Self-Healing Flexible Conductive Film by Repairing Defects via Flowable Liquid Metal Droplets

Abstract

1. Introduction

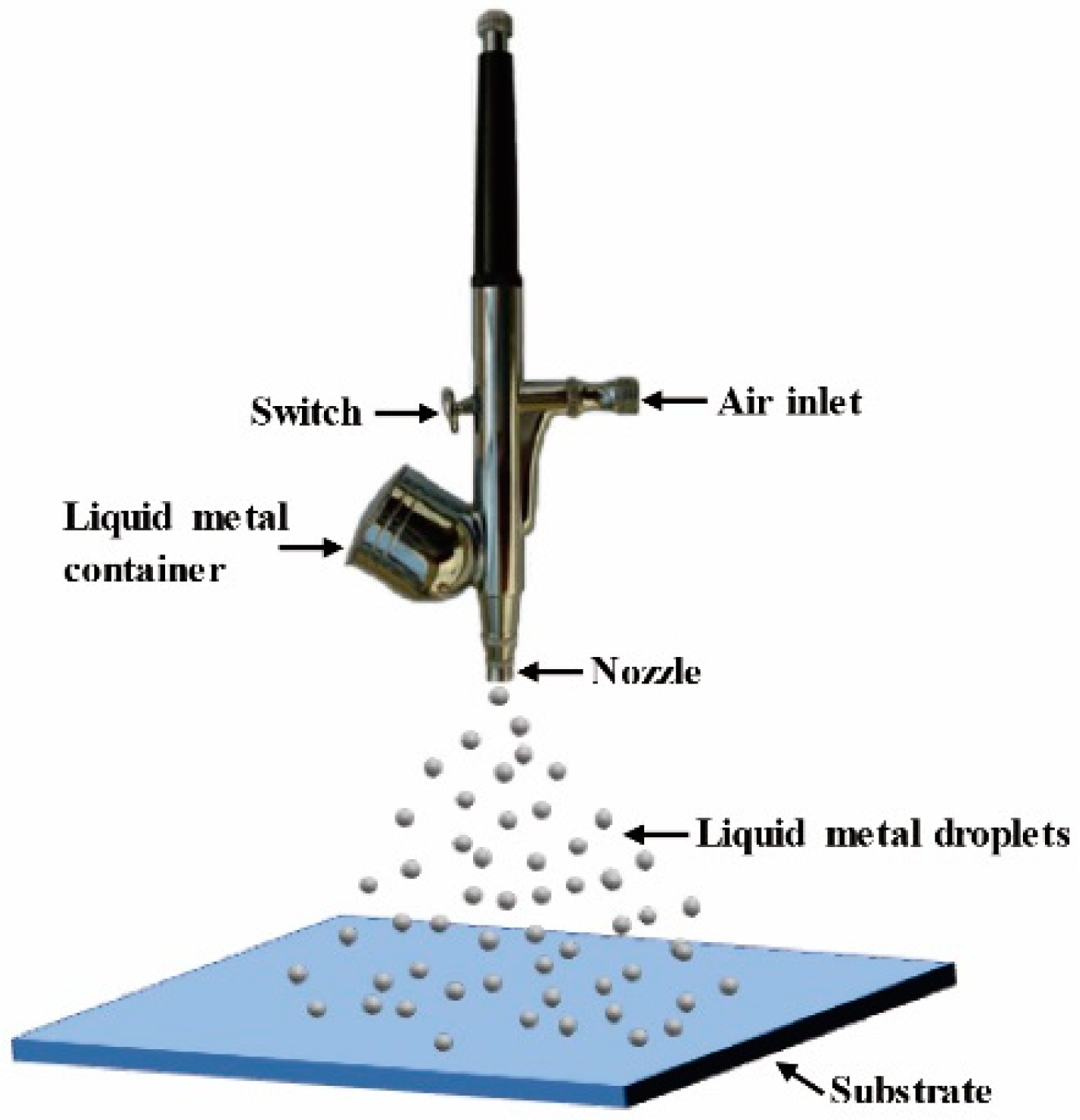

2. Materials and Methods

3. Results

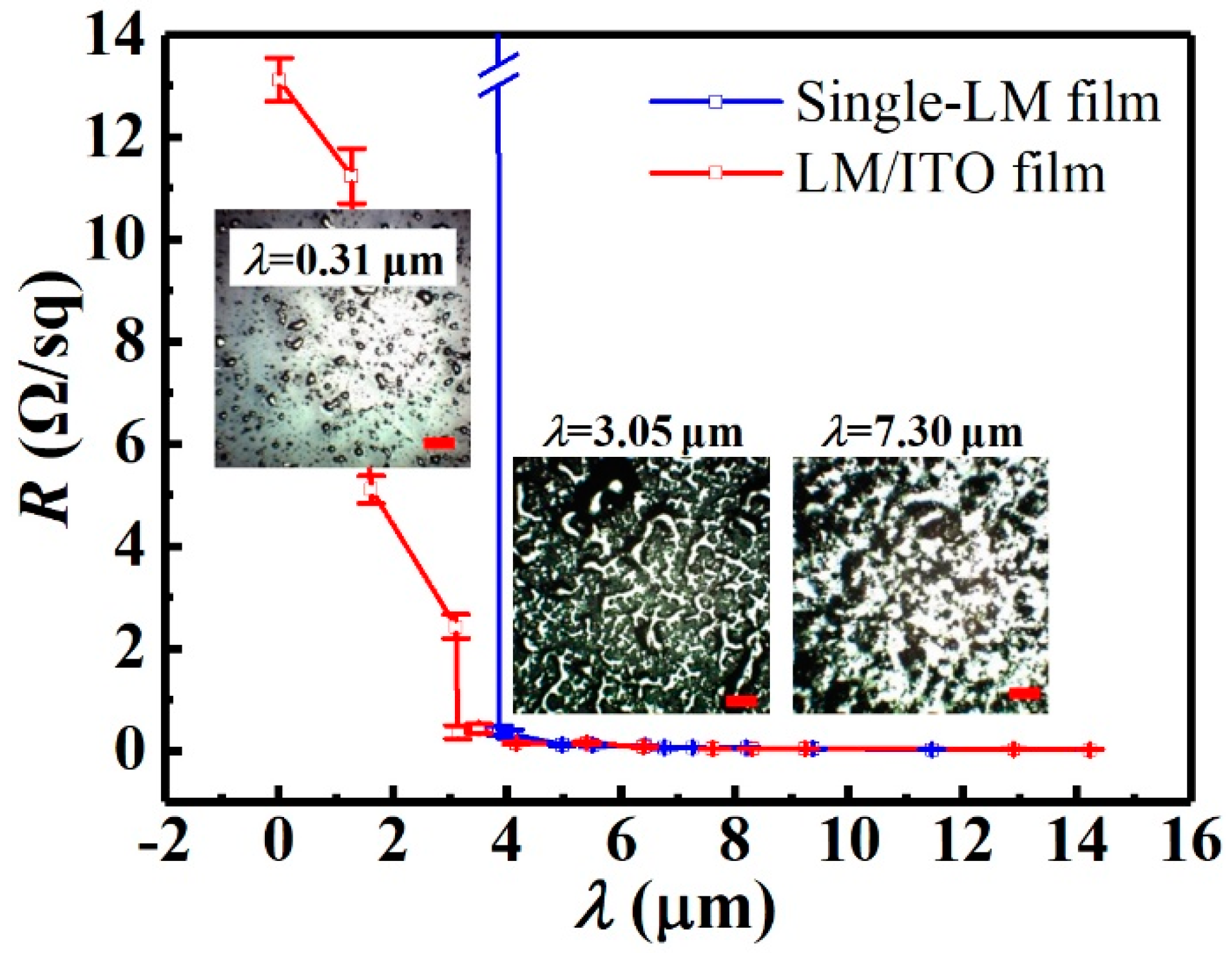

3.1. Electrical Conductivity of the Films

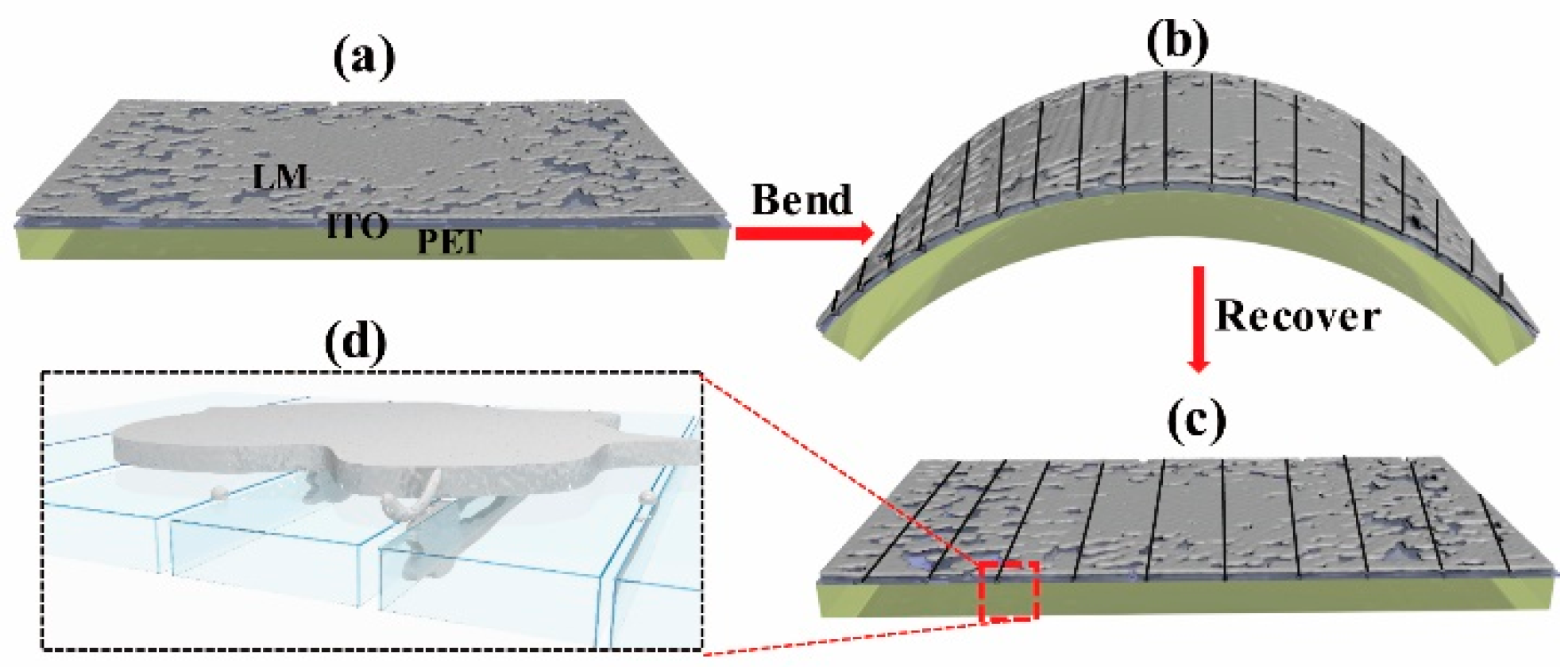

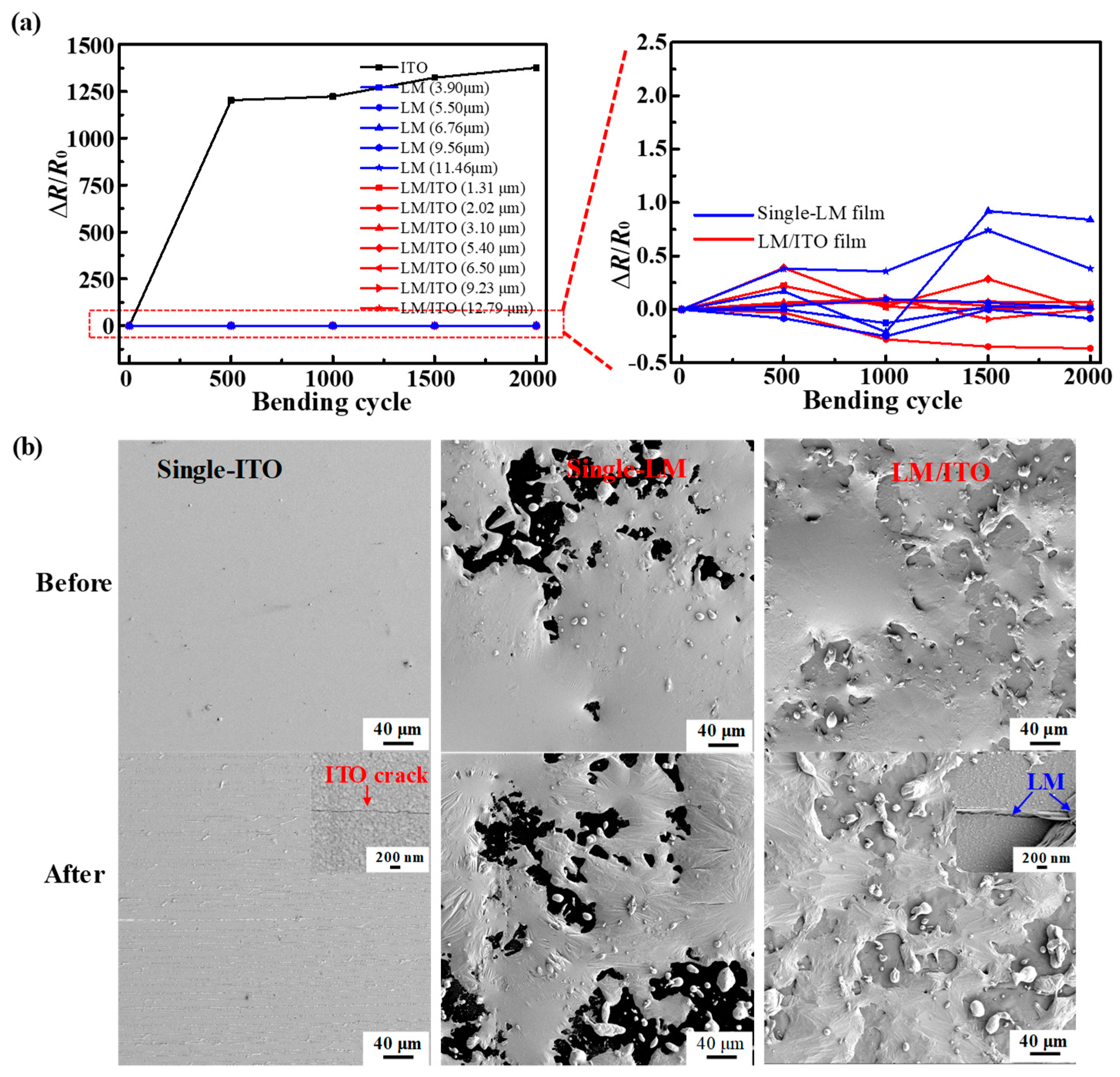

3.2. Flexibility and Self-Healing of the Films

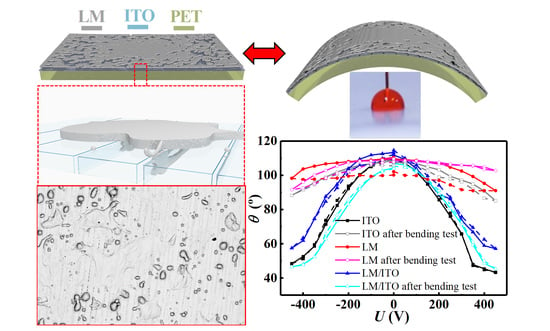

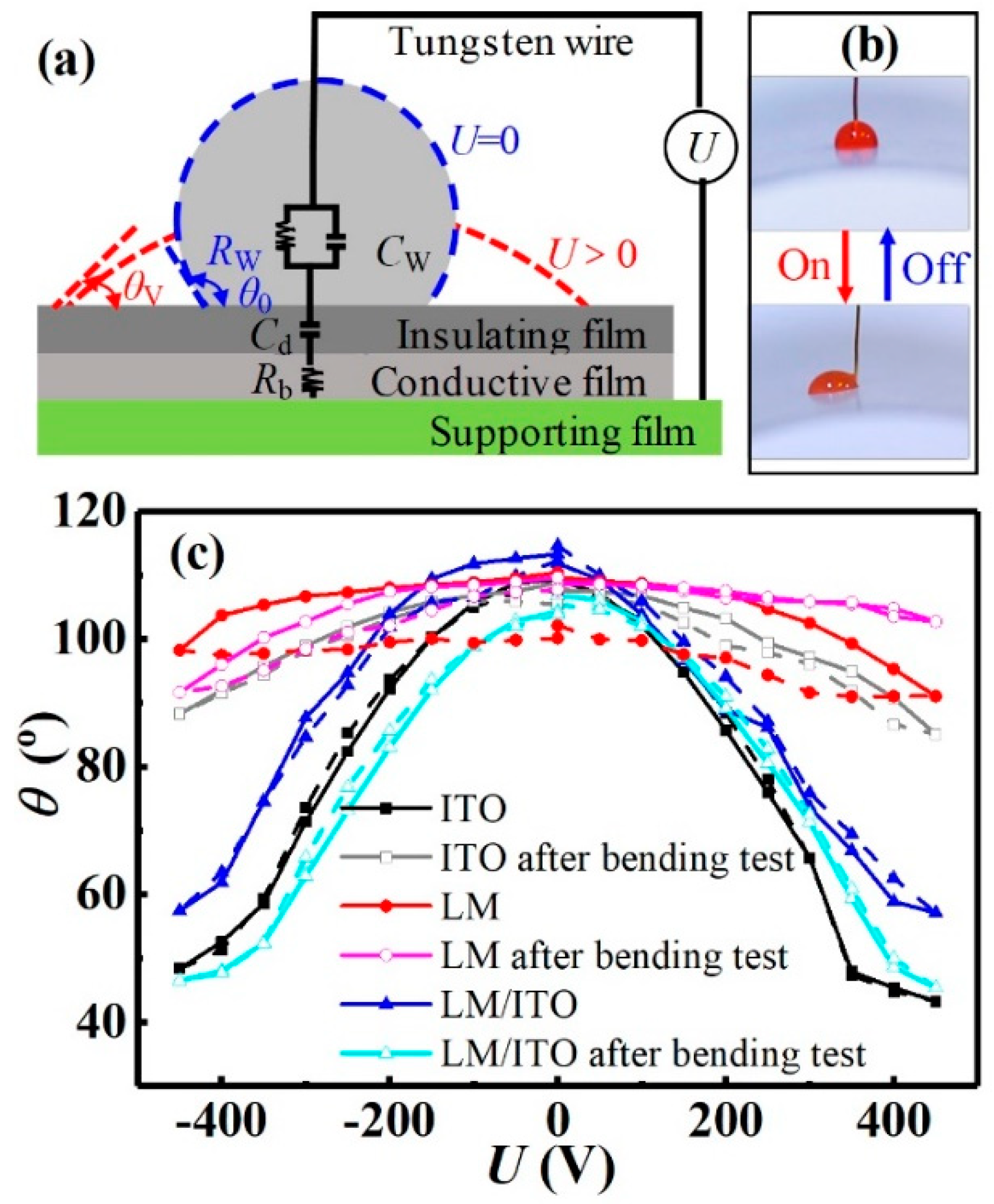

3.3. Electrowetting Performance on the Flexible Conductive Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Cai, L.; Zhang, S.; Zhang, Y.; Li, J.; Miao, J.; Wang, Q.; Yu, Z.; Wang, C. Direct Printing for Additive Patterning of Silver Nanowires for Stretchable Sensor and Display Applications. Adv. Mater. Technol.-US. 2017, 3, 1700232. [Google Scholar] [CrossRef]

- Kang, S.; Kim, T.; Cho, S.; Lee, Y.; Choe, A.; Walker, B.; Ko, S.-J.; Kim, J.Y.; Ko, H. Capillary printing of highly aligned silver nanowire transparent electrodes for high-performance optoelectronic devices. Nano Lett. 2015, 15, 7933–7942. [Google Scholar] [CrossRef] [PubMed]

- Sangoi, R.; Smith, C.G.; Seymour, M.D.; Venkataraman, J.N.; Clark, D.M.; Kleper, M.L.; Kahn, B.E. Printing radio frequency identification (RFID) tag antennas using inks containing silver dispersions. J. Disper. Sci. Technol. 2005, 25, 513–521. [Google Scholar] [CrossRef]

- Wong, F.; Fung, M.; Tong, S.; Lee, C.; Lee, S. Flexible organic light-emitting device based on magnetron sputtered indium-tin-oxide on plastic substrate. Thin Solid Films 2004, 466, 225–230. [Google Scholar] [CrossRef]

- Ahn, B.Y.; Duoss, E.B.; Motala, M.J.; Guo, X.; Park, S.-I.; Xiong, Y.; Yoon, J.; Nuzzo, R.G.; Rogers, J.A.; Lewis, J.A. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 2009, 323, 1590–1593. [Google Scholar] [CrossRef] [PubMed]

- Hao, C.; Liu, Y.; Chen, X.; He, Y.; Li, Q.; Li, K.; Wang, Z. Electrowetting on liquid-infused film (EWOLF): Complete reversibility and controlled droplet oscillation suppression for fast optical imaging. Sci. Rep.-UK. 2014, 4, 6846. [Google Scholar] [CrossRef] [PubMed]

- Narasimhan, V.; Park, S.Y. An Ion Gel as a Low-Cost, Spin-Coatable, High-Capacitance Dielectric for Electrowetting-on-Dielectric (EWOD). Langmuir 2015, 31, 8512–8518. [Google Scholar] [CrossRef]

- Yang, C.-W.; Park, J.-W. The cohesive crack and buckle delamination resistances of indium tin oxide (ITO) films on polymeric substrates with ductile metal interlayers. Surf. Coat. Technol. 2010, 204, 2761–2766. [Google Scholar] [CrossRef]

- Lin, H.; Chiu, S.; Cho, T.; Huang, J. Improved bending fatigue behavior of flexible PET/ITO film with thin metallic glass interlayer. Mater. Lett. 2013, 113, 182–185. [Google Scholar] [CrossRef]

- Parekh, D.P.; Ladd, C.; Panich, L.; Moussa, K.; Dickey, M.D. 3D printing of liquid metals as fugitive inks for fabrication of 3D microfluidic channels. Lab Chip. 2016, 16, 1812–1820. [Google Scholar] [CrossRef]

- Kurdesau, F.; Khripunov, G.; Da Cunha, A.; Kaelin, M.; Tiwari, A. Comparative study of ITO layers deposited by DC and RF magnetron sputtering at room temperature. J. Non-Cryst. Solids 2006, 352, 1466–1470. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, L.; Wu, F. Indium tin oxide@ carbon core–shell nanowire and jagged indium tin oxide nanowire. Nanoscale Res. Lett. 2010, 5, 1682. [Google Scholar] [CrossRef] [PubMed]

- Aouaj, M.A.; Diaz, R.; Belayachi, A.; Rueda, F.; Abd-Lefdil, M. Comparative study of ITO and FTO thin films grown by spray pyrolysis. Mater. Res. Bull. 2009, 44, 1458–1461. [Google Scholar] [CrossRef]

- Yong, T.-K.; Tan, S.-S.; Nee, C.-H.; Yap, S.-S.; Kee, Y.-Y.; Sáfrán, G.; Horváth, Z.E.; Moscatello, J.; Yap, Y.-K.; Tou, T.-Y. Pulsed laser deposition of indium tin oxide nanowires in argon and helium. Mater. Lett. 2012, 66, 280–281. [Google Scholar] [CrossRef]

- Herrero, J.; Guillen, C. Improved ITO thin films for photovoltaic applications with a thin ZnO layer by sputtering. Thin Solid Films 2004, 451, 630–633. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Z.; Du, X.; Logan, J.M.; Sippel, J.; Nikolou, M.; Kamaras, K.; Reynolds, J.R.; Tanner, D.B.; Hebard, A.F. Transparent, conductive carbon nanotube films. Science 2004, 305, 1273–1276. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Kim, H.R.; Song, Y.I. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Han, B.; Pei, K.; Huang, Y.; Zhang, X.; Rong, Q.; Lin, Q.; Guo, Y.; Sun, T.; Guo, C.; Carnahan, D. Uniform self-forming metallic network as a high-performance transparent conductive electrode. Adv. Mater. 2014, 26, 873–877. [Google Scholar] [CrossRef]

- Ding, X.; Yan, J.; Li, T.; Zhang, L. Transparent conductive ITO/Cu/ITO films prepared on flexible substrates at room temperature. Appl. Surf. Sci. 2012, 258, 3082–3085. [Google Scholar] [CrossRef]

- Palleau, E.; Reece, S.; Desai, S.C.; Smith, M.E.; Dickey, M.D. Self-Healing Stretchable Wires for Reconfi gurable Circuit Wiring and 3D Microfluidics. Adv. Mater. 2012, 25, 1589–1592. [Google Scholar] [CrossRef]

- Kim, M.G.; Alrowais, H.; Pavlidis, S.; Brand, O. Size-Scalable and High-Density Liquid-Metal-Based Soft Electronic Passive Components and Circuits Using Soft Lithography. Adv. Funct. Mater. 2017, 27, 1604466. [Google Scholar] [CrossRef]

- Liang, S.; Li, Y.; Chen, Y.; Yang, J.; Zhu, T.; Zhu, D.; He, C.; Liu, Y.; Handschuh-Wang, S.; Zhou, X. Liquid metal sponges for mechanically durable, all-soft, electrical conductors. J. Mater. Chem. C 2017, 5, 1586–1590. [Google Scholar] [CrossRef]

- Xu, Q.; Oudalov, N.; Guo, Q.; Jaeger, H.M.; Brown, E. Effect of oxidation on the mechanical properties of liquid gallium and eutectic gallium-indium. Phy. Fluids 2012, 24, 063101. [Google Scholar] [CrossRef]

- Lin, Y.L.; Cooper, C.; Wang, M.; Adams, J.J.; Genzer, J.; Dickey, M.D. Handwritten, Soft Circuit Boards and Antennas Using Liquid Metal Nanoparticles. Small 2015, 11, 6397–6403. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Gao, Y.; Liu, J. Atomized spraying of liquid metal droplets on desired substrate surfaces as a generalized way for ubiquitous printed electronics. Appl. Phys. A 2013, 116, 1091–1097. [Google Scholar] [CrossRef]

- Wu, Z.; Hjort, K.; Jeong, S.H. Microfluidic stretchable radio-frequency devices. Proc. IEEE 2015, 103, 1211–1225. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.; Grady, M.E.; McIlroy, D.A.; Moore, J.S.; Sottos, N.R.; White, S.R. Autonomic restoration of electrical conductivity. Adv. Mater. 2012, 24, 398–401. [Google Scholar] [CrossRef] [PubMed]

- Fritsching, U. Droplets and particles in sprays: tailoring particle properties within spray processes. China Part. 2005, 3, 125–133. [Google Scholar] [CrossRef]

- Modreanu, M.; Cosmin, P.; Cosmin, S.; Conianu, C.; Dunare, C. Measurement of CVD thin films thickness by sample weighing method. Int. Semicond. Conf. 1996, 2, 409–412. [Google Scholar]

- Martin, E.; Yan, M.; Lane, M.; Ireland, J.; Kannewurf, C.; Chang, R. Properties of multilayer transparent conducting oxide films. Thin Solid Films 2004, 461, 309–315. [Google Scholar] [CrossRef]

- Abdelgawad, M.; Wheeler, A.R. The digital revolution: a new paradigm for microfluidics. Adv. Mater. 2009, 21, 920–925. [Google Scholar] [CrossRef]

- Fan, S.-K.; Yang, H.; Hsu, W. Droplet-on-a-wristband: Chip-to-chip digital microfluidic interfaces between replaceable and flexible electrowetting modules. Lab Chip 2011, 11, 343–347. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Jiang, H. Fabrication and characterization of flexible electrowetting on dielectrics (EWOD) microlens. Micromachines 2014, 5, 432–441. [Google Scholar] [CrossRef]

- Kim, D.Y.; Steckl, A.J. Electrowetting on paper for electronic paper display. ACS Appl. Mater. Inter. 2010, 2, 3318–3323. [Google Scholar] [CrossRef] [PubMed]

- Welters, W.J.; Fokkink, L.G. Fast electrically switchable capillary effects. Langmuir 1998, 14, 1535–1538. [Google Scholar] [CrossRef]

- Wu, H.; Hayes, R.A.; Li, F.; Henzen, A.; Shui, L.; Zhou, G. Influence of fluoropolymer surface wettability on electrowetting display performance. Displays 2018, 53, 47–53. [Google Scholar] [CrossRef]

- Moon, H.; Cho, S.K.; Garrell, R.L.; Kim, C.-J.C. Low voltage electrowetting-on-dielectric. J. Appl. Phys. 2002, 92, 4080–4087. [Google Scholar] [CrossRef]

- Chen, X.; He, T.; Jiang, H.; Wei, B.; Chen, G.; Fang, X.; Jin, M.; Hayes, R.A.; Zhou, G.; Shui, L. Screen-printing fabrication of electrowetting displays based on poly (imide siloxane) and polyimide. Displays 2015, 37, 79–85. [Google Scholar] [CrossRef]

- Hu, L.; Gruner, G.; Gong, J.; Kim, C.-J.C.; Hornbostel, B. Electrowetting devices with transparent single-walled carbon nanotube electrodes. Appl. Phys. Lett. 2007, 90, 093124. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, R.; Jin, M.; Cao, J.; Yan, Z.; Gao, J.; Wu, H.; Zhou, G.; Shui, L. Self-Healing Flexible Conductive Film by Repairing Defects via Flowable Liquid Metal Droplets. Micromachines 2019, 10, 113. https://doi.org/10.3390/mi10020113

Niu R, Jin M, Cao J, Yan Z, Gao J, Wu H, Zhou G, Shui L. Self-Healing Flexible Conductive Film by Repairing Defects via Flowable Liquid Metal Droplets. Micromachines. 2019; 10(2):113. https://doi.org/10.3390/mi10020113

Chicago/Turabian StyleNiu, Ruiwen, Mingliang Jin, Jieping Cao, Zhibin Yan, Jinwei Gao, Hao Wu, Guofu Zhou, and Lingling Shui. 2019. "Self-Healing Flexible Conductive Film by Repairing Defects via Flowable Liquid Metal Droplets" Micromachines 10, no. 2: 113. https://doi.org/10.3390/mi10020113

APA StyleNiu, R., Jin, M., Cao, J., Yan, Z., Gao, J., Wu, H., Zhou, G., & Shui, L. (2019). Self-Healing Flexible Conductive Film by Repairing Defects via Flowable Liquid Metal Droplets. Micromachines, 10(2), 113. https://doi.org/10.3390/mi10020113