grilli, S.; De Natale, P.; Arie, A.; De Nicola, S. Measurement of the thermal expansion coefficients of ferroelectric crystals by a Moire interferometer. Opt. Commun. 2007, 277, 14–18. [Google Scholar] [CrossRef]

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the young modulus of Silicon? J. Microelectromech. Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef]

- Swenson, C.A. Recommended values for the thermal expansivity of silicon from 0 to 1000 K. J. Phys. Chem. Ref. Data 1983, 12, 179–182. [Google Scholar] [CrossRef]

- Zhao, J.H.; Ryan, T.; Ho, P.S.; McKerrow, A.J.; Shih, W.Y. Measurement of elastic modulus, Poisson ratio, and coefficient of thermal expansion of on-wafer submicron films. J. Appl. Phys. 1999, 85, 6421–6424. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takigawa, R.; Tomimatsu, T.; Higurashi, E.; Asano, T. Residual Stress in Lithium Niobate Film Layer of LNOI/Si Hybrid Wafer Fabricated Using Low-Temperature Bonding Method. Micromachines 2019, 10, 136. https://doi.org/10.3390/mi10020136

Takigawa R, Tomimatsu T, Higurashi E, Asano T. Residual Stress in Lithium Niobate Film Layer of LNOI/Si Hybrid Wafer Fabricated Using Low-Temperature Bonding Method. Micromachines. 2019; 10(2):136. https://doi.org/10.3390/mi10020136

Chicago/Turabian StyleTakigawa, Ryo, Toru Tomimatsu, Eiji Higurashi, and Tanemasa Asano. 2019. "Residual Stress in Lithium Niobate Film Layer of LNOI/Si Hybrid Wafer Fabricated Using Low-Temperature Bonding Method" Micromachines 10, no. 2: 136. https://doi.org/10.3390/mi10020136

APA StyleTakigawa, R., Tomimatsu, T., Higurashi, E., & Asano, T. (2019). Residual Stress in Lithium Niobate Film Layer of LNOI/Si Hybrid Wafer Fabricated Using Low-Temperature Bonding Method. Micromachines, 10(2), 136. https://doi.org/10.3390/mi10020136