Fumonisin Distribution in Maize Dry-Milling Products and By-Products: Impact of Two Industrial Degermination Systems

Abstract

1. Introduction

2. Results and Discussion

3. Conclusions

4. Material and Methods

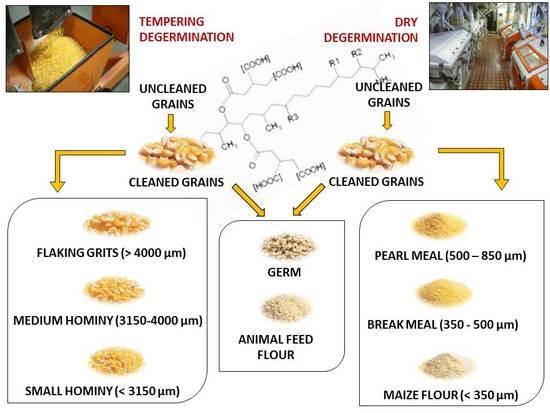

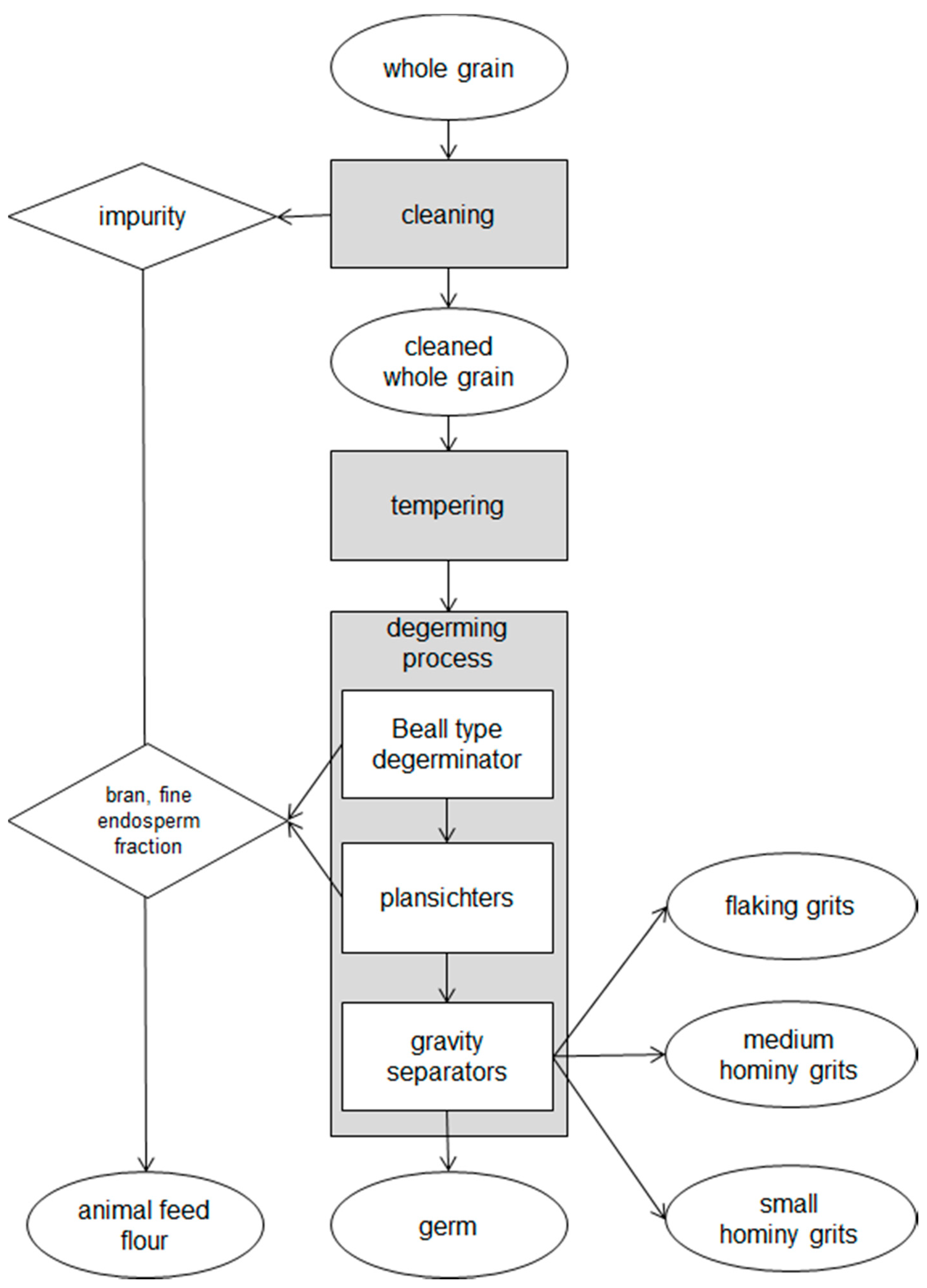

4.1. Maize Milling Processes

4.2. Sampling

4.3. FB Analysis

4.3.1. Sample Preparation, Extraction and Clean-Up

4.3.2. LC-MS/MS Analysis

4.4. Statistical Analysis

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ANOVA | analysis of variance |

| FB1 | fumonisin B1 |

| FB2 | fumonisin B2 |

| FBs, B-series fumonisins | sum of FB1 and FB2 |

| DD | dry degermination |

| TD | tempering-degermination |

| EC | European Commission |

| ESI | Electrospray ionization |

| LC | Liquid chromatography |

| MS | Mass spectrometry |

| PBS | Phosphate buffered saline |

| REGWF | Ryan-Einot-Gabriel-Welsh F test |

References

- Kent, N.L.; Evers, A.D. Technology of Cereals, 4th ed.; Pergamon Press: Oxford, UK, 1994; pp. 129–139. ISBN 9781855733619. [Google Scholar]

- Gwirtz, J.A.; Garcia-Casal, M.N. Processing maize flour and corn meal food products. Ann. N. Y. Acad. Sci. 2014, 1312, 66–75. [Google Scholar] [CrossRef] [PubMed]

- Mestres, C.; Matencio, F. Biochemical basis of kernel milling characteristics and endosperm vitreousness of maize. Cereal Chem. 1996, 24, 283–290. [Google Scholar] [CrossRef]

- Serna-Saldivar, S.O.; Gomez, M.H.; Rooney, L.W. Food uses of regular and specialty corns and their dry-milled fractions. In Specialty Corns, 2nd ed.; Hallauer, A.R., Ed.; CRC Press LLC: Boca Raton, FL, USA, 2001; pp. 303–337. ISBN 0849323770. [Google Scholar]

- Eckhoff, S.R. MAIZE/Dry milling. In Encyclopedia of Grain Science, 1st ed.; Wrigley, C., Walker, C., Corke, H., Eds.; Elsevier: Oxford, UK, 2004; pp. 216–225. ISBN 9780080926636. [Google Scholar]

- Blandino, M.; Sacco, D.; Reyneri, A. Prediction of the dry-milling performance of maize hybrids through hardness-associated properties. J. Sci. Food Agric. 2013, 93, 1356–1364. [Google Scholar] [CrossRef] [PubMed]

- Nuss, E.T.; Tanumihardjo, S.A. Maize: A paramount staple crop in the context of global nutrition. Compr. Rev. Food Sci. Food Saf. 2010, 9, 417–436. [Google Scholar] [CrossRef]

- Blandino, M.; Alfieri, M.; Giordano, D.; Vanara, F.; Redaelli, R. Distribution of bioactive compounds in maize fractions obtained in two different types of large scale milling processes. J. Cereal Sci. 2017, 77, 251–258. [Google Scholar] [CrossRef]

- Marin, S.; Ramos, A.J.; Cano-Sancho, G.; Sanchis, V. Mycotoxins: Occurrence, toxicology, and exposure assessment. Food Chem. Toxicol. 2013, 60, 218–237. [Google Scholar] [CrossRef] [PubMed]

- Logrieco, A.; Mulè, G.; Moretti, A.; Bottalico, A. Toxigenic Fusarium species and mycotoxins associated with maize ear rot in Europe. Eur. J. Plant Pathol. 2002, 108, 597–609. [Google Scholar] [CrossRef]

- Vanara, F.; Reyneri, A.; Blandino, M. Fate of fumonisin B1 in the processing of whole maize kernels during dry-milling. Food Control 2009, 20, 235–238. [Google Scholar] [CrossRef]

- Bullerman, L.B.; Bianchini, A. Stability of mycotoxins during food processing. Int. J. Food Microbiol. 2007, 123, 81–87. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Commission Regulation (EC) No. 1126/2007, of 28 September 2007 amending Regulation (EC) No 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards Fusarium toxins in maize and maize products. Off. J. Eur. Union 2007, 255, 14–17. [Google Scholar]

- Brera, C.; Debegnach, F.; Grossi, S.; Miraglia, M. Effect of the industrial processing on the distribution of fumonisin B1 in dry milling corn fractions. J. Food Protect. 2004, 67, 1261–1266. [Google Scholar] [CrossRef]

- Burger, H.-M.; Shephard, G.S.; Louw, W.; Rheeder, J.P.; Gelderblom, W.C.A. The mycotoxin distribution in maize milling fractions under experimental conditions. Int. J. Food Microbiol. 2013, 165, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Katta, S.K.; Cagampang, A.E.; Jackson, L.S.; Bullerman, L.B. Distribution of Fusarium molds and fumonisins in dry-milled corn fractions. Cereal Chem. 1997, 74, 858–863. [Google Scholar] [CrossRef]

- Reyneri, A.; Pietri, A.; Causin, R.; Brera, C.; Vanara, F.; Costa, E. Campionamento dei molini a mais italiani per la ricerca delle fumonisine nei prodotti della trasformazione industriale. In Proceedings of the 2° Congresso Nazionale, Le Micotossine Nella Filiera Agro-Alimentare, Roma, Italy, 16–18 October 2006; pp. 51–56. [Google Scholar]

- Pietri, A.; Zanetti, M.; Bertuzzi, T. Distribution of aflatoxins and fumonisins in dry-milled maize fractions. Food Addit. Contam. 2009, 26, 372–380. [Google Scholar] [CrossRef] [PubMed]

- Scudamore, K.A.; Patel, S. Survey for aflatoxins, ochratoxin A, zearalenone and fumonisins in maize imported into the United Kingdom. Food Addit. Contam. 2000, 17, 407–416. [Google Scholar] [CrossRef] [PubMed]

- Aprodu, I.; Banu, I. Co-occurrence of fumonisins and T-2 toxins in milling fractions under industrial conditions. CyTA J. Food 2015, 13, 102–106. [Google Scholar] [CrossRef]

- Castells, M.; Marin, S.; Sanchis, V.; Ramos, A.J. Distribution of fumonisins and aflatoxins in corn fractions during industrial cornflake processing. Int. J. Food Microbiol. 2008, 123, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Shim, W.; Flaherty, J.E.; Woloshuk, C.P. Comparison of fumonisin B1 biosynthesis in maize germ and degermed kernels by Fusarium verticillioides. J. Food Protect. 2003, 66, 2116–2122. [Google Scholar] [CrossRef]

- Philippeau, C.; Landry, J.; Michalet-Doreau, B. Influence of the protein distribution of maize endosperm on ruminal starch degradability. J. Sci. Food Agric. 2000, 80, 404–408. [Google Scholar] [CrossRef]

- Dombrink-Kurtzman, M.A.; Knutson, C.A. A study of maize endosperm hardness in relation to amylose content and susceptibility to damage. Cereal Chem. 1997, 74, 776–780. [Google Scholar] [CrossRef]

- Bluhm, B.H.; Woloshuk, C.P. Amylopectin induces fumonisin B1 production by fusarium verticillioides during colonization of maize kernels. Mol. Plant Microbe Interact. 2005, 18, 1333–1339. [Google Scholar] [CrossRef] [PubMed]

- Blandino, M.; Reyneri, A. Comparison between normal and waxy maize hybrids for fusarium-toxin contamination in NW Italy. Maydica 2007, 52, 127–134. [Google Scholar]

- Broggi, L.E.; Resnik, S.L.; Pacin, A.M.; Gonzalez, H.H.L.; Cano, G.; Taglieri, D. Distribution of fumonisins in dry-milled corn fractions in Argentina. Food Addit. Contam. 2002, 19, 465–469. [Google Scholar] [CrossRef] [PubMed]

- Scudamore, K.A.; Patel, S. Fusarium mycotoxins in milling streams from the commercial milling of maize imported to the UK, and relevance to current legislation. Food Addit. Contam. 2009, 26, 744–753. [Google Scholar] [CrossRef] [PubMed]

- Bordini, J.G.; Ono, M.A.; Garcia, G.T.; Fazani, V.H.M.; Vizoni, E.; Rodrigues, K.C.B.; Hirooka, E.Y.; Ono, E.Y.H. Impact of industrial dry-milling on fumonisin redistribution in non-transgenic corn in Brazil. Food Chem. 2017, 220, 438–443. [Google Scholar] [CrossRef] [PubMed]

- Generotti, S.; Cirlini, M.; Dall’Asta, C.; Suman, M. Influence of the industrial process from caryopsis to cornmeal semolina on levels of fumonisins and their masked forms. Food Control 2015, 48, 170–174. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EC) No. 401/2006, of 23 February 2006 laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off. J. Eur. Union 2006, 70, 12–34. [Google Scholar]

| Lots | Year | Hybrid | FB1 ± SD (µg·kg−1) | FB2 ± SD (µg·kg−1) | FBs ± SD (µg kg−1) |

|---|---|---|---|---|---|

| 1 | 2011 | DKC6795 | 407 ± 62 | 122 ± 5 | 529 ± 58 |

| 2 | 2011 | Pioneer P1543 | 211 ± 192 | 91 ± 63 | 302 ± 255 |

| 3 | 2011 | Pioneer 3245 | 170 ± 151 | 69 ± 70 | 239 ± 220 |

| 4 | 2012 | Pioneer P1547 | 866 ± 331 | 354 ± 154 | 1220 ± 483 |

| 5 | 2012 | Mixture of Pioneer P1543 and P1547 | 901 ± 285 | 385 ± 120 | 1286 ± 405 |

| 6 | 2012 | Pioneer 3245 | 999 ± 721 | 369 ± 303 | 1368 ± 995 |

| 7 | 2013 | Pioneer P1547 | 1418 ± 590 | 525 ± 203 | 1943 ± 685 |

| 8 | 2013 | Pioneer P1758 | 1259 ± 76 | 420 ± 25 | 1678 ± 97 |

| 9 | 2013 | Mixture of Pioneer 3245, P1543 and DKC6795 | 1979 ± 448 | 770 ± 266 | 2749 ± 706 |

| Factor | Dry Milling Process a | Source of Variation | FB1 | FB2 | FBs | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T | N (µg kg−1) | T | N (µg kg−1) | T | N (µg kg−1) | ||||||

| Year | - | 2011 | 4.6 | 255 | 3.7 | 84 | 4.9 | 340 | |||

| - | 2012 | 6.1 | 718 | 5.1 | 295 | 6.4 | 1013 | ||||

| - | 2013 | 6.3 | 860 | 5.3 | 395 | 6.6 | 1255 | ||||

| Milling fraction | - | pre-cleaned whole grain | 6.5 | b | 912 | 5.5 | b | 345 | 6.8 | b | 1257 |

| - | post-cleaned whole grain | 5.8 | c | 534 | 4.8 | c | 191 | 6.1 | c | 725 | |

| DD | germ | 5.7 | c | 396 | 4.6 | c | 132 | 6.0 | c | 528 | |

| animal feed flour | 7.3 | a | 1718 | 6.5 | a | 872 | 7.7 | a | 2591 | ||

| maize flour | 5.8 | c | 454 | 4.8 | c | 169 | 6.2 | c | 623 | ||

| break meal | 4.8 | de | 159 | 3.9 | de | 57 | 5.1 | de | 216 | ||

| pearl meal | 4.4 | e | 114 | 3.5 | de | 43 | 4.8 | e | 157 | ||

| TD | germ | 5.7 | c | 386 | 4.6 | c | 124 | 6.0 | c | 510 | |

| animal feed flour | 7.5 | a | 2069 | 6.7 | a | 1018 | 7.9 | a | 3087 | ||

| small hominy grits | 5.1 | d | 205 | 4.0 | d | 66 | 5.3 | d | 272 | ||

| medium hominy grits | 4.5 | e | 109 | 3.5 | e | 38 | 4.8 | e | 147 | ||

| flaking grits | 3.7 | f | 54 | 2.9 | f | 23 | 4.0 | f | 76 | ||

| p-value | <0.001 | - | <0.001 | - | <0.001 | - | |||||

| SEM b | 1 | - | 0.9 | - | 0.9 | - | |||||

| Milling fraction × year | p-value | 0.102 | - | 0.165 | - | 0.204 | - | ||||

| Dry Milling Process a | Products | Yield b (%) | FBs Mass Balance c (%) |

|---|---|---|---|

| DD | Germ | 10 | 3.9 |

| Animal feed flour | 35 | 67.3 | |

| Maize flour | 5 | 2.3 | |

| Break meal | 20 | 3.2 | |

| Pearl meal | 30 | 3.5 | |

| TD | Germ | 10 | 4.4 |

| Animal feed flour | 35 | 92.5 | |

| Small hominy grits | 7 | 2.1 | |

| Medium hominy grits | 19 | 2.4 | |

| Flaking grits | 29 | 1.6 |

| Degermination Process a | Type of Mill | Milling Fractions b | Particle Sizes (µm) | FBs c (%) | References |

|---|---|---|---|---|---|

| TD | Experimental | #12 grits | 1680–2830 | 54 | [16] |

| #7 grits | 2830–4000 | 42 | |||

| #5 grits | >4000 | 15 | |||

| special meal | <300 | 82 | [15] | ||

| semi coarse meal d | 710–2000 | 35 | |||

| super meal | 300–1400 | 15 | |||

| TD | Industrial | small hominy grits | 1000–2000 | 22 | Present manuscript |

| medium hominy grits | 2000–4000 | 12 | |||

| flaking grits | >4000 | 6 | |||

| small hominy grits | 2500–3000 | 48 | [17] | ||

| medium hominy grits | 3000–4000 | 10 | |||

| flaking grits | > 4000 | 12 | |||

| fine flour | <300 | 52 | [18] | ||

| coarse flour | 300–850 | 12 | |||

| flaking grits | >4000 | 8 | |||

| flour | 101 | [21] | |||

| Meal | 29 | ||||

| flaking grits | 14 | ||||

| flour | 23 | [27] | |||

| Meal | 10 | ||||

| Grits | 9 | ||||

| flour | 29 | [16] | |||

| flaking grits | 8 | ||||

| flour | 9 | [14] | |||

| small grits | 17 | ||||

| large grits | 8 | ||||

| special meal | <300 | 24 | [15] | ||

| super meal | 300–1400 | 1 | |||

| flour | 21% > 180 | 15 | [20] | ||

| superior meal | 31% > 500 | 12 | |||

| extra meal | 76% > 500 | 4 | |||

| flour | <500 | 93 | [28] | ||

| grits | >500 | 6 | |||

| endosperm | 30 | [29] | |||

| corn meal | 23 | ||||

| grits | 11 | ||||

| DD | Industrial | maize flour | <315 | 50 | Present manuscript |

| break meal | 315–500 µm | 17 | |||

| pearl meal | 500–1000 µm | 13 | |||

| maize flour | <350 µm | 61 | [17] | ||

| break meal | 350–500 µm | 22 | |||

| pearl meal | 500–800 µm | 15 | |||

| maize flour | <500 µm | 37 | [11] | ||

| pearl meal | 500–1000 µm | 11 | |||

| maize flour | 141 | [30] | |||

| cornmeal semolina | 60 |

| Dry Milling Process a | Products | Particle Size Distribution (%) | |||||

|---|---|---|---|---|---|---|---|

| <315 µm | 315–500 µm | 500–710 µm | 710–800 µm | 800–1000 µm | >1000 µm | ||

| DD | Maize flour | 95 | 5 | ||||

| Break meal | 3 | 70 | 20 | 5 | 2 | ||

| Pearl meal | 4 | 12 | 35 | 22 | 25 | 2 | |

| <2500 µm | 2500–3000 µm | 3000–4000 µm | >4000 µm | ||||

| TD | Small hominy grits | 40 | 60 | ||||

| Medium hominy grits | 5 | 20 | 73 | 2 | |||

| Flaking grits | 100 | ||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanara, F.; Scarpino, V.; Blandino, M. Fumonisin Distribution in Maize Dry-Milling Products and By-Products: Impact of Two Industrial Degermination Systems. Toxins 2018, 10, 357. https://doi.org/10.3390/toxins10090357

Vanara F, Scarpino V, Blandino M. Fumonisin Distribution in Maize Dry-Milling Products and By-Products: Impact of Two Industrial Degermination Systems. Toxins. 2018; 10(9):357. https://doi.org/10.3390/toxins10090357

Chicago/Turabian StyleVanara, Francesca, Valentina Scarpino, and Massimo Blandino. 2018. "Fumonisin Distribution in Maize Dry-Milling Products and By-Products: Impact of Two Industrial Degermination Systems" Toxins 10, no. 9: 357. https://doi.org/10.3390/toxins10090357

APA StyleVanara, F., Scarpino, V., & Blandino, M. (2018). Fumonisin Distribution in Maize Dry-Milling Products and By-Products: Impact of Two Industrial Degermination Systems. Toxins, 10(9), 357. https://doi.org/10.3390/toxins10090357