Acrylamide Reduction Strategy in Combination with Deoxynivalenol Mitigation in Industrial Biscuits Production

Abstract

:1. Introduction

2. Results and Discussion

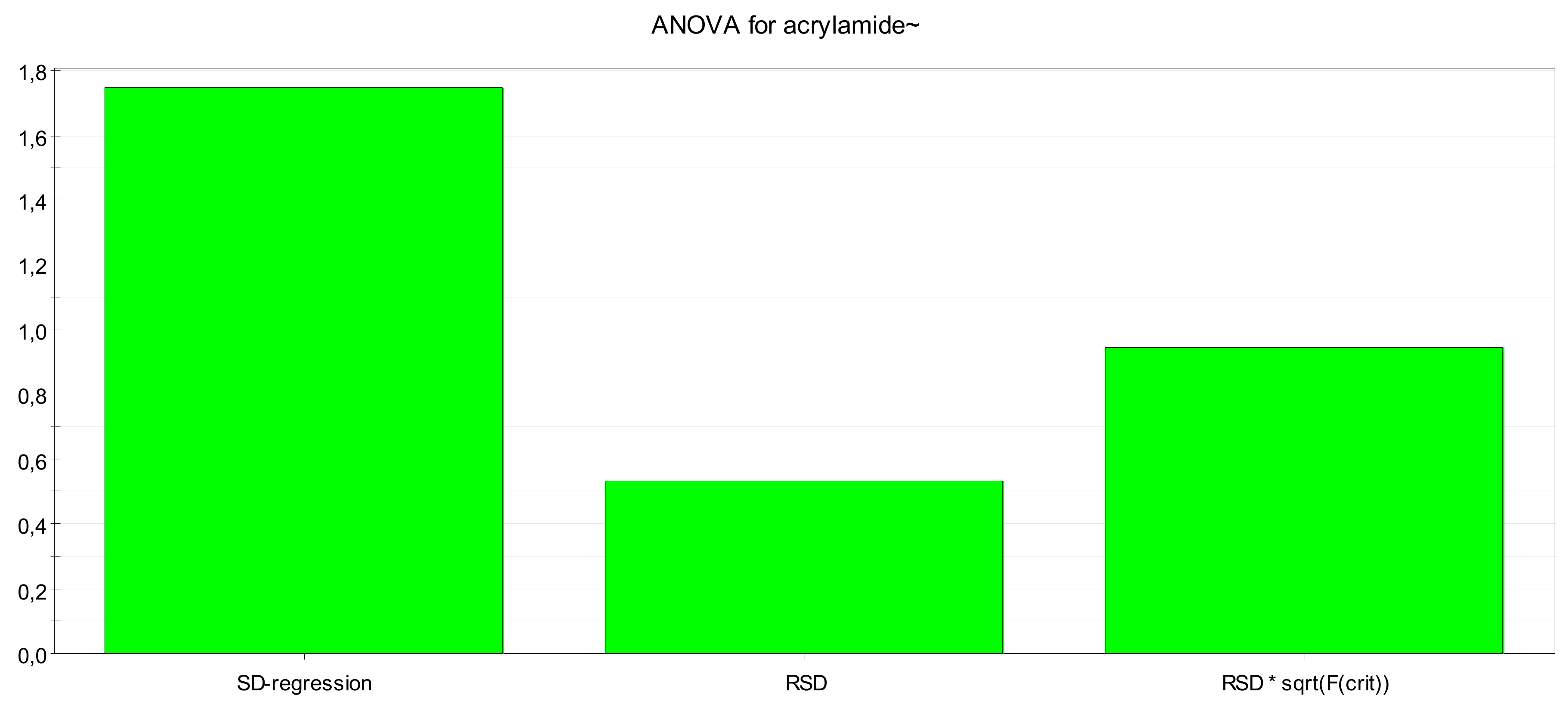

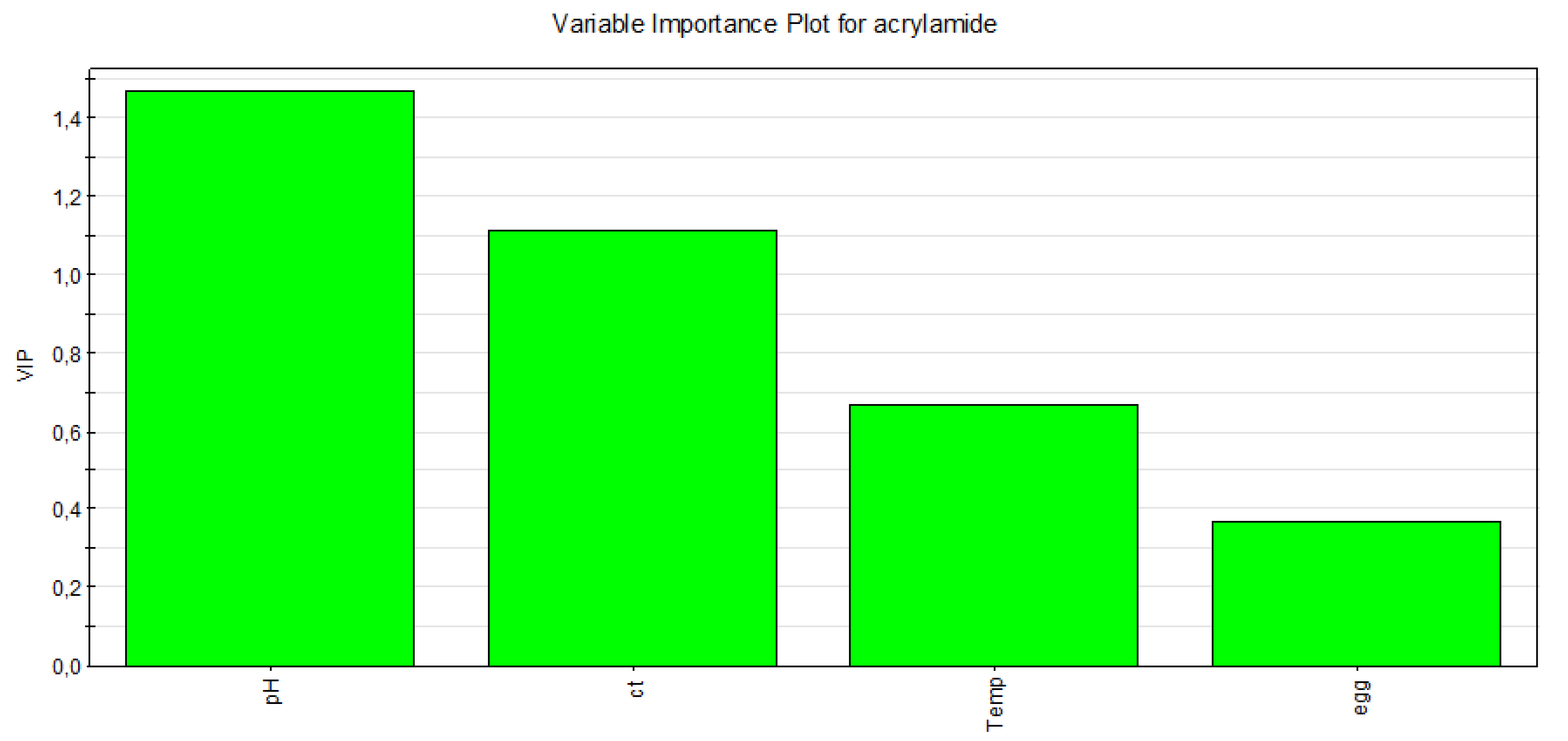

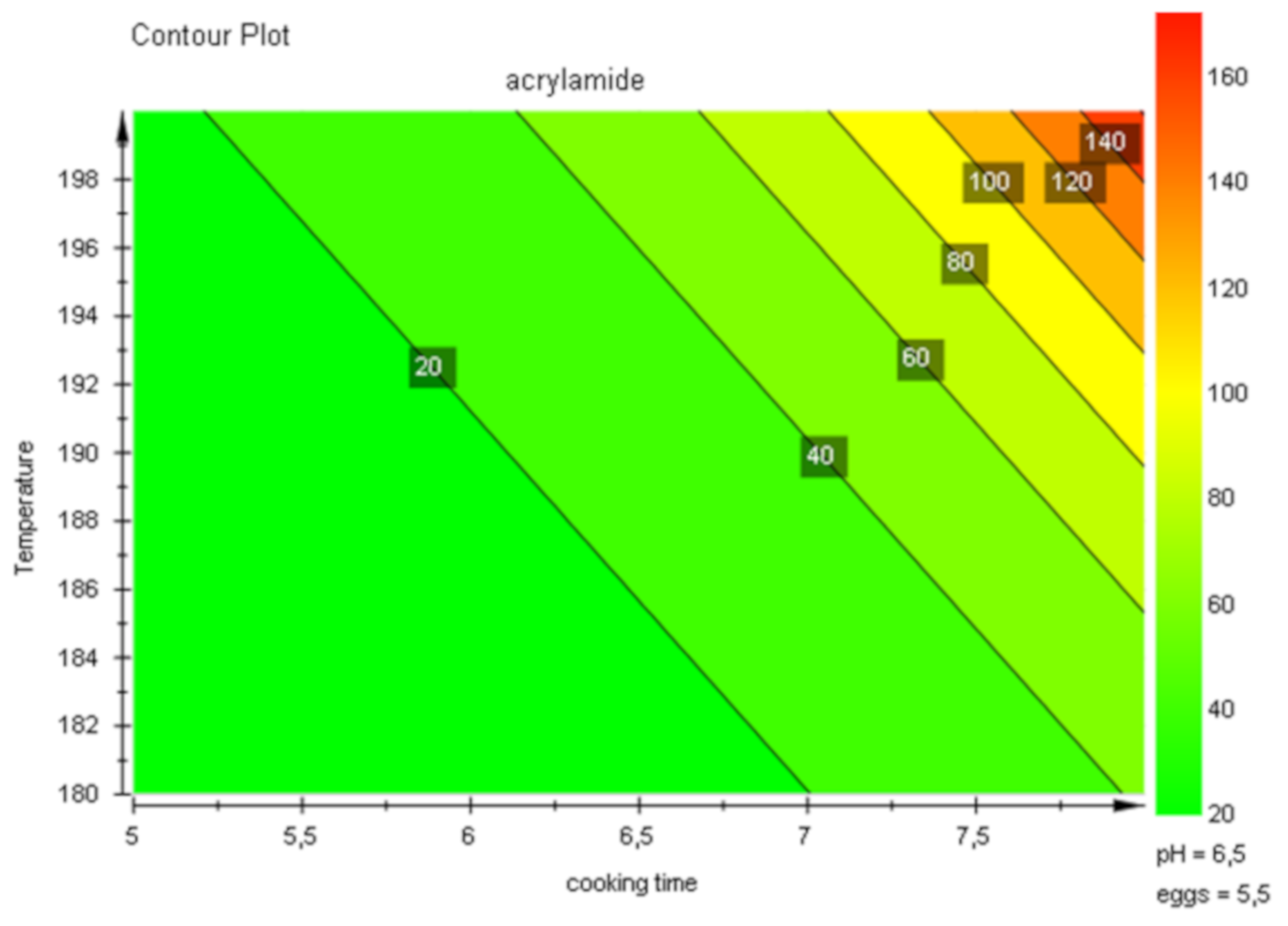

2.1. Statistical Elaboration of the Experimental Model

2.2. Acrylamide Evolution within Biscuit-Making Technology

3. Materials and Methods

3.1. Chemicals

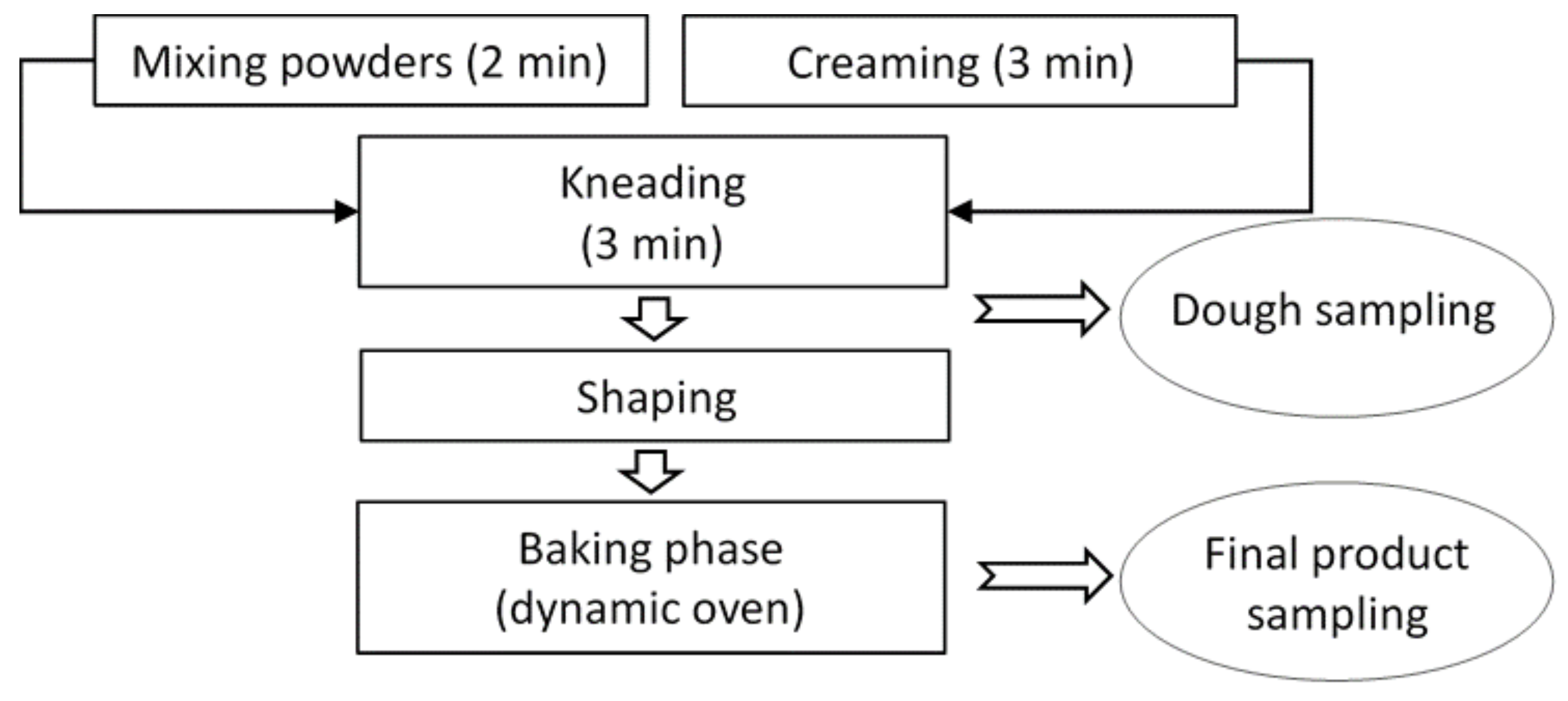

3.2. Biscuit-Making Production in Pilot-Plant Scale

3.3. Moisture Content Determination

3.4. Experimental Design and Statistical Evaluation

3.5. Sample Extraction and Instrumental Conditions—Deoxynivalenol

3.6. Sample Extraction and Instrumental Conditions—Acrylamide

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karlovsky, P.; Suman, M.; Berthiller, F.; De Meester, J.; Eisenbrand, G.; Perrin, I.; Oswald, I.P.; Speijers, G.; Chiodini, A.; Recker, T.; et al. Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res. 2016, 32, 179–205. [Google Scholar] [CrossRef] [PubMed]

- European Food Safety Authority. Deoxynivalenol in food and feed: Occurrence and exposure. EFSA J. 2013, 11, 3379–3435. [Google Scholar]

- Generotti, S.; Cirlini, M.; Šarkanj, B.; Sulyok, M.; Berthiller, F.; Dall’Asta, C.; Suman, M. Formulation and processing factors affecting trichothecene mycotoxins within industrial biscuit-making. Food Chem. 2017, 229, 597–603. [Google Scholar] [CrossRef] [PubMed]

- European Food Safety Authority. Guidance on harmonised methodologies for human health, animal health and ecological risk assessment of combined exposure to multiple chemicals. EFSA J. 2019, 17, 5634–5711. [Google Scholar]

- Mottram, D.S.; Wedzicha, B.L.; Dodson, A.T. Acrylamide is formed in the Maillard reaction. Nature 2004, 419, 448–449. [Google Scholar] [CrossRef] [PubMed]

- Törnqvist, M. Acrylamide in food: The discovery and its implication. In M. Friedman & D. Mottram, Chemistry and Safety of Acrylamide in Food; Springer Science: New York, NY, USA; Business Media, Inc.: New York, NY, USA, 2005; pp. 1–9. [Google Scholar]

- IARC (International Agency for Research on Cancer). IARC Monographs on the Evaluation of Carcinogenic Risk to Humans: Some Industrial Chemicals; pp. 39, 41 (1986); Suppl. 7, pp. 56 (1987); pp. 60, 389 (1994); IARC: Lyon, France, 1994; p. 60. [Google Scholar]

- European Commission. Commission Recommendation 2013/647/EU of 8 November 2013 on investigations into the levels of acrylamide in food. Off. J. Eur. Union 2013, 301, 15–17. [Google Scholar]

- Draft Commission Regulation (EU). Commission Reg. (EU) on the Application of Control & Mitigation Measures to Reduce the Presence of Acrylamide in Food Ref. Ares (2017)2895100-09/06/2017. Available online: https://ec.europa.eu/info/law/better-regulation/initiatives/ares-2017-2895100_en (accessed on 1 June 2019).

- Claus, A.; Carle, R.; Schieber, A. Acrylamide in cereal products: A review. J. Cereal Sci. 2008, 47, 118–133. [Google Scholar] [CrossRef]

- Konings, E.J.M.; Ashby, P.; Hamlet, C.G.; Thompson, G.A.K. Acrylamide in cereal and cereal products: A review on progress in level reduction. Food Addit. Contam. 2007, 24, 47–59. [Google Scholar] [CrossRef]

- Medeiros Vinci, R.; Mestdagh, F.; De Meulenaer, B. Acrylamide formation in fried potato products-present and future, a critical review on mitigation strategies. Food Chem. 2012, 133, 1138–1154. [Google Scholar] [CrossRef]

- Sadd, P.A.; Hamlet, C.G.; Liang, L. Effectiveness of methods for reducing acrylamide in bakery products. J. Agric. Food Chem. 2008, 50, 4998–5006. [Google Scholar] [CrossRef]

- Stadler, R.H. The formation of acrylamide in cereal products and coffee. In Acrylamide and Other Hazardous Compounds in Heat-Treated Foods; Skog, K., Alexander, J., Eds.; Woodhead Publishing: Cambridge, UK, 2006; pp. 23–40. [Google Scholar]

- Anese, M.; Suman, M.; Nicoli, M.C. Technological strategies to reduce acrylamide levels in heated foods. Food Eng. Rev. 2009, 1, 169. [Google Scholar] [CrossRef]

- Anese, M.; Suman, M.; Nicoli, M.C. Acrylamide removal from heated foods. Food Chem. 2010, 119, 791–794. [Google Scholar] [CrossRef]

- Taeymans, D.; Wood, J.; Ashby, P.; Blank, I.; Studer, A.; Stadler, R.H.; Gondé, P.; Eijck, P.; Lalljie, S.; Lingnert, H.; et al. A review of acrylamide: An industry perspective on research, analysis, formation and control. Crit. Rev. Food Sci. Nutr. 2004, 44, 323–347. [Google Scholar] [CrossRef] [PubMed]

- Biedermann, M.; Noti, A.; Biedermann-Brem, S.; Mozzetti, V.; Grob, K. Experiments on acrylamide formation and possibilities to decrease the potantial of acrylamide formation in potatoes. Mitt. Lebensm. Hyg. 2002, 93, 668–687. [Google Scholar]

- Elmore, J.S.; Koutsidis, G.; Dodson, A.T. Measurements of acrylamide and its precursors in potato, wheat, and rye model systems. J. Agric. Food Chem. 2005, 53, 1286–1293. [Google Scholar] [CrossRef] [PubMed]

- Hedegaard, R.V.; Frandsen, H.; Granby, K.; Apostolopoulou, A.; Skibsted, L.H. Model studies on acrylamide generation from glucose/asparagine in aqueous glycerol. J. Agric. Food Chem. 2007, 55, 486–492. [Google Scholar] [CrossRef] [PubMed]

- Biedermann, M.; Grob, K. Model studies on acrylamide formation in potato, wheat flour and corn starch; ways to reduce acrylamide contents in bakery ware. Mitt. Lebensm. Hyg. 2003, 94, 406–422. [Google Scholar]

- Bråthen, E.; Knutsen, S.H. Effect of temperature and time on the formation of acylamide in starch-based and cereal model systems, flat breads and bread. Food Chem. 2005, 92, 693–700. [Google Scholar] [CrossRef]

- Surdyk, N.; Rosén, J.; Andersson, R.; Åman, P. Effects of asparagine, fructose and baking conditions on acrylamide content in yeasts-leavened wheat bread. J. Agric. Food Chem. 2004, 52, 2047–2051. [Google Scholar] [CrossRef]

- Bergamini, E.; Catellani, D.; Dall’Asta, C.; Galaverna, G.; Dossena, A.; Marchelli, R.; Suman, M. Fate of Fusarium mycotoxins in the cereal product supply chain: The deoxynivalenol (DON) case within industrial bread-making technology. Food Addit. Contam. 2010, 27, 677–687. [Google Scholar] [CrossRef]

- Generotti, S.; Cirlini, M.; Malachova, A.; Sulyok, M.; Berthiller, F.; Dall’Asta, C.; Suman, M. Deoxyivalenol and deoxynivalenol-3-glucoside mitigation strategies: Effective experimental design within industrial rusk-making technology. Toxins 2015, 7, 2773–2790. [Google Scholar] [CrossRef] [PubMed]

- Suman, M.; Manzitti, A.; Catellani, D. A design of experiments approach to studying deoxynivalenol and deoxynivalenol-3-glucoside evolution throughout industrial production of wholegrain crackers exploiting LC-MS/MS techniques. World Mycotoxin J. 2012, 5, 241–249. [Google Scholar] [CrossRef]

- Generotti, S. Transformation of Regulated and Emerging Mycotoxins upon Food Processing: From Field to Digestion. Ph.D. Thesis, University of Parma, Parma, Italy, January 2016. [Google Scholar]

- Telford, J.K. A brief introduction to design of experiments. John Hopkins APL Tech. Dig. 2007, 27, 224–232. [Google Scholar]

- Calbiani, F.; Careri, M.; Elviri, L.; Mangia, A.; Zagnoni, I. Development and single-laboratory validation of a reversed-phase liquid chromatography-electrospray-tandem mass spectrometry method for the identification and determination of acrylamide in foods. J. AOAC Int. 2004, 87, 107–115. [Google Scholar] [PubMed]

- Gökmen, V.; Açar, O.C.; Köksel, H.; Acar, J. Effects of dough formula and baking conditions on acrylamide and hydroxymethylfurfural formation in cookies. Food Chem. 2007, 104, 1136–1142. [Google Scholar] [CrossRef]

- Graf, M.; Amrein, T.M.; Graf, S.; Szalay, R.; Escher, F.; Amadò, R. Reducing the acrylamide content of a semi-finished biscuit on industrial scale. LWT-Food Sci. Technol. 2006, 39, 724–728. [Google Scholar] [CrossRef]

- Vass, M.; Amrein, T.M.; Schönbächler, B.; Escher, F.; Amadò, R. Ways to reduce acrylamide formation in cracker production. Czech J. Food Sci. 2004, 22, 19–21. [Google Scholar] [CrossRef]

- Rydberg, P.; Eriksson, S.; Tareke, E.; Karlsson, P.; Ehrenberg, L.; Törnqvist, M. Investigations of factors that influence the acrylamide content of heated foodstuffs. J. Agric. Food Chem. 2003, 51, 7012–7018. [Google Scholar] [CrossRef]

- Vattem, D.A.; Shetty, K. Acrylamide in foods: A model for mechanism of formation and its reduction. Innov. Food Sci. Emerg. Technol. 2003, 4, 331–338. [Google Scholar] [CrossRef]

- Wedzicha, B.L.; Mottram, D.S.; Elmore, J.S. Kinetic models as a route to control acrylamide formation in food. In Chemistry and Safety of Acrylamide in Food; Friedman, M., Mottram, D., Eds.; Springer: New York, NY, USA, 2015. [Google Scholar]

- Farah, D.M.H.; Zaibunnisa, A.H.; Misnawi, J. Optimization of cocoa beans roasting process using Response Surface Methodology based on concentration of pyrazine and acrylamide. Int. Food Res. J. 2012, 19, 1355–1359. [Google Scholar]

| TREATMENT | WHOLEGRAIN BISCUIT MAKING | COCOA BISCUIT MAKING | ||||

|---|---|---|---|---|---|---|

| Minimum | Central Point | Maximum | Minimum | Central Point | Maximum | |

| DON bran level (µg/kg) | 600 | 1050 | 1500 | 600 | 1050 | 1500 |

| Dextrose (%) | 15 | 19 | 23 | 15 | 19 | 23 |

| Milk (%) | - | - | - | 5 | 6.5 | 8 |

| Eggs (%) | 4 | 6 | 7 | - | - | - |

| Margarine (%) | 10 | 15 | 20 | - | - | - |

| pH value | 5 | 6.5 | 8 | 5 | 6.5 | 8 |

| Baking time (min) | 5 | 6.5 | 8 | 5 | 6.5 | 8 |

| Baking temperature (°C) | 180 | 190 | 200 | 180 | 190 | 200 |

| Sample | Baking Stage | |||||

|---|---|---|---|---|---|---|

| DON in Wholegrain Flour (µg/kg d.m.) * | NaHCO3 (g) | Time (min) | Temperature (°C) | Acrylamide (µg/kg d.m.) * | DON (µg/kg d.m.) *§ | |

| Wholegrain biscuits | 219 ± 8 | 8 | 5 | 180 | 16 ± 3 | 154 ± 1 |

| 304 ± 9 | 8 | 8 | 180 | 125 ± 14 | 192 ± 4 | |

| 219 ± 8 | 8 | 5 | 200 | 66 ± 10 | 188 ± 7 | |

| 304 ± 9 | 8 | 8 | 200 | 306 ± 16 | 189 ± 7 | |

| Cocoa biscuits | 219 ± 8 | 8 | 5 | 180 | 43 ± 13 | 129 ± 7 |

| 304 ± 9 | 8 | 8 | 180 | 156 ± 15 | 208 ± 2 | |

| 219 ± 8 | 8 | 5 | 200 | 185 ± 15 | 154 ± 1 | |

| 304 ± 9 | 8 | 8 | 200 | 400 ± 27 | 192 ± 4 | |

| Experiment Number | DON in Bran (µg/kgd.m.) 1 | Dextrose (%) | Margarine (%) | pH | Eggs (%) | Baking Stage | |

|---|---|---|---|---|---|---|---|

| Time (min) | Temperature (°C) | ||||||

| 1 | 600 ± 16 | 15 | 10 | 5 | 4 | 5 | 180 |

| 2 | 1500 ± 92 | 15 | 10 | 5 | 7 | 5 | 200 |

| 3 | 600 ± 16 | 23 | 10 | 5 | 7 | 8 | 180 |

| 4 | 1500 ± 92 | 23 | 10 | 5 | 4 | 8 | 200 |

| 5 | 600 ± 16 | 15 | 20 | 5 | 7 | 8 | 200 |

| 6 | 1500 ± 92 | 15 | 20 | 5 | 4 | 8 | 180 |

| 7 | 600 ± 16 | 23 | 20 | 5 | 4 | 5 | 200 |

| 8 | 1500 ± 92 | 23 | 20 | 5 | 7 | 5 | 180 |

| 9 | 600 ± 16 | 15 | 10 | 8 | 4 | 8 | 200 |

| 10 | 1500 ± 92 | 15 | 10 | 8 | 7 | 8 | 180 |

| 11 | 600 ± 16 | 23 | 10 | 8 | 7 | 5 | 200 |

| 12 | 1500 ± 92 | 23 | 10 | 8 | 4 | 5 | 180 |

| 13 | 600 ± 16 | 15 | 20 | 8 | 7 | 5 | 180 |

| 14 | 1500 ± 92 | 15 | 20 | 8 | 4 | 5 | 200 |

| 15 | 600 ± 16 | 23 | 20 | 8 | 4 | 8 | 180 |

| 16 | 1500 ± 92 | 23 | 20 | 8 | 7 | 8 | 200 |

| 17 | 1050 ± 48 | 19 | 15 | 6.5 | 6 | 6.5 | 190 |

| 18 | 1050 ± 48 | 19 | 15 | 6.5 | 6 | 6.5 | 190 |

| 19 | 1050 ± 48 | 19 | 15 | 6.5 | 6 | 6.5 | 190 |

| Experiment Number | DON in Bran (µg/kgd.m.) 1 | Dextrose (%) | Milk (%) | pH | Baking Stage | |

|---|---|---|---|---|---|---|

| Time (min) | Temperature (°C) | |||||

| 1 | 600 ± 16 | 23 | 5 | 5 | 5 | 180 |

| 2 | 600 ± 16 | 15 | 8 | 8 | 5 | 180 |

| 3 | 1500 ± 92 | 15 | 5 | 5 | 8 | 180 |

| 4 | 1500 ± 92 | 23 | 8 | 8 | 8 | 180 |

| 5 | 600 ± 16 | 23 | 5 | 8 | 5 | 200 |

| 6 | 1500 ± 92 | 23 | 8 | 5 | 5 | 200 |

| 7 | 1500 ± 92 | 15 | 5 | 8 | 8 | 200 |

| 8 | 600 ± 16 | 15 | 8 | 5 | 8 | 200 |

| 9 | 1500 ± 92 | 23 | 5 | 8 | 5 | 180 |

| 10 | 600 ± 16 | 23 | 8 | 5 | 5 | 180 |

| 11 | 600 ± 16 | 15 | 5 | 8 | 8 | 180 |

| 12 | 1500 ± 92 | 15 | 8 | 5 | 8 | 180 |

| 13 | 600 ± 16 | 15 | 5 | 5 | 5 | 200 |

| 14 | 1500 ± 92 | 15 | 8 | 8 | 5 | 200 |

| 15 | 1500 ± 92 | 23 | 5 | 5 | 8 | 200 |

| 16 | 600 ± 16 | 23 | 8 | 8 | 8 | 200 |

| 17 | 1050 ± 48 | 19 | 6.5 | 6.5 | 6.5 | 190 |

| 18 | 1050 ± 48 | 19 | 6.5 | 6.5 | 6.5 | 190 |

| 19 | 1050 ± 48 | 19 | 6.5 | 6.5 | 6.5 | 190 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suman, M.; Generotti, S.; Cirlini, M.; Dall’Asta, C. Acrylamide Reduction Strategy in Combination with Deoxynivalenol Mitigation in Industrial Biscuits Production. Toxins 2019, 11, 499. https://doi.org/10.3390/toxins11090499

Suman M, Generotti S, Cirlini M, Dall’Asta C. Acrylamide Reduction Strategy in Combination with Deoxynivalenol Mitigation in Industrial Biscuits Production. Toxins. 2019; 11(9):499. https://doi.org/10.3390/toxins11090499

Chicago/Turabian StyleSuman, Michele, Silvia Generotti, Martina Cirlini, and Chiara Dall’Asta. 2019. "Acrylamide Reduction Strategy in Combination with Deoxynivalenol Mitigation in Industrial Biscuits Production" Toxins 11, no. 9: 499. https://doi.org/10.3390/toxins11090499

APA StyleSuman, M., Generotti, S., Cirlini, M., & Dall’Asta, C. (2019). Acrylamide Reduction Strategy in Combination with Deoxynivalenol Mitigation in Industrial Biscuits Production. Toxins, 11(9), 499. https://doi.org/10.3390/toxins11090499