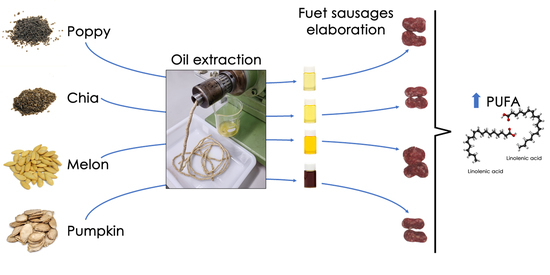

Development of Seed-Oil Based Dried Sausages, Considering Physicochemical and Nutritional Quality and the Role of Food Neophobia

Abstract

1. Introduction

2. Materials and Methods

2.1. Physical Analysis

2.2. Nutritional and Chemical Analysis

2.3. Consumer Evaluation

2.4. Statistical Analysis

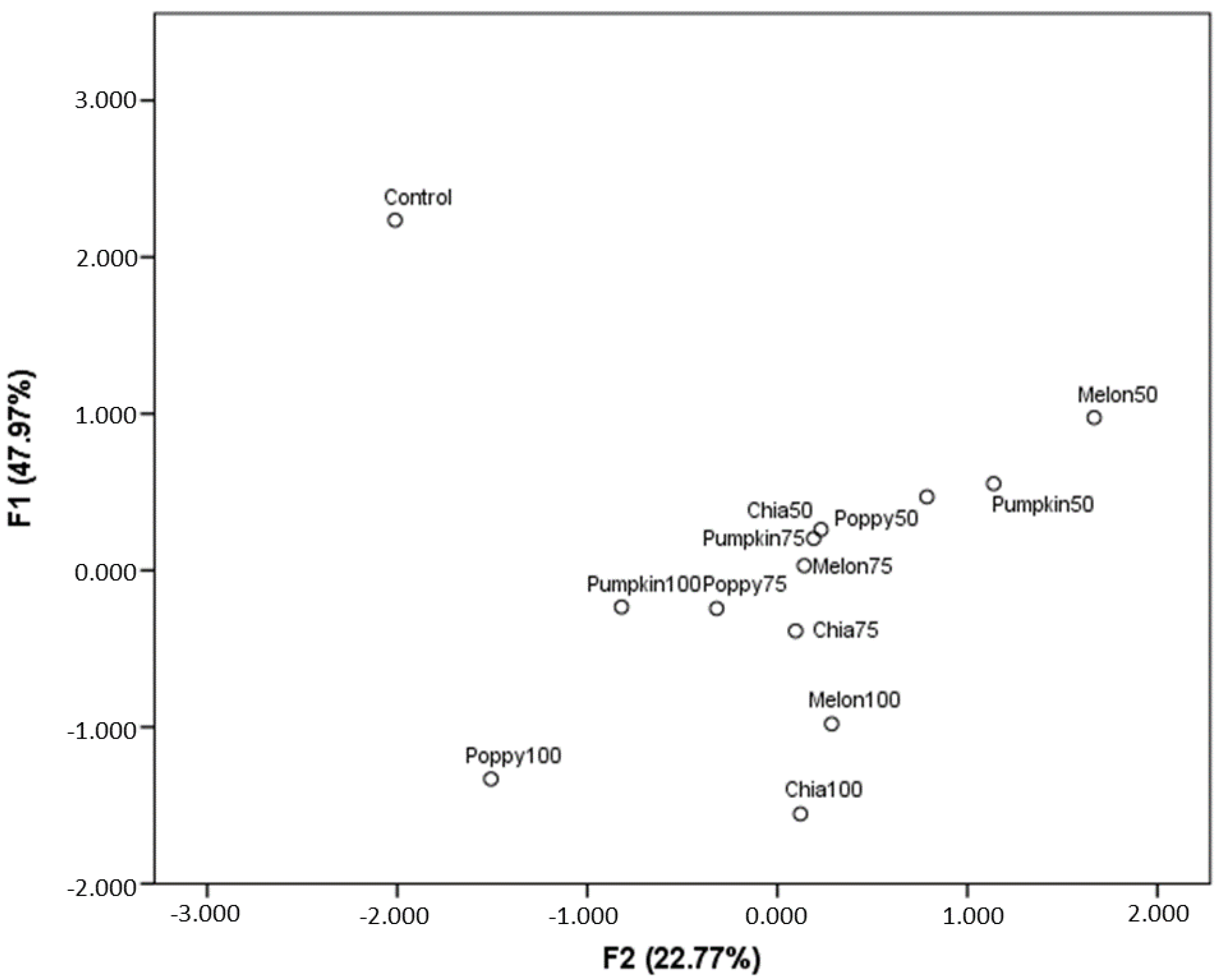

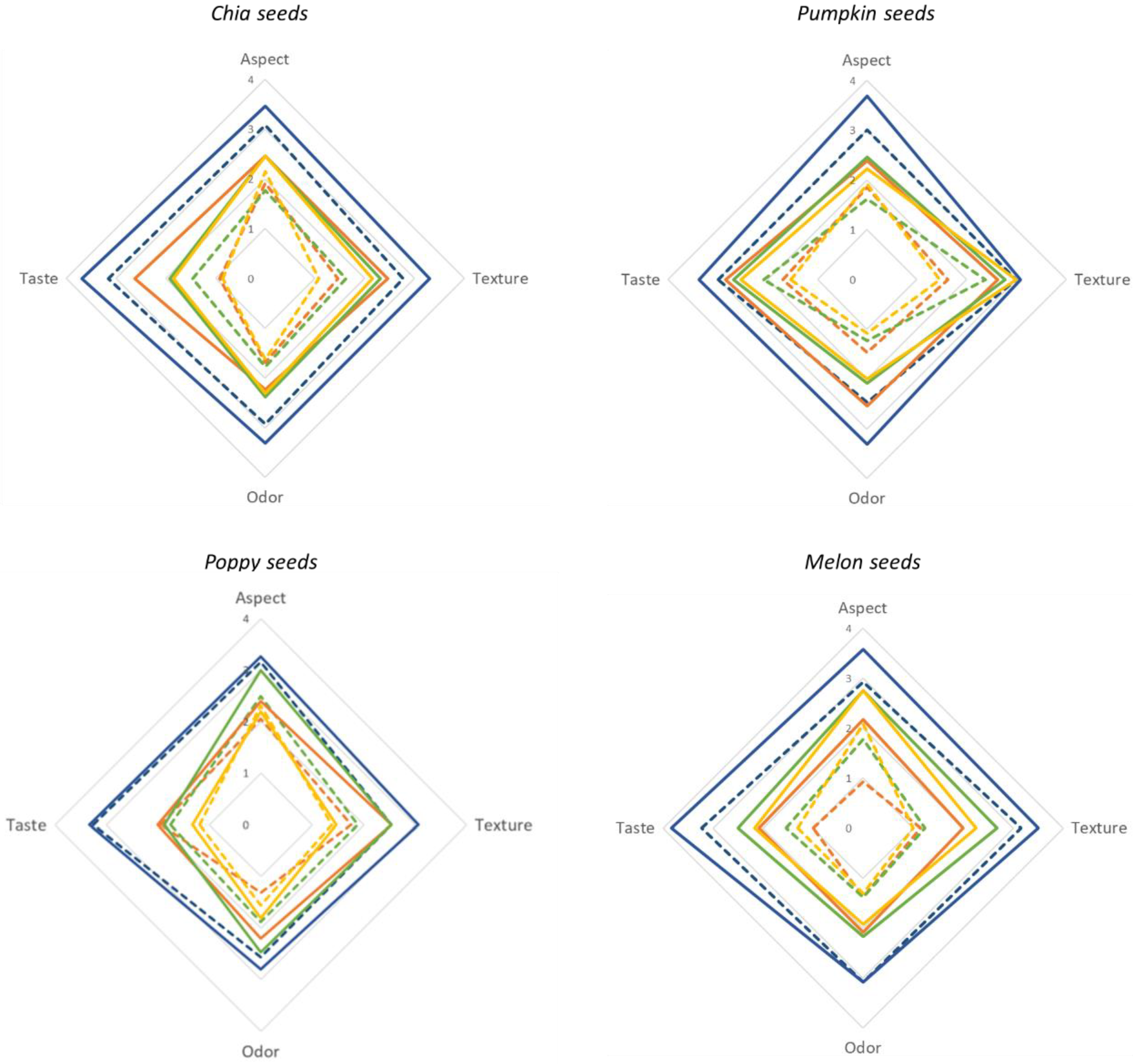

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Givens, D.; Kliem, K.E.; Gibbs, R.A. The role of meat as a source of n−3 polyunsaturated fatty acids in the human diet. Meat Sci. 2006, 74, 209–218. [Google Scholar] [CrossRef] [PubMed]

- WHO. Q&A on the Carcinogenicity of the Consumption of Red Meat and Processed Meat. Available online: https://www.who.int/features/qa/cancer-red-meat/en (accessed on 7 May 2022).

- AHA. Dietary guidelines for healthy adult Americans. Am. Heart Assn. Circulation 1986, 74, 1465–1475. [Google Scholar]

- Alshahrani, S.M.; Fraser, G.E.; Sabaté, J.; Knutsen, R.; Shavlik, D.; Mashchak, A.; Lloren, J.I.; Orlich, M.J. Red and Processed Meat and Mortality in a Low Meat Intake Population. Nutrients 2019, 11, 622. [Google Scholar] [CrossRef]

- Muguerza, E.; Gimeno, O.; Ansorena, D.; Bloukas, J.; Astiasarán, I. Effect of replacing pork backfat with pre-emulsified olive oil on lipid fraction and sensory quality of Chorizo de Pamplona—A traditional Spanish fermented sausage. Meat Sci. 2001, 59, 251–258. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Munekata, P.E.S.; Pateiro, M.; Franco, D.; Campagnol, P.C.B.; Tomasevic, I.; Domínguez, R.; Lorenzo, J.M. Physicochemical Composition and Nutritional Properties of Deer Burger Enhanced with Healthier Oils. Foods 2020, 9, 571. [Google Scholar] [CrossRef]

- World Health Organisation. Obesity and Overweight—Key Facts. 2018. Available online: http://www.who.int/news-room/fact-sheets/detail/obesity-and-overweight (accessed on 1 July 2020).

- NCEP. The effect of diet on plasma lipids, lipoproteins and coronary heart disease. J. Am. Diet Assoc. 1998, 88, 1373–1400. [Google Scholar]

- EC. European Comission. Farm to Fork Strategy: For a Fair, Healthy and Environmentally Friendly Food System; DG SAN-TE/Unit ‘Food Information and Composition, Food Waste’; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- EC. EU agricultural outlook 2020-30: Sustainability objectives to impact meat and dairy along the supply chain. European Commission. In Proceedings of the Agriculture and Rural Development, Brussels, Belgium, 16 December 2020; Available online: https://ec.europa.eu/info/news/eu-agricultural-outlook-2020-30-sustainability-objectives-impact-meat-and-dairy-along-supply-chain-2020-dec-16_en (accessed on 15 April 2022).

- MAPA. Informe Anual del Consumo Alimentario; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2020. [Google Scholar]

- Siegrist, M. Consumer attitudes to food innovation and technology. In Understanding Consumers of Food Products; CRC Press: Boca Raton, FL, USA, 2007; pp. 236–253. [Google Scholar] [CrossRef]

- Nguyen, A.N.; Johnson, T.E.; Jeffery, D.W.; Danner, L.; Bastian, S.E. A cross-cultural examination of Australian, Chinese and Vietnamese consumers’ attitudes towards a new Australian wine product containing Ganoderma lucidum extract. Food Res. Int. 2018, 115, 393–399. [Google Scholar] [CrossRef]

- Rabadán, A.; Álvarez-Ortí, M.; Martínez, E.; Pardo-Giménez, A.; Zied, D.; Pardo, J. Effect of replacing traditional ingredients for oils and flours from nuts and seeds on the characteristics and consumer preferences of lamb meat burgers. LWT 2020, 136, 110307. [Google Scholar] [CrossRef]

- Sharp, T. Technical constraints in the development of reduced-fat bakery products. Proc. Nutr. Soc. 2001, 60, 489–496. [Google Scholar] [CrossRef]

- Smith, G.C.; Carpenter, Z.L. Eating quality of animal products and their fat content. In Proceedings of the Symposium on Changing the Fat Content and Composition of Animal Products, Sciences, Washington, DC, USA, 12–13 December 1974; National Academies Press: Washington, DC, USA, 1976; p. 1074. [Google Scholar]

- Savell, J.W.; Cross, H.R. The Role of Fat in the Palatability of Beef, Pork, and Lamb. In Designing Foods: Animal Product Options in the Marketplace; National Research Council (US) Committee on Technological Options to Improve the Nutritional Attributes of Animal Products; National Academies Press (US): Washington, DC, USA, 1988. [Google Scholar]

- Vural, H. Effect of replacing beef fat and tail fat with interesterified plant oil on quality characteristics of Turkish semi-dry fermented sausages. Eur. Food Res. Technol. 2003, 217, 100–103. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Agregán, R.; Lorenzo, J.M. Effect of the partial replacement of pork backfat by microencapsulated fish oil or mixed fish and olive oil on the quality of frankfurter type sausage. J. Food Sci. Technol. 2017, 54, 26–37. [Google Scholar] [CrossRef]

- Gök, V.; Akkaya, L.; Obuz, E.; Bulut, S. Effect of ground poppy seed as a fat replacer on meat burgers. Meat Sci. 2011, 89, 400–404. [Google Scholar] [CrossRef]

- Polizer-Rocha, Y.J.; Lorenzo, J.M.; Pompeu, D.; Rodrigues, I.; Baldin, J.C.; Pires, M.A.; Freire, M.T.A.; Barba, F.J.; Trindade, M.A. Physicochemical and technological properties of beef burger as influenced by the addition of pea fibre. Int. J. Food Sci. Technol. 2019, 55, 1018–1024. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Guàrdia, M.D.; Serra, X.; Gou, P.; Arnau, J. Sensory characterisation and consumer acceptability of potassium chloride and sunflower oil addition in small-caliber non-acid fermented sausages with a reduced content of sodium chloride and fat. Meat Sci. 2016, 112, 9–15. [Google Scholar] [CrossRef]

- Colmenero, F.J. Relevant factors in strategies for fat reduction in meat products. Trends Food Sci. Technol. 2000, 11, 56–66. [Google Scholar] [CrossRef]

- Olivares, A.; Navarro, J.L.; Salvador, A.; Flores, M. Sensory acceptability of slow fermented sausages based on fat content and ripening time. Meat Sci. 2010, 86, 251–257. [Google Scholar] [CrossRef]

- Muguerza, E.; Fista, G.; Ansorena, D.; Astiasaran, I.; Bloukas, J. Effect of fat level and partial replacement of pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 2002, 61, 397–404. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Serra, X.; Guàrdia, M.D.; Miklos, R.; Lametsch, R.; Arnau, J. Effect of the type of fat on the physicochemical, instrumental and sensory characteristics of reduced fat non-acid fermented sausages. Meat Sci. 2013, 93, 668–674. [Google Scholar] [CrossRef]

- Mendoza, E.; García, M.; Casas, C.; Selgas, M. Inulin as fat substitute in low fat, dry fermented sausages. Meat Sci. 2001, 57, 387–393. [Google Scholar] [CrossRef]

- Pelser, W.M.; Linssen, J.P.; Legger, A.; Houben, J.H. Lipid oxidation in n−3 fatty acid enriched Dutch style fermented sausages. Meat Sci. 2007, 75, 1–11. [Google Scholar] [CrossRef]

- Safa, H.; Gatellier, P.; Berdagué, J.-L.; Kondjoyan, N.; Mercier, F.; Portanguen, S.; Favier, R.; Mirade, P.-S.; Safa, H. Physicochemical, Biochemical and Instrumental Attributes and Consumer Acceptability of Dry-Fermented Sausages Elaborated with Combined Partial Substitutions of Sodium Chloride and Pork Backfat Open Access. Food Nutr. Sci. 2016, 7, 1297–1314. [Google Scholar] [CrossRef][Green Version]

- Siegrist, M.; Hartmann, C. Consumer acceptance of novel food technologies. Nat. Food 2020, 1, 343–350. [Google Scholar] [CrossRef]

- Henriques, A.S.; King, S.C.; Meiselman, H.L. Consumer segmentation based on food neophobia and its application to product development. Food Qual. Prefer. 2009, 20, 83–91. [Google Scholar] [CrossRef]

- Rabadán, A.; Bernabéu, R. A systematic review of studies using the Food Neophobia Scale: Conclusions from thirty years of studies. Food Qual. Prefer. 2021, 93, 104241. [Google Scholar] [CrossRef]

- Pliner, P.; Hobden, K. Development of a scale to measure the trait of food neophobia in humans. Appetite 1992, 19, 105–120. [Google Scholar] [CrossRef]

- Choe, J.Y.; Cho, M.S. Food neophobia and willingness to try non-traditional foods for Koreans. Food Qual. Prefer. 2011, 22, 671–677. [Google Scholar] [CrossRef]

- Rabadán, A.; Álvarez-Ortí, M.; Gómez, R.; Alvarruiz, A.; Pardo, J.E. Optimization of pistachio oil extraction regarding processing parameters of screw and hydraulic presses. LWT-Food Sci. Technol. 2017, 83, 79–85. [Google Scholar] [CrossRef]

- da Silva, S.L.; Amaral, J.T.; Ribeiro, M.; Sebastião, E.E.; Vargas, C.; Franzen, F.D.L.; Schneider, G.; Lorenzo, J.M.; Fries, L.L.M.; Cichoski, A.J.; et al. Fat replacement by oleogel rich in oleic acid and its impact on the technological, nutritional, oxidative, and sensory properties of Bologna-type sausages. Meat Sci. 2018, 149, 141–148. [Google Scholar] [CrossRef]

- CIE. Colorimetry, 2nd ed.; Publication CIE no. 1 15; Central Bureau of the Commission, Internationale de ĹEclairage: Vienne, Austria, 1986. [Google Scholar]

- Gimeno, O.; Ansorena, D.; Astiasarán, I.; Bello, J. Characterization of chorizo de Pamplona: Instrumental measurements of colour and texture. Food Chem. 2000, 69, 195–200. [Google Scholar] [CrossRef]

- Hoz, L.; D’Arrigo, M.; Cambero, I.; Ordóñez, J. Development of an n-3 fatty acid and α-tocopherol enriched dry fermented sausage. Meat Sci. 2004, 67, 485–495. [Google Scholar] [CrossRef] [PubMed]

- EC. Commission Regulation (EC) No. 796/2002 of 6 May 2002 amending Regulation (EEC) No. 2568/91, in L 128: Official Journal, pp. 0008–0028, 2002.

- Santos, J.; Alvarez-Ortí, M.; Sena-Moreno, E.; Rabadán, A.; Pardo, J.E.; Oliveira, M.B.P. Effect of roasting conditions on the composition and antioxidant properties of defatted walnut flour. J. Sci. Food Agric. 2017, 98, 1813–1820. [Google Scholar] [CrossRef] [PubMed]

- Lau, O. Methods of chemical analysis of mushrooms. In Tropical Mushrooms. Biological Nature and Cultivation Methods; Chang, S.T., Quimio, T.H., Eds.; The Chinese University Press: Hong Kong, China, 1982; pp. 87–116. [Google Scholar]

- FOSS. The Determination of Nitrogen According to Kjeldahl Using Block Digestion and Steam Distillation; Oss Application Note AN 300: Höganäs, Sweden, 2003. [Google Scholar]

- ANKOM. ANKOM, Rapid Determination of Oil/Fat Utilizing High Temperature Solvent Extraction; ANKOM Technology: Macedon, NY, USA, 2009. [Google Scholar]

- ANKOM. Crude Fiber Analysis in Feeds by Filter Bag Technique; ANKOM Technology: Macedon, NY, USA, 2008. [Google Scholar]

- Sullivan, D.M. Proximate and mineral analysis. In Methods of Analysis for Nutrition Labeling; Sullivan, D.M., Carpenter, D.E., Eds.; AOAC International: Arlington, VA, USA, 1993. [Google Scholar]

- González, J.; Alvira, P.; González, G. La cascarilla de arroz en la alimentación animal. II. Composición químico-bromatológica. Rev. De Agroquímica Y Tecnol. De Aliment. 1987, 27, 139–149. [Google Scholar]

- Fernández-Ruiz, V.; Claret, A.; Chaya, C. Testing a Spanish-version of the Food Neophobia Scale. Food Qual. Prefer. 2013, 28, 222–225. [Google Scholar] [CrossRef]

- Salazar, P.; García, M.L.; Selgas, M.D. Short-chain fructooligosaccharides as potential functional ingredient in dry fermented sausages with different fat levels. Int. J. Food Sci. Technol. 2009, 44, 1100–1107. [Google Scholar] [CrossRef]

- Papadima, S.; Bloukas, J. Effect of fat level and storage conditions on quality characteristics of traditional Greek sausages. Meat Sci. 1999, 51, 103–113. [Google Scholar] [CrossRef]

- Bloukas, J.; Paneras, E.; Fournitzis, G. Effect of replacing pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 1997, 45, 133–144. [Google Scholar] [CrossRef]

- Timilsena, Y.P.; Vongsvivut, J.; Adhikari, R.; Adhikari, B. Physicochemical and thermal characteristics of Australian chia seed oil. Food Chem. 2017, 228, 394–402. [Google Scholar] [CrossRef]

- Fernandes, S.S.; Tonato, D.; Mazutti, M.A.; de Abreu, B.R.; Cabrera, D.D.C.; D’Oca, C.D.R.M.; Prentice-Hernández, C.; Salas-Mellado, M.D.L.M. Yield and quality of chia oil extracted via different methods. J. Food Eng. 2019, 262, 200–208. [Google Scholar] [CrossRef]

- Monteiro, G.; Souza, X.; Costa, D.; Faria, P.; Vicente, J. Partial substitution of pork fat with canola oil in Toscana sausage. Innov. Food Sci. Emerg. Technol. 2017, 44, 2–8. [Google Scholar] [CrossRef]

- de Carvalho, F.A.L.; Munekata, P.E.; Pateiro, M.; Campagnol, P.C.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of replacing backfat with vegetable oils during the shelf-life of cooked lamb sausages. LWT 2020, 122, 109052. [Google Scholar] [CrossRef]

- García, M.; Dominguez, R.; Galvez, M.; Casas, C.; Selgas, M. Utilization of cereal and fruit fibres in low fat dry fermented sausages. Meat Sci. 2002, 60, 227–236. [Google Scholar] [CrossRef]

- Mancini, A.; Imperlini, E.; Nigro, E.; Montagnese, C.; Daniele, A.; Orrù, S.; Buono, P. Biological and Nutritional Properties of Palm Oil and Palmitic Acid: Effects on Health. Molecules 2015, 20, 17339–17361. [Google Scholar] [CrossRef]

- Backes, A.M.; Nascimento, N.T.; Milani, L.I.G.; Rezer, A.P.S.; Ludtke, v.F.L.; Cavalheiro, C.P.; Fries, L.L.M. Características físico-químicas e aceitação sensorial de salame tipo Italiano com adição de óleo de canola. In Semina: Ciências Agrárias; Universidade Estadual de Londrina: Londrina, Brazil, 2013. [Google Scholar]

- Özcan, M.M.; Atalay, Ç. Determination of seed and oil properties of some poppy (Papaver somniferum L.) varieties. Grasas Y Aceites 2006, 57, 169–174. [Google Scholar] [CrossRef]

- Pintado, T.; Cofrades, S. Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer. Foods 2020, 9, 830. [Google Scholar] [CrossRef]

- Uzlaşır, T.; Aktaş, N.; Gerçekaslan, K.E. Pumpkin seed oil as a partial animal fat replacer in bologna-type sausages. Korean J. Food Sci. Anim. Resour. 2020, 40, 551–562. [Google Scholar] [CrossRef]

- Pires, M.A.; Rodrigues, I.; Barros, J.C.; Carnauba, G.; AL Carvalho, F.; Trindade, M.A. Partial replacement of pork fat by Echium oil in reduced sodium bologna sausages: Technological, nutritional and stability implications. J. Sci. Food Agric. 2019, 100, 410–420. [Google Scholar] [CrossRef]

- Saldaña, E.; Merlo, T.C.; Patinho, I.; Rios-Mera, J.D.; Contreras-Castillo, C.J.; Selani, M.M. Use of sensory science for the development of healthier processed meat products: A critical opinion. Curr. Opin. Food Sci. 2020, 40, 13–19. [Google Scholar] [CrossRef]

- Guerrero, A.; Sañudo, C.; Campo, M.D.M.; Olleta, J.L.; Muela, E.; Macedo, R.M.G.; Macedo, F.A.F. Consumer Acceptability of Dry Cured Meat from Cull Ewes Reared with Different Linseed Supplementation Levels and Feeding Durations. Foods 2018, 7, 89. [Google Scholar] [CrossRef]

| Sample | Hardness (N) | Stickiness (N⋅mm) | Cohesiveness | Springiness (mm) | Chewiness (N⋅mm) |

|---|---|---|---|---|---|

| Control | 440.03 a ± 26.16 | −0.48 cd ± 0.10 | 0.76 a ± 0.03 | 1.00 c ± 0.18 | 335.74 a ± 61.45 |

| Poppy 50% | 236.72 b ± 28.04 | −0.92 abc ± 0.08 | 0.54 cde ± 0.02 | 2.02 ab ± 0.55 | 255.37 b± 56.81 |

| Poppy 75% | 200.08 bc ± 9.78 | −0.36 d ±0.05 | 0.49 ef ± 0.03 | 1.90 ab ± 0.15 | 186.29 b ± 10.60 |

| Poppy 100% | 199.79 cd ± 22.65 | −0.38 d ± 0.07 | 0.48 ef ± 0.02 | 1.75 abc ± 0.14 | 168.49 b ± 25.96 |

| Pumpkin 50% | 241.81 b ± 17.17 | −1.28 a ± 0.38 | 0.50 def ± 0.03 | 1.99 ab ± 0.47 | 238.66 ab ± 57.33 |

| Pumpkin 75% | 241.81 b ± 19.93 | −0.84 abc ± 0.20 | 0.65 b ± 0.01 | 1.62 bc ± 0.53 | 246.86 ab ± 80.34 |

| Pumpkin 100% | 232.36 b ± 18.46 | −0.66 bcd± 0.14 | 0.49 ef ± 0.02 | 1.79 abc ± 0.32 | 204.22 b ± 37.07 |

| Chia 50% | 215.0 bc ± 16.91 | −0.65 bcd ± 0.28 | 0.50 def ± 0.06 | 1.84 ab ± 0.57 | 201.17 b ± 65.94 |

| Chia 75% | 167.26 d ± 25.34 | −0.56 cd ± 0.24 | 0.58 c ± 0.04 | 2.23 ab ± 0.37 | 211.96 b ± 23.22 |

| Chia 100% | 192.15 cd ± 22.12 | −0.52 cd ± 0.10 | 0.56 cd ± 0.03 | 1.52 bc ± 0.22 | 163.45 b ± 22.07 |

| Melon 50% | 208.59 bc ± 15.41 | −1.07 ab ± 0.33 | 0.47 f ± 0.03 | 2.54 a ± 0.26 | 247.16 ab ± 29.52 |

| Melon 75% | 219.17 bc ± 12.30 | −0.68 bcd ± 0.13 | 0.46 f ± 0.03 | 2.15 ab ± 0.29 | 214.25 b ± 23.17 |

| Melon 100% | 183.08 cd ± 16.71 | −0.52 cd ± 0.27 | 0.44 f ± 0.02 | 1.99 ab ± 0.22 | 159.48 b ± 21.70 |

| Sample | L* | a* | b* | C* | h* |

|---|---|---|---|---|---|

| Control | 36.53 ab ± 1.62 | 12.71 d ± 1.39 | 5.08 d ± 0.89 | 13.70 d ± 1.62 | 21.43 b ± 1.30 |

| Poppy 50% | 39.08 a ± 1.28 | 16.07 c ± 0.33 | 7.99 bc ± 0.28 | 18.06 c ± 0.50 | 26.28 a ± 0.57 |

| Poppy 75% | 35.57 abc ± 2.48 | 16.03 c ± 1.11 | 8.01 bc ± 0.81 | 17.92 c ± 1.29 | 26.43 a ± 1.54 |

| Poppy 100% | 31.95 c ± 1.77 | 15.95 c ± 0.85 | 7.80 c ± 0.68 | 17.82 c ± 1.08 | 25.91 a ± 1.12 |

| Pumpkin 50% | 36.44 ab ± 1.61 | 15.54 c ± 0.57 | 8.21 bc ± 0.37 | 17.58 c ± 0.49 | 27.92 a ± 1.75 |

| Pumpkin 75% | 33.99 bc ± 1.41 | 15.63 c ± 1.12 | 8.24 bc ± 0.83 | 17.68 c ± 1.25 | 27.77 a ± 2.07 |

| Pumpkin 100% | 35.20 abc ± 2.21 | 15.39 c ± 0.75 | 8.13 bc ± 0.28 | 17.42 c ± 0.68 | 27.89 a ± 1.51 |

| Chia 50% | 35.18 abc ± 1.72 | 17.21 ab ± 1.35 | 8.23 bc ± 0.77 | 19.07 abc ± 1.51 | 25.45 a ± 1.15 |

| Chia 75% | 35.25 abc ± 1.73 | 18.15 ab ± 0.66 | 9.31 ab ± 0.75 | 20.40 ab ± 0.92 | 27.05 a ± 1.16 |

| Chia 100% | 37.49 ab ± 3.01 | 18.75 a ± 0.98 | 9.92 a ± 0.73 | 21.21 a ± 1.16 | 27.77 a ± 1.09 |

| Melon 50% | 35.38 abc ± 1.76 | 16.52 bc ± 0.47 | 8.21 bc ± 0.53 | 18.45 bc ± 0.61 | 26.32 a ± 1.16 |

| Melon 75% | 36.45 ab ± 1.30 | 16.51 bc ± 0.38 | 8.14 bc ± 0.41 | 18.41 bc ± 0.45 | 26.15 a ± 1.06 |

| Melon 100% | 34.45 bc ± 0.83 | 16.28 bc ± 0.93 | 8.10 bc ± 0.90 | 18.62 bc ± 1.17 | 27.52 a ± 1.31 |

| Sample | H (%) | N (%) | P (%) | Ash (%) | F (%) | CHt (%) | E (Kcal) |

|---|---|---|---|---|---|---|---|

| Control | 8.3 ± 0.35 | 8.19 ± 0.89 | 51.19 ± 1.55 | 8.49 ± 0.67 | 37.78 a ± 1.67 | 2.54 d ± 0.54 | 555 ± 78.56 |

| Poppy 50% | 7.1 ± 0.76 | 7.22 ± 0.27 | 45.13 ± 1.77 | 7.96 ± 0.27 | 35.93 a ± 1.34 | 10.99 b ± 0.73 | 548 ± 65.35 |

| Poppy 75% | 6.7 ± 0.25 | 8.01 ± 0.82 | 50.06 ± 1.67 | 8.75 ± 0.57 | 29.93 b ± 1.61 | 11.26 b ± 0.89 | 515 ± 61.78 |

| Poppy 100% | 8.0 ± 0.77 | 8.32 ± 0.35 | 52.00 ± 1.23 | 10.25 ± 0.45 | 20.58 c ± 2.05 | 16.90 a ± 0.47 | 461 ± 34.34 |

| Pumpkin 50% | 8.0 ± 0.94 | 7.06 ± 0.68 | 44.12 ± 1.78 | 8.00 ± 0.91 | 35.02 a ± 1.81 | 11.87 b ± 0.71 | 539 ± 45.76 |

| Pumpkin 75% | 6.0 ± 0.35 | 7.11 ± 0.35 | 44.44 ± 1.89 | 9.16 ± 0.65 | 34.02 ab ± 1.32 | 12.38 b ± 0.68 | 533 ± 35.81 |

| Pumpkin 100% | 8.4 ± 0.34 | 7.55 ± 0.94 | 47.19 ± 1.34 | 10.29 ± 0.89 | 29.61 b ± 2.09 | 12.91 b ± 0.91 | 507 ± 67.38 |

| Chia 50% | 8.6 ± 0.36 | 7.23 ± 0.41 | 45.19 ± 1.56 | 8.91 ± 0.87 | 36.26 a ± 1.54 | 9.64 c ± 0.38 | 546 ± 52.65 |

| Chia 75% | 7.1 ± 0.28 | 7.59 ± 0.53 | 47.44 ± 1.36 | 9.26 ± 0.56 | 31.30 b ± 2.81 | 12.00 b ± 0.36 | 525 ± 46.90 |

| Chia 100% | 6.4 ± 0.77 | 7.80 ± 0.33 | 48.75 ± 1.47 | 9.54 ± 0.35 | 24.93 c ± 1.27 | 16.78 a ± 0.81 | 486 ± 64.34 |

| Melon 50% | 7.8 ± 0.75 | 7.25 ± 0.38 | 45.31 ± 2.01 | 8.36 ± 0.45 | 34.54 ab ± 1.61 | 7.79 c ± 0.54 | 523 ± 65.54 |

| Melon 75% | 7.9 ± 0.73 | 7.93 ± 0.75 | 49.56 ± 2.35 | 8.84 ± 0.45 | 33.17 b ± 2.21 | 8.43 c ± 0.35 | 530 ± 73.37 |

| Melon 100% | 7.7 ± 0.91 | 7.98 ± 0.67 | 49.88 ± 0.99 | 9.68 ± 1.03 | 28.69 b ± 1.83 | 11.76 b ± 1.01 | 505 ± 72.60 |

| Sample | Palmitic Acid (%) | Stearic Acid (%) | Oleic Acid (%) | Linoleic Acid (%) | Linolenic Acid (%) |

|---|---|---|---|---|---|

| Control | 23.30 a ± 0.22 | 11.80 a ± 0.35 | 45.70 a ± 1.19 | 12.60 c ± 0.36 | 0.66 d ± 0.10 |

| Poppy 50% | 21.90 ab ± 0.36 | 11.30 a ± 0.27 | 40.80 ab ± 1.45 | 20.20 bc ± 0.29 | 0.57 d± 0.05 |

| Poppy 75% | 20.00 b ±0.30 | 10.10 b ± 0.32 | 36.80 bc ± 0.98 | 28.30 b ± 0.33 | 0.57 d ± 0.08 |

| Poppy 100% | 16.90 c ± 0.15 | 7.82 c ± 0.29 | 31.00 bc ± 1.14 | 40.50 a ± 1.12 | 0.63 d ± 0.07 |

| Pumpkin 50% | 22.50 ab ± 0.51 | 11.50 a ± 0.31 | 42.50 ab ± 1.33 | 17.40 bc ± 0.26 | 1.09 d ± 0.28 |

| Pumpkin 75% | 19.90 b ± 0.20 | 10.90 b ± 0.18 | 41.50 ab ± 1.64 | 23.00 b ± 0.74 | 0.47 d ± 0.05 |

| Pumpkin 100% | 19.60 b ± 0.13 | 10.20 b ± 0.22 | 35.60 bc ± 1.32 | 31.20 ab ±1.01 | 0.51 d ± 0.07 |

| Chia 50% | 21.00 ab ± 0.29 | 10.70 b ± 0.21 | 39.00 b ± 1.29 | 12.50 c ± 0.28 | 11.90 c ± 0.37 |

| Chia 75% | 19.60 b ± 0.32 | 10.50 b ± 0.25 | 34.20 bc ± 1.32 | 13.80 c ± 0.34 | 17.80 b ± 0.25 |

| Chia 100% | 16.30 c ± 0.25 | 8.45 c ± 0.19 | 27.30 c ± 1.92 | 16.20 bc ± 0.26 | 28.40 a ± 0.36 |

| Melon 50% | 22.30 ab ± 0.34 | 11.90 a ± 0.33 | 44.70 a ± 1.06 | 15.70 bc ± 0.42 | 0.40 d ± 0.03 |

| Melon 75% | 19.90 b ± 0.19 | 10.90 b ± 0.26 | 41.50 ab ± 0.97 | 23.00 b ± 0.56 | 0.47 d ± 0.12 |

| Melon 100% | 17.00 c ± 0.23 | 9.42 bc ± 0.18 | 39.50 b ± 0.85 | 30.40 ab ± 1.21 | 0.45 d ± 0.16 |

| Sample | Aspect | Texture | Odor | Taste |

|---|---|---|---|---|

| Control | 3.22 + 1.12 a | 2.81 + 1.14 a | 2.68 + 1.30 a | 3.29 + 1.01 a |

| Poppy 50% | 2.13 + 1.28 b | 2.13 + 1.36 b | 1.74 + 1.39 b | 1.97 + 1.14 b |

| Poppy 75% | 2.64 + 1.13 ab | 2.19 + 1.40 ab | 2.16 + 1.32 ab | 1.81 + 1.38 bc |

| Poppy 100% | 2.16 + 1.26 b | 1.42 + 1.15 c | 1.68 + 1.45 b | 1.26 + 1.34 c |

| Control | 3.35 + 0.80 a | 3.04 + 1.00 a | 2.88 + 0.91 a | 3.19 + 0.85 a |

| Pumpkin 50% | 2.12 + 1.28 b | 2.12 + 1.27 b | 2.00 + 1.27 b | 2.27 + 1.22 b |

| Pumpkin 50% | 2.12 + 1.28 b | 2.12 + 1.27 b | 2.00 + 1.27 b | 2.27 + 1.22 b |

| Pumpkin 75% | 2.04 + 1.28 b | 2.58 + 0.95 ab | 1.65 + 1.23 b | 2.38 + 1.20 b |

| Pumpkin 100% | 2.08 + 1.32 b | 2.23 + 1.39 b | 1.54 + 1.27 b | 2.04 + 1.37 b |

| Control | 3.27 + 0.83 a | 3.04 + 1.00 a | 3.12 + 0.99 a | 3.42 + 0.81 a |

| Chia 50% | 2.19 + 1.27 b | 1.96 + 1.22 b | 1.96 + 1.11 b | 1.77 + 1.24 b |

| Chia 75% | 2.12 + 1.14 b | 1.96 + 1.11 b | 2.08 + 1.32 b | 1.69 + 1.09 b |

| Chia 100% | 2.31 + 1.35 b | 1.62 + 1.30 b | 1.96 + 1.22 b | 1.35 + 1.20 b |

| Control | 3.24 + 1.01 a | 3.32 + 0.90 a | 3.08 + 1.08 a | 3.52 + 0.96 a |

| Melon 50% | 1.52 + 1.48 c | 1.56 + 1.23 b | 1.71 + 1.37 b | 1.52 + 1.39 b |

| Melon 75% | 2.24 + 1.01 b | 1.92 + 1.38 b | 1.76 + 1.20 b | 2.00 + 1.19 b |

| Melon 100% | 2.40 + 1.19 b | 1.60 + 1.35 b | 1.60 + 1.26 b | 1.72 + 1.24 b |

| Frequency | Total Consumers Frequency | Consumer Segmentation | |

|---|---|---|---|

| Neophobic | Non-Neophobic | ||

| Once a week | 28.0% | 21.4% | 35.0% |

| Once a fortnight | 23.2% | 9.5% | 37.5% |

| Once a month | 22.0% | 21.4% | 22.5% |

| Once every two month or less | 26.8% | 47.6% | 5.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarjuelo, L.; Pardo, J.E.; Álvarez-Ortí, M.; Pardo-Giménez, A.; Millán, C.; Rabadán, A. Development of Seed-Oil Based Dried Sausages, Considering Physicochemical and Nutritional Quality and the Role of Food Neophobia. Nutrients 2022, 14, 3106. https://doi.org/10.3390/nu14153106

Tarjuelo L, Pardo JE, Álvarez-Ortí M, Pardo-Giménez A, Millán C, Rabadán A. Development of Seed-Oil Based Dried Sausages, Considering Physicochemical and Nutritional Quality and the Role of Food Neophobia. Nutrients. 2022; 14(15):3106. https://doi.org/10.3390/nu14153106

Chicago/Turabian StyleTarjuelo, Laura, José Emilio Pardo, Manuel Álvarez-Ortí, Arturo Pardo-Giménez, Cristina Millán, and Adrián Rabadán. 2022. "Development of Seed-Oil Based Dried Sausages, Considering Physicochemical and Nutritional Quality and the Role of Food Neophobia" Nutrients 14, no. 15: 3106. https://doi.org/10.3390/nu14153106

APA StyleTarjuelo, L., Pardo, J. E., Álvarez-Ortí, M., Pardo-Giménez, A., Millán, C., & Rabadán, A. (2022). Development of Seed-Oil Based Dried Sausages, Considering Physicochemical and Nutritional Quality and the Role of Food Neophobia. Nutrients, 14(15), 3106. https://doi.org/10.3390/nu14153106