Surface/Interface Engineering for Constructing Advanced Nanostructured Light-Emitting Diodes with Improved Performance: A Brief Review

Abstract

1. Introduction

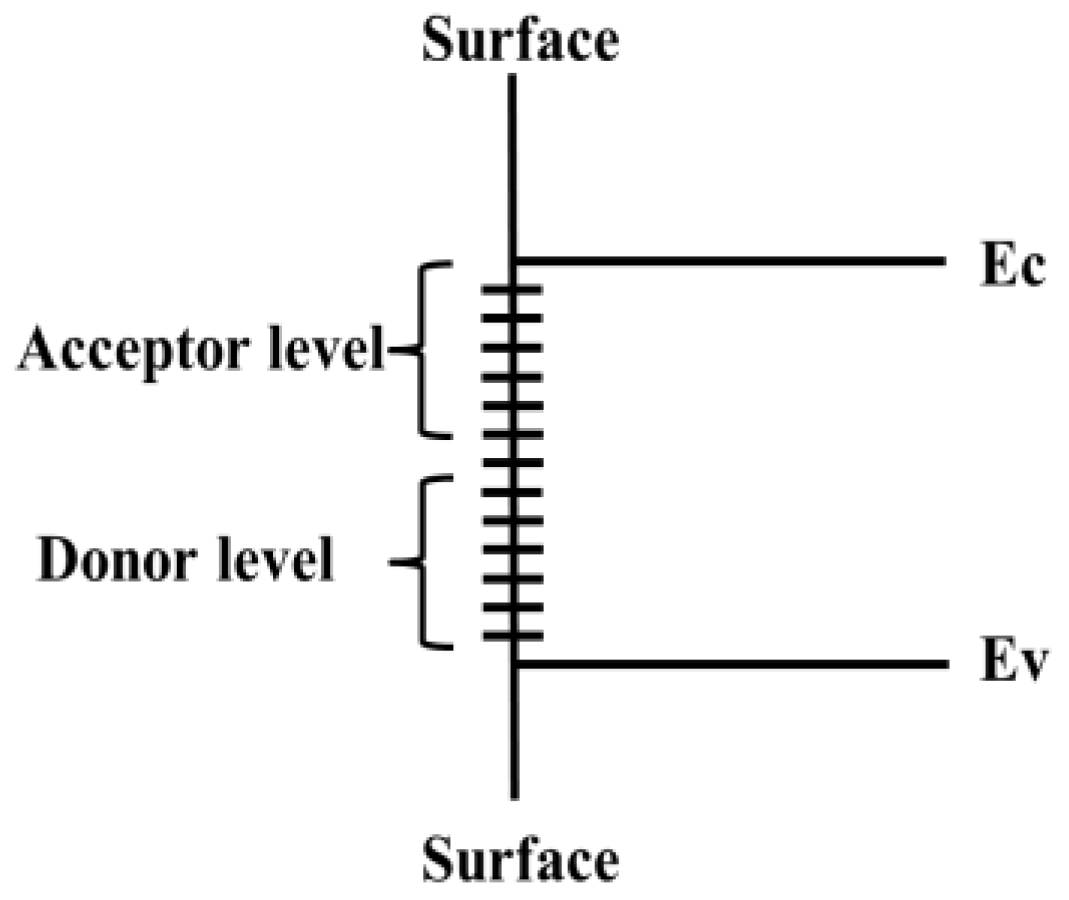

2. Surface/Interface Properties

3. Influence of Surface and Interface on LED and Optimization Method

3.1. Influence of Surface and Interface of 0D Nanomaterials on LED and Optimization Method

3.1.1. Surface Purification Methods

3.1.2. QDs Emitting Layer Method

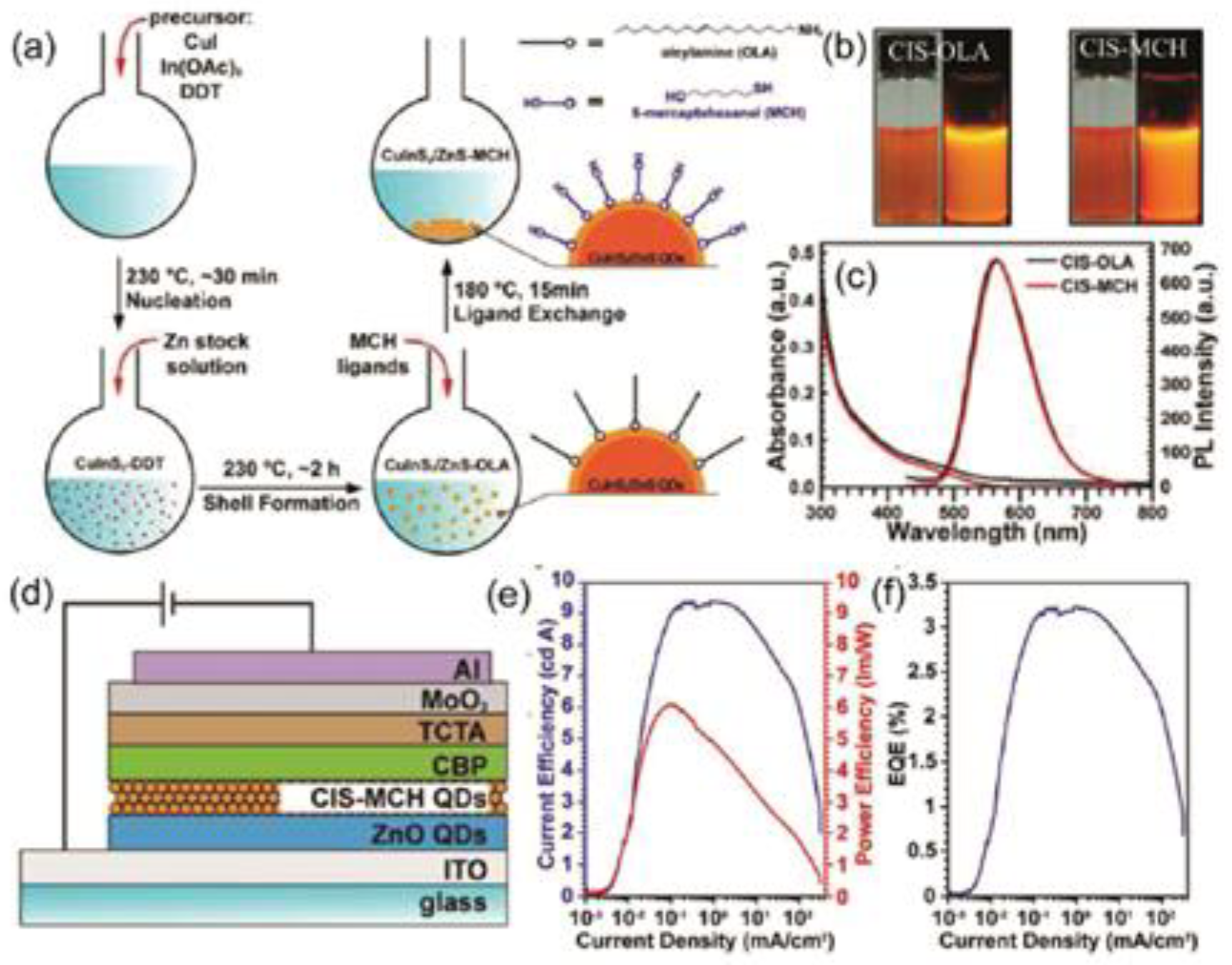

3.1.3. Surface Ligand Method

3.1.4. Core/Shell Interface Structure Method

3.1.5. Optimization of LED Device Interface Architecture Methods

3.2. Influence of Surface and Interface of 1D Nanomaterials on LED and Optimization Method

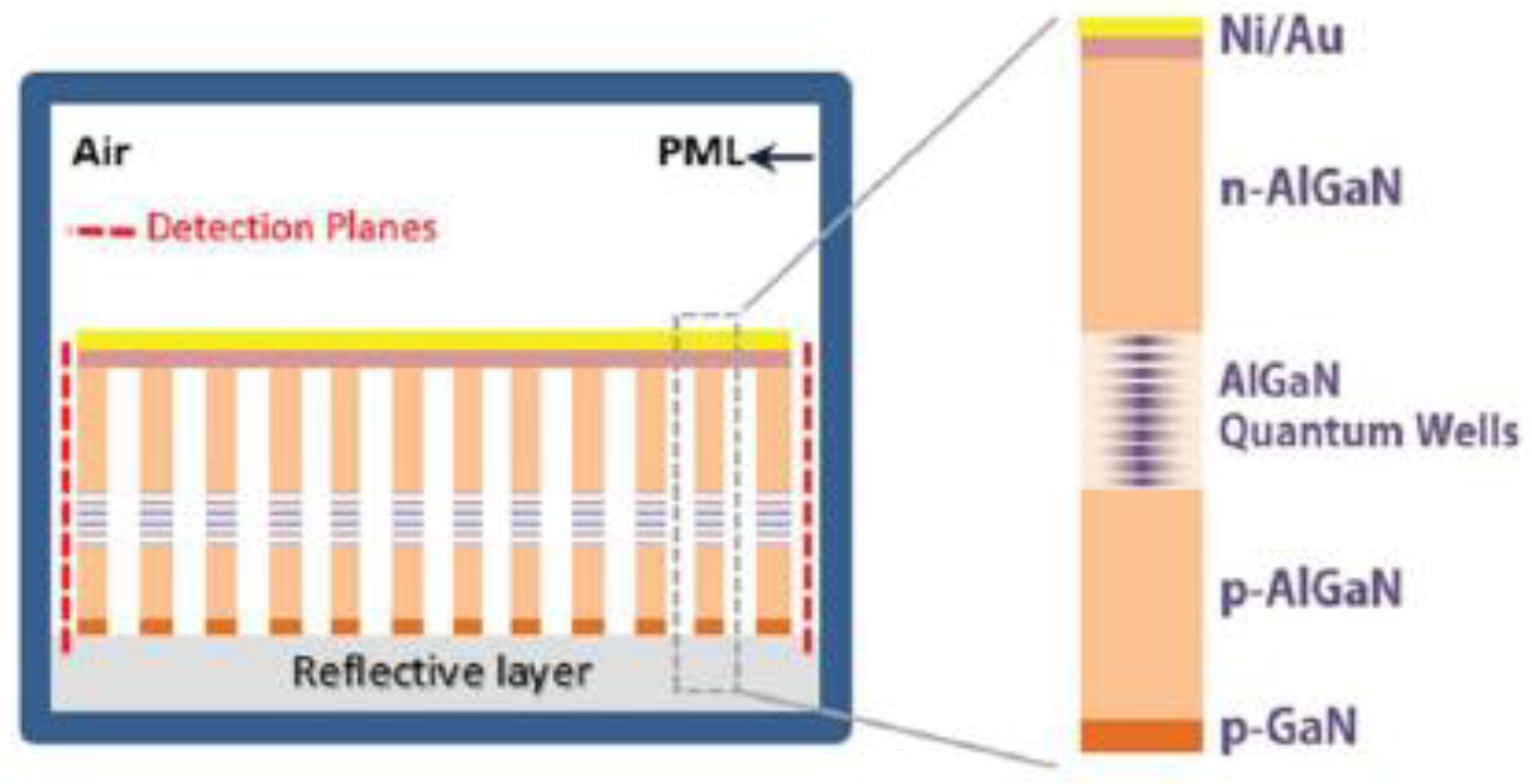

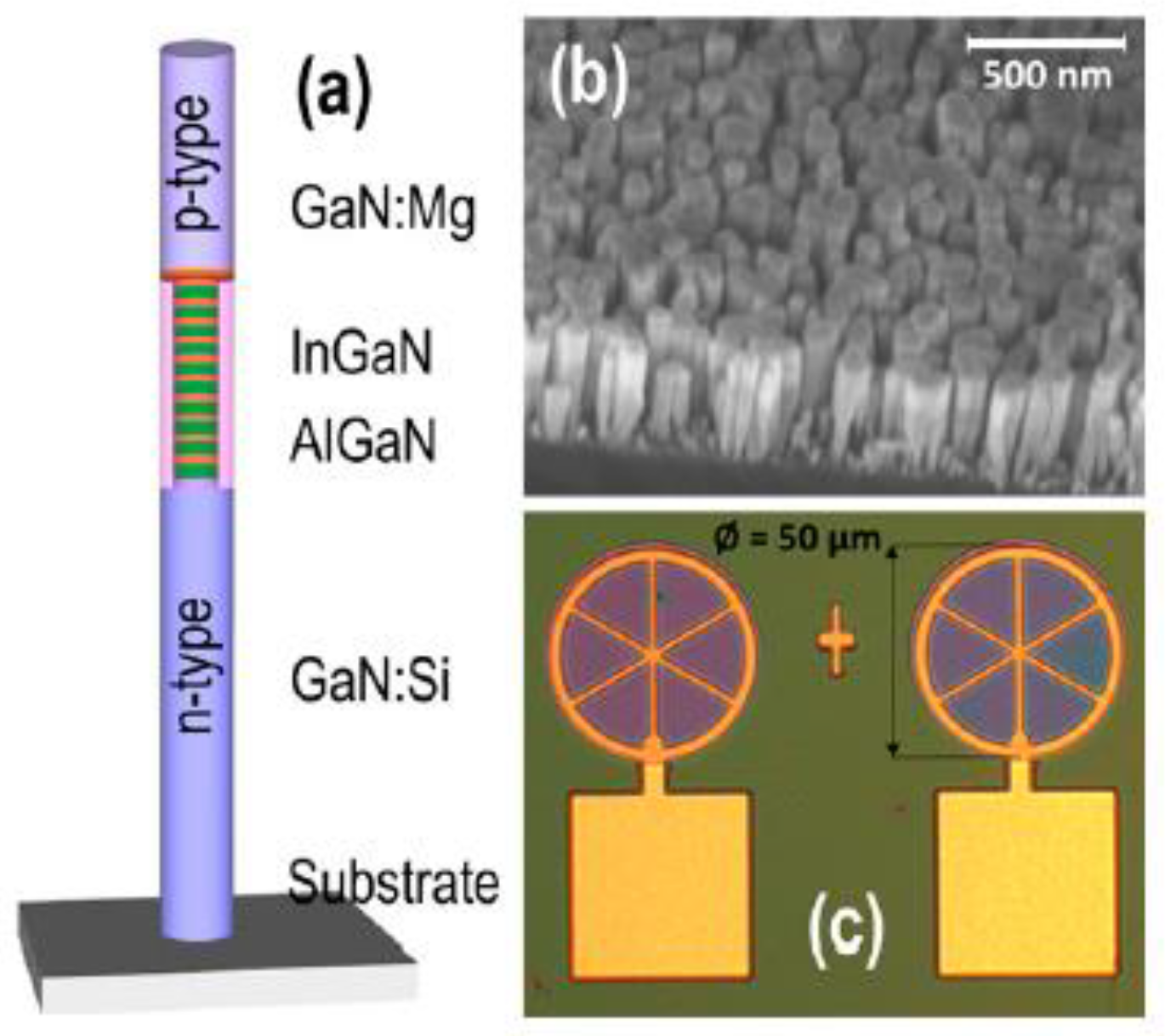

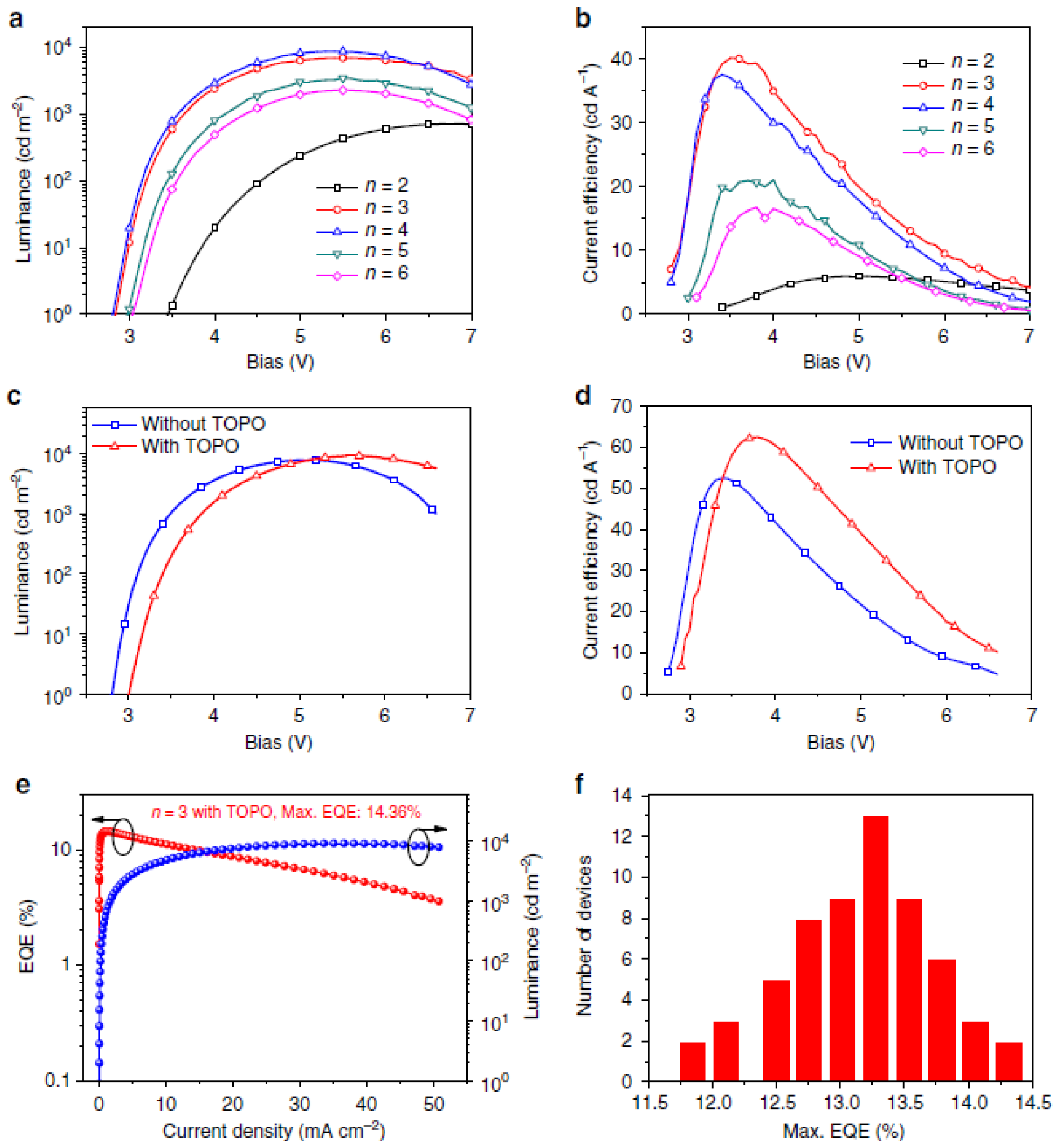

3.2.1. Surface or Interface Structure Design Methods

3.2.2. Interface Control 1D Nanomaterial Methods

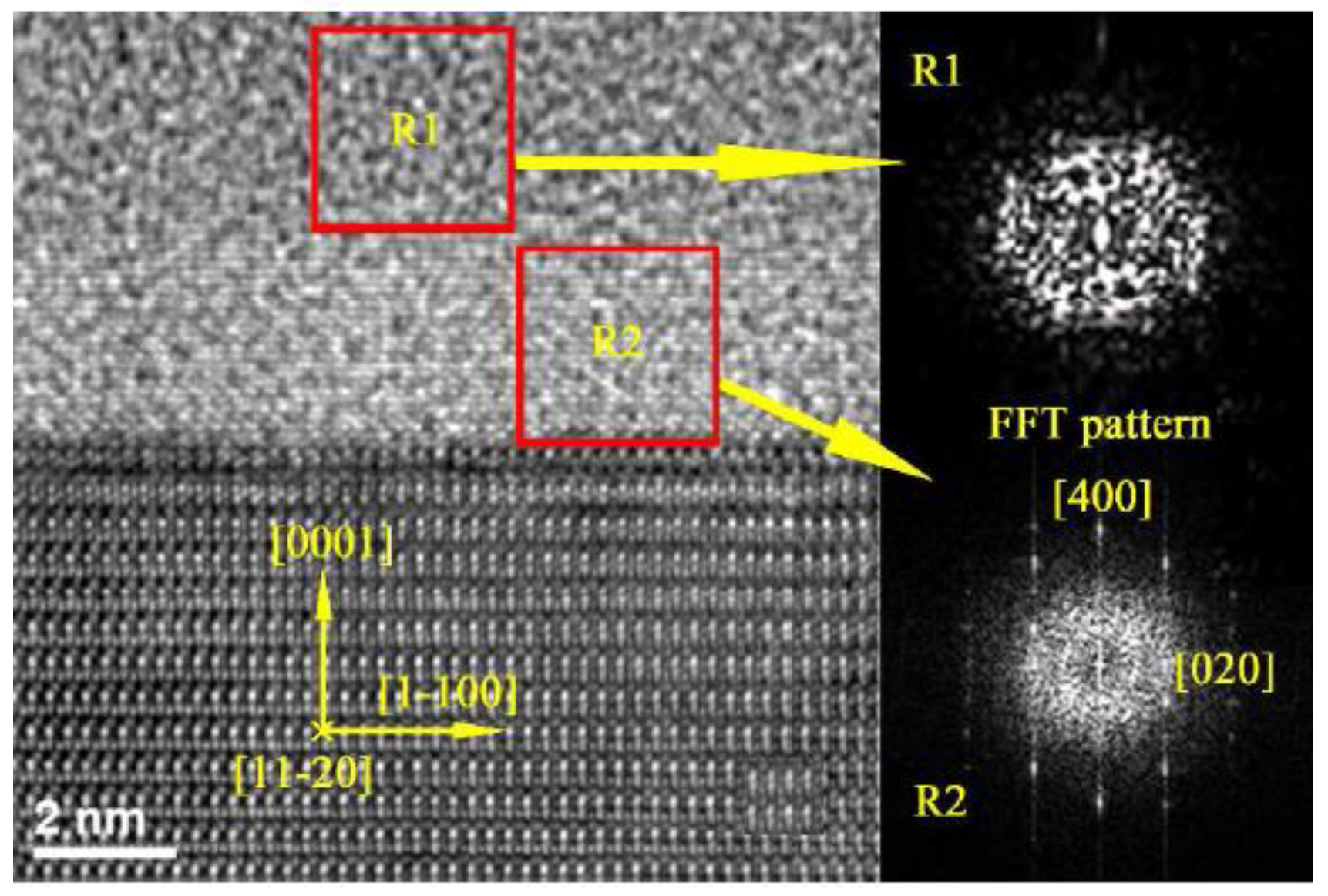

3.2.3. Interface Modification and Modulation 1D Nanomaterial Methods

3.2.4. Core/Shell Structure Methods

3.3. Influence of Surface and Interface of 2D Nanomaterials on LED and Optimization Method

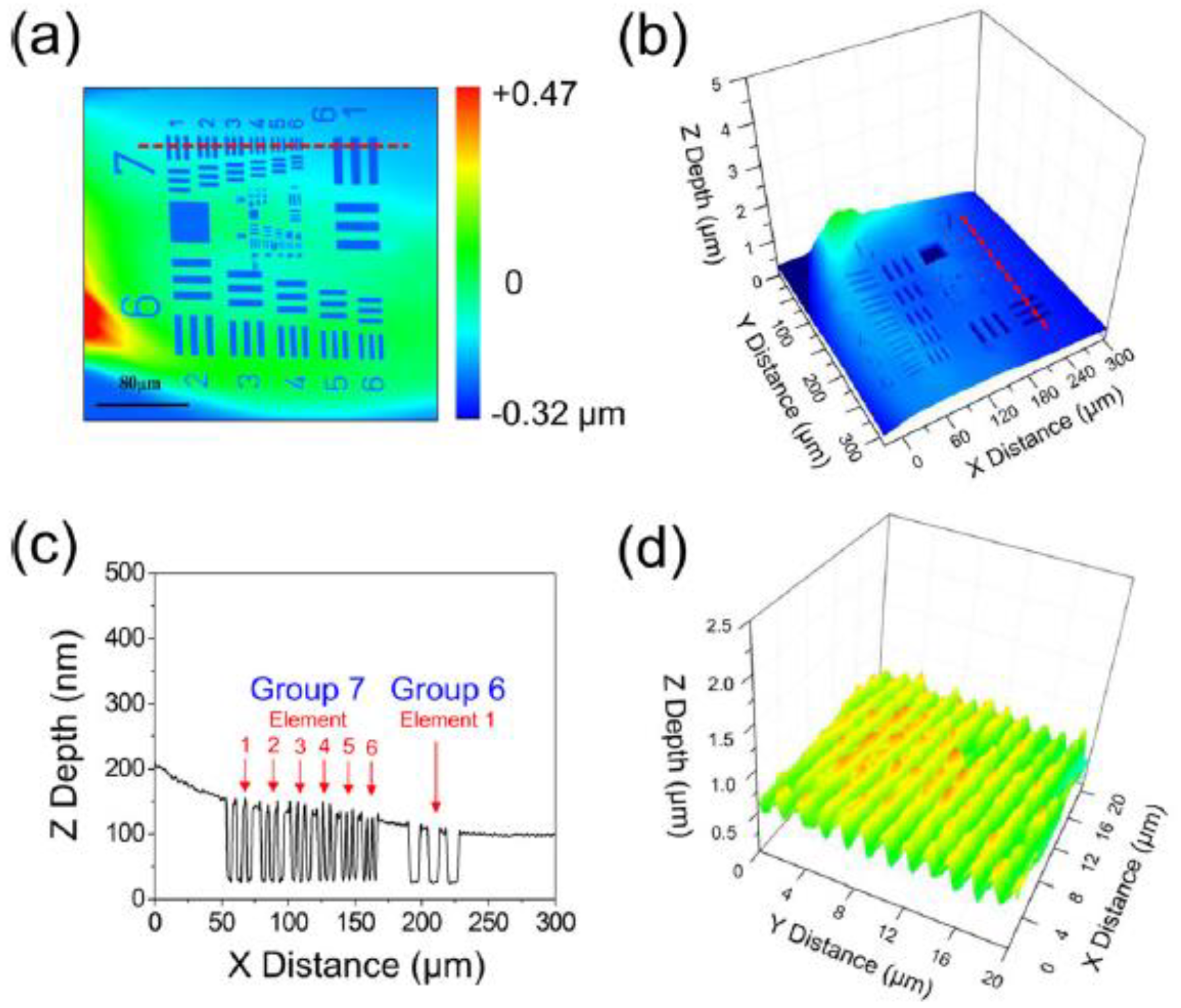

3.3.1. Surface Modification and Interface Engineering Method

3.3.2. Interface Structure Design Methods

4. Conclusions and Perspective

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jie, J.S.; Zhang, W.J.; Bello, I.; Lee, C.S.; Lee, S.T. One-dimensional II-VI nanostructures: Synthesis, properties and optoelectronic applications. Nano Today 2010, 5, 313–336. [Google Scholar] [CrossRef]

- Panda, D.; Tseng, T.Y. One-dimensional ZnO nanostructures: Fabrication, optoelectronic properties, and device applications. J. Mater. Sci. 2013, 48, 6849–6877. [Google Scholar] [CrossRef]

- Pascal, A.; Peter, R.; Jens, W.T.; Jean-Charles, R.; Iwan, M. Semiconductor nanostructures towards electronic and optoelectronic device applications. Phys. Status Solidi C 2014, 11, 193–194. [Google Scholar]

- Burak, G.; Hilmi, V.D. Near-field energy transfer using nanoemitters for optoelectronics. Adv. Funct. Mater. 2016, 26, 8158–8177. [Google Scholar]

- Sudaraka, M.; Sarath, D.G.; Mark, I.S.; Malin, P. Generalized superradiant assembly for nanophotonic thermal emitters. Phys. Rev. B 2018, 97, 125406. [Google Scholar]

- He, X.; Htoon, H.; Doorn, S.K.; Pernice, W.H.P.; Pyatkov, F.; Krupke, P.; Jeantet, A.; Chassagneux, Y.; Voisin, C. Carbon nanotubes as emerging quantum-light sources. Nat. Mater. 2018, 17, 663–670. [Google Scholar] [CrossRef]

- Gu, Q.Y.; Chen, J.N. Carbon-nanotube-based nano-emitters: A review. J. Lumin. 2018, 200, 181–188. [Google Scholar] [CrossRef]

- Liang, F.X.; Gao, Y.; Xie, C.; Tong, X.W.; Li, Z.J.; Luo, L.B. Recent advances in the fabrication of graphene-ZnO heterojunctions for optoelectronic device applications. J. Mater. Chem. C 2018, 6, 3815–3833. [Google Scholar] [CrossRef]

- Xie, C.; Wang, Y.; Zhang, Z.X.; Wang, D.; Luo, L.B. Graphene/semiconductor hybrid heterostructures for optoelectronic device applications. Nano Today 2018, 19, 41–83. [Google Scholar] [CrossRef]

- Arko, G.; Caroline, M.; Yuriy, Z.; Jana, Z.; Malte, C.G. Infrared organic light-emitting diodes with carbon nanotube emitters. Adv. Mater. 2018, 30, 1706711. [Google Scholar]

- Shen, H.; Cao, W.; Shewmon, N.T.; Yang, C.; Li, L.S.; Xue, J. High-efficiency, low turn-on voltage blue-violet quantum-dot-based light-emitting diodes. Nano Lett. 2015, 15, 1211–1216. [Google Scholar] [CrossRef] [PubMed]

- Nam, S.; Oh, N.; Zhai, Y.; Shim, M. High efficiency and optical anisotropy in double-heterojunction nanorod light-emitting diodes. ACS Nano 2015, 9, 878–885. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Chen, S.; Sun, X.W. Efficient red/green/blue tandem quantum-dot light-emitting diodes with external quantum efficiency exceeding. ACS Nano 2018, 12, 697–704. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.H.; Qi, L.M. Light management with patterned micro- and nanostructure arrays for photocatalysis, photovoltaics, and optoelectronic and optical devices. Adv. Funct. Mater. 2019, 29, 1807275. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Zhang, F.J.; Wang, H.Z.; Wang, L.; Wang, F.F.; Lin, Q.L.; Shen, H.B.; Li, L.S. High-efficiency CdSe/CdS nanorod-based red light-emitting diodes. Opt. Express 2019, 27, 7935–7944. [Google Scholar] [CrossRef]

- Allan, G.; Delerue, C.; Lannoo, M. Nature of luminescent surface states of semiconductor nanocrystallites. Phys. Rev. Lett. 1996, 76, 2961–2964. [Google Scholar] [CrossRef]

- He, G.H.; Jiang, M.M.; Li, B.H.; Zhang, Z.H.; Zhao, H.F.; Shan, C.X.; Shen, D.Z. Sb-doped ZnO microwires: Emitting filament and homojunction light-emitting diodes. J. Mater. Chem. C 2017, 5, 10938–10946. [Google Scholar] [CrossRef]

- Zhao, L.F.; Yeh, Y.W.; Tran, N.L.; Wu, F.; Xiao, Z.G.; Kerner, R.A.; Lin, Y.H.L.; Scholes, G.D.; Yao, N.; Rand, B.P. In situ preparation of metal halide perovskite nanocrystal thin films for improved light-emitting devices. ACS Nano 2017, 11, 3957–3964. [Google Scholar] [CrossRef]

- Ding, M.; Guo, Z.; Zhou, L.Q.; Fang, X.; Zhang, L.L.; Zeng, L.Y.; Xie, L.N.; Zhao, H.B. One-dimensional zinc oxide nanomaterials for application in high-performance advanced optoelectronic devices. Crystals 2018, 8, 223. [Google Scholar] [CrossRef]

- Zhu, L.L.; Tang, X.Y.; Wang, J.C.; Hou, Y. Modeling phonon thermal conductivity in spatially confined GaN nanofilms under stress fields and phonon surface scattering. AIP Adv. 2019, 9, 015024. [Google Scholar] [CrossRef]

- Shalish, I.; Temkin, H.; Narayanamurti, V. Size-dependent surface luminescence in ZnO nanowires. Phys. Rev. B 2004, 69, 245401. [Google Scholar] [CrossRef]

- Wang, X.F.; Zhao, F.L.; Xie, P.B.; Deng, S.Z.; Xu, N.S.; Wang, H.Z. Surface emission characteristics of ZnO nanoparticles. Chem. Phys. Lett. 2006, 423, 361–365. [Google Scholar] [CrossRef]

- Wen, X.M.; Chen, W.J.; Yang, J.F.; Ou, Q.D.; Yang, T.S.; Zhou, C.H.; Lin, H.; Wang, Z.Y.; Zhang, Y.P.; Conibeer, G.J.; et al. The role of surface recombination in halide perovskite nanoplatelets. ACS Appl. Mater. Interfaces 2018, 10, 31586–31593. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.F.; Qian, Q.K.; Li, B.K.; Chen, K.J. Interface engineering of monolayer MoS2/GaN hybrid heterostructure: Modified band alignment for photocatalytic water splitting application by nitridation treatment. ACS Appl. Mater. Interfaces 2018, 10, 17419–17426. [Google Scholar] [CrossRef]

- Mishra, K.C.; Piquette, A. The limits of transmittance of an interface and their effects on light extraction. ECS J. Solid State Sci. Technol. 2018, 9, 3016–3022. [Google Scholar] [CrossRef]

- Ciccullo, F.; Calzolari, A.; Bader, K.; Neugebauer, P.; Gallagher, N.M.; Rajca, A.; Slageren, J.V.; Casu, M.B. Interfacing a potential purely organic molecular quantum bit with a real-life surface. ACS Appl. Mater. Interfaces 2019, 11, 1571–1578. [Google Scholar] [CrossRef]

- Zhao, G.Y.; Hsu, C.H.; Wang, Y.H.; Chan, M.C. Chromatic confocal microscopy to rapidly reveal nanoscale surface/interface topography by position-sensitive detection. Appl. Phys. Lett. 2018, 113, 083106. [Google Scholar] [CrossRef]

- Angelika, M.; Dieter, I.; Thomas, B.; Mirjam, R.; Christof, P.; Herwig, B.; Holger, B.; Christina, S.; Jürgen, P. Analysis of organic multilayer structures using a combined grazing incidence X-ray fluorescence/X-ray reflectometry approach. Spectrochim. Acta Part B 2018, 148, 188–192. [Google Scholar]

- Singh, A.; Mathur, A.; Pal, D.; Sengupta, A.; Singh, R.; Chattopadhyay, S. Structure and morphology of atomic layer deposition grown ZnO thin film/nanostructure on polymeric template. Mater. Today Proc. 2019, 18, 1517–1523. [Google Scholar] [CrossRef]

- Daniela, C.; Maria, A.F. Electronic transitions in low dimensional semiconductor structures measured by surface photovoltage spectroscopy. Mater. Sci. Semicon. Proc. 2019, 92, 28–38. [Google Scholar]

- Park, J.H.; Sanne, A.; Guo, Y.Z.; Amani, M.; Zhang, K.H.; Movva, H.C.P.; Robinson, J.A.; Javey, A.; Robertson, J.; Banerjee, S.K.; et al. Defect passivation of transition metal dichalcogenides via a charge transfer van der Waals interface. Sci. Adv. 2017, 3, 1701661. [Google Scholar] [CrossRef]

- Chen, F.; Guan, Z.Y.; Tang, A.W. Nanostructure and device architecture engineering for high-performance quantum-dot light-emitting diodes. J. Mater. Chem. C 2018, 6, 10958–10981. [Google Scholar] [CrossRef]

- Yang, Y.; Li, J.Z.; Peng, X.G. An efficient and surface-benign purification scheme for colloidal nanocrystals based on quantitative assessment. Nano Res. 2015, 8, 3353–3364. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Lin, H.; Huang, H.; Reckmeier, C.; Zhang, Y.; Choy, W.C.H.; Rogach, A.L. Enhancing the brightness of cesium lead halide perovskite nanocrystal based green light-emitting devices through the interface engineering with perfluorinated ionomer. Nano Lett. 2016, 16, 1415–1420. [Google Scholar] [CrossRef]

- Zou, Y.T.; Ban, M.Y.; Cui, W.; Huang, Q.; Wu, C.; Liu, J.W.; Wu, H.H.; Song, T.; Sun, B.Q. A general solvent selection strategy for solution processed quantum dots targeting high performance light-emitting diode. Adv. Funct. Mater. 2017, 27, 1603325. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, Y.; Cao, W.; Titov, A.; Hyvonen, J.; Manders, J.R.; Xue, J.; Holloway, P.H.; Qian, L. High-efficiency light-emitting devices based on quantum dots with tailored nanostructures. Nat. Photonics 2015, 9, 259–266. [Google Scholar] [CrossRef]

- Cao, W.; Xiang, C.; Yang, Y.; Chen, Q.; Chen, L.; Yan, X.; Qian, L. Highly stable QLEDs with improved hole injection via quantum dot structure tailoring. Nat. Commun. 2018, 9, 2608. [Google Scholar] [CrossRef]

- Chiba, T.; Hayashi, Y.; Ebe, H.; Hoshi, K.; Sato, J.; Sato, S.; Pu, Y.J.; Ohisa, S.; Kido, J. Anion-exchange red perovskite quantum dots with ammonium iodine salts for highly efficient light-emitting devices. Nat. Photonics 2018, 12, 681–687. [Google Scholar] [CrossRef]

- Wang, J.P.; Wang, N.N.; Jin, Y.Z.; Si, J.J.; Tan, Z.K.; Du, H.; Cheng, L.; Dai, X.L.; Bai, S.; He, H.P.; et al. Interfacial control toward efficient and low-voltage perovskite light-emitting diodes. Adv. Mater. 2015, 27, 2311–2316. [Google Scholar] [CrossRef]

- Li, G.; Rivarola, F.W.; Davis, N.J.; Bai, S.; Jellicoe, T.C.; Pena, F.; de la Hou, S.; Ducati, C.; Gao, F.; Friend, R.H.; et al. Highly efficient perovskite nanocrystal light-emitting diodes enabled by a universal crosslinking method. Adv. Mater. 2016, 28, 3528–3534. [Google Scholar] [CrossRef]

- Wang, N.; Cheng, L.; Ge, R.; Zhang, S.T.; Miao, Y.F.; Zou, W.; Yi, C.; Sun, Y.; Cao, Y.; Yang, R.; et al. Perovskite light-emitting diodes based on solution-processed self-organized multiple quantum wells. Nat. Photonics 2016, 10, 699–704. [Google Scholar] [CrossRef]

- Yuan, M.J.; Quan, L.N.; Comin, R.; Walters, G.; Sabatini, R.; Voznyy, O.; Hoogland, S.; Zhao, Y.B.; Beauregard, E.M.; Kanjanaboos, P.; et al. Perovskite energy funnels for efficient light-emitting diodes. Nat. Nanotechnol. 2016, 11, 872–877. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Jeong, S.H.; Park, M.H.; Kim, Y.H.; Wolf, C.; Lee, C.L.; Heo, J.H.; Sadhanala, A.; Myoung, N.S.; Yoo, S.; et al. Overcoming the electroluminescence efficiency limitations of perovskite light-emitting diodes. Science 2015, 350, 1222–1225. [Google Scholar] [CrossRef] [PubMed]

- Protesescu, L.; Yakunin, S.; Bodnarchuk, M.I.; Krieg, F.; Caputo, R.; Hendon, C.H.; Yang, R.X.; Walsh, A.; Kovalenko, M.V. Nanocrystals of cesium lead halide perovskites (CsPbX3, X = Cl, Br, and I): Novel optoelectronic materials showing bright emission with wide color gamut. Nano Lett. 2015, 15, 3296–3692. [Google Scholar] [CrossRef]

- Nedelcu, G.; Protesescu, L.; Yakunin, S.; Bodnarchuk, M.I.; Grotevent, M.J.; Kovalenko, M.V. Fast anion-exchange in highly luminescent nanocrystals of cesium lead halide perovskites (CsPbX3, X = Cl, Br, I). Nano Lett. 2015, 15, 5635–5640. [Google Scholar] [CrossRef]

- Song, J.; Li, J.; Li, X.; Xu, L.; Dong, Y.; Zeng, H. Quantum dot light-emitting diodes based on inorganic perovskite cesium lead halides (CsPbX3). Adv. Mater. 2015, 27, 7162. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.M.; Song, J.Z.; Xiao, L.; Sun, H.D. All-inorganic colloidal perovskite quantum dots: A new class of lasing materials with favorable characteristics. Adv. Mater. 2015, 27, 7101–7108. [Google Scholar] [CrossRef]

- Owen, J. The coordination chemistry of nanocrystal surfaces. Science 2015, 347, 615–616. [Google Scholar] [CrossRef]

- Bai, Z.L.; Ji, W.Y.; Han, D.B.; Chen, L.L.; Chen, B.K.; Shen, H.B.; Zou, B.S.; Zhong, H.Z. Hydroxyl-terminated CuInS2 based quantum dots: Toward efficient and bright light emitting diodes. Chem. Mater. 2016, 28, 1085–1091. [Google Scholar] [CrossRef]

- Li, J.H.; Xu, L.M.; Wang, T.; Song, J.Z.; Chen, J.W.; Xue, J.; Dong, Y.H.; Cai, B.; Shan, Q.S.; Han, B.N.; et al. 50-Fold EQE improvement up to 6.27% of solution-processed all-inorganic perovskite CsPbBr3 QLEDs via surface ligand density control. Adv. Mater. 2017, 29, 1603885. [Google Scholar] [CrossRef]

- Dai, X.L.; Deng, Y.Z.; Peng, X.G.; Jin, Y.Z. Quantum-dot light-emitting diodes for large-area displays: Towards the dawn of commercialization. Adv. Mater. 2017, 29, 1607022. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Qin, H.; Jiang, M.; Lin, L.; Fu, T.; Dai, X.; Zhang, Z.; Niu, Y.; Cao, H.; Jin, Y.; et al. Entropic ligands for nanocrystals: From unexpected solution properties to outstanding processability. Nano Lett. 2016, 16, 2133–2138. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Qin, H.; Peng, X. Intramolecular entropy and size-dependent solution properties of nanocrystal-ligands complexes. Nano Lett. 2016, 16, 2127–2132. [Google Scholar] [CrossRef] [PubMed]

- Shang, Y.Q.; Ning, Z.J. Colloidal quantum-dots surface and device structure engineering for high-performance light-emitting diodes. Natl. Sci. Rev. 2017, 4, 170–183. [Google Scholar] [CrossRef]

- Pan, J.; Shang, Y.Q.; Yin, J.; Bastiani, M.D.; Peng, W.; Dursun, I.; Sinatra, L.; El-Zohry, A.M.; Hedhili, M.N.; Emwas, A.H.; et al. Bidentate ligand-passivated CsPbI3 perovskite nanocrystals for stable near-unity photoluminescence quantum yield and efficient red light-emitting diodes. J. Am. Chem. Soc. 2018, 140, 562–565. [Google Scholar] [CrossRef]

- Fokina, A.; Lee, Y.; Chang, J.H.; Park, M.; Sun, Y.; Bae, W.K.; Char, K.; Lee, C.; Zentel, R. The role of emission layer morphology on the enhanced performance of light-emitting diodes based on quantum dot-semiconducting polymer hybrids. Adv. Mater. Interfaces 2016, 3, 1600279. [Google Scholar] [CrossRef]

- Brown, P.R.; Kim, D.; Lunt, R.R.; Zhao, N.; Bawendi, M.G.; Grossman, J.C.; Bulovic, V. Energy level modification in lead sulfide quantum dot thin films through ligand exchange. ACS Nano 2014, 8, 5863–5872. [Google Scholar] [CrossRef]

- Chuang, C.H.M.; Brown, P.R.; Bulovic, V.; Bawendi, M.G. Improved performance and stability in quantum dot solar cells through band alignment engineering. Nat. Mater. 2014, 13, 796–801. [Google Scholar] [CrossRef]

- Yang, Z.; Voznyy, O.; Liu, M.; Yuan, M.; Ip, A.H.; Ahmed, O.S.; Levina, L.; Kinge, S.; Hoogland, S.; Sargent, E.H. All-quantum-dot infrared light-emitting diodes. ACS Nano 2015, 9, 12327–12333. [Google Scholar] [CrossRef]

- Chen, O.; Zhao, J.; Chauhan, V.P.; Cui, J.; Wong, C.; Harris, D.K.; Wei, H.; Han, H.S.; Fukumura, D.; Jain, R.K.; et al. Compact high-quality CdSe-CdS core-shell nanocrystals with narrow emission linewidths and suppressed blinking. Nat. Mater. 2013, 12, 445–451. [Google Scholar] [CrossRef]

- Pal, B.N.; Ghosh, Y.; Brovelli, S.; Laocharoensuk, R.; Klimov, V.I.; Hollingsworth, J.A.; Htoon, H. ‘Giant’ CdSe/CdS core/shell nanocrystal quantum dots as efficient electroluminescent materials: Strong influence of shell thickness on light-emitting diode performance. Nano Lett. 2012, 12, 331–336. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Chen, F.; Wang, L.; Shen, H.; Guo, L.; Kuang, Y.; Wang, H.; Li, N.; Li, L.S. Synthesis and evaluation of ideal core/shell quantum dots with precisely controlled shell growth: Nonblinking, single photoluminescence decay channel, and suppressed FRET. Chem. Mater. 2018, 30, 3668–3676. [Google Scholar] [CrossRef]

- Bae, W.K.; Padilha, L.A.; Park, Y.S.; McDaniel, H.; Robel, I.; Pietryga, J.M.; Klimov, V.I. Controlled alloying of the core-shell interface in CdSe/CdS quantum dots for suppression of auger recombination. ACS Nano 2013, 7, 3411–3419. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.S.; Bae, W.K.; Padilha, L.A.; Pietryga, J.M.; Klimov, V.I. Effect of the core/shell interface on auger recombination evaluated by single-quantum-dot spectroscopy. Nano Lett. 2014, 14, 396–402. [Google Scholar] [CrossRef]

- Cao, H.; Ma, J.; Huang, L.; Qin, H.; Meng, R.; Li, Y.; Peng, X. Design and synthesis of antiblinking and antibleaching quantum dots in multiple colors via wave function confinement. J. Am. Chem. Soc. 2016, 138, 15727–15735. [Google Scholar] [CrossRef]

- Kim, D.; Fu, Y.; Kim, S.; Lee, W.; Lee, W.; Lee, K.H.; Chung, H.K.; Lee, H.J.; Yang, H.; Chae, H. Polyethylenimine ethoxylated-mediated all-solution-processed high-performance flexible inverted quantum dot-light-emitting device. ACS Nano 2017, 11, 1982–1990. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, L.; Li, Z.; Shen, H.; Guo, L.; Kuang, Y.; Wang, H.; Li, L.S. Nonblinking quantum-dot-based blue light-emitting diodes with high efficiency and a balanced charge-injection process. ACS Photonics 2018, 5, 939–946. [Google Scholar] [CrossRef]

- Cai, J.G.; Qi, L.M. Recent advances in antireflective surfaces based on nanostructure arrays. Mater. Horiz. 2015, 2, 37–53. [Google Scholar] [CrossRef]

- Liu, S.Y.; Ho, S.H.; So, F. Novel patterning method for silver nanowire electrodes for thermal- evaporated organic light emitting diodes. ACS Appl. Mater. Interfaces 2016, 8, 9268–9274. [Google Scholar] [CrossRef]

- Rishinaramangalam, A.K.; Nami, M.; Fairchild, M.N.; Darryl, M.; Shima, D.M.; Balakrishnan, G.; Brueck, S.R.J.; Daniel, F.; Feezell, D.F. Semipolar InGaN/GaN nanostructure light-emitting diodes on c-plane sapphire. Appl. Phys. Express 2016, 9, 032101. [Google Scholar] [CrossRef]

- Djavid, M.; Mi, Z.T. Enhancing the light extraction efficiency of AlGaN deep ultraviolet light emitting diodes by using nanowire structures. Appl. Phys. Lett. 2016, 108, 051102. [Google Scholar] [CrossRef]

- Zhang, C.; Marvinney, C.M.; Xu, H.Y.; Liu, W.Z.; Wang, C.L.; Zhang, L.X.; Wang, J.N.; Ma, J.G.; Liu, Y.C. Enhanced waveguide-type ultraviolet electroluminescence from ZnO/MgZnO core/shell nanorod array light-emitting diodes via coupling with Ag nanoparticles localized surface plasmons. Nanoscale 2015, 7, 1073–1080. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.C.; Yang, Z.P.; Hwang, J.M.; Chuang, Y.L.; Lin, C.C.; Haung, J.Y.; Chou, C.Y.; Sheu, J.K.; Tsai, M.T.; Lee, Y.J. Enhancing UV-emissions through optical and electronic dual-function tunings of Ag nanoparticles hybridized with n-ZnO nanorods/p-GaN heterojunction light-emitting diodes. Nanoscale 2016, 8, 4463–4473. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Zhou, W.C.; Peng, Y.H.; Yin, Y.L.; Zhong, M.Y.; Zhuang Zhao, Z.; Zhang, Q.L.; Tang, D.S.; Zeng, R.S.; Zou, B.S. Surface polarons and optical micro-cavity modulated broad range multi-mode emission of Te-doped CdS nanowires. Nanotechnology 2018, 29, 465709. [Google Scholar] [CrossRef]

- You, D.T.; Xu, C.X.; Qin, F.F.; Zhu, Z.; Manohari, A.G.; Xu, W.; Zhao, J.; Liu, W. Interface control for pure ultraviolet electroluminescence from nano-ZnO-based heterojunction devices. Sci. Bull. 2018, 63, 38–45. [Google Scholar] [CrossRef]

- Casu, M.B. Nanoscale studies of organic radicals: Surface, interface, and interface. Acc. Chem. Res. 2018, 51, 753–760. [Google Scholar] [CrossRef]

- Guo, Y.N.; Yan, J.C.; Zhang, Y.; Wang, J.X.; Lia, J.M. Enhancing the light extraction of AlGaN-based ultraviolet light-emitting diodes in the nanoscale. J. Nanophotonics 2018, 12, 043510. [Google Scholar] [CrossRef]

- Lee, D.; Lee, J.W.; Jang, J.; Shin, I.S.; Jin, L.; Park, J.H.; Kim, J.; Lee, J.; Noh, H.S.; Kim, Y.; et al. Improved performance of AlGaN-based deep ultraviolet light-emitting diodes with nano-patterned AlN/sapphire substrates. Appl. Phys. Lett. 2017, 110, 191103. [Google Scholar] [CrossRef]

- Yun, J.; Hirayama, H. Investigation of the light-extraction efficiency in 280 nm AlGaN-based light-emitting diodes having a highly transparent p-AlGaN layer. J. Appl. Phys. 2017, 121, 013105. [Google Scholar] [CrossRef]

- Nguyen, H.P.T.; Zhang, S.; Connie, A.T.; Kibria, M.G.; Wang, Q.; Shih, I.; Mi, Z. Breaking the carrier injection bottleneck of phosphor-free nanowire white light-emitting diodes. Nano Lett. 2013, 13, 5437–5442. [Google Scholar] [CrossRef]

- Nguyen, H.P.T.; Djavid, M.; Mi, Z. Nonradiative recombination mechanism in phosphor-free GaN-based nanowire white light emitting diodes and the effect of ammonium sulfide surface passivation. ECS Trans. 2013, 53, 93–100. [Google Scholar] [CrossRef]

- Philip, M.R.; Choudhary, D.D.; Djavid, M.; Bhuyian, M.N.; Piao, J.; Pham, T.T.; Misra, D.; Nguyen, H.P.T. Controlling color emission of InGaN/AlGaN nanowire light-emitting diodes grown by molecular beam epitaxy. J. Vac. Sci. Technol. B 2017, 35, 02B108. [Google Scholar] [CrossRef]

- Ledig, J.; Wang, X.; Fündling, S.; Schuhmann, H.; Seibt, M.; Jahn, U.; Wehmann, H.H.; Waag, A. Characterization of the internal properties of InGaN/GaN core-shell LEDs. Phys. Status Solidi A 2016, 213, 11–18. [Google Scholar] [CrossRef]

- Müller, M.; Veit, P.; Krause, F.F.; Schimpke, T.; Metzner, S.; Bertram, F.; Mehrtens, T.; Muller-Caspary, K.; Avramescu, A.; Strassburg, M.; et al. Nanoscopic insights into InGaN/GaN core-shell nanorods: Structure, composition, and luminescence. Nano Lett. 2016, 16, 5340–5346. [Google Scholar] [CrossRef]

- Philip, M.R.; Choudhary, D.D.; Djavid, M.; Le, K.Q.; Piao, J.; Nguyen, H.P.T. High efficiency green/yellow and red InGaN/AlGaN nanowire light-emitting diodes grown by molecular beam epitaxy. J. Sci. Adv. Mater. Devices 2017, 2, 150–155. [Google Scholar] [CrossRef]

- Sadaf, S.M.; Zhao, S.; Wu, Y.; Ra, Y.H.; Liu, X.; Vanka, S.; Mi, Z. An AlGaN core-shell tunnel junction nanowire light-emitting diode operating in the ultraviolet‑C band. Nano Lett. 2017, 17, 1212–1218. [Google Scholar] [CrossRef]

- Sim, Y.C.; Lim, S.H.; Yoo, Y.S.; Jang, M.H.; Choi, S.H.; Yeo, H.S.; Woo, K.Y.; Lee, S.W.; Song, H.G.; Cho, Y.H. Three-dimensional GaN dodecagonal ring structures for highly efficient phosphor-free warm white light-emitting diodes. Nanoscale 2018, 10, 4686–4695. [Google Scholar] [CrossRef]

- Ra, Y.H.; Lee, C.R. Understanding the p‑type GaN nanocrystals on InGaN nanowire heterostructures. ACS Photonics 2019, 6, 2397–2404. [Google Scholar] [CrossRef]

- Bui, H.Q.T.; Velpula, R.T.; Jain, B.; Aref, O.H.; Nguyen, H.D.; Lenka, T.R.; Nguyen, H.P.T. Full-color InGaN/AlGaN nanowire micro light-emitting diodes grown by molecular beam epitaxy: A promising candidate for next generation micro displays. Micromachines 2019, 10, 492. [Google Scholar] [CrossRef]

- Cheng, S.B.; Langelier, B.; Ra, Y.H.; Rashid, R.T.; Mi, Z.T.; Botton, G.A. Structural origin of the high-performance light-emitting InGaN/AlGaN quantum disks. Nanoscale 2019, 11, 8994–8999. [Google Scholar] [CrossRef]

- Pimputkar, S.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Prospects for LED lighting. Nat. Photonics 2009, 3, 180–182. [Google Scholar] [CrossRef]

- Oliver, R.A.; Massabuau, F.C.P.; Kappers, M.J.; Phillips, W.A.; Thrush, E.J.; Tartan, C.C.; Blenkhorn, W.E.; Badcock, T.J.; Dawson, P.; Hopkins, M.A.; et al. The impact of gross well width fluctuations on the efficiency of GaN-based light emitting diodes. Appl. Phys. Lett. 2013, 103, 141114. [Google Scholar] [CrossRef]

- Barettin, D.; Maur, M.A.D.; Carlo, A.D.; Pecchia, A.; Tsatsulnikov, A.F.; Sakharov, A.V.; Lundin, W.V.; Nikolaev, A.E.; Usov, S.O.; Cherkashin, N.; et al. Influence of electromechanical coupling on optical properties of InGaN quantum-dot based light-emitting diodes. Nanotechnology 2016, 28, 015701. [Google Scholar] [CrossRef] [PubMed]

- Barrettes, D.; Maur, M.A.D.; Carlo, A.D.; Pecchia, A.; Tsatsulnikov, A.F.; Lundin, W.V.; Sakharov, A.V.; Nikolaev, A.E.; Korytov, M.; Cherkashin, N.; et al. Carrier transport and emission efficiency in InGaN quantum-dot based light-emitting diodes. Nanotechnology 2017, 28, 275201. [Google Scholar]

- Hinzmann, C.; Magen, O.; Hofstetter, Y.J.; Hopkinson, P.E.; Tessler, N.; Vaynzof, Y.N. Effect of injection layer sub-bandgap states on electron injection in organic light-emitting diodes. ACS Appl. Mater. Interfaces 2017, 9, 6220–6227. [Google Scholar] [CrossRef] [PubMed]

- Borges, B.G.A.L.; Veiga, A.G.; Gioti, M.; Laskarakis, A.; Tzounis, L.; Logothetidis, S.; Rocco, M.L.M. Surface, interface and electronic properties of f8:f8bt polymeric thin films used for OLED applications. Polym. Int. 2018, 67, 691–699. [Google Scholar] [CrossRef]

- Thomas, J.R.; David, G.L.; Alastair, R.B. Ultrasonic spray coating as an approach for large-area polymer OLEDs: The influence of thin film processing and surface roughness on electrical performance. AIP Adv. 2019, 9, 015330. [Google Scholar]

- Zhao, L.; Guo, Z.X.; Zhang, M.; Yang, S.; Zhao, L. Surface-interface analysis of InxGa1-xAs/InP heterostructure in positive and negative mismatch system. Surf. Interface Anal. 2019, 51, 498–505. [Google Scholar] [CrossRef]

- Wang, J.; Fu, W.F.; Jariwala, S.; Sinha, I.; Jen, A.K.Y.; Ginger, D.S. Reducing surface recombination velocities at the electrical contacts will improve perovskite photovoltaics. ACS Energy Lett. 2019, 4, 222–227. [Google Scholar] [CrossRef]

- Jin, Y.H.; Li, Q.Q.; Chen, M.; Li, G.H.; Zhao, Y.D.; Xiao, X.Y.; Wang, J.P.; Jiang, K.L.; Fan, S.S. Study of carbon nanotubes as etching masks and related applications in the surface modification of GaAs-based light-emitting diodes. Small 2015, 11, 4111–4116. [Google Scholar] [CrossRef]

- Seo, T.H.; Lee, S.; Min, K.H.; Chandramohan, S.; Park, A.H.; Lee, G.H.; Park, M.; Suh, E.K.; Kim, M.J. The role of graphene formed on silver nanowire transparent conductive electrode in ultraviolet light emitting diodes. Sci. Rep. 2016, 6, 29464. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.T.; Kim, J.; Lee, H.; Moon, J.; Kwon, B.H.; Ahn, S.; Cho, N.S.; Ahn, B.W.; Lee, J.I.; Ihm, K.; et al. Unraveled face-dependent effects of multilayered graphene embedded in transparent organic light-emitting diodes. ACS Appl. Mater. Interfaces 2017, 9, 43105–43112. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.R.; Lee, S.; Park, J.H.; Jung, E.D.; Yu, J.C.; Nam, Y.S.; Heo, J.; Kim, J.Y.; Kim, B.S.; Song, M.H. Amine-based interfacial molecules for inverted polymer-based optoelectronic devices. Adv. Mater. 2015, 27, 3553–3559. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.L.; Zhang, X.W.; Deng, J.X.; Chu, Z.M.; Jiang, Q.; Meng, J.H.; Wang, P.Y.; Zhang, L.Q.; Yin, Z.G.; You, J.B. Efficient green light-emitting diodes based on quasi-two-dimensional composition and phase engineered perovskite with surface passivation. Nat. Commun. 2018, 9, 570. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Y.; Sun, C.; Zhang, Y.; Wu, H.; Ji, C.Y.; Chuai, Y.H.; Wang, P.; Wen, S.P.; Zhang, C.F.; Yu, W.W. Bright perovskite nanocrystal films for efficient light-emitting devices. J. Phys. Chem. Lett. 2016, 7, 4602–4610. [Google Scholar] [CrossRef]

- Chen, Z.M.; Zhang, C.Y.; Jiang, X.F.; Liu, M.Y.; Xia, R.X.; Shi, T.T.; Chen, D.C.; Xue, Q.F.; Zhao, Y.J.; Su, S.J.; et al. High-performance color-tunable perovskite light emitting devices through structural modulation from bulk to layered film. Adv. Mater. 2017, 29, 1603157. [Google Scholar] [CrossRef]

- Zhang, X.W.; Mao, J.; Shao, Z.B.; Diao, S.L.; Hu, D.; Tang, Z.J.; Wu, H.H.; Jie, J.S. Efficient photovoltaic devices based on p-ZnSe/n-CdS core-shell heterojunctions with high open-circuit voltage. J. Mater. Chem. C 2017, 5, 2107–2113. [Google Scholar] [CrossRef]

- Varun, V.; Takuya, A. Molecular orientation of conjugated polymer chains in nanostructures and thin films: Review of processes and application to optoelectronics. J. Nanomater. 2017, 2017, 3624750. [Google Scholar]

- Liu, X.Y.; Wang, X.H.; Zhang, Y.G.; Wei, K.; Zheng, Y.K.; Xuanwu Kang, X.W.; Jiang, H.J.; Li, J.F.; Wang, W.W.; Wu, X.B.; et al. Insight into the near-conduction band states at the crystallized interface between GaN and SiNx grown by low-pressure chemical vapor deposition. ACS Appl. Mater. Interfaces 2018, 10, 21721–21729. [Google Scholar] [CrossRef]

- Chen, Y.J.; Lee, W.K.; Chen, Y.T.; Lin, C.Y.; Wen, S.W.; Jiao, M.; Su, G.D.; Lin, H.Y.; Visser, R.J.; Kwak, B.L.; et al. A vision toward ultimate optical out-coupling for organic light-emitting diode displays: 3D pixel configuration. Adv. Sci. 2018, 5, 1800467. [Google Scholar] [CrossRef]

- Muhammad, S.I.; Shanmugan, S.; Wan, M.W.A.K.; Mutharasu, D. Synthesis of MgO thin film on aluminum and copper substrates as thermal interface materials. IEEE Trans. Electron. Dev. 2019, 66, 1450–1457. [Google Scholar]

- Bulling, A.F.; Venter, P.J. Improved light extraction efficiency of complementary metal-oxide semiconductor hot carrier lights sources with the use of improved back-end-of-line light directing structures. Opt. Eng. 2019, 58, 065105. [Google Scholar] [CrossRef]

- Lei, P.H.; Yang, C.D.; Po-Chun Huang, P.C.; Yeh, S.J. Enhancement of light extraction efficiency for InGaN/GaN light-emitting diodes using silver nanoparticle embedded ZnO thin films. Micromachines 2019, 10, 239. [Google Scholar] [CrossRef] [PubMed]

| Analysis Method | Acquired Information |

|---|---|

| Auger electron spectrum (AES) X-ray photoelecgon spectroscopy (XPS) Secondary ion mass spectrometry (SIMS) Ion scattering spectroscopy (ISS) | Surface/interface composition |

| Transmission electron microscopy (TEM) Scanning electron microscope (SEM) Scanning tunneling microscopy (STM) Atomic force microscope (AFM) | Surface/interface morphology |

| Low-energy electron diffraction (LEED) Field ion microscope (FIM) High-resolution transmission electron Microscopy (HRTEM) | Surface/interface structure |

| X-ray photoelecgon spectroscopy (XPS) Ultraviolet photoelectron spectroscopy (UPS) Electron energy loss spectroscopy (EELS) Ion neutralization spectroscopy (INS) Deep level transient spectrum (DLTS) Pulsed I–V measurement Conductance | Surface/interface energy state |

| Materials | Structures | Spectral Range of LEDs | Ref. |

|---|---|---|---|

| CsPbBr3 | Nanocrystals | Green | [34] |

| CdSe/ZnS | QDs | Blue, Green, Red | [36] |

| CdSe/Cd1-xZnxSe | QDs | Red | [37] |

| CsPbBr3 | QDs | Deep-red | [38] |

| CH3NH3Pb3-xClx | Films | Near-infrared | [39] |

| CsPbX3 | QDs | Red, Orange, Green, Blue | [40] |

| NFPI7 | QWs | Near-Infrared | [41] |

| CH3NH3PbI3 | Quasi-2D | Near-Infrared | [42] |

| CH3NH3PbBr3 | QDs to Nanograins | Green | [43] |

| CsPbX3 (X = Cl, Br, I) | Nanocrystals | Blue, Green | [44] |

| CsPbX3 (X = Cl, Br, I) | Nanocrystals | Blue to Red | [45] |

| CsPbBr3 | QDs | Blue to Red | [46] |

| CsPbX3 | QDs | Blue to Red | [47] |

| CuInS2 | QDs | Green | [49] |

| CsPbX3 | QDs | Green | [50] |

| CsPbI3 | Nanocrystals | Red | [55] |

| Colloidal | QDs | Near-Infrared | [59] |

| CdSe/CdS | Nanocrystals | ~ | [60] |

| CdSe/CdS | QDs | Red | [61] |

| Materials | Structures | Spectral Range of LEDs | Ref. |

|---|---|---|---|

| Ag | Nanowires | Green | [69] |

| InGaN/GaN | Nanostructure | ~ | [70] |

| AlGaN | Nanowires | Deep ultraviolet | [71] |

| ZnO/MgZnO | Nanorods | Ultraviolet | [72] |

| ZnO/GaN | Nanorods | Ultraviolet | [73] |

| CdS | Nanowires | Red | [74] |

| ZnO | Nanowires | Ultraviolet | [75] |

| AlGaN | Nanowires | Ultraviolet | [77] |

| AlGaN | Nanoscale | Deep ultraviolet | [78] |

| InGaN/GaN/AlGaN | Nanowires | White | [80] |

| GaN | Nanowires | White | [81] |

| InGaN/AlGaN | Nanowires | Full color | [82] |

| InGaN/GaN | Nanorods | Green | [84] |

| InGaN/AlGaN | Nanowires | Green, Yellow | [85] |

| AlGaN | Nanowires | Ultraviolet | [86] |

| InGaN/AlGaN | Nanowires | Full color | [89] |

| InGaN/AlGaN | Quantum disks | ~ | [90] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Liu, X.; Guo, Z.; Zhou, L. Surface/Interface Engineering for Constructing Advanced Nanostructured Light-Emitting Diodes with Improved Performance: A Brief Review. Micromachines 2019, 10, 821. https://doi.org/10.3390/mi10120821

Cao L, Liu X, Guo Z, Zhou L. Surface/Interface Engineering for Constructing Advanced Nanostructured Light-Emitting Diodes with Improved Performance: A Brief Review. Micromachines. 2019; 10(12):821. https://doi.org/10.3390/mi10120821

Chicago/Turabian StyleCao, Lianzhen, Xia Liu, Zhen Guo, and Lianqun Zhou. 2019. "Surface/Interface Engineering for Constructing Advanced Nanostructured Light-Emitting Diodes with Improved Performance: A Brief Review" Micromachines 10, no. 12: 821. https://doi.org/10.3390/mi10120821

APA StyleCao, L., Liu, X., Guo, Z., & Zhou, L. (2019). Surface/Interface Engineering for Constructing Advanced Nanostructured Light-Emitting Diodes with Improved Performance: A Brief Review. Micromachines, 10(12), 821. https://doi.org/10.3390/mi10120821