Application of Nanoparticles in Human Nutrition: A Review

Abstract

1. Introduction

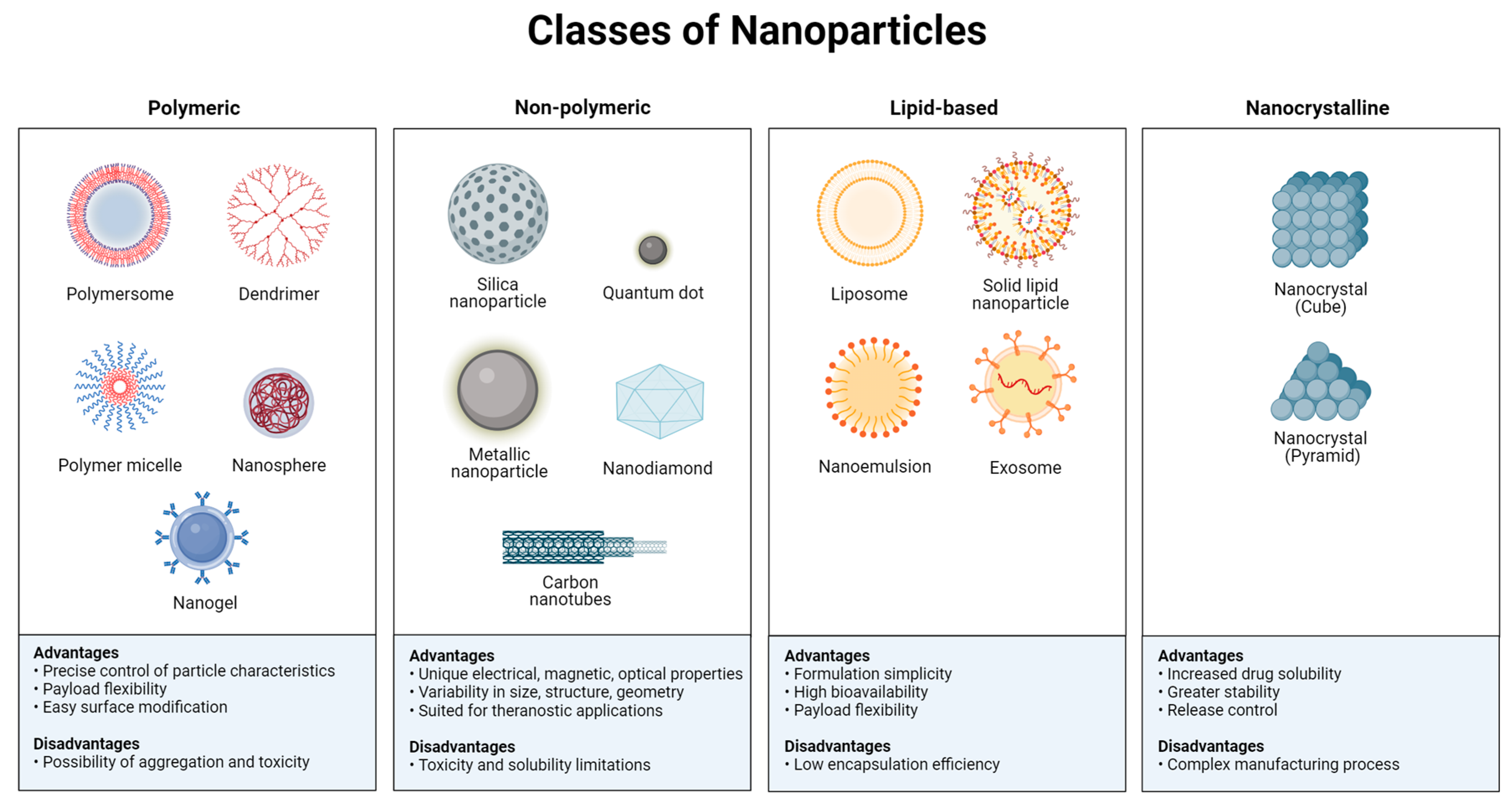

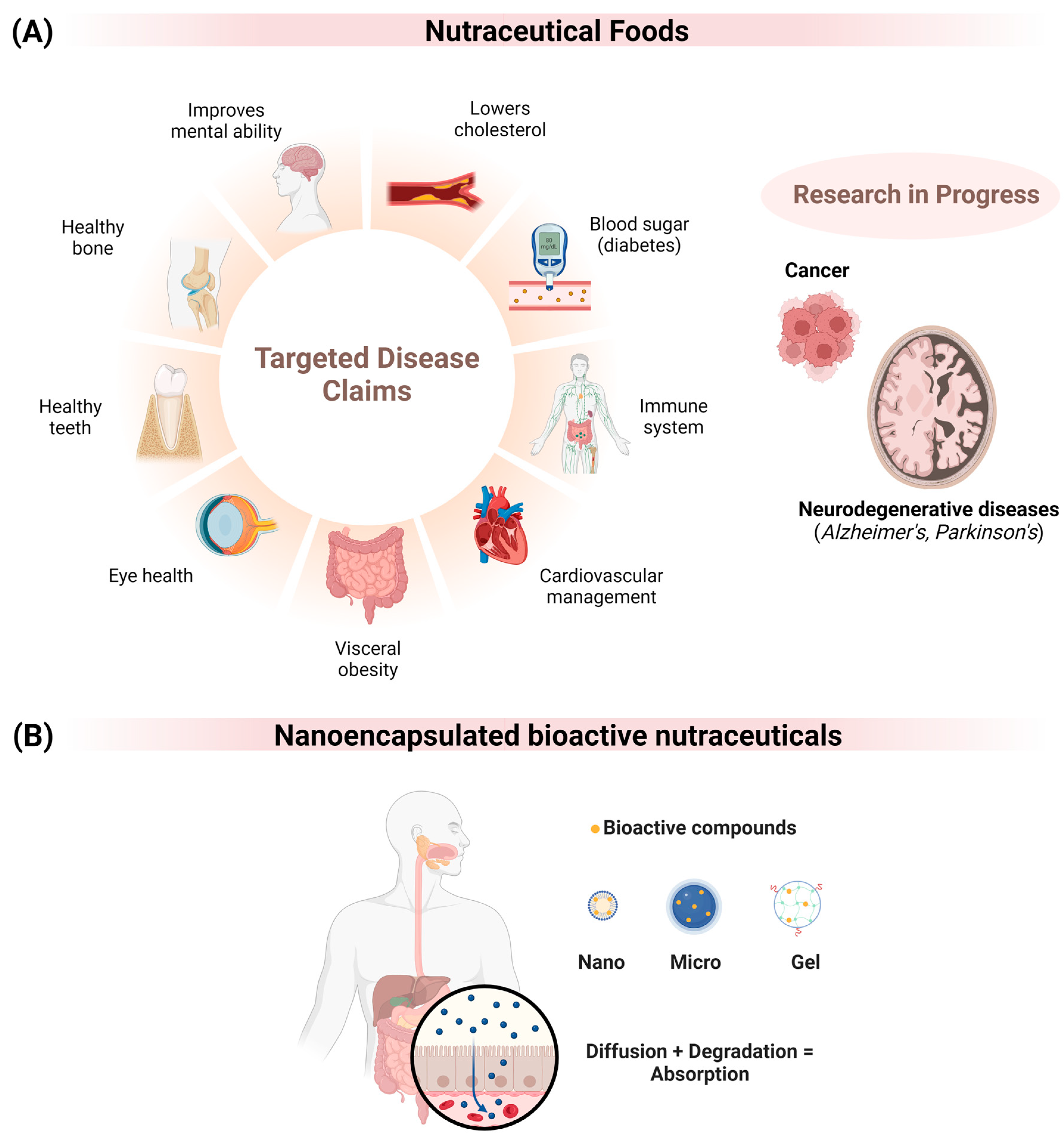

2. The Role of Nanotechnology in Human Nutrition

3. Nanoencapsulation of Bioactive Nutraceuticals

4. Bioavailability of Nanoencapsulated Bioactive Compounds

| Complex | Classifications | Operational Capabilities | References |

|---|---|---|---|

| Antioxidants | Flavonoids, tocopherols, and polyphenols are compounds with antioxidant properties. | Preventing coronary heart disease, cancer, and urinary tract disease. | [86] |

| Carotenoids | The compounds β-Carotene, lycopene, lutein, and zeaxanthin. | Prophylaxis against coronary heart disease, macular degeneration, cataracts, and cancer. | [87] |

| Essential oils (EOs) | The herbs oregano, sage, clove, and mint, as well as the compound limonene, among others. | Effect of flavorings on microbiological growth. | [88] |

| Fatty acids (FAs) | Omega-3 fatty acids, conjugated linoleic acid, and butyric acid. | The benefits of this intervention include reducing the risk of stroke, cancer, immune response problems, and heart disease. It also enhances optical acuity, bone health, and emotional well-being. | [89] |

| Phytosterols | Stigmasterol, β-sitosterol, and campesterol. | Coronary heart disease prevention. | [90] |

| Quinones | Coenzyme Q10 | Antioxidant activity | [91] |

| The Company | The Item | Features of the Product |

|---|---|---|

| Assam Company India Ltd. | Gold nano-tea | Gold nano-tea stimulates the immune system and prevents sickness, making it a wonderful daily supplement for cancer patients. |

| LivOn Labs | Lypo-spheric vitamin C | Smart liposomal Nano-spheres® with Lypo-Spheric™ Vitamin C enters the bloodstream through the intestinal wall. They cross a narrow nutrient transport channel that limits non-liposome-encapsulated vitamin C absorption. |

| NutraLease Ltd. Israel | NSSL food and beverage supplements | Patent-pending NSSL technology is involved. Nutraceuticals and medications are transported via nano-sized vehicles (micelles with a diameter of 30 nm). |

| RBC Life Sciences® industrial company | Nanoceuticals™ Slim Shake Chocolate | Nanoscale components scavenge more free radicals, boost hydration, balance pH, reduce lactic acid during exercise, lower food surface tension, and increase moisture and nutrient absorption. |

| Shemen Industries Ltd. | Canola active oil | Compressed nanodrops produce NSSL. These micelles transport water- and lipid-insoluble vitamins, minerals, and phytochemicals. During digestion, food micelles remain intact. Large bile acid micelles compete with cholesterol for phytosterols from tiny micelles. Micelle phytosterols block intestinal cholesterol absorption. This unique approach helped Shemen Industries make canola active oil. |

| Shenzhen (later known as China Industry & Trade Co., Ltd). | Nano-tea | Gold Nano-tea’s anti-aging qualities revitalize the body and keep the skin young. |

| PureHealth® Research | The product is nano-powered omega-3 with DHA and EPA, a non-GMO fish oil supplement that comes in a package of 60 soft gels. | Employs nanotechnology to turn large molecules into millions of little ones for the body to absorb like a sponge. It can benefit the heart, brain, joints, and skin. |

| Tip Top, India | Tip Top UP® DHA, an omega-3 fatty acid | The bread is enhanced with nanocapsules that contain omega-3 DHA-rich tuna fish oil. |

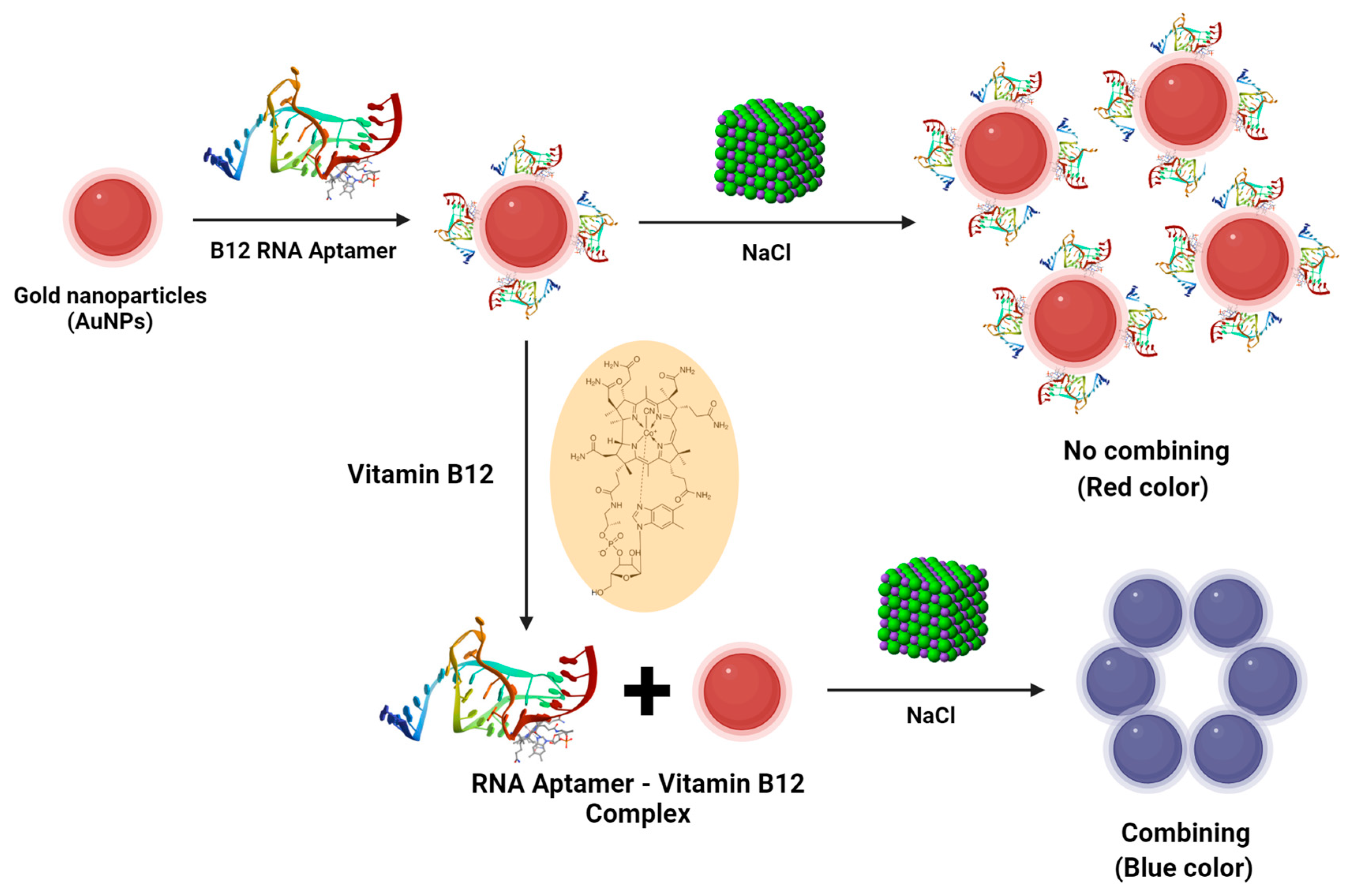

5. Application of Nanoparticle-Based Nanosensors in Food

| Agrifood Sector | Possible Uses | Occurrence of NPs | References |

|---|---|---|---|

| Agriculture | Nanosensor for the quantification of pesticides, such as phosmet. | Use of AgNPs and spectroscopic approach | [100] |

| Processing food | NPs for augmenting viscosity. | Starch NPs | [103] |

| Food packaging | Electromechanical nanosensors for ethylene. | The nanocomposite consists of palladium (Pd), rGO, and α-Fe2O3 | [102] |

| Transportation of food | Aptasensors to detect microbial cells like Staphylococcus aureus. | PMB-capped silver NPs | [104] |

| Food safety | Food pathogen detection. | AuNPs functionalized with oligonucleotides | [105] |

| Human nutrition | Utilization of nanocapsules in food for targeted nutrient delivery. | ENVs | [106] |

| Key food ingredient instability detection | Folate and vitamin B9, ascorbic acid, glucose, fructose, sucrose, glutamic acid, caffeic acid, gallic acid catechol, and chlorogenic acid. | AgNPs, multi-walled carbon nanotubes, Ag, and tin dioxide NPs. | [107,108,109,110] |

6. Limitations and Further Research

7. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nile, S.H.; Baskar, V.; Selvaraj, D.; Nile, A.; Xiao, J.; Kai, G. Nanotechnologies in Food Science: Applications, Recent Trends, and Future Perspectives. Nano-Micro Lett. 2020, 12, 45. [Google Scholar] [CrossRef] [PubMed]

- Vieira, I.R.S.; Tessaro, L.; Lima, A.K.O.; Velloso, I.P.S.; Conte-Junior, C.A. Recent Progress in Nanotechnology Improving the Therapeutic Potential of Polyphenols for Cancer. Nutrients 2023, 15, 3136. [Google Scholar] [CrossRef] [PubMed]

- Sekhon, B.S. Food Nanotechnology—An Overview. Nanotechnol. Sci. Appl. 2010, 3, 1–15. [Google Scholar] [PubMed]

- Ndlovu, N.; Mayaya, T.; Muitire, C.; Munyengwa, N. Nanotechnology Applications in Crop Production and Food Systems. Int. J. Plant Breed 2020, 7, 624–634. [Google Scholar]

- Brandelli, A.; Pinilla, C.M.B.; Lopes, N.A. Nanotechnology in Food Preservation. Adv. Process. Technol. Bio-Based Nanosyst. Food 2019, 9, 277–311. [Google Scholar] [CrossRef]

- Jain, K.K. Role of Nanobiotechnology in Drug Delivery. Methods Mol. Biol. 2020, 2059, 55–73. [Google Scholar] [CrossRef]

- Sajid, A.; Manzoor, Q.; Sajid, A.; Imran, M.; Khalid, S.; Arshad, Z.; Saleem, A.; Iahtisham-Ul-Haq; Aslam, F. Characterization and Antibacterial Properties of Eriobotrya Japonica Extract Loaded Silver-Nanoparticles. Curr. Bioact. Compd. 2020, 17, 58–63. [Google Scholar] [CrossRef]

- Yao, M.; McClements, D.J.; Xiao, H. Improving Oral Bioavailability of Nutraceuticals by Engineered Nanoparticle-Based Delivery Systems. Curr. Opin. Food Sci. 2015, 2, 14–19. [Google Scholar] [CrossRef]

- Jafari, S.M.; McClements, D.J. Nanotechnology Approaches for Increasing Nutrient Bioavailability. Adv. Food Nutr. Res. 2017, 81, 1–30. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Recent Advances in the Production and Application of Nano-Enabled Bioactive Food Ingredients. Curr. Opin. Food Sci. 2020, 33, 85–90. [Google Scholar] [CrossRef]

- Mirbagheri, R.; Elhamifar, D.; Shaker, M. Yolk–Shell Structured Magnetic Mesoporous Silica: A Novel and Highly Efficient Adsorbent for Removal of Methylene Blue. Sci. Rep. 2021, 11, 23259. [Google Scholar] [CrossRef] [PubMed]

- Yetisgin, A.A.; Cetinel, S.; Zuvin, M.; Kosar, A.; Kutlu, O. Therapeutic Nanoparticles and Their Targeted Delivery Applications. Molecules 2020, 25, 2193. [Google Scholar] [CrossRef]

- Abolmaali, S.S.; Tamaddon, A.M.; Salmanpour, M.; Mohammadi, S.; Dinarvand, R. Block Ionomer Micellar Nanoparticles from Double Hydrophilic Copolymers, Classifications and Promises for Delivery of Cancer Chemotherapeutics. Eur. J. Pharm. Sci. 2017, 104, 393–405. [Google Scholar] [CrossRef] [PubMed]

- Ognik, K.; Cholewińska, E.; Czech, A.; Kozłowski, K.; Wlazło, Ł.; Nowakowicz-Dȩbek, B.; Szlązak, R.; Tutaj, K. Effect of Silver Nanoparticles on the Immune, Redox, and Lipid Status of Chicken Blood. Czech J. Anim. Sci. 2016, 61, 450–461. [Google Scholar] [CrossRef]

- Kothamasu, P.; Kanumur, H.; Ravur, N.; Maddu, C.; Parasuramrajam, R.; Thangavel, S. Nanocapsules: The Weapons for Novel Drug Delivery Systems. Bioimpacts 2012, 2, 71–81. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Modeling the Rheological Properties of Plant-Based Foods: Soft Matter Physics Principles. Sustain. Food Proteins 2023, 1, 101–132. [Google Scholar] [CrossRef]

- Zhang, L.; Yin, S.; Hou, J.; Zhang, W.; Huang, H.; Li, Y.; Yu, C. Detection of Choline and Hydrogen Peroxide in Infant Formula Milk Powder with near Infrared Upconverting Luminescent Nanoparticles. Food Chem. 2019, 270, 415–419. [Google Scholar] [CrossRef]

- Jäger, A.; Stefani, V.; Guterres, S.S.; Pohlmann, A.R. Physico-Chemical Characterization of Nanocapsule Polymeric Wall Using Fluorescent Benzazole Probes. Int. J. Pharm. 2007, 338, 297–305. [Google Scholar] [CrossRef]

- Vieira, I.R.S.; Conte-Junior, C.A. Nano-Delivery Systems for Food Bioactive Compounds in Cancer: Prevention, Therapy, and Clinical Applications. Crit. Rev. Food Sci. Nutr. 2024, 64, 381–406. [Google Scholar] [CrossRef]

- Lima, A.L.; Gratieri, T.; Cunha-Filho, M.; Gelfuso, G.M. Polymeric Nanocapsules: A Review on Design and Production Methods for Pharmaceutical Purpose. Methods 2022, 199, 54–66. [Google Scholar] [CrossRef]

- Sozer, N.; Kokini, J.L. Use of Quantum Nanodot Crystals as Imaging Probes for Cereal Proteins. Food Res. Int. 2014, 57, 142–151. [Google Scholar] [CrossRef]

- Zambrano-Zaragoza, M.L.; Mercado-Silva, E.; Gutiérrez-Cortez, E.; Castaño-Tostado, E.; Quintanar-Guerrero, D. Optimization of Nanocapsules Preparation by the Emulsion–Diffusion Method for Food Applications. LWT—Food Sci. Technol. 2011, 44, 1362–1368. [Google Scholar] [CrossRef]

- Yang, H.; Mendon, S.K.; Rawlins, J.W. Nanoencapsulation of Blocked Isocyanates through Aqueous Emulsion Polymerization. Express Polym. Lett. 2008, 2, 349–356. [Google Scholar] [CrossRef]

- Fan, Y.; Marioli, M.; Zhang, K. Analytical Characterization of Liposomes and Other Lipid Nanoparticles for Drug Delivery. J. Pharm. Biomed. Anal. 2021, 192, 113642. [Google Scholar] [CrossRef]

- Guo, Y.; Zhai, X.; Li, N.; Zan, X. Recent Progress in Protein-Polyphenol Assemblies for Biomedical Applications. Langmuir 2024, 40, 2005–2014. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Geng, D.; Zhang, W.; Liu, W.; Ma, X.; Zhang, Z. Synthesis of a New Type of GdAl2 Nanocapsule with a Large Cryogenic Magnetocaloric Effect and Novel Coral-like Aggregates Self-Assembled by Nanocapsules. Nanotechnology 2006, 17, 5406. [Google Scholar] [CrossRef]

- Chen, L.; Remondetto, G.E.; Subirade, M. Food Protein-Based Materials as Nutraceutical Delivery Systems. Trends Food Sci. Technol. 2006, 17, 272–283. [Google Scholar] [CrossRef]

- Chang, C.; Meikle, T.G.; Su, Y.; Wang, X.; Dekiwadia, C.; Drummond, C.J.; Conn, C.E.; Yang, Y. Encapsulation in Egg White Protein Nanoparticles Protects Anti-Oxidant Activity of Curcumin. Food Chem. 2019, 280, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Ban, Q.; Wang, W.; Hou, J.; Jiang, Z. Novel Nano-Encapsulated Probiotic Agents: Encapsulate Materials, Delivery, and Encapsulation Systems. J. Control. Release 2022, 349, 184–205. [Google Scholar] [CrossRef] [PubMed]

- Centurion, F.; Basit, A.W.; Liu, J.; Gaisford, S.; Rahim, M.A.; Kalantar-Zadeh, K. Nanoencapsulation for Probiotic Delivery. ACS Nano 2021, 15, 18653–18660. [Google Scholar] [CrossRef] [PubMed]

- Ghorbani, S.; Maryam, A. Encapsulation of Lactic Acid Bacteria and Bifidobacteria Using Starch-Sodium Alginate Nanofibers to Enhance Viability in Food Model. J. Food Process. Preserv. 2021, 45, e16048. [Google Scholar] [CrossRef]

- Teng, Z.; Luo, Y.; Wang, Q. Nanoparticles Synthesized from Soy Protein: Preparation, Characterization, and Application for Nutraceutical Encapsulation. J. Agric. Food Chem. 2012, 60, 2712–2720. [Google Scholar] [CrossRef]

- Arroyo-Maya, I.J.; McClements, D.J. Biopolymer Nanoparticles as Potential Delivery Systems for Anthocyanins: Fabrication and Properties. Food Res. Int. 2015, 69, 1–8. [Google Scholar] [CrossRef]

- Shanthilal, J.; Bhattacharya, S. Nanoparticles and Nanotechnology in Food. In Conventional and Advanced Food Processing Technologies; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 567–594. ISBN 9781118406328. [Google Scholar] [CrossRef]

- Nicolescu, A.; Babotă, M.; Barros, L.; Rocchetti, G.; Lucini, L.; Tanase, C.; Mocan, A.; Bunea, C.I.; Crișan, G. Bioaccessibility and Bioactive Potential of Different Phytochemical Classes from Nutraceuticals and Functional Foods. Front. Nutr. 2023, 10, 1184535. [Google Scholar] [CrossRef] [PubMed]

- Rashidi, L. Different Nano-Delivery Systems for Delivery of Nutraceuticals. Food Biosci. 2021, 43, 101258. [Google Scholar] [CrossRef]

- Akhavan, S.; Assadpour, E.; Katouzian, I.; Jafari, S.M. Lipid Nano Scale Cargos for the Protection and Delivery of Food Bioactive Ingredients and Nutraceuticals. Trends Food Sci. Technol. 2018, 74, 132–146. [Google Scholar] [CrossRef]

- Poonia, A. Potential of Milk Proteins as Nanoencapsulation Materials in Food Industry. In Nanoscience in Food and Agriculture 5; Springer: Cham, Switzerland, 2017; pp. 139–168. [Google Scholar] [CrossRef]

- Lozano, O.; Lázaro-Alfaro, A.; Silva-Platas, C.; Oropeza-Almazán, Y.; Torres-Quintanilla, A.; Bernal-Ramírez, J.; Alves-Figueiredo, H.; García-Rivas, G. Nanoencapsulated Quercetin Improves Cardioprotection during Hypoxia-Reoxygenation Injury through Preservation of Mitochondrial Function. Oxid. Med. Cell. Longev. 2019, 2019, 7683051. [Google Scholar] [CrossRef] [PubMed]

- Kole, S.; Qadiri, S.S.N.; Shin, S.M.; Kim, W.S.; Lee, J.; Jung, S.J. Nanoencapsulation of Inactivated-Viral Vaccine Using Chitosan Nanoparticles: Evaluation of Its Protective Efficacy and Immune Modulatory Effects in Olive Flounder (Paralichthys Olivaceus) against Viral Haemorrhagic Septicaemia Virus (VHSV) Infection. Fish Shellfish Immunol. 2019, 91, 136–147. [Google Scholar] [CrossRef] [PubMed]

- Desai, K.G.H.; Park, H.J. Recent Developments in Microencapsulation of Food Ingredients. Dry. Technol. 2005, 23, 1361–1394. [Google Scholar] [CrossRef]

- Saifullah, M.; Shishir, M.R.I.; Ferdowsi, R.; Tanver Rahman, M.R.; Van Vuong, Q. Micro and Nano Encapsulation, Retention and Controlled Release of Flavor and Aroma Compounds: A Critical Review. Trends Food Sci. Technol. 2019, 86, 230–251. [Google Scholar] [CrossRef]

- Dima, C.; Assadpour, E.; Dima, S.; Jafari, S.M. Bioavailability of Nutraceuticals: Role of the Food Matrix, Processing Conditions, the Gastrointestinal Tract, and Nanodelivery Systems. Compr. Rev. Food Sci. Food Saf. 2020, 19, 954–994. [Google Scholar] [CrossRef]

- Perry, S.L.; McClements, D.J. Recent Advances in Encapsulation, Protection, and Oral Delivery of Bioactive Proteins and Peptides Using Colloidal Systems. Molecules 2020, 25, 1161. [Google Scholar] [CrossRef]

- Boostani, S.; Jafari, S.M. A Comprehensive Review on the Controlled Release of Encapsulated Food Ingredients; Fundamental Concepts to Design and Applications. Trends Food Sci. Technol. 2021, 109, 303–321. [Google Scholar] [CrossRef]

- Acosta, E. Bioavailability of Nanoparticles in Nutrient and Nutraceutical Delivery. Curr. Opin. Colloid Interface Sci. 2009, 14, 3–15. [Google Scholar] [CrossRef]

- Pateiro, M.; Gómez, B.; Munekata, P.E.S.; Barba, F.J.; Putnik, P.; Bursać, D.B.; Kovačević, K.; Lorenzo, J.M.; Pellegrino, F.; Cesano, F.; et al. Nanoencapsulation of Promising Bioactive Compounds to Improve Their Absorption, Stability, Functionality and the Appearance of the Final Food Products. Molecules 2021, 26, 1547. [Google Scholar] [CrossRef]

- Neilson, A.P.; Goodrich, K.M.; Ferruzzi, M.G. Bioavailability and Metabolism of Bioactive Compounds from Foods. In Nutrition in the Prevention and Treatment of Disease, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 301–319. [Google Scholar] [CrossRef]

- Gorantla, S.; Wadhwa, G.; Jain, S.; Sankar, S.; Nuwal, K.; Mahmood, A.; Dubey, S.K.; Taliyan, R.; Kesharwani, P.; Singhvi, G. Recent Advances in Nanocarriers for Nutrient Delivery. Drug Deliv. Transl. Res. 2021, 12, 2359–2384. [Google Scholar] [CrossRef]

- Venugopalan, V.K.; Gopakumar, L.R.; Kumaran, A.K.; Chatterjee, N.S.; Soman, V.; Peeralil, S.; Mathew, S.; McClements, D.J.; Nagarajarao, R.C. Encapsulation and Protection of Omega-3-Rich Fish Oils Using Food-Grade Delivery Systems. Foods 2021, 10, 1566. [Google Scholar] [CrossRef] [PubMed]

- Jafari, S.M. Nanoencapsulation Technologies for the Food and Nutraceutical Industries; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Hosseini, S.F.; Ramezanzade, L.; McClements, D.J. Recent Advances in Nanoencapsulation of Hydrophobic Marine Bioactives: Bioavailability, Safety, and Sensory Attributes of Nano-Fortified Functional Foods. Trends Food Sci. Technol. 2021, 109, 322–339. [Google Scholar] [CrossRef]

- Rao, P.J.; Naidu, M.M. Nanoencapsulation of Bioactive Compounds for Nutraceutical Food. In Nanoscience in Food and Agriculture 2; Springer: Cham, Switzerland, 2016; pp. 129–156. [Google Scholar] [CrossRef]

- Dima, C.; Assadpour, E.; Dima, S.; Jafari, S.M. Nutraceutical Nanodelivery; an Insight into the Bioaccessibility/Bioavailability of Different Bioactive Compounds Loaded within Nanocarriers. Crit. Rev. Food Sci. Nutr. 2021, 61, 3031–3065. [Google Scholar] [CrossRef] [PubMed]

- Rostamabadi, H.; Falsafi, S.R.; Boostani, S.; Katouzian, I.; Rezaei, A.; Assadpour, E.; Jafari, S.M. Design and Formulation of Nano/Micro-Encapsulated Natural Bioactive Compounds for Food Applications. In Application of Nano/Microencapsulated Ingredients in Food Products; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–41. [Google Scholar] [CrossRef]

- Jafari, S.M. Nanoencapsulation of Food Bioactive Ingredients: Principles and Applications; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Shubham, K.; Anukiruthika, T.; Dutta, S.; Kashyap, A.V.; Moses, J.A.; Anandharamakrishnan, C. Iron Deficiency Anemia: A Comprehensive Review on Iron Absorption, Bioavailability and Emerging Food Fortification Approaches. Trends Food Sci. Technol. 2020, 99, 58–75. [Google Scholar] [CrossRef]

- Al-Duhaidahawi, D. Nano and Microencapsulation of Foods, Vitamins and Minerals. In Application of Nanotechnology in Food Science, Processing and Packaging; Springer: Cham, Switzerland, 2022; pp. 47–72. [Google Scholar] [CrossRef]

- Vatandoust, A.; Venkatesh Mannar, M.G.; Diosady, L.L. Organoleptic Effects of Salt Fortification with Iron and Iodine: A Review. J. Nutr. 2021, 151, 1690–1702. [Google Scholar] [CrossRef] [PubMed]

- Janjetic, M.; Barrado, A.; Torti, H.; Weill, R.; Orlandini, J.; Urriza, R.; Boccio, J. Iron Bioavailability from Fortified Petit Suisse Cheese Determined by the Prophylactic-Preventive Method. Biol. Trace Elem. Res. 2006, 109, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Kahraman, O.; Ustunol, Z. Effect of Zinc Fortification on Cheddar Cheese Quality. J. Dairy Sci. 2012, 95, 2840–2847. [Google Scholar] [CrossRef]

- Badii, A.; Nekouei, N.; Fazilati, M.; Shahedi, M.; Badiei, S. Effect of Consuming Zinc-Fortified Bread on Serum Zinc and Iron Status of Zinc-Deficient Women: A Double Blind, Randomized Clinical Trial. Int. J. Prev. Med. 2012, 3, S124. [Google Scholar] [PubMed]

- Tsikritzi, R.; Moynihan, P.J.; Gosney, M.A.; Allen, V.J.; Methven, L. The Effect of Macro- and Micro-Nutrient Fortification of Biscuits on Their Sensory Properties and on Hedonic Liking of Older People. J. Sci. Food Agric. 2014, 94, 2040–2048. [Google Scholar] [CrossRef]

- Assadpour, E.; Mahdi Jafari, S. A Systematic Review on Nanoencapsulation of Food Bioactive Ingredients and Nutraceuticals by Various Nanocarriers. Crit. Rev. Food Sci. Nutr. 2019, 59, 3129–3151. [Google Scholar] [CrossRef]

- Dima, C.; Assadpour, E.; Dima, S.; Jafari, S.M. Bioactive-Loaded Nanocarriers for Functional Foods: From Designing to Bioavailability. Curr. Opin. Food Sci. 2020, 33, 21–29. [Google Scholar] [CrossRef]

- Matsson, P.; Doak, B.C.; Over, B.; Kihlberg, J. Cell Permeability beyond the Rule of 5. Adv. Drug Deliv. Rev. 2016, 101, 42–61. [Google Scholar] [CrossRef]

- Doak, B.C.; Kihlberg, J. Drug Discovery beyond the Rule of 5—Opportunities and Challenges. Expert Opin. Drug Discov. 2017, 12, 115–119. [Google Scholar] [CrossRef]

- Boostani, S.; Jafari, S.M. Controlled Release of Nanoencapsulated Food Ingredients. In Release and Bioavailability of Nanoencapsulated Food Ingredients; Academic Press: Cambridge, MA, USA, 2020; pp. 27–78. ISBN 9780128156650. [Google Scholar]

- Huang, K.; Yuan, Y.; Baojun, X. A Critical Review on the Microencapsulation of Bioactive Compounds and Their Application. Food Rev. Int. 2023, 39, 2594–2634. [Google Scholar] [CrossRef]

- Martins, V.F.R.; Pintado, M.E.; Morais, R.M.S.C.; Morais, A.M.M.B. Valorisation of Micro/Nanoencapsulated Bioactive Compounds from Plant Sources for Food Applications Towards Sustainability. Foods 2022, 12, 32. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Huang, H.; Chen, H.; Lin, J.; Wang, Q. Food-Grade Nanoemulsions: Preparation, Stability and Application in Encapsulation of Bioactive Compounds. Molecules 2019, 24, 4242. [Google Scholar] [CrossRef] [PubMed]

- Vieira, I.R.S.; Silva, A.C.L.N.; Castro, N.R.; Pinto, C.d.S.C.; de Freitas, Z.M.F.; Ricci-Júnior, E.; Dos Santos, E.P.; Camara, A.L.; Costa, M.C.P.; Conte-Junior, C.A. Development and Characterization of Photoprotective Nanoemulsions Containing Babassu (Orbignya phalerata Mart.) Lipophilic Extract. Braz. J. Pharm. Sci. 2023, 59, e23011. [Google Scholar] [CrossRef]

- Golding, M.; Wooster, T.J. The Influence of Emulsion Structure and Stability on Lipid Digestion. Curr. Opin. Colloid Interface Sci. 2010, 15, 90–101. [Google Scholar] [CrossRef]

- McClements, D.J.; Li, Y. Structured Emulsion-Based Delivery Systems: Controlling the Digestion and Release of Lipophilic Food Components. Adv. Colloid Interface Sci. 2010, 159, 213–228. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Zhang, Z.; Zhang, H.; Decker, E.A.; McClements, D.J. Influence of Lipid Type on Gastrointestinal Fate of Oil-in-Water Emulsions: In Vitro Digestion Study. Food Res. Int. 2015, 75, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Reis, P.; Holmberg, K.; Watzke, H.; Leser, M.E.; Miller, R. Lipases at Interfaces: A Review. Adv. Colloid Interface Sci. 2009, 147–148, 237–250. [Google Scholar] [CrossRef]

- Patel, A.; Mohanan, A.; Ghosh, S. Effect of Protein Type, Concentration and Oil Droplet Size on the Formation of Repulsively Jammed Elastic Nanoemulsion Gels. Soft Matter 2019, 15, 9762–9775. [Google Scholar] [CrossRef]

- Salvia-Trujillo, L.; Qian, C.; Martín-Belloso, O.; McClements, D.J. Modulating β-Carotene Bioaccessibility by Controlling Oil Composition and Concentration in Edible Nanoemulsions. Food Chem. 2013, 139, 878–884. [Google Scholar] [CrossRef]

- Pouton, C.W.; Porter, C.J.H. Formulation of Lipid-Based Delivery Systems for Oral Administration: Materials, Methods and Strategies. Adv. Drug Deliv. Rev. 2008, 60, 625–637. [Google Scholar] [CrossRef]

- McClements, D.J.; Decker, E.A.; Weiss, J. Emulsion-Based Delivery Systems for Lipophilic Bioactive Components. J. Food Sci. 2007, 72, R109–R124. [Google Scholar] [CrossRef]

- Milinčić, D.D.; Salević-Jelić, A.S.; Kostić, A.; Stanojević, S.P.; Nedović, V.; Pešić, M.B. Food Nanoemulsions: How Simulated Gastrointestinal Digestion Models, Nanoemulsion, and Food Matrix Properties Affect Bioaccessibility of Encapsulated Bioactive Compounds. Crit. Rev. Food Sci. Nutr. 2023, 1, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, K.; Li, Y.; McClements, D.J.; Xiao, H. Nanoemulsion- and Emulsion-Based Delivery Systems for Curcumin: Encapsulation and Release Properties. Food Chem. 2012, 132, 799–807. [Google Scholar] [CrossRef]

- McClements, D.J. The Biophysics of Digestion: Lipids. Curr. Opin. Food Sci. 2018, 21, 1–6. [Google Scholar] [CrossRef]

- Mu, H.; Høy, C.E. The Digestion of Dietary Triacylglycerols. Prog. Lipid Res. 2004, 43, 105–133. [Google Scholar] [CrossRef]

- Yu, H.; Huang, Q. Investigation of the Cytotoxicity of Food-Grade Nanoemulsions in Caco-2 Cell Monolayers and HepG2 Cells. Food Chem. 2013, 141, 29–33. [Google Scholar] [CrossRef] [PubMed]

- Feki, F.; Taarji, N.; Vodo, S.; Chamkha, M.; Bouallagui, Z.; Nakajima, M.; Isoda, H.; Neves, M.A.; Sayadi, S. Physicochemical Stability Enhancement of β-Carotene-Rich O/W Nanoemulsions Using a New Natural Emulsifier Developed from Pistacia Lentiscus Fruit Residue. Food Biophys. 2023, 18, 249–261. [Google Scholar] [CrossRef]

- İnan-Çınkır, N.; Ağçam, E.; Altay, F.; Akyıldız, A. Emulsion Electrospinning of Zein Nanofibers with Carotenoid Microemulsion: Optimization, Characterization and Fortification. Food Chem. 2024, 430, 137005. [Google Scholar] [CrossRef] [PubMed]

- da Silva, B.D.; do Rosário, D.K.A.; Neto, L.T.; Lelis, C.A.; Conte-Junior, C.A. Antioxidant, Antibacterial and Antibiofilm Activity of Nanoemulsion-Based Natural Compound Delivery Systems Compared with Non-Nanoemulsified Versions. Foods 2023, 12, 1901. [Google Scholar] [CrossRef]

- Nunes, R.; Pereira, B.D.A.; Cerqueira, M.A.; Silva, P.; Pastrana, L.M.; Vicente, A.A.; Martins, J.T.; Bourbon, A.I. Lactoferrin-Based Nanoemulsions to Improve the Physical and Chemical Stability of Omega-3 Fatty Acids. Food Funct. 2020, 11, 1966–1981. [Google Scholar] [CrossRef]

- Wang, T.; Ma, C.; Hu, Y.; Guo, S.; Bai, G.; Yang, G.; Yang, R. Effects of Food Formulation on Bioavailability of Phytosterols: Phytosterol Structures, Delivery Carriers, and Food Matrices. Food Funct. 2023, 14, 5465–5477. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Becerra, C.; Rojas, A.; Höcht, C.; Bernabeu, E.; Chiappetta, D.; Tevez, S.; Lucangioli, S.; Flor, S.; Tripodi, V. Characterization and Bioavailability of a Novel Coenzyme Q10 Nanoemulsion Used as an Infant Formula Supplement. Int. J. Pharm. 2023, 634, 122656. [Google Scholar] [CrossRef] [PubMed]

- Nejatian, M.; Darabzadeh, N.; Bodbodak, S.; Saberian, H.; Rafiee, Z.; Kharazmi, M.S.; Jafari, S.M. Practical Application of Nanoencapsulated Nutraceuticals in Real Food Products; a Systematic Review. Adv. Colloid Interface Sci. 2022, 305, 102690. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, A.K.; Dev, A.; Karmakar, S. Nanosensors and Nanobiosensors in Food and Agriculture. Environ. Chem. Lett. 2017, 16, 161–182. [Google Scholar] [CrossRef]

- Harrison, R.P.; Chauhan, V.M. Enhancing Cell and Gene Therapy Manufacture through the Application of Advanced Fluorescent Optical Sensors (Review). Biointerphases 2018, 13, 01A301. [Google Scholar] [CrossRef]

- Muthukrishnan, L. An Overview on the Nanotechnological Expansion, Toxicity Assessment and Remediating Approaches in Agriculture and Food Industry. Environ. Technol. Innov. 2022, 25, 102136. [Google Scholar] [CrossRef]

- Ling, Z.; Yang, L.; Zhang, W.; Yao, T.; Xu, H. Detection of Food Contaminants: A Review of Established Rapid Analytical Techniques and Their Applications and Limitations. Food Saf. Health 2024, 2, 72–95. [Google Scholar] [CrossRef]

- Himshweta; Singh, M. Nanosensor Platforms for Detection of Milk Adulterants. Sens. Actuators Rep. 2023, 5, 100159. [Google Scholar] [CrossRef]

- Vieira, I.R.S.; de Carvalho, A.P.A.; Conte-Junior, C.A. Recent Advances in Biobased and Biodegradable Polymer Nanocomposites, Nanoparticles, and Natural Antioxidants for Antibacterial and Antioxidant Food Packaging Applications. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3673–3716. [Google Scholar] [CrossRef]

- King, T.; Osmond-McLeod, M.J.; Duffy, L.L. Nanotechnology in the Food Sector and Potential Applications for the Poultry Industry. Trends Food Sci. Technol. 2018, 72, 62–73. [Google Scholar] [CrossRef]

- Chen, X.; Wang, D.; Li, J.; Xu, T.; Lai, K.; Ding, Q.; Lin, H.; Sun, L.; Lin, M. A Spectroscopic Approach to Detect and Quantify Phosmet Residues in Oolong Tea by Surface-Enhanced Raman Scattering and Silver Nanoparticle Substrate. Food Chem. 2020, 312, 126016. [Google Scholar] [CrossRef]

- Wasilewska, A.; Bielicka, M.; Klekotka, U.; Kalska-Szostko, B. Nanoparticle Applications in Food—A Review. Food Funct. 2023, 14, 2544–2567. [Google Scholar] [CrossRef]

- Li, B.; Li, M.; Meng, F.; Liu, J. Highly Sensitive Ethylene Sensors Using Pd Nanoparticles and RGO Modified Flower-like Hierarchical Porous α-Fe2O3. Sens. Actuators B Chem. 2019, 290, 396–405. [Google Scholar] [CrossRef]

- Kaur, J.; Kaur, G.; Sharma, S.; Jeet, K. Cereal Starch Nanoparticles—A Prospective Food Additive: A Review. Crit. Rev. Food Sci. Nutr. 2018, 58, 1097–1107. [Google Scholar] [CrossRef]

- Abdalhai, M.H.; Fernandes, A.M.; Xia, X.; Musa, A.; Ji, J.; Sun, X. Electrochemical Genosensor to Detect Pathogenic Bacteria (Escherichia coli O157:H7) As Applied in Real Food Samples (Fresh Beef) to Improve Food Safety and Quality Control. J. Agric. Food Chem. 2015, 63, 5017–5025. [Google Scholar] [CrossRef] [PubMed]

- Tessaro, L.; Aquino, A.; Panzenhagen, P.; Ochioni, A.C.; Mutz, Y.S.; Raymundo-pereira, P.A.; Rennan, I.; Vieira, S.; Kilsy, N.; Belem, R.; et al. Development and Application of an SPR Nanobiosensor Based on AuNPs for the Detection of SARS-CoV-2 on Food Surfaces. Biosensors 2022, 12, 1101. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Cao, Y.; Huang, Q. Edible Nanoencapsulation Vehicles for Oral Delivery of Phytochemicals: A Perspective Paper. J. Agric. Food Chem. 2017, 65, 6727–6735. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Zhao, F.; Xu, Z.; Zeng, B. Voltammetric Determination of Folic Acid with a Multi-Walled Carbon Nanotube-Modified Gold Electrode. Microchim. Acta 2006, 152, 285–290. [Google Scholar] [CrossRef]

- Xiao, F.; Ruan, C.; Liu, L.; Yan, R.; Zhao, F.; Zeng, B. Single-Walled Carbon Nanotube-Ionic Liquid Paste Electrode for the Sensitive Voltammetric Determination of Folic Acid. Sens. Actuators B Chem. 2008, 134, 895–901. [Google Scholar] [CrossRef]

- Welch, C.M.; Banks, C.E.; Simm, A.O.; Compton, R.G. Silver Nanoparticle Assemblies Supported on Glassy-Carbon Electrodes for the Electro-Analytical Detection of Hydrogen Peroxide. Anal. Bioanal. Chem. 2005, 382, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yu, J.; Ju, H. Renewable Phenol Biosensor Based on a Tyrosinase-Colloidal Gold Modified Carbon Paste Electrode. J. Electroanal. Chem. 2003, 540, 61–67. [Google Scholar] [CrossRef]

- Hao, L.; Chen, J.; Chen, X.; Ma, T.; Cai, X.; Duan, H.; Leng, Y.; Huang, X.; Xiong, Y. A Novel Magneto-Gold Nanohybrid-Enhanced Lateral Flow Immunoassay for Ultrasensitive and Rapid Detection of Ochratoxin A in Grape Juice. Food Chem. 2021, 336, 127710. [Google Scholar] [CrossRef]

- Mohkam, M.; Sadraeian, M.; Lauto, A.; Gholami, A.; Nabavizadeh, S.H.; Esmaeilzadeh, H.; Alyasin, S. Exploring the Potential and Safety of Quantum Dots in Allergy Diagnostics. Microsyst. Nanoeng. 2023, 9, 145. [Google Scholar] [CrossRef]

- Selvakumar, L.S.; Thakur, M.S. Nano RNA Aptamer Wire for Analysis of Vitamin B12. Anal. Biochem. 2012, 427, 151–157. [Google Scholar] [CrossRef]

- Shafiq, M.; Anjum, S.; Hano, C.; Anjum, I.; Abbasi, B.H. An Overview of the Applications of Nanomaterials and Nanodevices in the Food Industry. Foods 2020, 9, 148. [Google Scholar] [CrossRef]

- Zahin, N.; Anwar, R.; Tewari, D.; Kabir, M.T.; Sajid, A.; Mathew, B.; Uddin, M.S.; Aleya, L.; Abdel-Daim, M.M. Nanoparticles and Its Biomedical Applications in Health and Diseases: Special Focus on Drug Delivery. Environ. Sci. Pollut. Res. 2019, 27, 19151–19168. [Google Scholar] [CrossRef]

- Corsi, I.; Venditti, I.; Trotta, F.; Punta, C. Environmental Safety of Nanotechnologies: The Eco-Design of Manufactured Nanomaterials for Environmental Remediation. Sci. Total Environ. 2023, 864, 161181. [Google Scholar] [CrossRef] [PubMed]

- Henchion, M.; McCarthy, M.; Dillon, E.J.; Greehy, G.; McCarthy, S.N. Big Issues for a Small Technology: Consumer Trade-Offs in Acceptance of Nanotechnology in Food. Innov. Food Sci. Emerg. Technol. 2019, 58, 102210. [Google Scholar] [CrossRef]

- Sahani, S.; Sharma, Y.C. Advancements in Applications of Nanotechnology in Global Food Industry. Food Chem. 2021, 342, 128318. [Google Scholar] [CrossRef] [PubMed]

- Rubio, L.; Barguilla, I.; Domenech, J.; Marcos, R.; Hernández, A. Biological Effects, Including Oxidative Stress and Genotoxic Damage, of Polystyrene Nanoparticles in Different Human Hematopoietic Cell Lines. J. Hazard. Mater. 2020, 398, 122900. [Google Scholar] [CrossRef] [PubMed]

- Ferdous, Z.; Nemmar, A. Health Impact of Silver Nanoparticles: A Review of the Biodistribution and Toxicity Following Various Routes of Exposure. Int. J. Mol. Sci. 2020, 21, 2375. [Google Scholar] [CrossRef] [PubMed]

- Cary, C.; Stapleton, P. Determinants and Mechanisms of Inorganic Nanoparticle Translocation across Mammalian Biological Barriers. Arch. Toxicol. 2023, 97, 2111–2131. [Google Scholar] [CrossRef] [PubMed]

- Meng, H.; Leong, W.; Leong, K.W.; Chen, C.; Zhao, Y. Walking the Line: The Fate of Nanomaterials at Biological Barriers. Biomaterials 2018, 174, 41–53. [Google Scholar] [CrossRef] [PubMed]

- Ilinskaya, A.N.; Dobrovolskaia, M.A. Understanding the Immunogenicity and Antigenicity of Nanomaterials: Past, Present and Future. Toxicol. Appl. Pharmacol. 2016, 299, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Ernst, L.M.; Casals, E.; Italiani, P.; Boraschi, D.; Puntes, V. The Interactions between Nanoparticles and the Innate Immune System from a Nanotechnologist Perspective. Nanomaterials 2021, 11, 2991. [Google Scholar] [CrossRef] [PubMed]

- Kermanizadeh, A.; Balharry, D.; Wallin, H.; Loft, S.; Møller, P. Nanomaterial Translocation-the Biokinetics, Tissue Accumulation, Toxicity and Fate of Materials in Secondary Organs-A Review. Crit. Rev. Toxicol. 2015, 45, 837–872. [Google Scholar] [CrossRef]

- Kehrer, J.P.; Klotz, L.O. Free Radicals and Related Reactive Species as Mediators of Tissue Injury and Disease: Implications for Health. Crit. Rev. Toxicol. 2015, 45, 765–798. [Google Scholar] [CrossRef]

- Schoonjans, R.; Castenmiller, J.; Chaudhry, Q.; Cubadda, F.; Daskaleros, T.; Franz, R.; Gott, D.; Mast, J.; Mortensen, A.; Oomen, A.G.; et al. Regulatory Safety Assessment of Nanoparticles for the Food Chain in Europe. Trends Food Sci. Technol. 2023, 134, 98–111. [Google Scholar] [CrossRef]

- Rehman, N.; Moore, S. An Overview of the State of the Regulatory and Preclinical Requirements for Nanomaterials Including Medical Devices. Integr. Environ. Assess. Manag. 2021, 17, 1098–1104. [Google Scholar] [CrossRef]

- Schneider, T.; Westermann, M.; Glei, M. In Vitro Uptake and Toxicity Studies of Metal Nanoparticles and Metal Oxide Nanoparticles in Human HT29 Cells. Arch. Toxicol. 2017, 91, 3517–3527. [Google Scholar] [CrossRef]

- Fröhlich, E.E.; Fröhlich, E.; Routledge, M.; Yan, B. Cytotoxicity of Nanoparticles Contained in Food on Intestinal Cells and the Gut Microbiota. Int. J. Mol. Sci. 2016, 17, 509. [Google Scholar] [CrossRef]

- Kyriakidou, K.; Brasinika, D.; Trompeta, A.F.A.; Bergamaschi, E.; Karoussis, I.K.; Charitidis, C.A. In Vitro Cytotoxicity Assessment of Pristine and Carboxyl-Functionalized MWCNTs. Food Chem. Toxicol. 2020, 141, 111374. [Google Scholar] [CrossRef]

- Mohammadi, S.; Babaei, A. Poly (Vinyl Alcohol)/Chitosan/Polyethylene Glycol-Assembled Graphene Oxide Bio-Nanocomposites as a Prosperous Candidate for Biomedical Applications and Drug/Food Packaging Industry. Int. J. Biol. Macromol. 2022, 201, 528–538. [Google Scholar] [CrossRef] [PubMed]

- Wooster, T.J.; Moore, S.C.; Chen, W.; Andrews, H.; Addepalli, R.; Seymour, R.B.; Osborne, S.A. Biological Fate of Food Nanoemulsions and the Nutrients They Carry—Internalisation, Transport and Cytotoxicity of Edible Nanoemulsions in Caco-2 Intestinal Cells. RSC Adv. 2017, 7, 40053–40066. [Google Scholar] [CrossRef]

- Kunjiappan, S.; Sankaranarayanan, M.; Karan Kumar, B.; Pavadai, P.; Babkiewicz, E.; Maszczyk, P.; Glodkowska-Mrowka, E.; Arunachalam, S.; Ram Kumar Pandian, S.; Ravishankar, V.; et al. Capsaicin-Loaded Solid Lipid Nanoparticles: Design, Biodistribution, in Silico Modeling and in Vitro Cytotoxicity Evaluation. Nanotechnology 2020, 32, 095101. [Google Scholar] [CrossRef] [PubMed]

- Contado, C. Nanomaterials in Consumer Products: A Challenging Analytical Problem. Front. Chem. 2015, 3, 154429. [Google Scholar] [CrossRef] [PubMed]

| Name of the Product | Bioactive Compounds | Claims Related to Health | Manufacturer’s Country of Origin |

|---|---|---|---|

| Creatine Nano by Azgard Nutrition. | Pure creatine nano monohydrate. | Increases muscle power. | Austria |

| IÖGO® | Source of calcium and vitamin D. | Helps in growing bones | Canada |

| B-B-Red Label Tea | 6-Gingerol, withaferin A, glycyrrhetinic acid, and ursolic acid. | Enhancement of vitality (increase in natural killer cell activity). | Hindustan Unilever |

| Nano-Deca by Swayamacare | L-carnitine, L-arginine, ginko biloba (antioxidant), zinc, co-enzyme Q10. | Extends the length of time that the penis remains erect and enhances erectile function. | India |

| NANO™ COMBI: 7XORIGINAL 4XVEGGI HOT MEALS | Macro- and micronutrients, vitamins, and minerals. | Promotion of health | Netherland |

| NUTRASORB™ PROCES Ingredient | Polyphenols, gingerols, and beneficial alkaloids. | Promotion of health | New Jersey |

| NanOmega® | Vitamins (B6, B12, E, D3, and folic acid). | Important to eye, brain, and heart health. | USA |

| NanoMineral by NanoGreens | Contain 12 minerals in each packet. | Regulates blood glucose levels/improves metabolic function, assists in weight reduction, and improves muscle performance. | USA |

| NutriNoche Magnesium Supplement 30 PPM Nano Magnesium | Vitamins and minerals. | Crucial for the optimal operation of the kidneys, muscles, and heart. | USA |

| Tea tablets by Nanolabs™ Global | Hemp oil contains polyphenols (primarily flavonoids, stilbenes, and lignan-amides), alkaloids, cannabinoids, and terpenoids. | Burns fat, hydrates, and boosts metabolism. | USA |

| Type of Food | Mineral Type: Form | Detrimental Effects and Bioavailability | References |

|---|---|---|---|

| Petit Suisse cheese | Fe: C12H24FeO14 | The industrial-enriched sample exhibited a significantly increased rate of Fe bioavailability. | [60] |

| Cheddar cheese | Zn: ZnSO4 | The cheese fortified with zinc, containing five times more zinc than the control sample, had a harder texture. However, there were no differences seen in terms of its sensory qualities and overall quality. | [61] |

| Bread | Zn: H14O11SZn | All groups experienced a notable rise in serum Zn and Fe levels, except for the control group. The group that consumed high-Zn bread showed considerably higher Zn and Fe absorption compared to the group that consumed low-Zn bread. | [62] |

| Oat biscuit | The product is a premix including 11 minerals and 13 vitamins. | Whey protein fortification imparts a flavor that makes it less popular compared to commercial alternatives. | [63] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altemimi, A.B.; Farag, H.A.M.; Salih, T.H.; Awlqadr, F.H.; Al-Manhel, A.J.A.; Vieira, I.R.S.; Conte-Junior, C.A. Application of Nanoparticles in Human Nutrition: A Review. Nutrients 2024, 16, 636. https://doi.org/10.3390/nu16050636

Altemimi AB, Farag HAM, Salih TH, Awlqadr FH, Al-Manhel AJA, Vieira IRS, Conte-Junior CA. Application of Nanoparticles in Human Nutrition: A Review. Nutrients. 2024; 16(5):636. https://doi.org/10.3390/nu16050636

Chicago/Turabian StyleAltemimi, Ammar B., Halgord Ali M. Farag, Tablo H. Salih, Farhang H. Awlqadr, Alaa Jabbar Abd Al-Manhel, Italo Rennan Sousa Vieira, and Carlos Adam Conte-Junior. 2024. "Application of Nanoparticles in Human Nutrition: A Review" Nutrients 16, no. 5: 636. https://doi.org/10.3390/nu16050636

APA StyleAltemimi, A. B., Farag, H. A. M., Salih, T. H., Awlqadr, F. H., Al-Manhel, A. J. A., Vieira, I. R. S., & Conte-Junior, C. A. (2024). Application of Nanoparticles in Human Nutrition: A Review. Nutrients, 16(5), 636. https://doi.org/10.3390/nu16050636