Influence of Waterproof Films on the Atomization Behavior of Surface Acoustic Waves

Abstract

1. Introduction

2. Experiment Approach

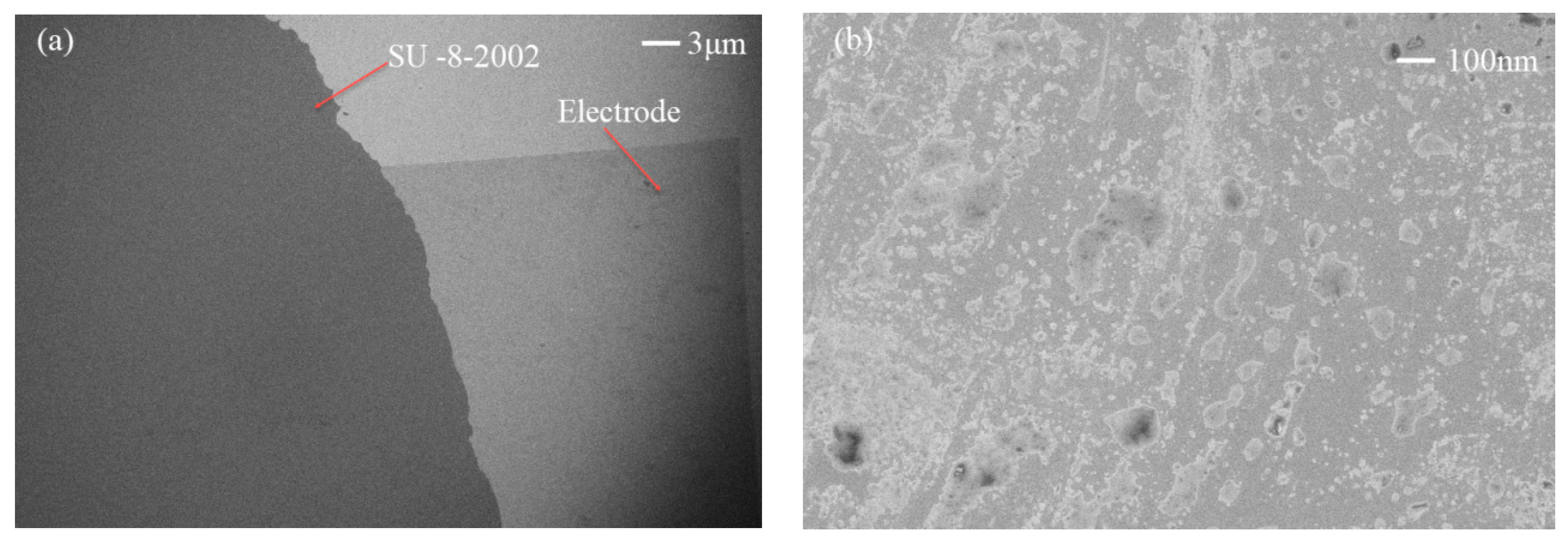

2.1. SAW Device Design

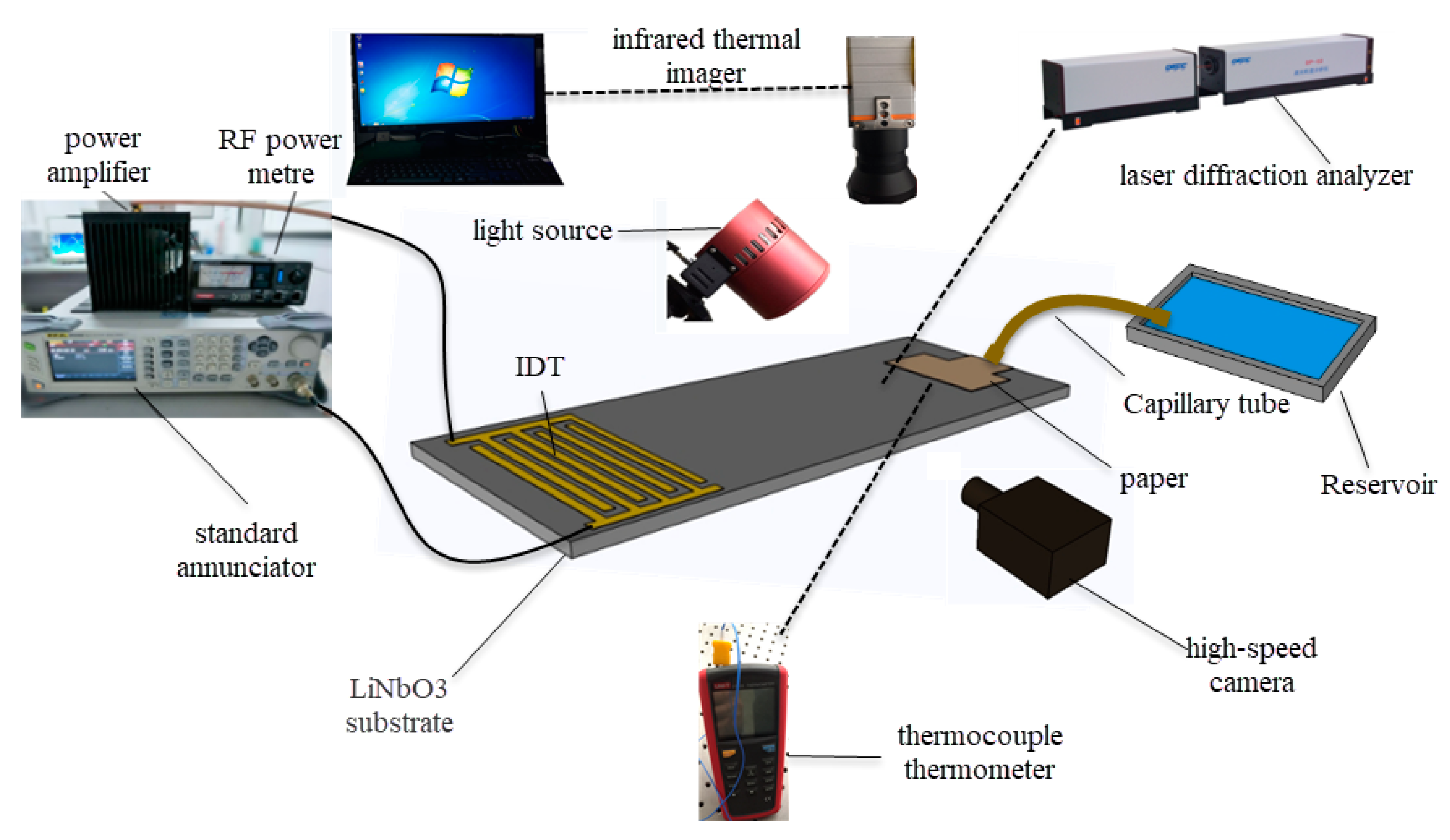

2.2. Experimental Setup

3. Results and Discussion

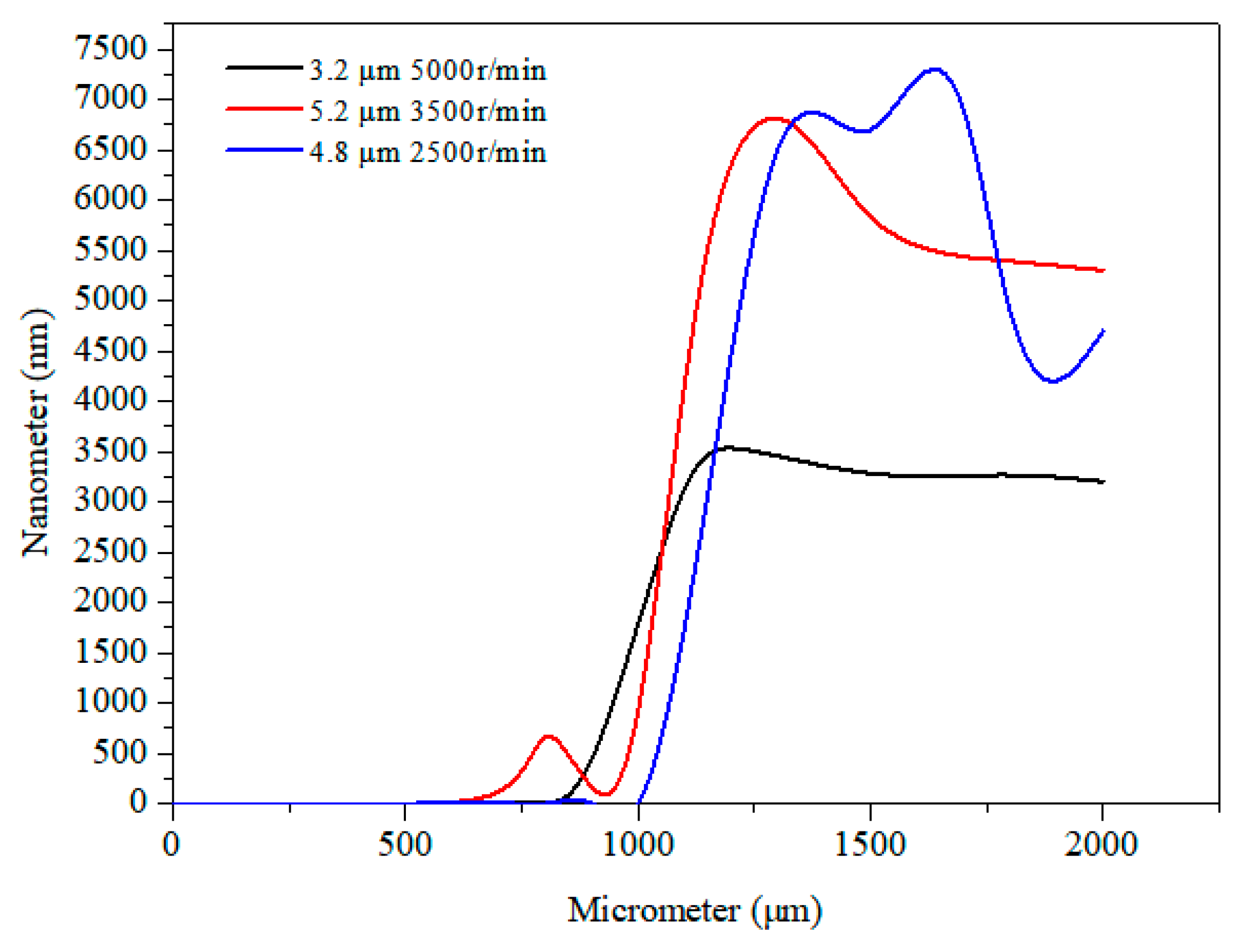

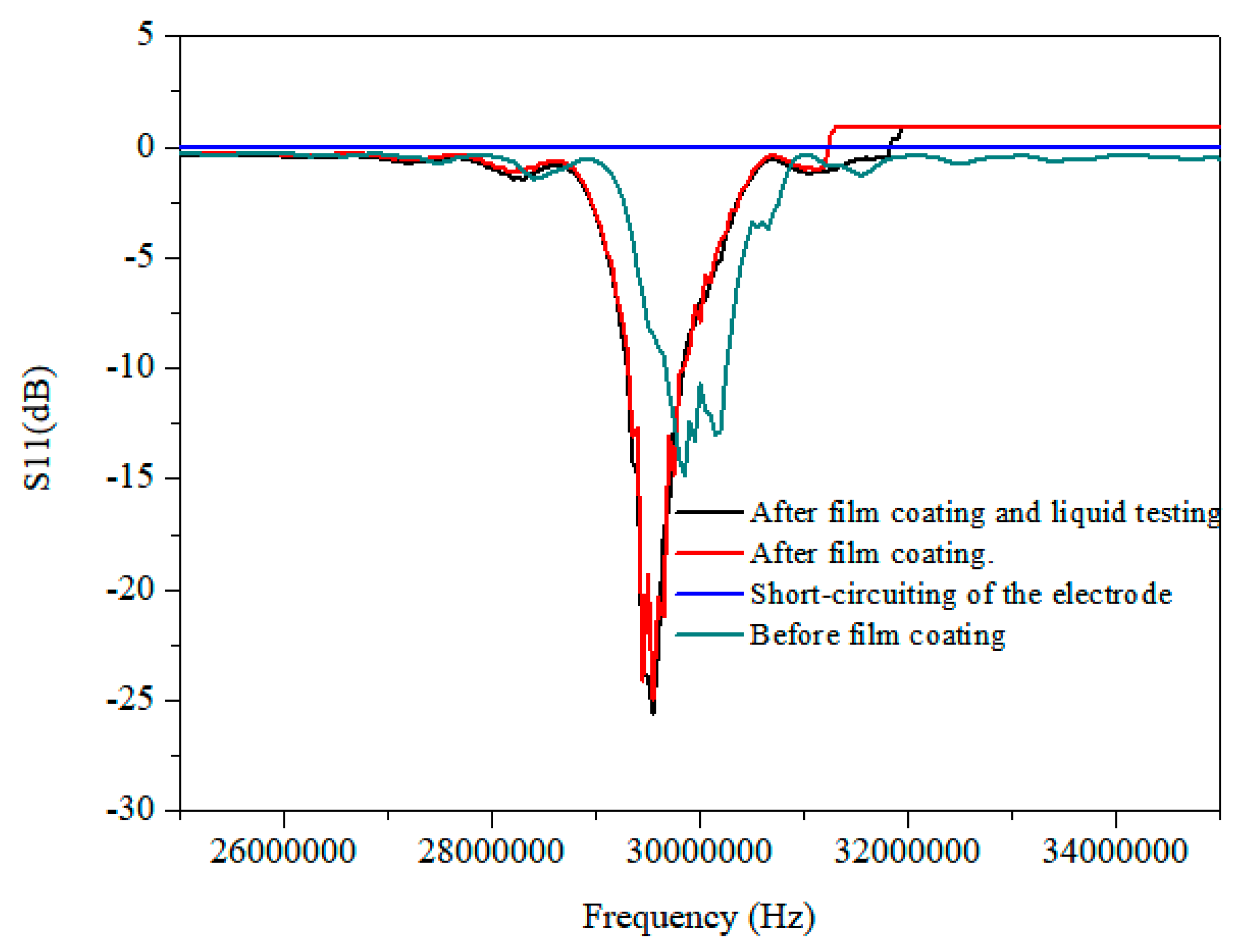

3.1. Waterproof Test and the Influence of the Film Coating on Energy Radiation from the SAW

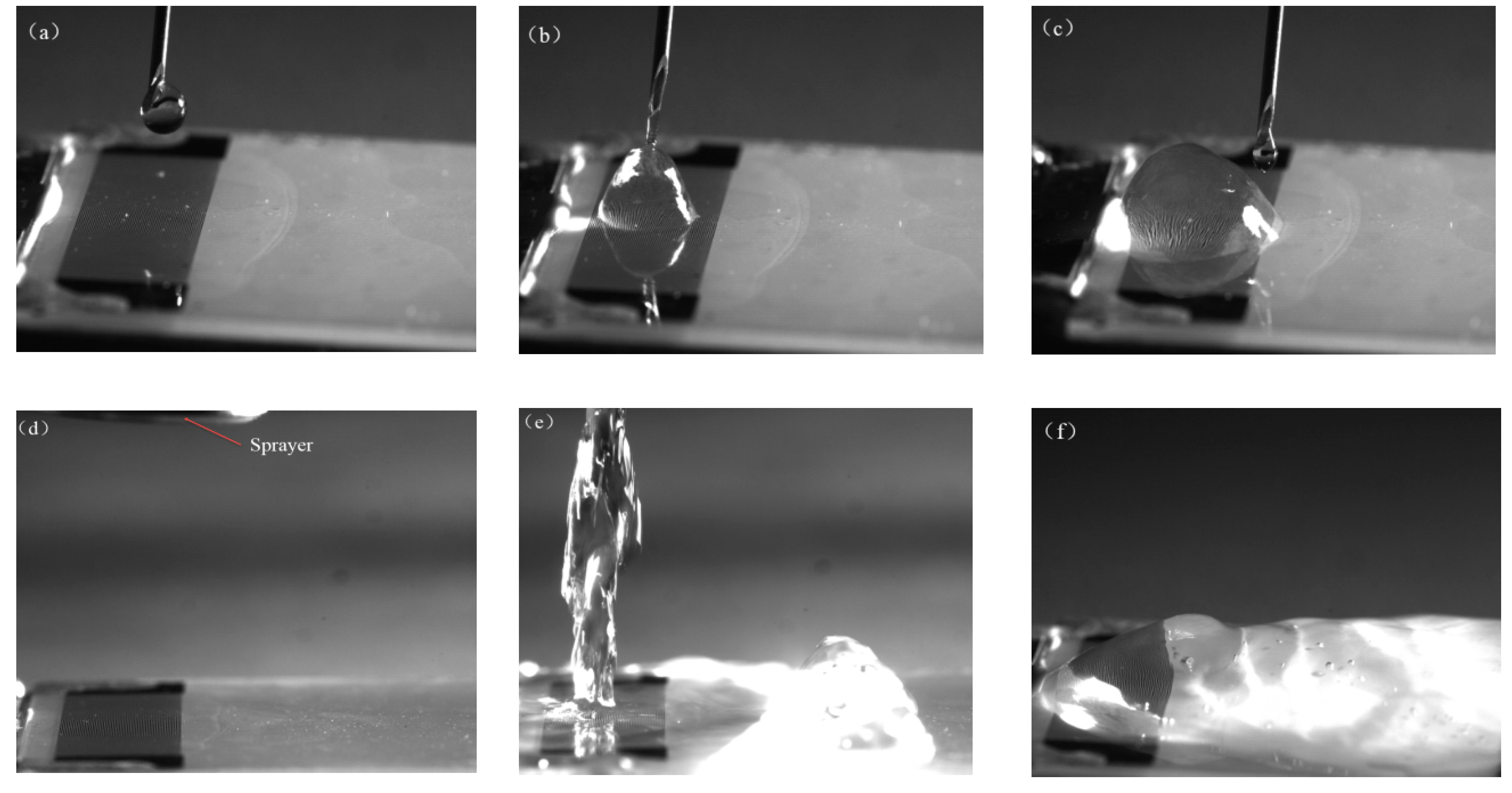

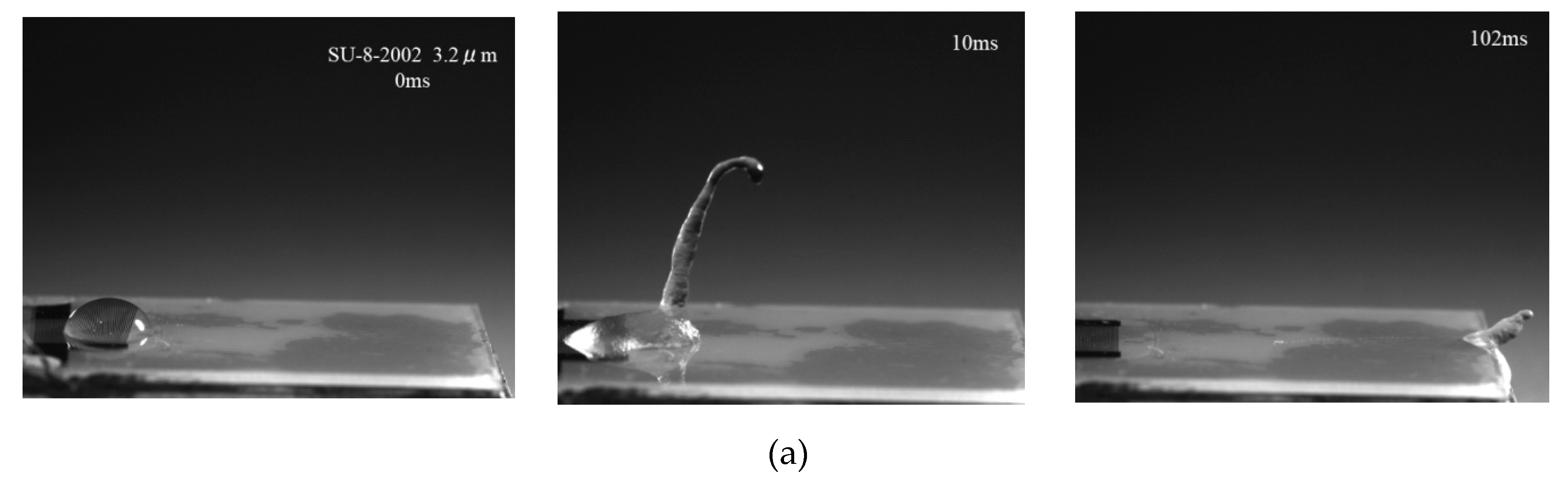

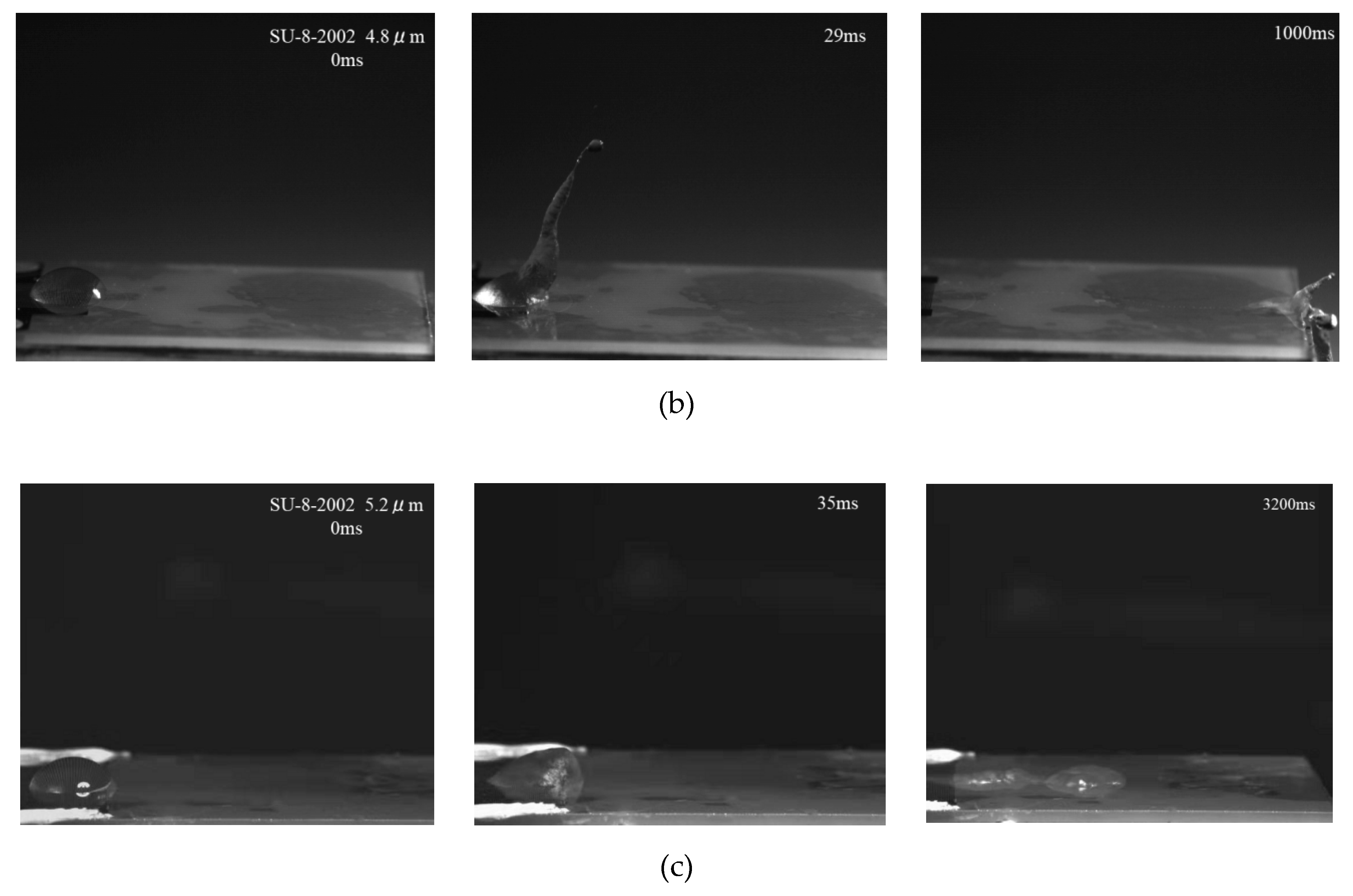

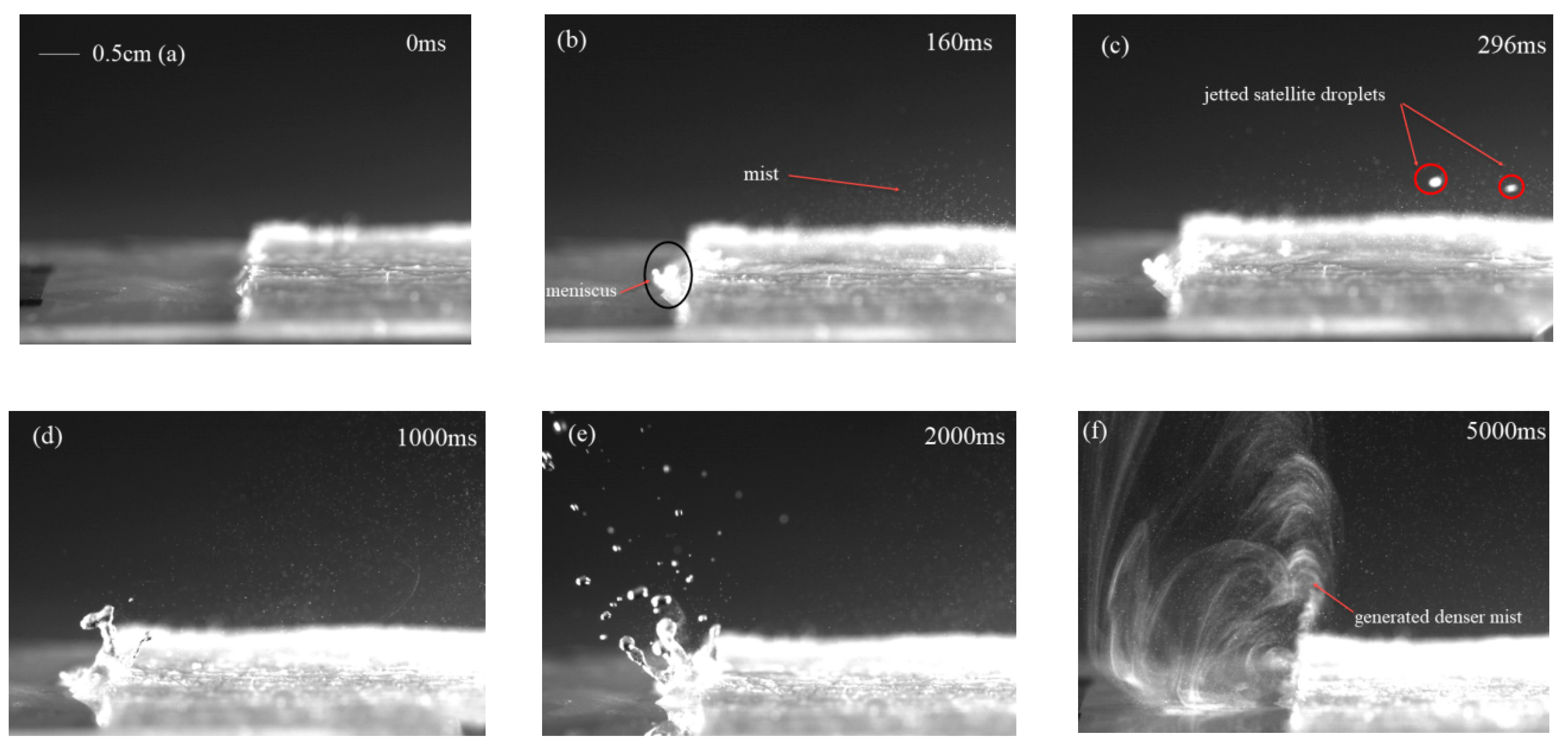

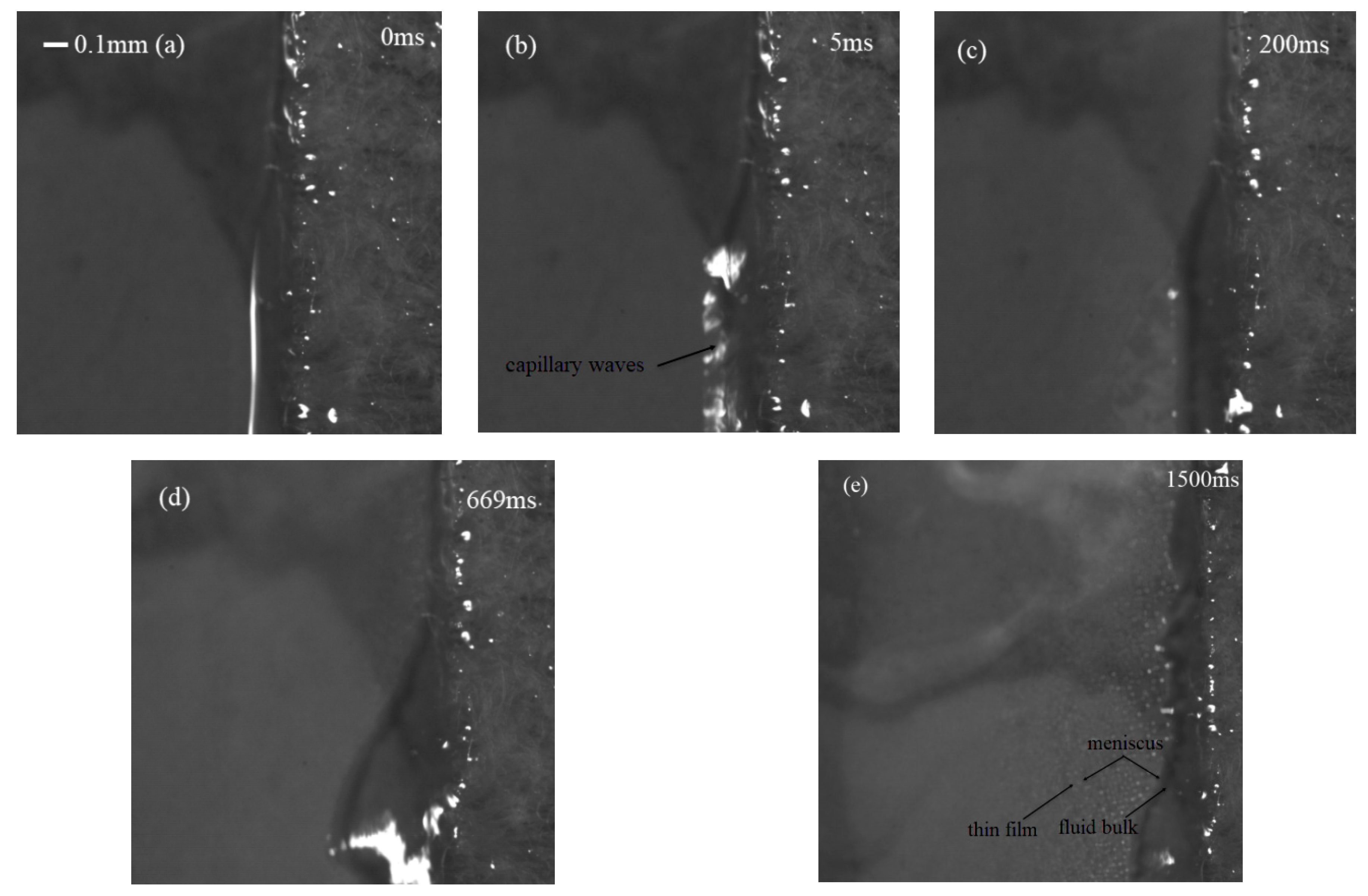

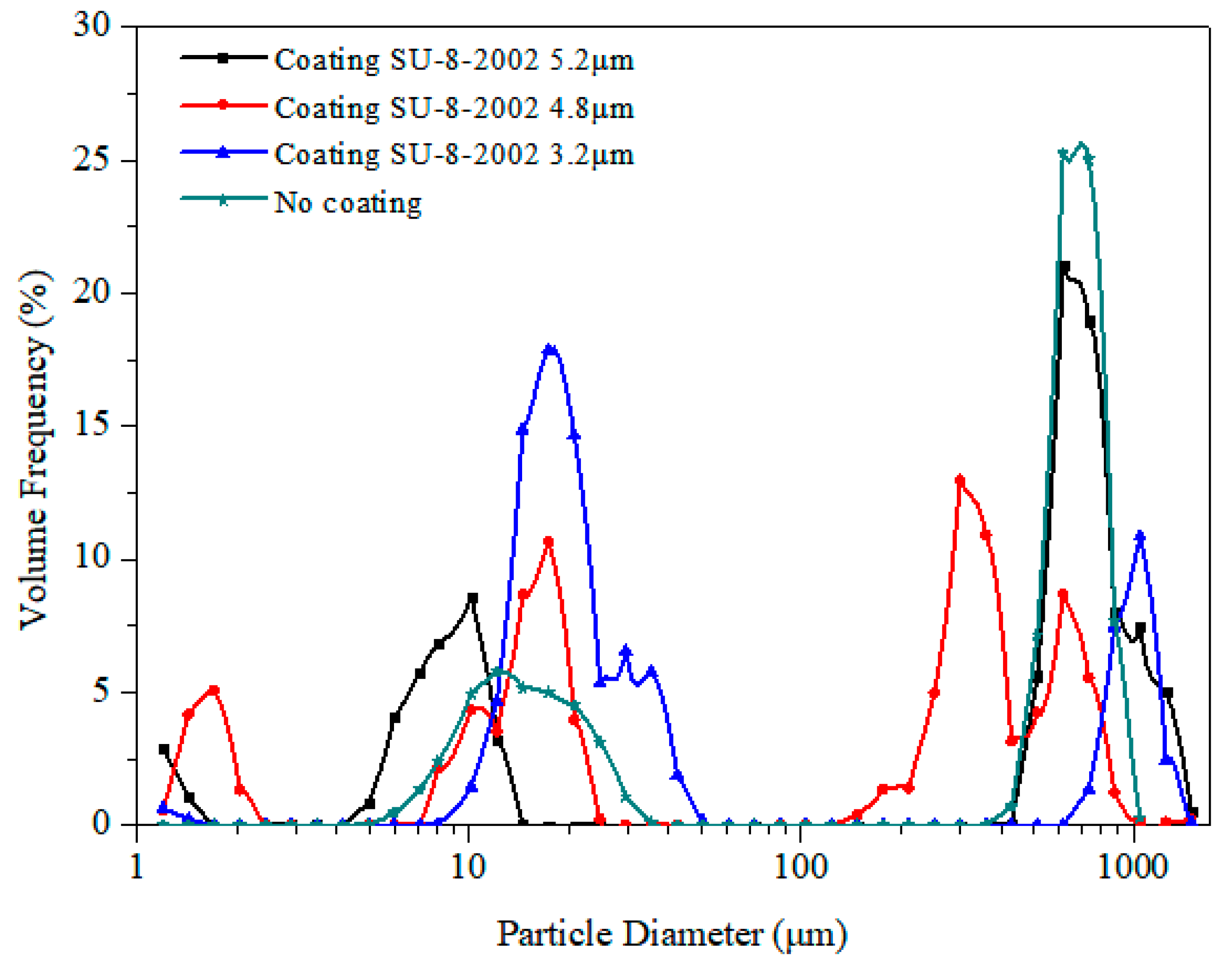

3.2. Atomization Behavior

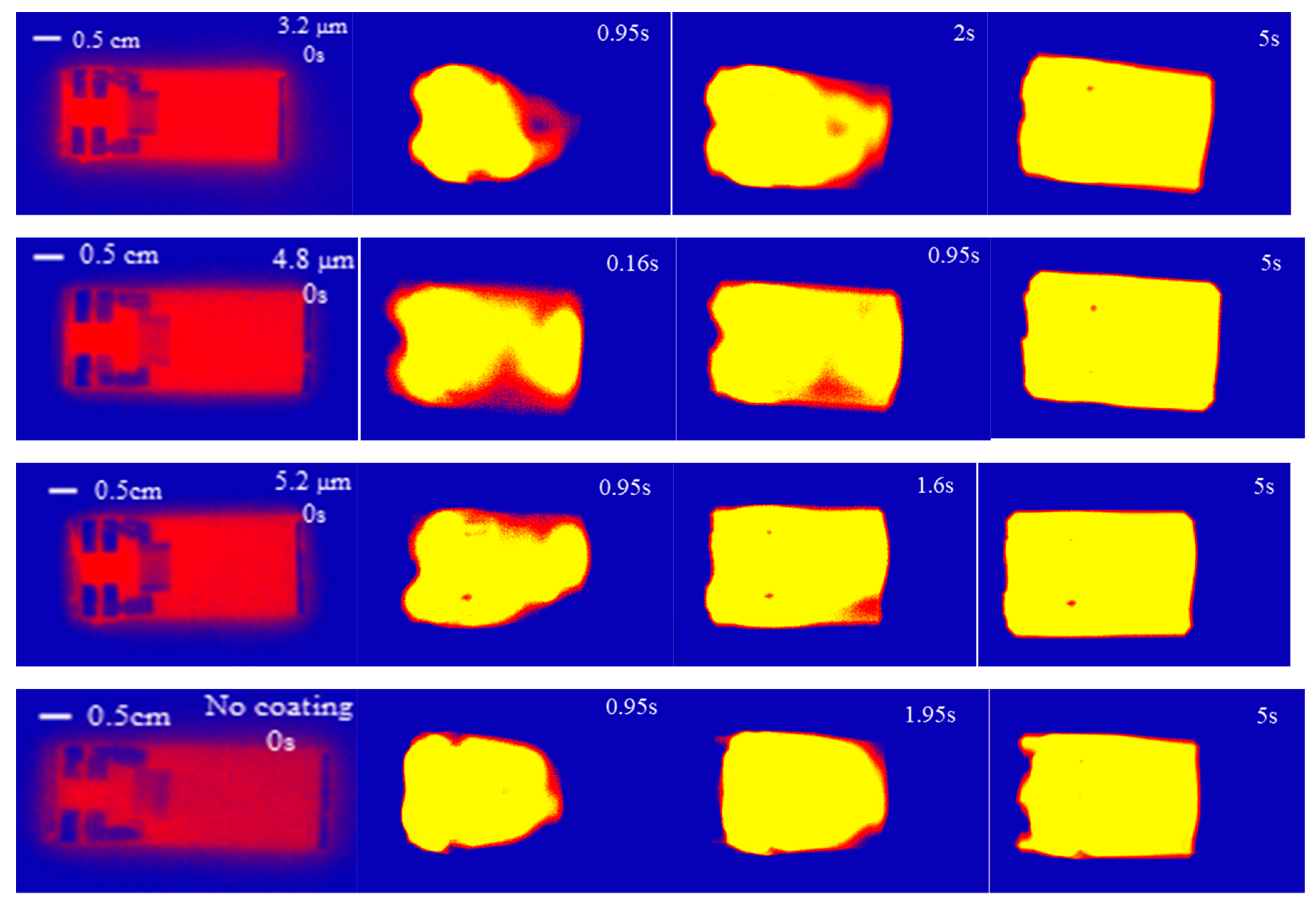

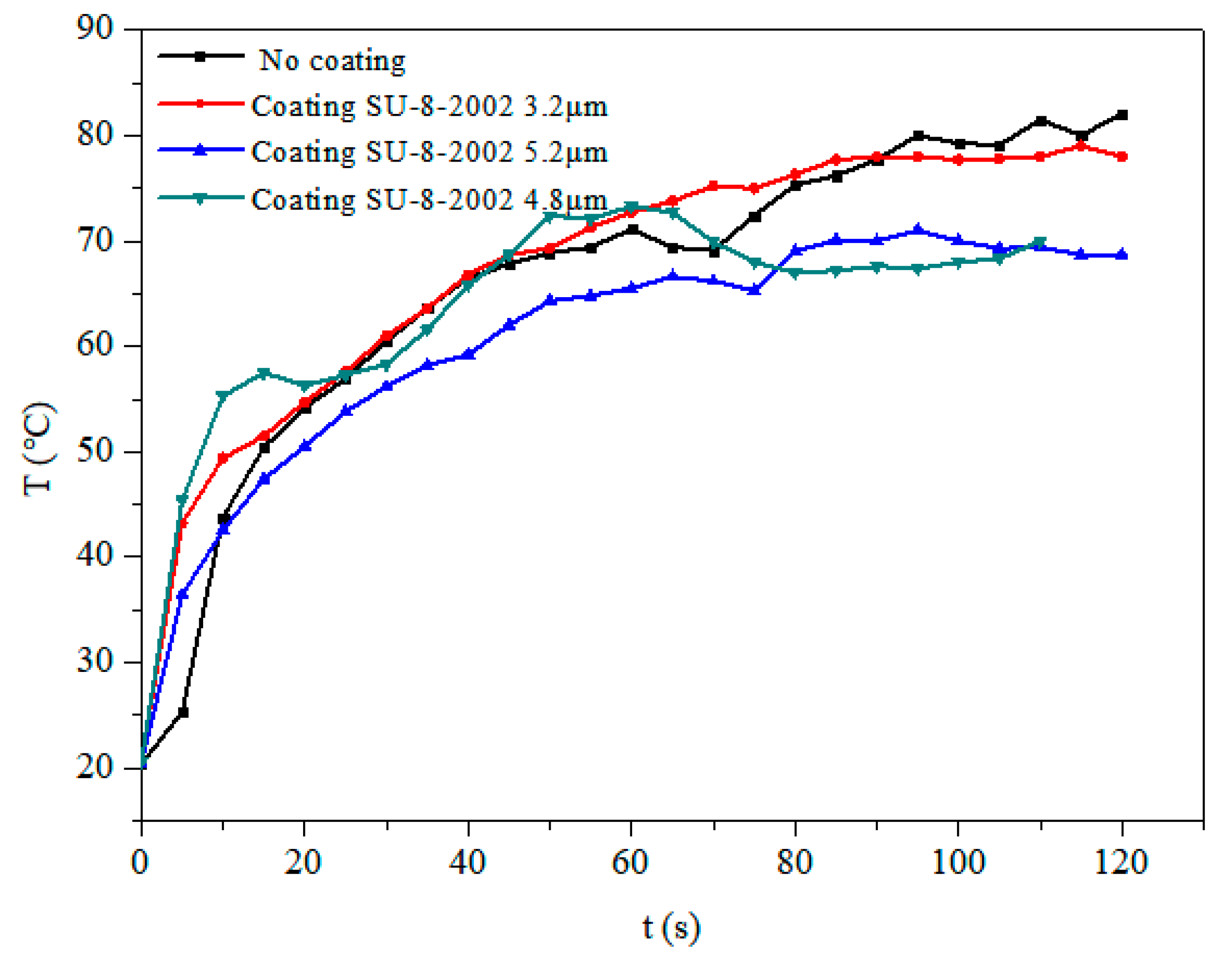

3.3. Heating Effects

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wood, R.W.; Loomis, A.L. The physical and biological effects of high-frequency sound-waves of great intensity. J. Frankl. Inst. 1928, 205, 151–153. [Google Scholar] [CrossRef]

- Lang, R.J. Ultrasonic atomization of liquids. J. Acoust. Soc. Am. 1962, 34, 6–8. [Google Scholar] [CrossRef]

- Kurosawa, M.; Watanabe, T.; Futami, A.; Higuchi, T. Surface acoustic wave atomizer. Sens. Actuators A Phys. Sens. 1995, 50, 69–74. [Google Scholar] [CrossRef]

- Kurosawa, M.; Watanabe, T.; Higuchi, T. Surface Acoustic Wave Atomizer with Pumping Effect. In Proceedings of the IEEE Micro Electro Mechanical Systems, Amsterdam, The Netherlands, 29 January–2 February 1995; pp. 25–30. [Google Scholar]

- Wang, J.X.; Hu, H.; Ye, A.; Chen, J.; Zhang, P. Experimental investigation of surface acoustic wave atomization. Sens. Actuators A Phys. 2016, 238, 1–7. [Google Scholar] [CrossRef]

- Ju, J.; Yamagata, Y.; Ohmori, H.; Higuchi, T. Standing wave type surface acoustic wave atomizer. Sens. Actuators A Phys. 2008, 147, 570–575. [Google Scholar] [CrossRef]

- Qi, A.; Friend, J.R.; Yeo, L.Y.; Morton, D.A.; McIntosh, M.P.; Spiccia, L. Miniature inhalation therapy platform using surface acoustic wave microfluidic atomization. Lab A Chip 2009, 9, 2184–2193. [Google Scholar] [CrossRef]

- Qi, A.; Friend, J.R.; Ho, J. The extraction of liquid, protein molecules and yeast cells from paper through surface acoustic wave atomization. Lab A Chip 2010, 10, 470–476. [Google Scholar] [CrossRef]

- Qi, A.; Friend, J.R.; Yeo, L.Y. Investigation of SAW Atomization. In Proceedings of the IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009; pp. 787–790. [Google Scholar]

- Qi, A.; Friend, J.R.; Yeo, L.Y.; Friend, J.R. Interfacial destabilization and atomization driven by surface acoustic waves. Phys. Fluids 2008, 20, 074103. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Li, Y.; Zhao, C.; Placido, F.; Walton, A.J. Surface acoustic wave nebulization on nanocrystalline ZnO film. Appl. Phys. Lett. 2012, 101, 194101. [Google Scholar] [CrossRef]

- Guo, Y.J.; Dennison, A.P.; Li, Y.; Luo, J.; Zu, X.T.; Mackay, C.L.; Langridge-Smith, P.; Walton, A.J.; Fu, Y.Q. Nebulization of water/glycerol droplets generated by ZnO/Si surface acoustic wave devices. Microfluid. Nanofluidics 2015, 19, 273–282. [Google Scholar] [CrossRef]

- Anand, S.; Nylk, J.; Neale, S.L.; Dodds, C.; Grant, S.; Ismail, M.H.; Reboud, J.; Cooper, J.M.; McGloin, D. Aerosol droplet optical trap loading using surface acoustic wave nebulization. Optics Express 2013, 21, 30148–30155. [Google Scholar] [CrossRef] [PubMed]

- Ju, J.; Yamagata, Y.; Ohmori, H.; Higuchi, T. High-frequency surface acoustic wave atomizer. Sens. Actuators A Phys. 2008, 145, 437–441. [Google Scholar] [CrossRef]

- Winkle, A.; Harazim, S.M.; Menzel, S.B.; Schmidt, H. SAW-based fluid atomization using mass-producible chip devices. Lap A Chip 2015, 15, 3793–3799. [Google Scholar] [CrossRef]

- Rajapaksa, A.; Qi, A.; Yeo, L.Y.; Coppel, R.; Friend, J.R. Enabling practical surface acoustic wave nebulizer drug delivery via amplitude modulation. Lap A Chip 2014, 14, 1858–1865. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Hu, H.; Chen, Y. Experimental investigation of microchannel ejection based on a novel microfluidic coating nozzle. Surf. Coat. Technol. 2019, 38, 721–725. [Google Scholar] [CrossRef]

- Yeo, L.Y.; Friend, J.R.; McIntosh, M.P.; Meeusen, E.N.; Morton, D.A. Ultrasonic nebulization platforms for pulmonary drug delivery. Expert Opin. Drug Deliv. 2010, 7, 663–679. [Google Scholar] [CrossRef] [PubMed]

- Friend, J.R.; Yeo, L.Y.; Arifin, D.R.; Mechler, A. Evaporative self-assembly assisted synthesis of polymeric nanoparticles by surface acoustic wave atomization. Nanotechnology 2008, 19, 145301. [Google Scholar] [CrossRef]

- Tan, M.K.; Friend, J.R.; Yeo, L.Y. Direct visualization of surface acoustic waves along substrates using smoke particles. Appl. Phys. Lett. 2007, 91, 224101. [Google Scholar] [CrossRef]

- Kurosawa, M.; Futami, A.; Higuchi, T. Characteristics of liquid atomization using surface acoustic wave. Transducers 1997, 97, 801–804. [Google Scholar]

- Collins, D.J.; Manor, O.; Winkler, A.; Schmidt, H.; Friend, J.R.; Yeo, L.Y. Atomization off thin water films generated by high-frequency substrate wave vibrations. Phys. Rev. E 2012, 86, 056312. [Google Scholar] [CrossRef]

- Huang, H.Y.; Chiang, H.J.; Wu, C.Z.; Lin, Y.; Shen, Y.K. Analysis on Characteristics of ZnO Surface Acoustic Wave with and without Micro-Structures. Micromachines 2019, 10, 434. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Q.-Y.; Hu, H.; Han, J.-L.; Lei, Y.-L.; Yang, X.-Q. Influence of Waterproof Films on the Atomization Behavior of Surface Acoustic Waves. Micromachines 2019, 10, 794. https://doi.org/10.3390/mi10110794

Huang Q-Y, Hu H, Han J-L, Lei Y-L, Yang X-Q. Influence of Waterproof Films on the Atomization Behavior of Surface Acoustic Waves. Micromachines. 2019; 10(11):794. https://doi.org/10.3390/mi10110794

Chicago/Turabian StyleHuang, Qing-Yun, Hong Hu, Jun-Long Han, Yu-Lin Lei, and Xiao-Qing Yang. 2019. "Influence of Waterproof Films on the Atomization Behavior of Surface Acoustic Waves" Micromachines 10, no. 11: 794. https://doi.org/10.3390/mi10110794

APA StyleHuang, Q.-Y., Hu, H., Han, J.-L., Lei, Y.-L., & Yang, X.-Q. (2019). Influence of Waterproof Films on the Atomization Behavior of Surface Acoustic Waves. Micromachines, 10(11), 794. https://doi.org/10.3390/mi10110794